Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Efficient passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

Passivation improver for heavy metal pollution farmland and using method thereof

ActiveCN104031651AEfficient passivationImprove repair effectAgriculture tools and machinesContaminated soil reclamationSoil remediationZeolite

The invention provides a passivation improver for a heavy metal pollution farmland and a using method of the passivation improver. The raw materials comprise coal ash, nano iron powder, zeolite, medical stone, calcium magnesium phosphate, hydroxypropyl modified SiO2 / chitosan nanoparticles and porous spherical cellulose. According to the composite passivation improver, the passivation effect on heavy metals cadmium, lead, arsenic and chromium in soil can be improved, copper and zinc in soil are well passivated, and the soil remediation effect is improved.

Owner:爱土工程环境科技有限公司

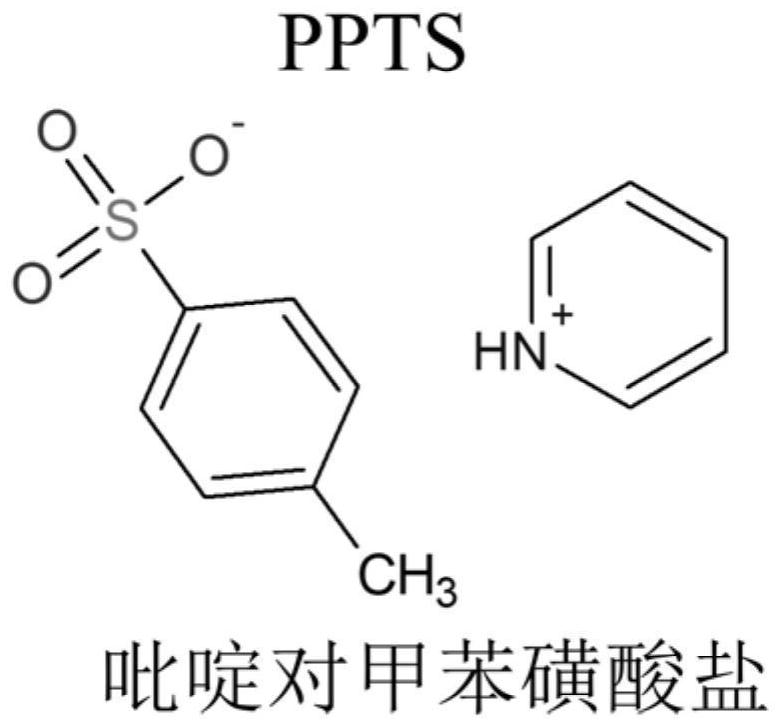

Electrolyte for lithium ion secondary battery and lithium ion secondary battery comprising the same

InactiveUS20140356734A1Avoid reactionImprove polymerizationCell electrodesOrganic electrolyte cellsLithiumOrganic solvent

An electrolyte for a lithium ion secondary battery and a lithium ion secondary battery including the same are provide. The electrolyte includes a non-aqueous organic solvent, a lithium salt which is dissolved in the non-aqueous solvent and a additive shown as general formula I. Wherein R1, R2 and R3 are each independently selected from H, alkyl group including from 1 to 12 carbon atoms, cycloalkyl group including from 3 to 8 carbon atoms and aromatic group including 6 to 12 carbon atoms; n represents an integer from 0 to 7. This additive in electrolyte can passivate cathode and anode effectively, restrain their reaction with electrolyte, reduce gases generation and battery's expansion in high temperature surrounding, provide as safety lithium ion secondary batteries.

Owner:NINGDE AMPEREX TECH

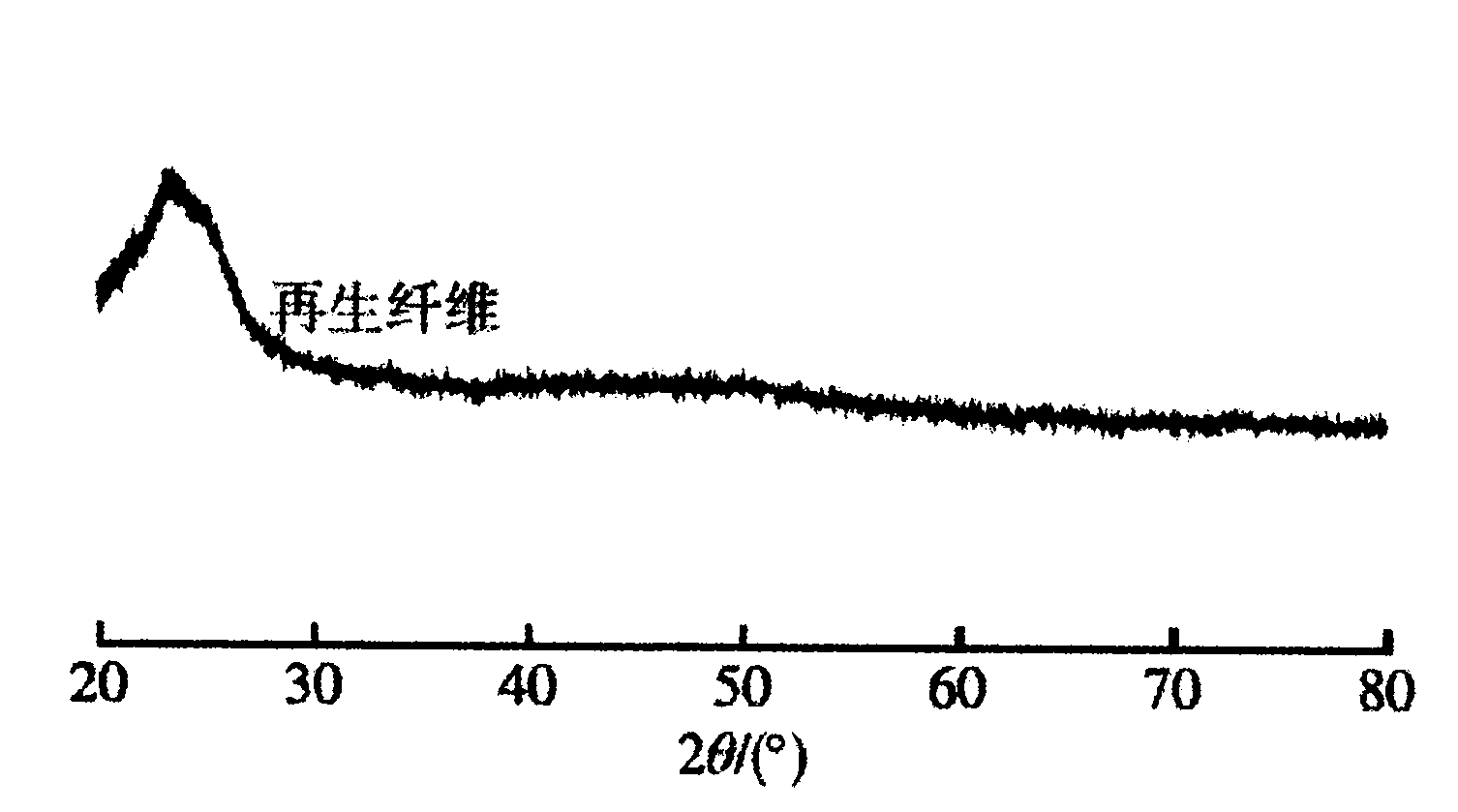

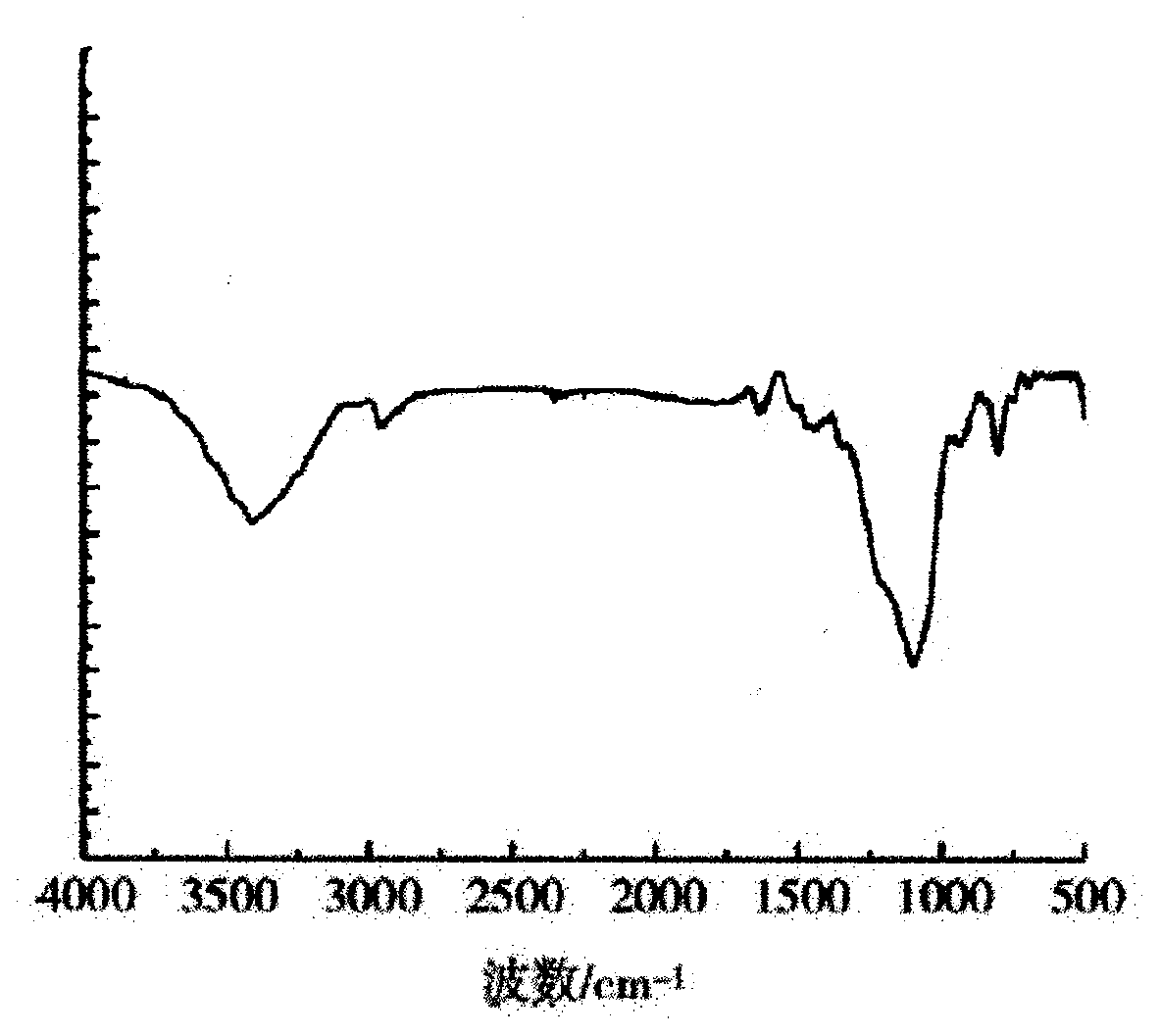

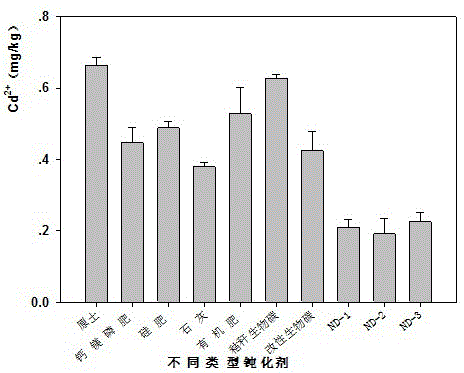

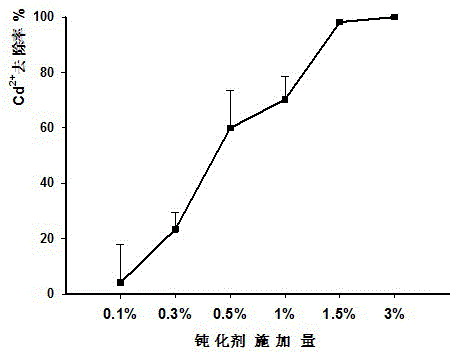

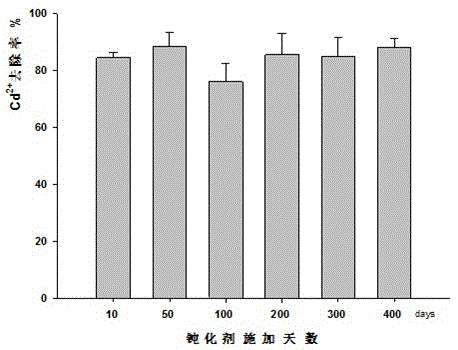

Passivating agent for weakly acidic cadmium contaminated soil and application thereof

ActiveCN105542775AImprove stabilityMeet efficient and fast repairOther chemical processesContaminated soil reclamationContaminated soilsEnvironmental chemistry

The invention discloses a passivating agent for weakly acidic cadmium contaminated soil and application thereof. The passivating agent is compounded and mixed from modified biological carbon, and mineral materials including calcium oxide, a calcium magnesium phosphate fertilizer and a silicon fertilizer beneficial to the soil. The passivating agent is applied to the surface of the weakly acidic cadmium contaminated farmland soil, and the application amount of passivating agent is controlled at more than 1.5 wt% of the soil; and then soil and passivating agent rotary tillage is carried out on a plough layer 20cm above the land surface, and the maximum field water holding capacity is maintained at more than 70% stably for more than ten days to complete the in situ remediation of the weakly acidic cadmium contaminated soil. The passivating agent can effectively reduce the content of available cadmium in soil, restore agricultural function of the polluted land, and ensure food security; the passivating agent contains a lot of organic matters and other nutrients, can provide abundant nutrition for the growth of crops, and has the advantages of environment-friendliness, high repair rate, long-term stability, and high application value.

Owner:NANJING UNIV

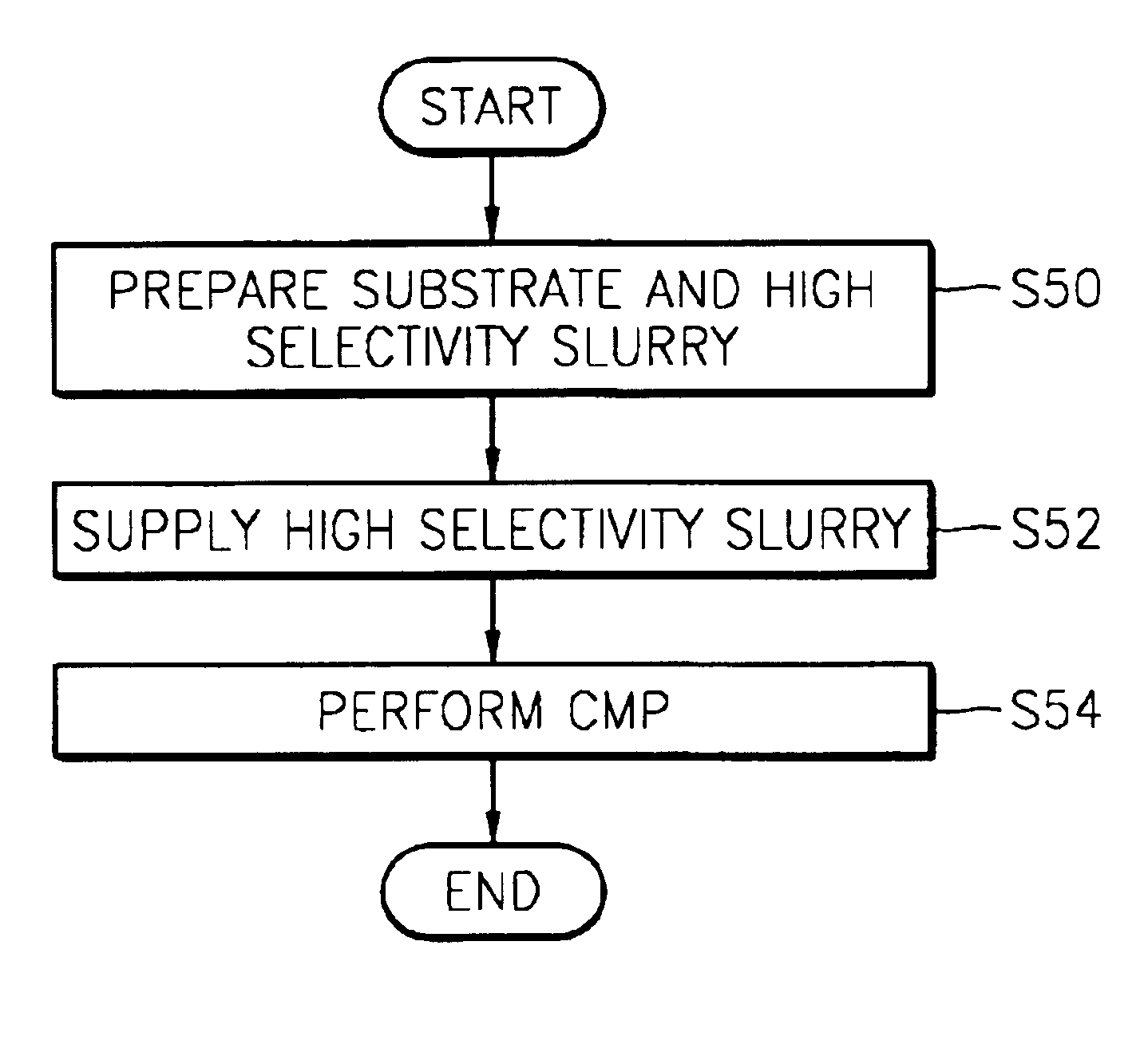

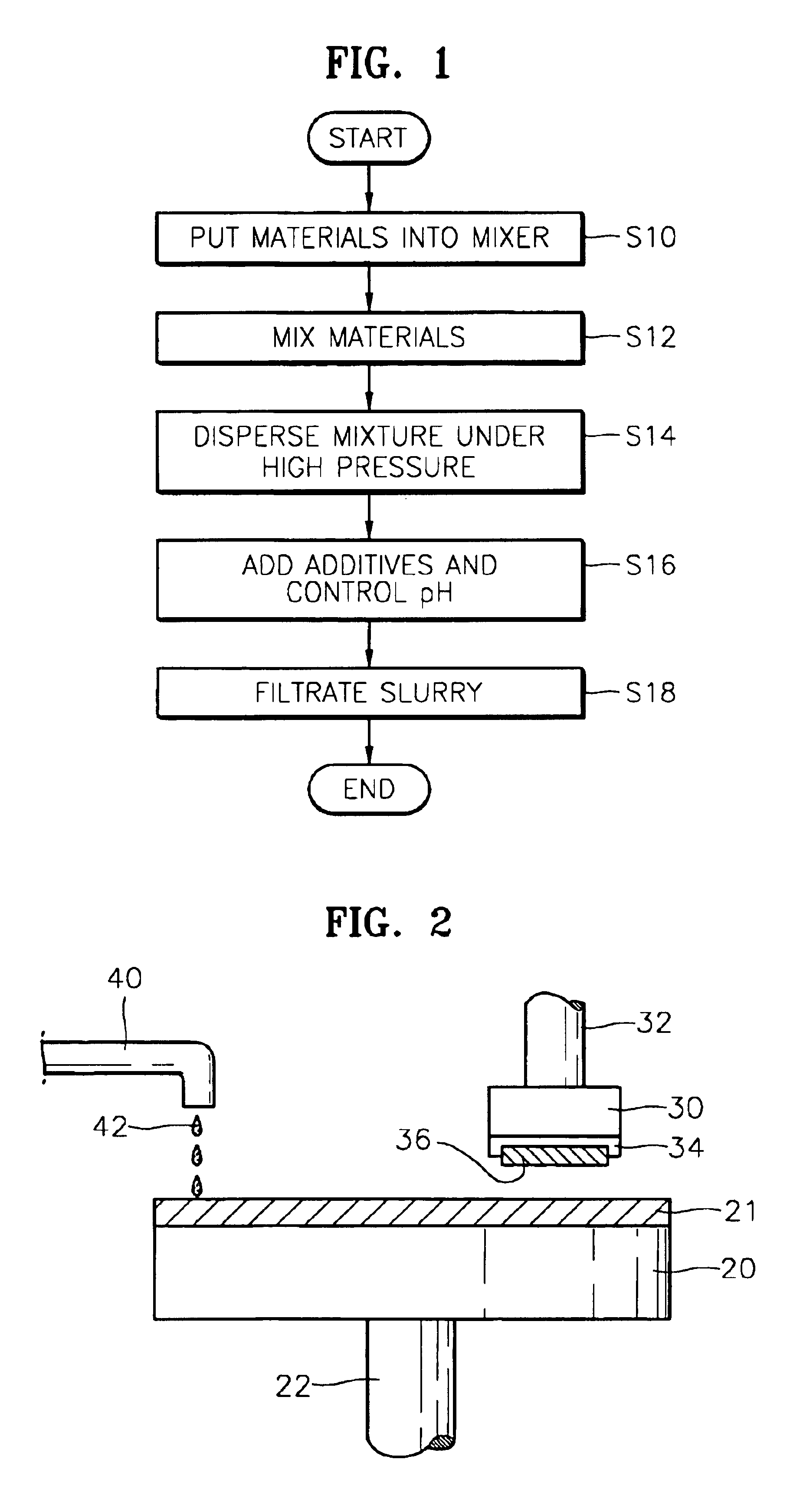

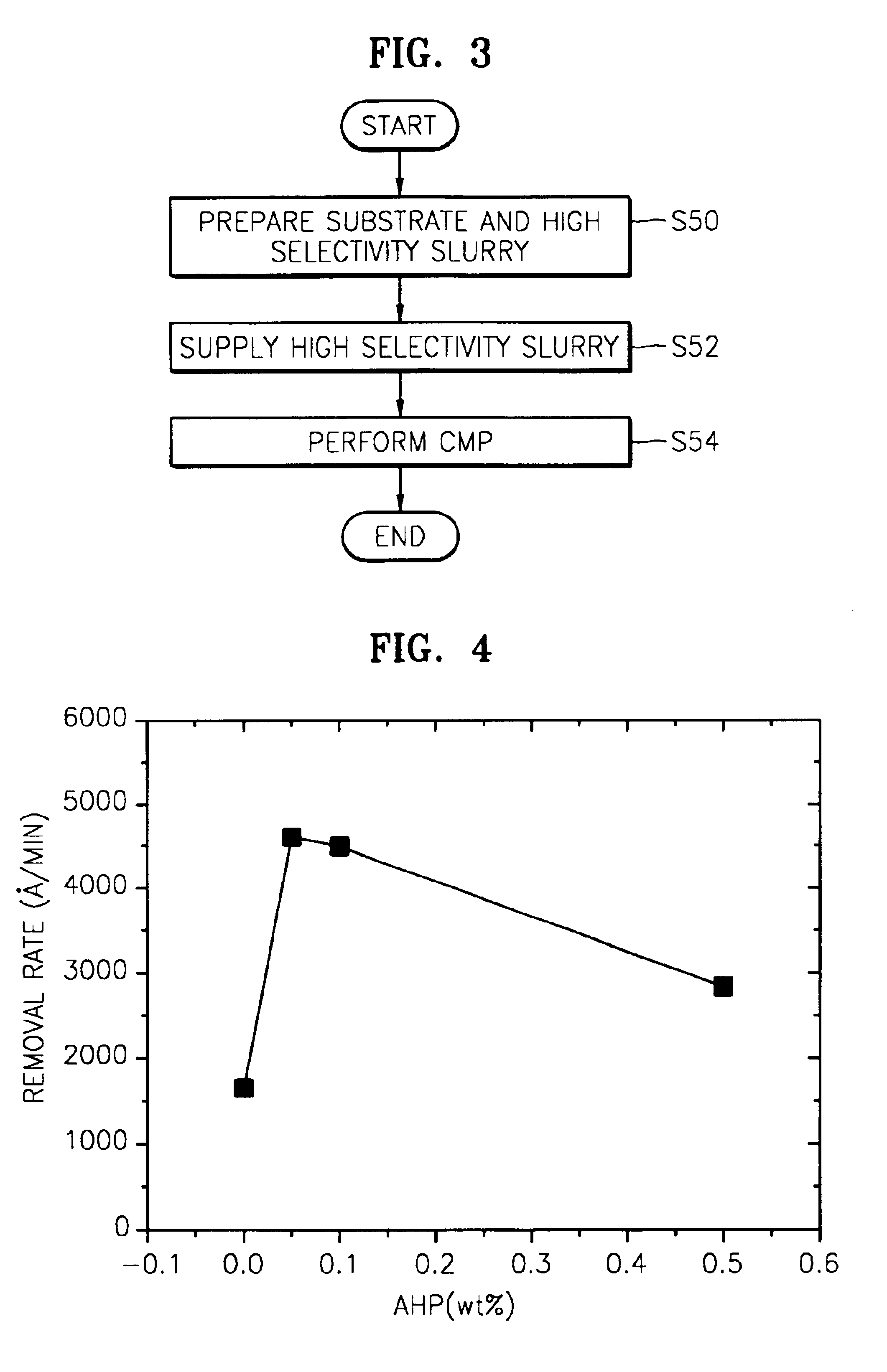

Chemical/mechanical polishing slurry and chemical mechanical polishing method using the same

InactiveUS6863592B2High selectivityEasy to removePigmenting treatmentOther chemical processesCompound (substance)Anionic polymers

CMP (chemical / mechanical polishing) slurries that can rapidly remove a target layer and can effectively passivate a polishing stopper, with high selectivity. In one aspect, a CMP slurry comprises metal oxide abrasive particles, a removal rate accelerator, an anionic polymeric passivation agent having a molecular weight in a range of about 1,000 to about 100,000, a C1-C12 anionic passivation agent, and water.

