Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Excellent hydrophobic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of cast aluminum alloy film coat

InactiveCN101781763AGood compatibilityImprove corrosion resistanceMetallic material coating processesDuraluminFluorine containing

The invention relates to a preparation method of a cast aluminum alloy film coat, which is characterized by cleaning a cast aluminum alloy component firstly, performing chromate oxidation treatment secondly, and then preparing a film sealing coat of fluorine containing acrylicester on a chromate oxide film. Construction methods such as brushing or spraying is used for the invention, the methods are flexible and simple and has high maneuverability; the invention can be applied in the protective treatment for cast aluminum alloy of ZL102, ZL104, ZL107, ZL112, ZL114 and the like, and is particularly suitable for treatment of the cast aluminum alloy component used in the ocean environment; and the invention is also suitable for the protective treatment of other aluminum alloy materials or components, such as treatment of duralumin, super duralumin, wrought aluminum and rust-proof aluminum alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for preparing hydrophobic wood

InactiveCN102001117AWith self-cleaning abilityStrong self-cleaningPressure impregnationWood impregnation detailsRoom temperatureWater contact

The invention discloses a method for preparing hydrophobic wood, relates to a method for modifying wood, and solves the problems that a modifier has high toxicity and peculiar smell and changes wood color, the treatment process is complex and only single performance of the wood can be improved in the conventional wood modification method. The method comprises the following steps of: mixing a fluorine-containing polymerizable monomer, an unsaturated monomer and an initiator to prepare impregnation liquid; adding the wood and the impregnation liquid into a reaction tank, vacuumizing, performing pressure treatment so as to inject the impregnation liquid into a pore structure of the wood, coating a test piece and ageing at room temperature and constant pressure; and heating and performing vacuum drying to prepare the hydrophobic wood. The method is simple, the wood color is not changed, peculiar smell is absent, the parallel-to-grain compressive strength is 70 to 98 MPa, the expansion resistance rate after the wood is continuously soaked in water for 200 hours is 48 to 65 percent, the weight loss ratio after 12 weeks of fungi erosion is 6 to 13 percent, the water contact angle is more than 130 degrees, and the wood can be widely used as indoor and outdoor structural materials and decorative materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

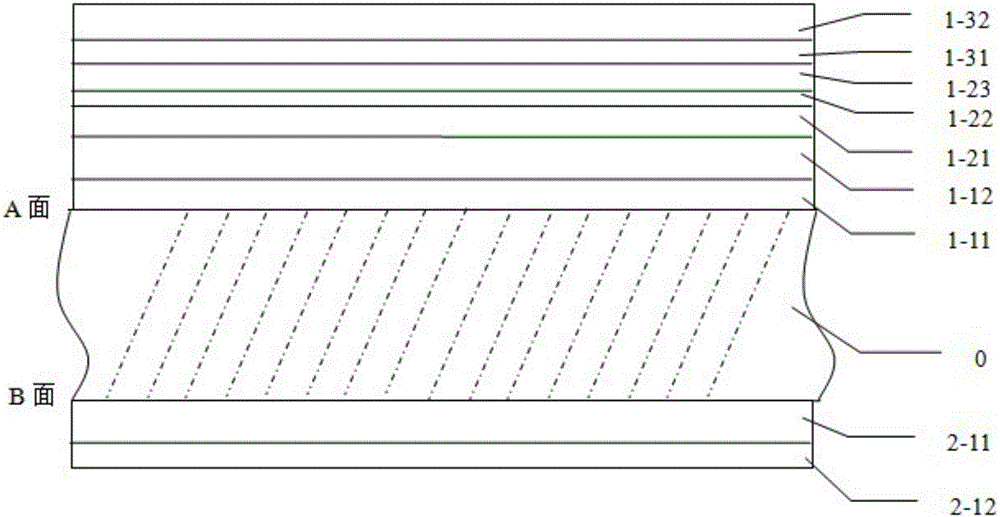

Transparent energy-saving hydrophobic film used for civil aircraft porthole glass and preparation method thereof

InactiveCN106222612AImprove corrosion resistanceGood weather resistanceVacuum evaporation coatingSputtering coatingInfraredWeather resistance

The invention discloses a transparent energy-saving lyophobic film used for civil aircraft porthole glass and a preparation method thereof. An organic glass substrate involved in the transparent energy-saving hydrophobic film used for the civil aircraft porthole glass comprises a surface A and a surface B. Different transparent film bodies are arranged on the surface A and the surface B. A transparent energy-saving conductive film system is arranged on the surface A, and a transparent hydrophobic film system is arranged on the surface B. The energy-saving film system comprises an isolation layer, an energy-saving functional layer and a protective layer sequentially from inside to outside in the organic glass substrate. The hydrophobic film system comprises an attaching layer and a hydrophobic functional layer sequentially from inside to outside in the organic glass substrate. The inner side of the transparent energy-saving hydrophobic film can achieve the infrared reflecting and energy saving function, the outer side of the transparent energy-saving hydrophobic film can achieve the hydrophobic, oleophobic and anti-dirt functions, the film layers on the two sides are coordinated in function, the effects of high light transparency and excellent energy conservation are achieved, the film layers are high in corrosion resistance and weather resistance, the production process is simple and can be autonomously controlled, and the technological process can be adjusted according to performance parameter requirements.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Environment-friendly anticorrosive paint and preparation method thereof

ActiveCN105969050AImprove anti-corrosion performanceGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

