Gear shaft sleeve and die and method for machining same

A gear bushing and mold processing technology, which is applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems affecting the comprehensive performance of the finished product, poor powder fluidity, and easy breakage of the gear bushing, and achieves uniform density. The effect of good pressing performance and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

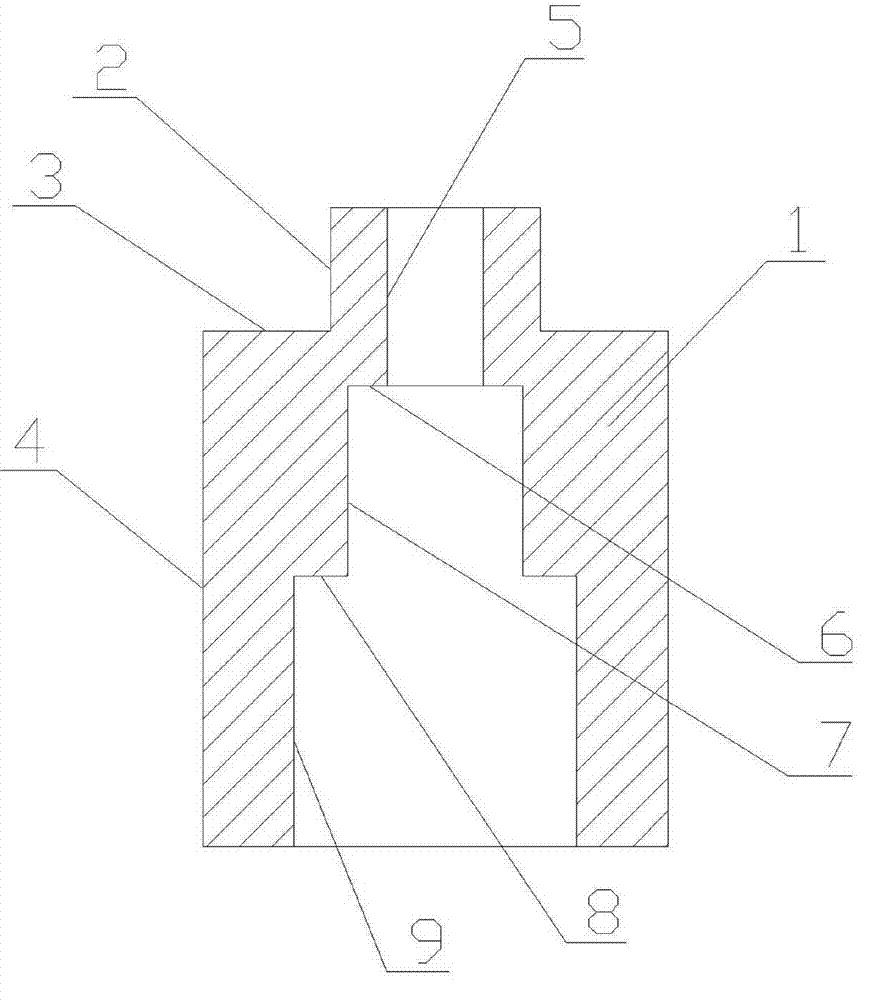

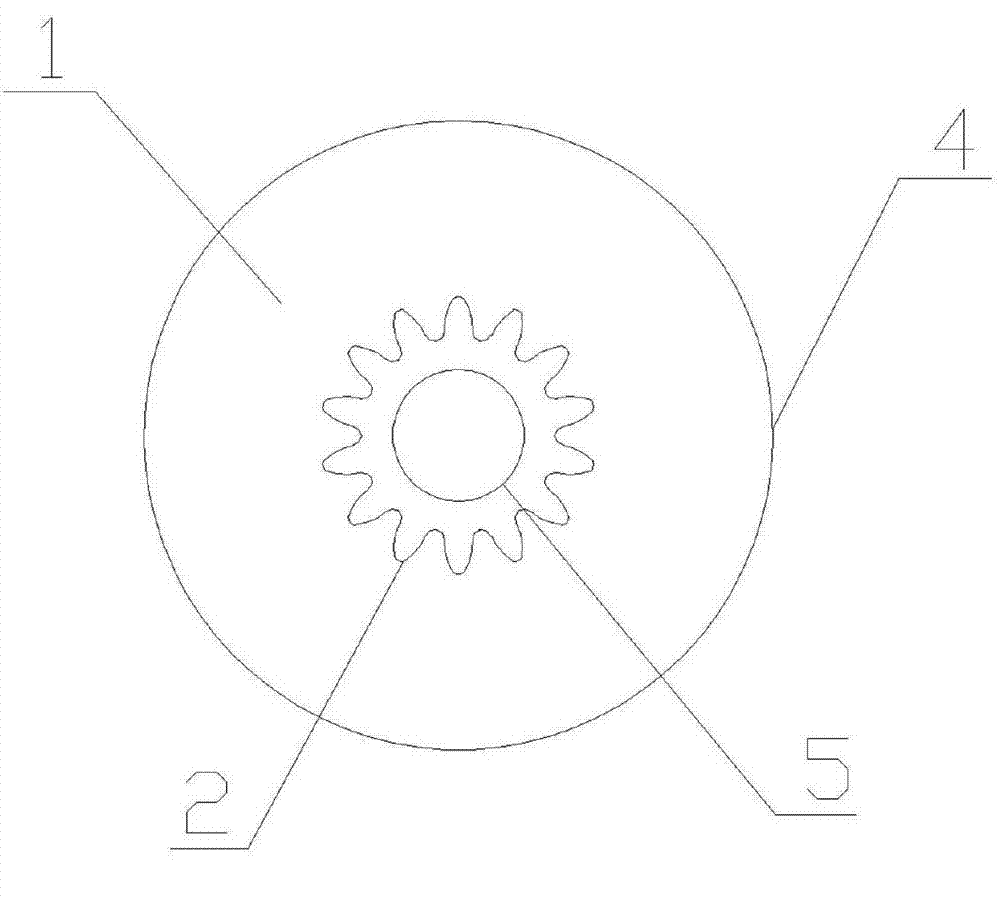

[0043]A gear bushing, the gear bushing is formed by machining a gear bushing blank 1, the outer surface of the gear bushing blank 1 is a gear surface 2, an outer ring connected in sequence from top to bottom Mesa 3, outer peripheral surface 4, the diameter of the addendum circle of the gear surface 2 is smaller than the cross-sectional diameter of the outer peripheral surface 4, and the inner surface of the gear sleeve blank 1 is the first inner surface connected sequentially from top to bottom. Circumferential surface 5, first inner circumferential surface 6, second inner circumferential surface 7, second inner circumferential surface 8, third inner circumferential surface 9, said first inner circumferential surface 5, second inner circumferential surface 7, The cross-sectional circle diameter of the third inner peripheral surface 9 gradually increases. The upper end surface and the lower end surface of the gear sleeve blank 1 are respectively a torus, wherein the outer porti...

Embodiment 2

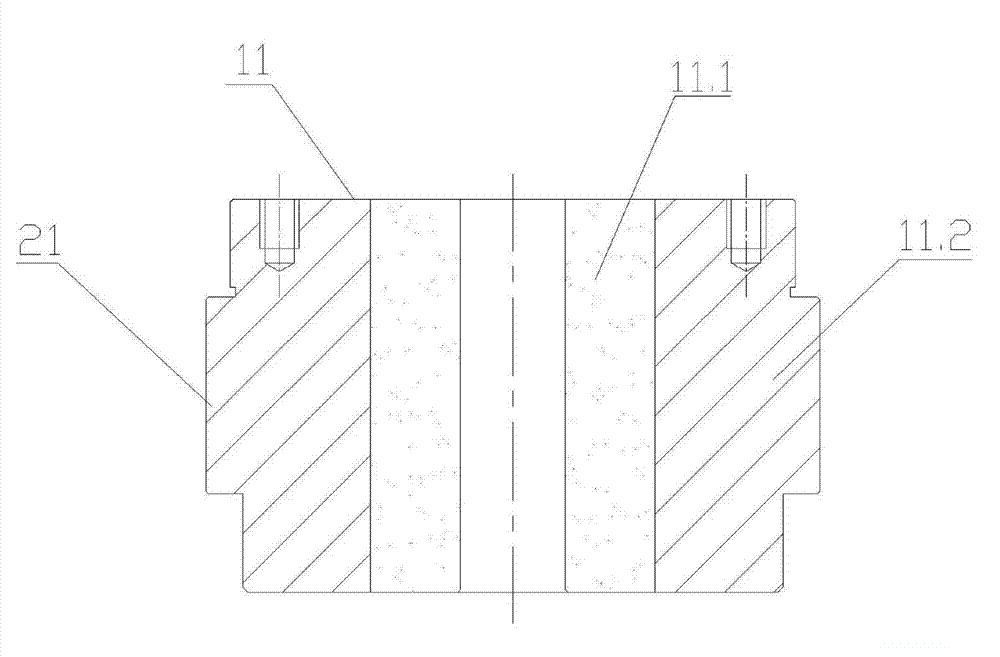

[0047] A kind of mold that is used to process the gear bushing of embodiment 1, it comprises female die 11, an upper punching die 12, two upper punching dies 13, one punching die 14, two lower punching dies 15, three lower punching dies 16, mandrel 17.