Owner:SAMSUNG ELECTRONICS CO LTD

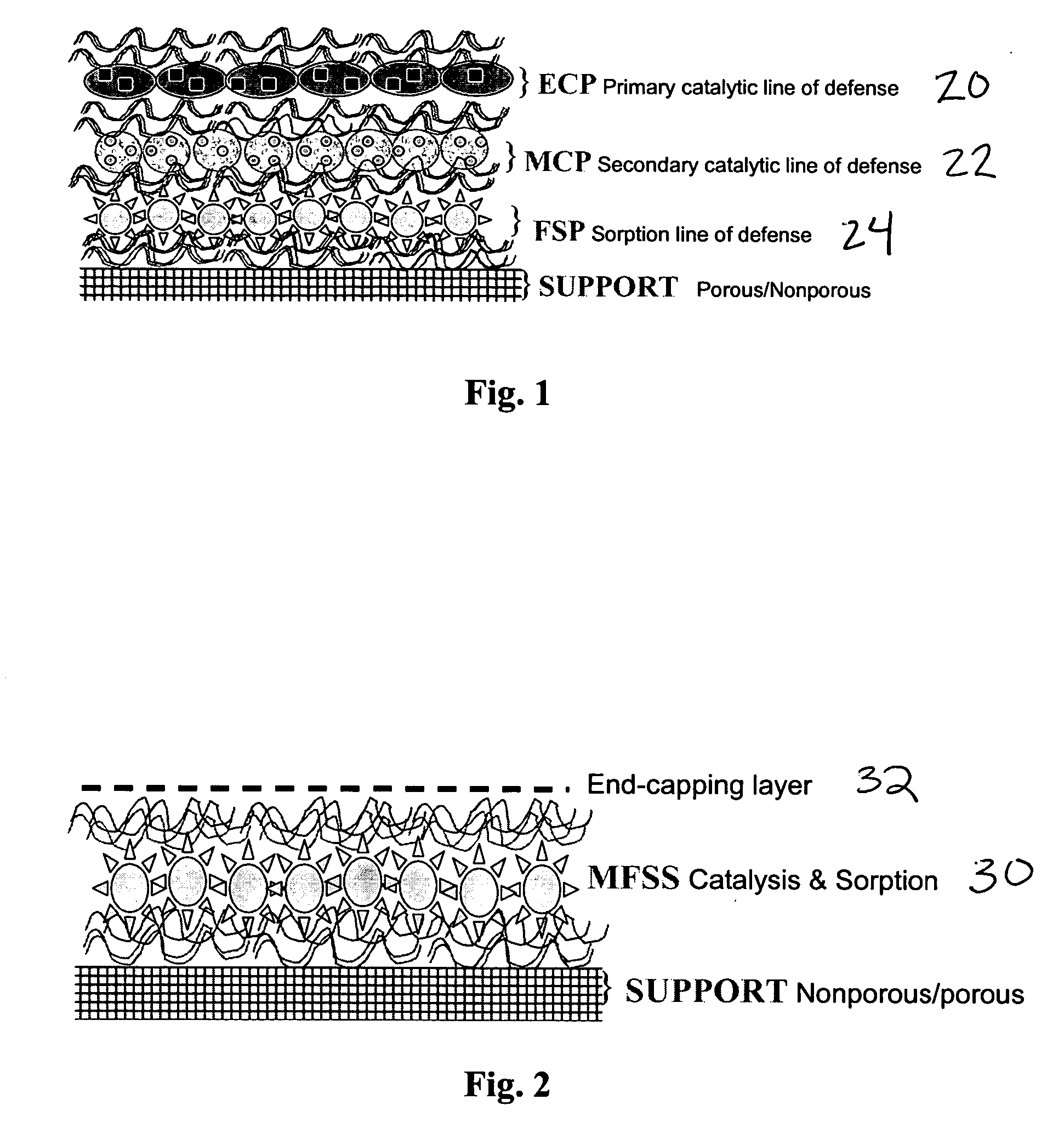

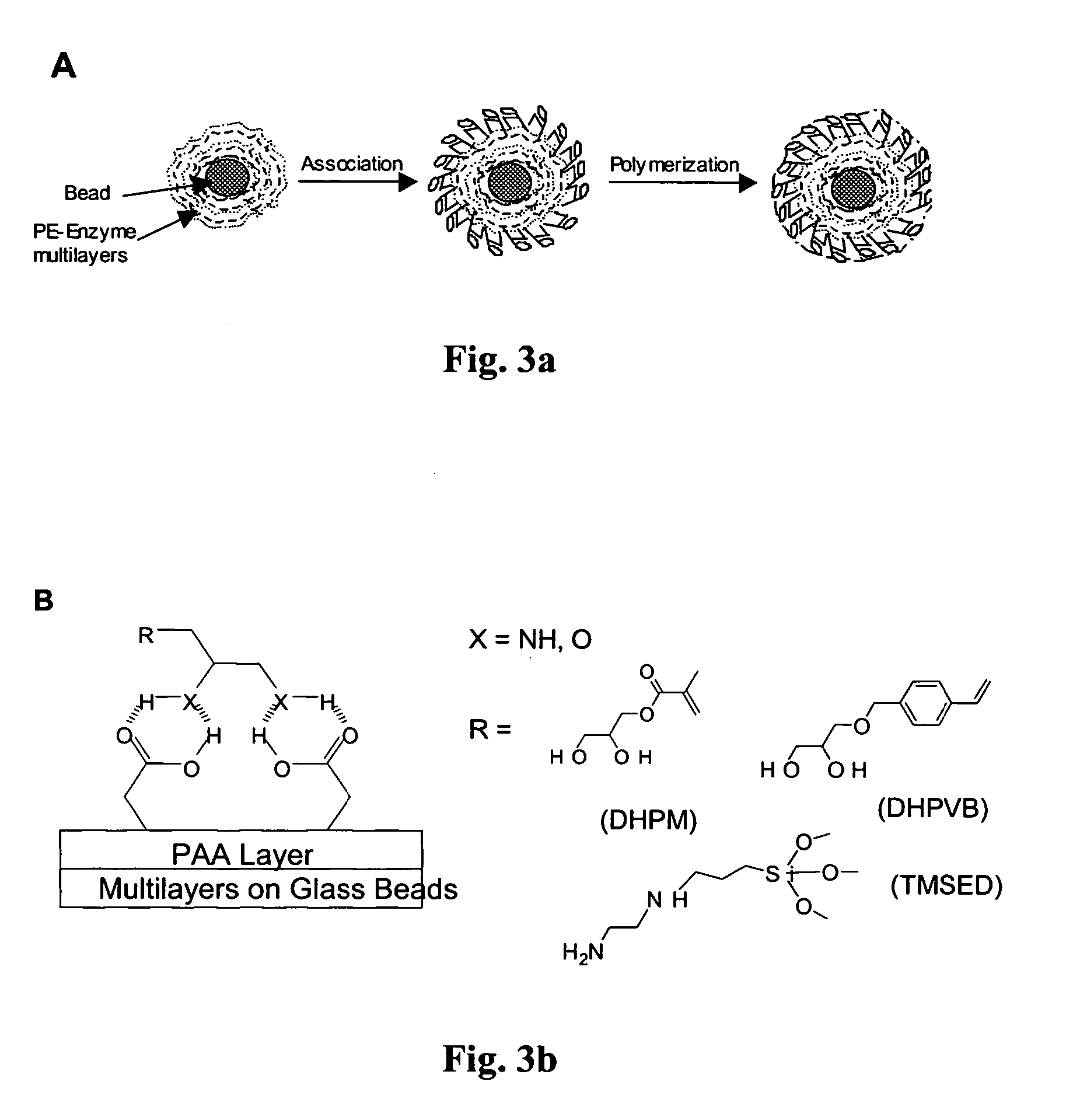

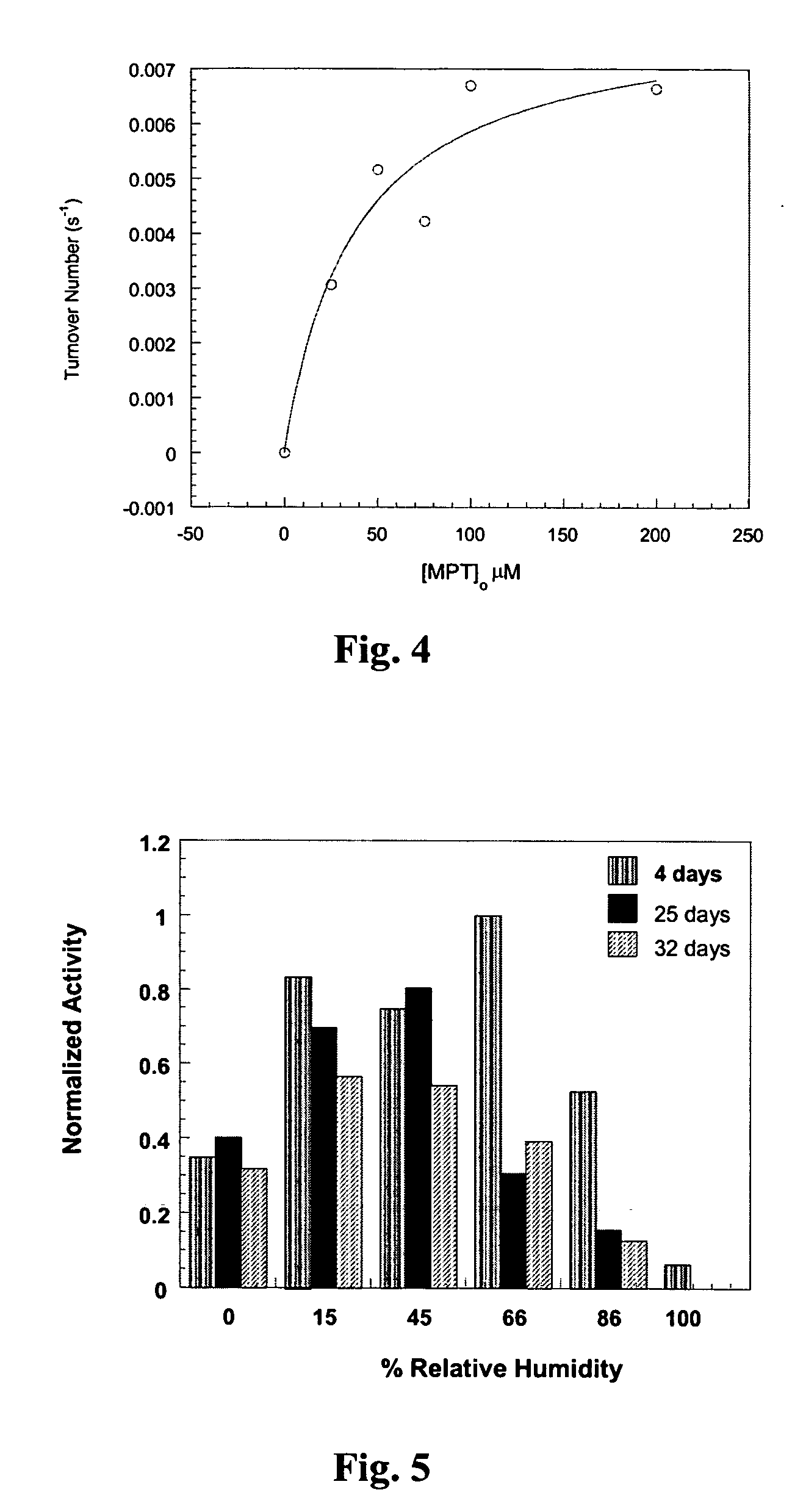

Catalytic surfaces for active protection from toxins

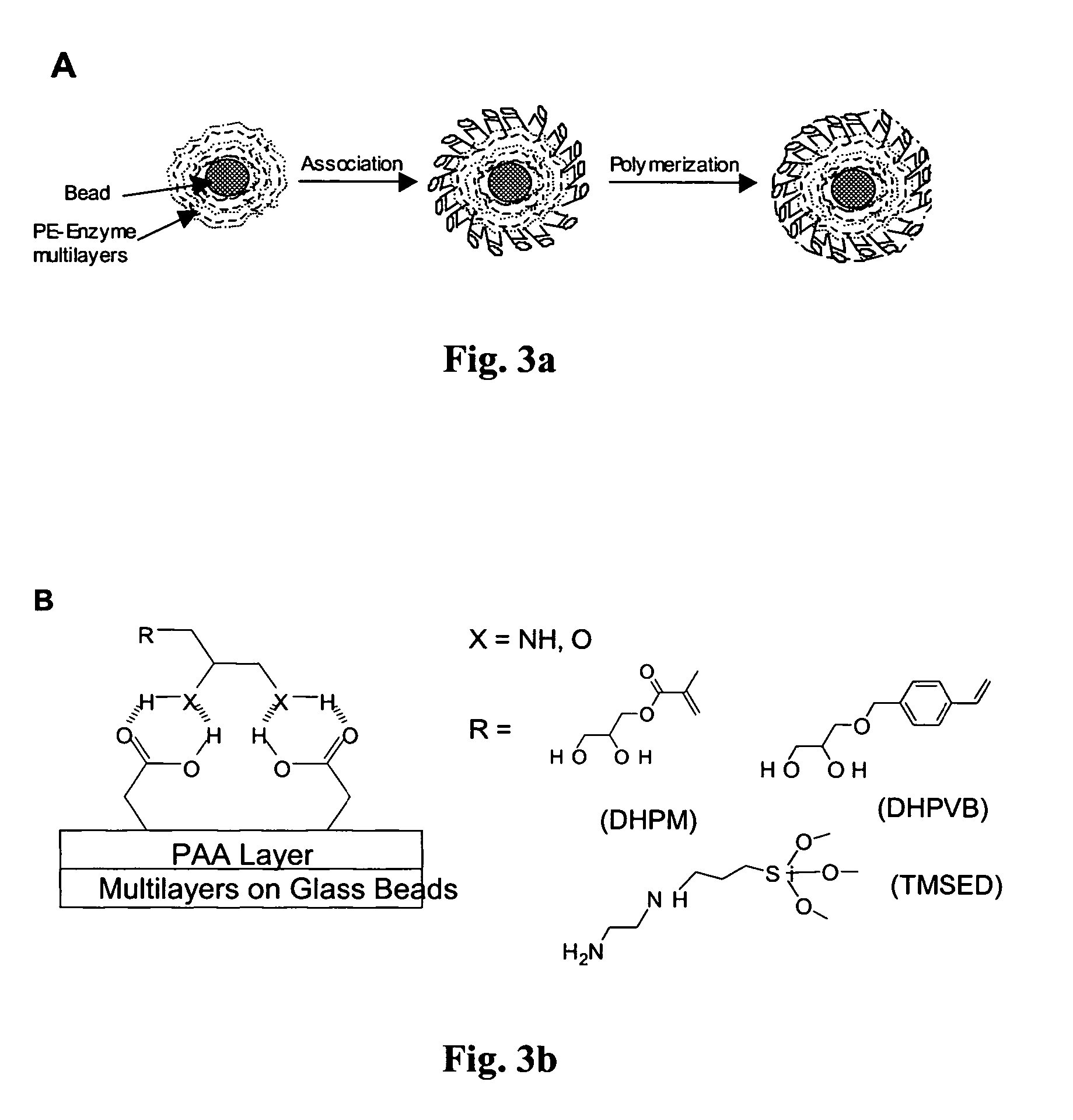

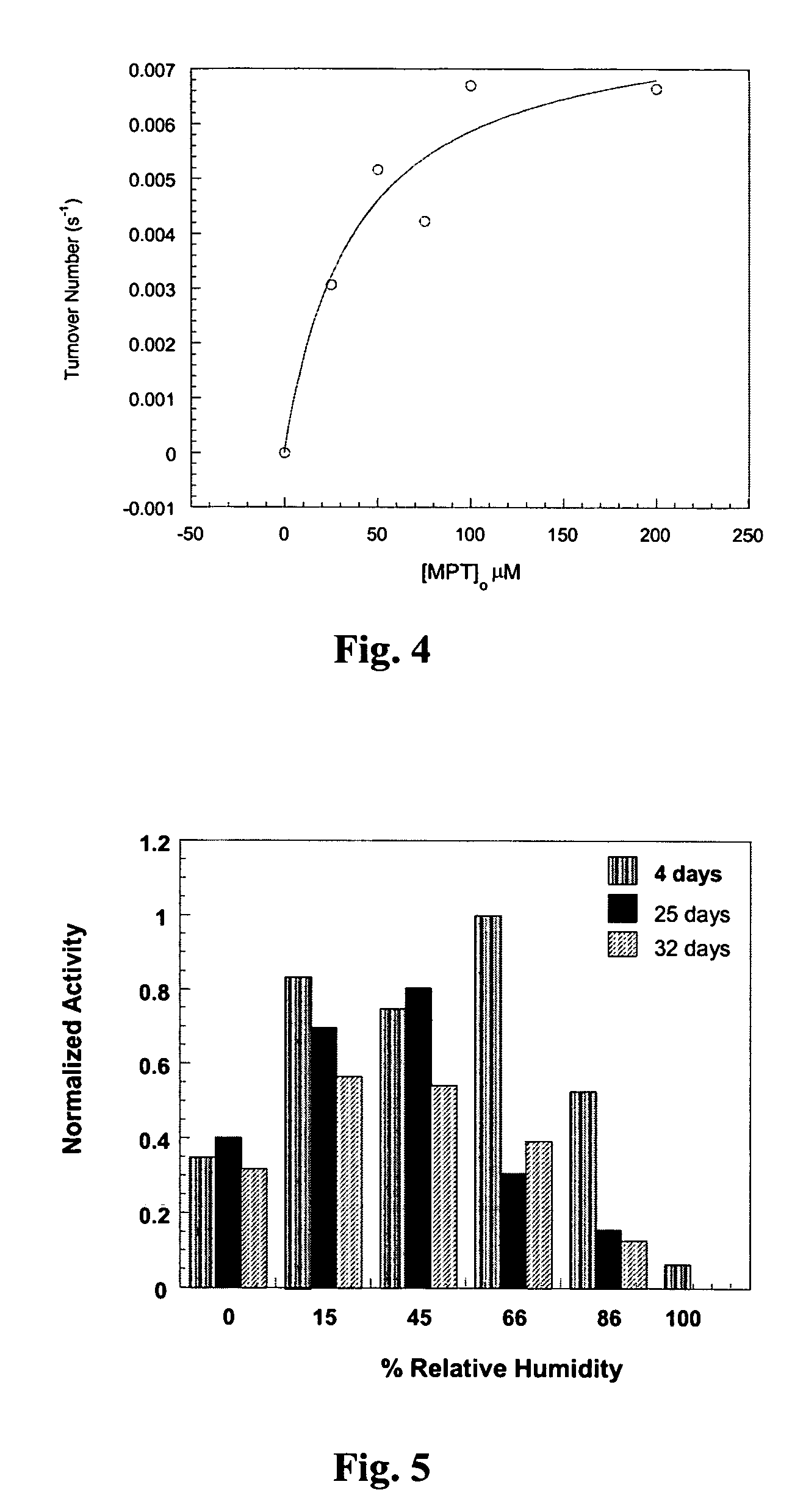

InactiveUS7067294B2High catalytic activityIncrease contactPeptide/protein ingredientsHydrolasesPolyelectrolyteChemical exposure

A bioactive catalytic material is disclosed for providing protection from chemical exposure. The material is composed of enzymes immobilized within polyelectrolyte multilayers and a polymerizable end-capping layer to render stability to enzymes. Also disclosed is the related method for making a bioactive catalytic material and their deposition on substrates of varying size, shape and flexibility for providing active protection from chemical exposure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

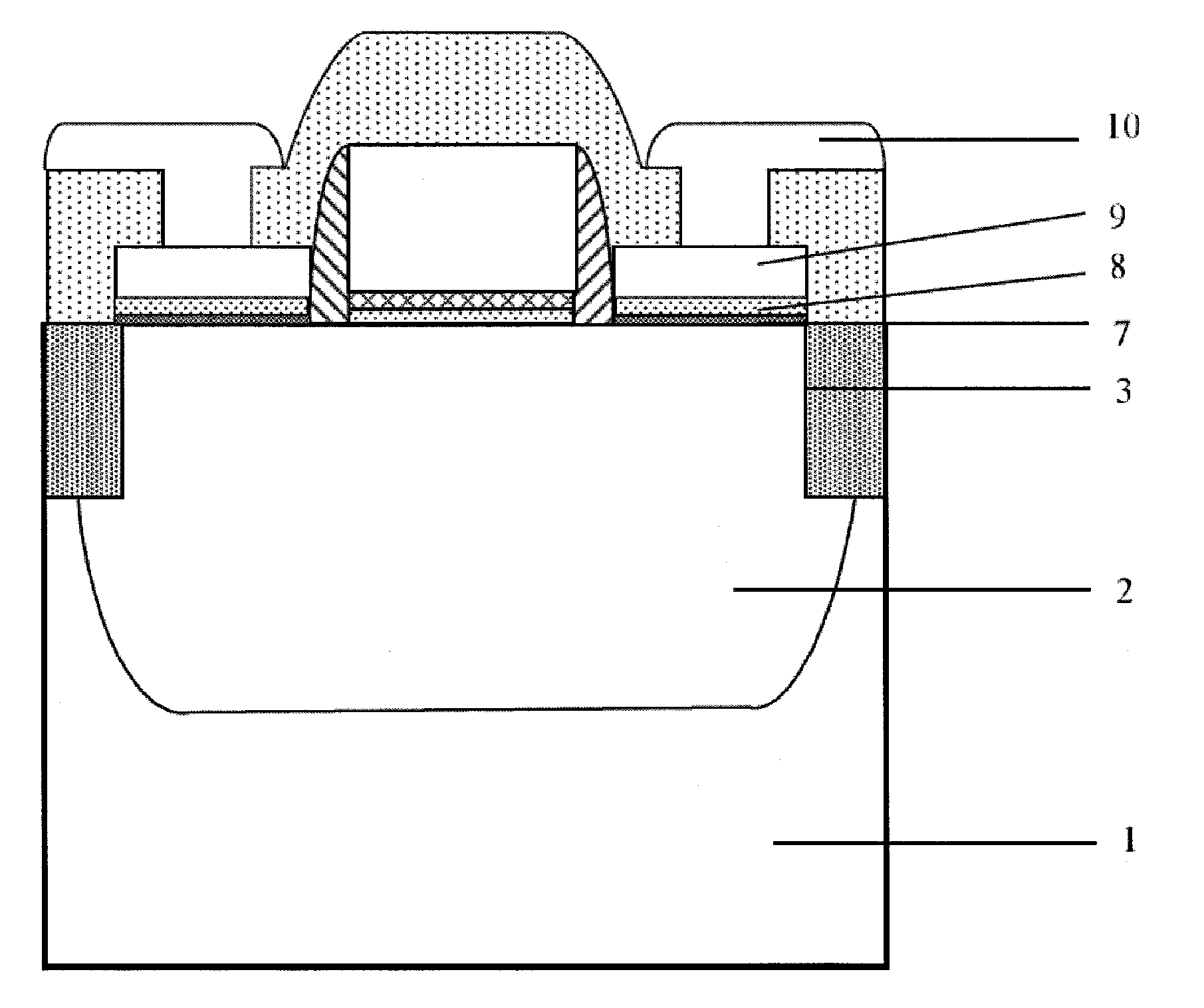

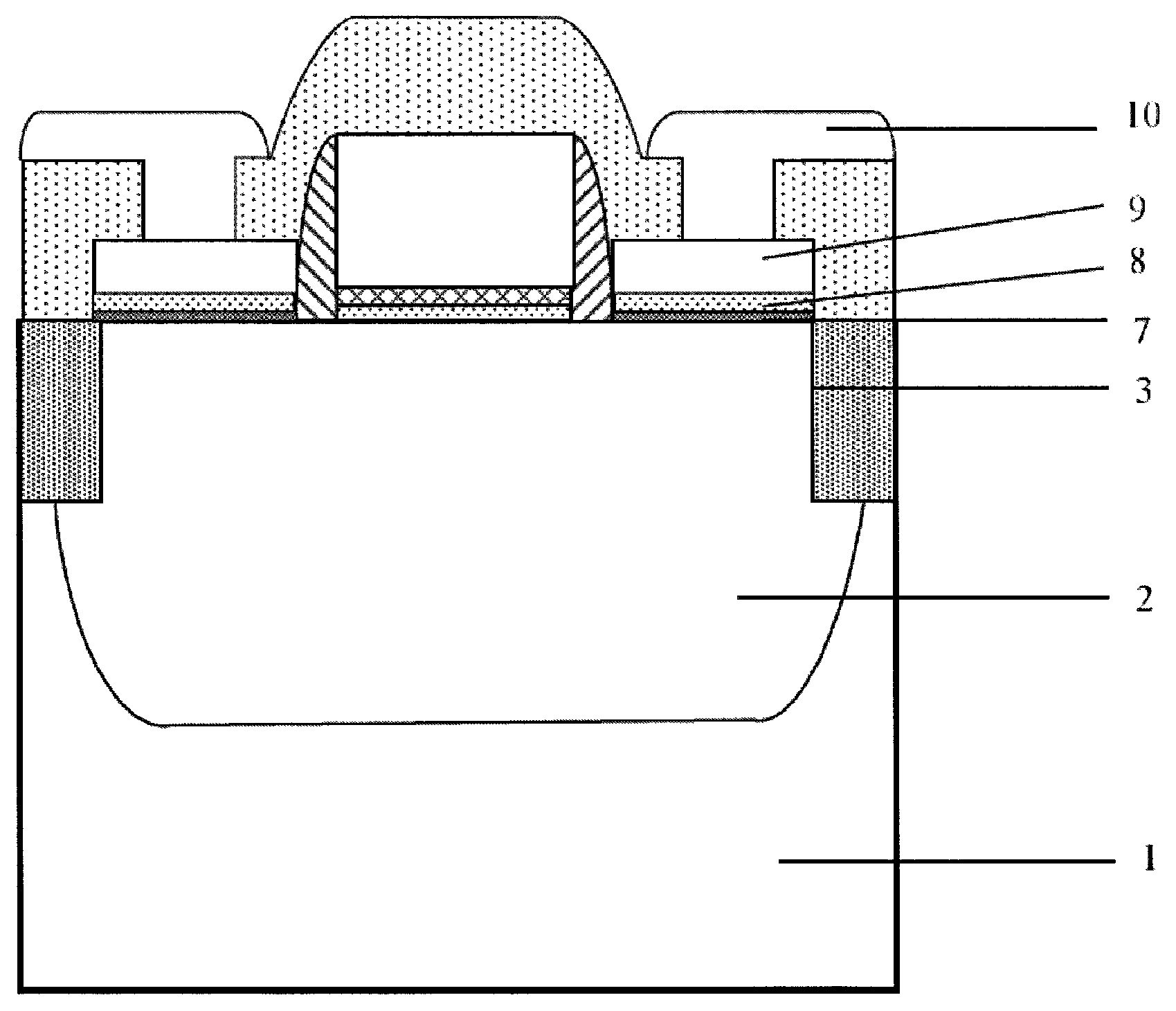

Ge-based nmos device and method for fabricating the same

ActiveUS20140117465A1Alleviate Fermi level pinning effectReduce electron barrierSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierDielectric layer