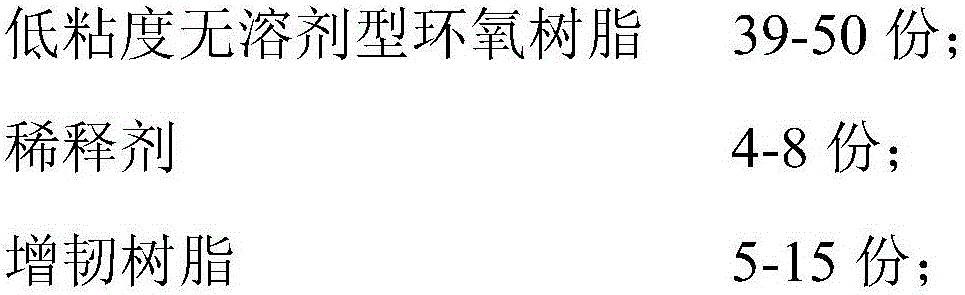

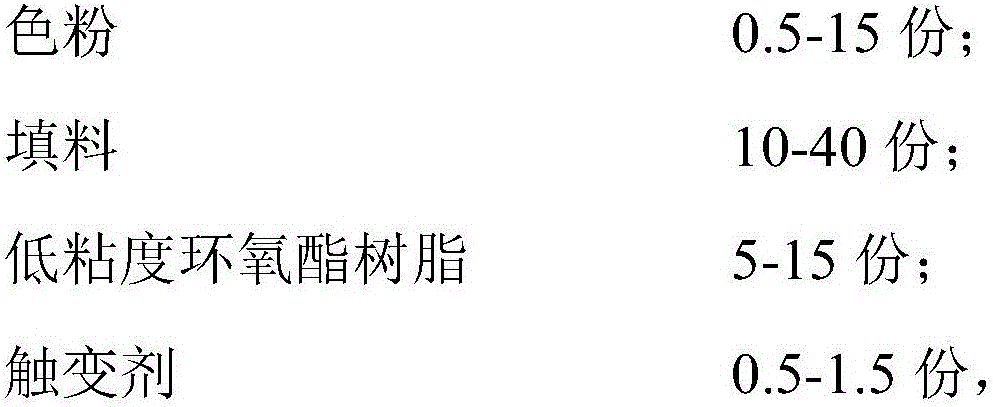

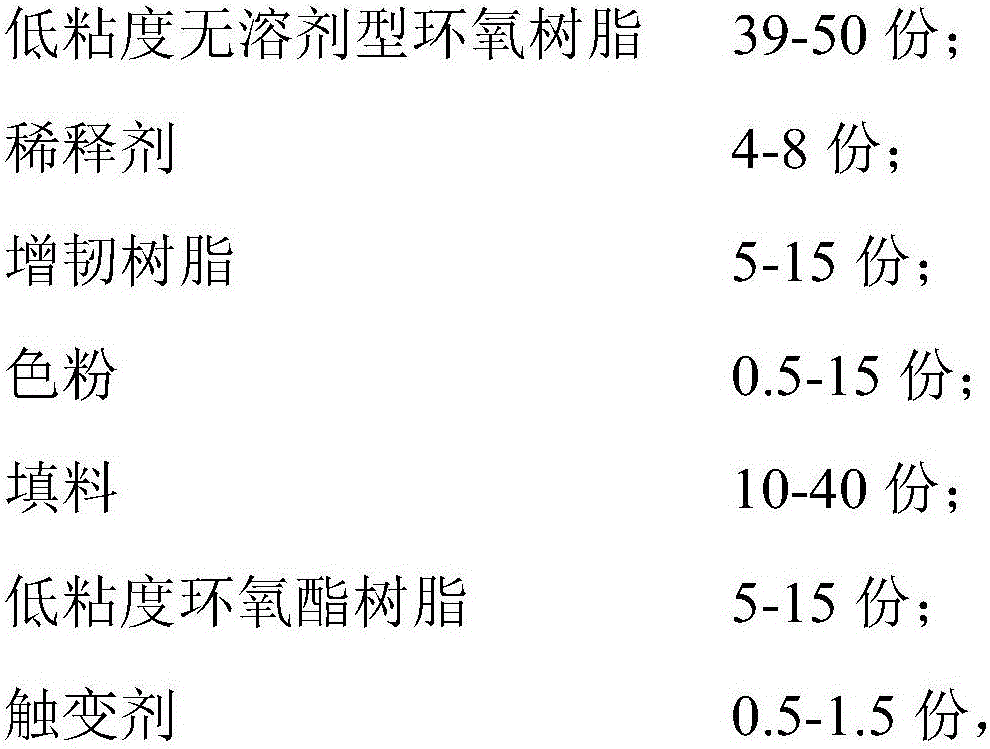

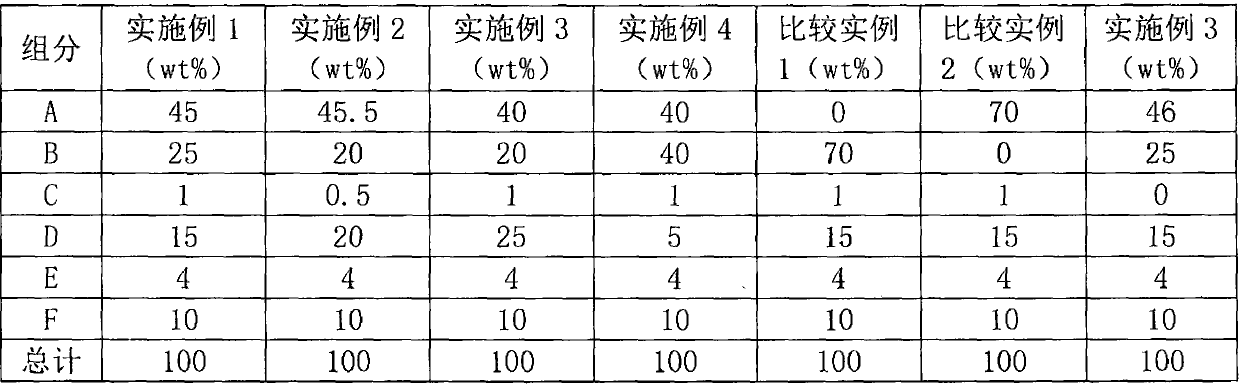

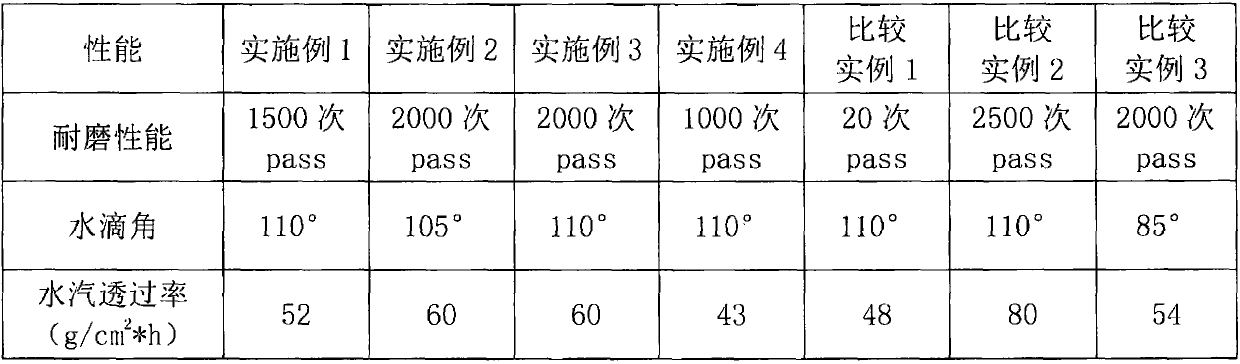

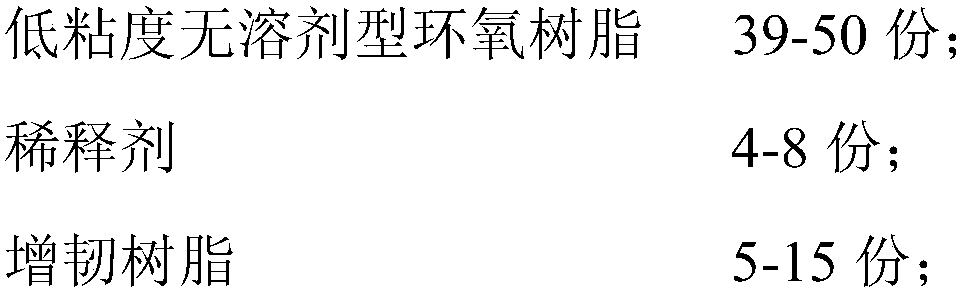

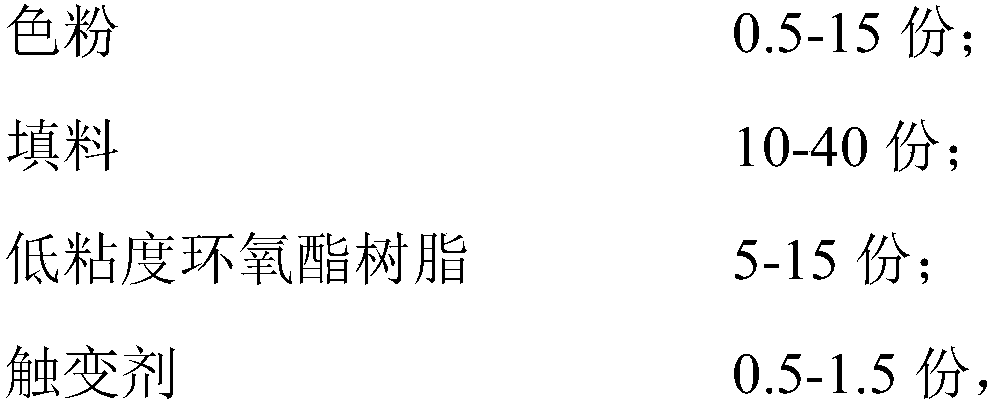

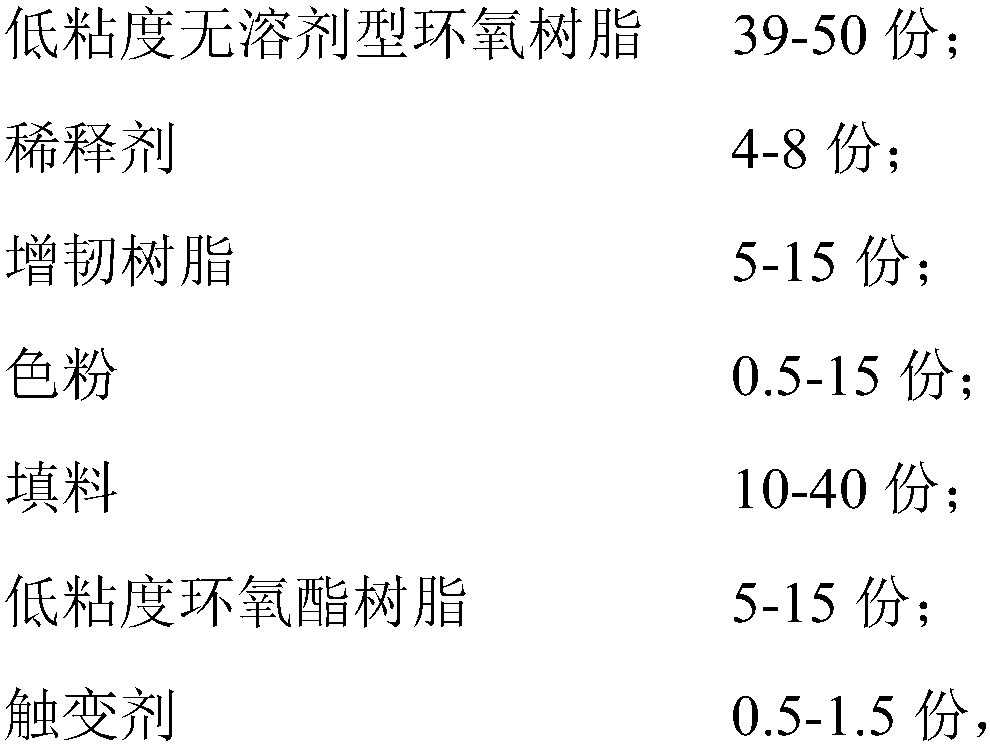

The invention provides environment-friendly anticorrosive paint and a preparation method thereof. The environment-friendly anticorrosive paint comprises a main agent and a curing agent. The main agent is prepared from, by weight of 100 parts, 39-50 parts of low-viscosity solvent-free epoxy resin, 4-8 parts of diluents, 5-15 parts of toughening resin, 0.5-15 parts of toner, 10-40 parts of filler, 5-15 parts of low-viscosity epoxy ester resin and 0.5-1.5 parts of a thixotropic agent. The curing agent is modified amine resin.

Owner:CHINA PAINT MFG CO SHENZHEN

Nano thermal insulation reflective coating additive for exterior wall

ActiveCN103834216ARealize self-cleaning functionExcellent hydrophobic functionReflecting/signal paintsEmulsionThermal insulation

The invention discloses a nano thermal insulation reflective coating additive for an exterior wall. The nano thermal insulation reflective coating additive comprises the main components in weight ratio: 160-250 parts of water, 1-2 parts of defoaming agent, 8-12 parts of dispersing agent, 0.5-2 parts of hydroxyethyl cellulose, 400-500 parts of thermal insulation reflective powder, 5-10 parts of nano TiO2 powder, 5-10 parts of nano SiO2 powder, 5-12 parts of ethylene glycol, 5-10 parts of film-forming additive, 200-300 parts of AC-261P waterborne acrylic emulsion and 1.0-2.0 parts of thickening agent. The nano thermal insulation reflective coating additive is prepared by stirring all the components according to the weight ratio. The coating additive for the exterior wall can be used for realizing the thermal insulation reflection of a color coating for the exterior wall, and furthermore, the energy conservation of a building is realized; water is used as a solvent, so that the nano thermal insulation reflective coating additive has the advantages of environment friendliness, exterior wall hydrophobicity, self-cleaning and the like.

Owner:深圳市文浩科技有限公司

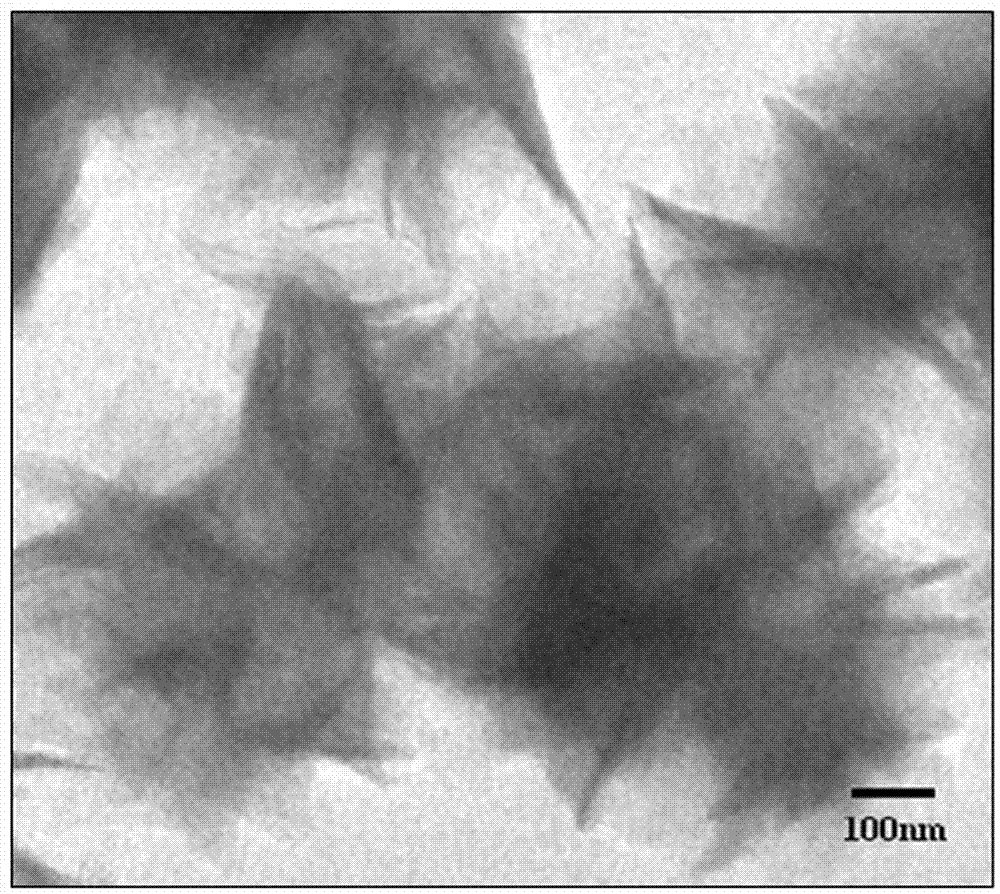

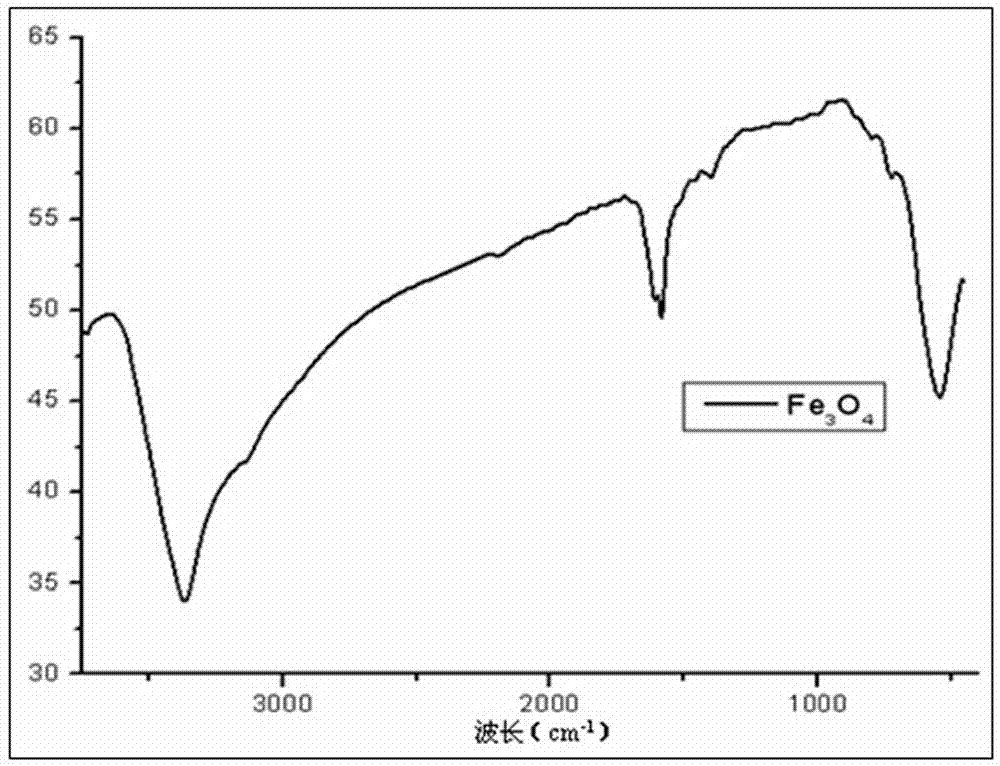

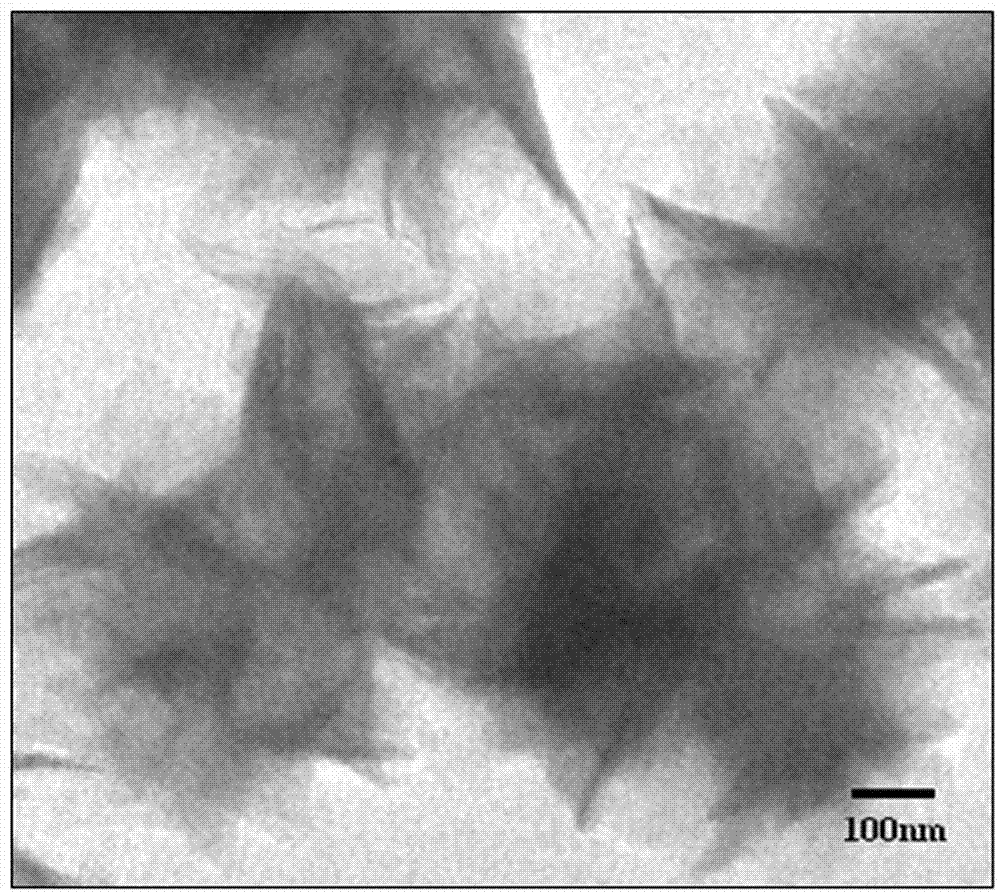

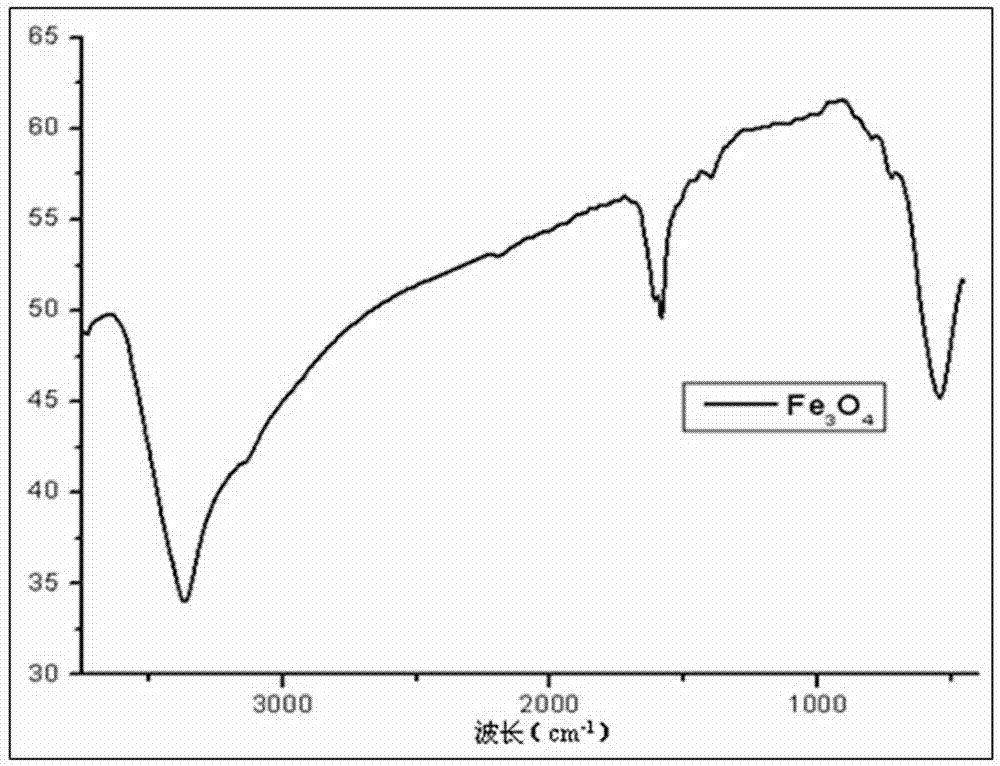

Preparation method of hydrophobic material with surface modified by Fe3O4 nanoflower

