Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film having low refractive index and method for producing the same, anti-reflection film and method for producing the same, coating liquid set for film having low refractive index, substrate having microparticle-laminated thin film, and method for pr

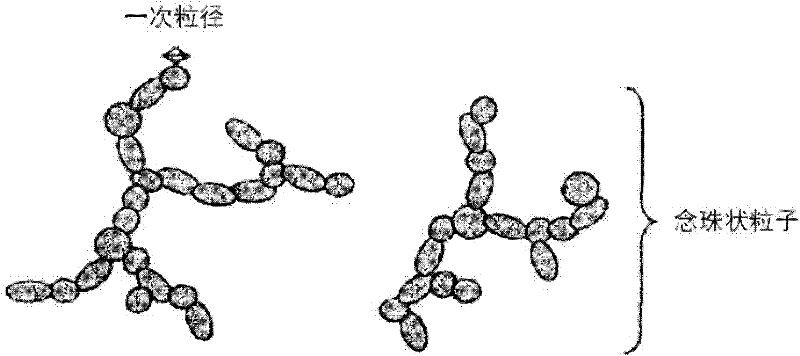

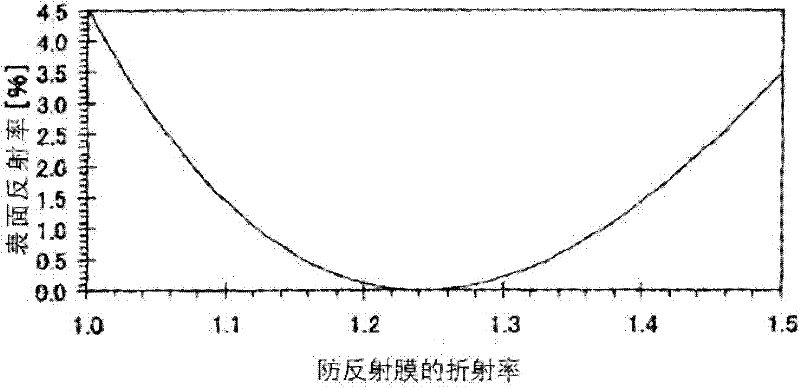

ActiveCN102186668ALow refractive indexImprove adhesionSynthetic resin layered productsAnti-reflective coatingsRefractive indexMicroparticle

Provided is a film having a low refractive index, which can be formed under normal temperature and pressure while obtaining a lower refractive index, has excellent adhesion with a solid substrate, and does not lose geometric optical properties, such as the diffusibility or light-harvesting capability attributed to the microstructure. Also disclosed is a method for producing the same. The film having a low refractive index is obtained by causing an electrolyte polymer and microparticles to be alternately adsorbed on the surface of a solid substrate and bringing the resulting microparticle-laminated film into contact with a silicon compound solution in order to bond the solid substrate with microparticles and microparticles with microparticles. The silicon compound solution is selected from (1) the hydrolysis product of alkoxysilane (I) wherein the functional groups are formed from hydrolyzable groups and non-hydrolyzable organic groups, and the condensation reaction product thereof, (2) the hydrolysis product of a mixture of alkoxysilane (I) and alkoxysilane (II) wherein the functional groups are formed from hydrolyzable groups alone, and the condensation reaction product thereof; and (3) a mixture of hydrolysis product and condensation product thereof according to (1) and alkoxysilane (II).

Owner:RESONAC CORPORATION

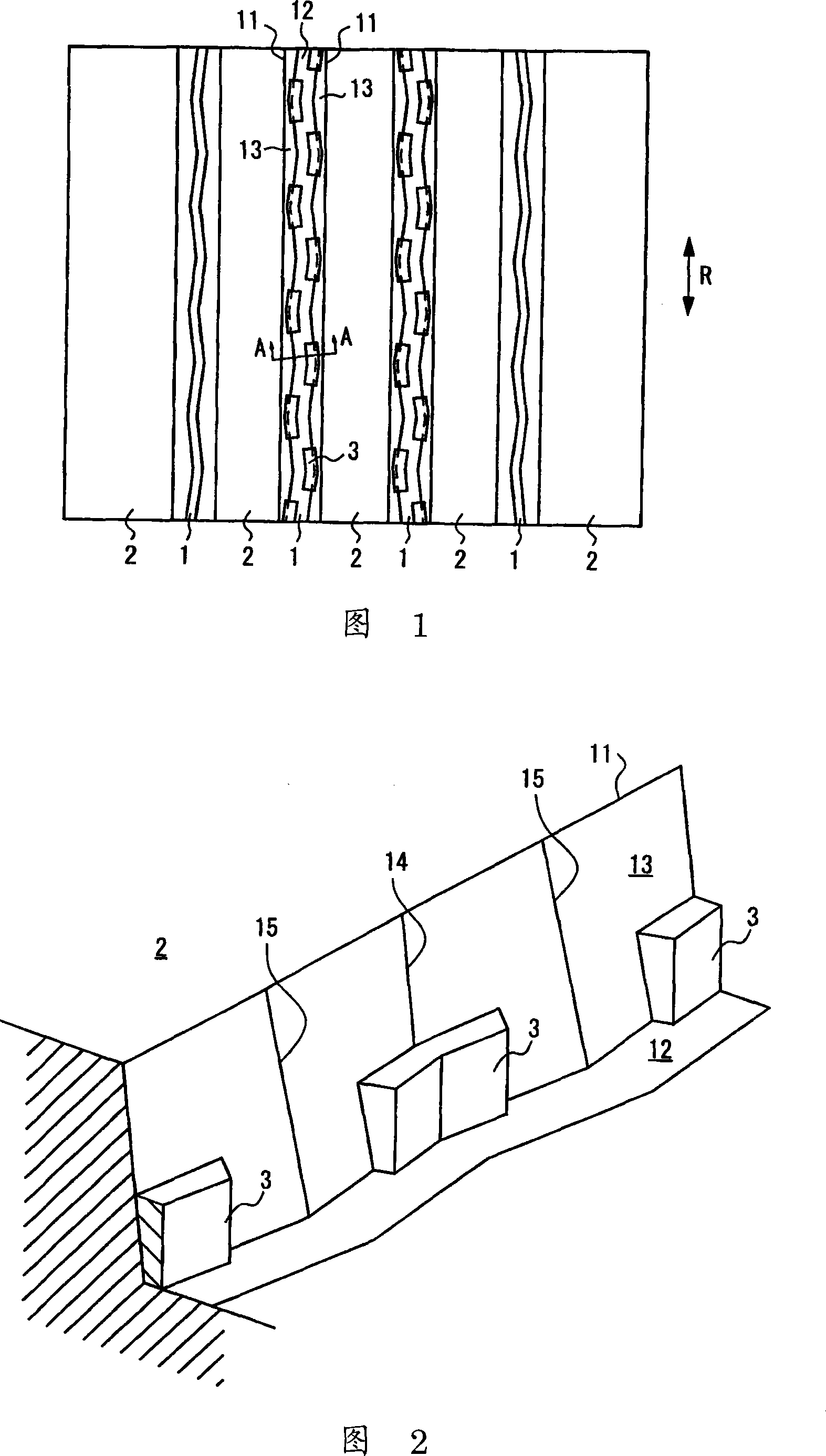

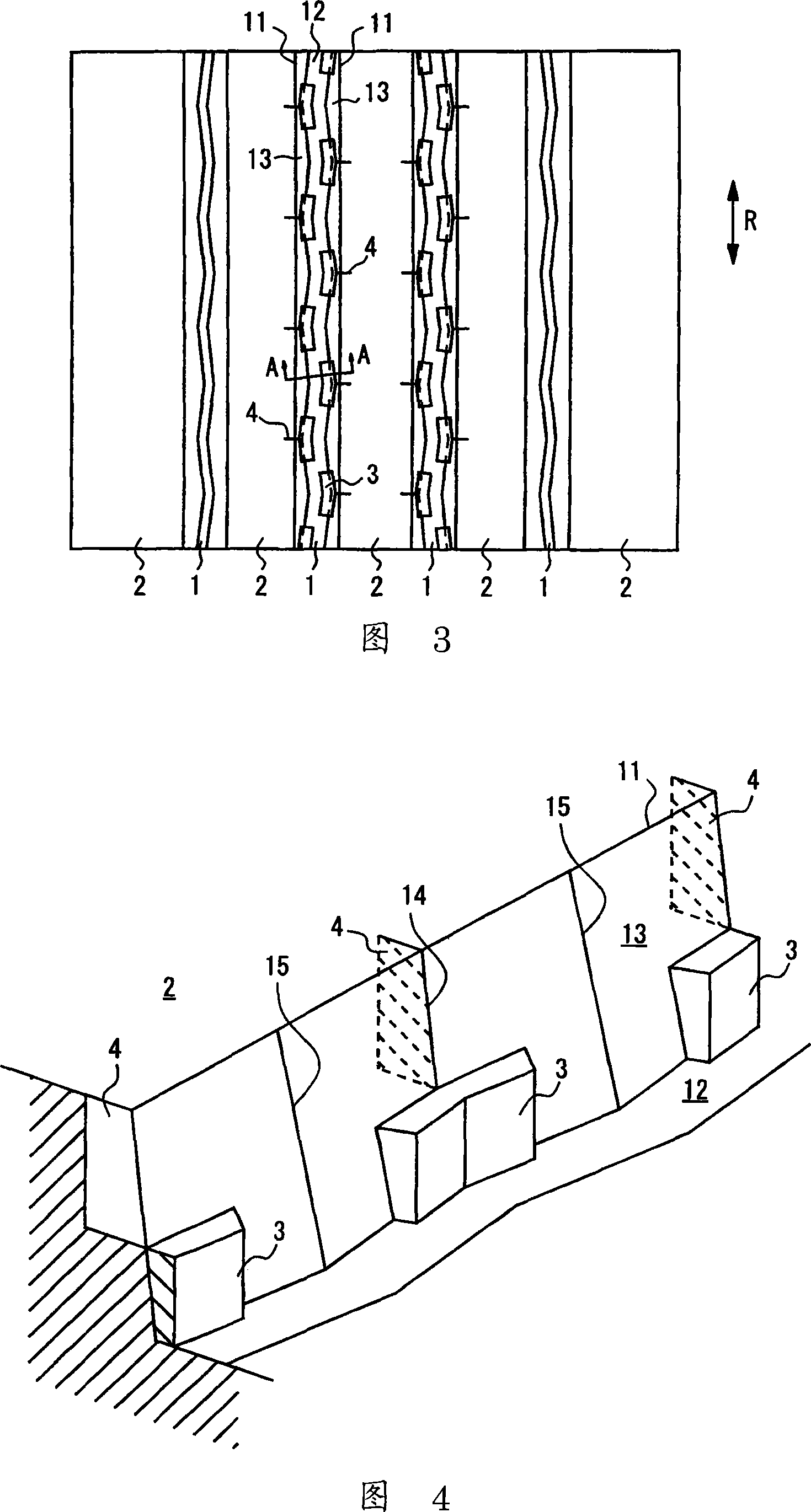

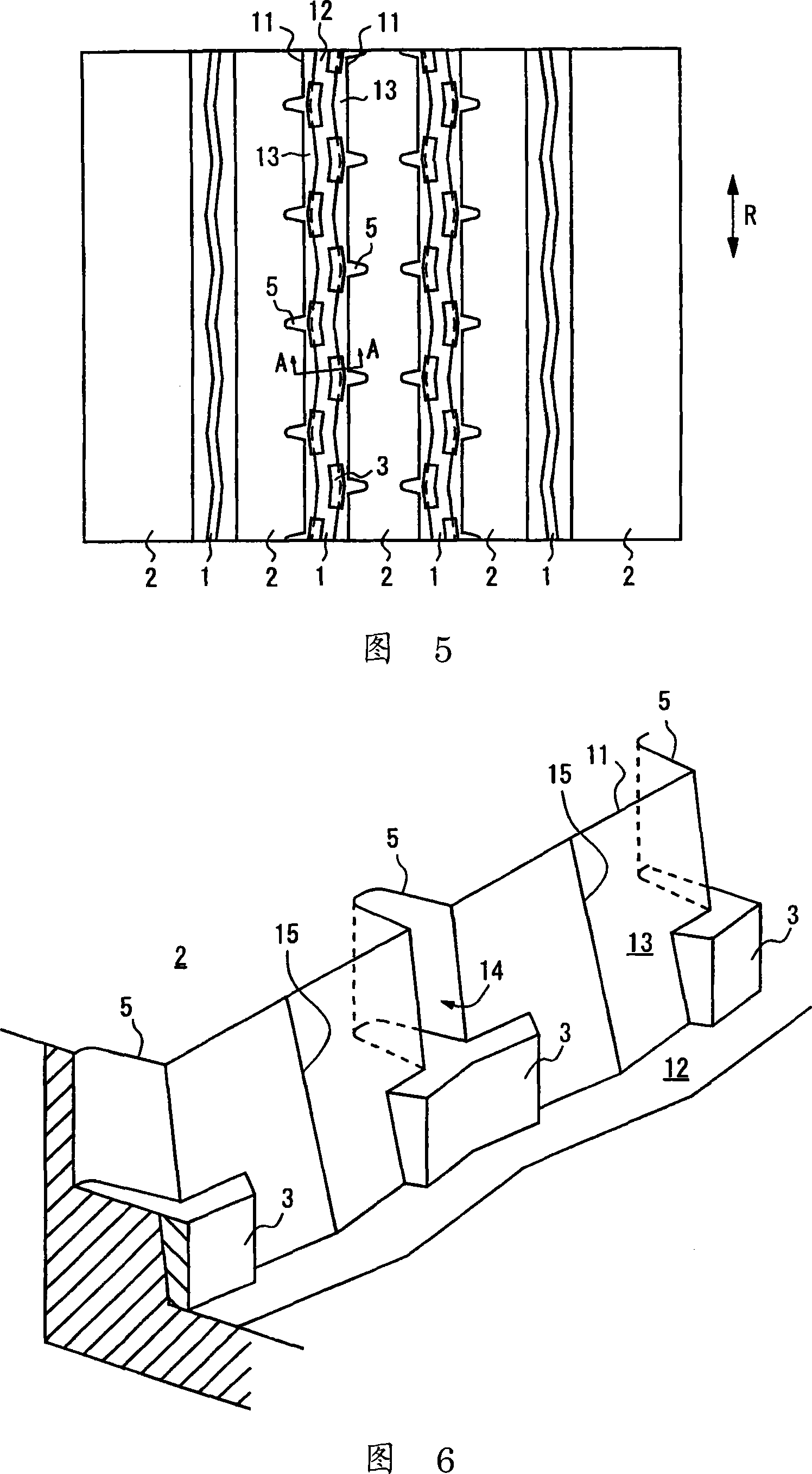

Pneumatic tire

InactiveCN101168342AImprove traction performanceImprove braking effectTyre tread bands/patternsEngineering

Owner:TOYO TIRE & RUBBER CO LTD

Nutritious plumule biscuit and its production process

InactiveCN1973634AHigh nutritional valuePromote peristalsisDough treatmentBakery productsFermentationChemistry

The nutritious plumule biscuit and its production process belong to the field of food producing technology. The nutritious plumule biscuit is produced with wheat plumule powder, flour, starch, sugar powder, ammonium bicarbonate, water, palm oil and compound enzyme preparation, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time. The nutritious plumule biscuit has less damping, less breaking and long shelf life.