The embodiments of the present invention provide a Ge-based NMOS device structure and a method for fabricating the same. By using the method, double dielectric layers of germanium oxide (GeO2) and metal oxide are deposited between the source / drain region and the substrate. The present invention not only reduces the electron Schottky barrier height of metal / Ge contact, but also improves the current switching ratio of the Ge-based Schottky and therefore, it will improve the performance of the Ge-based Schottky NMOS transistor. In addition, the fabrication process is very easy and completely compatible with the silicon CMOS process. As compared with conventional fabrication method, the Ge-based NMOS device structure and the fabrication method in the present invention can easily and effectively improve the performance of the Ge-based Schottky NMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

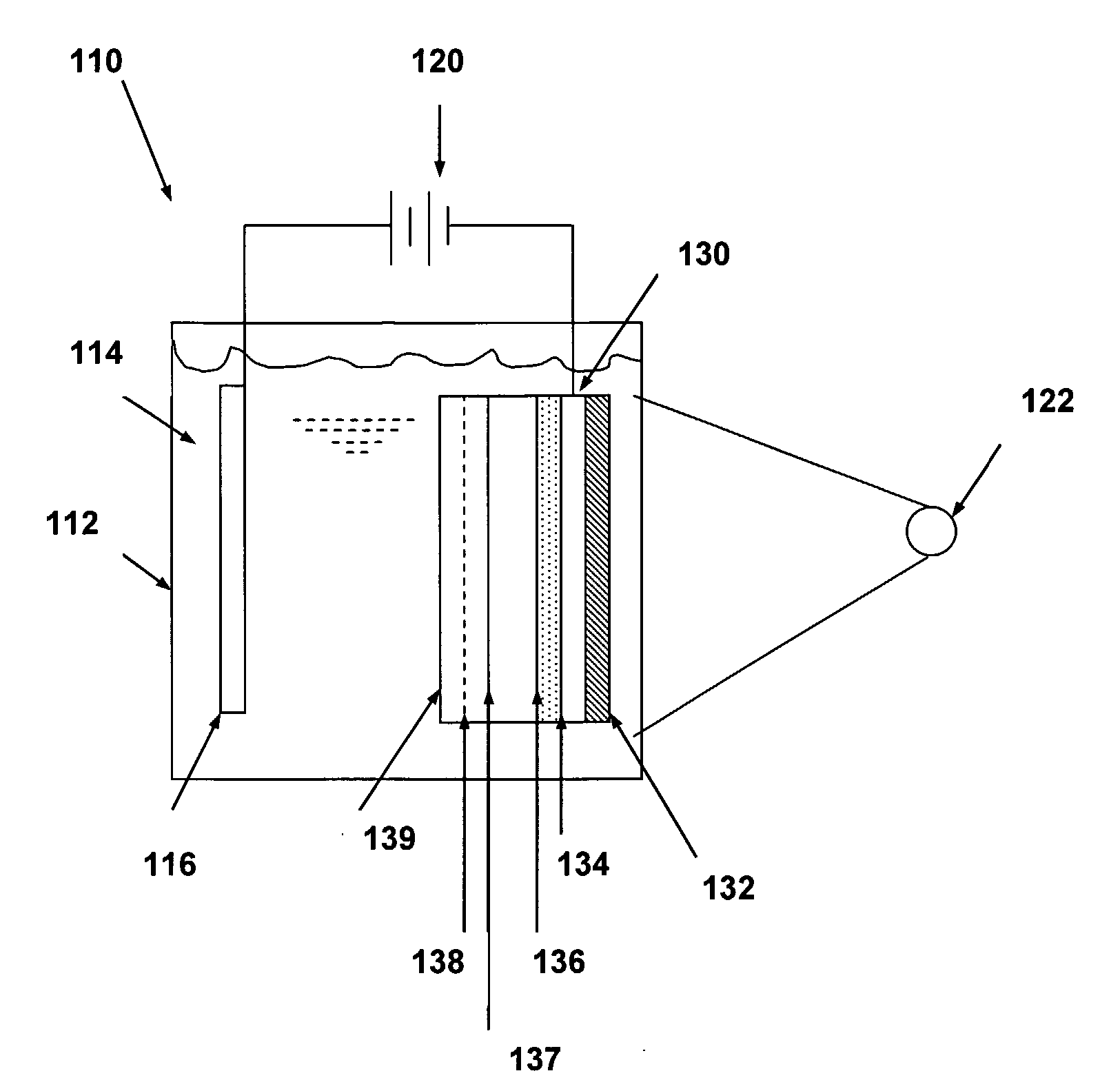

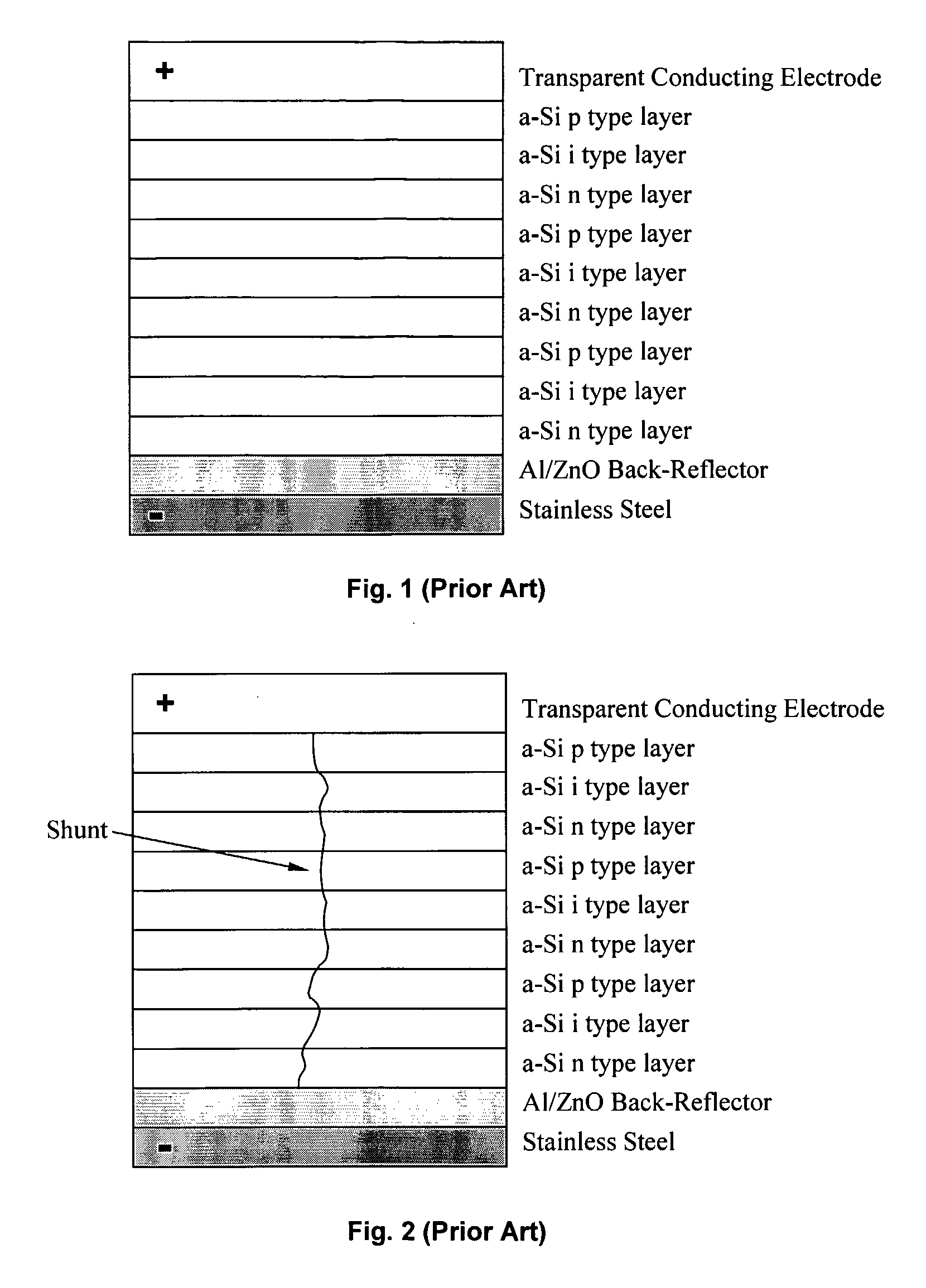

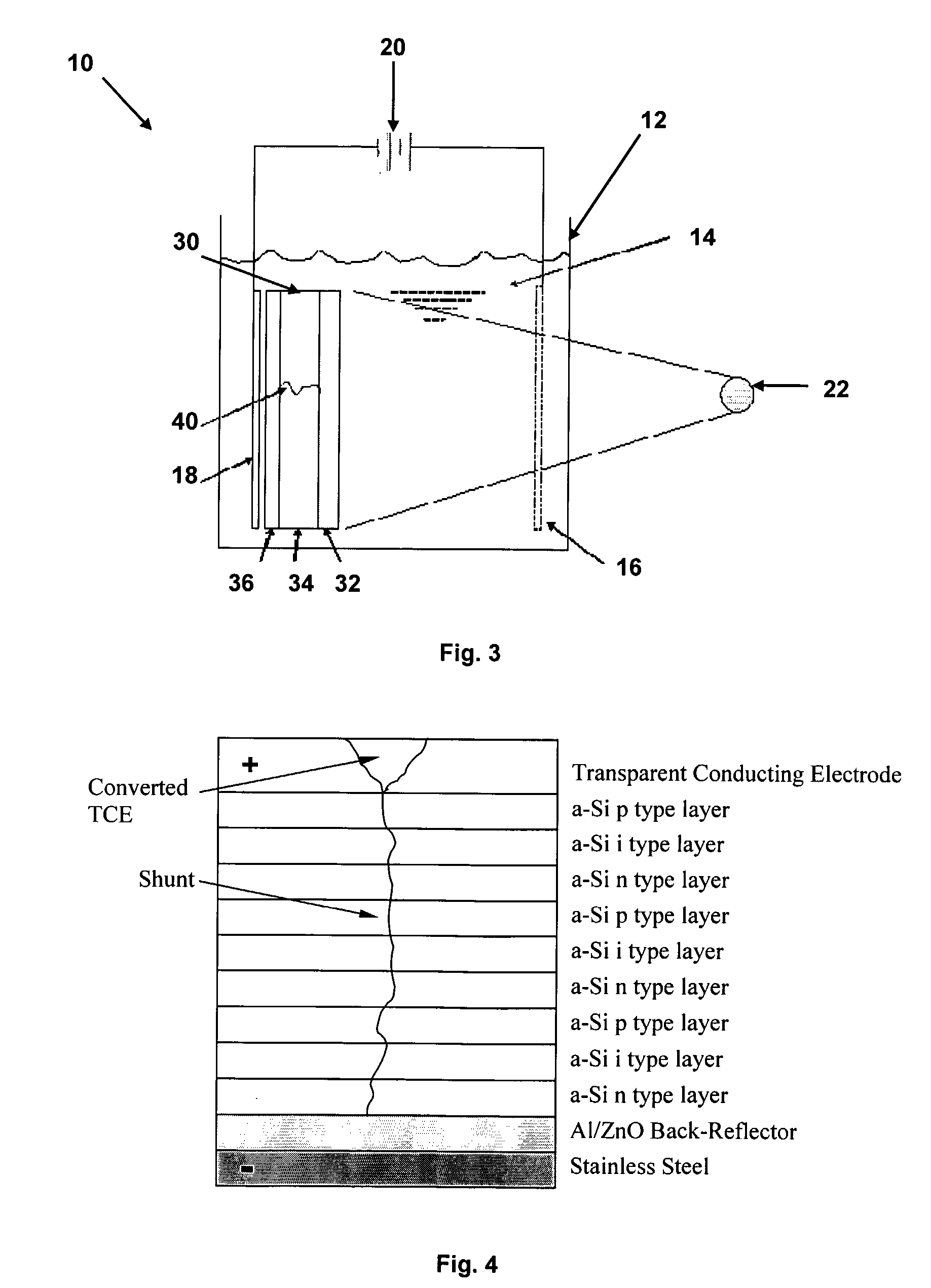

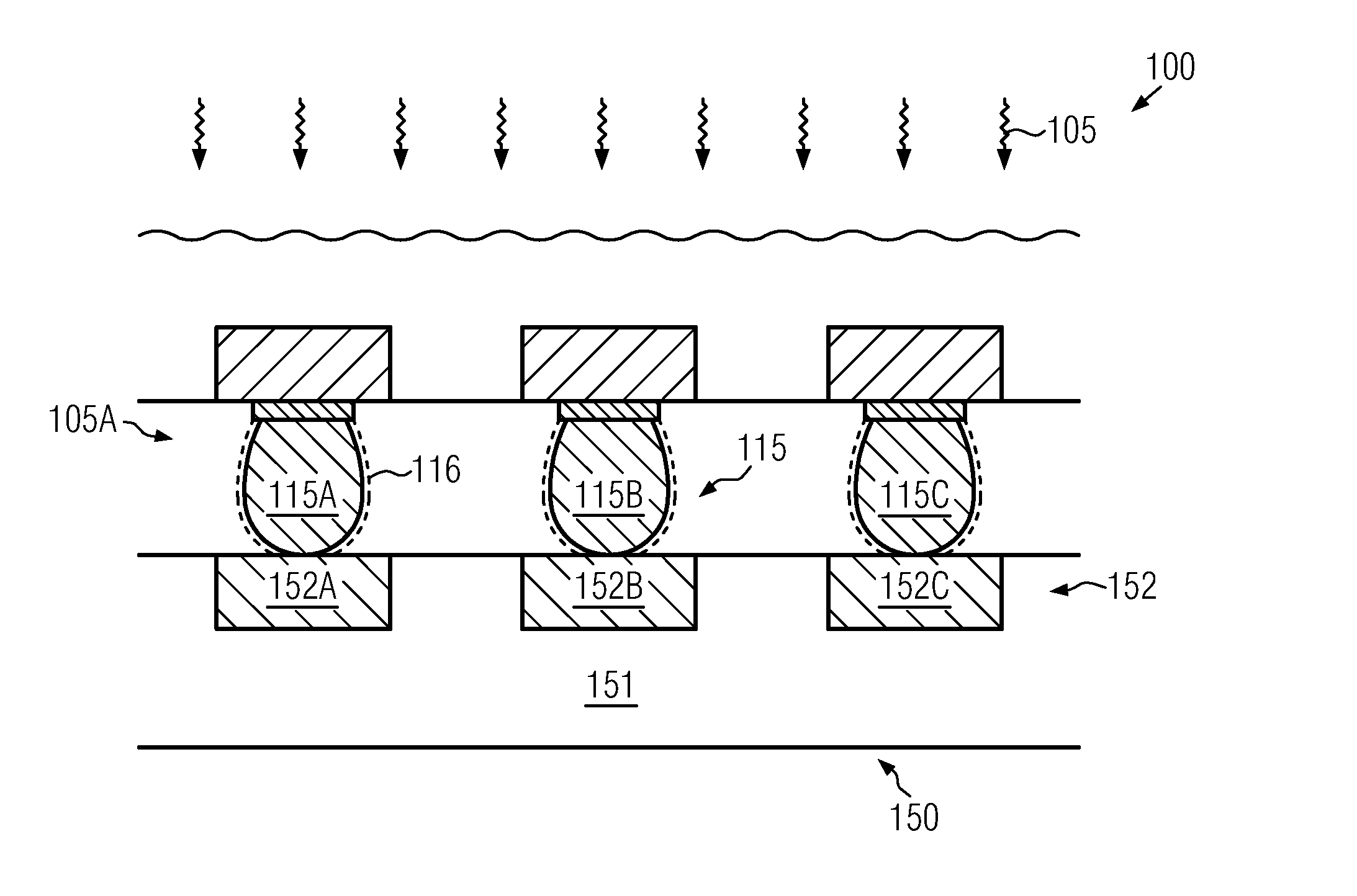

Light-Assisted Electrochemical Shunt Passivation for Photovoltaic Devices

InactiveUS20070256729A1Efficient passivationReduce and eliminate effectFinal product manufactureSolid-state devicesHigh resistivityElectrically conductive

A method of passivating current-shunting defects in a photovoltaic device and such passivated photovoltaic devices are described. The photovoltaic device includes a thin film body with a superposed electrode comprised of a layer of transparent electrically conductive electrode material. The method includes converting the transparent, electrically conductive electrode material to a material having a higher electrical resistivity than the transparent electrically conductive electrode material or by removing the transparent conducting electrode material, by simultaneously: 1) immersing at least a portion of the electrode in a conversion reagent, 2) illuminating the immersed electrode with a suitable source of illumination, and 3) applying an appropriate electrical bias to activate the conversion.