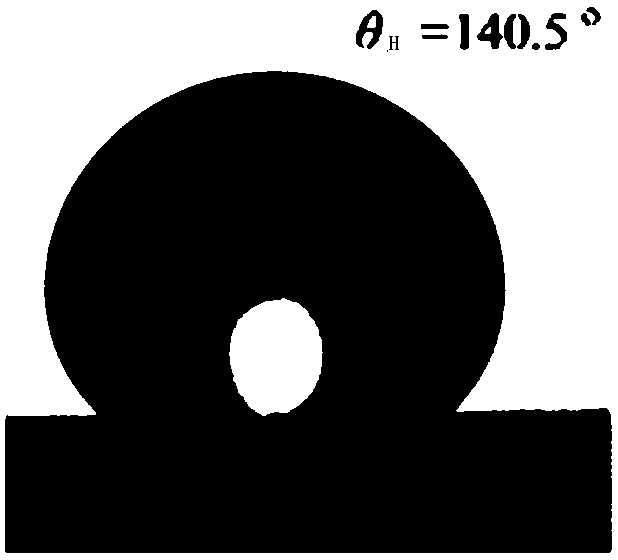

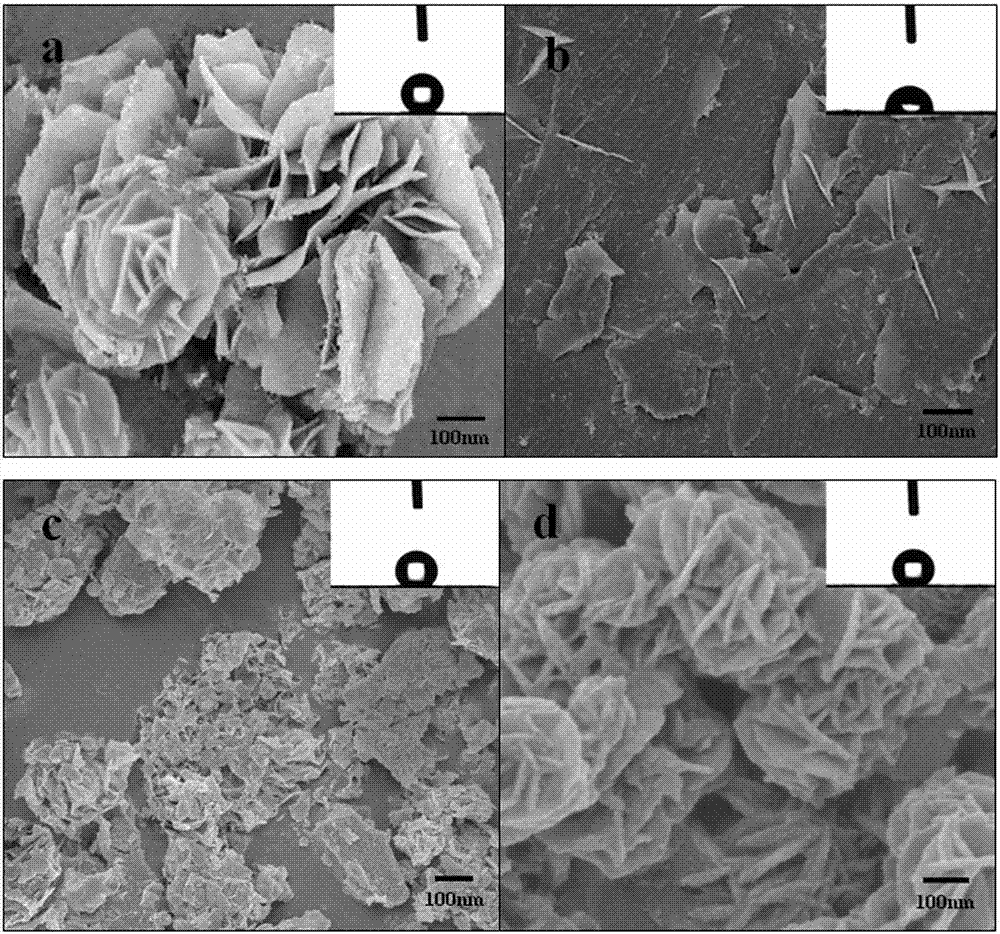

InactiveCN103112903APlay a protective effectWith super hydrophobic functionMaterial nanotechnologyFerroso-ferric oxidesEngineeringHydrophobe

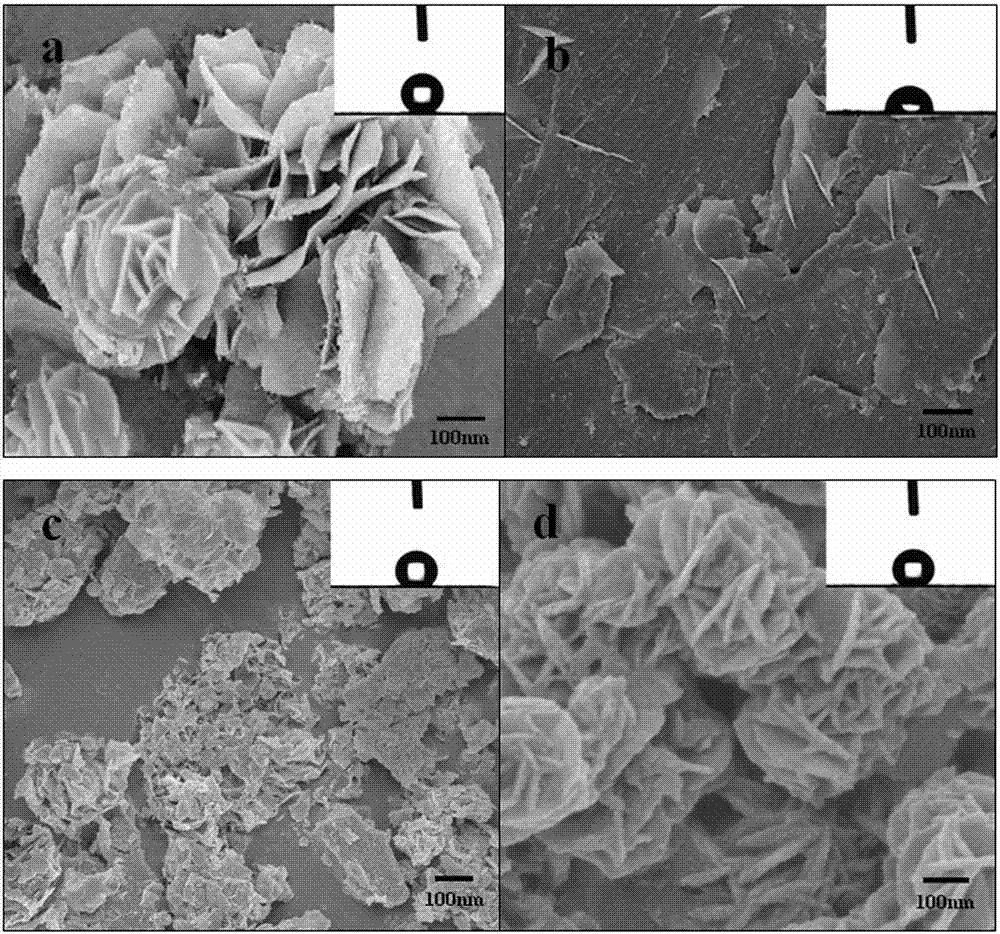

The invention provides a hydrophobic material with a surface modified by Fe3O4 nanoflower. A preparation method comprises the following steps of: soaking a cleaned pure iron sheet in a nitric acid solution with concentration of 0.5-2.5mol / L, and enabling reaction at 30-50 DEG C for 5-15 minutes; slowly introducing ammonia gas into the reaction system in the condition of external magnetic field so that the acid solution of the system gradually becomes alkaline; heating the system to 230-285 DEG C, and enabling reaction for 30-90 minutes to generate black brown Fe3O4 particles on the iron sheet; cooling, washing and drying to obtain a hydrophobic material with a surface modified by Fe3O4 nanoflower, wherein the contact angle can reach 136.23-146.12 degrees according to measurement, and good hydrophobicity is realized; and performing heat treatment of the hydrophobic material at 150-200 DEG C to obtain a hydrophobic material modified by gamma-Fe2O3 nanoflower and having stable performance and excellent hydrophobicity. The hydrophobic material provided by the invention has a broad application prospect in the field of antiseptic and self-cleaning materials.