Owner:SHANDONG ZHENGHANG FOODSTUFF

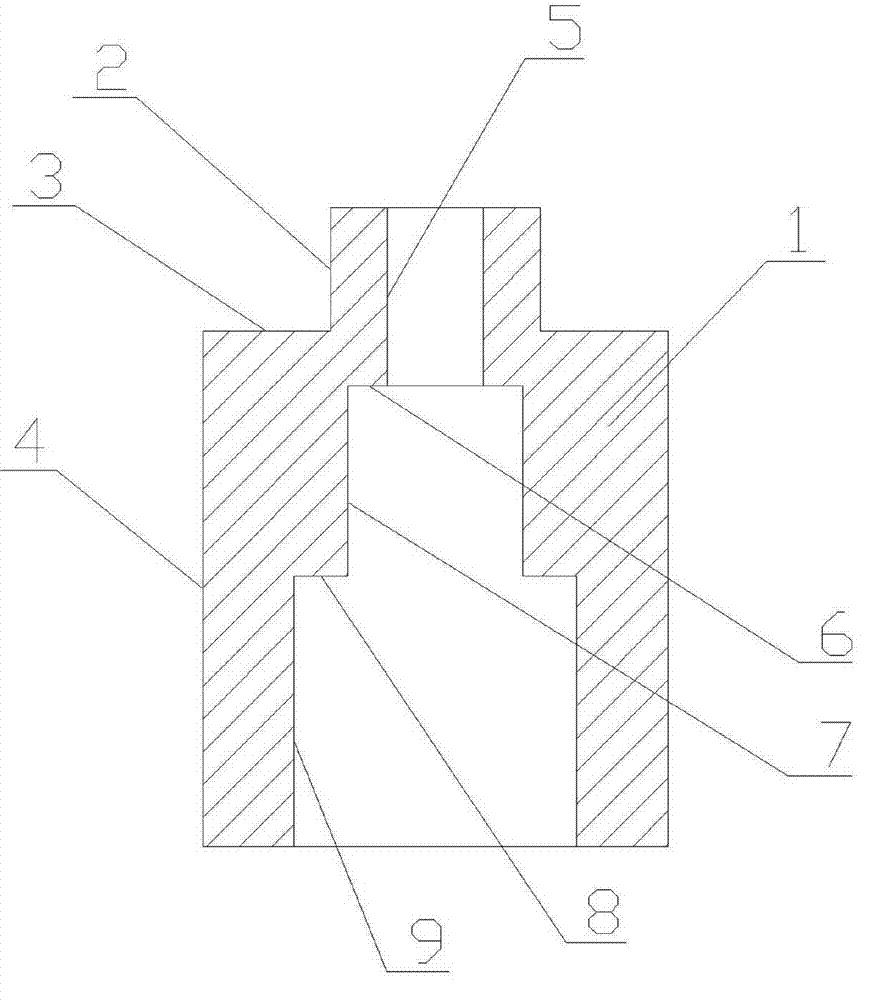

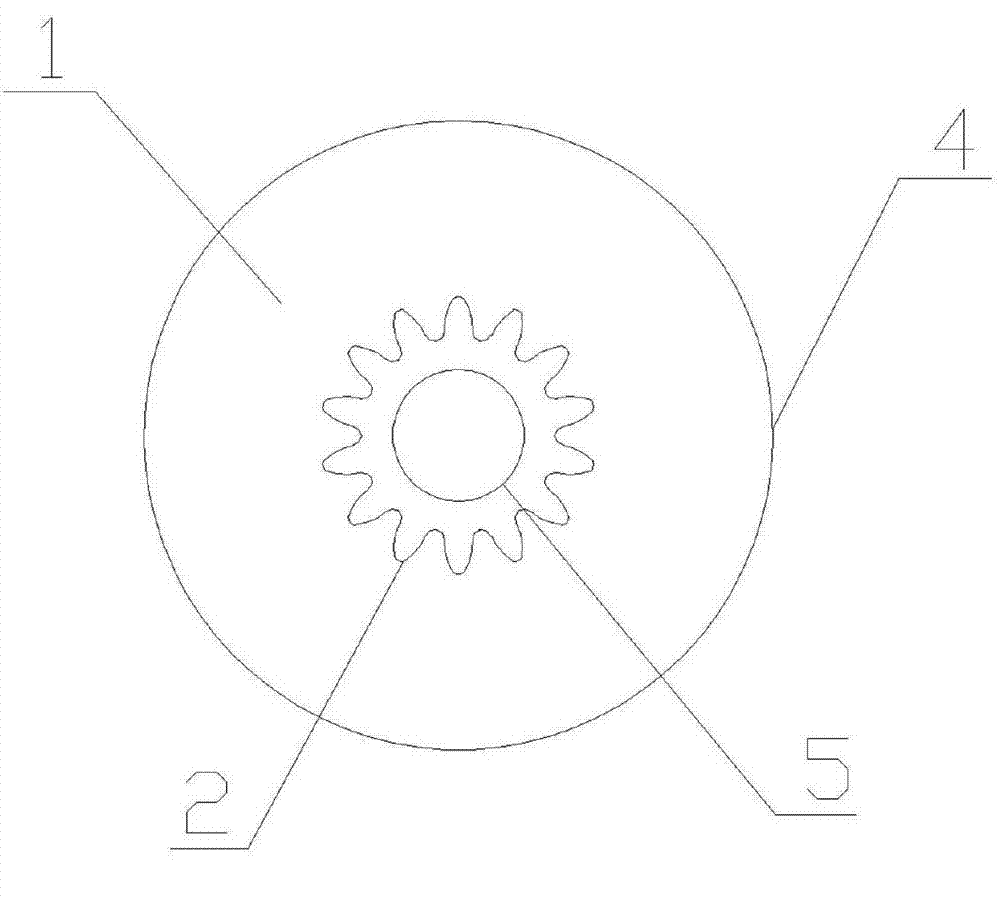

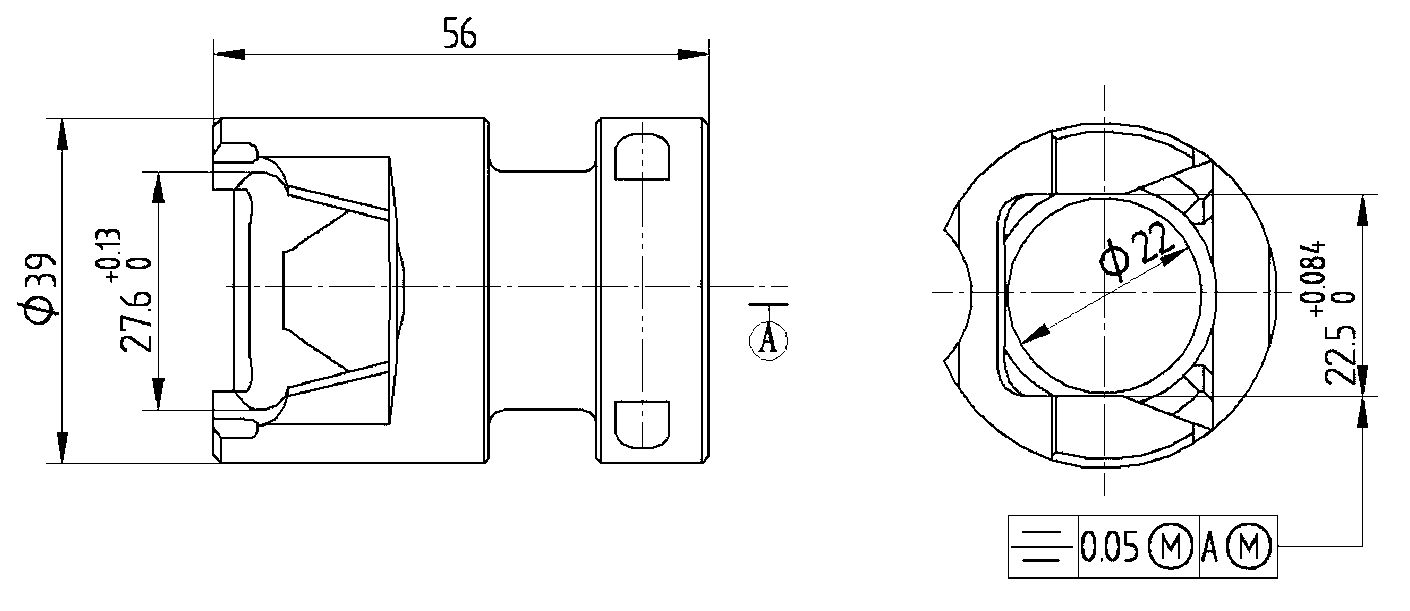

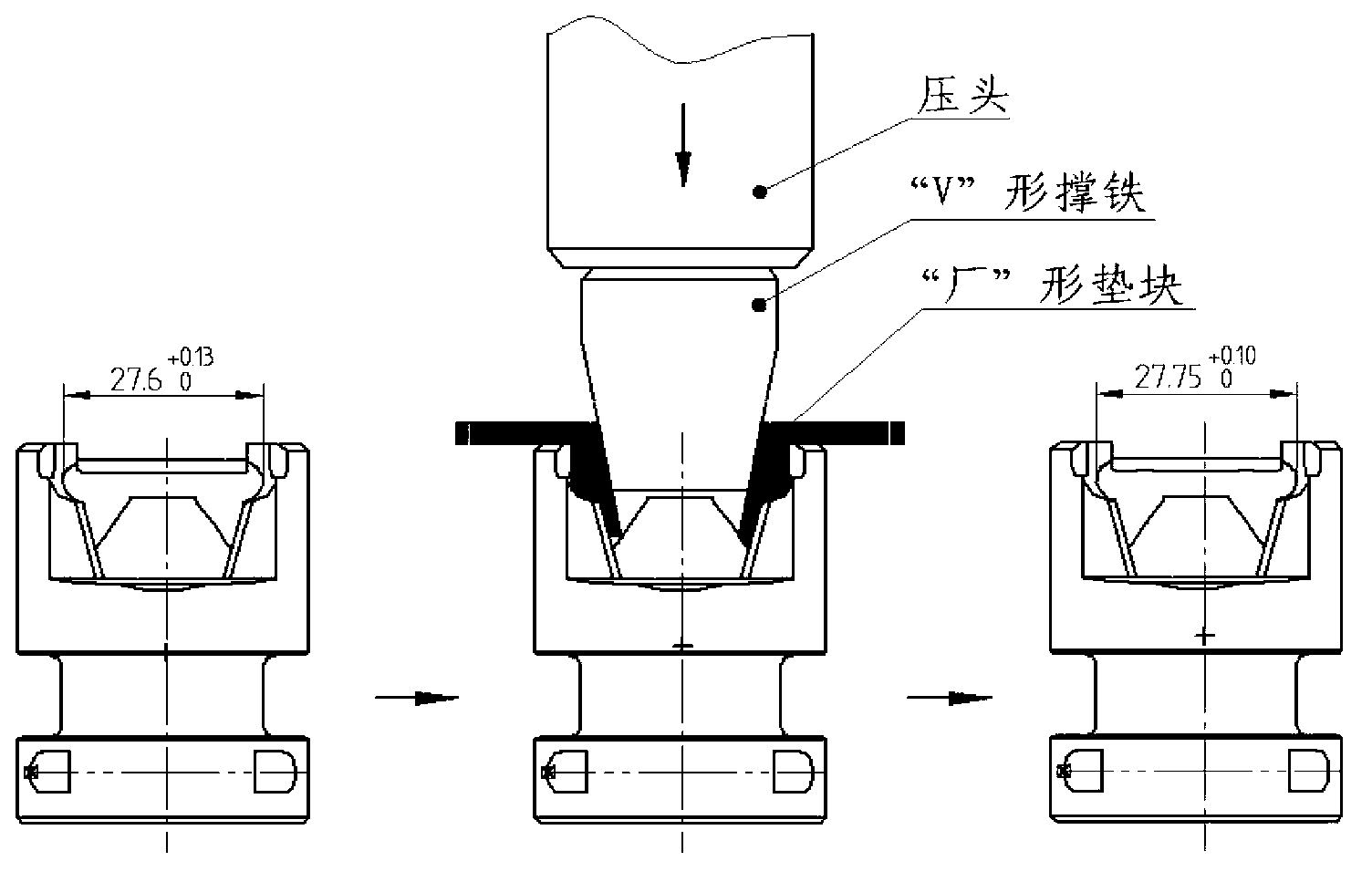

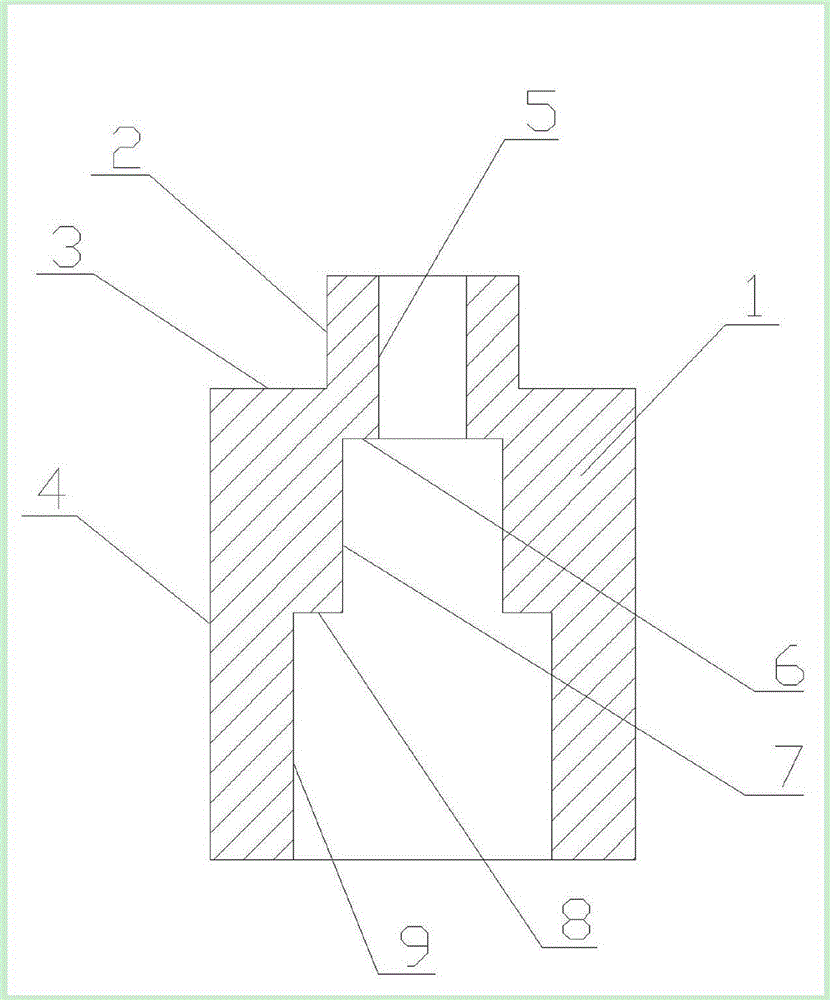

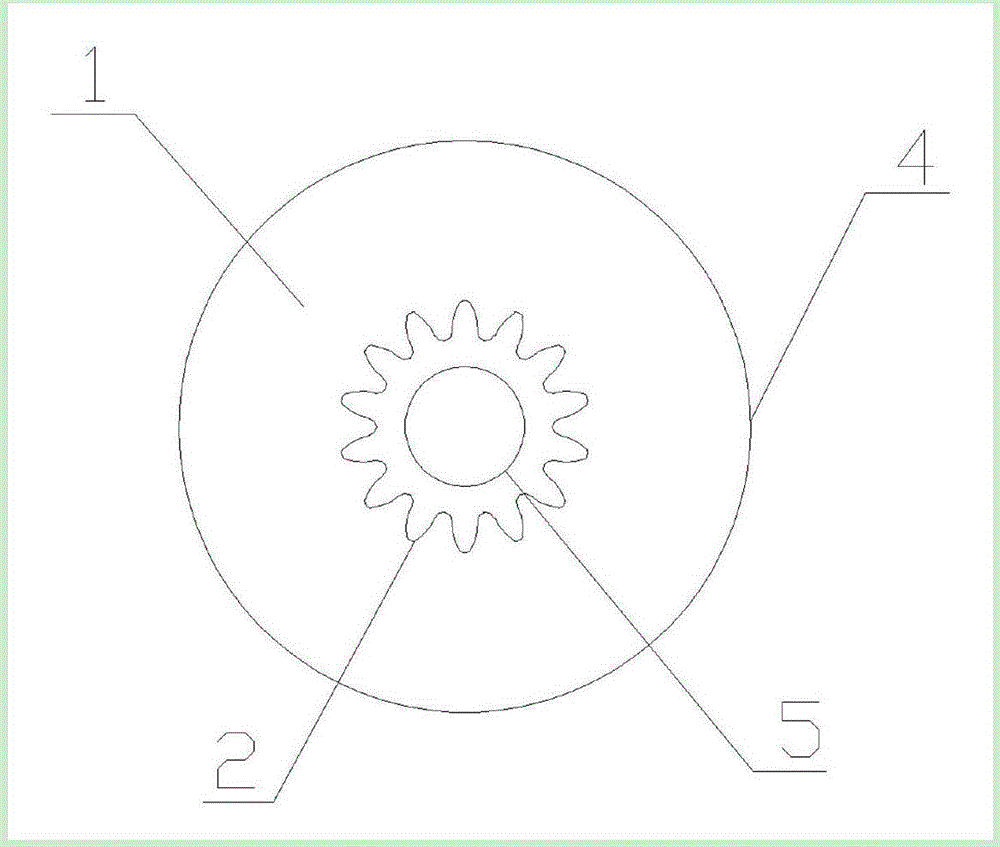

Gear shaft sleeve and die and method for machining same

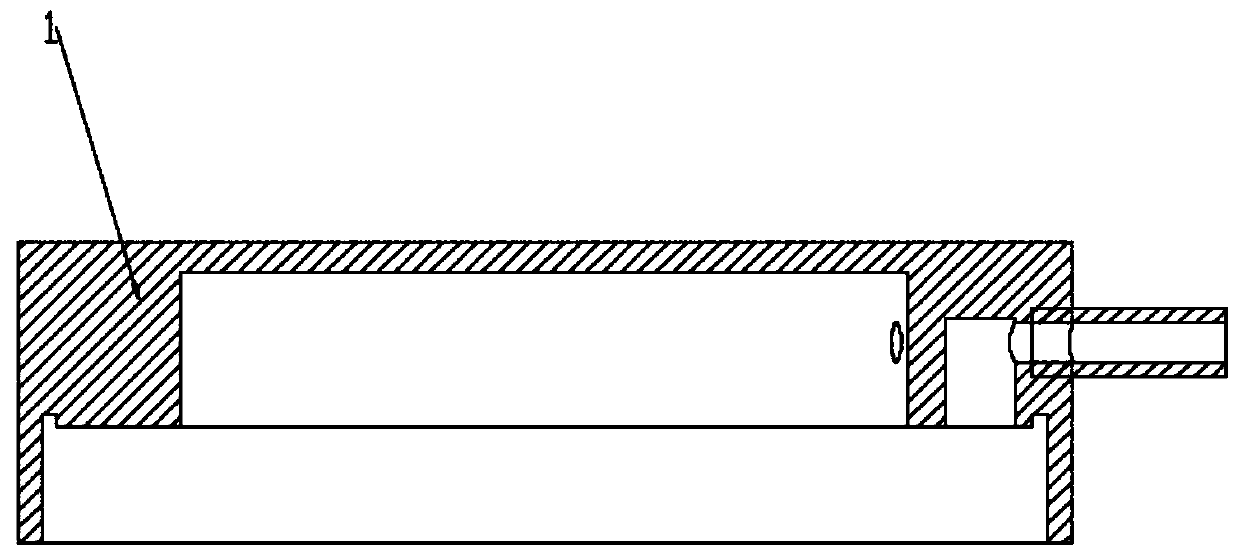

The invention provides a gear shaft sleeve which is formed by machining gear shaft sleeve blank (1). The gear shaft sleeve is formed by the following components in a cold pressing mode, the ingredients comprise 0.6%-1.2% of carbon, 1.3%-1.7% of copper, 1.55%-1.95% of nickel, 0.4%-0.6% of molybdenum, 0.3%-0.5% of AncorMax200 and the balance iron. The machining method of the gear shaft sleeve includes the steps that the components required by a formula are weighed and mixed evenly; when a pressing machine is in a loose state, materials to be pressed are added into a material cavity, the size of the material cavity is three times of the size of the gear shaft sleeve blank (1); when the pressing machine is in a pressing state, the materials to be pressed are formed in a cold pressing mode; when the pressing machine is in a demoulding state, the finished gear shaft sleeve blank (1) is output; machining such as numerical control lathe machining, 30-degree big chamber chambering, large outer circle clamping and small outer circle turning is conducted. The density of the gear shaft sleeve obtained through the method can reach 6.9-7.0 g / cm<3>, and the overall quality is high.

Owner:宁波金钟粉末冶金有限公司

Brazing filler metal for connecting copper and stainless steel, application of brazing filler metal and method for welding silencer

InactiveCN103252595AImprove the noise reduction effectReduce manufacturing costWelding/cutting media/materialsSoldering mediaMischmetalRare earth

The invention relates to brazing filler metal for connecting copper and stainless steel, application of the brazing filler metal and a method for welding a silencer and belongs to the field of brazing filler metal and silencer welding methods. The brazing filler metal comprises, by weight, 26-34 percent of Cu, 34-35 percent of Ag, 5-8 percent of Co, 2-4.5 percent of Li, 1-1.5 percent of Sn, 0.2-1.8 percent of Ni, 1.8-2 percent of B, 0.5-1.3 percent of Mn, 0.1-1.4 percent of Si, 0.03-0.16 percent of mischmetal and the balance of Zn. The mischmetal is composed of La and Pr, the mass ratio of La and Pr is equal to the mass ratio of Cu and Ag. When the brazing filler metal for connecting the copper and the stainless steel is applied to welding of the silencer, flames are utilized for welding, the requirement for welding is met, meanwhile, welding efficiency is high, production cost is low, a noise reduction effect after the silencer is welded is good, and the service life of the silencer is prolonged.

Owner:ANHUI ZHONGHUI REFRIGERATION

AlxCoCrFeNi multi-element alloy wire material and preparation method thereof

The invention relates to an AlxCoCrFeNi multi-element alloy wire material and a preparation method thereof. The component atom expression of a multi-element alloy is AlxCoCrFeNi, wherein x is more than or equal to 0 and less than or equal to 0.5. A phase structure of the alloy takes a face-centered cubic solid solution as a main part. The preparation method of the AlxCoCrFeNi multi-element alloy wire material, disclosed by the invention, comprises the following steps of vacuum suspension smelting, die forging, rotary forging and hot drawing. A traditional rotary forging and drawing method can be used for preparing the multi-element alloy wire material with a certain diameter and random length; the production cost is low, the product performance is stable and the quality is high; and the application of the multi-element alloy wire material to the industrial field becomes possible.

Owner:UNIV OF SCI & TECH BEIJING

Clear dimension compression molding method for phenolic resin based complex profile product

InactiveCN101920562ADense inside the partImprove surface qualityCompression moldingMaterial consumption

The invention discloses a clear dimension compression molding method for a phenolic resin based complex profile product, which comprises the following steps of: firstly, preforming a plurality of equivalent flat plates, wherein each equivalent flat plate corresponds to one part of the phenolic resin based complex profile product; and then, superposing the equivalent flat plates, and matching the mold for molding to obtain the product. The method effectively improves the quality and the qualification rate of the product, reduces working procedures and material consumption, lowers cost and increases product efficiency.