Owner:UNIVERSITY OF TOLEDO

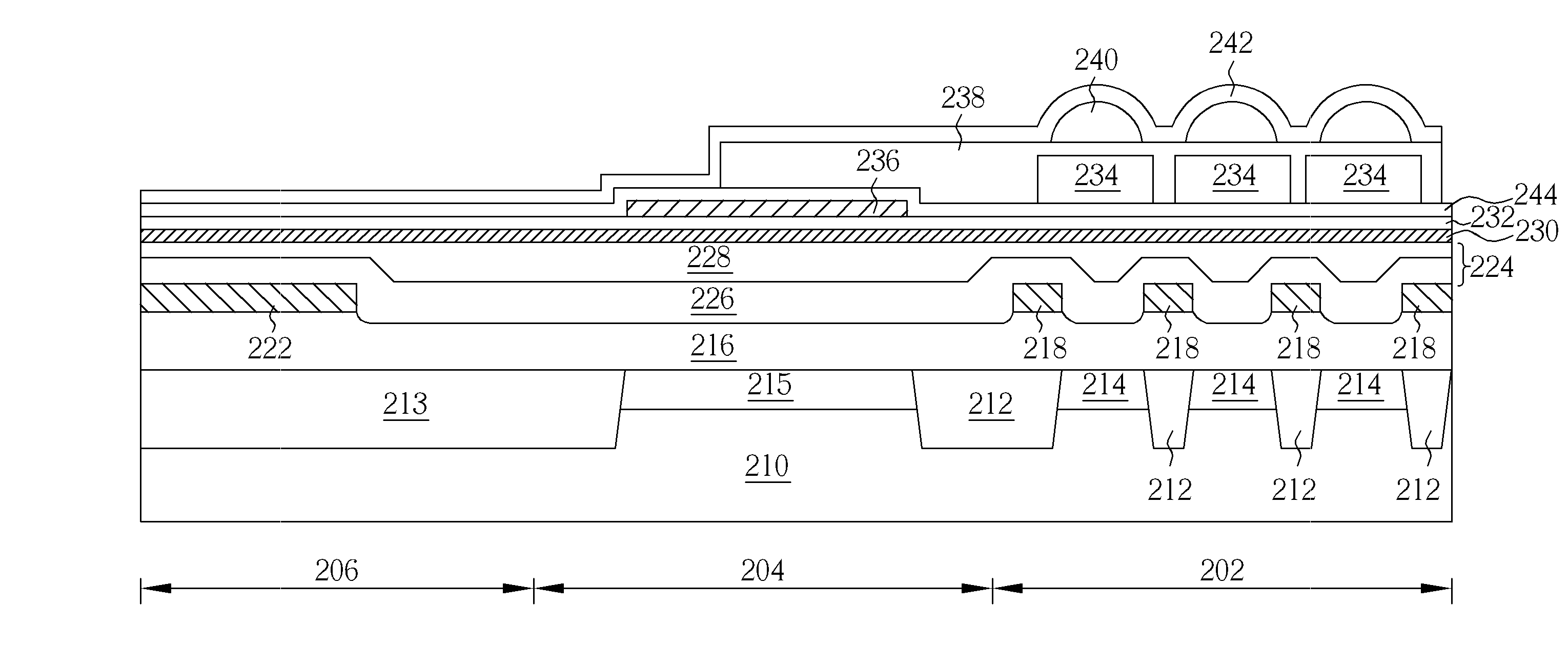

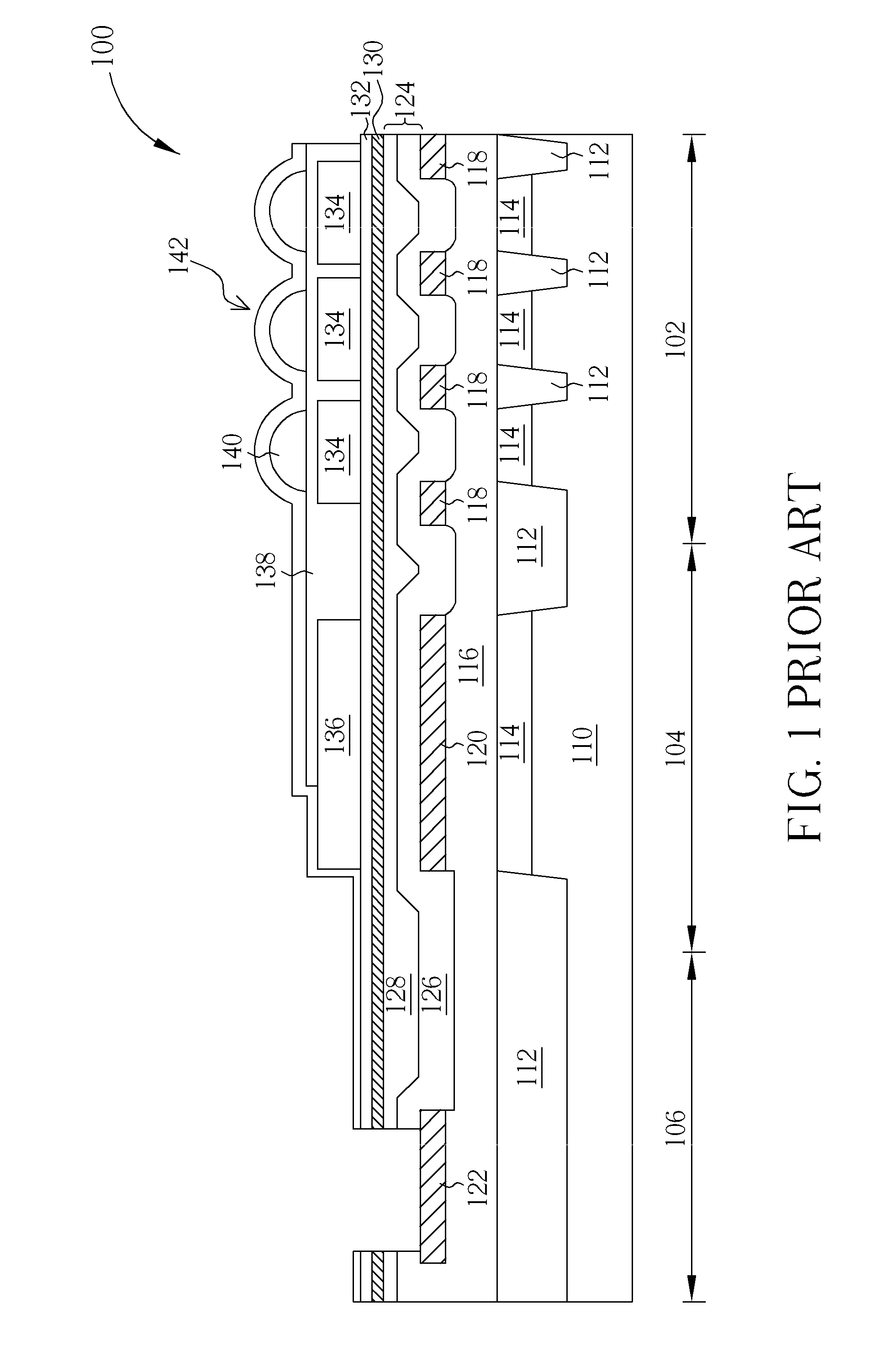

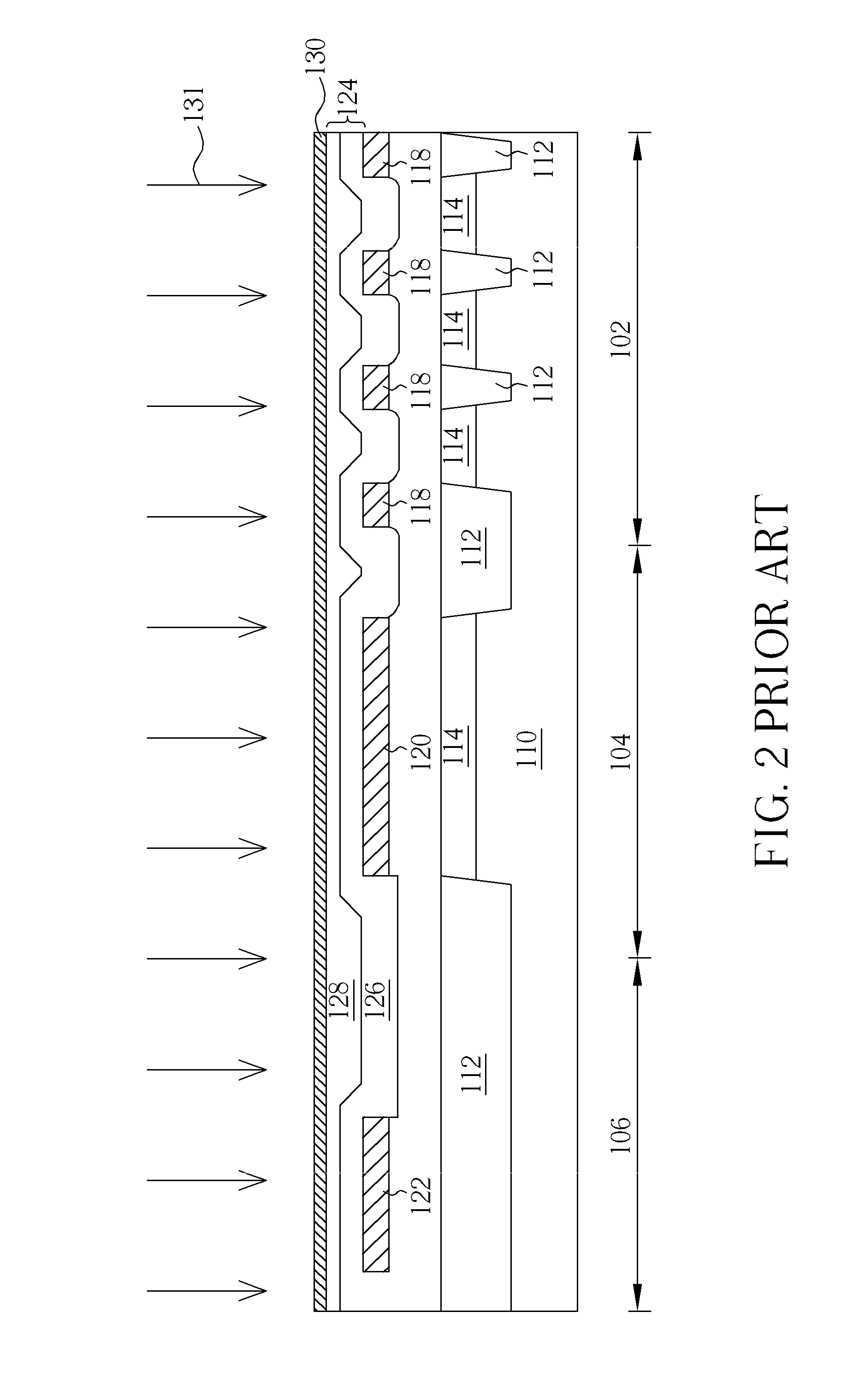

Image sensor

ActiveUS20080265354A1Improve dark currentGood shading effectSolid-state devicesRadiation controlled devicesOptoelectronicsColor filter array

An image sensor, in which, a planarized layer is formed on a semiconductor substrate including a pixel array region, an optical black region, and a logic region to cover a photo sensing unit array in the pixel array region, a patterned metal layer is formed on the planarized layer corresponding to the pixel array region and the logic region, but not the optical black region. An optical black layer is formed in the optical black region after a passivation layer is formed and before a color filter array is formed at a temperature less than about 400° C., and preferably contains metal material.

Owner:UNITED MICROELECTRONICS CORP +1

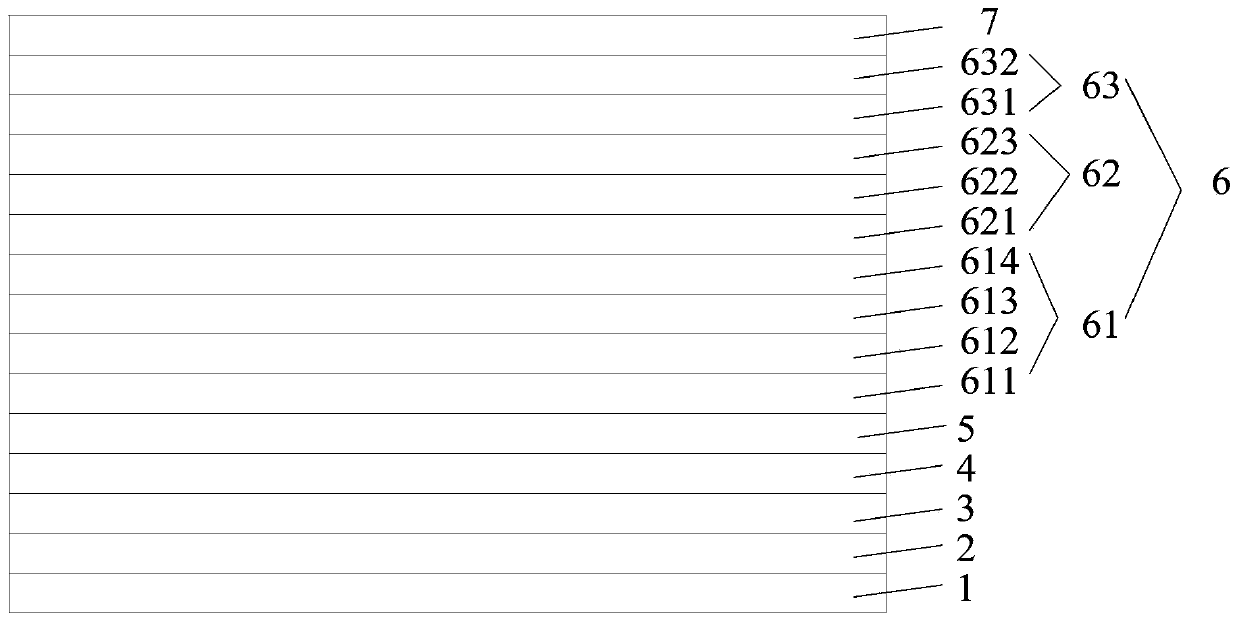

Solar cell for all-black crystalline silicon photovoltaic module and preparation method of solar cell

PendingCN111106186AEliminate unevennessLow refractive indexFinal product manufacturePhotovoltaic energy generationSilver electrodeRefractive index

The invention discloses a solar cell for an all-black crystalline silicon photovoltaic module and a preparation method of the solar cell. A front composite film is prepared by adopting tubular PECVD equipment and comprises a SiNx: Hy layer, a SiOxNy layer and a SiOx layer. The SiNx:Hy layer is connected with the n-type doped layer, and the SiOx layer is connected with a front silver electrode. TheSiNx: Hy layer is composed of 3 to 4 SiNx: Hy layers with different refractive indexes and thicknesses. The SiOxNy layer is composed of 2 to 3 SiOxNy layers with different refractive indexes and thicknesses. The SiOx layer is composed of 1 to 2 SiOx layers with different refractive indexes and thicknesses. By the adoption of the method, the requirement of the all-black crystalline silicon photovoltaic module can be completely met; the appearance color difference of the black module is remarkably eliminated; and the method can be applied to a traditional white backboard photovoltaic module.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

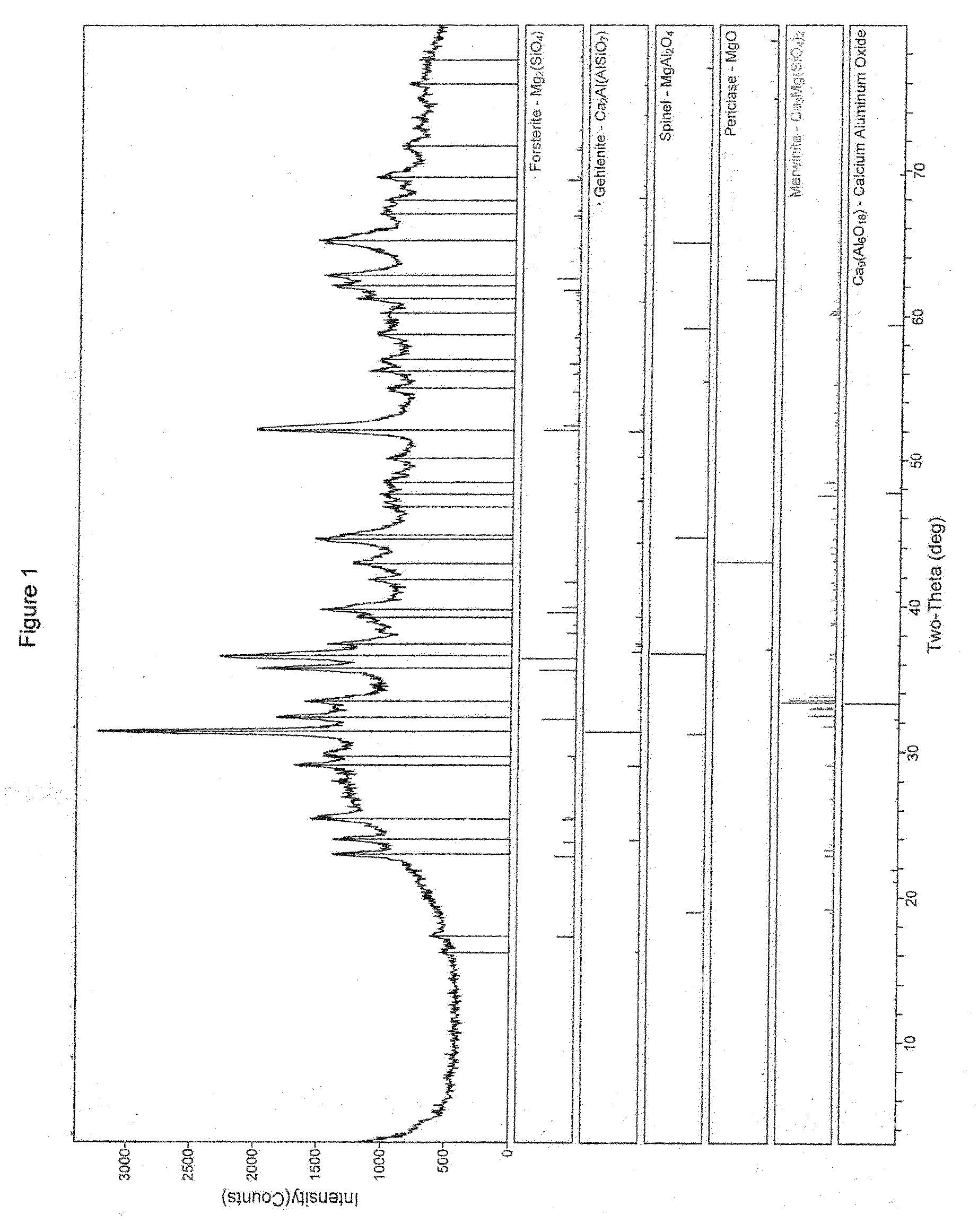

Heavy Metals Trapping Co-Catalyst For FCC Processes

ActiveUS20110079543A1Reduced responseEfficient passivationCatalytic crackingCatalyst activation/preparationTrappingMetal

A metal trap particle used for passivation of metals during FCC cracking comprises a calcined spray dried particle formed from kaolin, magnesium oxide or magnesium hydroxide and calcium carbonate. The metal trap particle contains at least 10 wt. % magnesium oxide which improves metals passivation during FCC cracking.

Owner:BASF CORP

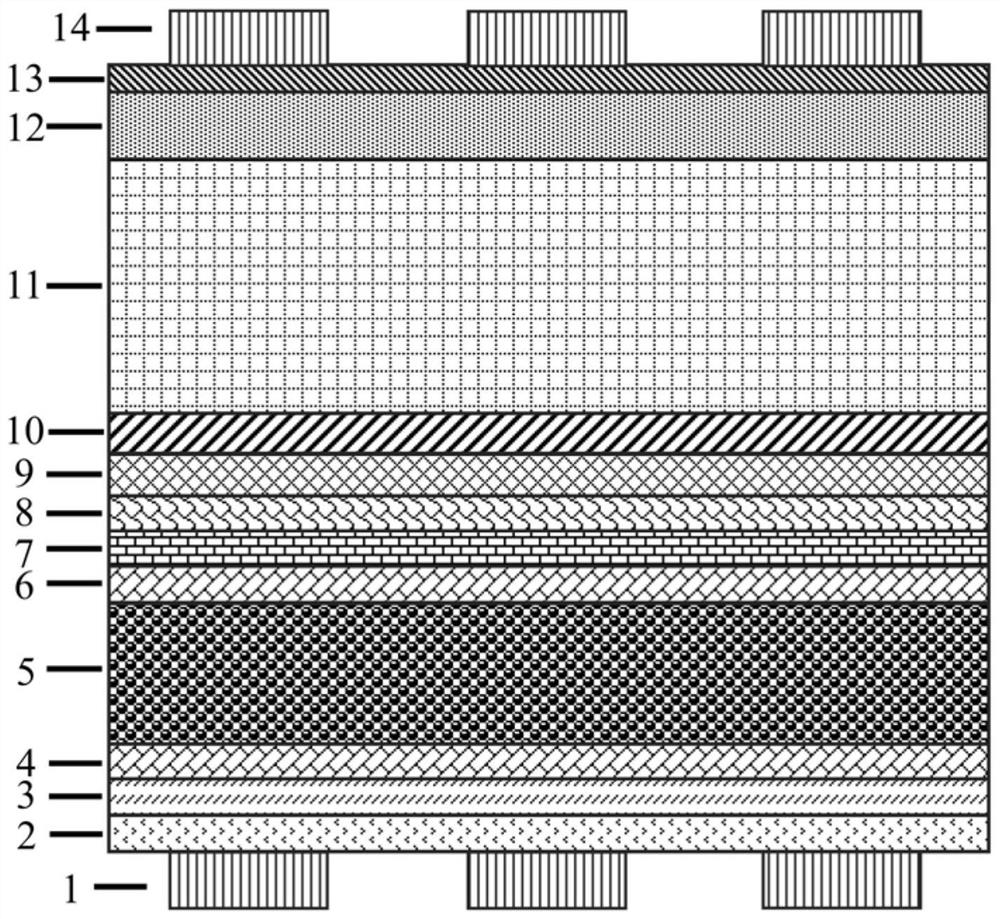

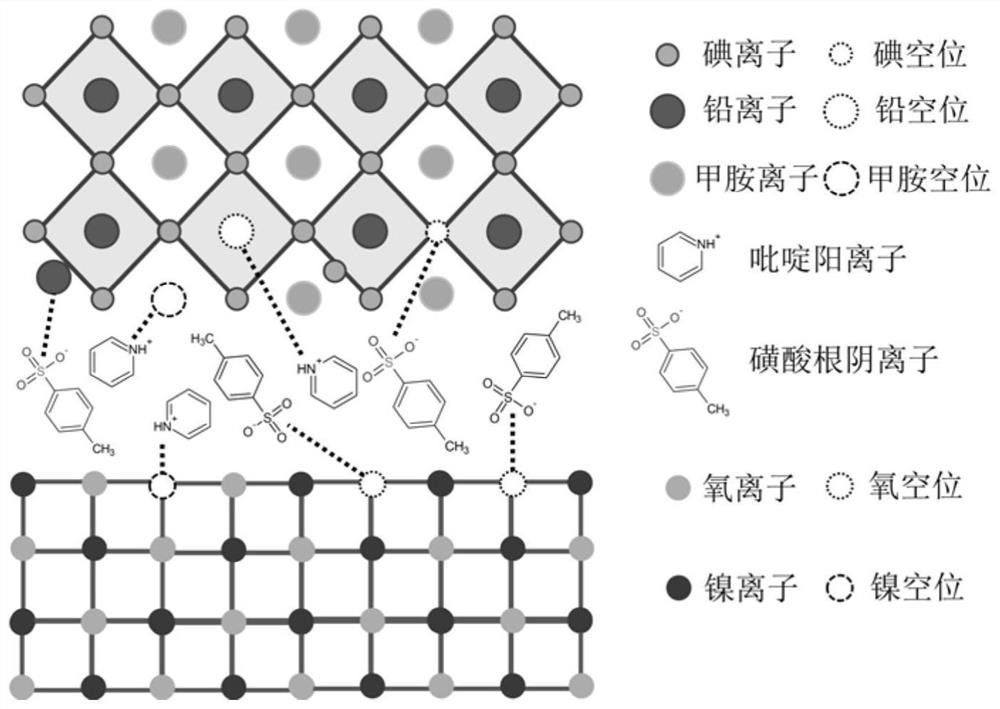

Perovskite/silicon laminated solar cell and preparation method thereof

InactiveCN113193002AImplement synchronous passivationEfficient passivationNanoinformaticsSolid-state devicesLattice mismatchSolar cell

The invention belongs to the technical field of solar cells, provides a perovskite / silicon laminated solar cell and a preparation method thereof, and aims to solve the problems that synchronous passivation of multiple types of defects cannot be realized by perovskite material interface passivation in the prior art, the suppression efficiency of carrier interface recombination is low and the like. An organic ionic modifier passivation layer is introduced between a perovskite light absorption layer and a hole transport layer of the perovskite / silicon laminated cell, so that synchronous and efficient passivation of multiple types of defects of an interface is realized, and the defect state density is remarkably reduced; and meanwhile, lattice mismatch at the interface is effectively prevented, and the defect passivation effect is further optimized. In conclusion, the perovskite / silicon laminated solar cell has lower defect state density and higher short-circuit current density and open-circuit voltage, and the overall performance of the perovskite / silicon laminated solar cell is remarkably improved; and moreover, the organic ionic modifier passivation layer is mature in synthesis process and low in price, and has the advantages of high efficiency, stability and low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