Owner:NORTHWEST NORMAL UNIVERSITY

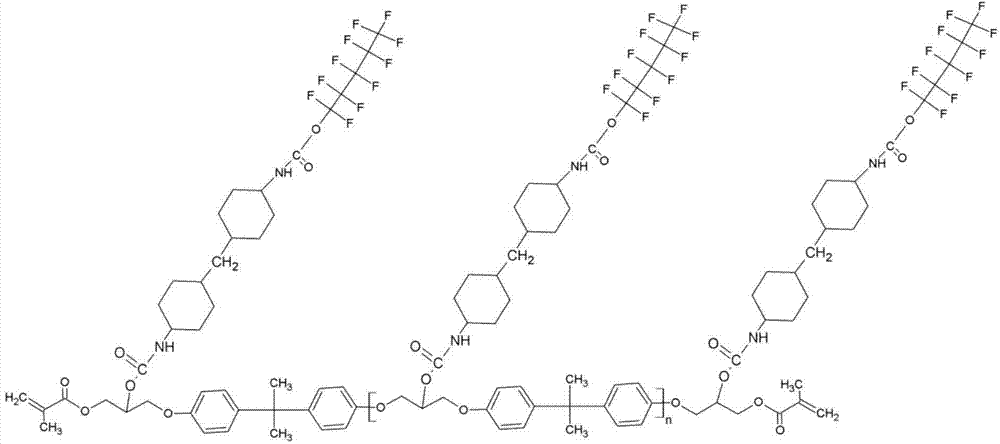

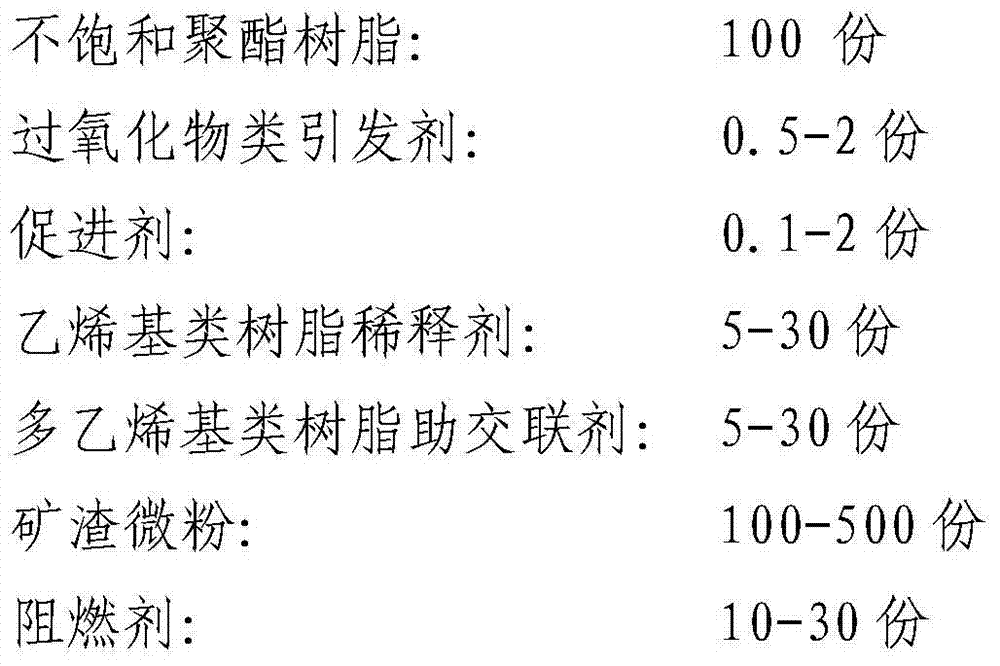

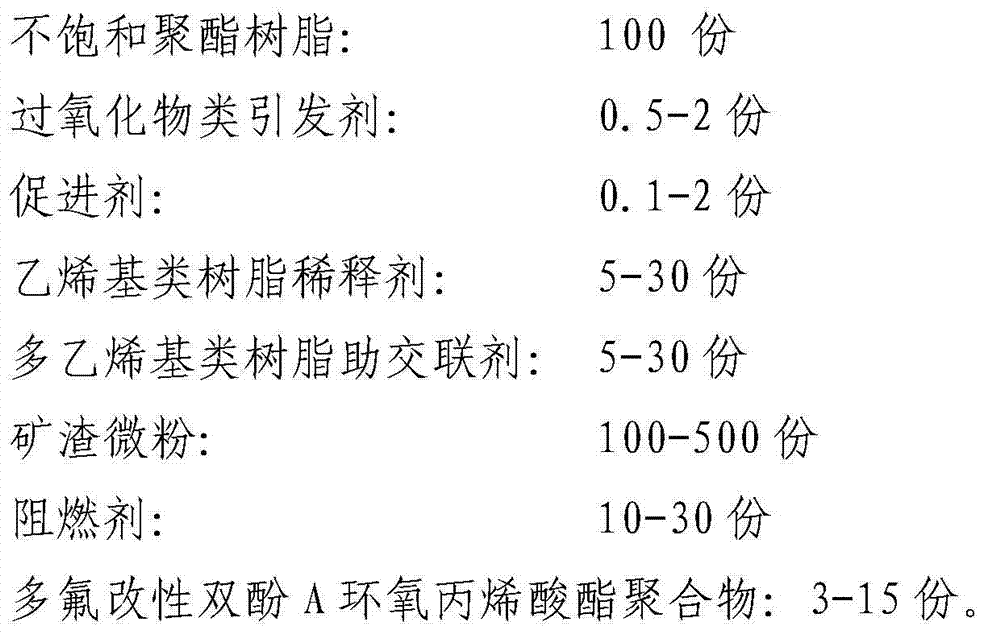

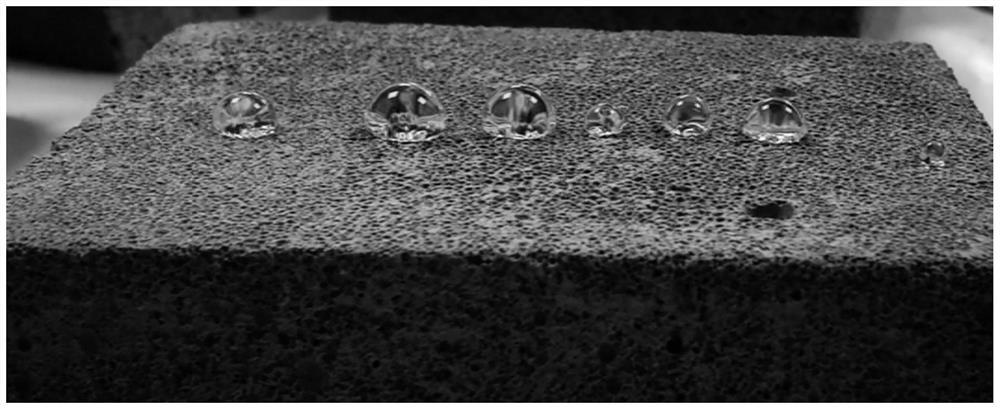

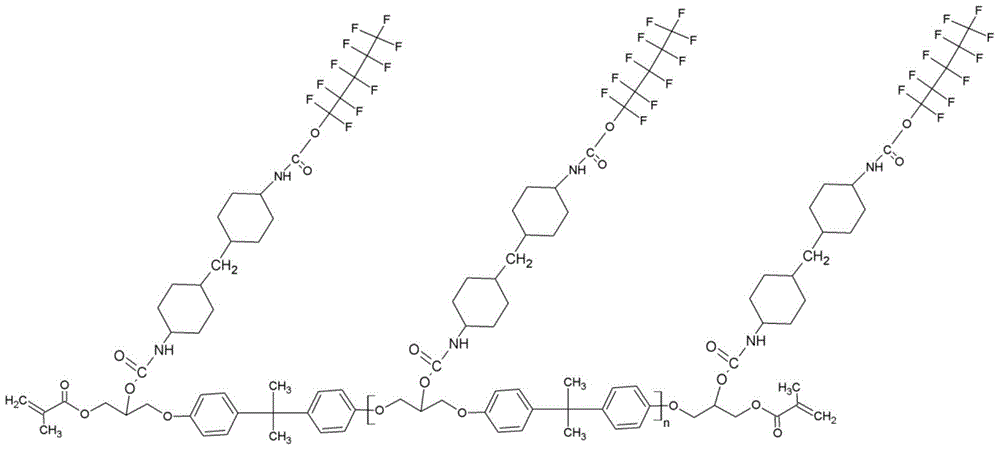

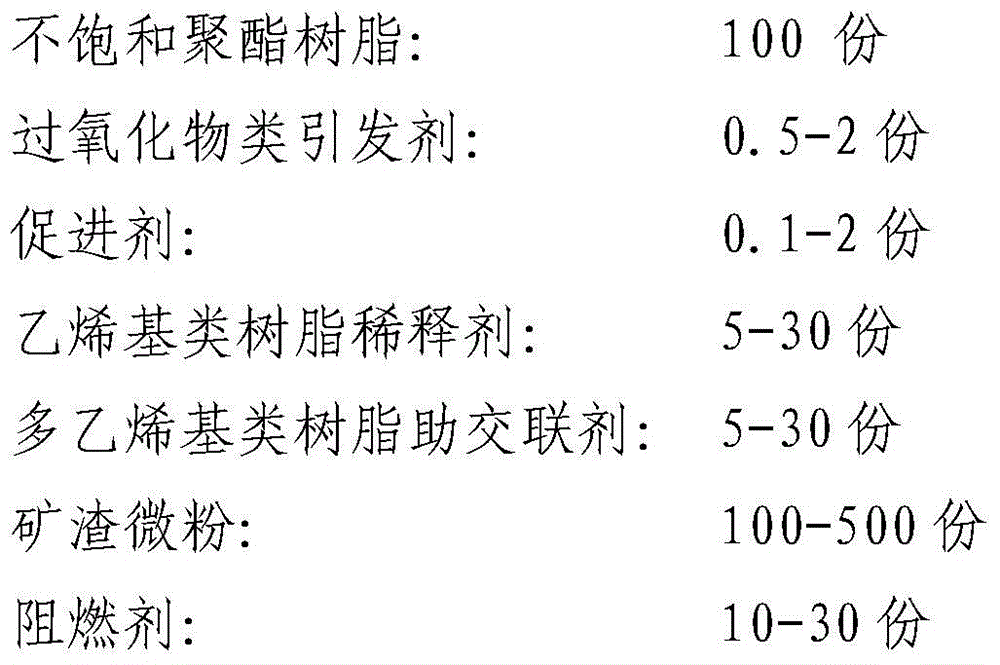

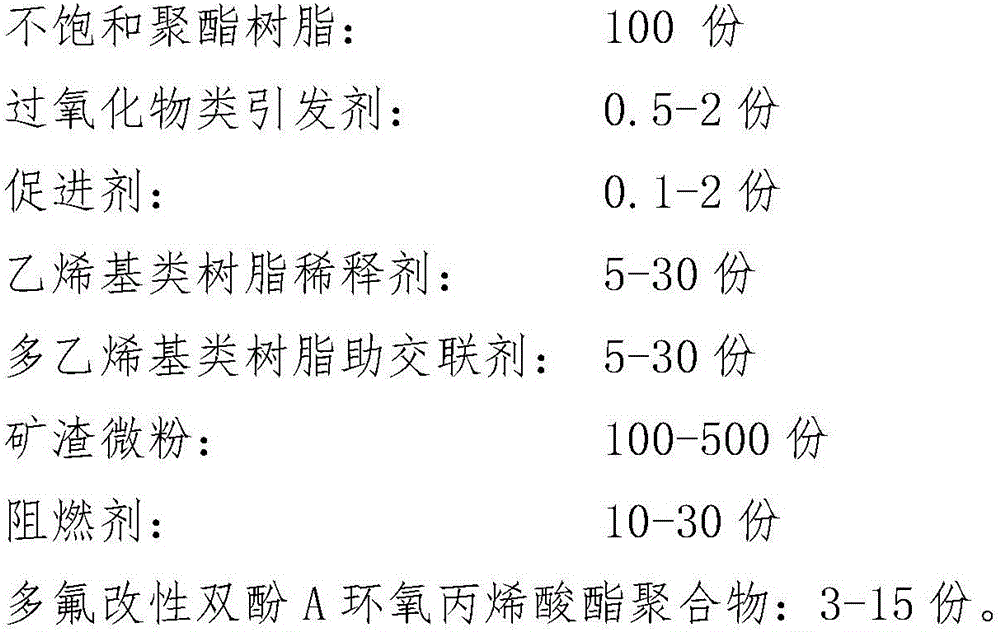

Super-hydrophobic artificial marble and preparation method thereof

ActiveCN104761183AGood super hydrophobic functionExcellent hydrophobic functionSolid waste managementSlagFire retardant

The invention relates to the technical field of building materials and particularly relates to super-hydrophobic artificial marble which is composed of following components, by weight: 100 parts of unsaturated polyester resin, 0.5-2 parts of a peroxide-type initiator, 0.1-2 parts of an accelerant, 5-30 parts of vinyl-type resin diluent, 5-30 parts of polyvinyl-type resin assistant crosslinker, 100-500 parts of ore slag micro powder, 10-30 parts of a flame retardant, and 3-15 parts of polyfluoro-modified bisphenol A epoxy acrylate polymer. In the invention, the polyfluoro-modified bisphenol A epoxy acrylate polymer, which has a super-hydrophobic function, is employed as a hydrophobic additive to prepare the artificial marble, so that the artificial marble is excellent in hydrophobic performance. A contact angle between the surface of the super-hydrophobic artificial marble and water is 150-170 degrees so that the surface of the super-hydrophobic artificial marble has an excellent self-cleaning function. In addition, the marble in deep color series is high in strength, is good in waterproof performance and is strong in corrosion resistance.

Owner:宝武环科(湛江)资源循环利用有限公司

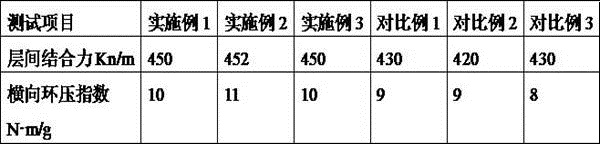

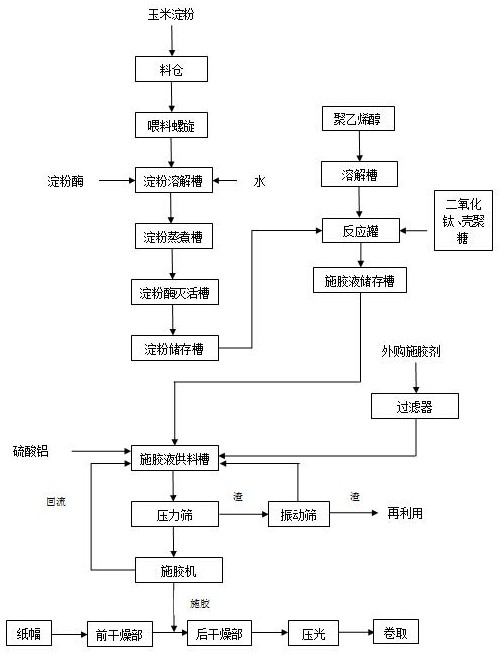

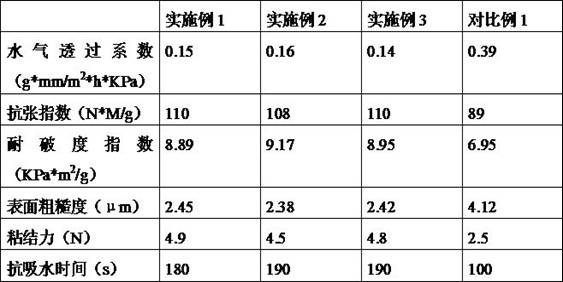

Preparation method of moisture-regaining-resistant anti-layering high-strength environment-friendly kraft liner cardboard paper

InactiveCN111979815AEasy to preparePhysical indicators improvedNon-fibrous pulp additionDryer sectionCardboardProcess engineering

The invention discloses a preparation method of moisture-regaining-resistant anti-layering high-strength environment-friendly kraft liner cardboard paper. The preparation method comprises the following steps of (1) pulping; (2) grading; (3) papermaking and forming; (4) squeezing and drying; and (5) sizing. The preparation method is simple, and the interlayer bonding force of the prepared finishedpaper reaches 450 KN / m; the water absorption degree of the finished paper reaches 40s / 50s on the front and back sides, and the complete penetration of the paper sheet is more than 180s; the energy consumption of the finished paper reaches 195 kgce / t and reaches the advanced value specified in GB 31825-2015 'pulping and papermaking unit product energy consumption limit'; and the physical index of the finished paper is higher than the quality requirement of GBT 13024-2016 'box board'.

Owner:JIANGSU LEE & MAN PAPER MFG

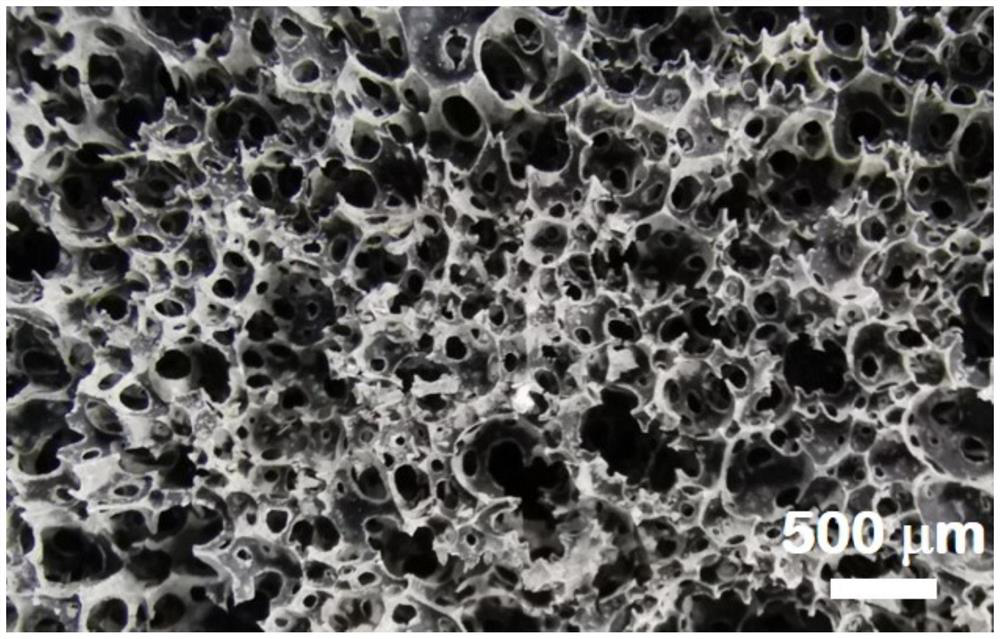

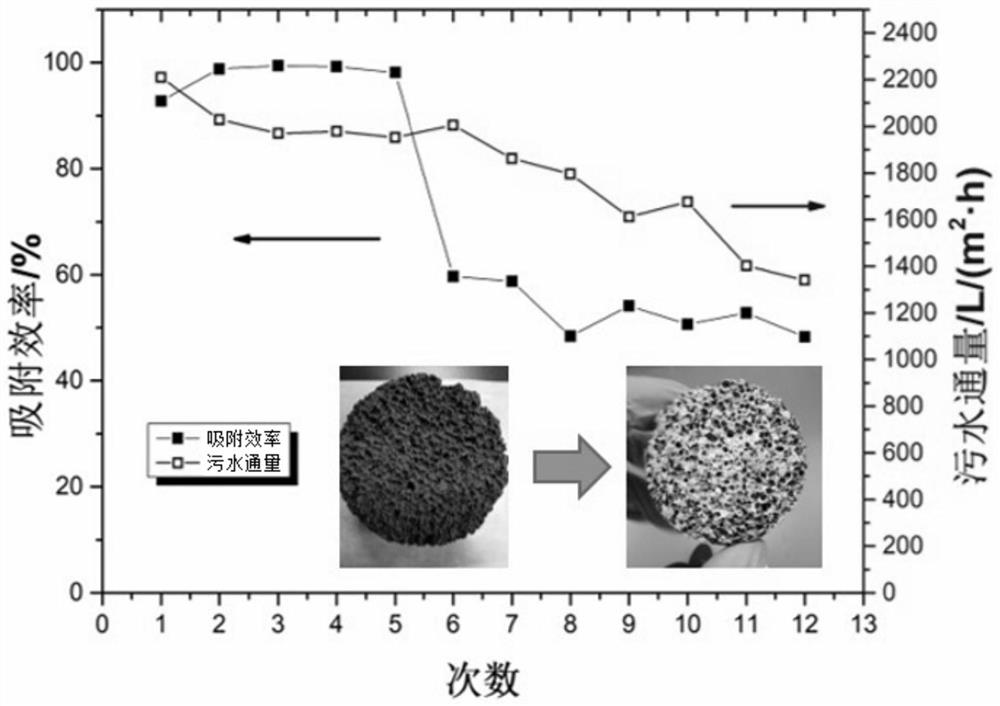

Foam geopolymer adsorbing material as well as preparation method and application thereof

ActiveCN113426421AAvoid alkali lossImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSlagSlurry

The invention relates to the technical field of solid waste resource utilization, and particularly discloses a foam geopolymer adsorption material as well as a preparation method and application thereof. The preparation method of the foam geopolymer adsorption material comprises the following process steps: a, mixing fly ash, blast furnace slag and activated carbon according to a mass ratio to obtain a mixed dry material, adding the mixed dry material into an exciting agent, and stirring the mixture to obtain a stirred slurry; b, adding hydrogen peroxide and a lauryl sodium sulfate solution into the mixed slurry, stirring and mixing the mixture, adding the mixture into a mold, and sealing and curing the mixture to obtain an initial module; c, immersing the initial module into a modifier for ultrasonic impregnation, taking out and drying the initial module to obtain the foam geopolymer adsorption material. According to the preparation method of the foam geopolymer adsorption material provided by the invention, the foam geopolymer with high through holes and good hydrophobic performance can be obtained. The foam geopolymer has an efficient adsorption effect on various pollutants such as heavy metals and oil stains, and has an extremely high application prospect in the field of water pollution control.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Preparation method for modified polyamide composite material

The invention discloses a preparation method for a modified polyamide composite material, which relates to the field of novel polyamide materials. The preparation method comprises the following steps:preparation of maleic anhydride-grafted polyphenyl ether; surface treatment of graphene oxide; preparation of modified graphene oxide; preparation of polyphenyl ether-grafted graphene oxide; and preparation of modified polyamide composite material. According to the preparation method disclosed by the invention, by grafting polyphenyl ether onto the graphene oxide to modify polyamide, the grapheneoxide grafted onto the polyphenyl ether is highly compatible with the polyamide, the binding force is high, and the tensile strength and mechanical impact resistance of the composite material can beeffectively increased, and moreover, the water absorption and friction coefficient of the composite material can be effectively decreased.

