Composite material for treating heavy metal-organic pollution, and preparation method and application thereof

A composite material and heavy metal technology, applied in the field of environmental management, can solve the problem of not having continuous repair of the environment, and achieve the effect of efficient and stable repair, increased stability, and efficient passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

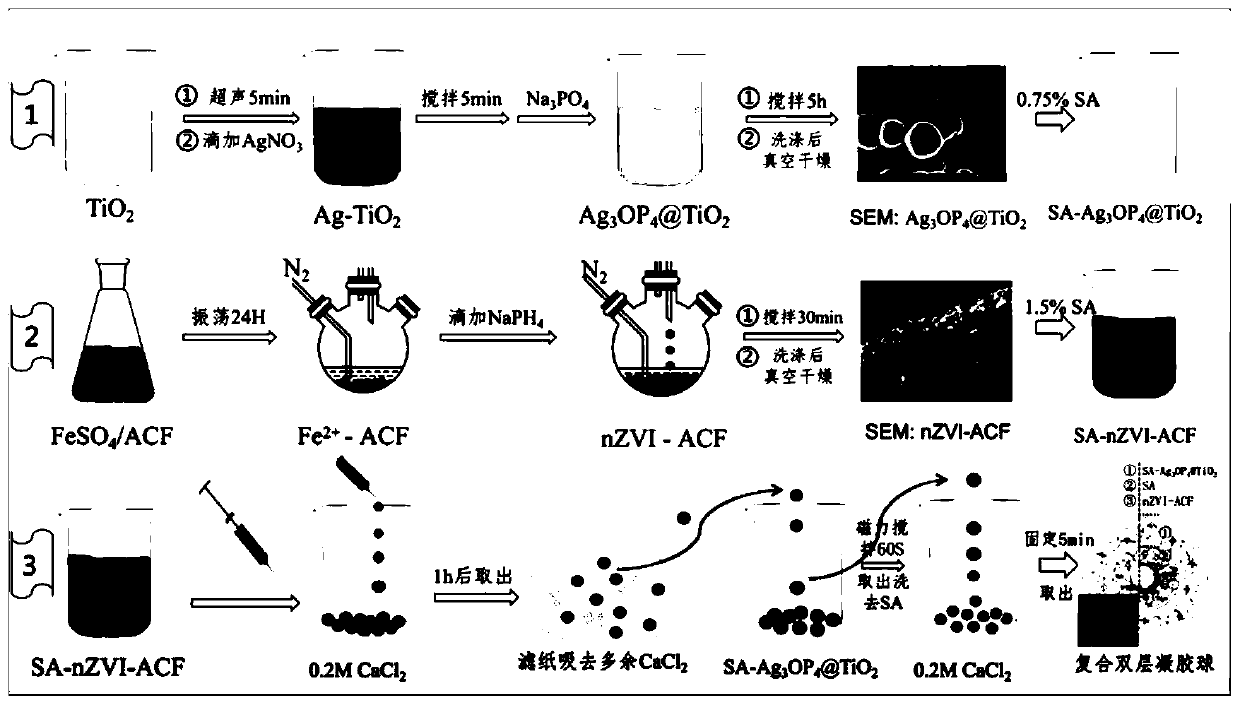

[0022] The embodiment of the present invention provides a kind of preparation method that is used for the composite material of treatment heavy metal-organic matter, please refer to figure 1 ,include:

[0023] S1. Preparation of silver phosphate-titanium dioxide composite material

[0024] Silver phosphate-titanium dioxide composites include silver phosphate and titanium dioxide. The inventors found that titanium dioxide can improve the photocatalytic activity and photocatalytic stability of silver phosphate, which may be due to the use of titanium dioxide on Ag 3 PO 4 Modification can enhance the separation and transport of photogenerated electron holes, make more active species on the surface of the catalyst material, increase the active sites on the catalyst surface, and thus improve the photocatalytic activity. Insoluble TiO 2 with Ag 3 PO 4 Compounding, reduces the Ag 3 PO 4 Solubility, thereby reducing the degree of photocorrosion, increasing the Ag 3 PO 4 stab...