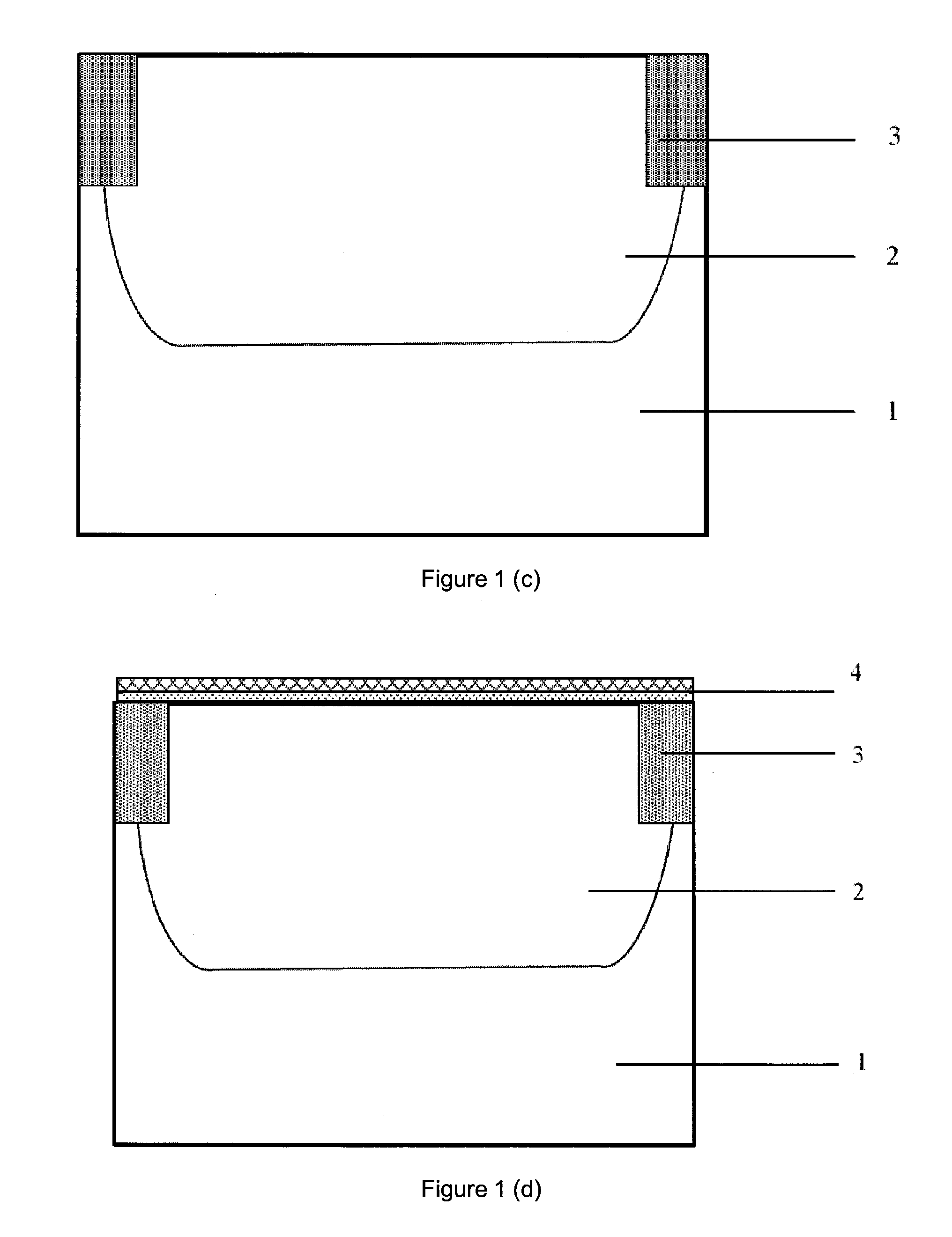

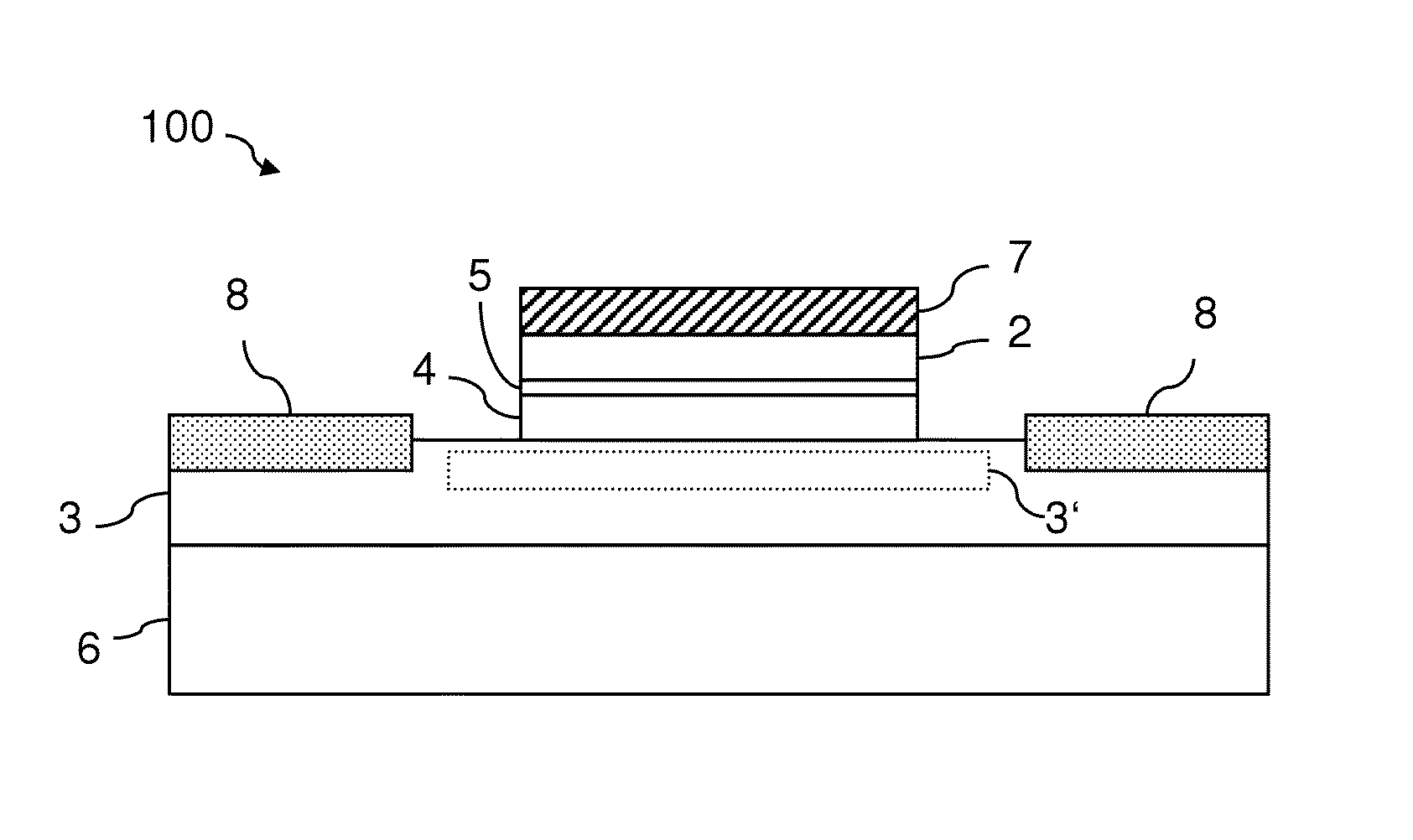

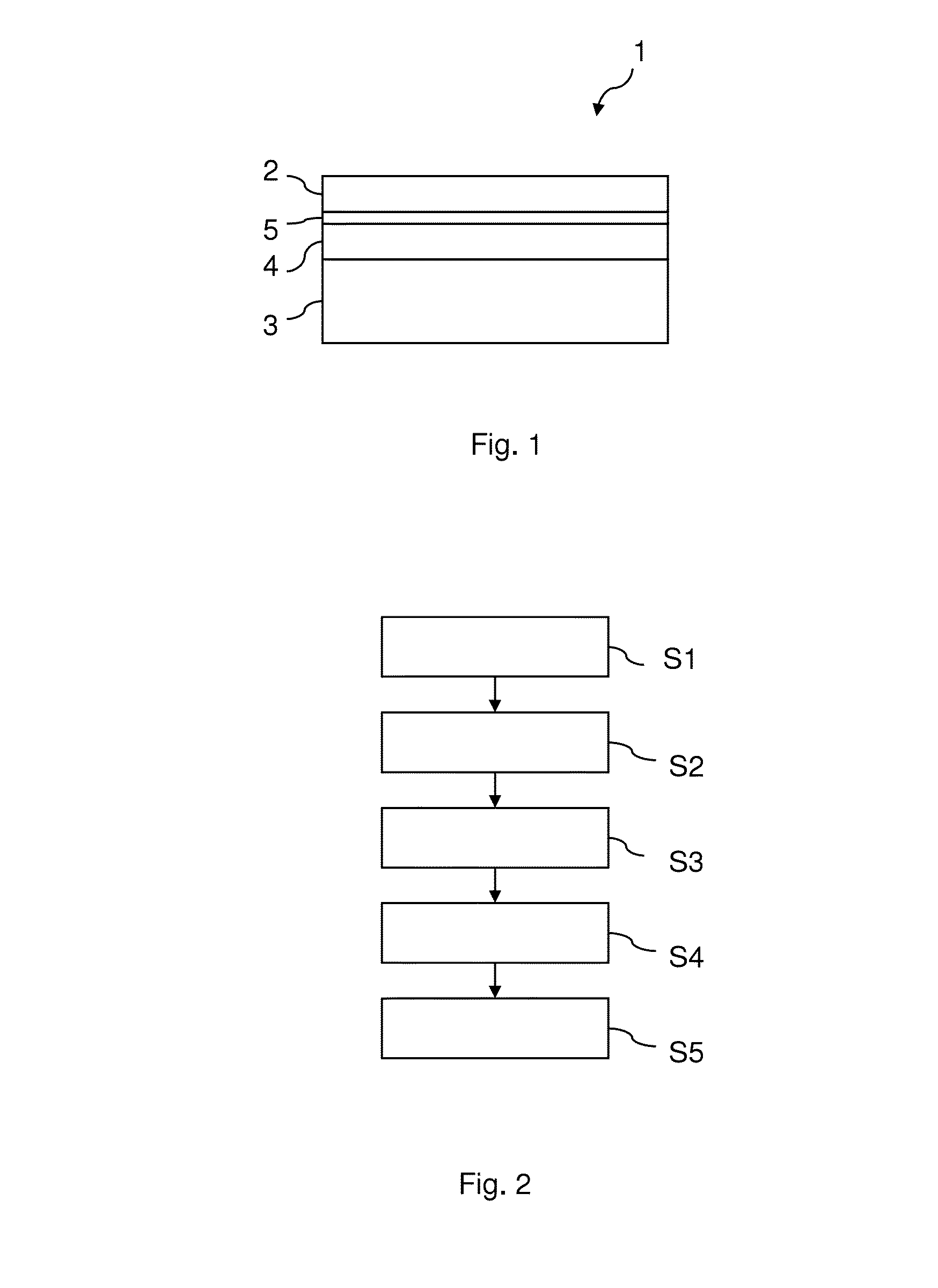

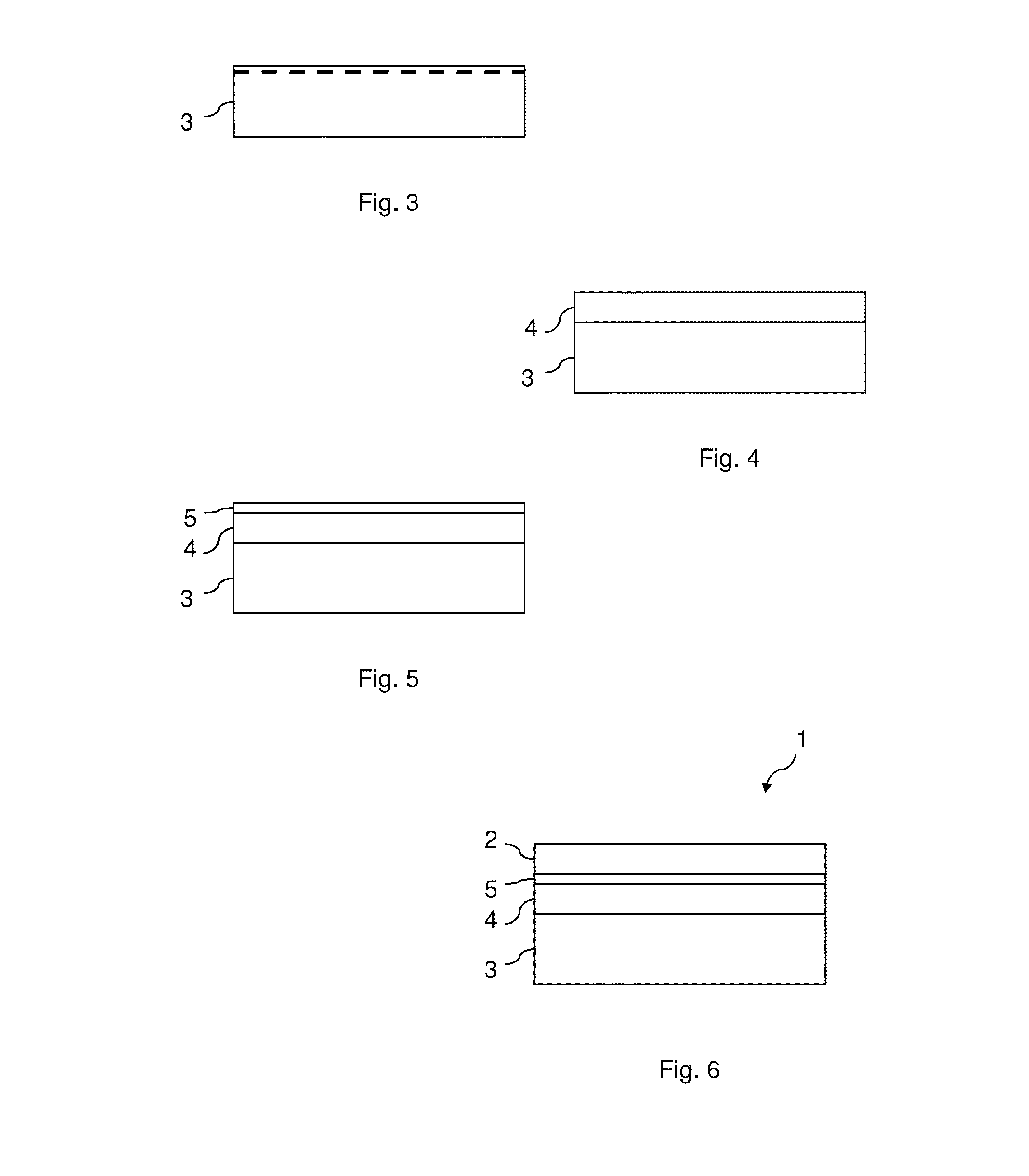

Compound semiconductor structure

InactiveUS20140035001A1Reduce capacitanceAvoid contaminationSemiconductor/solid-state device manufacturingSemiconductor devicesChemical reactionSemiconductor structure

A semiconductor structure (1) comprises a dielectric layer (2) including a dielectric material having a dielectric constant higher than that of silicon oxide; a channel region (3) including a compound semiconductor material; a passivation layer (4) including a passivation material between the channel region (3) and the dielectric layer (2); and a barrier layer (5) including a barrier material between the dielectric layer (2) and the passivation layer (4) for reducing a chemical reaction of the dielectric material of the dielectric layer (2) with the passivation material of the passivation layer (4).

Owner:IBM CORP

Semiconductor Device, In Particular Solar Cell

ActiveUS20110290318A1Low expenditureEfficient passivationPhotovoltaic energy generationSemiconductor devicesAluminium oxynitrideSemiconductor

A semiconductor device, in particular a solar cell, comprises a semiconductor substrate having a semiconductor substrate surface and a passivation composed of at least one passivation layer which surface-passivates the semiconductor substrate surface, wherein the passivation layer comprises a compound composed of aluminium oxide, aluminium nitride or aluminium oxynitride and at least one further element.

Owner:Q CELLS SE

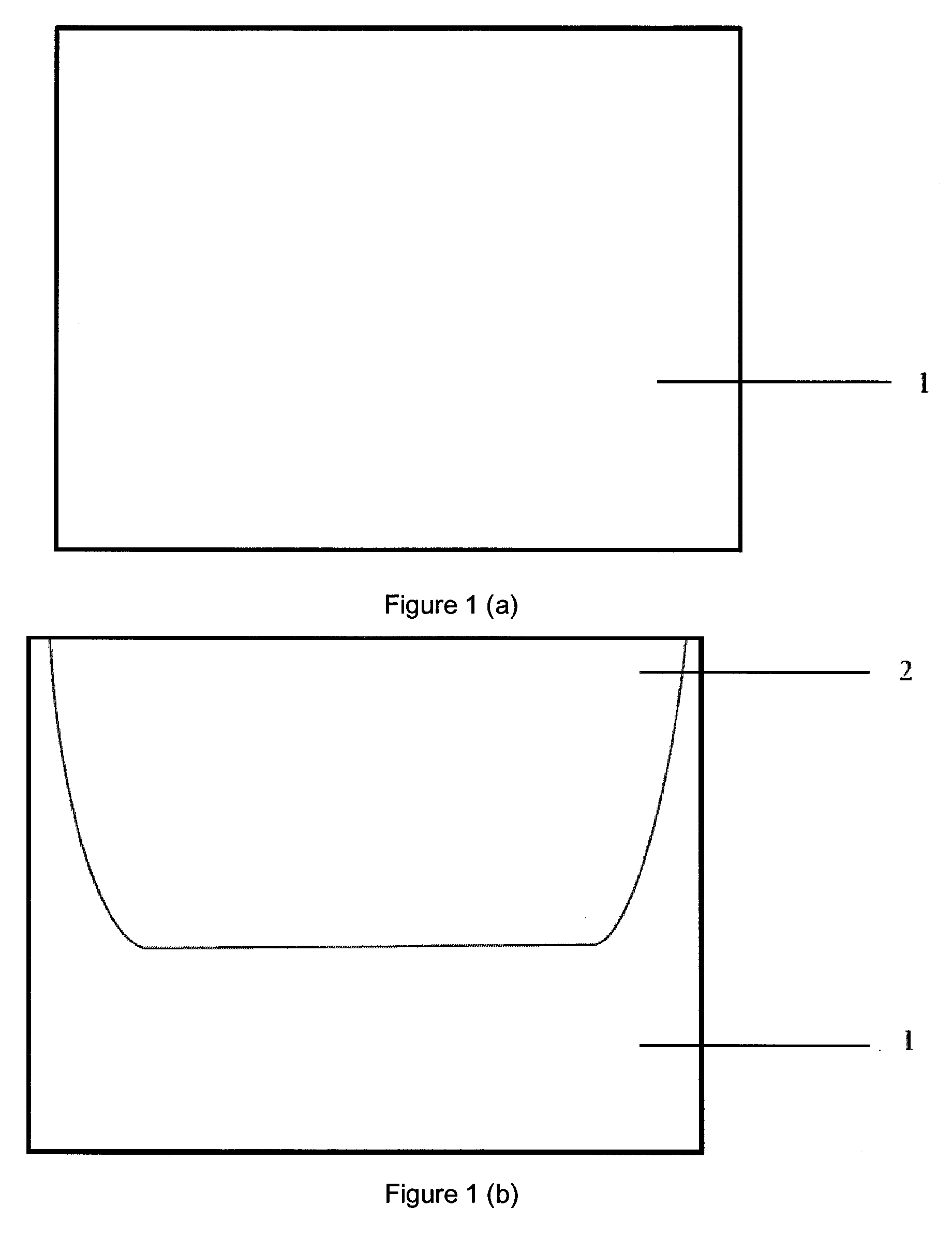

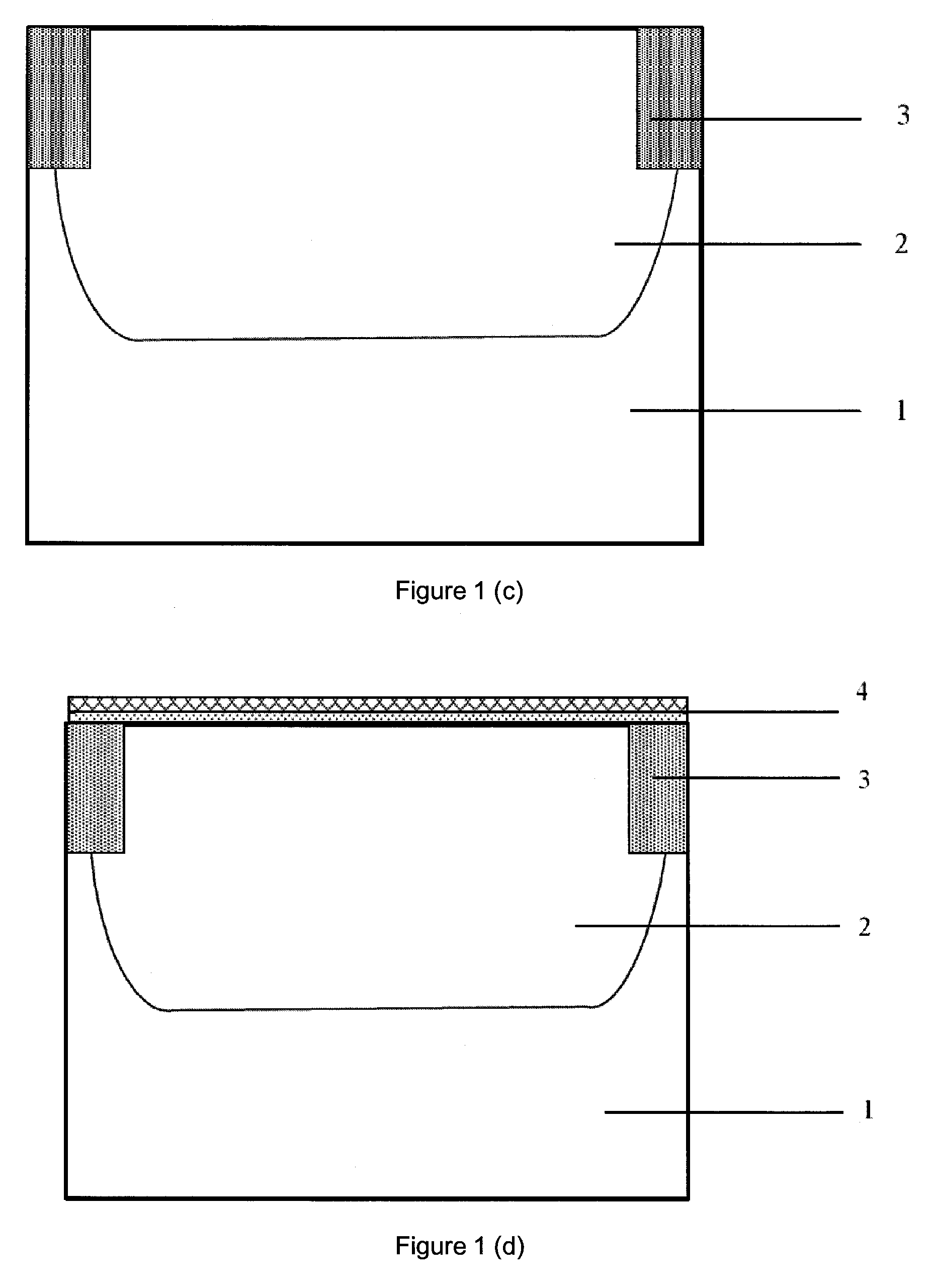

Composite passivated reflection reducing membrane for crystalline silicon solar cell and preparation thereof

InactiveCN101383382ASimple manufacturing processEfficient passivationFinal product manufacturePhotovoltaic energy generationThermal sprayingGas phase

The invention relates to a composite passivation antireflective film used for a crystal silicon solar cell. The invention is characterized in that the composite passivation antireflective film is composed of a layer of amorphous silicon layer (2) and a layer of titanium dioxide layer (3), wherein the amorphous silicon layer (2) is directly deposited on the irradiation surface of a solar cell (1) and plays the role of surface passivation, and the titanium dioxide layer (3) is deposited on the amorphous silicon layer (2) and plays the role of reducing the reflection of light of the battery. The invention also relates to a method for preparing the passivation antireflective film, and the method comprises the following steps: firstly, the amorphous silicon layer (2) is deposited and prepared on the solar cell (1) by adopting a PECVD (plasma enhanced chemical vapor deposition) process, and then the titanium dioxide layer is deposited on the amorphous silicon layer (2) by adopting an APCVD (atmospheric pressure chemical vapor deposition) process, or the titanium dioxide layer (3) is deposited on the amorphous silicon layer (2) by adopting a thermal spraying process.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