Owner:安徽菲扬新材料有限公司

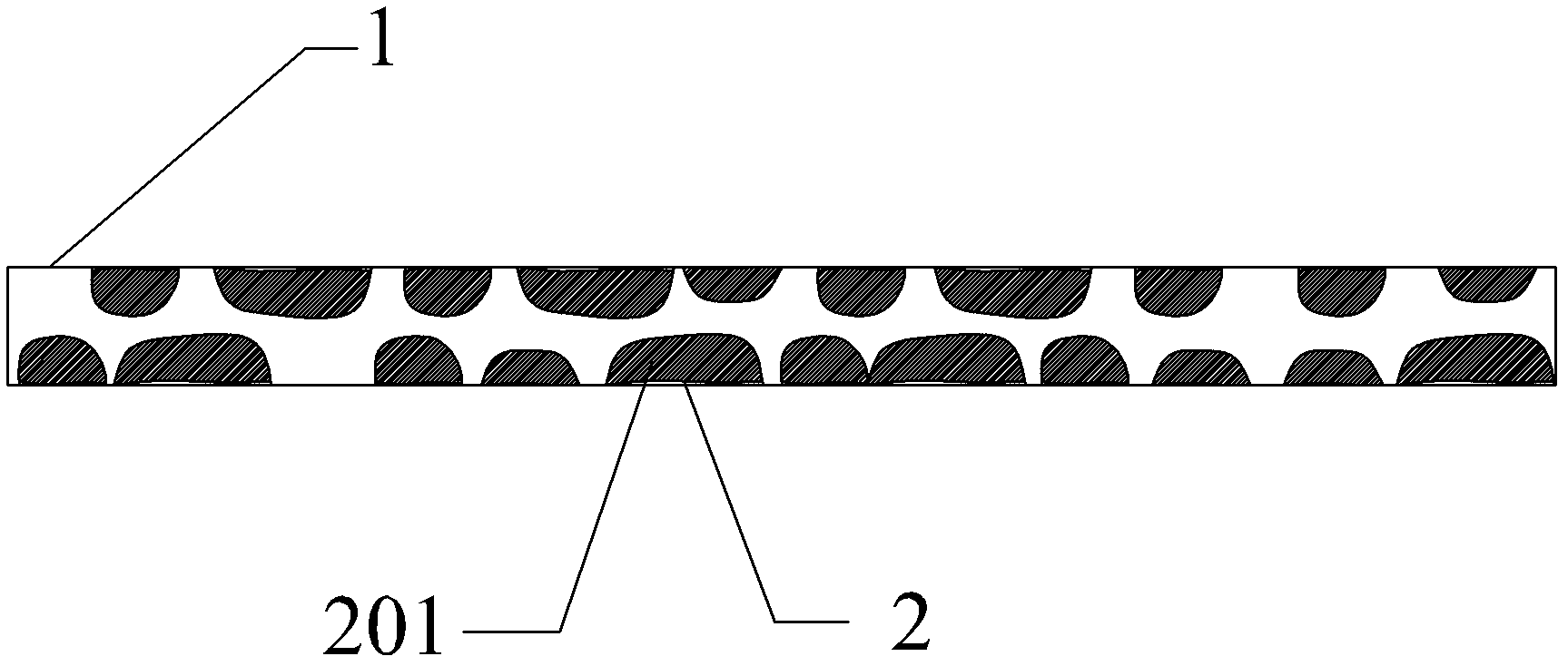

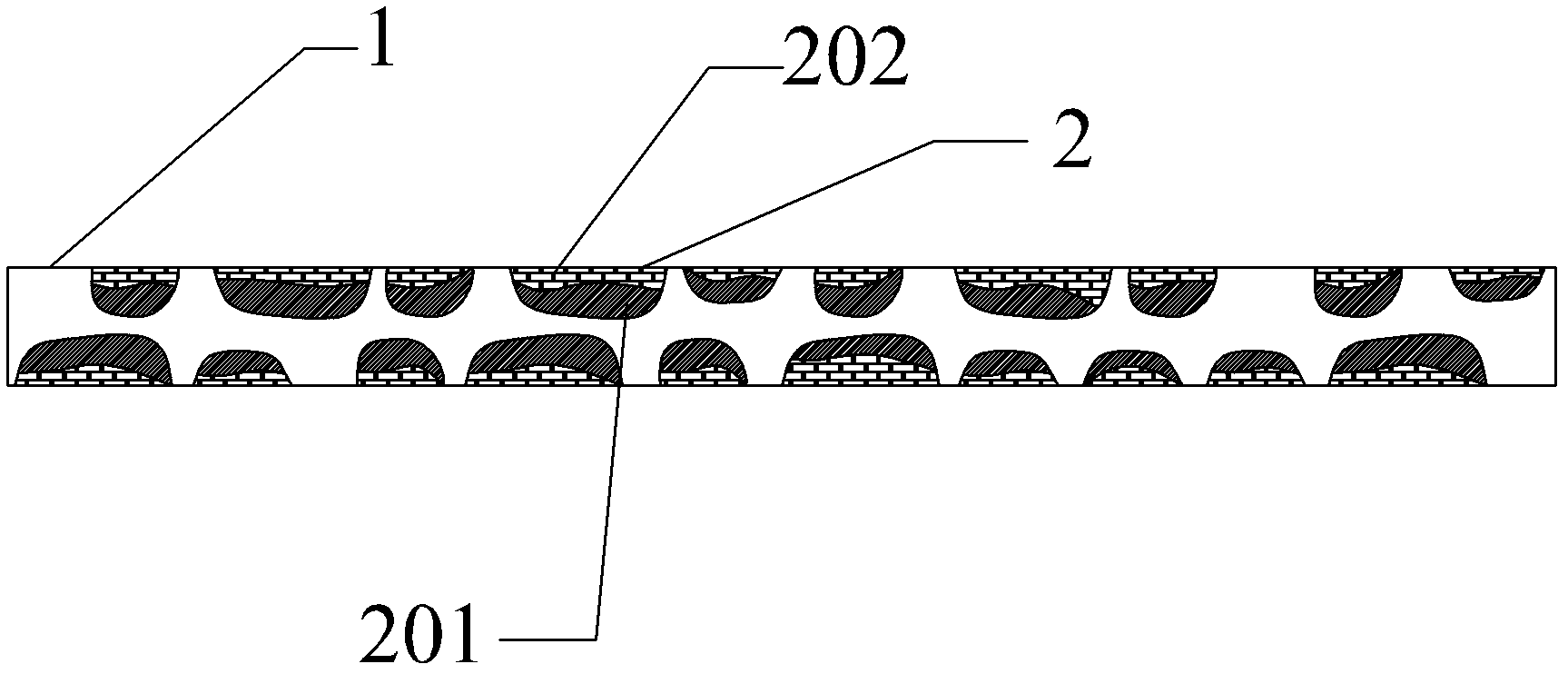

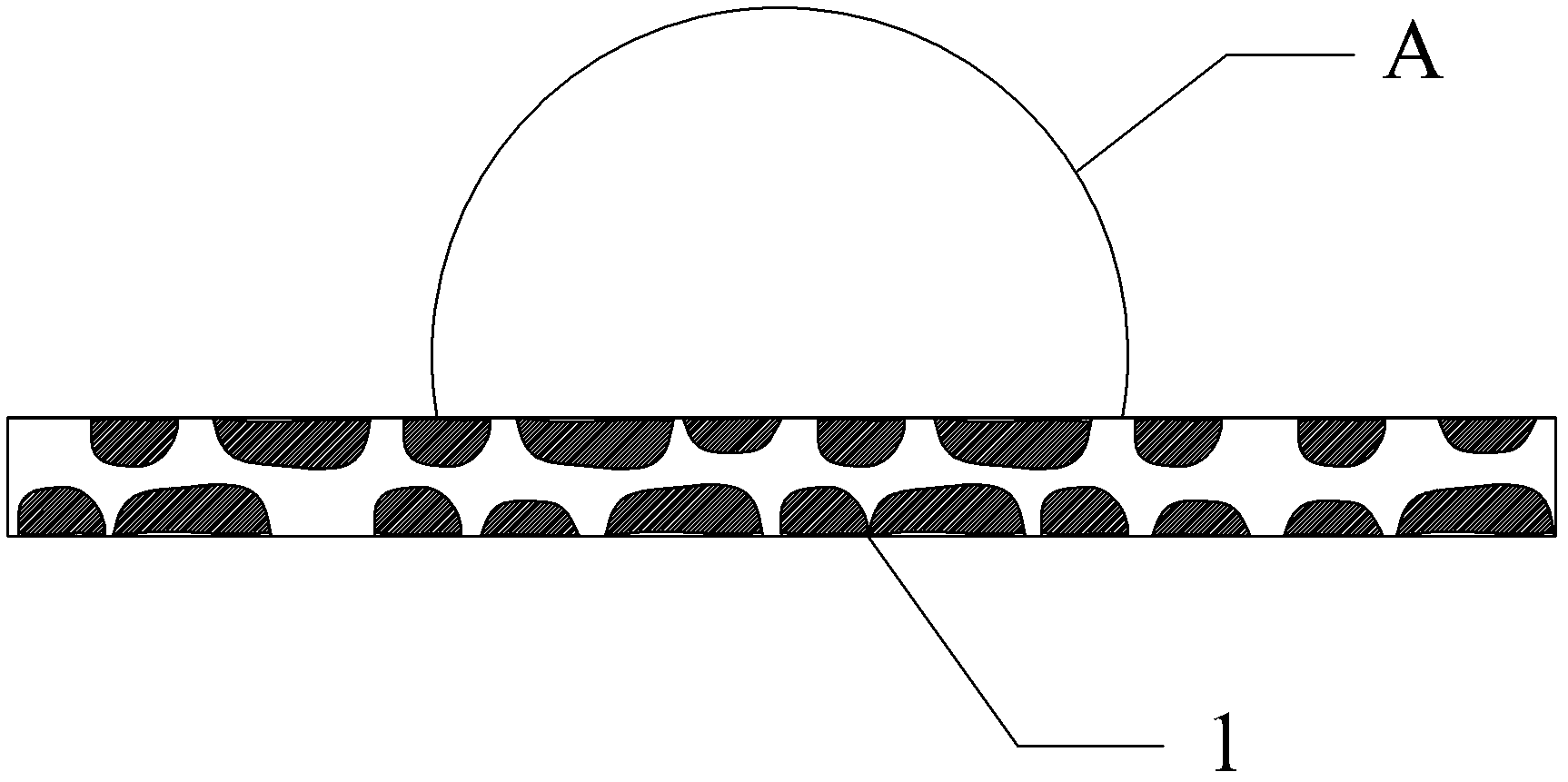

Hydrophobization fuel cell expanded graphite flow field and manufacturing method thereof

InactiveCN102544548AImprove water repellencyExcellent hydrophobic functionCell electrodesFinal product manufactureFuel cellsLiquid water

The invention discloses a hydrophobization fuel cell expanded graphite flow field and a manufacturing method thereof. The hydrophobization fuel cell expanded graphite flow field is manufactured by a porous expanded graphite material, and is characterized in that holes of the expanded graphite material are provided with hydrophobic fillers, and the upper surfaces of the hydrophobic fillers and the surface of the expanded graphite material are arranged on the same horizontal plane. The hydrophobization fuel cell expanded graphite flow field disclosed by the invention is manufactured simply, has a hydrophobization function, prompts drainage of liquid water during running of a cell and prevents MEA (Membrane Electrode Assembly) from being flooded during the running of the cell; and by utilizing the hydrophobization fuel cell expanded graphite flow field manufactured by the method disclosed by the invention, water management pressure can be effectively reduced and utilization ratio of reaction gas is improved during the running of the fuel cell.

Owner:SUNRISE POWER CO LTD

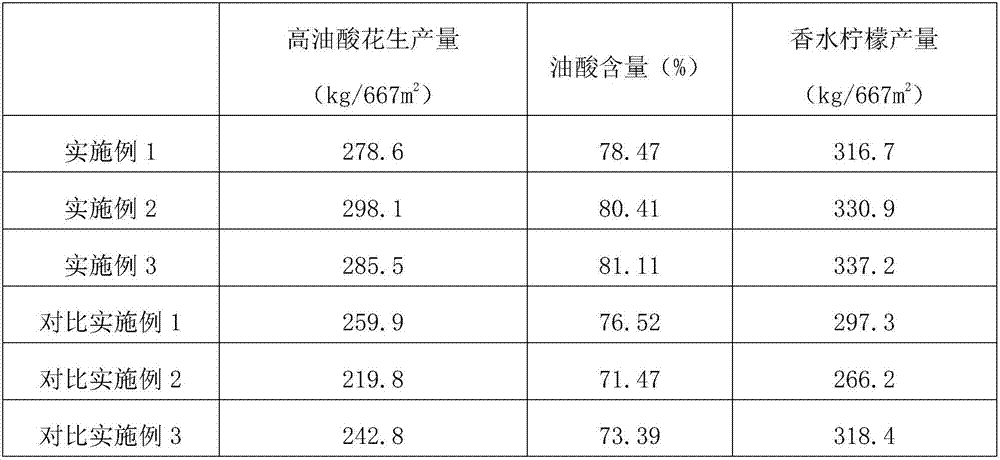

Method for intercropping lemons and high-oleic peanuts

InactiveCN107960253AImprove fertilityIncrease productionSuperphosphatesAnimal corpse fertilisersLimoniumMicrobial agent

The invention relates to the technical field of plant cultivation, in particular to a method for intercropping lemons and high-oleic peanuts. The method for intercropping the lemons and the high-oleicpeanuts comprises the steps of (1) selecting a land, applying a base fertilizer and ridging; (2) planting the lemons and sowing the high-oleic peanuts; (3) performing field management including fertilizer and water management and fruiting period management; (4) harvesting fruits when more than 85% of legumes of the high oleic peanuts are full and ripe, the lemons are in long-round shapes, and thepericarp of the lemons is bright. The method adopts furrow and ridge tillage and adds microbial agents and peanut shells to prepare decomposed organic fertilizers, the yield and quality of the lemonsand the high-oleic peanuts are ensured, and meanwhile, economic benefits and land utilization are improved.