Embodiment 1

[0048] The present embodiment provides a composite material for controlling heavy metal-organic matter, which comprises the following steps:

[0049] (1) Preparation of Ag 3 PO 4 @TiO 2

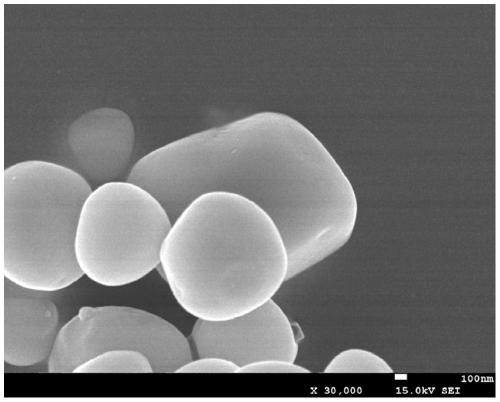

[0050] Disperse 1.595g (0.02mol) of titanium dioxide in 50ml of pure water, sonicate for 5min, then add 3.05766g of silver nitrate (0.018mol), stir magnetically for 10min, then add 2.28072g of sodium phosphate 50ml solution (0.006mol) dropwise, and continue stirring for 4h. After stirring completely, the prepared Ag 3 PO 4 @TiO 2 Centrifuge at 4000 rpm for 10 minutes. After centrifugation, wash with deionized water three times, and finally dry in a vacuum oven (50° C., 14 hours). Ag produced 3 PO 4 / TiO 2 The molar ratio is close to 3:10.

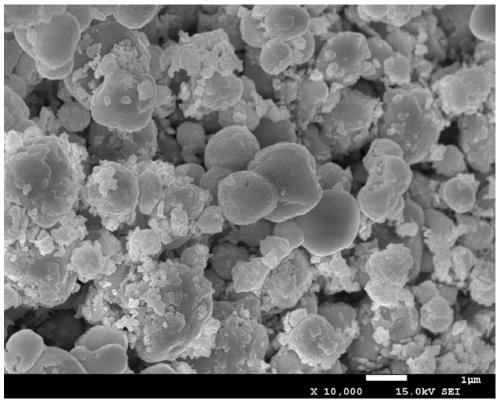

[0051] (2) Preparation of ACF-nZVI

[0052] 5.0 g of ferrous sulfate and 1 g of activated carbonyl carbon fibers were mixed in 150 mL of distilled water (pH adjusted to 4.0), and then shaken at 150 rpm and 20° C. for 30 hours. Transfer the abov...

Embodiment 2

[0057] The present embodiment provides a composite material for controlling heavy metal-organic matter, which comprises the following steps:

[0058] (1) Preparation of Ag 3 PO 4 @TiO 2

[0059] Disperse 1.595g (0.02mol) of titanium dioxide in 50ml of pure water, sonicate for 5min, then add 3.05766g of silver nitrate (0.018mol), stir magnetically for 10min, then add 2.28072g of sodium phosphate 50ml solution (0.006mol) drop by drop, and continue stirring for 8h. After stirring completely, the prepared Ag 3 PO 4 @TiO 2 Centrifuge at 4000 rpm for 10 minutes. After centrifugation, wash with deionized water three times, and finally dry in a vacuum oven (70° C., 10 hours). Ag produced 3 PO 4 / TiO 2 The molar ratio is close to 3:10.

[0060] (2) Preparation of ACF-nZVI

[0061] 5.0 g of ferrous sulfate and 1 g of activated carbonyl carbon fibers were mixed in 150 mL of distilled water (pH adjusted to 4.0), and then shaken at 150 rpm and 30° C. for 20 hours. Transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com