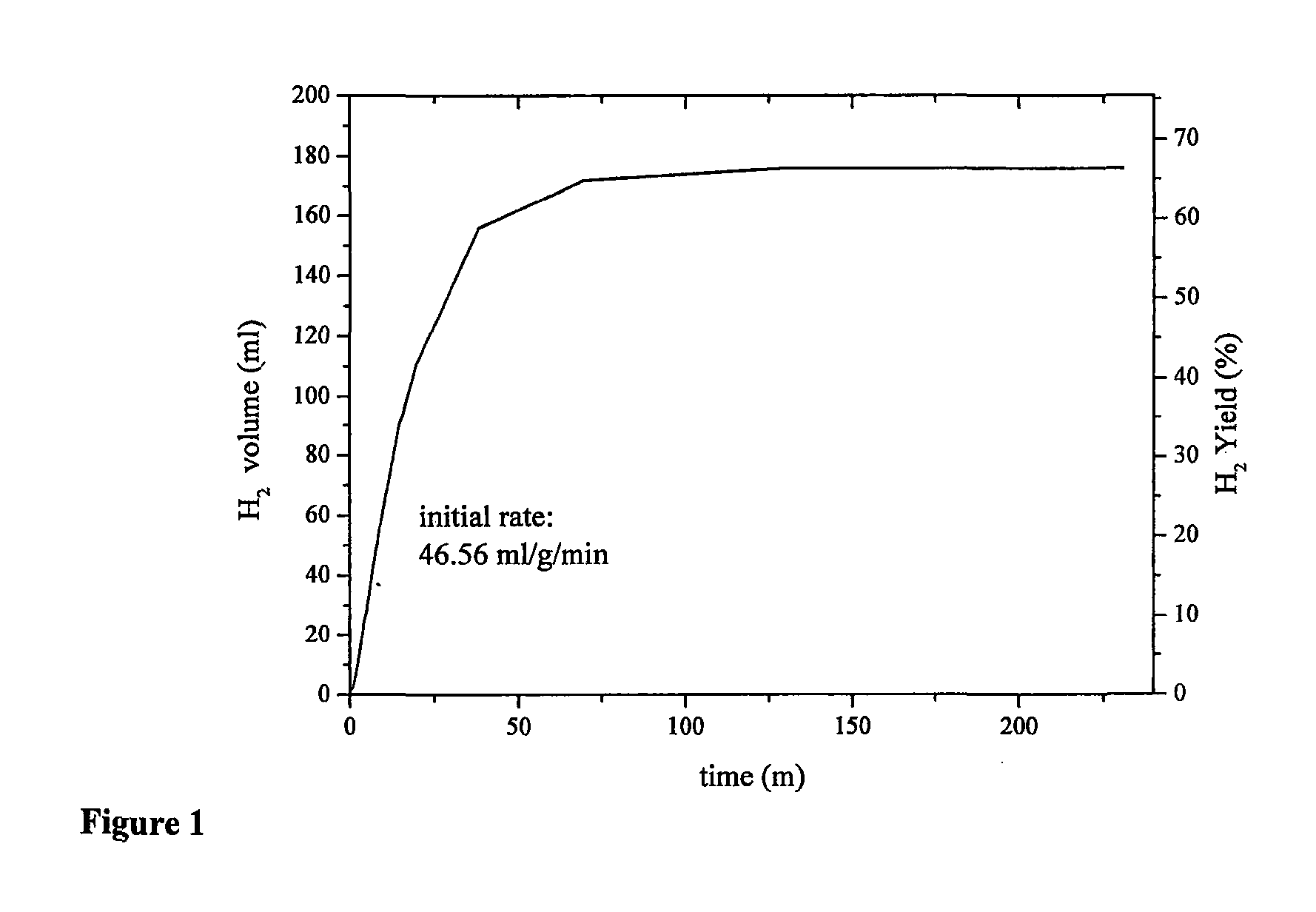

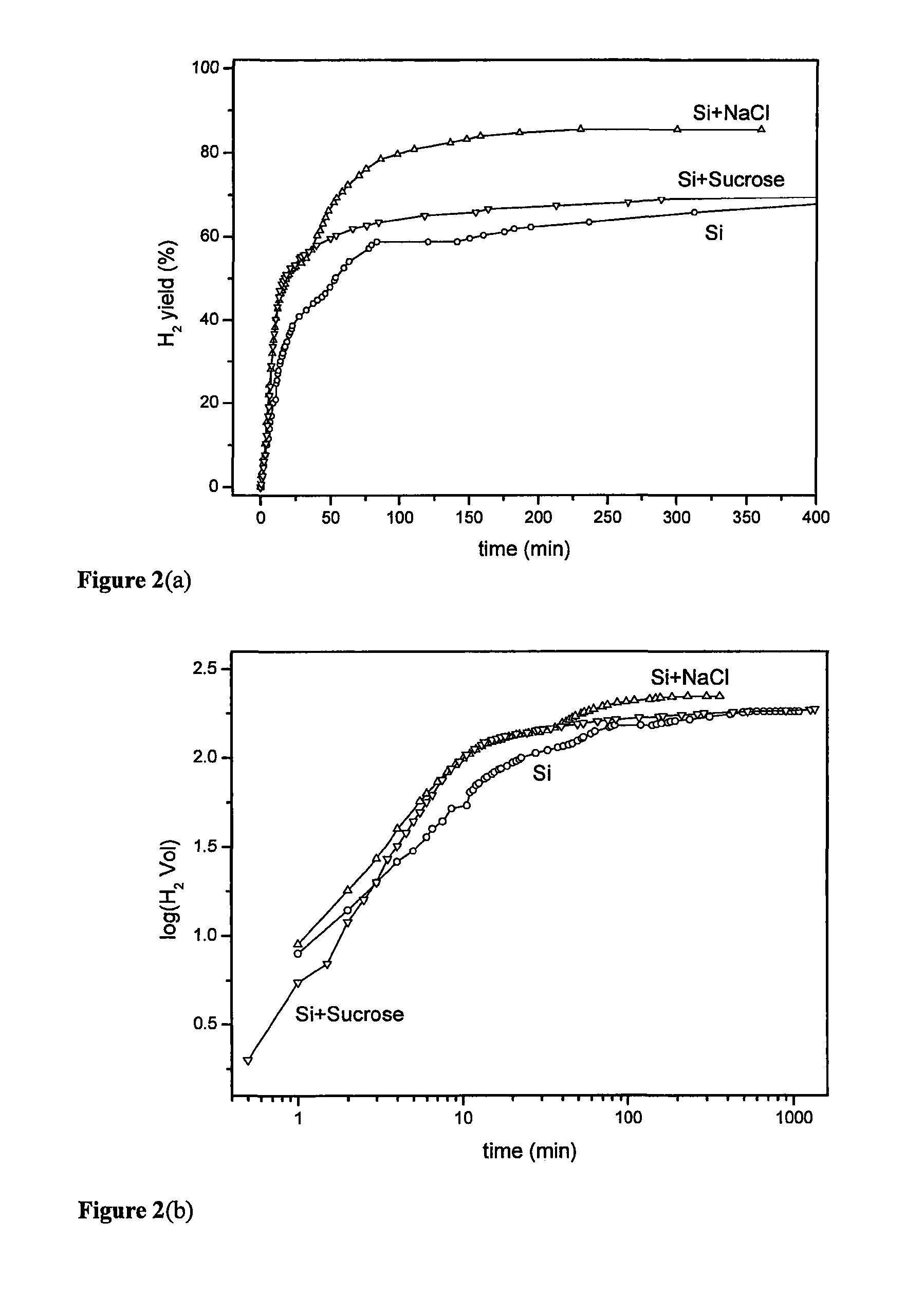

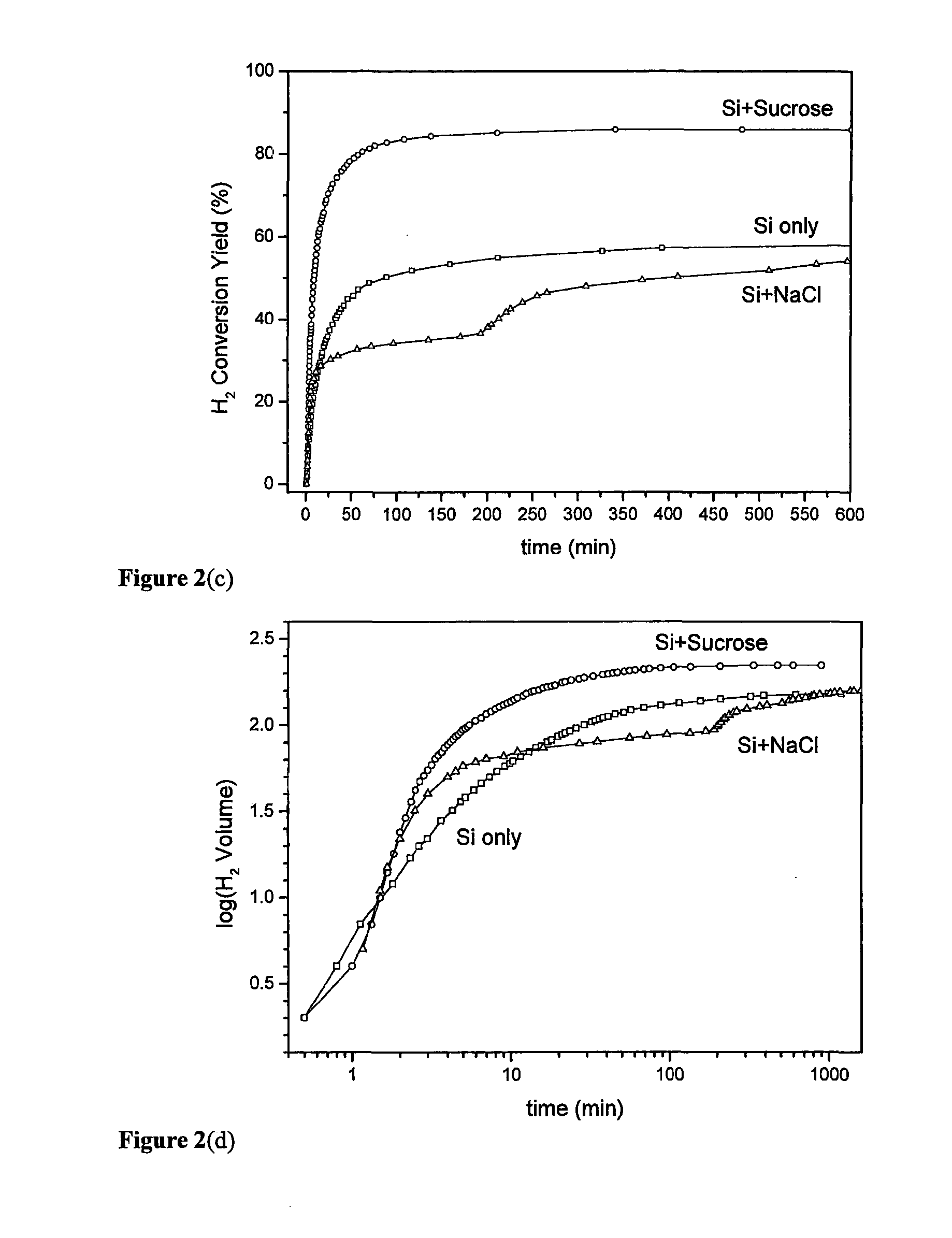

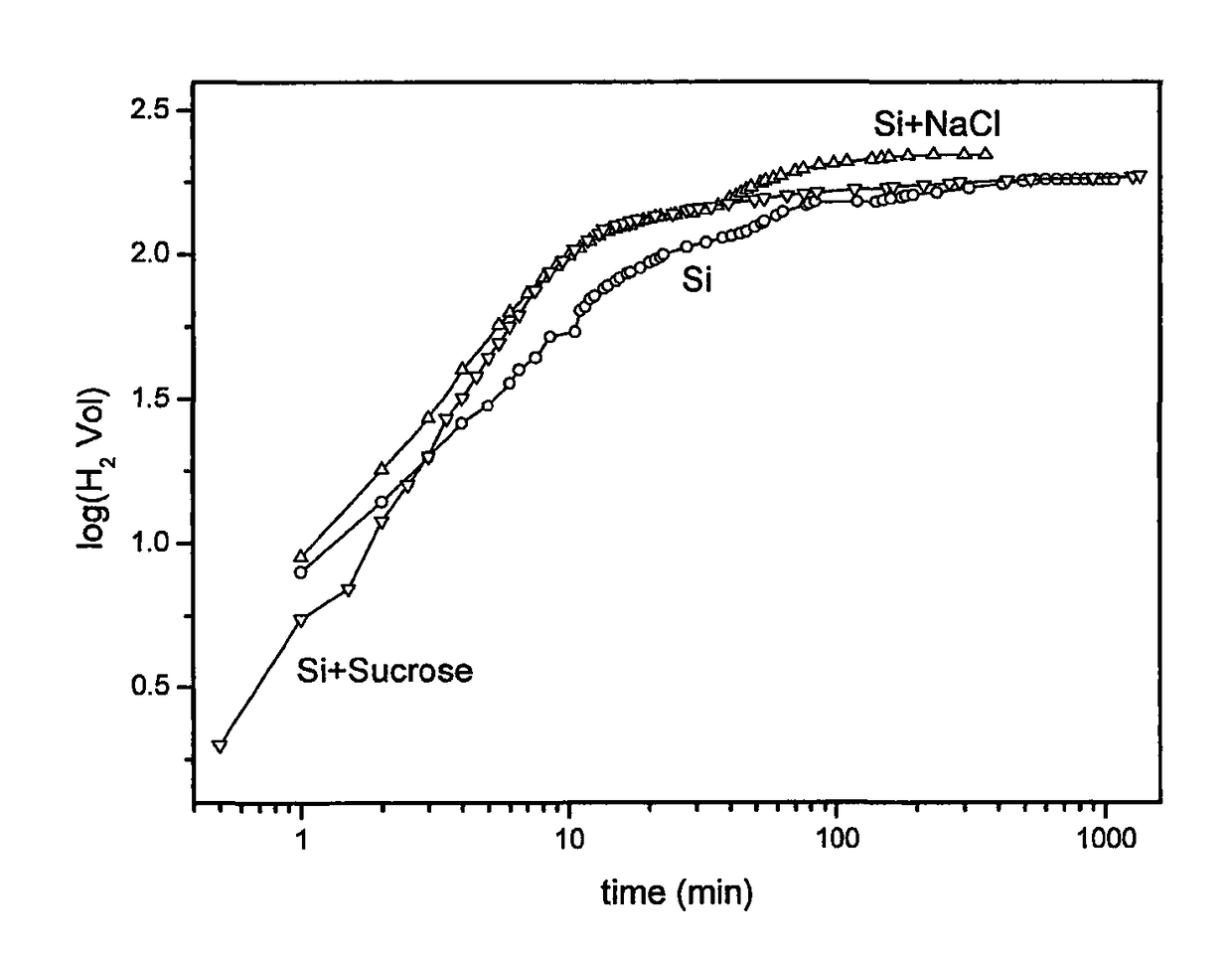

Composition For Hydrogen Generation

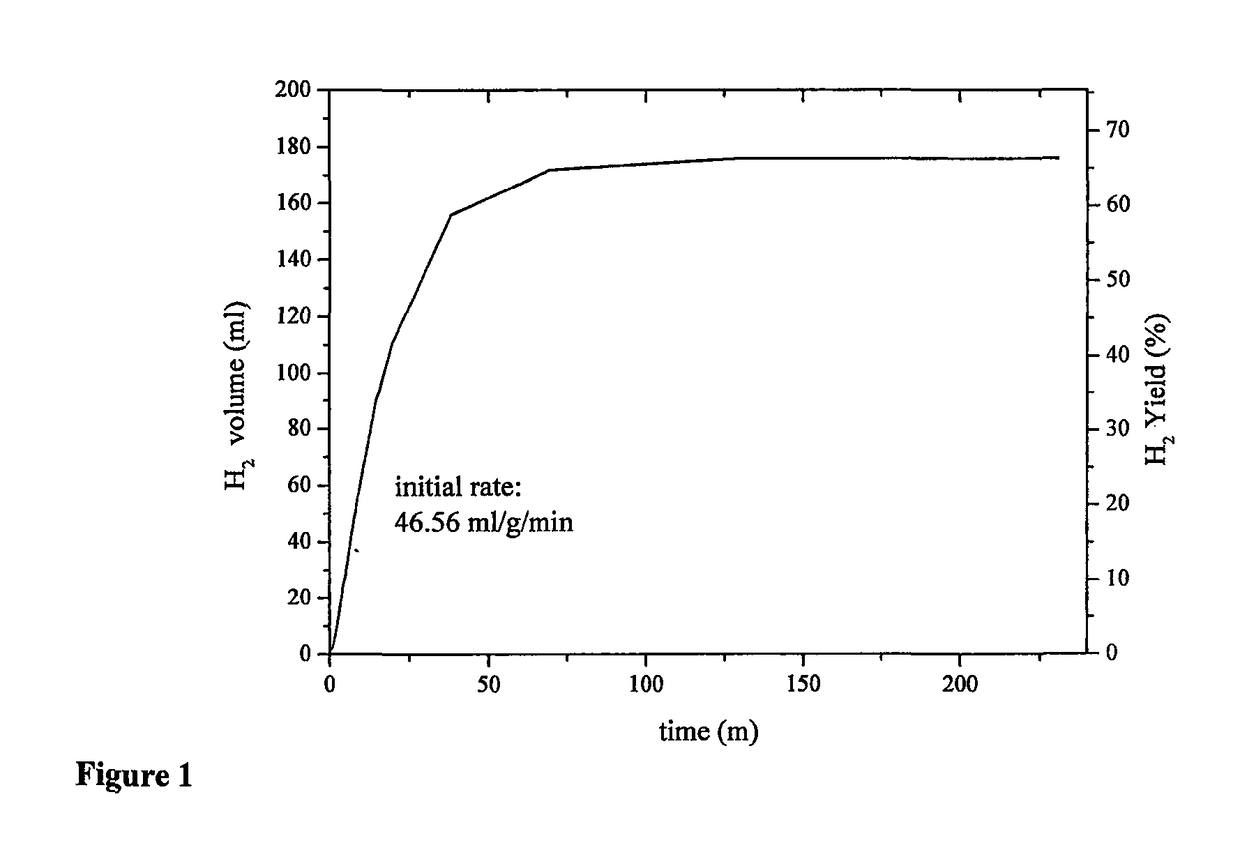

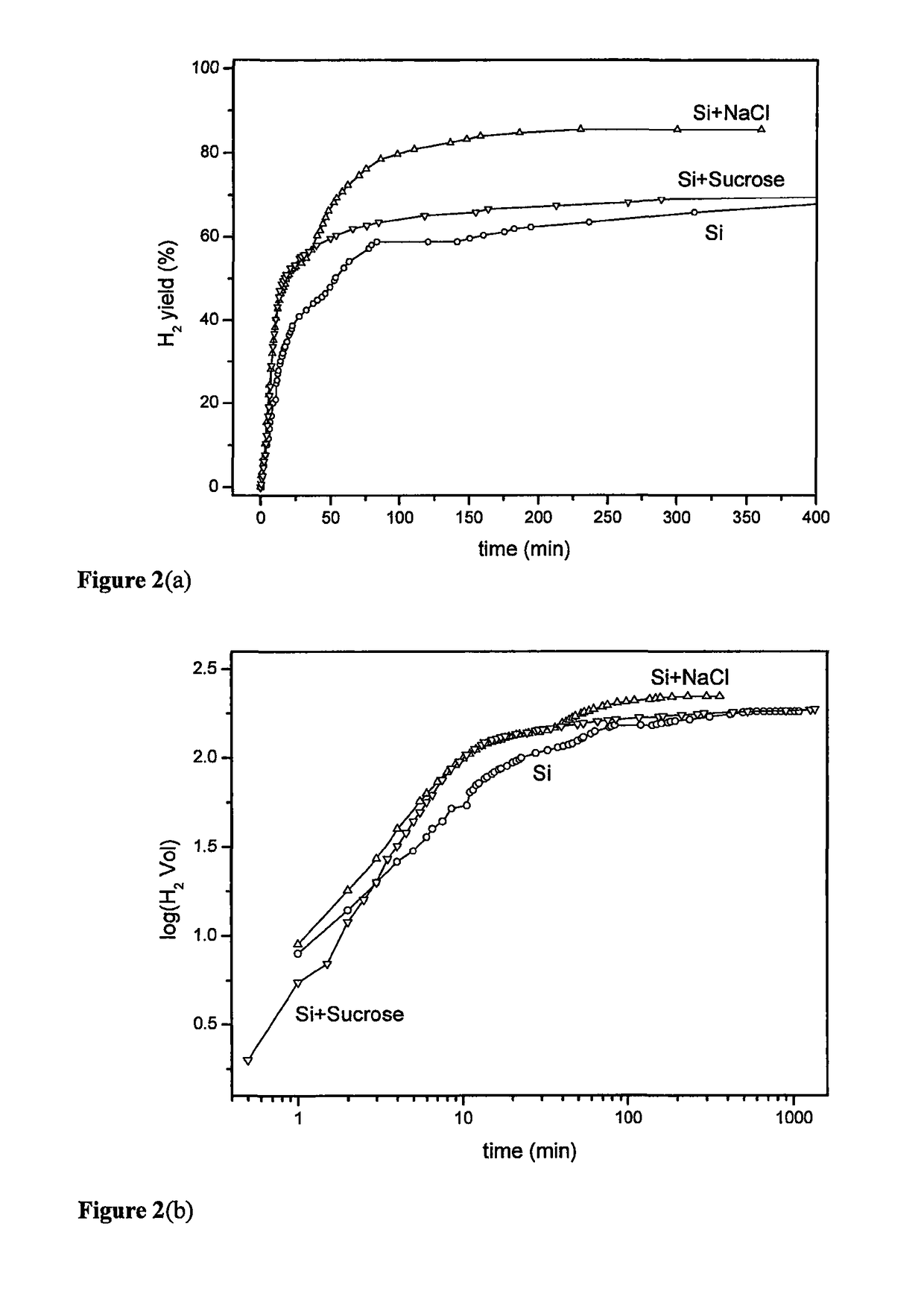

ActiveUS20150266729A1Increase ratingsHigh yieldPigmenting treatmentMaterial nanotechnologyHydrogenHydrolysis

The invention relates to the use of nonpassivated silicon to produce hydrogen, by hydrolysis of the nonpassivated silicon. In particular, the invention relates to a composition comprising nonpassivated silicon, a process for producing a composition comprising nonpassivated silicon, and a process for producing hydrogen by reacting the composition with water.

Owner:OXFORD UNIV INNOVATION LTD

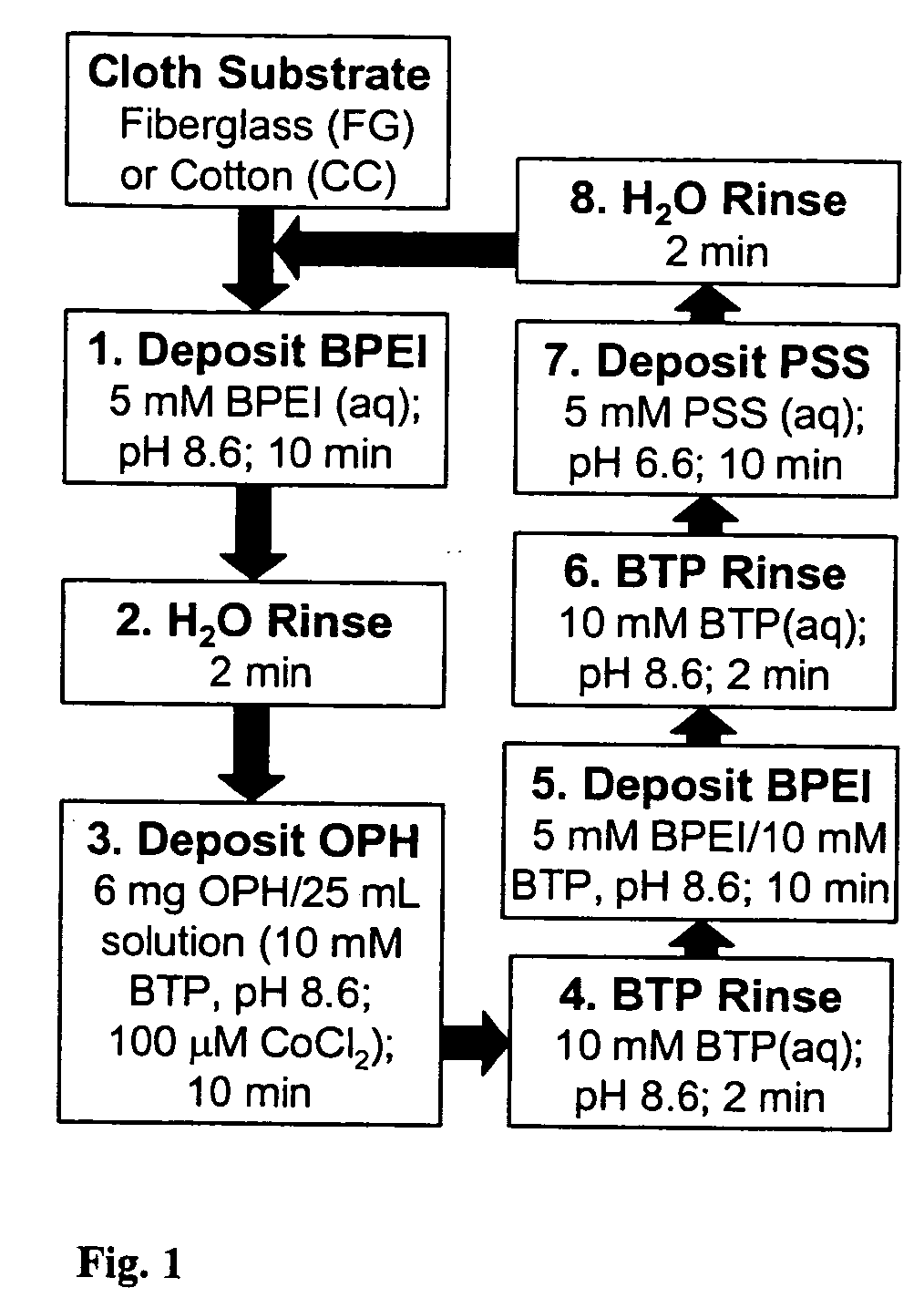

Catalytic surfaces for active protection from toxins

InactiveUS20050136522A1Passivate them efficientlyFacilitate contactPeptide/protein ingredientsHydrolasesEnzymePolyelectrolyte

A bioactive catalytic material is disclosed for providing protection from chemical exposure. The material is composed of enzymes immobilized within polyelectrolyte multilayers and a polymerizable end-capping layer to render stability to enzymes. Also disclosed is the related method for making a bioactive catalytic material and their deposition on substrates of varying size, shape and flexibility for providing active protection from chemical exposure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

