A low temperature current transformer coil

A current transformer, low-temperature technology, applied in the direction of inductors, transformers/inductor coils/windings/connections, coil manufacturing, etc., can solve problems such as deformation of manganese-copper wires that are not mentioned, and achieve insulation strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

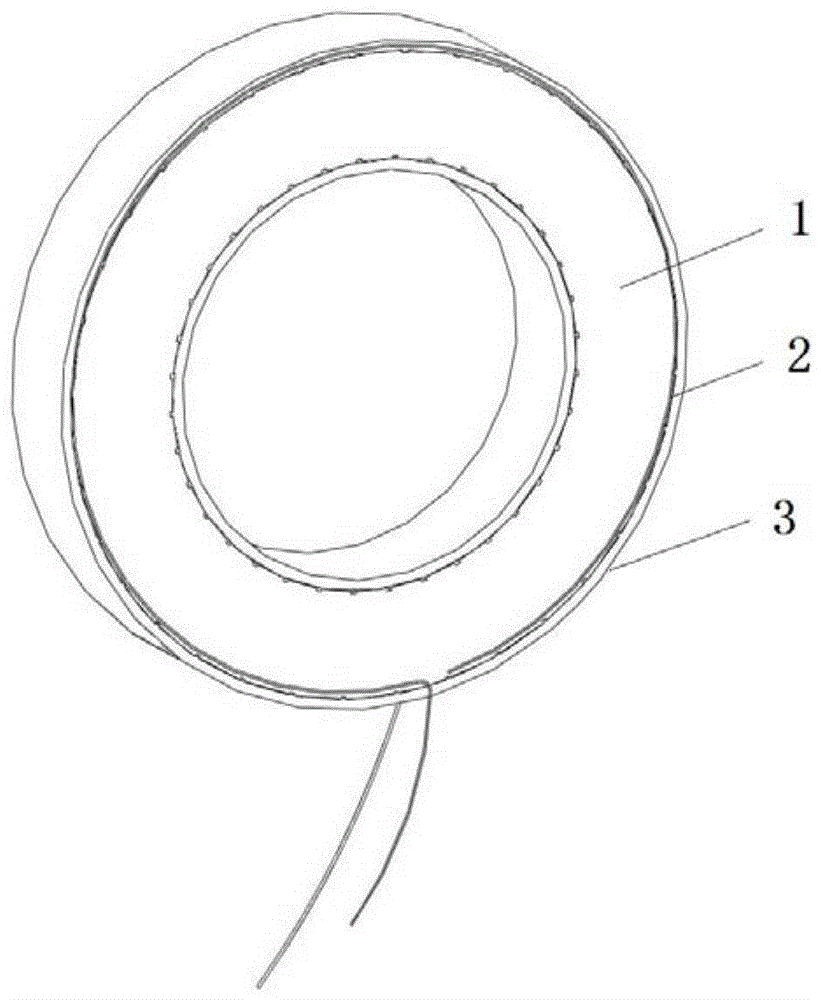

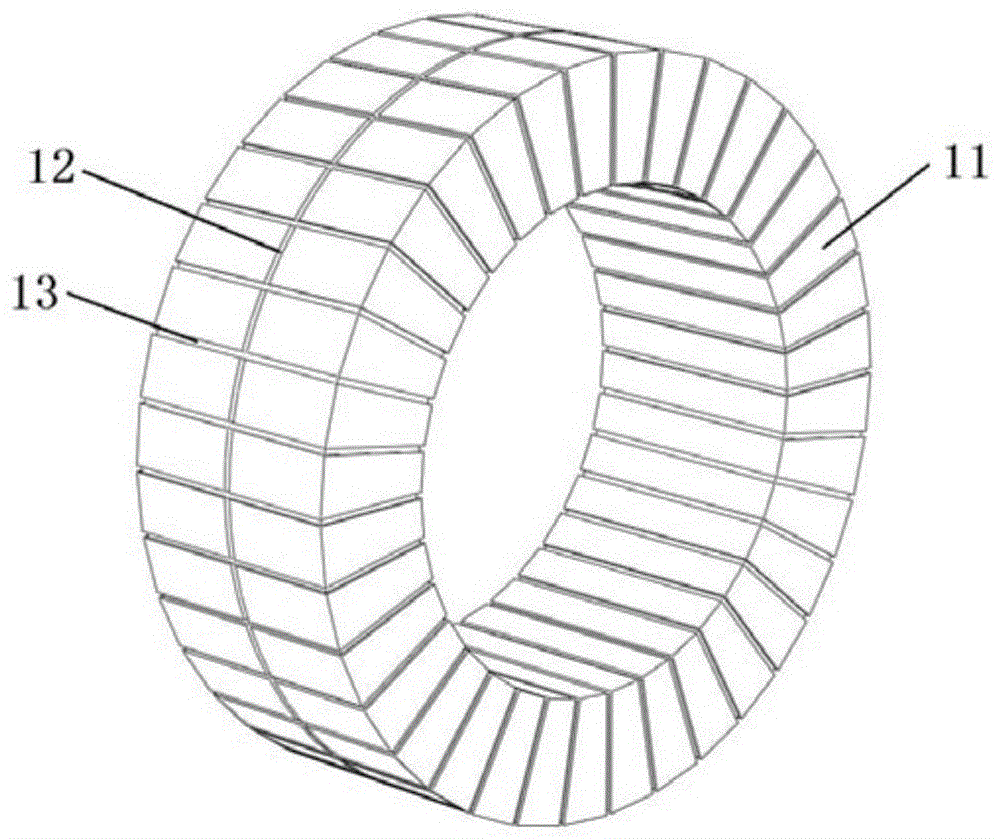

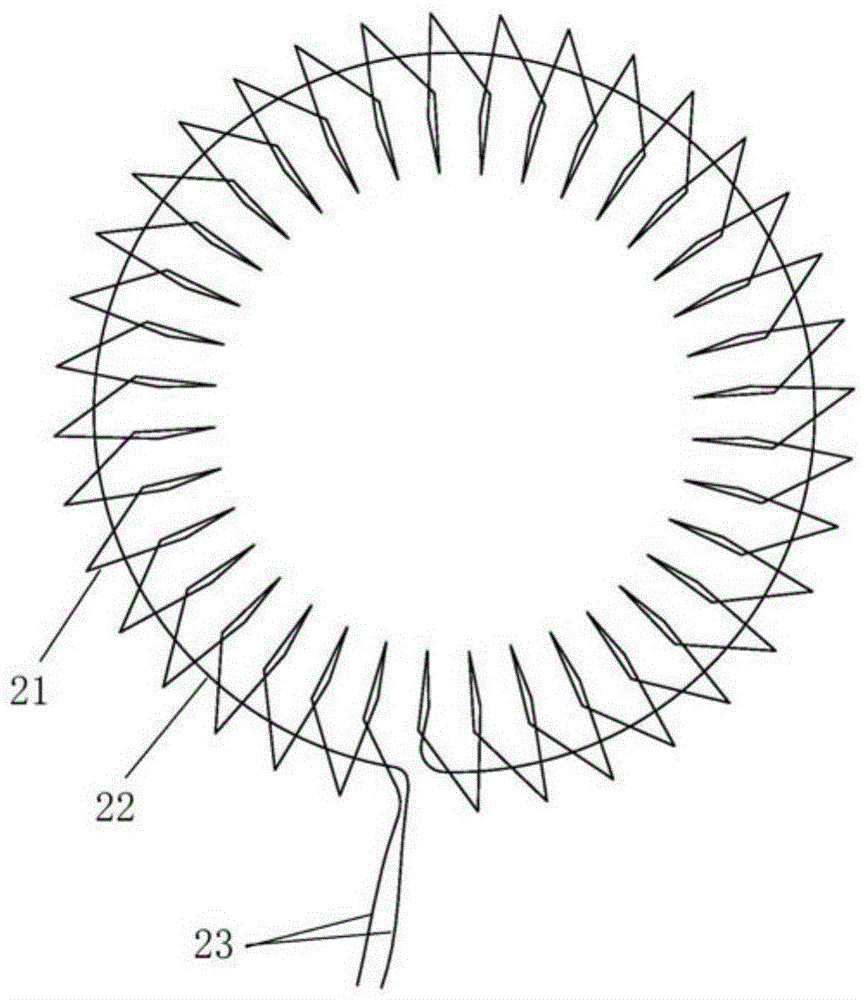

[0029] Such as figure 1 As shown, the low-temperature current transformer coil of the present invention mainly includes a low-temperature rubber inner frame 1 , low-temperature insulated wire turns 2 and a low-temperature rubber outer frame 3 . First, the low-temperature rubber inner frame 1 is manufactured and processed; secondly, the low-temperature insulating wire turns 2 are uniformly wound on the low-temperature rubber inner frame 1 as required; finally, the low-temperature rubber outer frame 3 is manufactured and processed. The low-temperature rubber inner frame 1 is located at the center of the low-temperature current transformer coil, and is a hollow ring structure; the low-temperature insulated wire turns 2 adopt low-temperature insulating enameled wires that can withstand not lower than -208°C along the diameter of the low-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com