Owner:国营江北机械厂

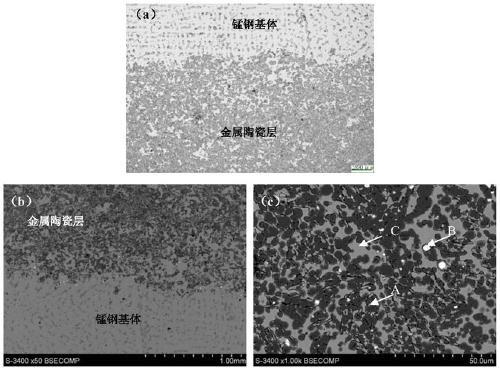

Manganese-steel-based complex phase particle enhanced metal ceramic surface composite material, casting and manufacturing method of casting

ActiveCN111455249AIncrease volume fractionEvenly distributedIncreasing energy efficiencyCeramic particleCermet

The invention discloses a manganese-steel-based complex phase particle enhanced metal ceramic surface composite material, a casting and a manufacturing method of the casting. The casting preparing technology comprises the processes that firstly, prepared titanium powder, tungsten powder, gel graphite powder and an alloy agent are evenly mixed, a proper number of water-based bonding agents are added for uniform stirring, and the mixture is placed in a die to be punched into a prefabricated block; secondly, after the prefabricated block is dried, the prefabricated block is fixed to a foam modelcorresponding to the part, needing to be strengthened, of the casting, coating of a fireproof coating is conducted, and modeling is conducted after drying; and thirdly, austenitic manganese steel metal liquid is poured, the high temperature of alloy liquid is utilized for inducing the metal elements Ti and W in the prefabricated block to generate the high-temperature combustion synthesis reactionwith the C element, in-situ generation of TiC, WC and (Ti, W) C and other complex phase ceramic particle enhanced bodies is achieved, and the particle enhanced manganese-steel-based metal ceramic surface composite casting is manufactured.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

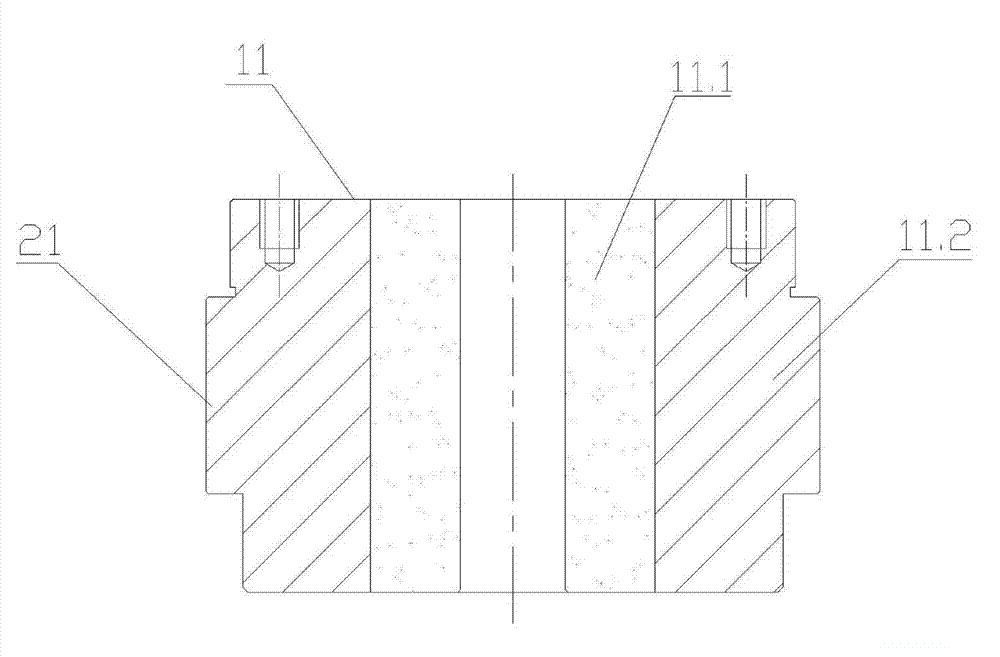

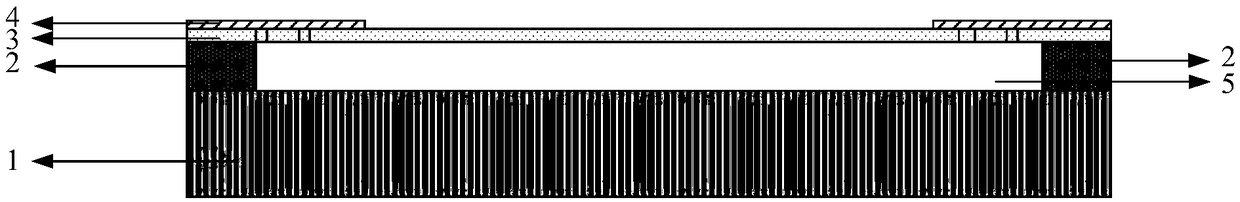

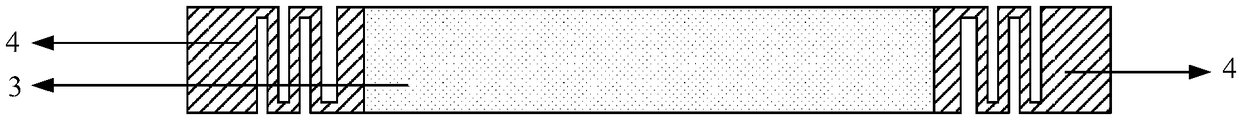

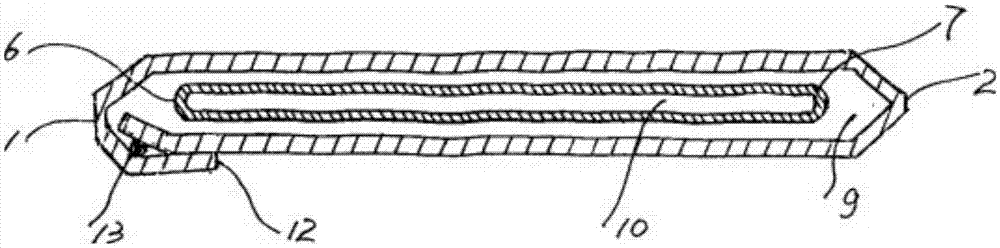

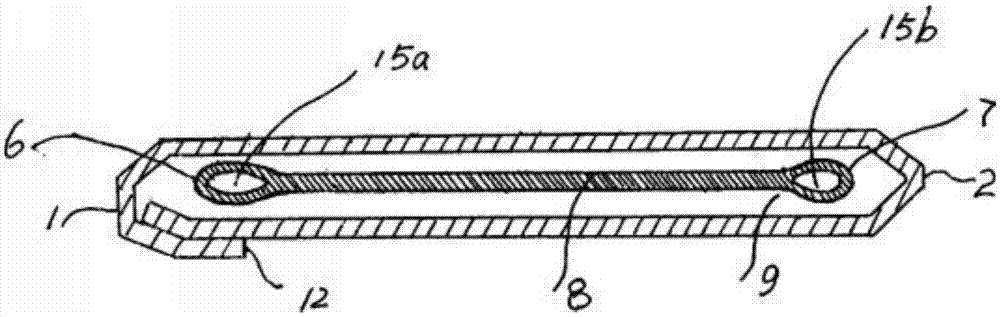

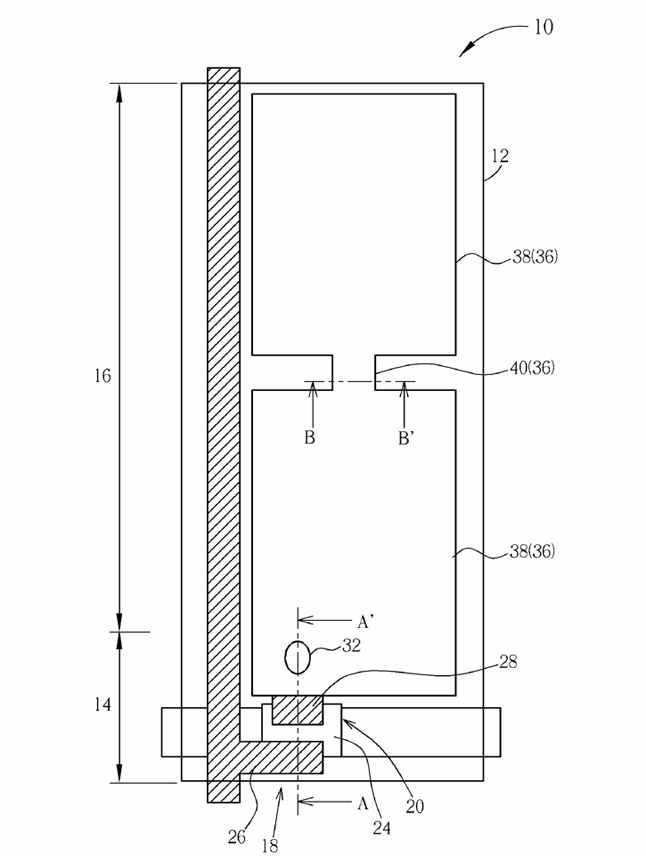

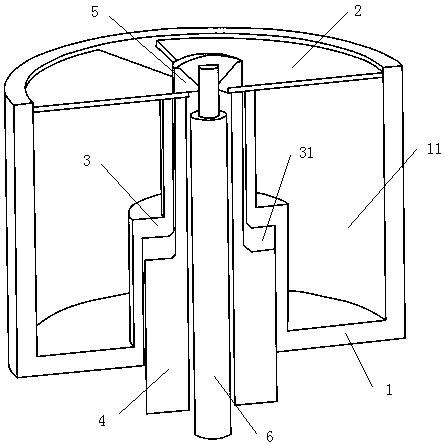

Low-temperature current transformer coil

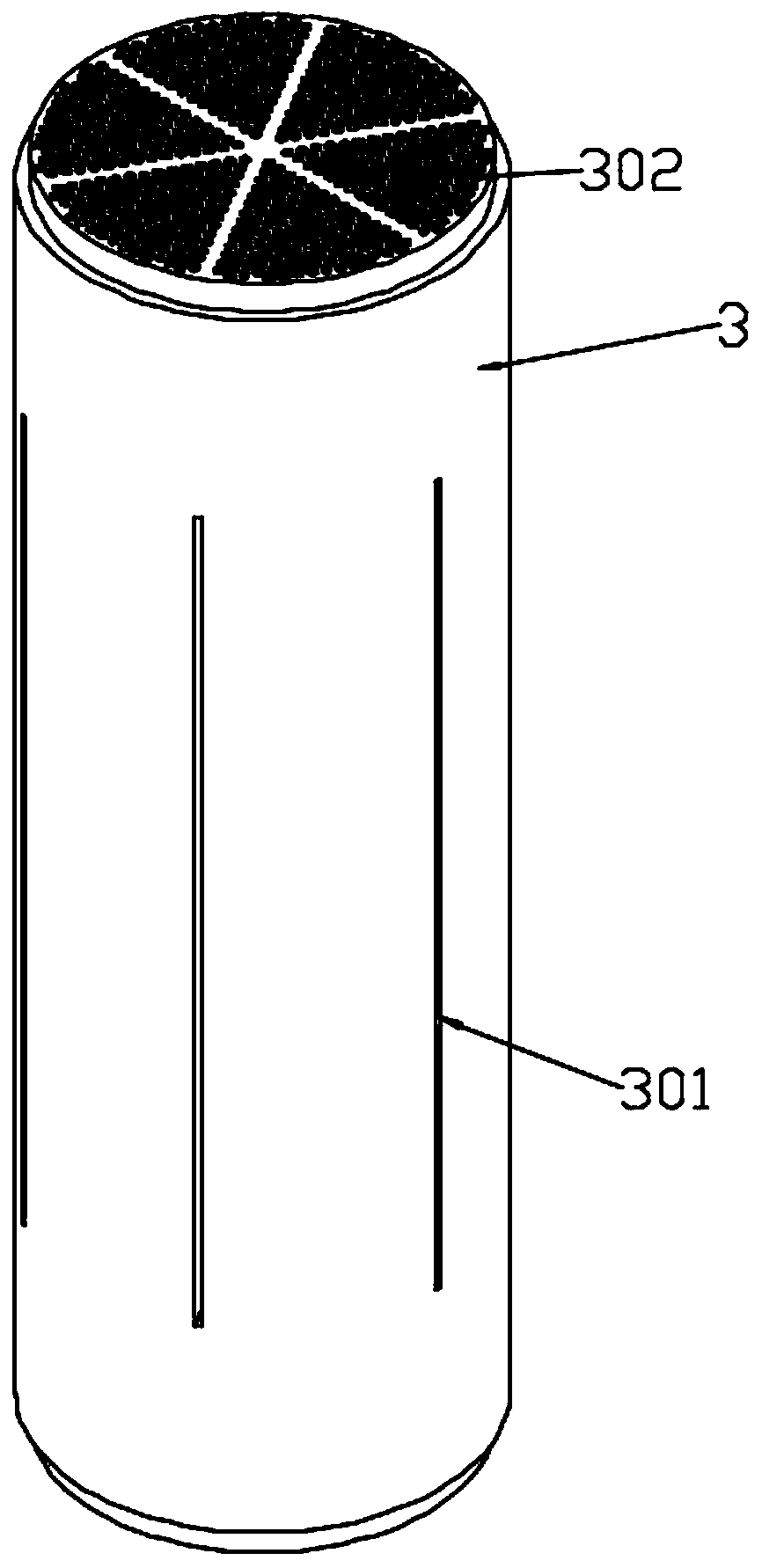

InactiveCN104200979AGuaranteed Dielectric StrengthNo embrittlementTransformersTransformers/inductances coils/windings/connectionsConductor CoilElectrical and Electronics engineering