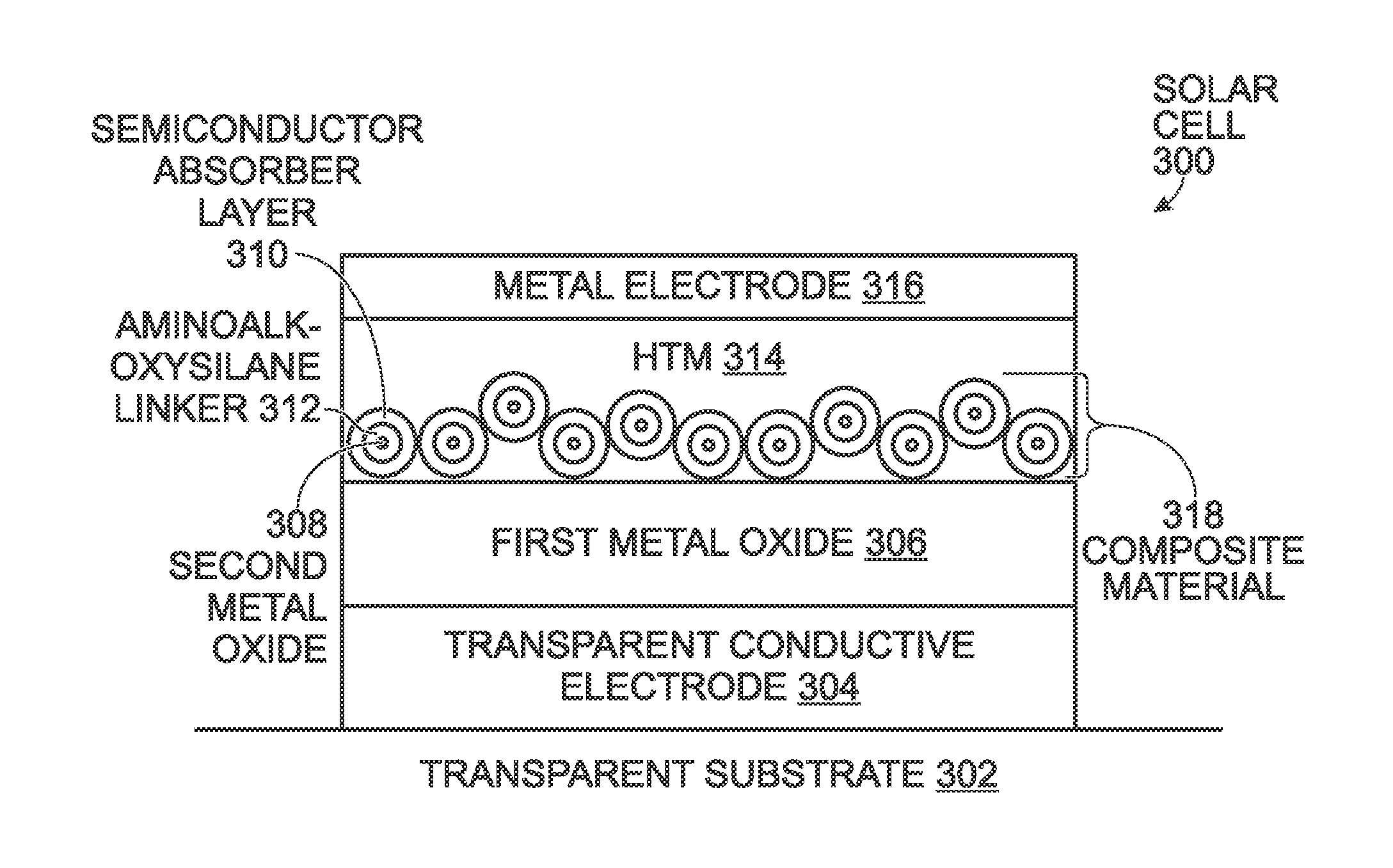

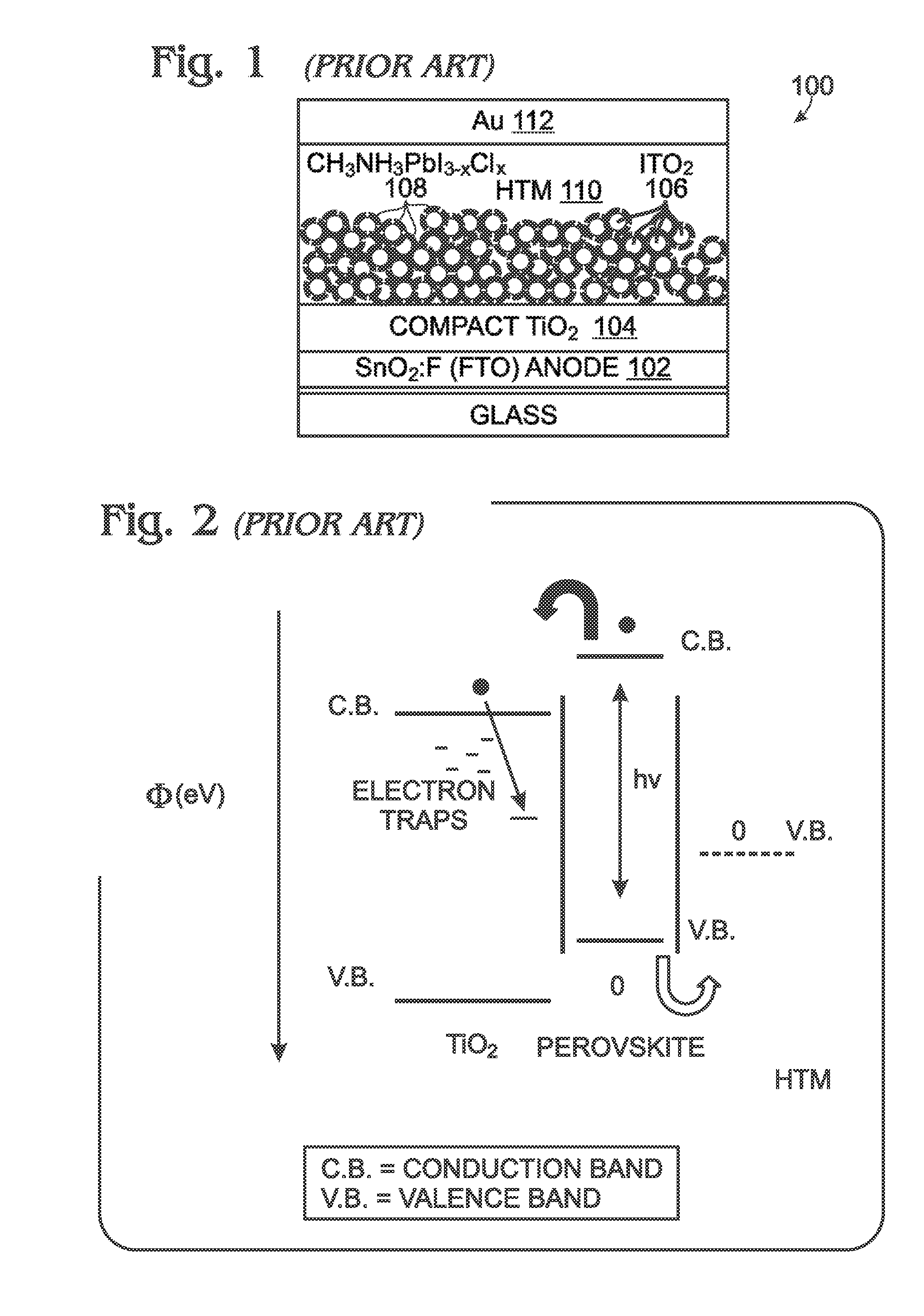

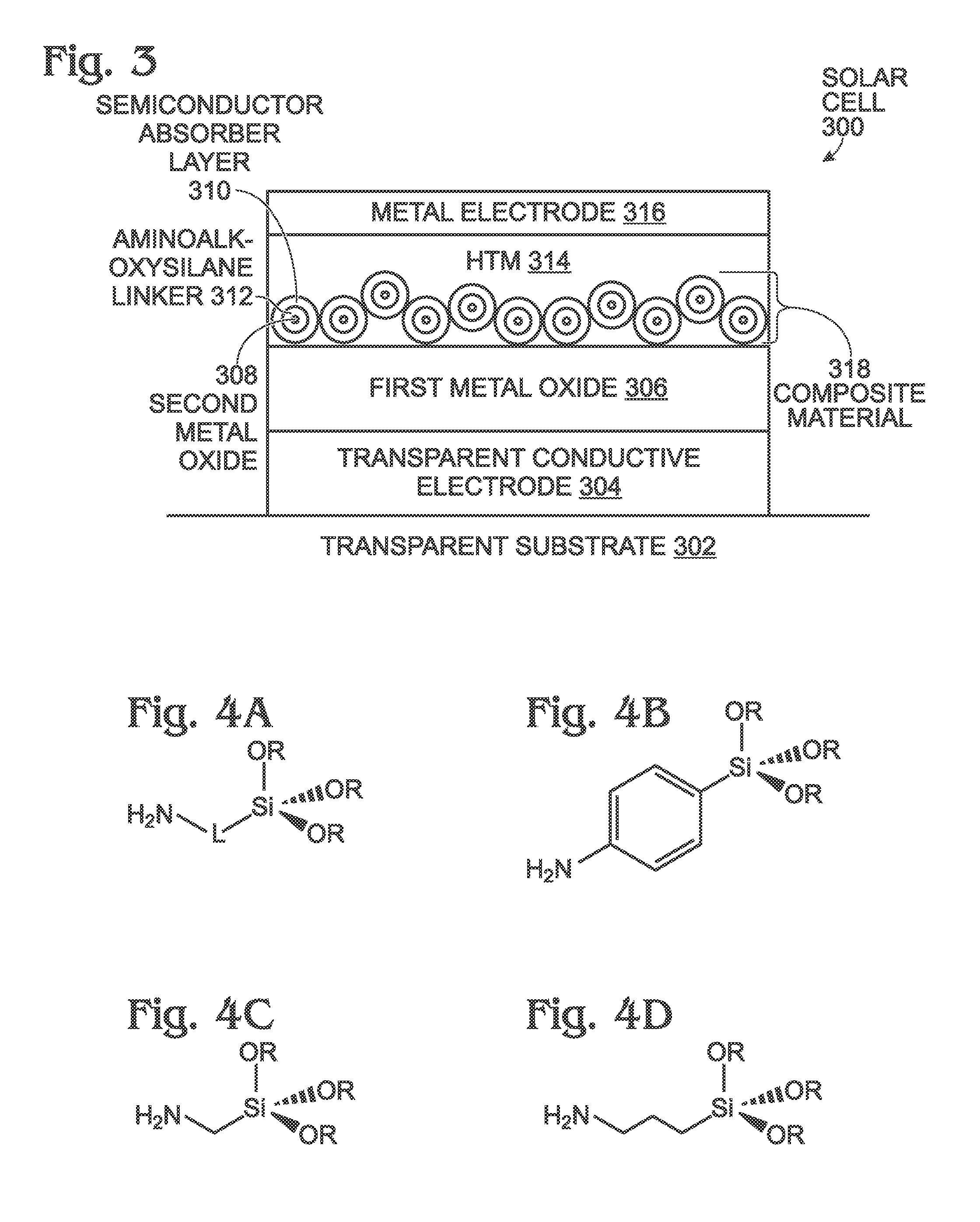

Mesoporous Structure Solar Cell with Siloxane Barrier

InactiveUS20150380170A1Efficient passivationFacilitate proper formationLight-sensitive devicesSolid-state devicesSilanesMesoporous material

A method is provided for forming a mesoporous-structured solar cell with a silane or siloxane barrier. The method forms a transparent conductive electrode overlying a transparent substrate. A non-mesoporous layer of a first metal oxide overlies the transparent conductive electrode, with a mesoporous layer of a second metal oxide overlying the non-mesoporous layer of first metal oxide. An aminoalkoxysilane layer overlies the mesoporous layer of second metal oxide. Over the aminoalkoxysilane layer is deposited a semiconductor absorber layer comprising organic and inorganic components. Using the aminoalkoxysilane linker, the mesoporous layer of second metal oxide is linked to the semiconductor absorber layer. A hole-transport material (HTM) layer is formed overlying the semiconductor absorber layer, and a metal electrode overlies the HTM layer. A mesoporous-structured solar cell with a silane or siloxane barrier is also provided.

Owner:SHARP LAB OF AMERICA INC

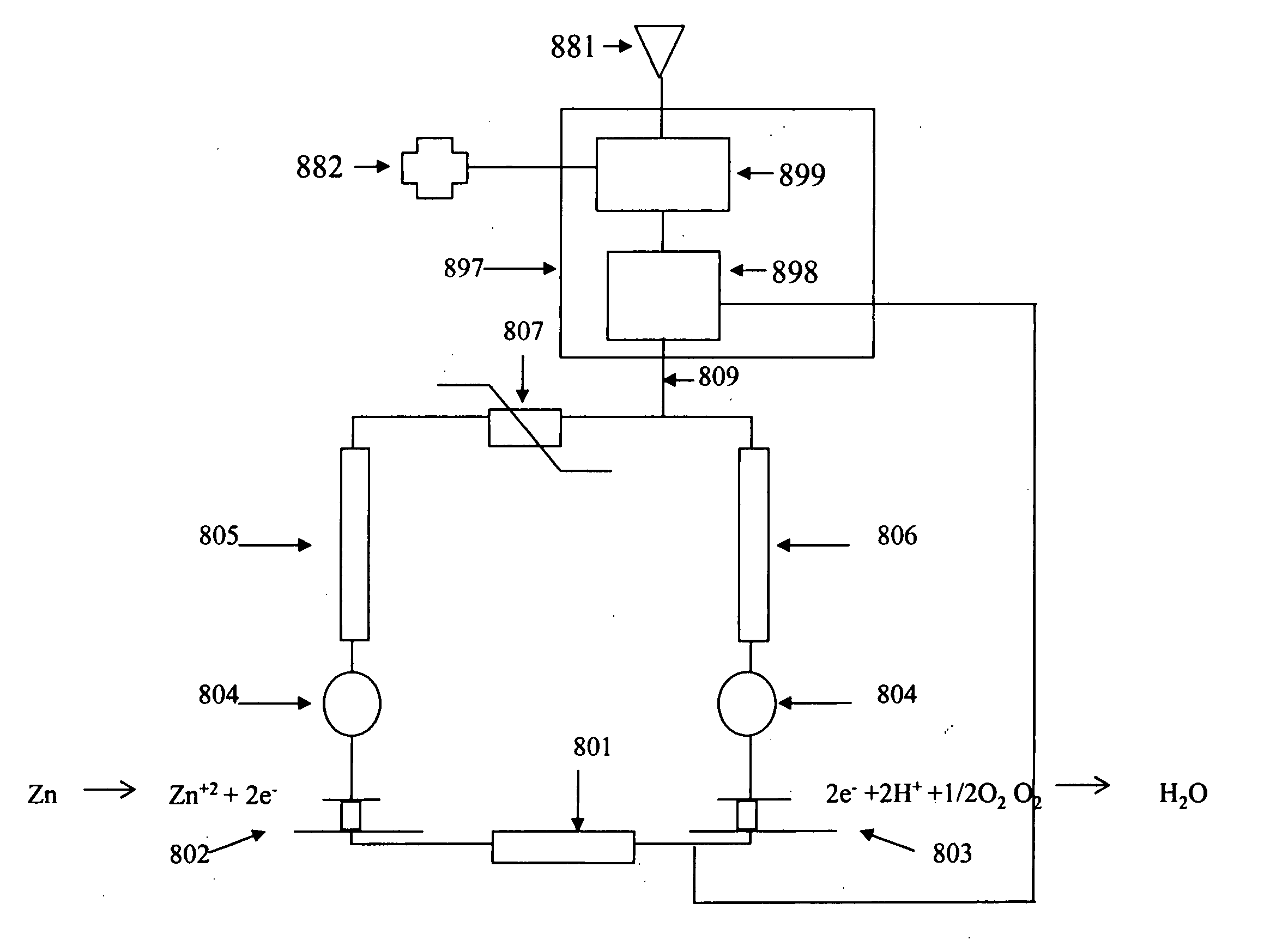

Semiconductive corrosion and fouling control apparatus, system, and method

An apparatus, system, method and computer program product directed to controlling corrosion of a conductive structure in contact with a corrosive environment and coated with a semiconductive coating, where the corrosion is controlled by a controllable filter and a corresponding electronic control unit configured to process at least one stored or measured parameter.

Owner:APPLIED SEMICON INT

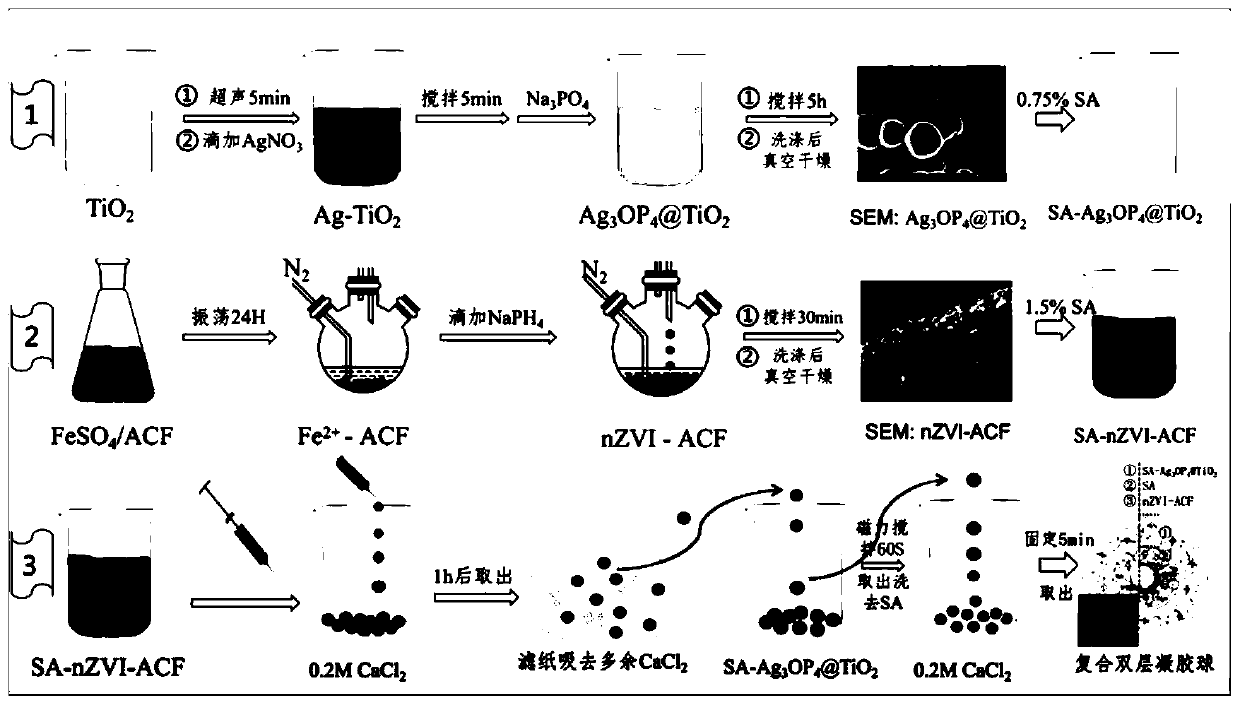

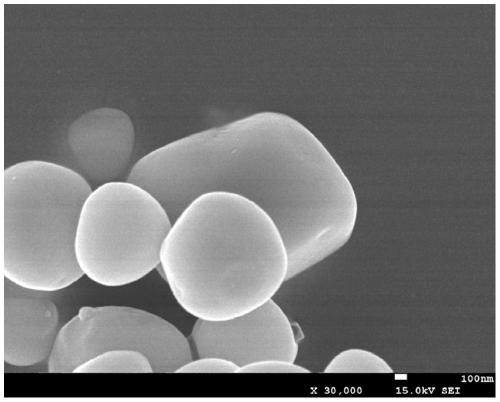

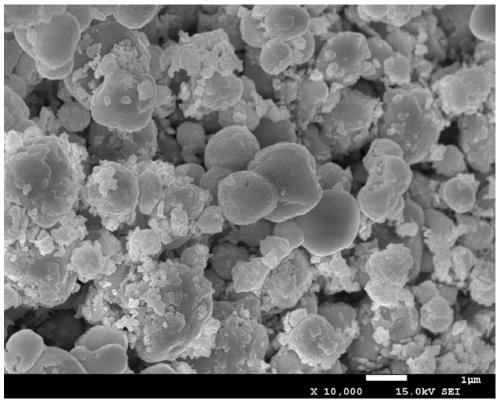

Composite material for treating heavy metal-organic pollution, and preparation method and application thereof

ActiveCN110013883AEfficient passivationImprove degradation efficiencyWater/sewage treatment by irradiationWater treatment compoundsSoil remediationSilver phosphate

The invention discloses a composite material for treating heavy metal-organic pollution, and a preparation method and application thereof, and relates to the technical field of environmental treatment. The composite material for treating heavy metal-organic pollution comprises a silver phosphate-titanium dioxide composite material and a zero-valent iron composite material, wherein the zero-valentiron composite material is formed by loading zero-valent iron on an adsorption substrate. The preparation method comprises the following steps: carrying out wrapping formation on the silver phosphate-titanium dioxide composite material and the zero-valent iron composite material in a form of layering the substrate. The composite material provided by the invention can be used for simultaneously andefficiently passivating heavy metals and degrading organic matters, can be continuously and stably repaired, and can be applied to a water body or soil remediation process.

