Foam geopolymer adsorbing material as well as preparation method and application thereof

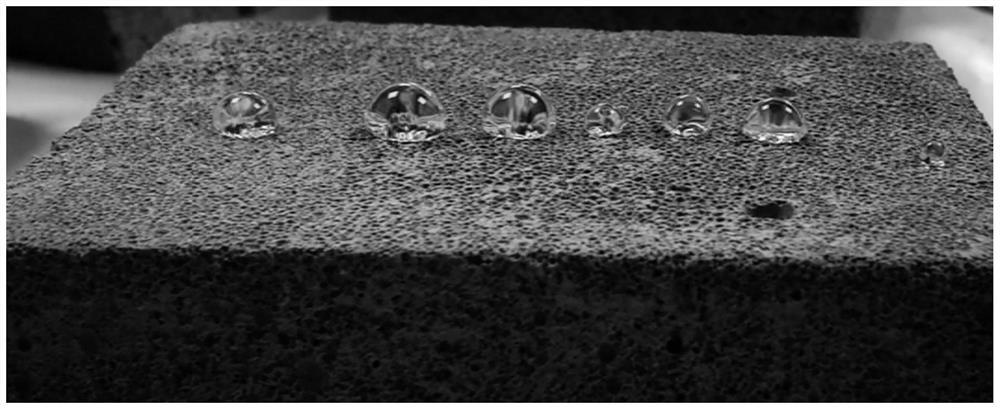

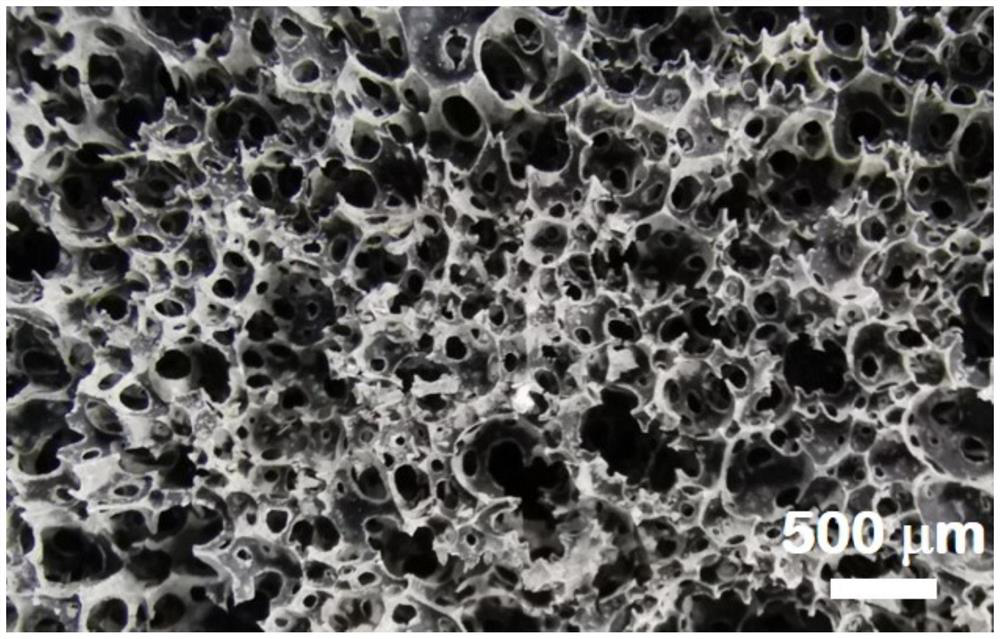

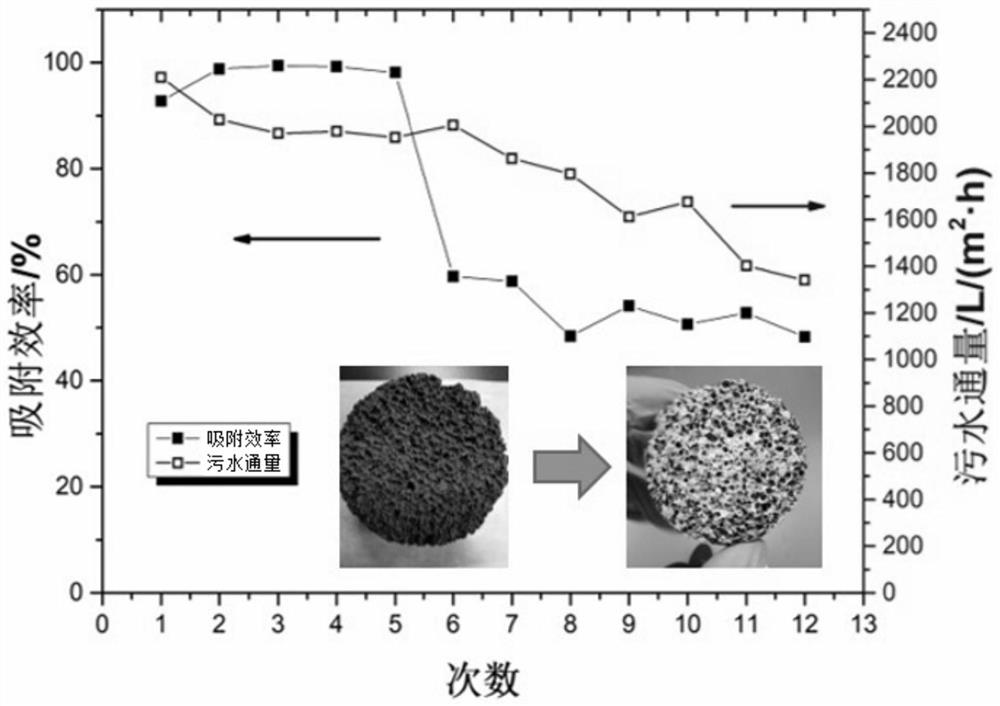

A technology of geopolymers and adsorbent materials, which is applied in the fields of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., which can solve the problems of not being effectively developed, difficult to achieve pore connectivity, and difficult to control the pore structure. , to achieve the effect of excellent hydrophobic function, avoid alkali loss and efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of foam geopolymer adsorption material, comprising the following process steps:

[0036] a. Mix 5 parts of fly ash, 2 parts of blast furnace slag and 3 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator at 100r / min and stir for 1min to obtain a mixing slurry, mix The mass ratio of dry material to the activator is 5:3.5; wherein, the particle size of fly ash and blast furnace slag is ≤45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1mm-2mm at 100°C for 15h; The preparation method of the activator is as follows: after stirring and mixing the alkali solution and the sodium water glass according to the mass ratio of 4:1 for 20min, then leave it to stand for 24h to obtain; the alkali solution is a sodium hydroxide solution of 3.5mol / L; the sodium The modulus of water glass is 3.4;

Embodiment 2

[0041] A preparation method of foam geopolymer adsorption material, comprising the following process steps:

[0042] a. Mix 5 parts of fly ash, 3 parts of blast furnace slag and 2 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator at 110r / min and stir for 2min to obtain a mixing slurry, mix The mass ratio of dry material to the activator is 5:4; wherein, the particle size of fly ash and blast furnace slag is ≤45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1mm-2mm at 110°C for 12h; The preparation method of the activator is: after stirring and mixing the alkali solution and the sodium water glass according to a mass ratio of 5:1 for 30 minutes, leave it to stand for 28 hours to obtain; the alkali solution is a sodium hydroxide solution of 4mol / L; the sodium water The modulus of the glass is 3.5;

Embodiment 3

[0047] A preparation method of foam geopolymer adsorption material, comprising the following process steps:

[0048] a. Mix 6 parts of fly ash, 2 parts of blast furnace slag and 2 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator at 120r / min and stir for 3min to obtain a mixing slurry, mix The mass ratio of dry material to the activator is 5:4.5; wherein, the particle size of fly ash and blast furnace slag is ≤45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1mm-2mm at 120°C for 10h; The preparation method of the activator is as follows: after stirring and mixing the alkali solution and the sodium water glass according to a mass ratio of 6:1 for 40 minutes, leave it to stand for 30 hours to obtain; the alkali solution is a sodium hydroxide solution of 4.5mol / L; the sodium The modulus of water glass is 3.6;

[0049] b. Add 35wt% hydrogen perox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com