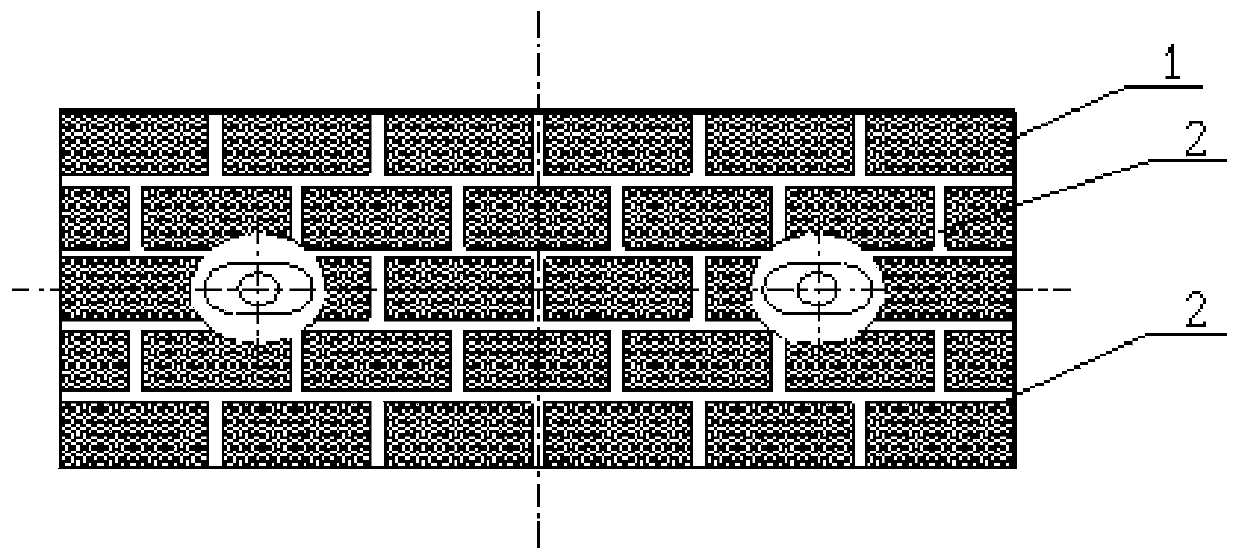

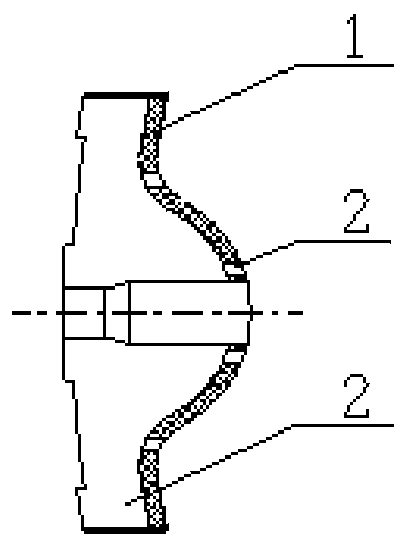

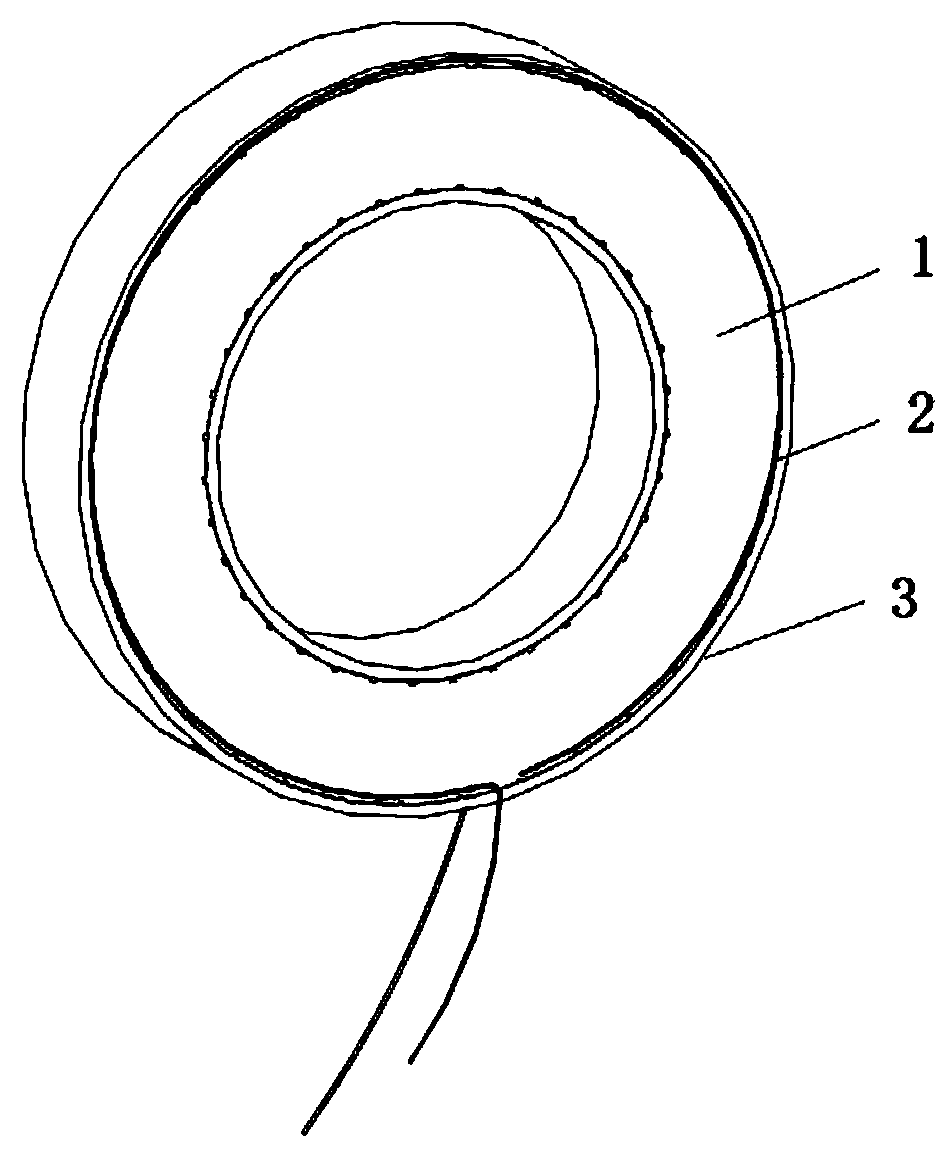

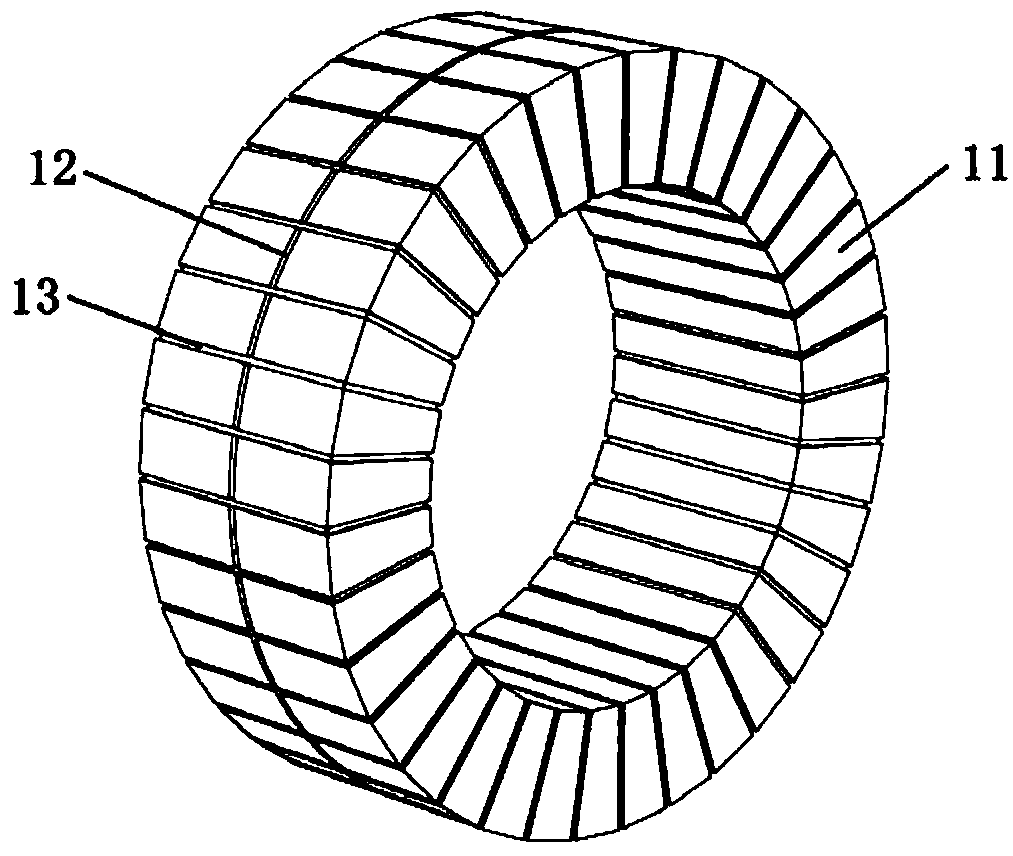

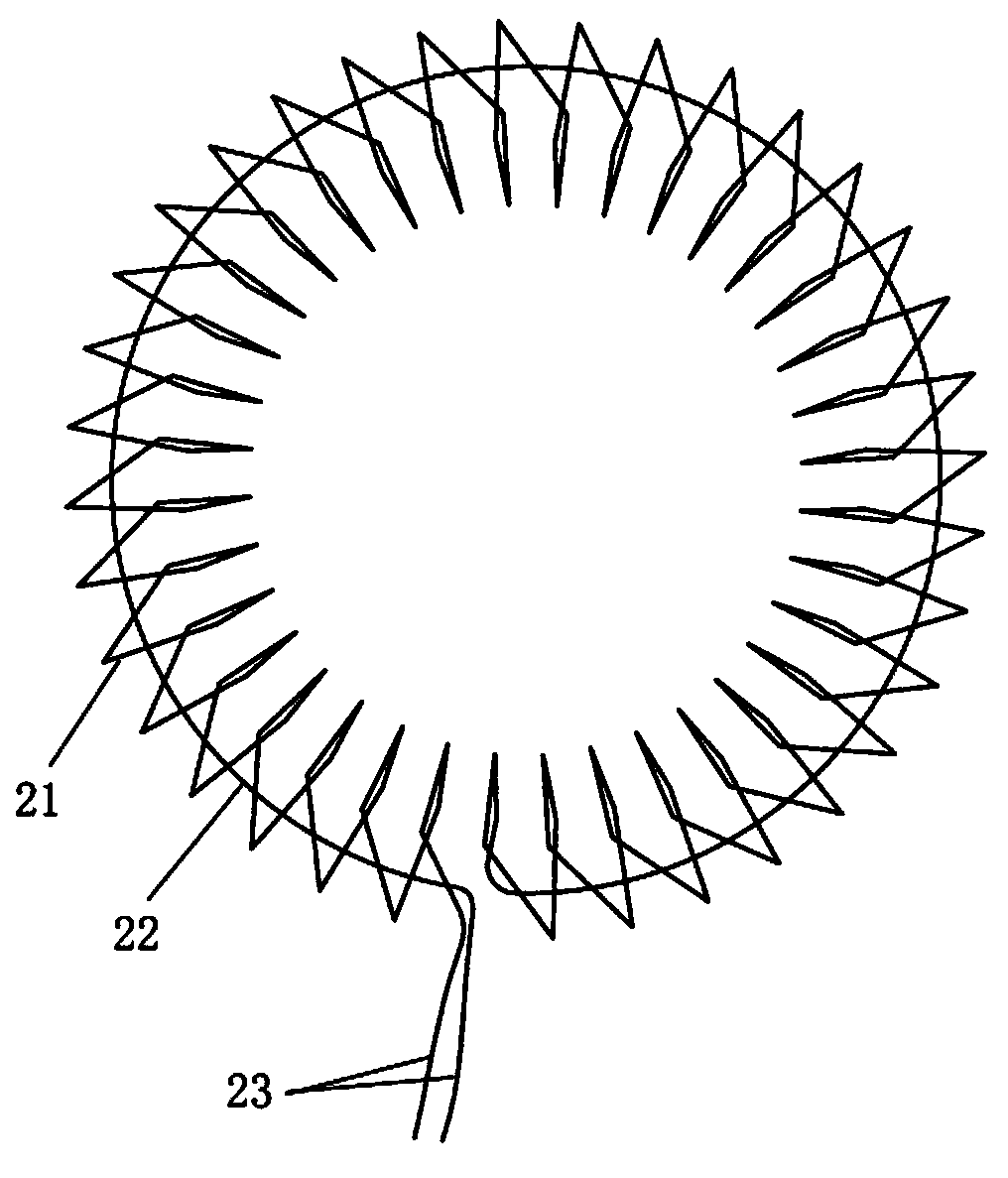

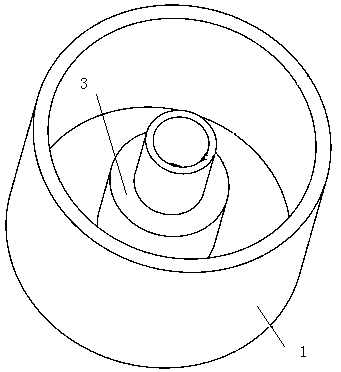

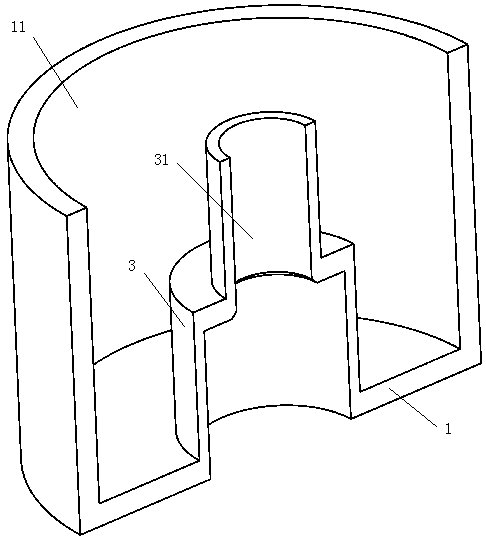

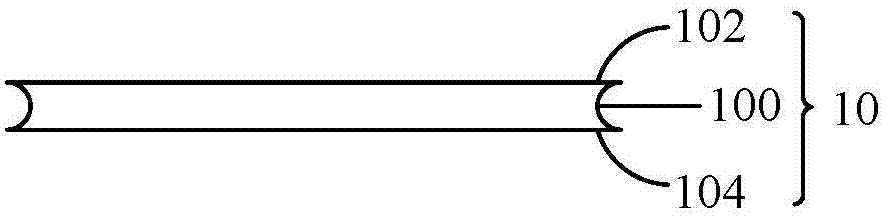

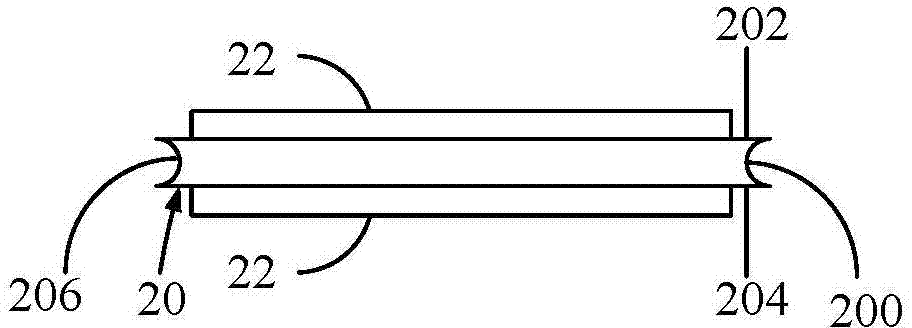

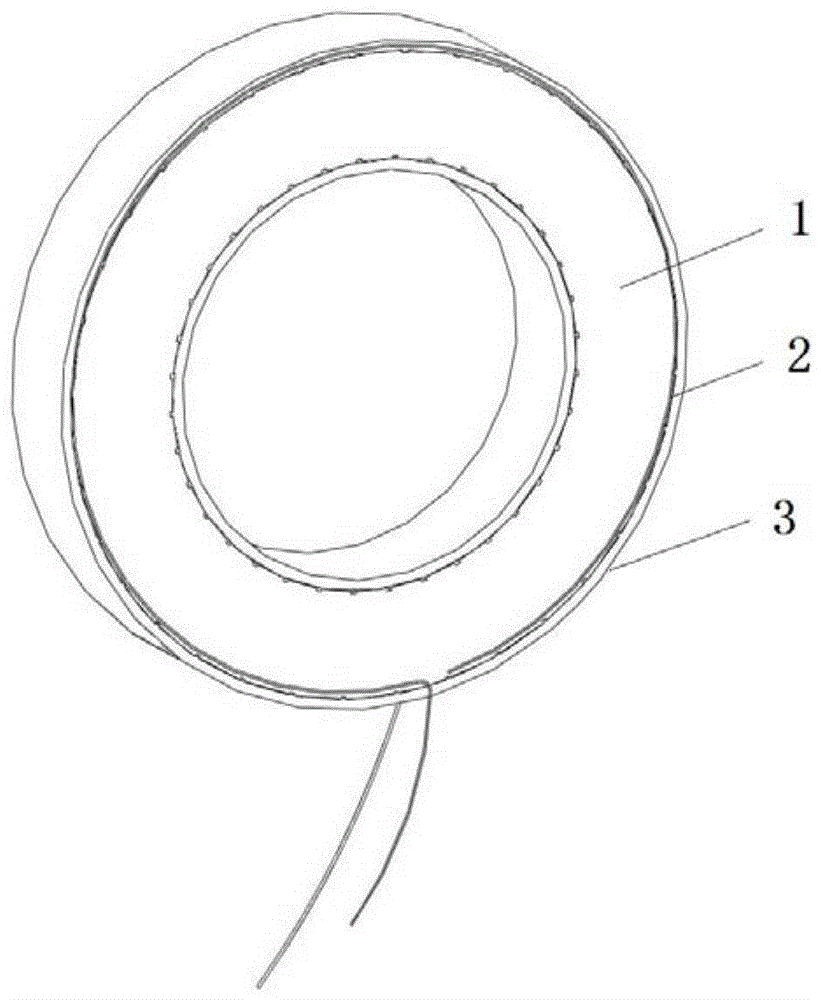

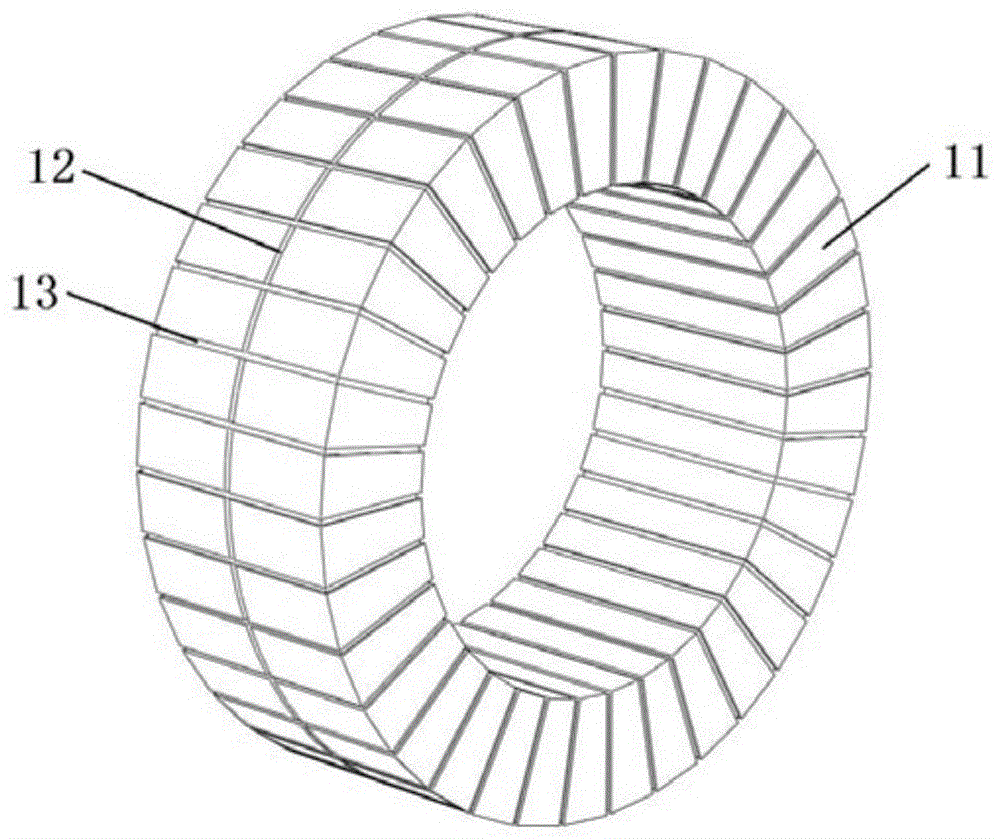

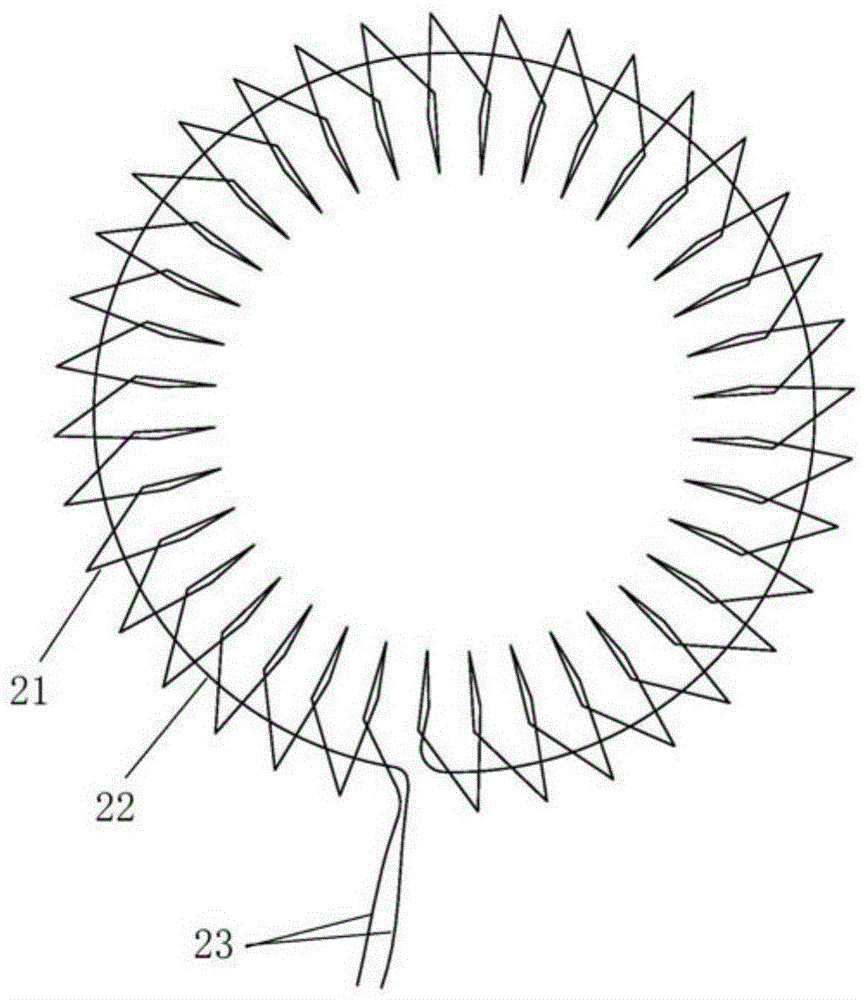

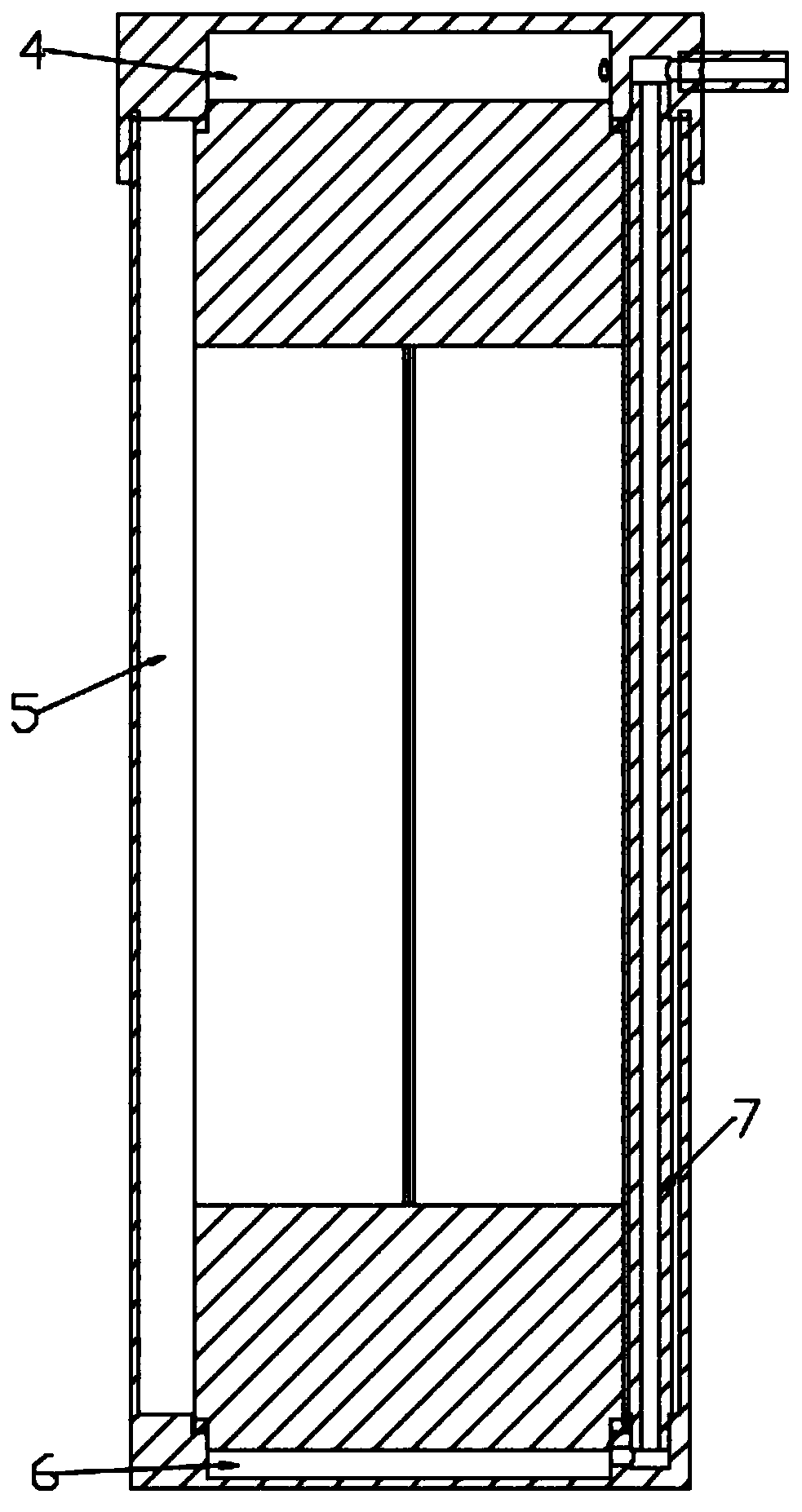

The invention discloses a low-temperature current transformer coil. The low-temperature current transformer coil mainly comprises a low-temperature glue inner frame (1), a low-temperature insulated wire turn (2) and a low-temperature glue outer frame (3), wherein the low-temperature glue inner frame (1) is arranged in the center of the low-temperature current transformer coil, and adopts a hollow ring-shaped structure; the low-temperature insulated wire turn (2) is formed by uniform winding in the radial direction of the low-temperature glue inner frame (1) of low temperature resistant insulation varnished wire; the head and tail lead wires (23) of the low-temperature insulated wire turn (2) are clung to the outer wall of the low-temperature glue inner frame (1), and are led out from a wire return groove (12) in the outer wall of the low-temperature glue inner frame (1); the low-temperature glue outer frame (3) is ring-shaped, and wraps the low-temperature insulated wire turn (2) and the low-temperature glue inner frame (1) except the lead wires (23).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