Owner:柳州农投生态农业科技有限公司

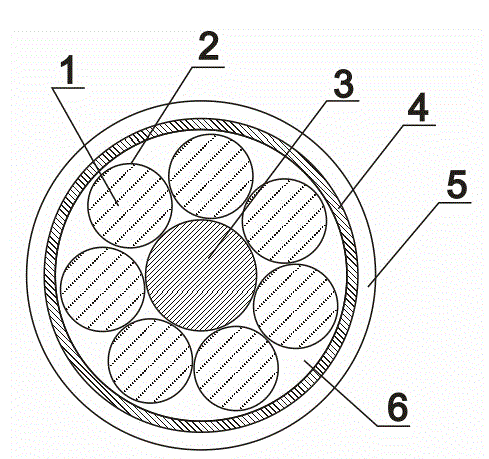

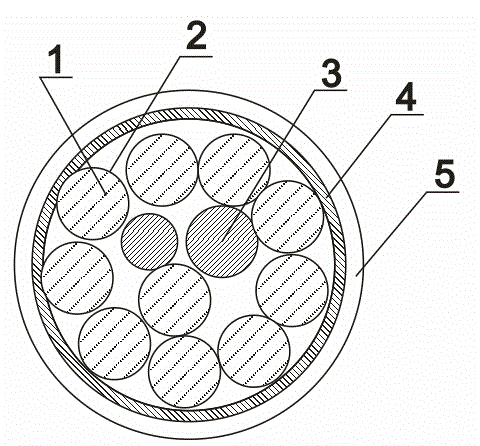

Dewatering anti-icing high-voltage power transmission line

InactiveCN105761822AExcellent hydrophobic functionWaterproof, anti-fouling and anti-icing abilityClimate change adaptationInsulated cablesThermodynamicsInsulation layer

The invention discloses a dewatering anti-icing high-voltage power transmission line comprising a metal twisted cable core formed by a plurality of metal conductors, an electric heating wire, a sheath layer and a dewatering anti-icing layer. The metal twisted cable core is externally provided with an insulation layer; the electric heating wire and the metal twisted cable core are disposed in the sheath layer; and the dewatering anti-icing layer is disposed outside the sheath layer, and is provided with a vertical water flowing groove. Power transmission is carried through the dewatering anti-icing high-voltage power transmission line; since the sheath layer is externally provided with the dewatering anti-icing layer, and the material has the excellent dewatering function, when the material is applied to a cable, the cable is allowed to have the waterproof antifouling anti-icing capabilities; and meanwhile, the electric heating wire in the cable can be used for heating the cable to melt the ice on the cable, and therefore, functions of the cable cannot be affected.

Owner:CHENGDU SHENGERJIA SCI & TECH

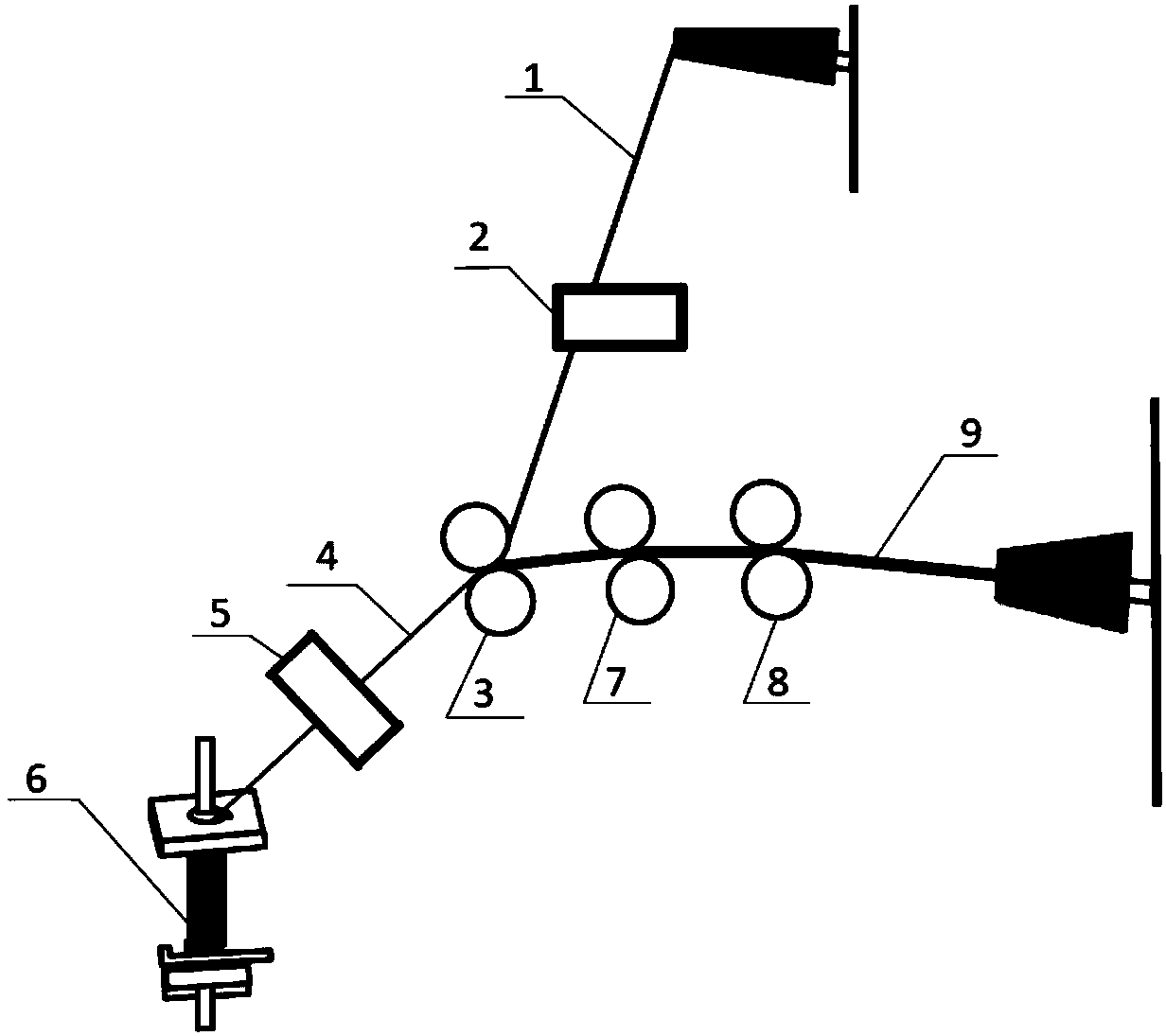

Online preparation method of hydrophobic yarn of sirofil composite spinning

InactiveCN108035023ASpeed up evaporationReduce manufacturing costYarnVegetal fibresViscoseEngineering

The invention relates to an online preparation method of a hydrophobic yarn of sirofil composite spinning, and belongs to the technical field of textile processing. The method has a characteristic oflong filament winding to short fiber by using a method of sirofil composite spinning, a modification device is arranged at the operation path portion of viscose filament yarn between a filament cylinder and a front roller, and a drying device is arranged at the operating path portion of spun yarn between the front roller and a spun yarn tube. The modification device applies modifying liquid to viscose filament yarn, the drying device dries the twisted spun yarn, and the viscose filament yarn in a shape of spatial spiral is used to wrap on the outer side of cotton roving, the hydrophobic yarn is prepared by transferring the modifying liquid on the viscose filament yarn to cotton fiber in contact with the viscose filament yarn. The method changes a method of subsequent modification of an existing yarn or fabric in general, spinning is synchronized with modification, the method shortens the production cycle, saves the production cost, and simplifies the operation steps.

Owner:WUHAN TEXTILE UNIV

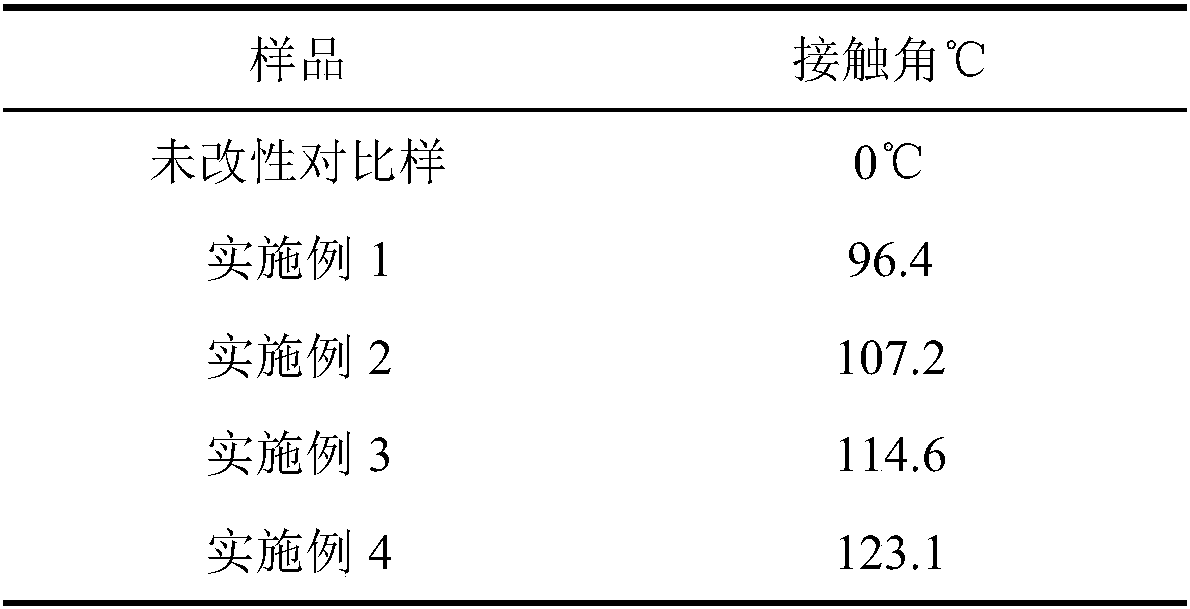

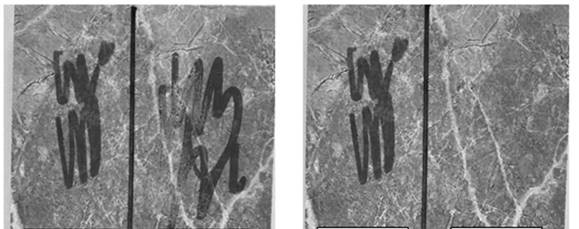

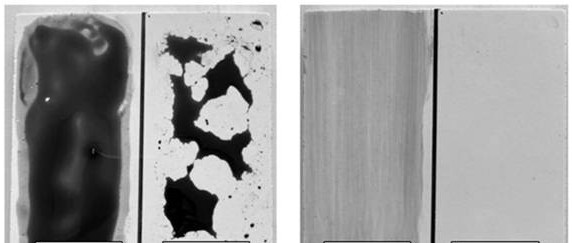

Anti-fouling nano easy-to-clean liquid and preparation method thereof, and preparation method of anti-fouling nano easy-to-clean ceramic

The invention belongs to the field of ceramic tile surface anti-fouling easy-cleaning materials, and particularly discloses an anti-fouling nanometer easy-cleaning liquid and a preparation method thereof, and an anti-fouling nanometer easy-cleaning ceramic preparation method, the anti-fouling nanometer easy-cleaning liquid comprises, by weight, 40-80 parts of micromolecule organosiloxane, 10-40 parts of hydroxyl silicone oil, 5-40 parts of ethanol silica sol, 0.1-5 parts of a catalyst, 5-30 parts of isocyanate silane, and 10-40 parts of a mercapto silane coupling agent. The invention further discloses a preparation method of the organic silicon nano easy-cleaning liquid and a method for preparing anti-fouling nano easy-cleaning ceramic from the organic silicon nano easy-cleaning liquid. The anti-fouling nano easy-to-clean liquid is simple in preparation process, safe, non-toxic, green, environment-friendly, durable and efficient in anti-fouling and easy-to-clean effect and long in service life, and caters to the pursuit of people for clean and comfortable living space.

Owner:FOSHAN CITY GANI CERAMICS CO LTD +2

Novel wear-resistant waterproof electronic material coating and preparation method thereof

InactiveCN110713784AWear-resistantWaterproofPolyurea/polyurethane coatingsElectronic materialsOligomer

The invention discloses a novel wear-resistant waterproof electronic material coating and a preparation method thereof. The invention provides a UV-cured waterproof wear-resistant coating composition.The UV-cured waterproof wear-resistant coating composition comprises fluorine-containing acrylate, an acrylate monomer, a urethane acrylate oligomer and wear-resistant nanoparticles. Besides the hydrophobic and waterproof properties of the fluorine-containing coating, the coating has the properties of a wear-resistant hard coating. The invention provides a wear-resistant waterproof coating for electronic products.

Owner:荀为伟

Special hydrophobic coating for aluminum strip

ActiveCN103965728AExcellent hydrophobic functionReduce adhesionEpoxy resin coatingsEpoxyPhenyl Ethers

A special hydrophobic coating for an aluminum strip is a coating coated on a metal plate. The special hydrophobic coating is produced by adopting a routine production technology of coatings, and is characterized in that the special hydrophobic coating comprises 25-35wt% of a water-soluble acrylic resin, 5-15wt% of amino resin for coatings, 1-4wt% of water-soluble epoxy resin, 0.5-2.0wt% of water-soluble silicone oil, 0.5-1.5wt% of dimethyl ethanolamine, 0.5-1.5wt% of ethylene glycol monobutylether, 0.1-0.4wt% of dinonylnaphthalenedisulphonic acid, 0.3-0.8wt% of NP-40 polyoxyethylene nonyl phenyl ether, and the balance purified water. The surface of the aluminum strip is coated with the coating obtained in the invention through a roller coating technology to form the hydrophobic aluminum strip, and use and examination results show that compared with common aluminum strips in the prior art, the coated aluminum strip obtained in the invention has a good hydrophobic function, the contact angle of water drops on the surface of the aluminum strip is 155-165DEG, and the water drops do not adhere with each other, and highly likely tumble; and the hydrophobic aluminum strip can be used in a refrigeration system in order to improve the heat exchange effect, reduce energy consumption and prolong the service life.

Owner:ZHENJIANG WANYUAN ELECTRONICS

A kind of environment-friendly anticorrosion coating and preparation method thereof

ActiveCN105969050BImprove anti-corrosion performanceGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyDiluent

The invention provides environment-friendly anticorrosive paint and a preparation method thereof. The environment-friendly anticorrosive paint comprises a main agent and a curing agent. The main agent is prepared from, by weight of 100 parts, 39-50 parts of low-viscosity solvent-free epoxy resin, 4-8 parts of diluents, 5-15 parts of toughening resin, 0.5-15 parts of toner, 10-40 parts of filler, 5-15 parts of low-viscosity epoxy ester resin and 0.5-1.5 parts of a thixotropic agent. The curing agent is modified amine resin.

