A kind of foam geopolymer adsorption material and its preparation method and application

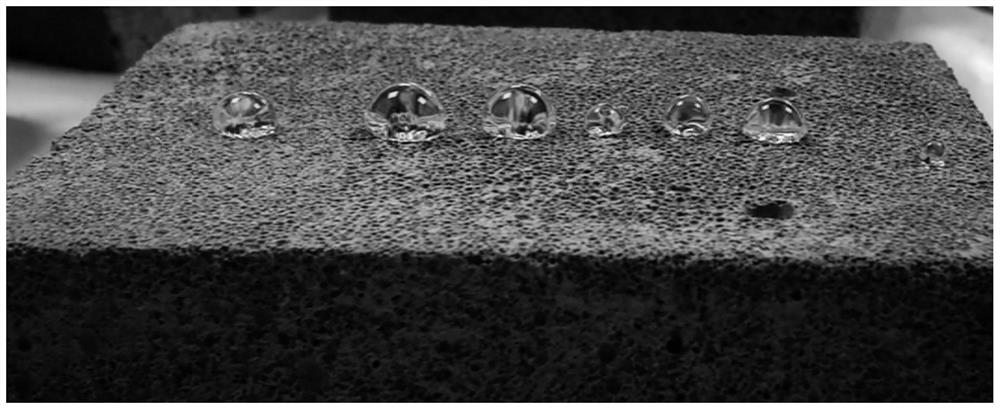

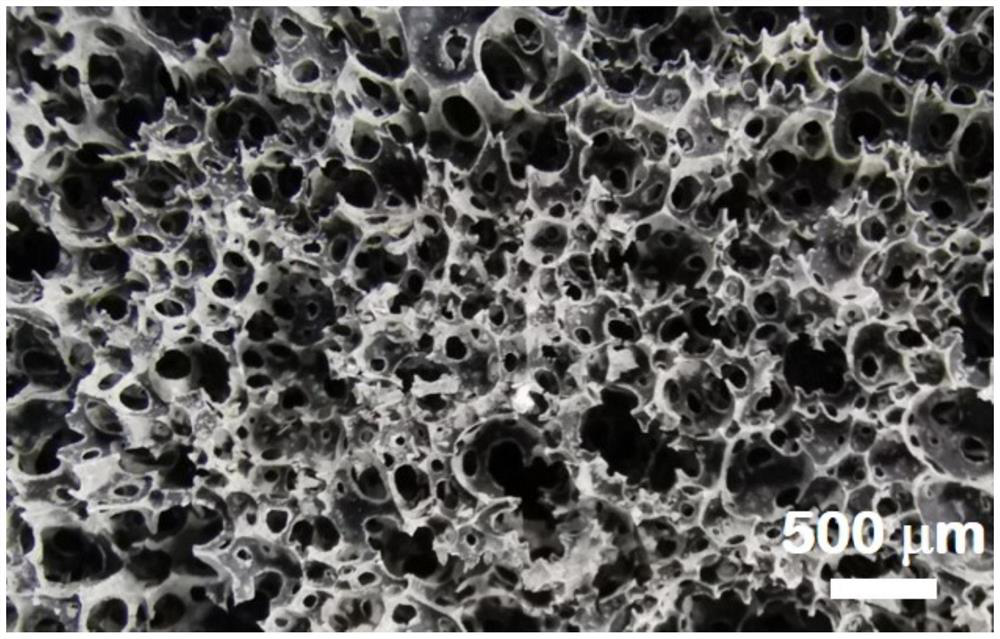

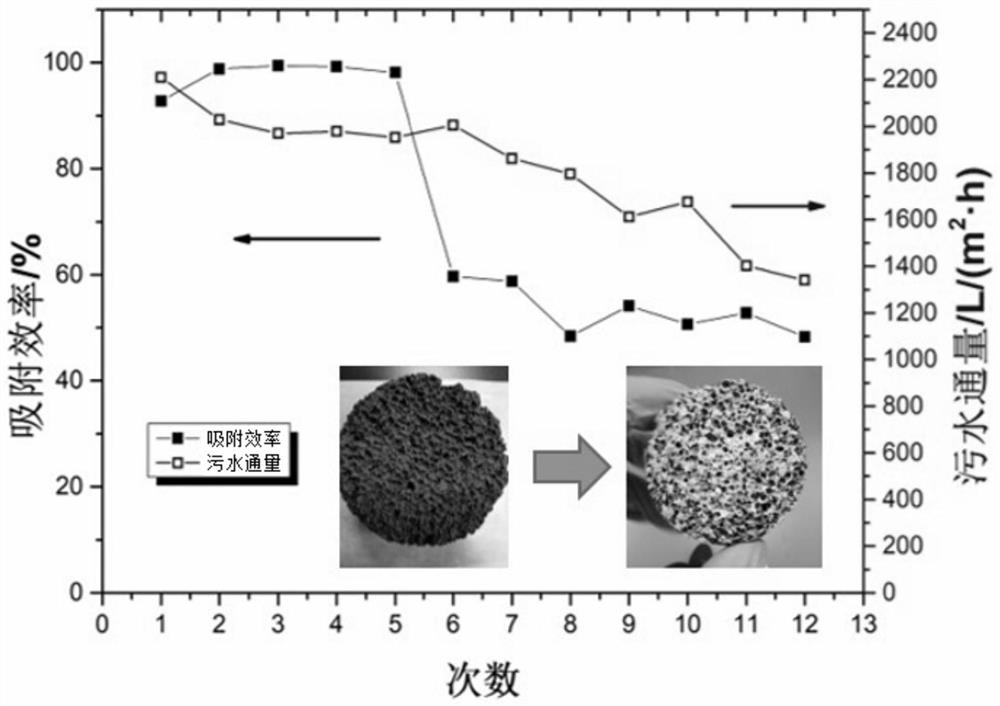

A technology of geopolymers and adsorption materials, applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems that have not been effectively developed, difficult to achieve pore connectivity, difficult to control pore structure, etc. , to achieve excellent hydrophobic function, avoid alkali loss, and high-efficiency adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a foam geopolymer adsorbent material, comprising the following process steps:

[0036] a. Mix 5 parts of fly ash, 2 parts of blast furnace slag and 3 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator and stir at 100 r / min for 1 min to obtain a mixing slurry, mix The mass ratio of dry material to the activator is 5:3.5; wherein the particle size of fly ash and blast furnace slag is less than or equal to 45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1mm-2mm at 100°C for 15h; The preparation method of the activator is as follows: the alkali solution and sodium water glass are stirred and mixed for 20 minutes according to a mass ratio of 4:1, and then left to stand for 24 hours; the alkali solution is a 3.5 mol / L sodium hydroxide solution; the sodium The modulus of water glass is 3.4;

[0037] b. Add 25wt% hydrog...

Embodiment 2

[0041] A preparation method of a foam geopolymer adsorbent material, comprising the following process steps:

[0042] a. Mix 5 parts of fly ash, 3 parts of blast furnace slag and 2 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator and stir at 110 r / min for 2 min to obtain a mixed slurry, mix The mass ratio of dry material to the activator is 5:4; wherein, the particle size of fly ash and blast furnace slag is less than or equal to 45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1 mm-2 mm at 110 ° C for 12 hours; The preparation method of the activator is as follows: the alkali solution and sodium water glass are stirred and mixed for 30 minutes according to a mass ratio of 5:1, and then left for 28 hours to obtain; the alkali solution is a 4 mol / L sodium hydroxide solution; the sodium water The modulus of the glass is 3.5;

[0043]b, add 30w...

Embodiment 3

[0047] A preparation method of a foam geopolymer adsorbent material, comprising the following process steps:

[0048] a. Mix 6 parts of fly ash, 2 parts of blast furnace slag and 2 parts of activated carbon according to the mass ratio to obtain a mixed dry material; add the mixed dry material to the activator and stir at 120 r / min for 3 min to obtain a mixing slurry, mix The mass ratio of dry material to the activator is 5:4.5; wherein, the particle size of fly ash and blast furnace slag is less than or equal to 45 μm, and the activated carbon is obtained by drying activated carbon particles with a particle size of 1 mm-2 mm at 120 ° C for 10 hours; The preparation method of the activator is as follows: the alkali solution and sodium water glass are stirred and mixed for 40 minutes according to a mass ratio of 6:1, and then left to stand for 30 hours; the alkali solution is a 4.5 mol / L sodium hydroxide solution; the sodium The modulus of water glass is 3.6;

[0049] b. Add 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com