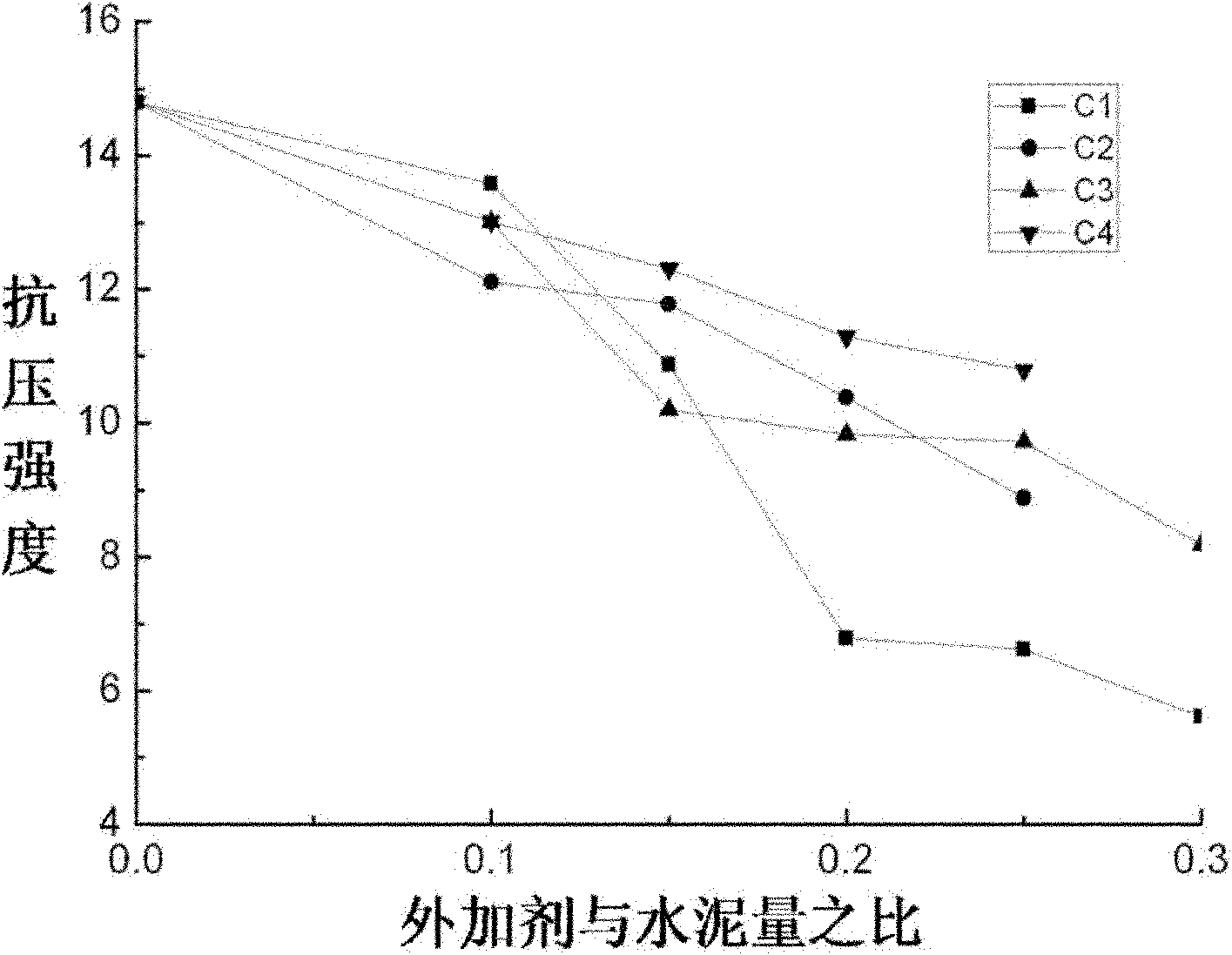

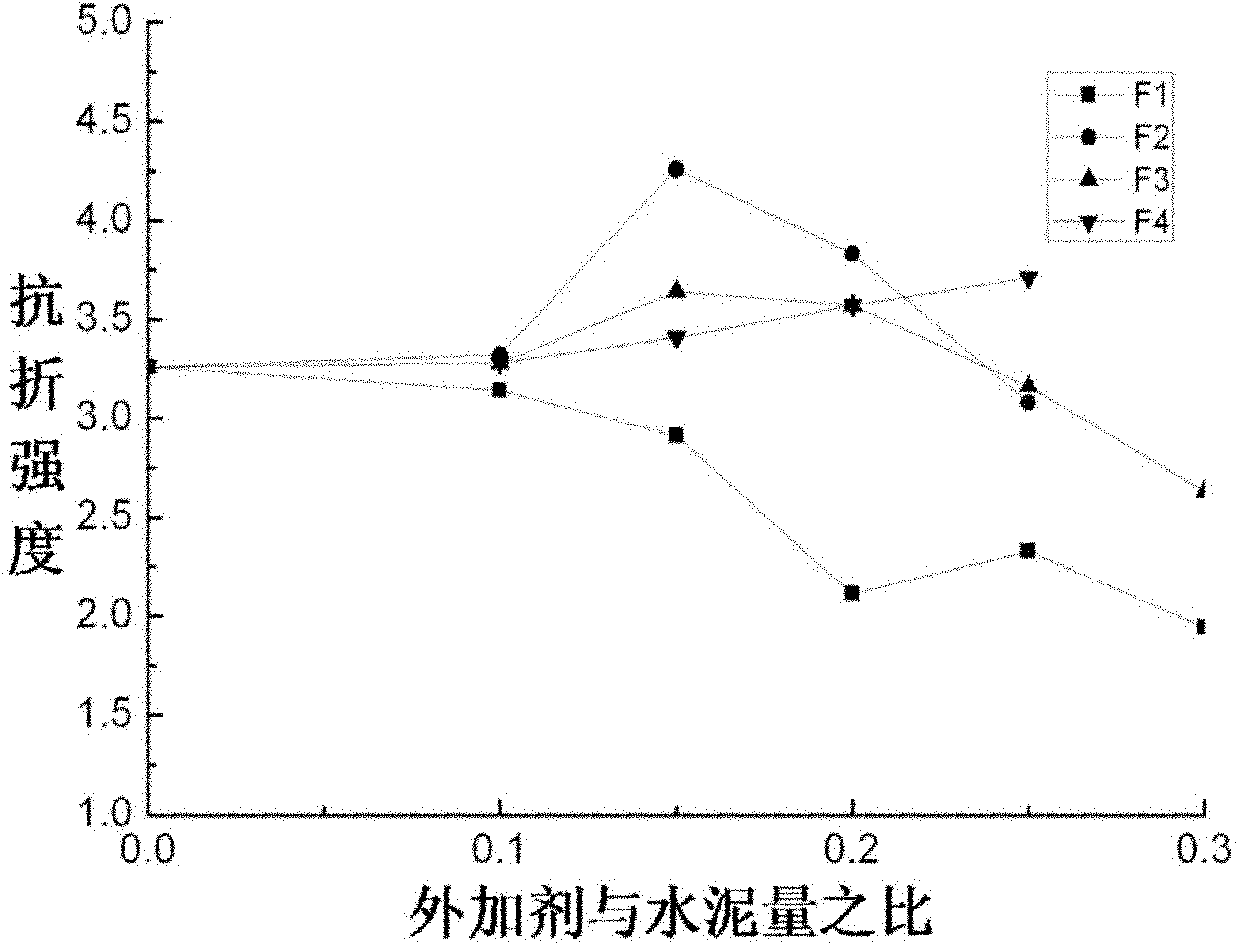

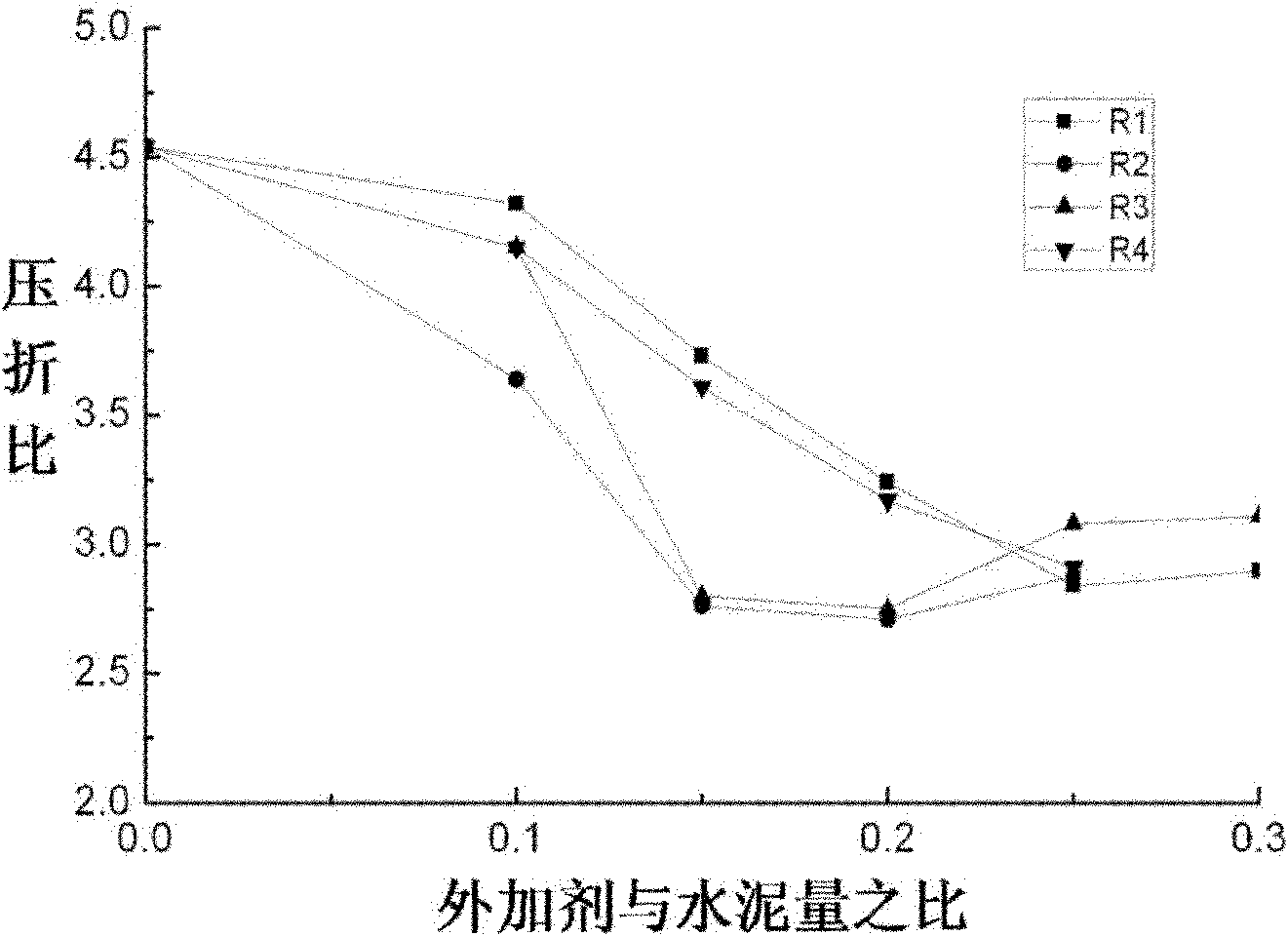

Expanded perlite fine powder-polymer latex powder composite modified dry mortar

InactiveCN102153319AImprove water retentionReduce water retentionSolid waste managementCelluloseFiber

The invention relates to expanded perlite fine powder-polymer latex powder composite modified dry mortar, which comprises the following components in percentage by weight: 2.5 to 4.5 percent of composite dry mortar admixture, 23.1 to 23.6 percent of cement, 69.4 to 70.9 percent of river sand, 0.7 to 1.4 percent of cellulose ether, 0.5 to 0.8 percent of acrylic staple fiber, and 0.5 to 0.8 percent of wood fiber. The pressing-breaking ratio of the dry mortar is less than 3, the compressive strength is over 8.8MPa, and the cost of the dry mortar is lowest and only 1 / 3 of polymer latex powder admixture; and the composite dry mortar admixture has remarkable water holding effect, and increases the stretching adhesive strength of the water soaked mortar besides the effect of optimizing mortar construction and accessibility.

Owner:宁波荣山新型材料有限公司

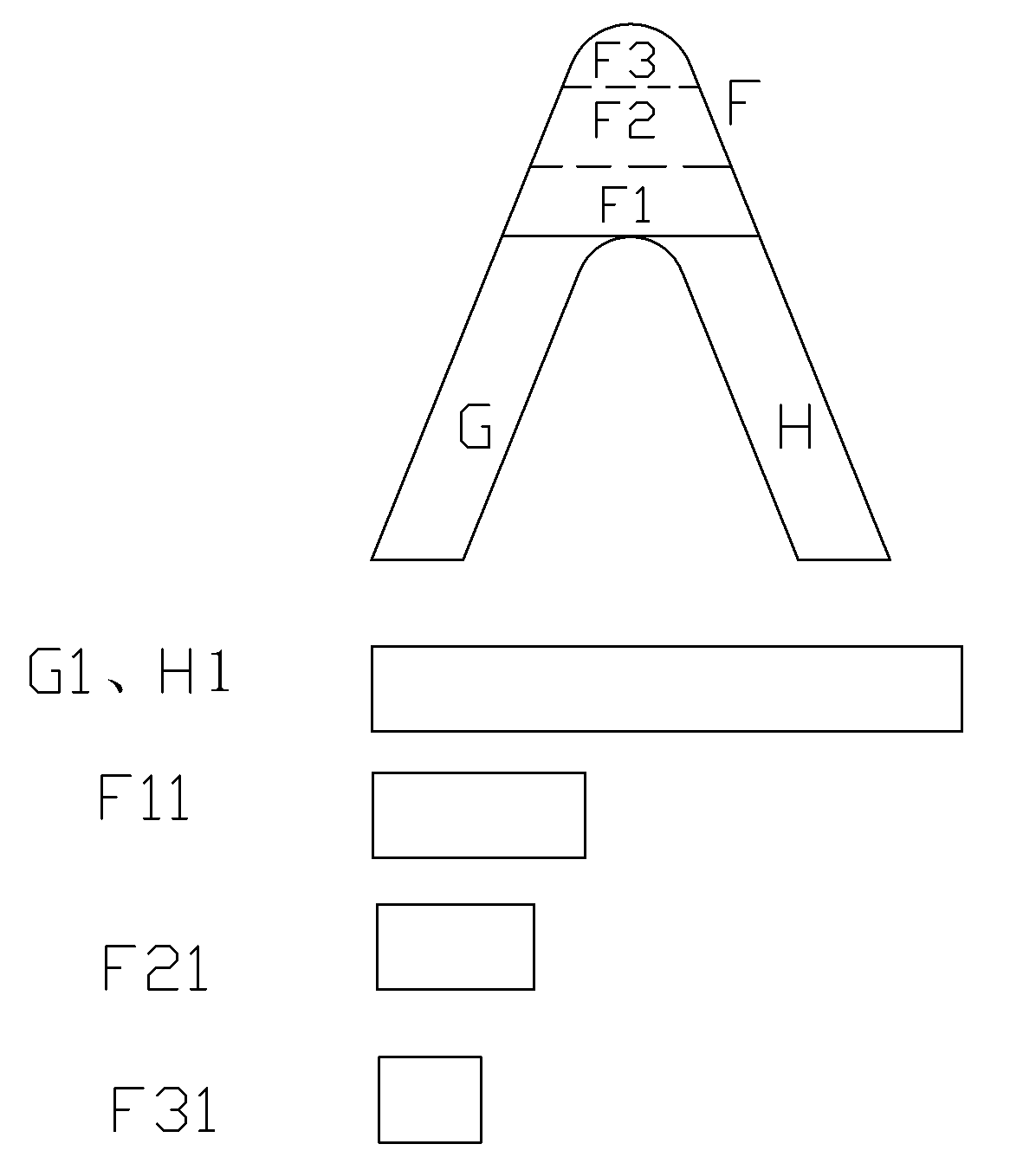

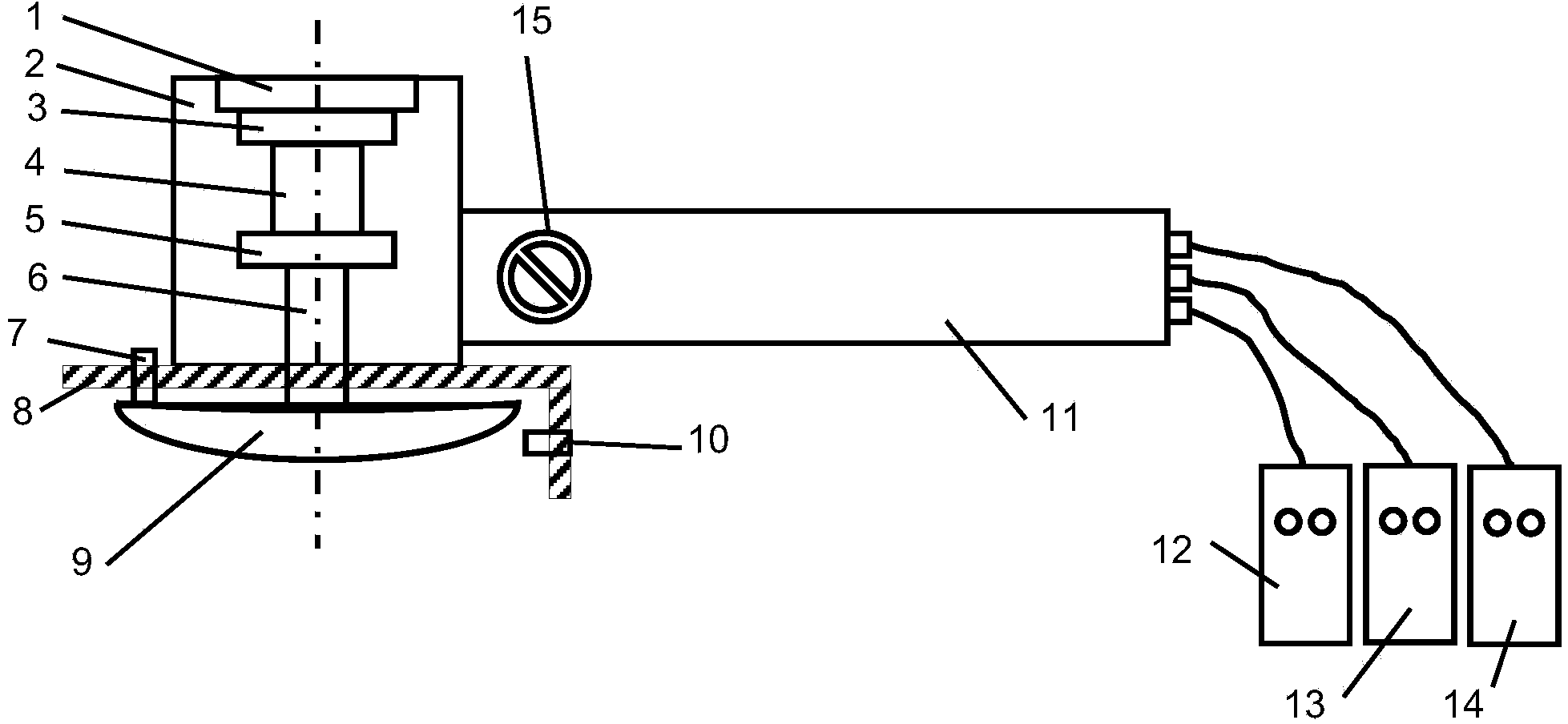

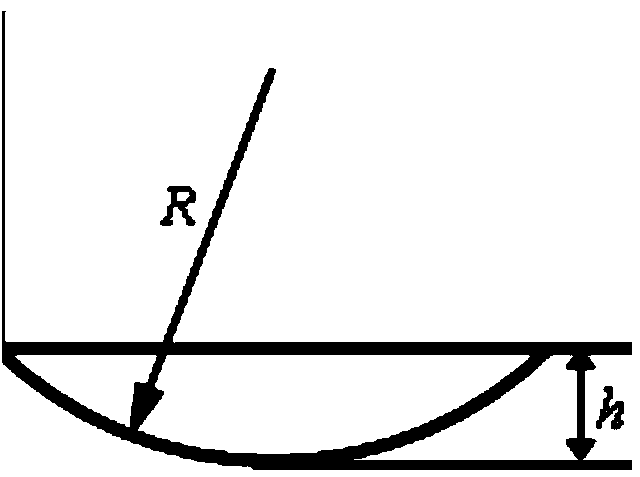

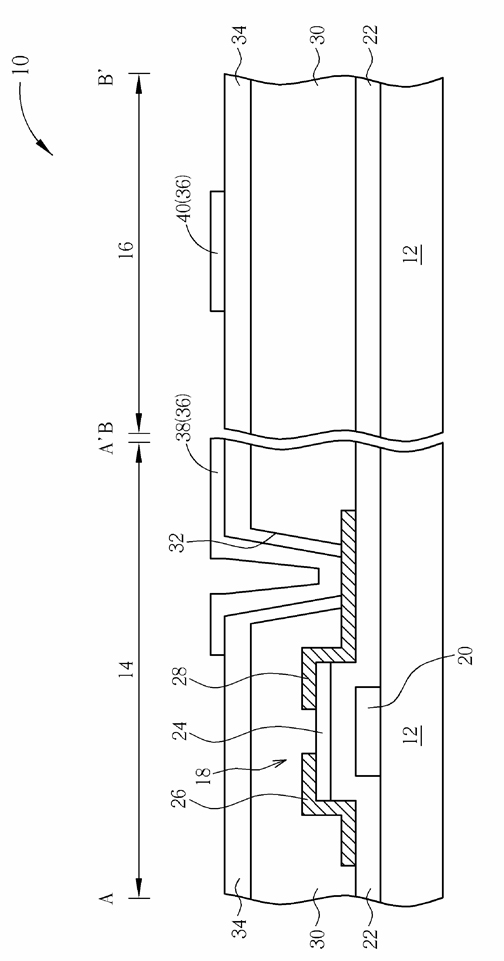

Manganese-cobalt-nickel-oxygen thermistor detector with bent supporting leg micro-bridge structure and method