Owner:CHINA PAINT MFG CO SHENZHEN

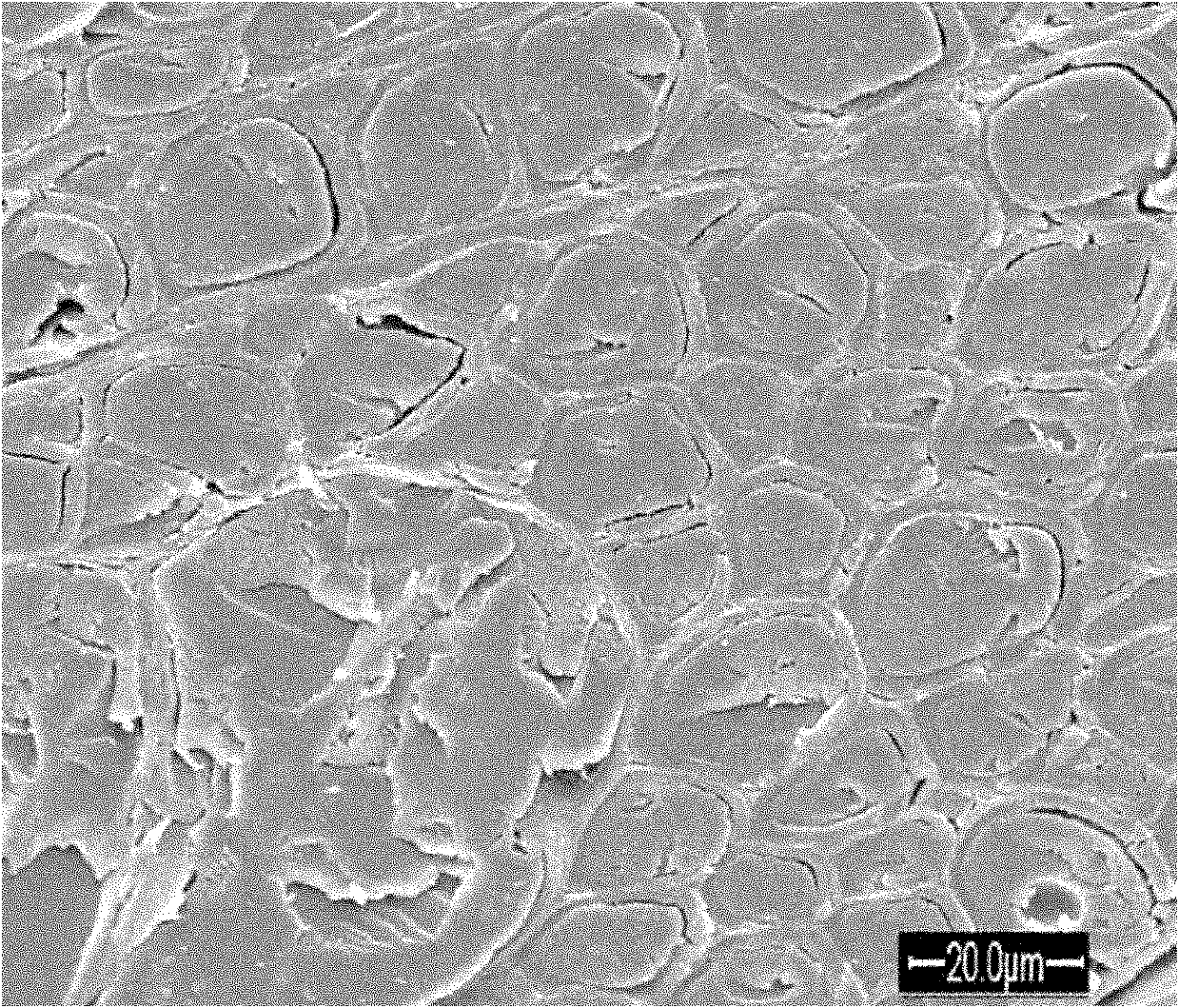

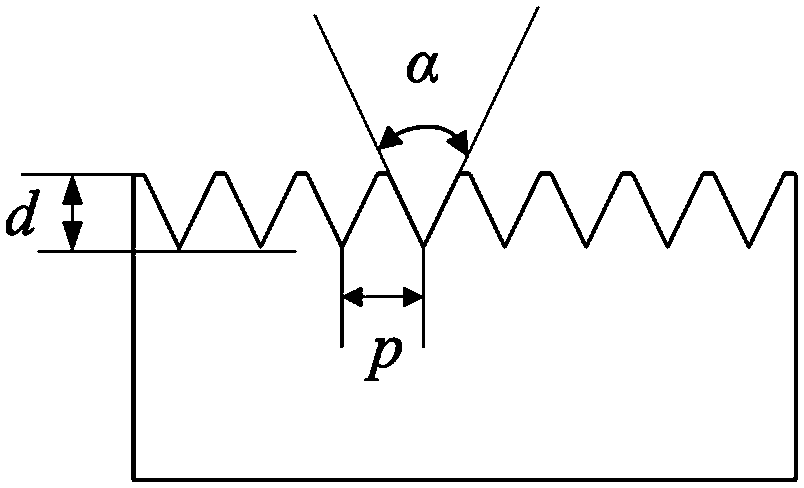

Titanium-silicon-carbon ceramic structure with hydrophobic microstructure and preparation method of titanium-silicon-carbon ceramic structure

The invention discloses a titanium-silicon-carbon ceramic structure with a hydrophobic microstructure. The titanium-silicon-carbon ceramic structure comprises a titanium-silicon-carbon ceramic workpiece, a working face of the titanium-silicon-carbon ceramic workpiece is uniformly provided with a micro-groove array structure composed of a plurality of longitudinal micro-groove structures parallel with a length direction of the working face, the depth of the longitudinal micro-groove structures is 50-200 microns, and the distance between every two adjacent micro-groove structures is 60-1000 microns. The invention further discloses a preparation method of the titanium-silicon-carbon ceramic structure with the hydrophobic microstructure. The method and structure has the effects that 1, fine electric spark discharge machining is carried out, and the micro-groove structures with high quality and regular shape can be processed, and have relatively high shape precision; 2, the preparation method can be used for allowing the surface of titanium-silicon-carbon ceramic structure to be machined the micro-groove structures, the micro-scale can be controlled to hundred microns or even several microns, and shape features can also be controlled; and 3, compared with a traditional ceramic workpiece, the ceramic workpiece with the microstructure array has a good hydrophobic function.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of hydrophobic material with surface modified by Fe3O4 nanoflower

InactiveCN103112903BPlay a protective effectWith super hydrophobic functionMaterial nanotechnologyFerroso-ferric oxidesHydrophobeAntiseptic

The invention provides a hydrophobic material with a surface modified by Fe3O4 nanoflower. A preparation method comprises the following steps of: soaking a cleaned pure iron sheet in a nitric acid solution with concentration of 0.5-2.5mol / L, and enabling reaction at 30-50 DEG C for 5-15 minutes; slowly introducing ammonia gas into the reaction system in the condition of external magnetic field so that the acid solution of the system gradually becomes alkaline; heating the system to 230-285 DEG C, and enabling reaction for 30-90 minutes to generate black brown Fe3O4 particles on the iron sheet; cooling, washing and drying to obtain a hydrophobic material with a surface modified by Fe3O4 nanoflower, wherein the contact angle can reach 136.23-146.12 degrees according to measurement, and good hydrophobicity is realized; and performing heat treatment of the hydrophobic material at 150-200 DEG C to obtain a hydrophobic material modified by gamma-Fe2O3 nanoflower and having stable performance and excellent hydrophobicity. The hydrophobic material provided by the invention has a broad application prospect in the field of antiseptic and self-cleaning materials.

Owner:NORTHWEST NORMAL UNIVERSITY

Sizing process suitable for moisture-regaining-resistant kraft liner cardboard paper

PendingCN112695566AExcellent hydrophobic functionGood adhesivenessCoatings with pigmentsWater-repelling agents additionCardboardPolymer science

The invention discloses a sizing process suitable for moisture-regaining-resistant kraft liner cardboard paper. The method comprises the steps of (1) pretreating corn starch; (2) preparing a sizing agent; (3) conducting sizing, specifically, drying the paper web and then sizing; and (4) carrying out sizing post-treatment. According to the sizing process, polyvinyl alcohol, titanium dioxide and corn starch are mixed to prepare the novel sizing agent, so that the sizing agent has a good hydrophobic function, and meanwhile, chitosan is added, so that the adhesiveness of the sizing agent is improved.

Owner:JIANGSU LEE & MAN PAPER MFG

Waterproof energy-saving heat insulation material

The invention discloses a waterproof energy-saving heat insulation material, which is prepared from the following ingredients in parts by weight: 18 to 28 parts of calcium silicate, 5 to 10 parts of diatomite, 30 to 50 parts of sepiolite, 18 to 26 parts of waste ceramic powder, 10 to 16 parts of pure acrylic ester, 20 to 30 parts of open hole expanded perlite, 3 to 8 parts of antimony-based nanometer composite environment-friendly fire retardants, 8 to 14 parts of magnesium sulfate, 4 to 9 parts of polypropylene fiber, 2 to 5 parts of acrylic emulsion, 6 to 12 parts of hydroxypropyl methyl cellulose water-retaining agents, 5 to 14 parts of stearic acid, 2 to 5 parts of aminopropyltriethoxysilane, 1 to 5 parts of aldehyde acetone polycondensate, 8 to 14 parts of seaweed glue, 1 to 3 parts of 2-acrylamide-2-methylpropane sulfonic acid copolymers, 3 to 8 parts of dodecayl dimethyl amine oxide and 5 to 12 parts of modified light calcium carbonate. The waterproof energy-saving heat insulation material has the advantages that the heat insulation performance is good; the hydrophobic function is good; the material per se has good ventilation performance; the waterproof performance of the thermal isolation and heat insulation material is good; the room temperature favorably keeps stable; the waterproof energy-saving heat insulation material is used for improving the living comfort, prolonging the building service life, and reducing the heating heat loss and cold air loss, so that the goal of reducing the energy consumption is reached.

Owner:GUANGXI BEIHAI HAOBANG NEW ENERGY TECH CO LTD

Preparation method of reflective insulation decorative mortar

The invention discloses a preparation method of reflective insulation decorative mortar. The preparation method comprises the following steps: selecting white cement, high-strength gypsum, infrared colored sand, infrared titanium dioxide, nano rare earth, silica fume, sepiolite powder, renewable latex powder, a water-retaining agent, starch ether, a thixotropic agent, an organic silicon water-increasing agent, a water reducing agent, a dispersing agent, a retarder and a proper amount of water according to the dosage percentage; and then performing stirring, mixing, inspecting and packaging insequence. The reflective insulation decorative mortar has a reflective thermal insulation function, a polymer high polymer material and a plurality of infrared reflective thermal insulation functionalmaterials are adopted, the reflective insulation decorative mortar has the characteristics of decorative mortar, and the sunlight reflectance of the product is 0.71 or above; near infrared rays account for 80% or above, heat absorption of the outer wall facing layer is effectively reduced, and the wall temperature is reduced.

Owner:HANGZHOU MINMIN PAINT CO LTD

A kind of external wall nano-heat insulation reflective paint additive

ActiveCN103834216BRealize self-cleaning functionExcellent hydrophobic functionReflecting/signal paintsThermal insulationNano sio2

The invention discloses a nano thermal insulation reflective coating additive for an exterior wall. The nano thermal insulation reflective coating additive comprises the main components in weight ratio: 160-250 parts of water, 1-2 parts of defoaming agent, 8-12 parts of dispersing agent, 0.5-2 parts of hydroxyethyl cellulose, 400-500 parts of thermal insulation reflective powder, 5-10 parts of nano TiO2 powder, 5-10 parts of nano SiO2 powder, 5-12 parts of ethylene glycol, 5-10 parts of film-forming additive, 200-300 parts of AC-261P waterborne acrylic emulsion and 1.0-2.0 parts of thickening agent. The nano thermal insulation reflective coating additive is prepared by stirring all the components according to the weight ratio. The coating additive for the exterior wall can be used for realizing the thermal insulation reflection of a color coating for the exterior wall, and furthermore, the energy conservation of a building is realized; water is used as a solvent, so that the nano thermal insulation reflective coating additive has the advantages of environment friendliness, exterior wall hydrophobicity, self-cleaning and the like.

