High-tension porcelain seal component welding tool and application method thereof

A technology for component welding and high-pressure porcelain, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as cracks, low assembly qualification rate of high-pressure porcelain-sealed parts, and damage to porcelain-sealed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

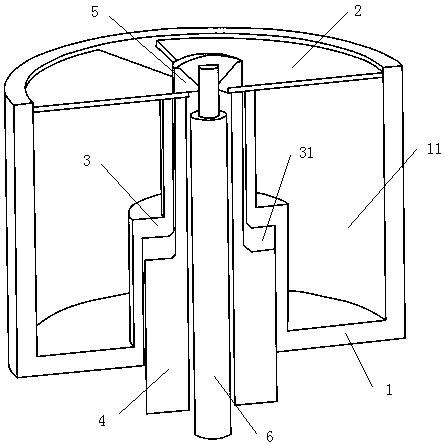

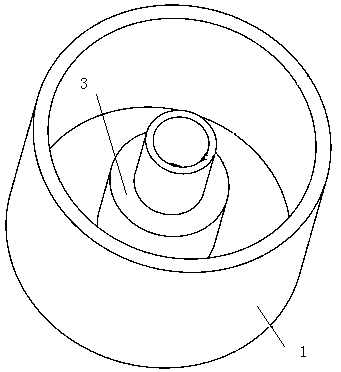

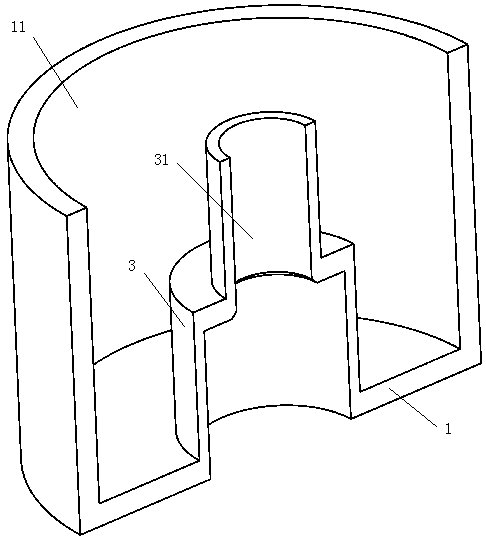

[0032] combined with Figure 1-4 As shown, a welding tool for high-voltage ceramic sealing parts 4 includes a protective box 1 provided with a groove 11 and a protective cover 2 provided with an A through hole 21. The bottom of the groove 11 is integrally formed with a B through hole. The cylinder 3 of the hole 31, the protective cover 2 is installed in the groove 11 of the protective box 1 and the A through hole 21 and the B through hole 31 are coaxial, and the protective cover 2 is provided with a gap 22 , the notch 22 communicates with the A through hole 21 .

[0033] The present invention is a new type of welding tool for high-voltage ceramic seal parts 4. The cylinder 3 in the protection box 1 is used to support the protection cover plate 2, and the groove 11 is used to store clear water for cooling during welding, and the cylinder 3 needs The B through hole 31 is used to install the high-voltage ceramic seal part 4; the A through hole 21 on the protective cover 2 needs ...

Embodiment 2

[0035] On the basis of the above-mentioned embodiments, this embodiment combines the attached figure 2 and 3 Said, further defined, the distance between the two ends of the cylinder 3 is less than the distance between the notch of the groove 11 and the groove bottom of the groove 11, and the diameter of the A through hole 21 is smaller than that of the B through hole 31 close to The diameter of one end of the protective cover plate 2. Wherein the notch of cylinder 3 lower than groove 11 is set, after protective cover plate 2 is installed in protective box 1, protective cover plate 2 can keep in touch with the clear water in groove 11, when carrying out high-temperature brazing, utilize water The volatilization produces steam to cool down the protective cover plate 2 and the melted solder, so that the temperature is not higher than 100 degrees; it is useful to protect the high-voltage ceramic sealing part 4 and the insulating layer in the high-voltage ceramic sealing part 4. ...

Embodiment 3

[0039] On the basis of the above-mentioned embodiments, this embodiment combines the attached figure 2 and 3 As shown, it is further defined that the B through hole 31 is composed of parts A and B and is in a stepped shape, and the part A is close to the protective cover 2 and has a diameter smaller than that of the part B. Wherein the stepped B through hole 31 is set, so that each section of the stepped high voltage ceramic seal part 4 is closer to the side wall of the B through hole 31; because it is closer to the inner wall of the B through hole 31, its own heat is quickly absorbed B The inner wall of the through hole 31 is sucked away, and will not accumulate in the through hole, causing the insulating layer in the high voltage ceramic sealing part 4 to melt due to high temperature.

[0040] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com