InactiveCN109238475ALow thermal conductivityImprove response ratePyrometry using electric radation detectorsResponsivityManganese

The invention discloses a manganese-cobalt-nickel-oxygen thermistor detector with a bent supporting leg micro-bridge structure and a method. The thermistor detector comprises a double parabolic sapphire substrate, a SiO2 bridge pier grown by a magnetron sputtering method, a manganese-cobalt-nickel-oxygen thin film material and an ohmic contact electrode of a bent leg structure. After the bent legand a sacrificial layer below the manganese-cobalt-nickel material are released, a self-supporting suspended structure is formed. According to the structure, the direct heat conduction between a photosensitive surface and the lower substrate is reduced, and the heat conduction between the electrode and the substrate is effectively reduced, so that a response ratio of the thermistor detector is greatly improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Handheld high-speed electric arc machining equipment and method

InactiveCN103752989ACompact structureReduce weightOther manufacturing equipments/toolsWelding/cutting media/materialsUltrasonic generatorElectric arc

The invention discloses handheld high-speed electric arc machining equipment and method, and belongs to the field of non-traditional machining equipment. The handheld high-speed electric arc machining equipment comprises a shell, a motor, a coupler, a spindle, a connection flange, an amplitude transformer, a protection cover, an electric brush, a conductive grinding wheel, a handle, an ultrasonic generator and an electric arc machining control power supply. The motor drives the spindle to rotate via the coupler. The amplitude transformer penetrates through the lower end of the shell and is fixedly connected with the conductive grinding wheel in an insulation manner. The spindle drives the amplitude transformer to rotate via the connection flange. Amplitude and vibrating frequency of the amplitude transformer are adjusted via the ultrasonic generator. The conductive grinding wheel is connected with a cathode of the electric arc machining control power supply via the electric brush. Three machining modes including high-speed electric arc machining, ultrasonic vibrating and grinding are combined, and by means of combining the machining modes, and a material removal rate of the handheld high-speed electric arc machining equipment can reach 6-8 times of that of normal electrosparking, and even more than 10 times for parts of materials, so that the handheld high-speed electric arc machining equipment is quite applicable to onsite repairing and machining for surface fatigue layers of parts of large and non-movable waste machines.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Novel ceramic bearing composite material

InactiveCN111943684AReduce coefficient of frictionCorrosion resistantCarbon graphiteDefoaming Agents

The invention discloses a novel ceramic bearing composite material, and relates to the technical field of ceramic materials. The novel ceramic bearing composite material is prepared from the followingraw materials in parts by weight: 45-65 parts of silicon nitride, 10-20 parts of carbon graphite powder, 10-15 parts of zirconium oxide, 5-10 parts of aluminum oxide, 3-5 parts of cerium oxide, 3-5 parts of yttrium oxide, 3-5 parts of titanium powder, 0.8-1.2 parts of a binder and 0.2-0.5 part of a defoaming agent. In addition, the invention also provides a preparation method of the novel ceramicbearing composite material. The novel ceramic bearing composite material has excellent wear resistance, high strength and high toughness, so that a bearing works under a high-temperature condition, is not easy to deform, wear and break, the service lifetime of the bearing is prolonged, the sintering temperature is relatively low, the preparation process is simple, and the processing cost is relatively low.

Owner:新化县正能精细陶瓷有限公司

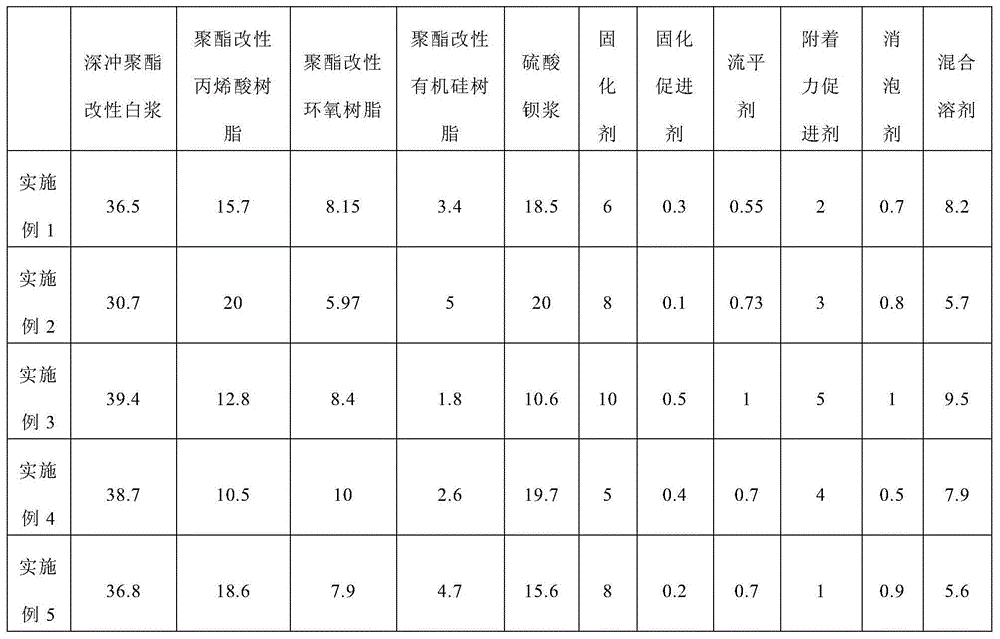

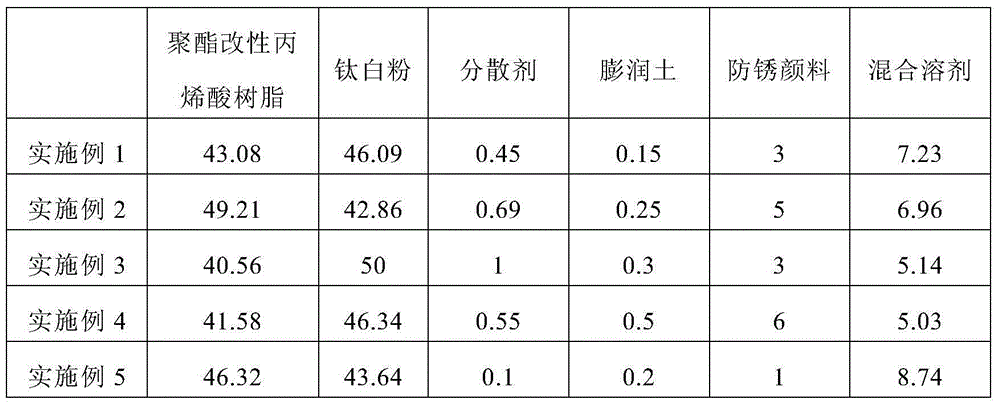

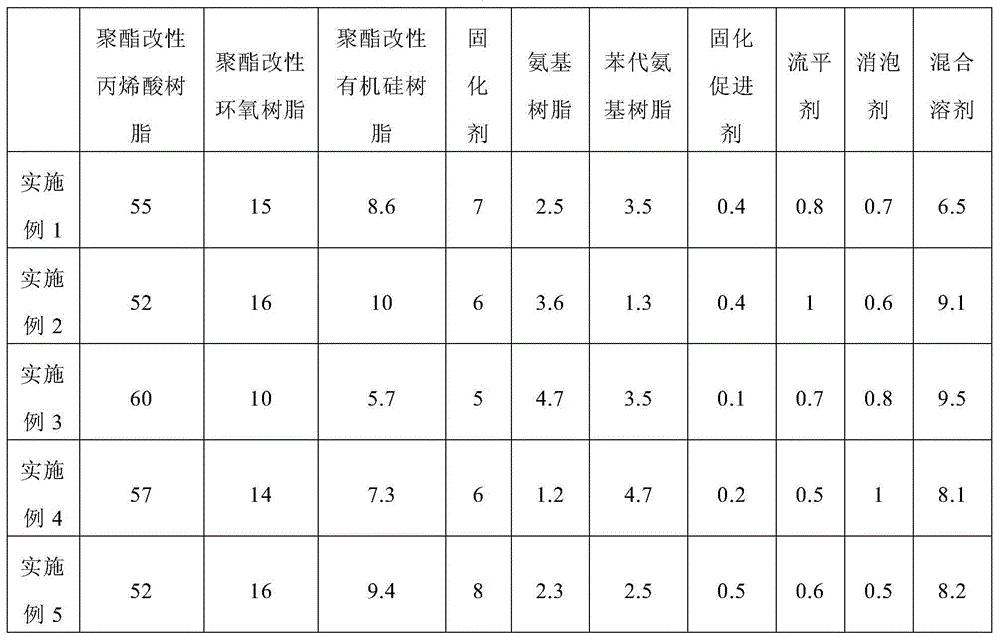

Acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and application method thereof

ActiveCN104817936AStrong adhesionImprove ductilityPretreated surfacesEpoxy resin coatingsMetal sheetDeep drawing

The invention provides an acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and an application method thereof. The paint comprises a white primer and a finish paint. The paint has the advantages of high adhesive force, favorable ductility, high temperature resistance and long service life, changes the processing technique of the metal sheet products, simplifies the processing procedure, centrally completes the roller coating treatment on the metal deep drawing sheet, and does not need to independently arrange any spray workshop.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

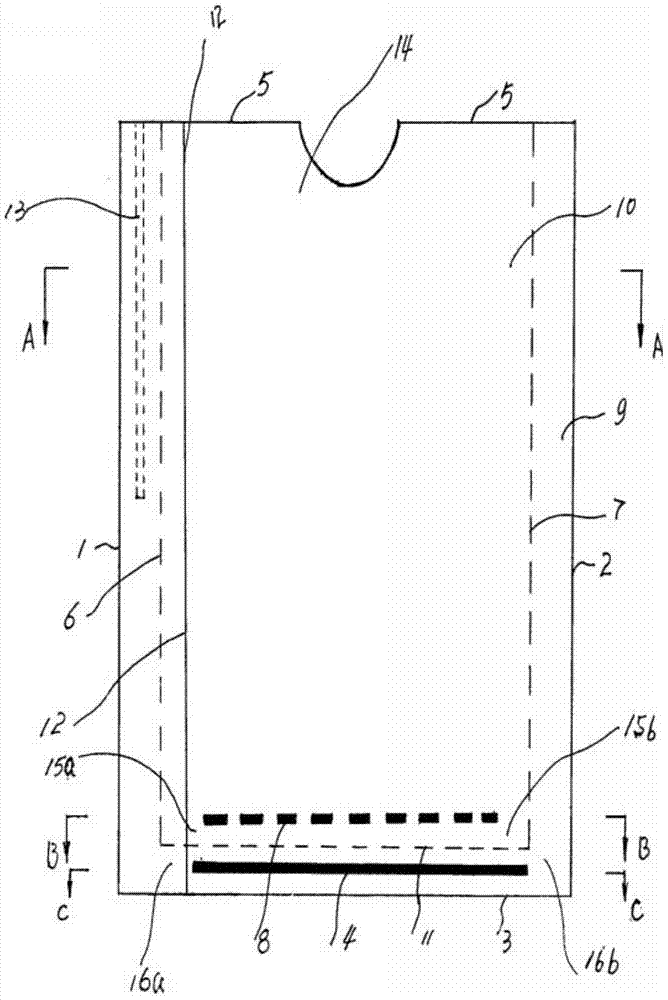

Double-layer breathable bag for fruit bagging

A double-layer air-permeable fruit bag, comprising two layers of bag bodies inside and outside, the outer bag body is a paper bag, the inner layer bag body is a breathable film bag with micropores, the inner layer bag body is placed in the outer layer bag body, the The left and right peripheries of the outer paper bag body are closed edges and are parallel to each other, and the upper and lower peripheries are open edges. The adjacent part of the lower periphery is provided with a bonding layer for bonding the paper bag, and the inner gas-permeable membrane The left and right peripheries of the bag are closed sides and are parallel to each other, the upper and lower peripheries are open sides, and the adjacent parts of the lower peripheries are provided with heat sealing lines for laminating the films. The surrounding positions are coincident. When using, put the young fruit in and tie the top of the bag tightly. After the fruit is ripe, remove the outer paper bag, leaving only the inner film bag to color the fruit. The fruit bagging of this structure has good ventilation function and bright color, no cracks in the fruit, no bean spot disease, bitter bean disease, the finished fruit is uniform in size, and the commodity value is greatly improved.

Owner:BADONG FENGTAI AGRI SPECIALIZED COOP

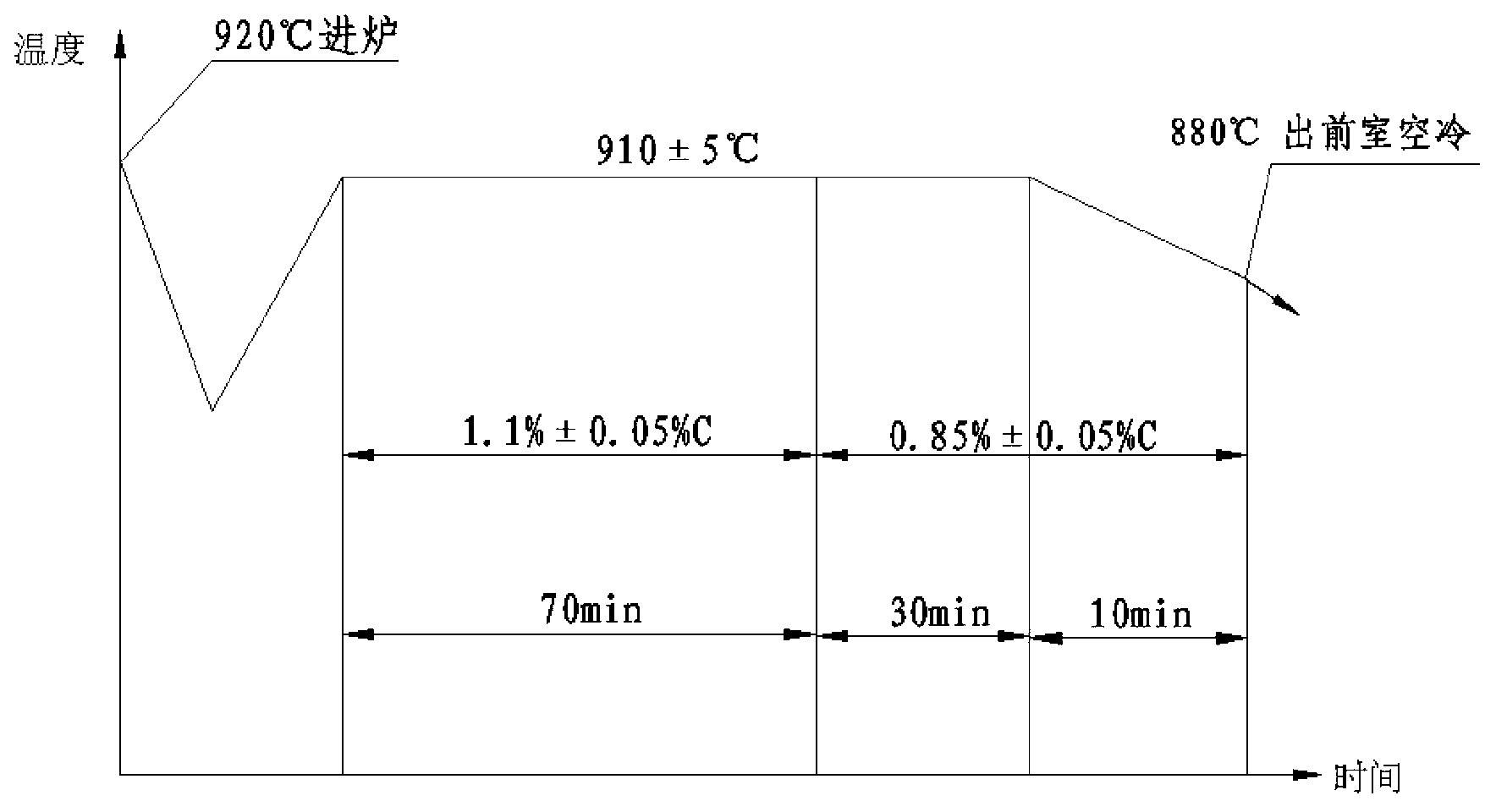

Steel heat treatment deformation treatment method

The invention discloses a steel heat treatment deformation treatment method aiming at easily deformable parts during a heat treatment process, such as a part manufactured from 25Cr2Ni4WA steel and the like. Before heat treatment, certain heat shrinkage deformation amount is reserved, such that the part is restored to an original size after heat treatment. Also, according to the method, with a direct air-cooling quenching method, the part does not deform or slightly deforms. Therefore, with the steel heat treatment deformation treatment method provided by the invention, a problem of severe deformation of a part prepared form easily deformable materials such as 25Cr2Ni4WA steel during the heat treatment process can be effectively solved.

Owner:CHONGQING JIANSHE IND GRP

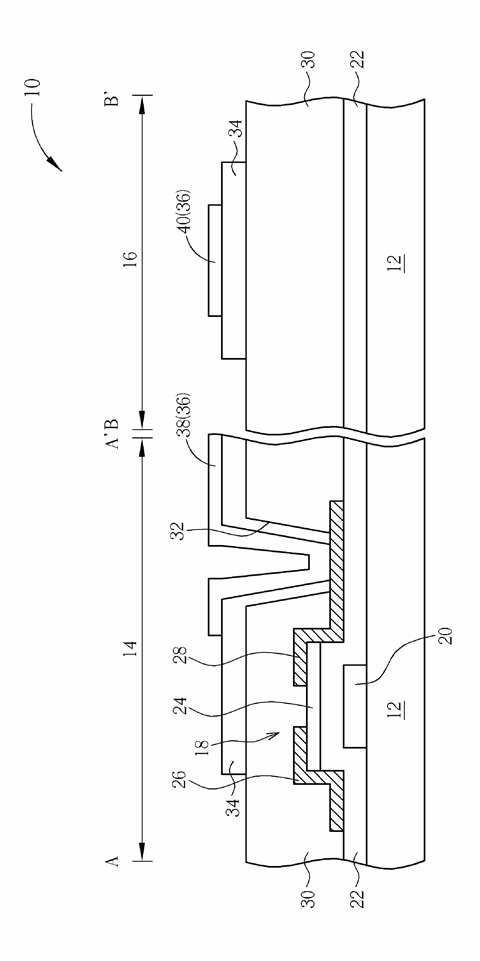

Array substrate and preparation method thereof

InactiveCN101969045ANo crackCrackSolid-state devicesSemiconductor/solid-state device manufacturingArray data structureInorganic materials

The invention relates to an array substrate. The array substrate comprises a substrate, wherein a thin-film transistor which comprises a drain electrode is arranged on the substrate; an organic material layer covers the substrate and the thin-film transistor; an opening passes through the organic material layer; the drain electrode is exposed out of the opening; an inorganic material layer at least covers the side wall of the opening and part of the organic material layer; the drain electrode is exposed out of the opening; and a patterned transparent pixel electrode layer is positioned on the inorganic material layer and in the opening and contacts the drain electrode.