Owner:深圳市文浩科技有限公司

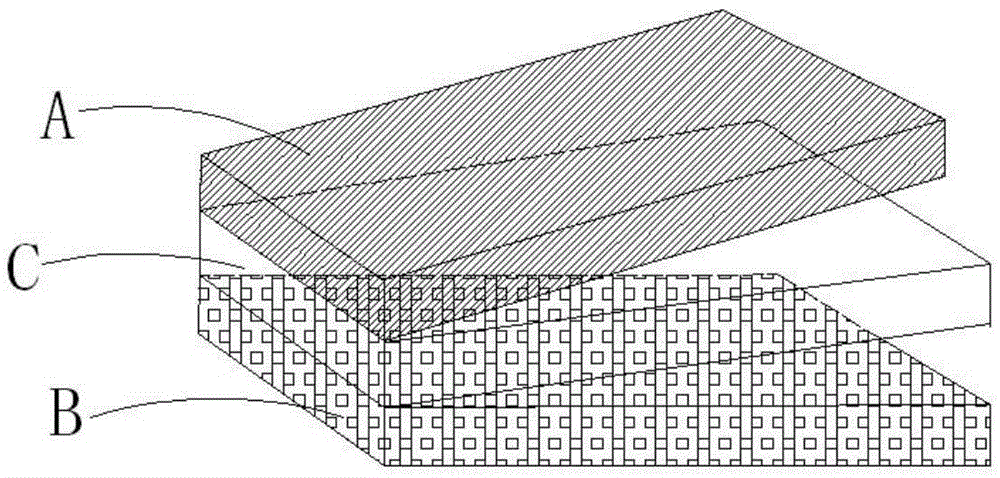

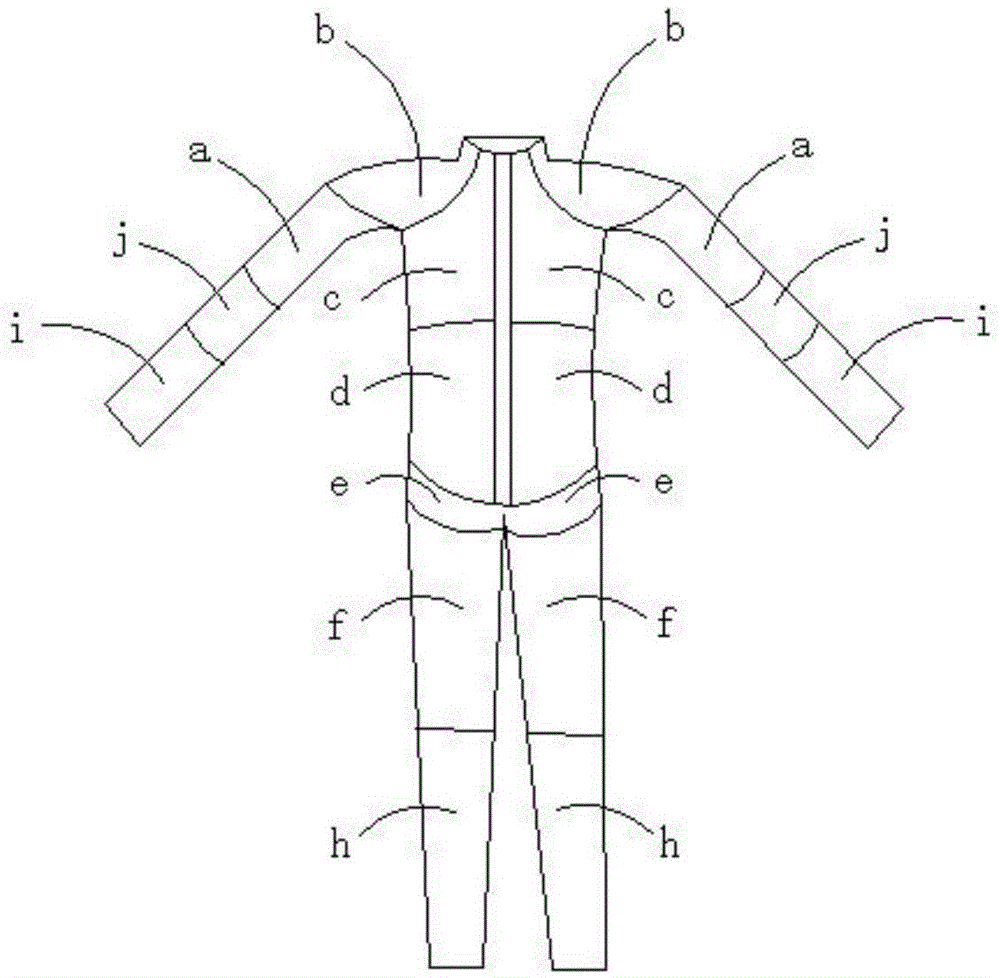

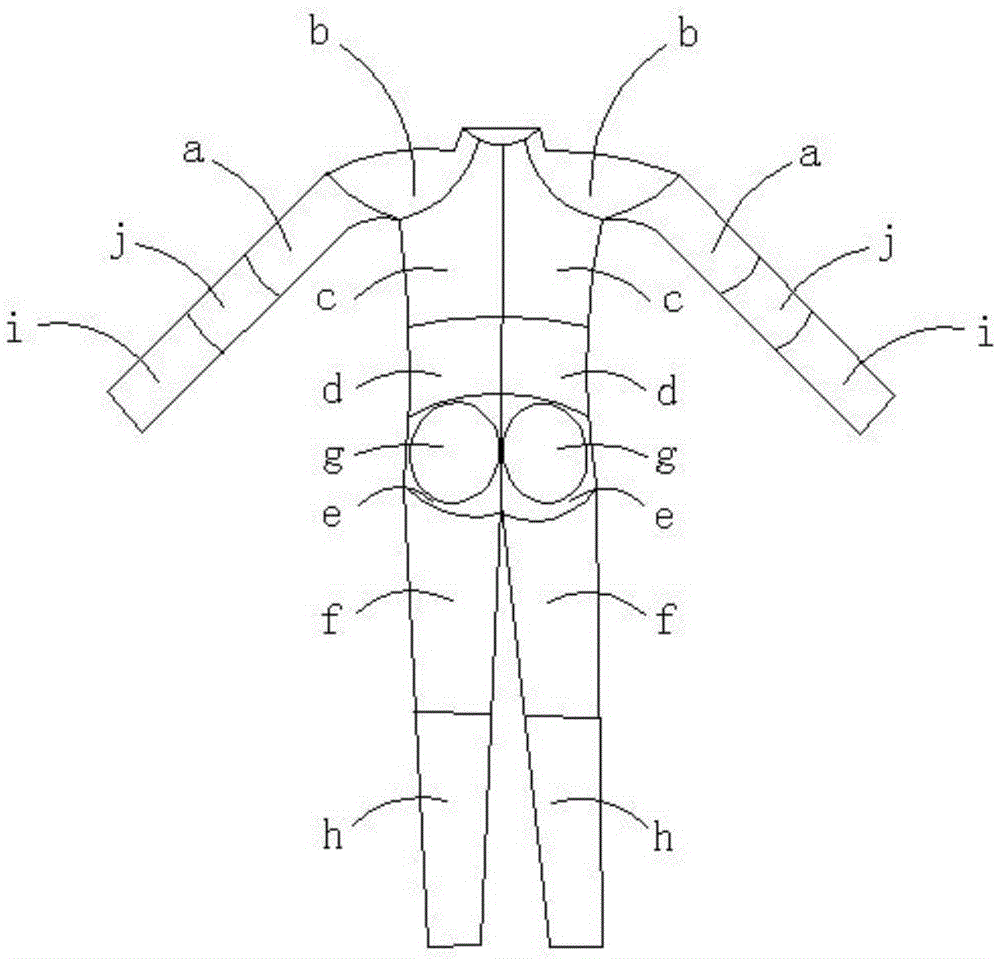

Functional clothing for improving metabolic syndrome and manufacturing method thereof

A functional clothing for alleviating metabolic syndromes and manufacturing method thereof. The raw material of the functional clothing comprises primary functional layer fabric (C), and can further comprise secondary functional layer fabric (B). The inside surface of the primary functional layer fabric (C) is obtained through processing under a preset first process condition with a preset first coagent; the inside surface of the secondary functional layer fabric (B) is obtained through processing under a preset second process condition with a preset second coagent. The first coagent gives the inside surface of the primary functional layer fabric (C) hydrophilicity, warmth and breathability functions; the second coagent enables the inside surface of the secondary functional layer fabric (B) to have L-carnitine adhere. The functional clothing can directly contact skin, and the outside surface thereof has good hydrophobicity. By control of the functions of good hydrophilicity, warmth and excellent breathability of the inside surface thereof, and by utilizing the temperature and humidity environment of the skin surface to establish a drug transdermal release system to facilitate transdermal absorption of the micromolecular hydrophilic drug L-carnitine, the functional clothing worn by a user for a long time can alleviate secretion of insulin and obesity related factors, further alleviating metabolic syndromes. The method of manufacturing the functional clothing is easy of operation and has a low cost.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Anti-fog lens coating method

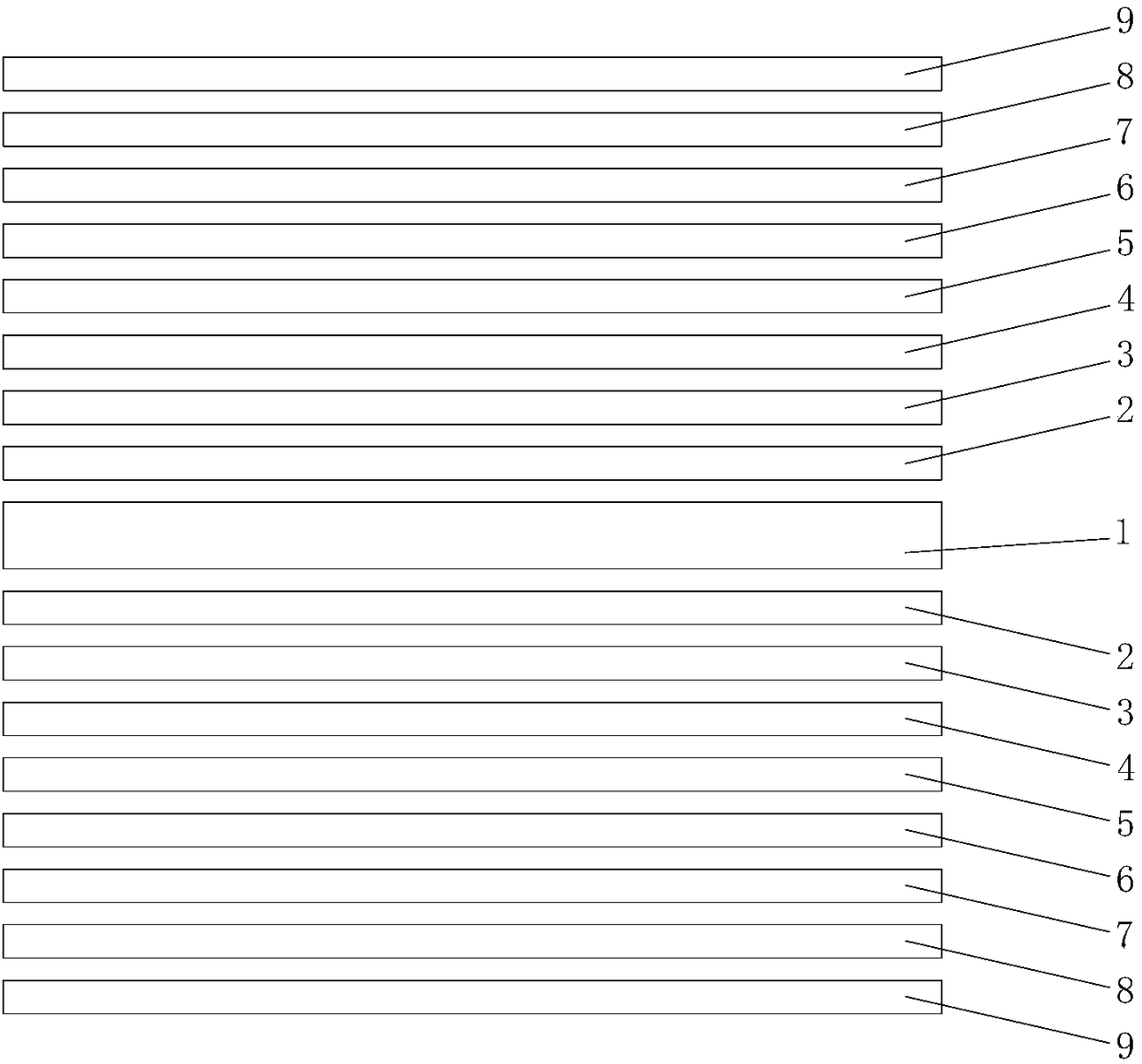

InactiveCN108060396AHigh refractive indexGood coating workabilityVacuum evaporation coatingSputtering coatingAnti-fogMaterials science

The invention relates to an anti-fog lens coating method. The anti-fog lens coating method comprises the following steps that (1), a substrate is cleaned and dried; and (2), the inner surface and theouter surface of the substrate are coated separately, specifically, the two surfaces are coated with first films, second films, third films, fourth films, fifth films, sixth films, seventh films and eighth films separately. According to the anti-fog lens coating method, the multiple films on the lens can effectively prevent fog, metal layers can effectively improve the definition and the anti-dazzle and anti-blue-ray effects, therefore, the overall definition of the lens is improved, contribution is made to the definition and reality of the vision, and visual fatigue can be effectively relieved.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Thermal insulation water-based paint capable of being constructed at low temperature and preparation method thereof

PendingCN114163886ALow thermal conductivityReduce risk of defectsCoatingsCelluloseThermal insulation

The invention relates to the technical field of water-based paint, in particular to heat-preservation water-based paint capable of being constructed at low temperature and a preparation method of the heat-preservation water-based paint. The heat-preservation water-based paint is prepared from the following raw materials in percentage by weight: 0.2 to 0.6 percent of dispersing agent, 0.1 to 0.4 percent of hydroxyethyl cellulose, 0.1 to 0.4 percent of defoaming agent, 0.2 to 0.5 percent of wetting leveling agent, 1 to 4 percent of anti-freezing agent, 0.8 to 2 percent of coalescing agent, 14 to 18 percent of titanium dioxide, 0.4 to 1.2 percent of fumed silica, 0.7 to 1.7 percent of sericite, 4 to 7 percent of nano coated ceramic microbeads, 1.5 to 6 percent of expanded perlite, 7 to 13 percent of floating beads, 6 to 12 percent of aerogel, 0.3 to 0.7 percent of thickening agent, 0.05 to 0.25 percent of mildew preventive and the balance of water. The coating is prepared from the following components in percentage by weight: 0.05-0.25% of a light stabilizer, 0.2-0.6% of an ultraviolet light absorber, 1.5-4% of a silane coupling agent, 9-14% of deionized water and the balance of hydroxyl acrylic emulsion. The thermal-insulation water-based paint has the advantage that the thermal-insulation water-based paint can be constructed at a low temperature.

Owner:北京安连科技股份有限公司

A kind of superhydrophobic artificial marble and preparation method thereof

ActiveCN104761183BGood super hydrophobic functionExcellent hydrophobic functionSolid waste managementSlagFire retardant

The invention relates to the technical field of building materials and particularly relates to super-hydrophobic artificial marble which is composed of following components, by weight: 100 parts of unsaturated polyester resin, 0.5-2 parts of a peroxide-type initiator, 0.1-2 parts of an accelerant, 5-30 parts of vinyl-type resin diluent, 5-30 parts of polyvinyl-type resin assistant crosslinker, 100-500 parts of ore slag micro powder, 10-30 parts of a flame retardant, and 3-15 parts of polyfluoro-modified bisphenol A epoxy acrylate polymer. In the invention, the polyfluoro-modified bisphenol A epoxy acrylate polymer, which has a super-hydrophobic function, is employed as a hydrophobic additive to prepare the artificial marble, so that the artificial marble is excellent in hydrophobic performance. A contact angle between the surface of the super-hydrophobic artificial marble and water is 150-170 degrees so that the surface of the super-hydrophobic artificial marble has an excellent self-cleaning function. In addition, the marble in deep color series is high in strength, is good in waterproof performance and is strong in corrosion resistance.

Owner:宝武环科(湛江)资源循环利用有限公司

Preparation method of cast aluminum alloy film coat

InactiveCN101781763BGood compatibilityImprove corrosion resistanceMetallic material coating processesDuraluminFluorine containing

The invention relates to a preparation method of a cast aluminum alloy film coat, which is characterized by cleaning a cast aluminum alloy component firstly, performing chromate oxidation treatment secondly, and then preparing a film sealing coat of fluorine containing acrylicester on a chromate oxide film. Construction methods such as brushing or spraying is used for the invention, the methods are flexible and simple and has high maneuverability; the invention can be applied in the protective treatment for cast aluminum alloy of ZL102, ZL104, ZL107, ZL112, ZL114 and the like, and is particularly suitable for treatment of the cast aluminum alloy component used in the ocean environment; and the invention is also suitable for the protective treatment of other aluminum alloy materials or components, such as treatment of duralumin, super duralumin, wrought aluminum and rust-proof aluminum alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A kind of preparation method of using geothermal water to construct superhydrophobic layer on bamboo/wood surface

ActiveCN109015982BImprove responseControl shapeWood treatment detailsPretreatment apparatusGlycidyl methacrylatePolydimethyl siloxane

The invention relates to a preparation method for constructing a super-hydrophobic layer on the surface of bamboo / wood by using geothermal water. Firstly, the lignin on the surface of bamboo / wood is treated with NaOH solution, so that the hydroxyl group is exposed on the surface as much as possible, and then it is immersed in methacrylic acid to shrink React in a glyceride solution, and finally deposit calcium carbonate crystals on the surface of bamboo and wood by hydrothermal method, and combine the low surface energy material polydimethylsiloxane to construct an aragonite calcium carbonate surface layer with hydrophobic function on the surface of bamboo / wood. Advantages: 1) NaOH solution is used to remove the lignin components on the surface of bamboo / wood, so that the hydroxyl groups in bamboo / wood are exposed on the surface as much as possible, which is beneficial to the next reaction. 2) Using GMA as the coupling agent, the epoxy group reacts with the hydroxyl group to fix it on the bamboo / wood surface, and the carboxyl group reacts with the Ca 2+ Formation of complexes, by regulating the carboxyl group and Ca 2+ The complexes formed control the growth crystal form and morphology of calcium carbonate. 3) Environmental protection, good biocompatibility, low production cost, and good hydrophobicity.

Owner:桂东众意竹木开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com