Sizing process suitable for moisture-regaining-resistant kraft liner cardboard paper

A technology of liner board and kraft leather, applied in the field of papermaking, can solve the problems of paper webs not having moisture resistance, and achieve the effect of improving adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

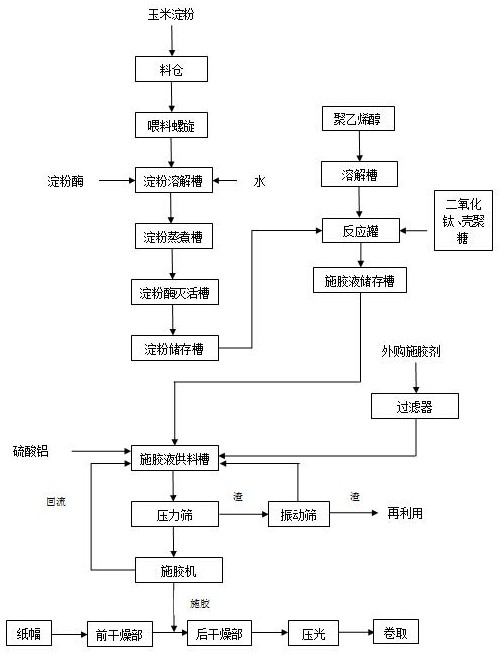

[0026] The specific process is as figure 1 As shown, a sizing process suitable for moisture-resistant kraft liner linerboard includes the following steps:

[0027] (1) Corn starch pretreatment: After mixing corn starch, water and amylase for 60-90 minutes, heat up to 85-90°C, react for 20-30 minutes, then heat up to 130-140°C, and react for 5-10 minutes; Keep the temperature at 85-90°C to obtain a starch solution for later use;

[0028] (2) Sizing agent preparation: mix polyvinyl alcohol and water and put it in the reaction kettle, then add the starch solution in step (1) to the reaction kettle, then add titanium dioxide and chitosan, mix well and then add sulfuric acid Aluminum, placed together in the sizer;

[0029] (3) Sizing: After the paper web is dried at 60-80°C, sizing is performed on both sides;

[0030] (4) Post-sizing treatment: After sizing, dry again at a temperature of 60-80°C. After drying, calender and coil.

[0031] In the step (1), based on 10 parts by we...

Embodiment 2

[0035] The specific process is as figure 1 As shown, a sizing process suitable for moisture-resistant kraft liner linerboard includes the following steps:

[0036] (1) Corn starch pretreatment: After mixing corn starch, water and amylase for 60-90 minutes, heat up to 85-90°C, react for 20-30 minutes, then heat up to 130-140°C, and react for 5-10 minutes; Keep the temperature at 85-90°C to obtain a starch solution for later use;

[0037] (2) Sizing agent preparation: mix polyvinyl alcohol and water and put it in the reaction kettle, then add the starch solution in step (1) to the reaction kettle, then add titanium dioxide and chitosan, mix well and then add sulfuric acid Aluminum, placed together in the sizer;

[0038] (3) Sizing: After the paper web is dried at 60-80°C, sizing is performed on both sides;

[0039] (4) Post-sizing treatment: After sizing, dry again at a temperature of 60-80°C. After drying, calender and coil.

[0040] In the step (1), based on 10 parts by we...

Embodiment 3

[0044] The specific process is as figure 1 As shown, a sizing process suitable for moisture-resistant kraft liner linerboard includes the following steps:

[0045] (1) Corn starch pretreatment: After mixing corn starch, water and amylase for 60-90 minutes, heat up to 85-90°C, react for 20-30 minutes, then heat up to 130-140°C, and react for 5-10 minutes; Keep the temperature at 85-90°C to obtain a starch solution for later use;

[0046] (2) Sizing agent preparation: mix polyvinyl alcohol and water and put it in the reaction kettle, then add the starch solution in step (1) to the reaction kettle, then add titanium dioxide and chitosan, mix well and then add sulfuric acid Aluminum, placed together in the sizer;

[0047] (3) Sizing: After the paper web is dried at 60-80°C, sizing is performed on both sides;

[0048] (4) Post-sizing treatment: After sizing, dry again at a temperature of 60-80°C. After drying, calender and coil.

[0049] In the step (1), based on 10 parts by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com