[0048] The female mold 11 is a cylindrical body with a continuous cylindrical cavity (inner hole), which is formed by the interference and thermal sleeve of the inner mold core 11.1 and the outer mold sleeve 11.2, wherein the material of the mold core 11.1 is hard Quality alloy, the material of the mold cover 11.2 is 40Cr steel. The diameter of the inner hole of the female mold 11 is equal to the cross-sectional circle diameter of the outer peripheral surface 4 of the gear sleeve blank 1 . The outer periphery of the female mold 11 is provided with a first protrusion 21 for fixed connection with the lower punching plate of the press.

[0049] The inside of the first upper die 12 has a through circular cavity for socketing the ...

Embodiment 3

[0054] The method for the gear bushing of embodiment 1 according to the mold processing embodiment 1 of embodiment 2, it comprises the following steps:

[0055] (1) Weigh each component of formula content, fully mix uniformly, form stamping material;

[0056] (2) In the loose state of the press, the stamping material is added through the feeding channel into the material cavity formed by the mandrel 17, the first punch 14, the second lower punch 15, the third lower punch 16, and the female mold 11;

[0057] (3) Then the press enters the pressing state, and the stamping material is cold-pressed;

[0058] (4) Finally, the press enters the demoulding state, and the formed gear sleeve blank 1 is output;

[0059] (5) machining the obtained gear shaft sleeve blank 1, specifically including:

[0060] (a) CNC lathe processing, large inner hole Φ7.984±0.009, Φ12.98±0.009, steps 8.7±0.15, 5±0.15, 16.8±0.10,

[0061] (b) The large chamfering angle is 30°, the car chamfering angle is R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Addendum circle diameter | aaaaa | aaaaa |

| Circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com