Owner:CHUNGHWA PICTURE TUBES LTD

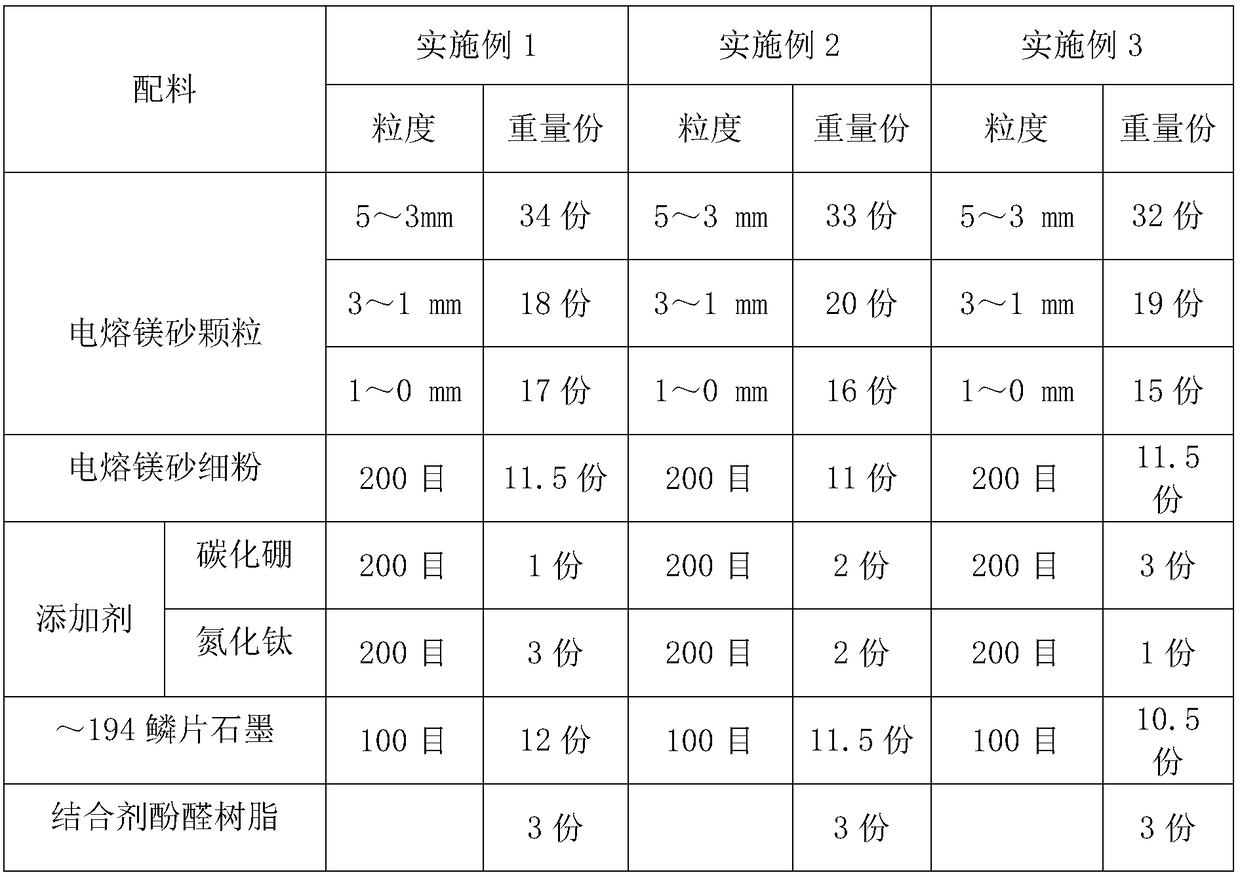

Converter body brick with titanium nitride added and preparation method thereof

InactiveCN109265144AImprove antioxidant capacityExtended service lifeManufacturing convertersPorosityBrick

The invention relates to a converter body brick with titanium nitride added. According to the physicochemical indexes of the converter body brick, MgO is greater than or equal to 75.0%, the volume density after baking at 200 DEG C is greater than or equal to 2.98 g / cm<3>, the apparent porosity is less than or equal to 4%, the compression strength is greater than or equal to 35 MPa, the linear change rate is 0-1.0%, and the high-temperature bending strength is greater than or equal to 12 MPa. The converter body brick is prepared from the following components in parts by weight: 32-34 parts of fused magnesite particles with the particle size larger than or equal to 3 mm and smaller than 5 mm, 16-20 parts of fused magnesite particles with the particle size larger than or equal to 1 mm and smaller than 3 mm, 13-17 parts of fused magnesite particles with the particle size smaller than 1 mm, 10-12 parts of 200-mesh fused magnesite fine powder, 1-3 parts of 200-mesh boron carbide fine powder,1-3 parts of 200-mesh titanium nitride fine powder, 10-13 parts of 100-mesh crystalline flake graphite and 2-4 parts of a binding agent of phenolic resin. According to the converter body brick, composite additives of boron carbide and titanium nitride are added, so that the oxidation resistance of the converter body brick is improved, the service life of the converter body brick is remarkably prolonged, and therefore the steel-making efficiency of a steel mill is improved, the steel-making cost is lowered, and the steel-making quality and safety are ensured.

Owner:海城利尔麦格西塔材料有限公司

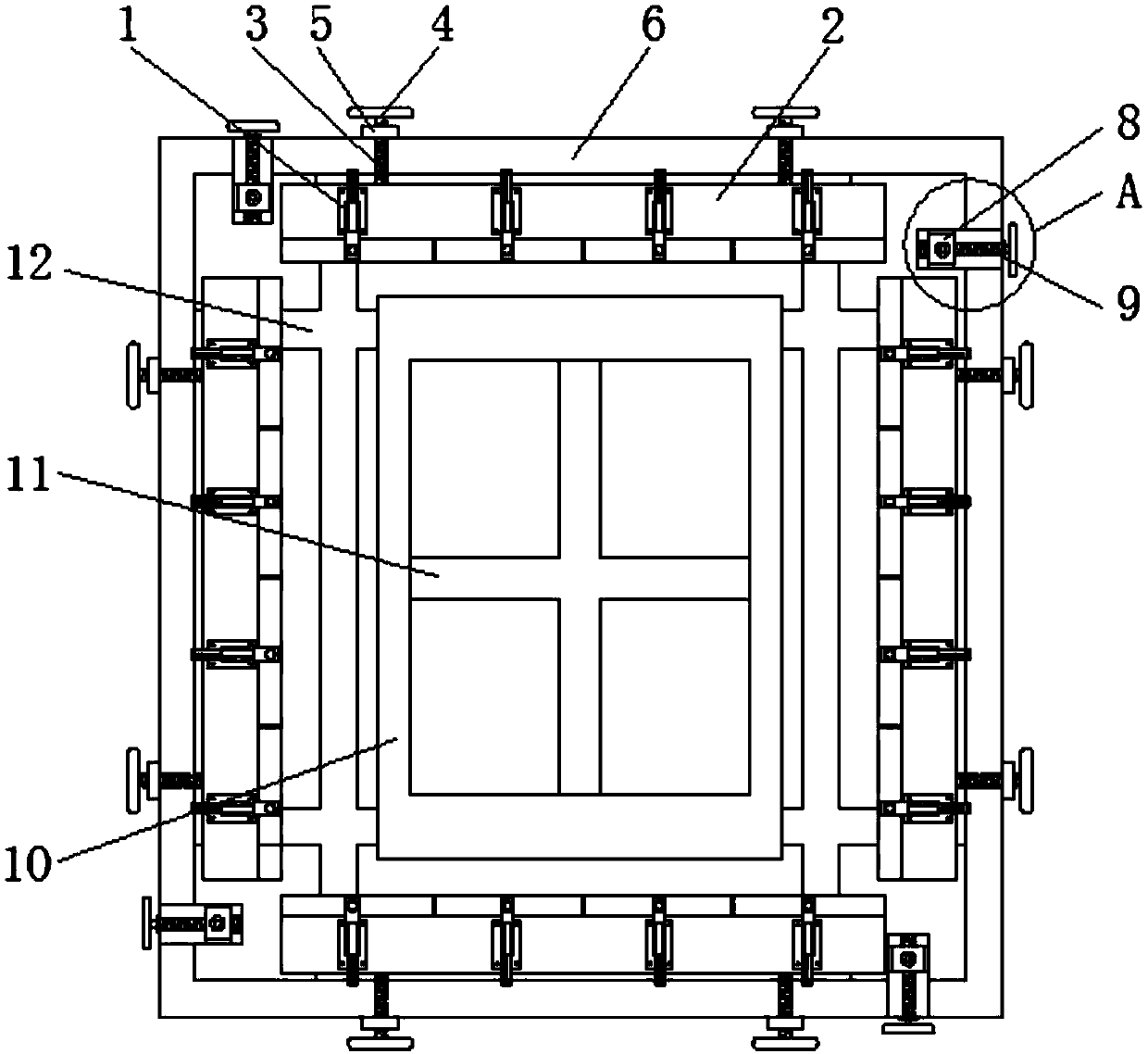

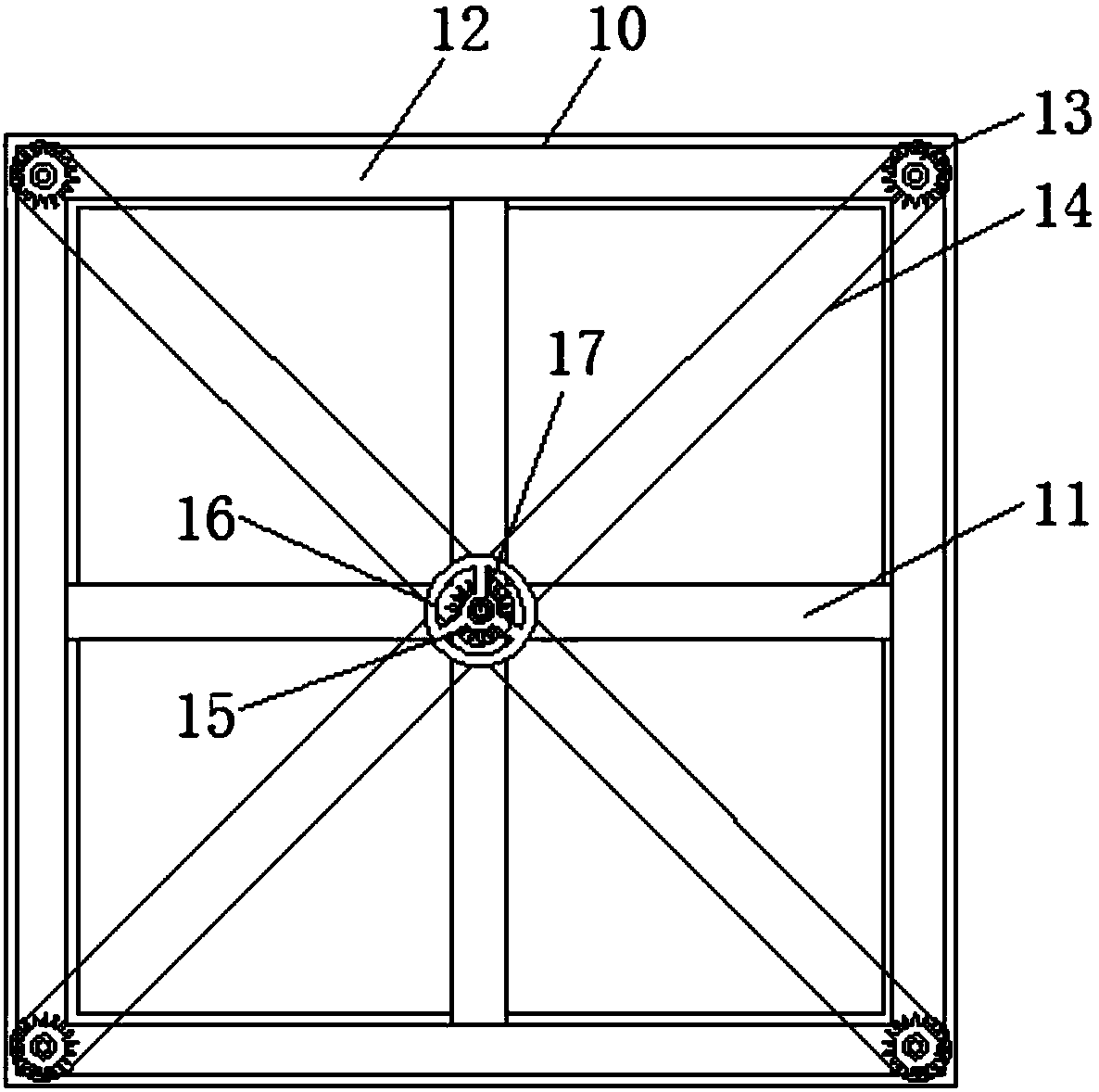

High-tension porcelain seal component welding tool and application method thereof

The invention discloses a high-tension porcelain seal component welding tool and an application method thereof. The high-tension porcelain seal component welding tool comprises a protective box with agroove and a protective cover plate provided with a through hole A. A cylinder with a through hole B is integrally formed at the bottom of the groove. The protective cover plate is separably mountedin the groove of the protective box, and the through hole A and the through hole B are coaxial. The protective cover pale is provided with a notch. The notch communicates with the through hole A. Whenconducting welding on a high-tension porcelain seal component mounted in the welding tool, the welding tool continuously adds clear water into the protective box, heat energy in the welding process is dissipated through evaporation of the clean water to cool the high-tension porcelain seal component. The problem that a porcelain component bears high and low-temperature impact during conventionalwelding and is damaged is solved.

Owner:四川泛华航空仪表电器有限公司

A method for enhancing the mechanical strength of glass

InactiveCN103359946AHigh mechanical strengthImprove production yieldGlass/slag layered productsStress concentrationEngineering

Provided is a method for enhancing the mechanical strength of glass. The glass comprises a top surface, a bottom surface, and at least one side surface. The method comprises: forming protection layers on the top surface and the bottom surface, wherein the protection layers expose an area which is on the top surface and which is close to the side surface and an area which is on the bottom surface and which is close to the side surface; etching the side surface of the glass and one side surface of each protection layer; and removing the protection layers. In the method for enhancing the glass mechanical strength of glass, the side surface of the glass is made flat by etching the glass. Stress concentration does not occur when the side surface of the glass undergoes collision so that the mechanical strength of the glass is enhanced.

Owner:GLOBAL DISPLAY

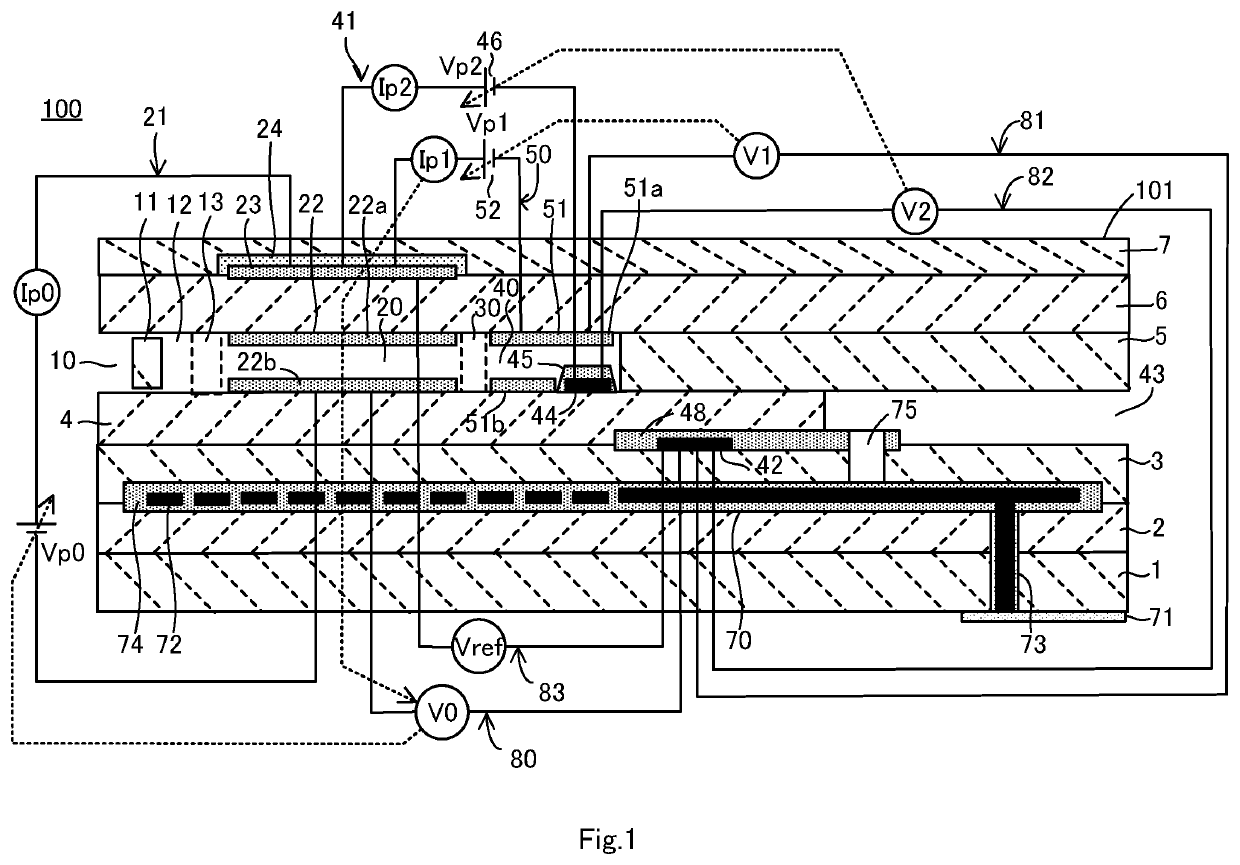

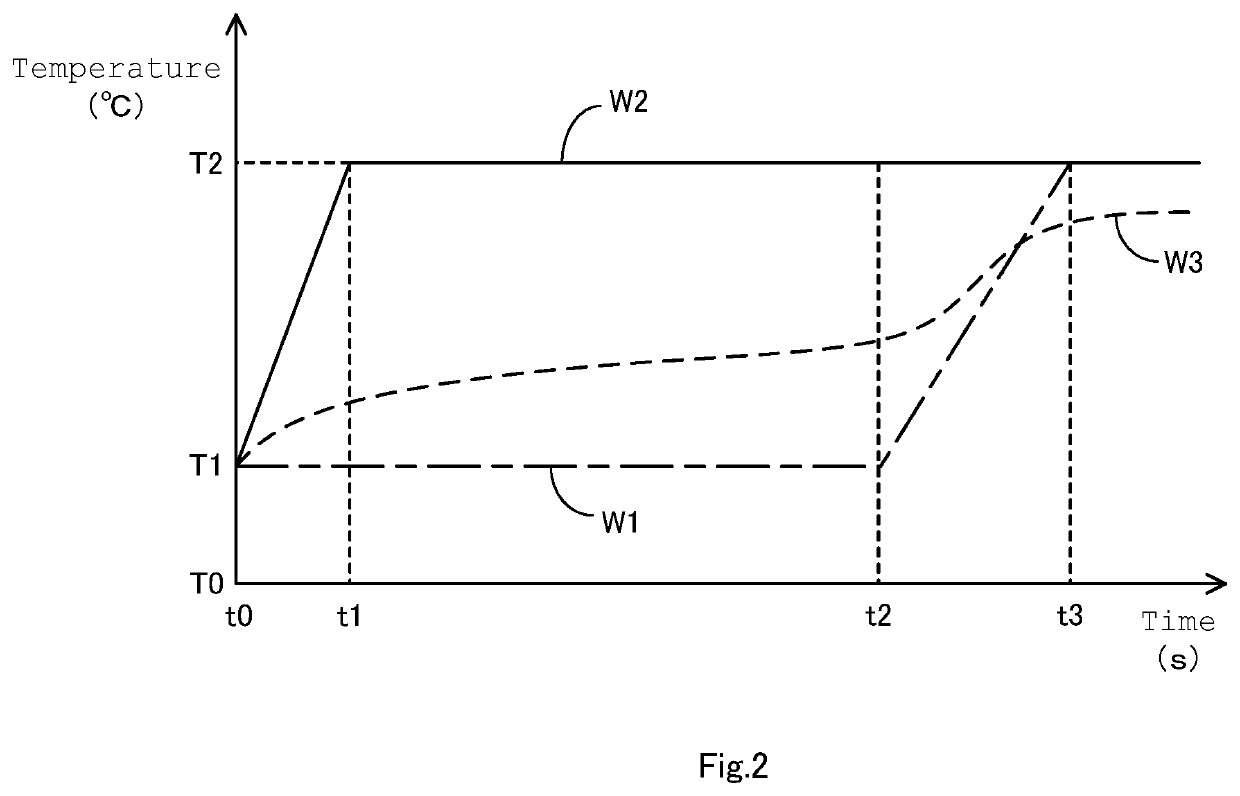

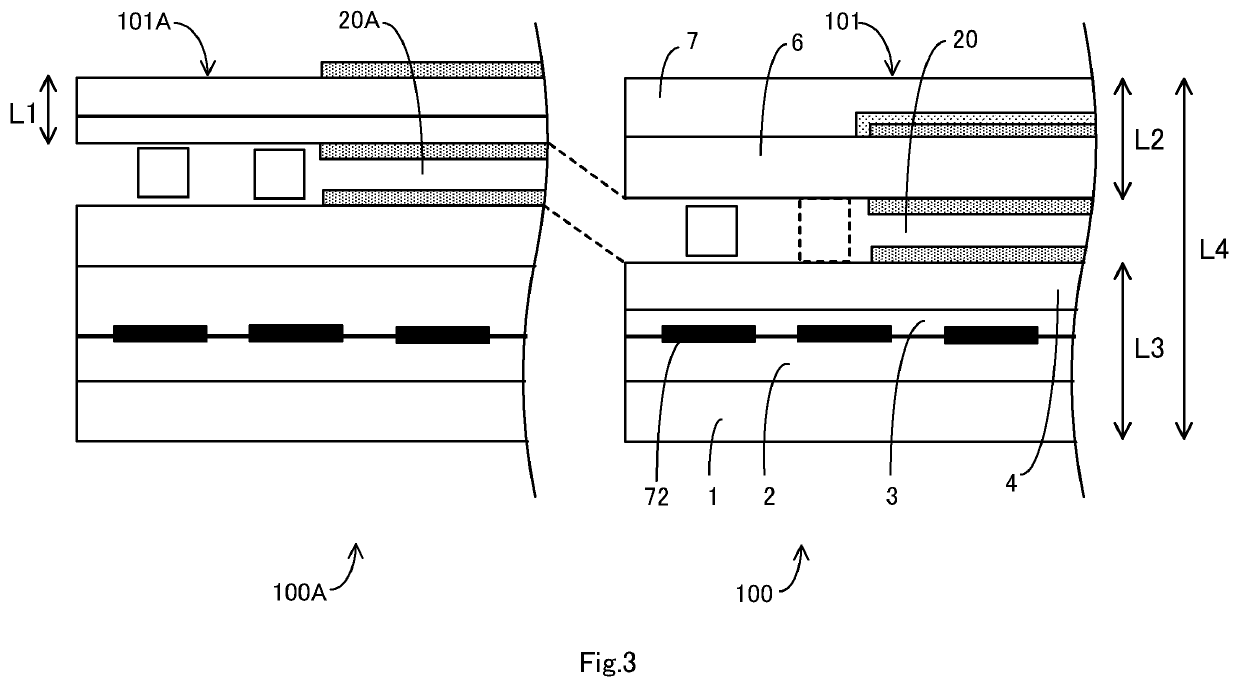

Gas sensor

PendingUS20220107288A1Efficient dischargeCrackMaterial electrochemical variablesEngineeringLower face

Owner:NGK INSULATORS LTD

Solid preparation containing ibuprofen, tranexamic acid and calcium silicate

InactiveCN101332177AInhibit swellingStability of expansion inhibitionOrganic active ingredientsPeptide/protein ingredientsCalcium silicateTranexamic acid

The invention provides a solid preparation with restrained expansion under high temperature preservation condition, containing ibuprofen and tranexamic acid. The solid preparation containing ibuprofen and tranexamic acid is characterized in that the solid preparation contains calcium silicate.

