Method for rapidly preparing carbon/carbon composite material under physics field by CVD

A technology of chemical vapor deposition and carbon composite materials, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor densification uniformity and long CVI cycle, and achieve the reduction of intermediate machining links, The effect of shortening the preparation cycle and reasonably shortening the heat transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

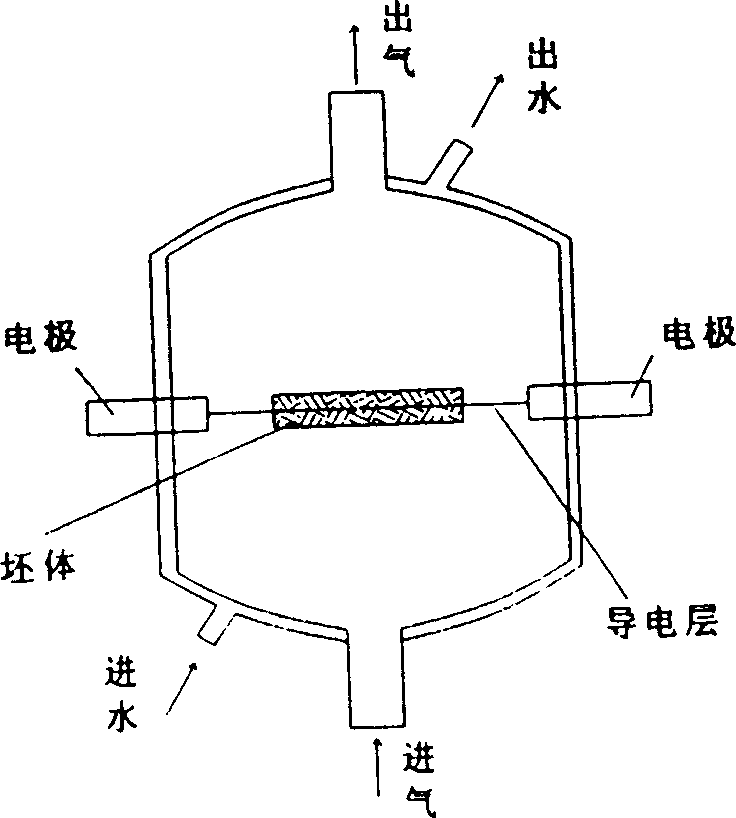

[0031] (1) figure 2 It is the deposition condition of carbon / carbon composite thin-layer cylindrical products in the deposition furnace. The graphite sheet is used as the conductive layer, the needle-punched carbon felt is used as the green body, nitrogen is used as the carrier gas, and liquefied petroleum gas is used as the carbon source. The carbon source and The volume ratio of the carrier gas is 1:1, the temperature of the conductive layer is controlled at 850°C, the system pressure is 10kPa, and the material density reaches 1.6g / cm after deposition for 20 hours 3 , the substrate pyrolytic carbon structure is a smooth layer.

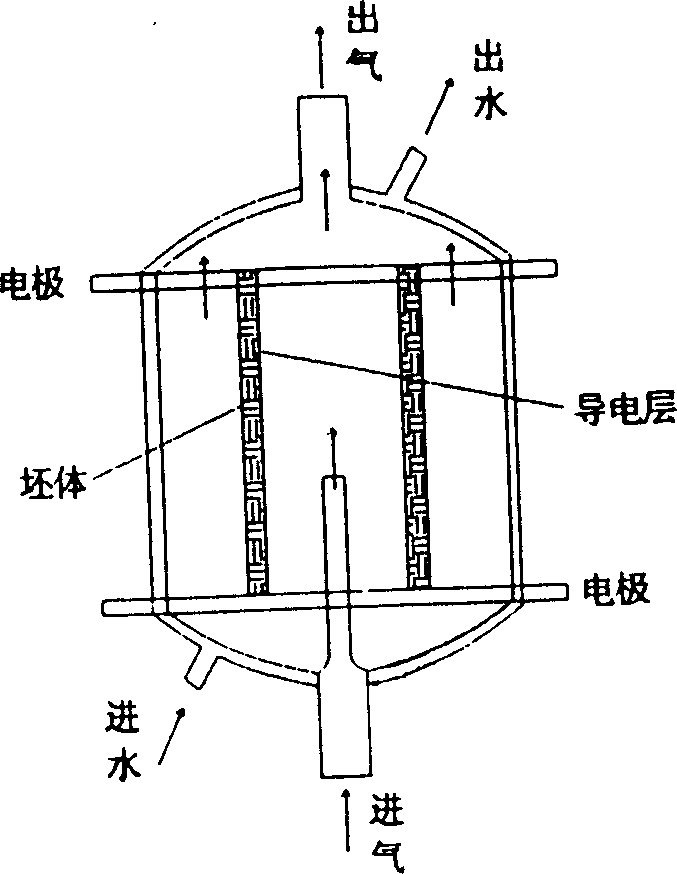

[0032] (2) image 3 It is the deposition condition of disc-shaped products of carbon / carbon composite materials in the deposition furnace. Three discs are installed in the furnace. The actual width of each part of the green body is the same. The needle-punched carbon felt is used as the green body, graphite is used as the conductive layer, and nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com