Owner:SICHUAN UNIV

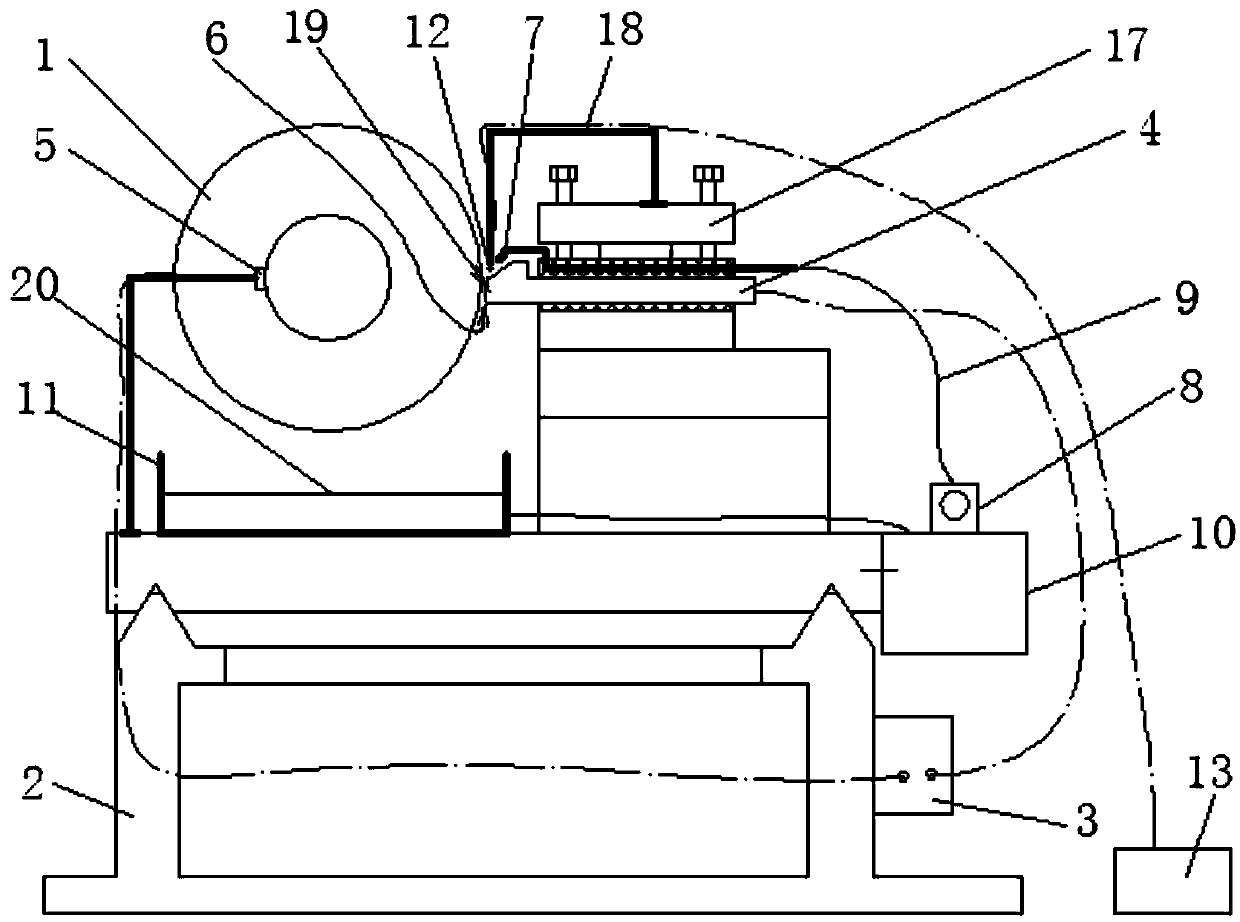

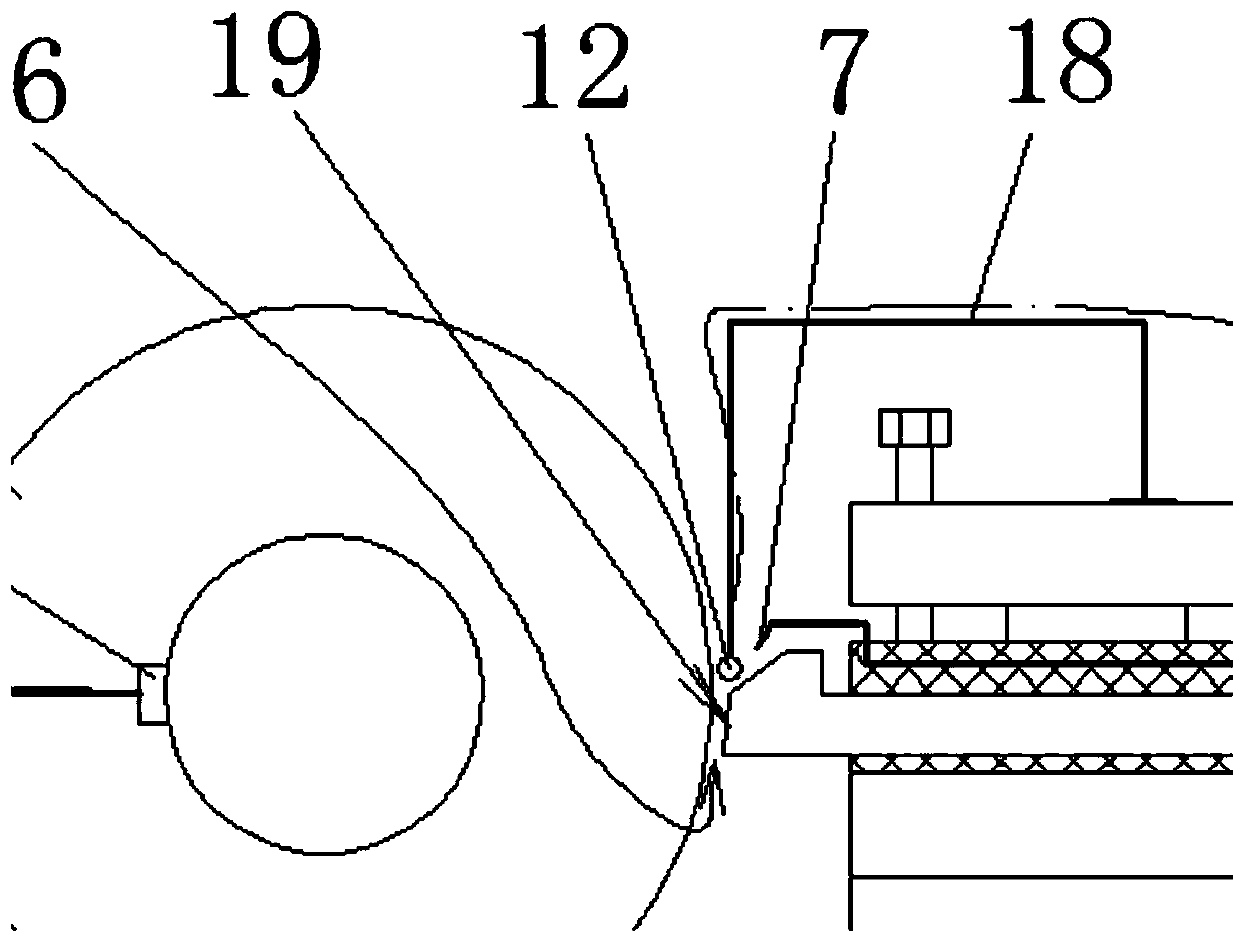

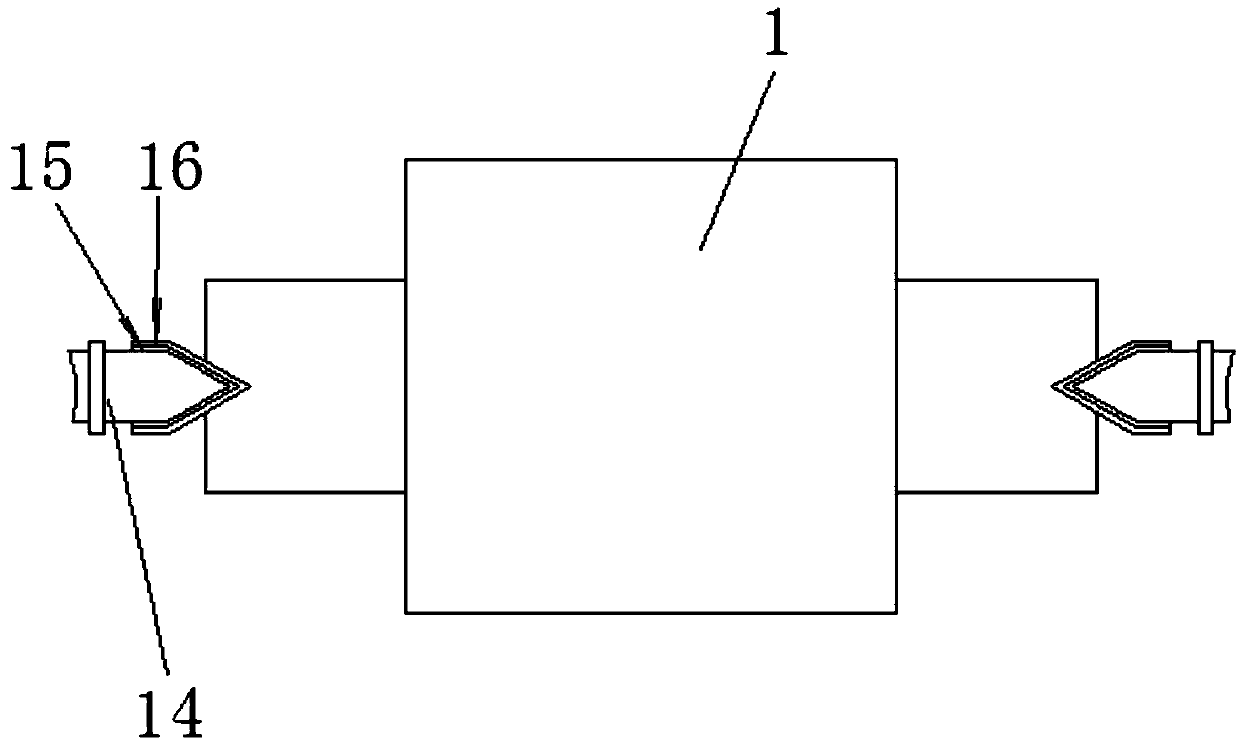

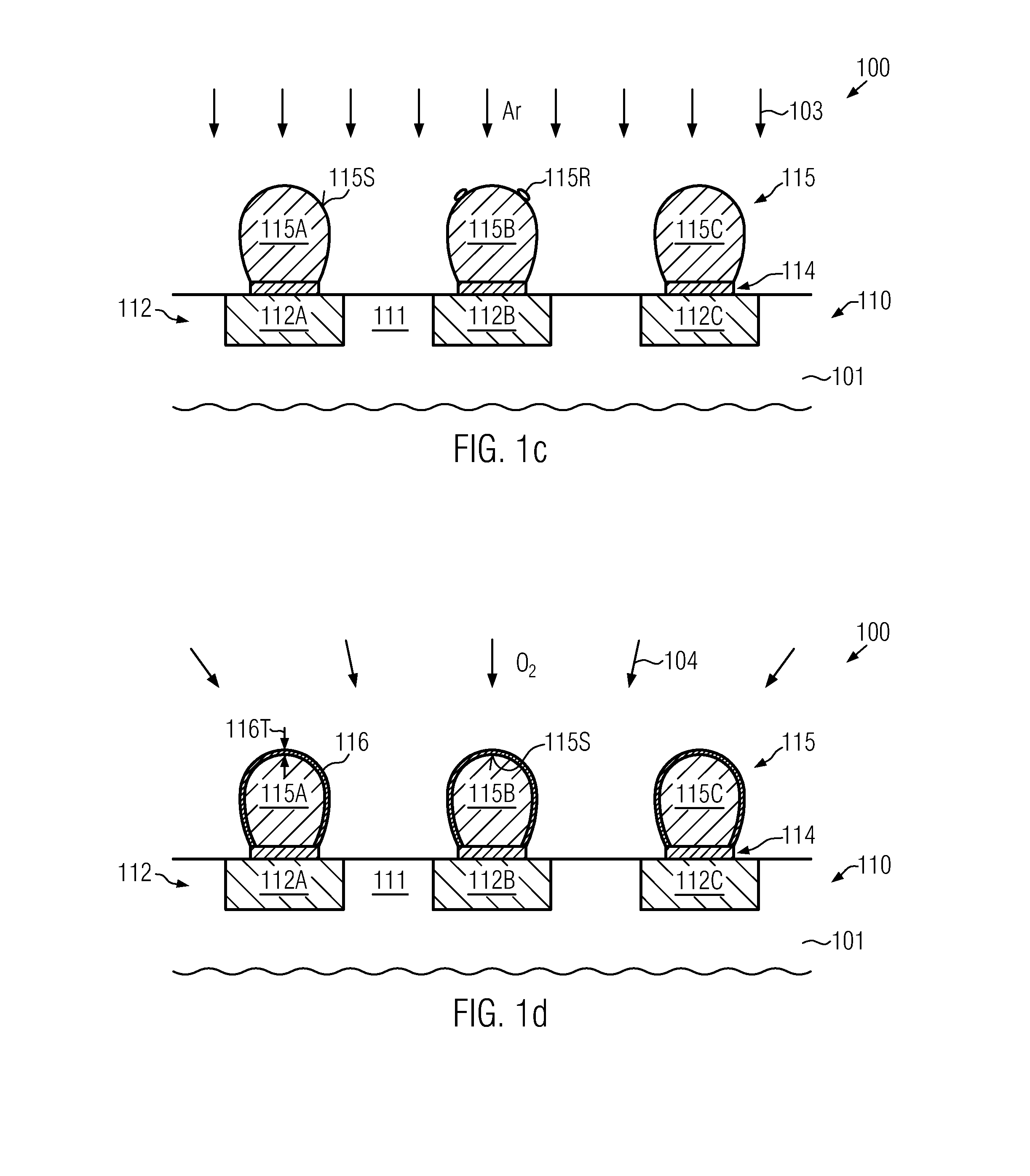

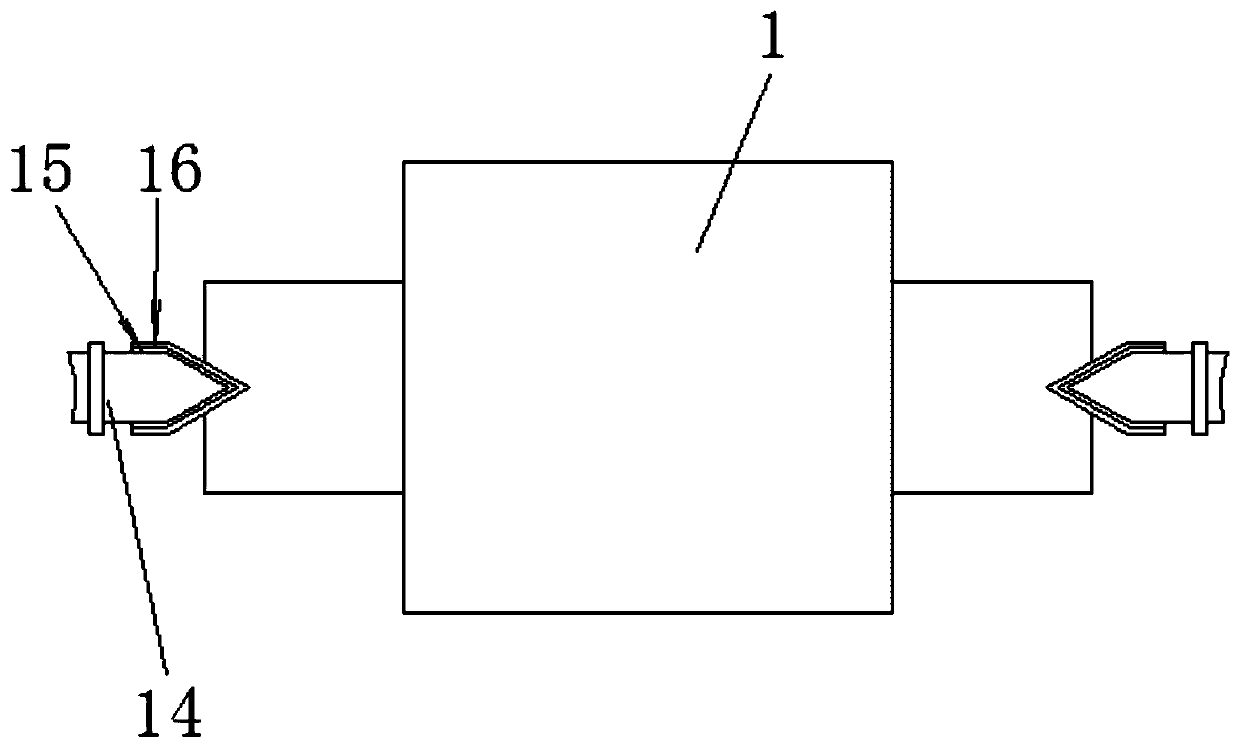

Surface passivation system for prolonging service life of EDT roughened cold rollers

ActiveCN109514012AExtended service lifeAchieve passivation effectMachining electrodesMachining working media supply/regenerationElectrolysisManufacturing technology

The invention relates to the technical field of cold roller manufacturing, and discloses a surface passivation system for prolonging service life of EDT roughened cold rollers. The system comprises rotary driving equipment and a pulse electrochemical burr removing device; the pulse electrochemical burr removing device comprises a pulse power supply, a tool electrode and an electric brush; the electric brush is contacted with outer circle surfaces of cold rollers; the head part of the tool electrode is near roughened outer circle surfaces of the cold rollers; a gap for enabling electrolyte to pass through is formed between the head part of the tool electrode and the roughened outer circle surfaces of the cold rollers; an electrolyte nozzle with a spout aligned to the gap is arranged above the gap; the electrolyte nozzle is connected to an electrolyte box through a pump and a pipeline; an electrolyte collecting tank for collecting electrolyte is arranged under the roughened outer circlesof the cold rollers; and the electrolyte collecting tank is connected with the electrolyte box. The system prolongs the service life of the EDT roughened cold rollers, improves the quality of rolledparts, and reduces the roller change efficiency.

Owner:JIANGYIN RUNYUAN MACHINERY

Composition for hydrogen generation

ActiveUS9751759B2Increase ratingsHigh yieldPigmenting treatmentMaterial nanotechnologyHydrogenHydrolysis

The invention relates to the use of nonpassivated silicon to produce hydrogen, by hydrolysis of the nonpassivated silicon. In particular, the invention relates to a composition comprising nonpassivated silicon, a process for producing a composition comprising nonpassivated silicon, and a process for producing hydrogen by reacting the composition with water.

Owner:OXFORD UNIV INNOVATION LTD

Catalytic enzyme-modified textiles for active protection from toxins

InactiveUS20050136523A1Do not damage the environmentEffective protectionHydrolasesPeptide/protein ingredientsPolyelectrolyteChemical exposure

Catalytic enzyme-modified textiles are disclosed for providing protection from chemical exposure. The textiles are composed of a cloth substrate, at least one polyelectrolyte layer, at least one enzyme layer to degrade the chemical agent, and at least one capping layer. Also disclosed is the related method for making catalytic enzyme-modified textiles.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Catalytic enzyme-modified textiles for active protection from toxins

InactiveUS20070014838A1Do not damage the environmentEffective protectionHydrolasesPeptide/protein ingredientsPolyelectrolyteChemical exposure

Catalytic enzyme-modified textiles are disclosed for providing protection from chemical exposure. The textiles are composed of a cloth substrate, at least one polyelectrolyte layer, at least one enzyme layer to degrade the chemical agent, and at least one capping layer. Also disclosed is the related method for making catalytic enzyme-modified textiles.

Owner:U S A AS REPRESENTED BY THE SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCCIP THE

Tin plate passivation solution and passivation process

ActiveCN110373661AEnvironmentally friendlyUniform passivationMetallic material coating processesHydrofluoric acidPhosphate

The invention discloses a tin plate passivation solution and a passivation process. The passivation solution comprises the following composition according to mass concentration: 30-40g / L of fluorotitanate ion, 30-40g / L of fluorozirconate ion, 10-20g / L of permanganate ion, 2-3ml / L of hydrofluoric acid, 5-15g / L of phosphate, 5-8g / L of organosilane, and the rest of water.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Profile fluorocarbon coating process

InactiveCN108380471AImprove adhesionFinished surface is smoothPretreated surfacesCoatingsEpoxySprayer

The invention discloses a coating process, and particularly provides a profile fluorocarbon coating process. The profile fluorocarbon coating process aims at solving the problems that in the prior art, the thickness of a fluorocarbon coating is not uniform, and due to the fact that the coating is too thick, the texture is cheap, the adhesive force of the coating is insufficient, and the coating isprone to peel. The profile fluorocarbon coating process includes the following steps of (1), polishing; (2), alkaline etching; (3), washing; (4), passivating; (5), primer spraying, wherein epoxy zincrich primer is sprayed twice by an airless sprayer, the thickness of the epoxy zinc rich primer sprayed each time is 8 micrometers, and the spraying interval is 2.5 h; (6), finish paint spraying, wherein embroidery fluorocarbon paint is sprayed twice by a high-voltage static spray gun, the spraying interval is 24 h, surface drying is carried out after the embroidery fluorocarbon paint is sprayed,the surface drying time ranges from 38 h to 48 h, and the thickness of a fluorocarbon embroidery paint dry film formed after surface drying ranges from 40 micrometers to 50 micrometers; and (7), lustering. The paint thickness can meet the beautifying effect of profiles, the paint is not too thick, meanwhile the profiles can be protected sufficiently, and the texture is shown better.

Owner:ZIGONG DONGFANG STEEL STRUCTURE

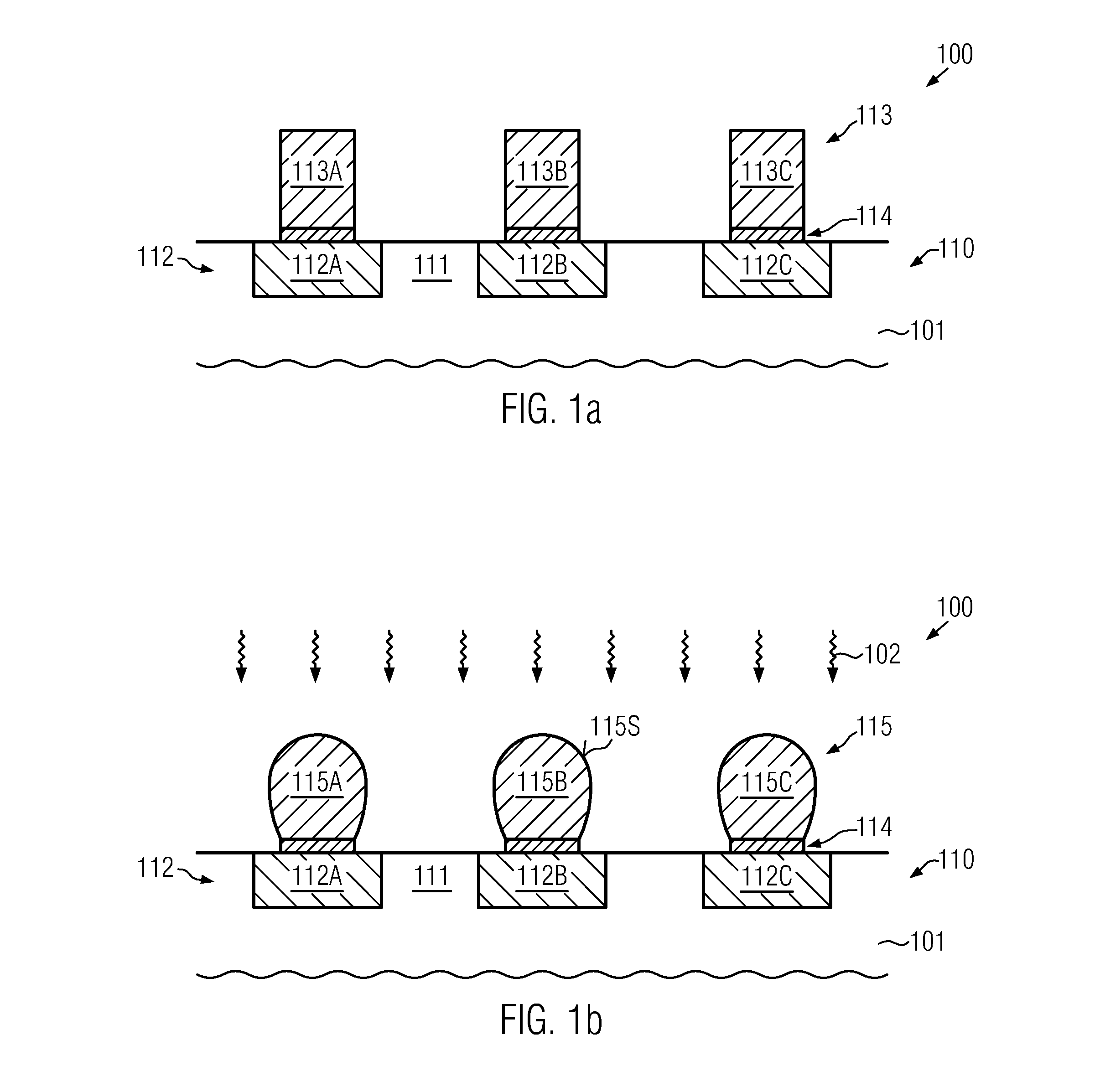

Method for Forming Lead-Free Solder Balls with a Stable Oxide Layer Based on a Plasma Process

InactiveUS20120052677A1Efficient passivationImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSolder ballSemiconductor

Solder balls of semiconductor devices and, in particular, lead-free solder balls receive a very uniform passivation layer, for instance in the form of an oxide layer, which is formed by applying a plasma treatment. For example, the passivation layer may be provided with a thickness of 5-50 nm which may thus allow, due to the superior uniformity, a reliable protection of the solder balls while nevertheless ensuring a reliable removal during the final solder process.

Owner:GLOBALFOUNDRIES INC

Manufacturing process for cold-rolling roll

ActiveCN109807554AAchieve passivation effectExtended service lifeIncreasing energy efficiencyFurnace typesCold treatmentManufacturing technology

The invention relates to the technical field of rolling roll manufacturing, and discloses a manufacturing process for a cold-rolling roll. The manufacturing process for the cold-rolling roll sequentially comprises the procedures of ingot casting, forging, heat treatment after forging, rough turning machining, quenching and tempering treatment, finish turning machining, surface quenching, cold treatment, low-temperature tempering, accurate grinding machining, surface texturing, and electrochemical passivation, wherein in the procedure of surface quenching, double-frequency quenching treatment is carried out on the working surface of the cold-rolling roll through a double-frequency quenching machine tool; in the procedure of surface texturing, texturing treatment is carried out on the working surface of the cold-rolling roll through an EDT electric spark texturing machine tool; and in the procedure of electrochemical passivation, deburring passivation treatment is carried out on microcosmic tip parts on the working surface of the cold-rolling roll through pulse electrochemical deburring equipment. According to the manufacturing process for the cold-rolling roll, the service life of the EDT textured cold-rolling roll is prolonged, the quality of a rolled part is improved, and the roll changing frequency is reduced.

Owner:JIANGYIN RUNYUAN MACHINERY

Ge-based NMOS device and method for fabricating the same

ActiveUS8865543B2Improve performanceGuaranteed flatnessSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierPower flow

The embodiments of the present invention provide a Ge-based NMOS device structure and a method for fabricating the same. By using the method, double dielectric layers of germanium oxide (GeO2) and metal oxide are deposited between the source / drain region and the substrate. The present invention not only reduces the electron Schottky barrier height of metal / Ge contact, but also improves the current switching ratio of the Ge-based Schottky and therefore, it will improve the performance of the Ge-based Schottky NMOS transistor. In addition, the fabrication process is very easy and completely compatible with the silicon CMOS process. As compared with conventional fabrication method, the Ge-based NMOS device structure and the fabrication method in the present invention can easily and effectively improve the performance of the Ge-based Schottky NMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

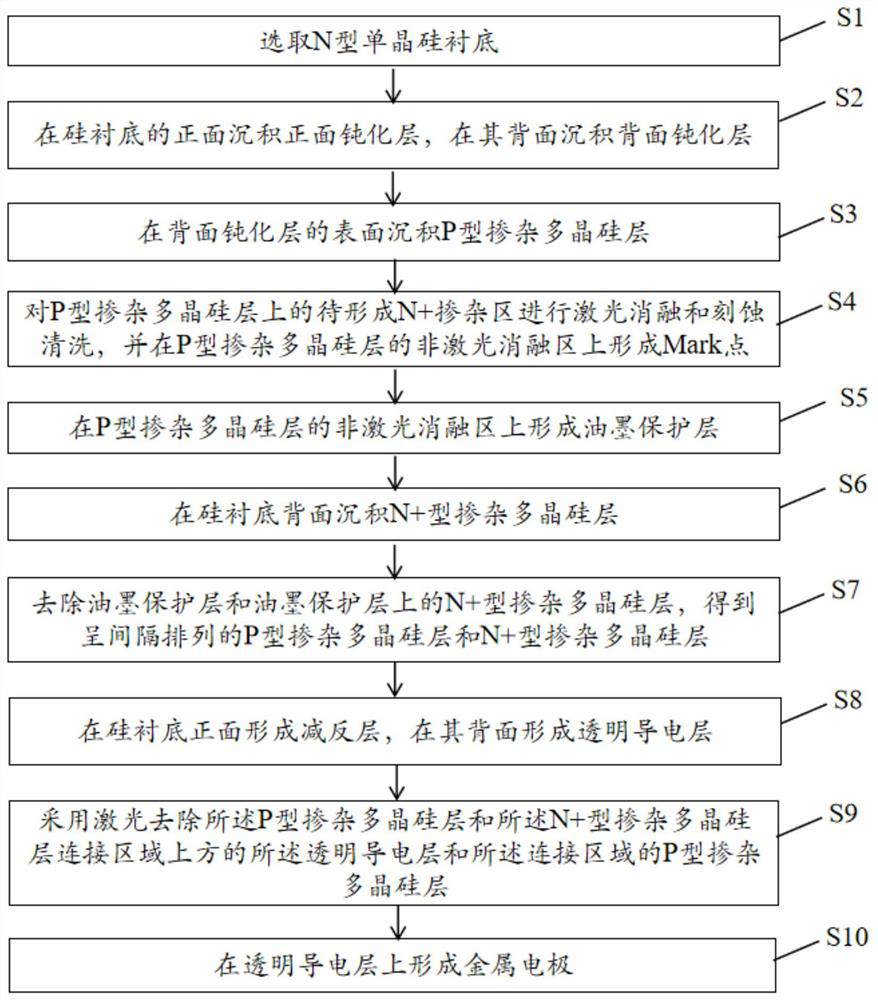

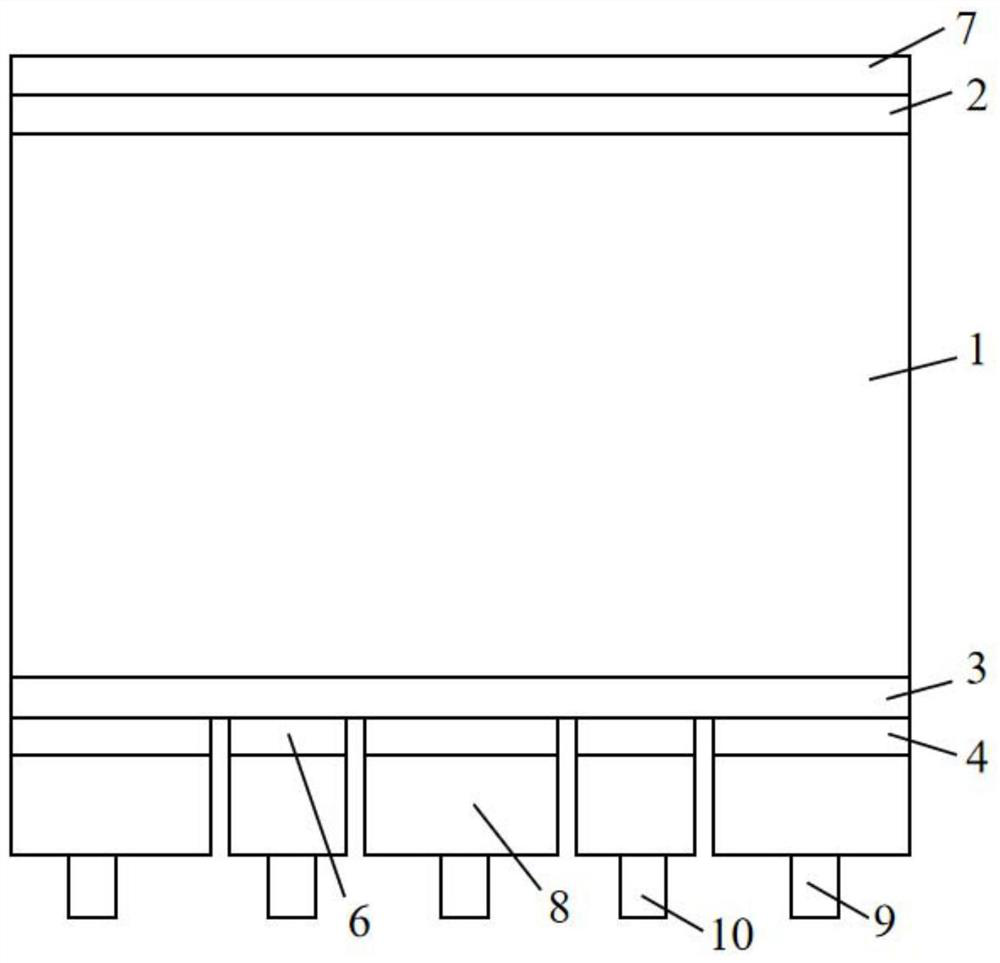

N-type monocrystalline silicon HBC solar cell preparation method

InactiveCN112490324AReduce process stepsLow costFinal product manufactureSemiconductor/solid-state device detailsPhysicsMonocrystalline silicon

The invention discloses an N-type monocrystalline silicon HBC solar cell preparation method, and the method comprises the steps: employing LPCVD equipment and Mark point positioning technology, employing a laser ablation technology to cooperate with an ink protection layer to prepare a P-type doped polycrystalline silicon layer and an N+type doped polycrystalline silicon layer which are arranged at intervals in an interdigital manner, and obtaining an HBC cell with better passivation, higher open-circuit voltage, higher efficiency and lower cost. By adopting the method, the preparation methodof the N-type monocrystalline silicon HBC solar cell is simplified, the N-type monocrystalline silicon HBC solar cell which is good in passivation effect, high in starting voltage and high in efficiency is obtained, and the simple-process, low-cost and high-efficiency large-scale production of the N-type monocrystalline silicon HBC solar cell is realized.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com