Owner:KOWA CO LTD

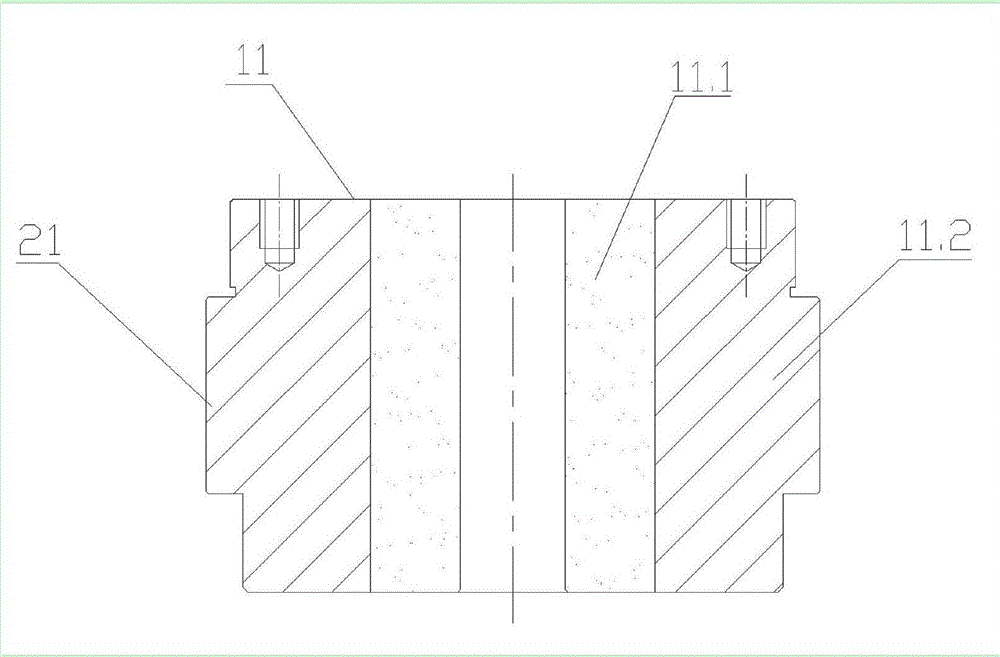

A mold for processing a gear bushing and a method for processing a gear bushing using the mold

ActiveCN104117679BImprove liquidityRepressiveBearing componentsNumerical controlVolumetric Mass Density

Owner:宁波金钟粉末冶金有限公司

Methacrylate building waterproofing material

The invention relates to the field of building material production, and in particular relates to a methacrylate building waterproofing material. The methacrylate building waterproofing material is prepared from the following raw materials in parts by weight: 35-50 parts of methacrylate, 20-30 parts of stearic acid, 4-9 parts of phthalic anhydride, 10-16 parts of portland cement, 4-6 parts of petroleum resin, 4-8 parts of nitrile rubber, 8-14 parts of glass fibers, 4-10 parts of diethylenetriamine, 5-11 parts of acrylic ester, 8-16 parts of mineral powder, 3-6 parts of rosin, 2-4 parts of anhydrous calcium chloride, 2-6 parts of an adhesive, 2-6 parts of an active agent, 2-4 parts of a stabilizer, 1-3 parts of a flame retardant, 1-3 parts of an antioxidant and the like. The methacrylate building waterproofing material has the advantages of being excellent in waterproof performance, crack-resistant, good in anti-softening performance, high in compression resistance and anti-permeabilityperformance, good in stability and not liable to aging.

Owner:安庆越球建筑防水材料有限公司

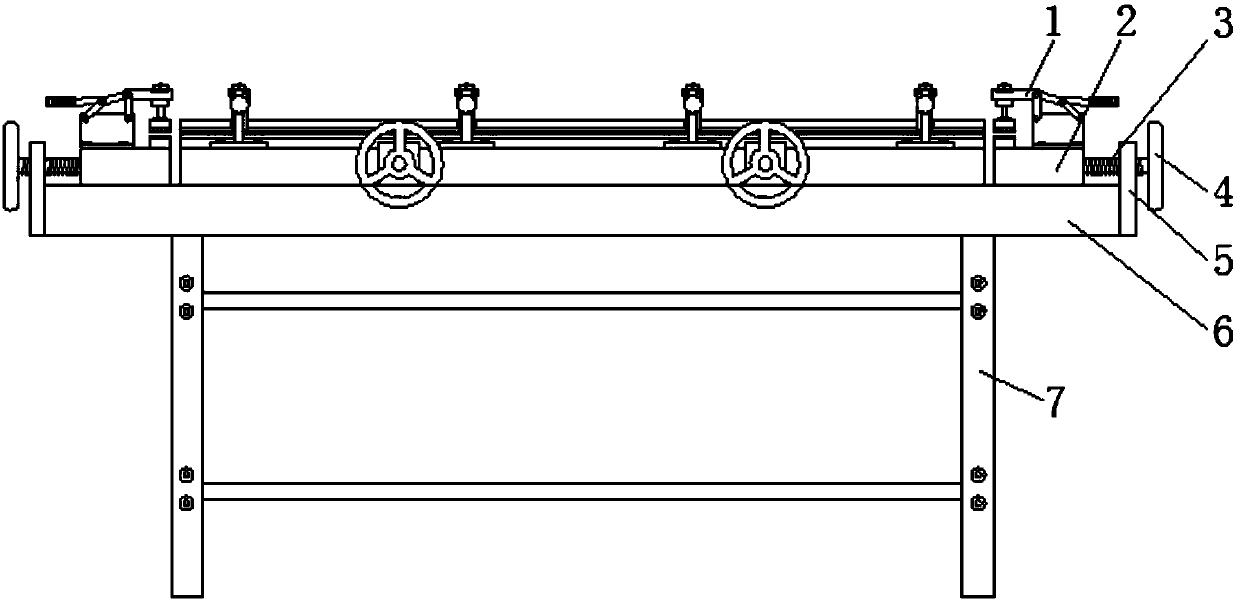

Manual net pulling machine convenient for fixing cloth

The invention discloses a manual net pulling machine convenient for fixing cloth. The manual net pulling machine comprises a working platform, supporting legs are welded to the four corners of the bottom of the working platform, a fixing plate is welded on the outer wall of one side of the working platform, the central position of the outer wall of one side of the fixing plate is connected with afirst screw rod in a screwed mode through threads, one end of the first screw rod is welded to a first hand wheel, the other end of the first screw rod is welded to a movable seat, the top of the movable seat is fixedly connected to a clamp through a bolt, a supporting frame is welded on the inner wall of one side of the working platform, a supporting rod is welded inside the supporting frame, a rotating shaft is embedded in the central position of the bottom of the supporting rod, and a second hand wheel is welded to one end of the rotating shaft. According to the manual net pulling machine convenient for fixing cloth, the problem that the material is stressed uniformly in the ascending process of a lifting plate is guaranteed, the phenomenon that the cloth is cracked due to uneven stressis avoided, so that the stability of the cloth structure is ensured, on the other hand, the labor intensity of a user is reduced, and time and labor are saved.

Owner:SHAOXING KOOLYI NETWORK TECH SERVICES CO LTD

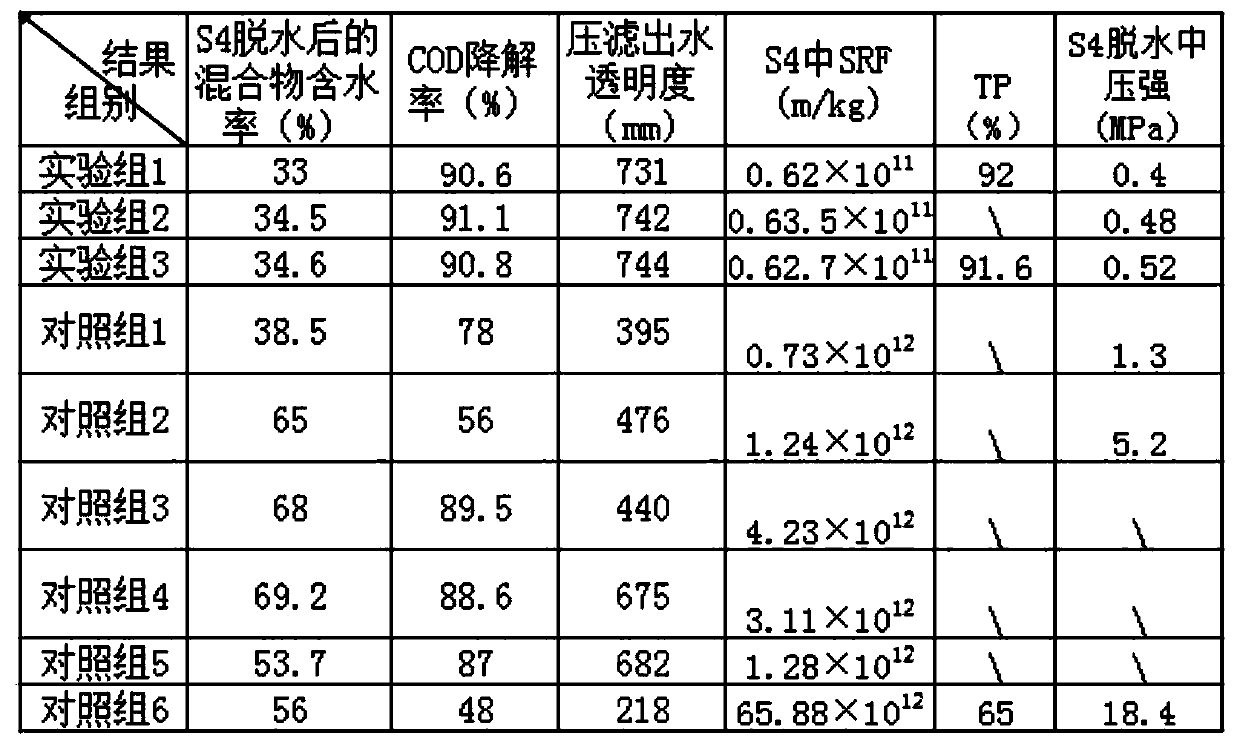

Sludge heat treatment recycling process

PendingCN111533412APromote hydrolysisImprove acidificationWater treatment parameter controlSludge treatment by thermal conditioningMicroorganismCompression molding

The invention belongs to the technical field of sludge treatment, and particularly relates to a sludge heat treatment recycling process which comprises the following steps: S1, preheating sludge, S2,carrying out heat treatment, S3, cooling, S4, dehydrating, and S5, carrying out compression molding. According to the sludge heat treatment recycling process, the sludge is deeply dewatered, the effects of disintegrating the sludge and improving organic matter dissolution can be achieved, and therefore the phosphorus release capacity of the sludge is improved, the pH value of a sludge system aftertreatment is 7, a treatment container is not corroded, and the salinity in the system cannot be improved. The process can be used for effectively sterilizing, killing germs in sludge and inhibiting fermentation microorganisms from generating a large amount of acidic biogas, so that pipeline equipment is corroded and damaged, and the burst risk caused by more biogas is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

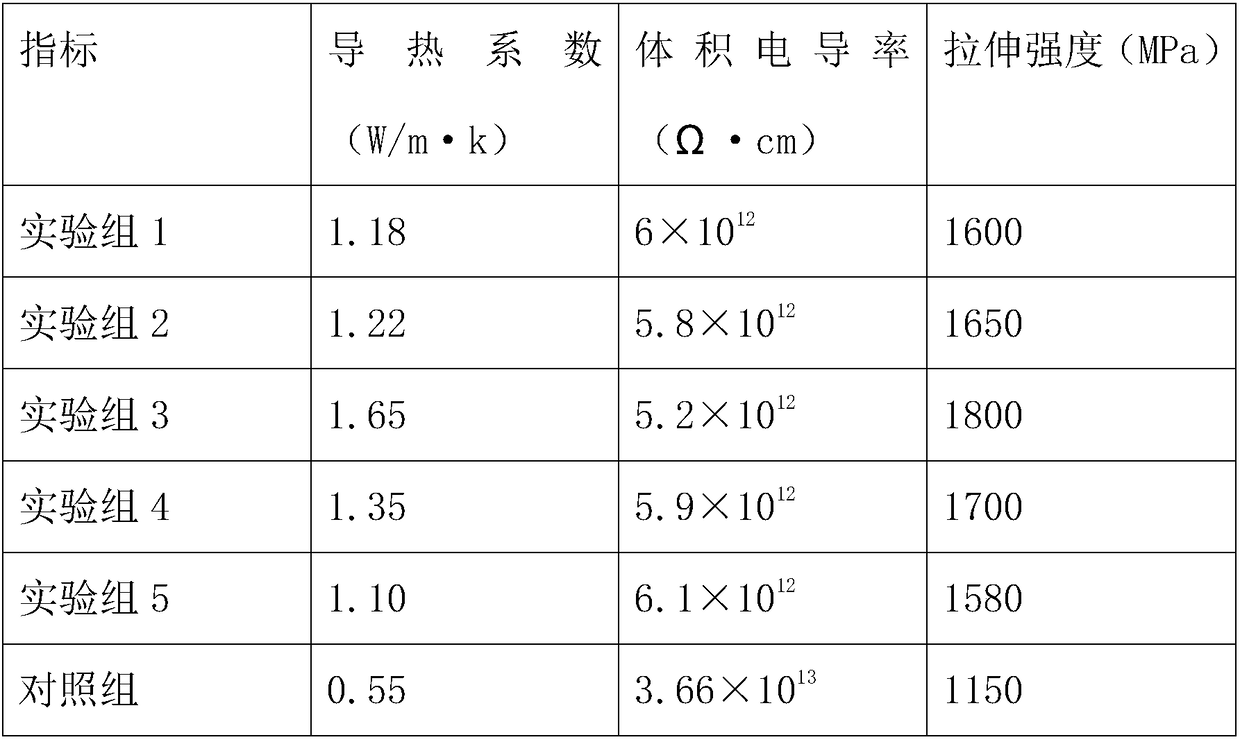

Electronic insulating encapsulating material and preparation method thereof

ActiveCN108588594AHigh thermal conductivityImprove thermal conductivityVacuum evaporation coatingSputtering coatingEpoxyFiber

The invention discloses an electronic insulating encapsulating material and a preparation method of the electronic insulating encapsulating material. The electronic insulating encapsulating material comprises, by weight, 10-15 parts of diamond, 20-30 parts of silicon carbide, 10-20 parts of carbon fiber, 15-30 parts of epoxy resin, 20-30 parts of heat conducting inorganic nanoparticles, 10-20 parts of anticorrosive agent, 10-15 parts flexibilizer, 20-25 parts of polyamide and 30-40 parts of matrix. According to the electronic insulating encapsulating material, the diamond, the silicon carbideand the carbon fiber all have high hardness, so that the composite prepared from the mixture of the diamond, the silicon carbide and the carbon fiber has quite high hardness, and compared with the hardness of an ordinary material, the hardness of the electronic insulating encapsulating material is improved by 20%-30%; meanwhile, the carbon fiber has quite strong heat conducting performance, so that heat dissipation of an electronic product is facilitated; due to addition of the flexibilizer, the tenacity of the material is improved by 37%-57%, an electronic element is protected against crackscaused by shake and impact, the electronic element is effectively protected, and the service life of the electronic element is prolonged by 2-3 times. The electronic insulating encapsulating materialis high in hardness and tenacity, the heat conducting performance and the insulating performance of the electronic insulating encapsulating material are greatly improved, and the electronic insulatingencapsulating material has great significance in development of heat conducting insulating materials.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

Building waterproof material and preparation method thereof

The invention specifically relates to a building waterproof material and a preparation method thereof. The building waterproof material consists of the following raw materials in parts by weight: 30-40 parts of metacrylic acid ester, 20-35 parts of stearic acid, 8-15 parts of aluminum potassium sulfate dodecahydrate, 10-20 parts of rubber powder, 10-20 parts of mineral powder, 3-8 parts of rosin and 3-8 parts of an adhesive. The building waterproof material has the beneficial effects of being adaptive to change of weather and temperature, not easy to soften or crack, good in waterproof property and not easy to age.

Owner:成都创意云科技有限公司

A low temperature current transformer coil

InactiveCN104200979BNo embrittlementCrackTransformersTransformers/inductances coils/windings/connectionsBobbinEngineering

A low-temperature current transformer coil, the low-temperature current transformer coil mainly includes a low-temperature glue inner skeleton (1), a low-temperature insulating wire turn (2) and a low-temperature glue outer skeleton (3); the low-temperature glue inner skeleton ( 1) Located in the center of the low temperature current transformer coil, it is a hollow ring structure; the low temperature insulated wire turns (2) are formed by winding low temperature resistant insulating enameled wire along the radial direction of the low temperature rubber inner skeleton (1); the low temperature insulated wire turns (2) ) lead-out wires (23) close to the outer wall of the low-temperature rubber inner skeleton (1) and lead out from the loop groove (12) on the outer wall of the low-temperature rubber inner skeleton (1); the low-temperature rubber outer skeleton (3) is ring-shaped, and the The low-temperature insulated wire turns (2) and the low-temperature glue inner skeleton (1) outside the lead-out wire (23) are covered.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Ceramic nanofiltration membrane assembly for water purifier

PendingCN110386642ANo crackUniform pressure distributionWater/sewage treatment bu osmosis/dialysisReverse osmosisFiltrationNanofiltration

The invention discloses a ceramic nanofiltration membrane assembly for a water purifier. The ceramic nanofiltration membrane assembly comprises a shell, a ceramic nanofiltration membrane filter element and an upper cover which are arranged in the shell, the upper cover is provided with a water inlet, a water outlet and a concentrated water outlet, the ceramic nanofiltration membrane filter elementis internally provided with a plurality of filtration channels and water purification channels, the water purification channels are enclosed plate-shaped cavities, the outer wall face of the ceramicnanofiltration membrane filter element is provided with a plurality of water outlet grooves, a water inlet cavity is formed between the inner wall of the upper cover and the upper end face of the ceramic nanofiltration membrane filter element, a water outlet cavity is formed between the inner wall of the shell, the outer wall of the ceramic nanofiltration membrane filter element and the water outlet grooves, and a concentrated water cavity is formed between the bottom of the shell and the lower end face of the ceramic nanofiltration membrane filter element. The filter element is the ceramic nanofiltration membrane filter element, compared with a method of a coating in the past, the service life is longer, and the filtration effect is better; by arranging the purification channels in the ceramic nanofiltration membrane filter element, filtration areas are larger, pressure of the filtration wall is even, and during use for a long time, crack on the ceramic nanofiltration membrane filterelement is not prone to being formed.

Owner:清华苏州环境创新研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com