Clear dimension compression molding method for phenolic resin based complex profile product

A technology of phenolic resin and complex profile, which is applied in the field of phenolic resin-based molded composite material preparation, can solve the problems of high fiber content at the thin wall of the product, difficult machining, and long process, so as to improve the material rate and product quality, Good surface quality and interior quality, good surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: A molding method of a certain type of wave-transparent product.

[0024] (1) Prepare the premix.

[0025] The conventional preparation method is adopted: the high-silica glass fiber cut-to-length yarn is immersed in the aminophenolic resin (616#), and the preparation is carried out according to the following weight ratio: high-silica glass fiber cut-to-length yarn: phenolic resin = 60: 40, repeatedly extruded Press until the impregnation is uniform, then dry, loosen, and dry to make a fibrous premix, and then cut the premix according to the required length.

[0026] (2) Preform 5 equivalent slabs.

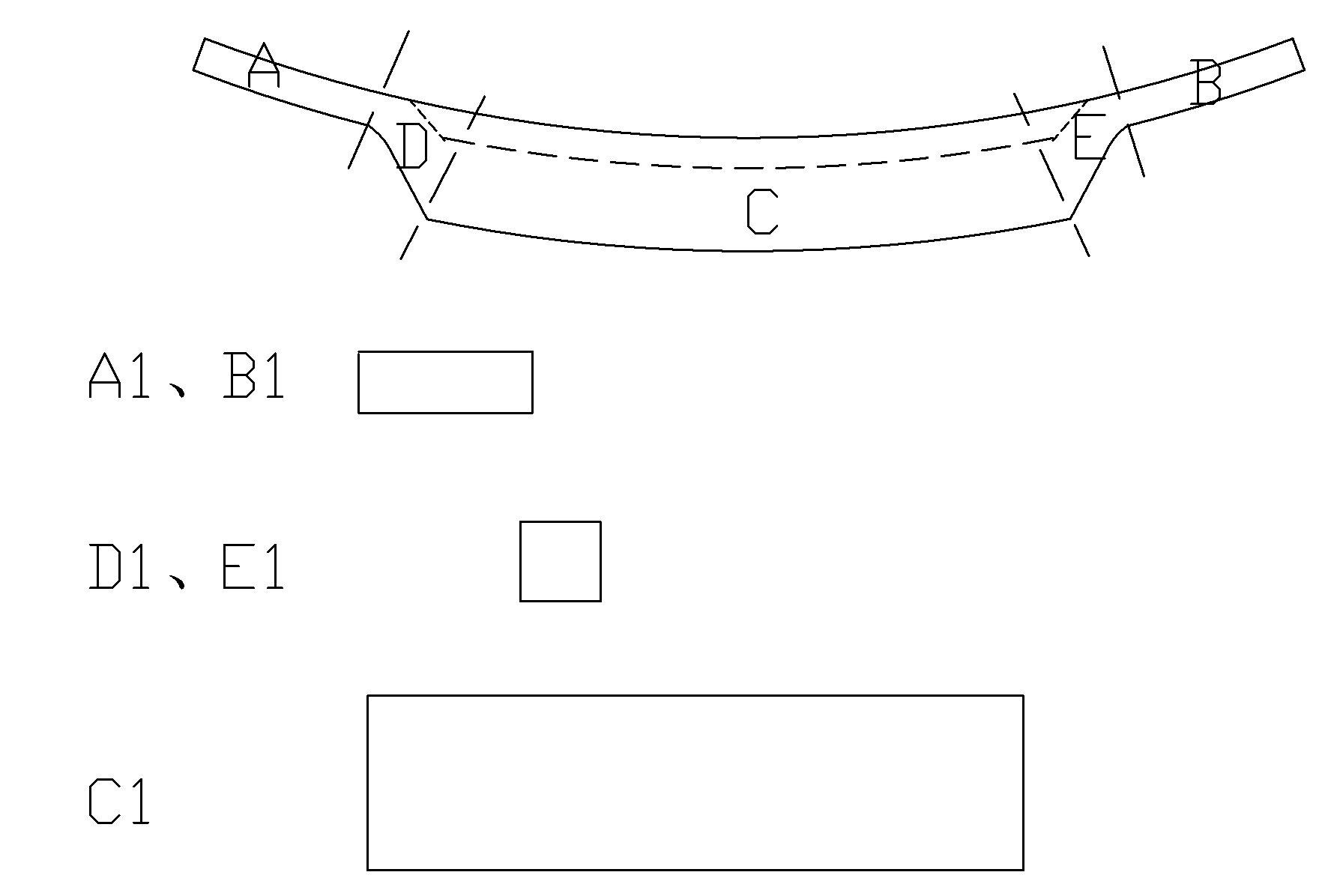

[0027] First divide the corresponding 5 equivalent flat plates: determine the geometric dimensions of the wave-transparent product according to the requirements, and divide them into blocks, see figure 1 As shown, it is divided into 5 parts A, B, C, D, and E, and corresponds to 5 equivalent plates of A1, B1, C1, D1, and E1. It is required that A and A1, B and B1...

Embodiment 2

[0036] Example 2: A molding method of a certain type of wave-transparent insert.

[0037] (1) Prepare the premix.

[0038] Adopt conventional preparation method: impregnate high-silica glass fiber cut-to-length yarn in aminophenol-formaldehyde resin (616#), prepare according to the following weight ratio: high-silica glass fiber cut-to-length yarn: phenolic resin = 60: 40 and repeatedly extrude , until the impregnation is uniform, then dry, loosen, and dry to make a fibrous premix, and then cut the premix according to the required length.

[0039] (2) Preform 5 equivalent slabs.

[0040] First divide the corresponding 5 equivalent flat plates: determine the geometric size and block of the wave-transparent product according to the requirements, see figure 1 As shown, it is divided into 5 parts A, B, C, D, and E, and corresponds to 5 equivalent plates of A1, B1, C1, D1, and E1. It is required that A and A1, B and B1, C and C1, and D The thicknesses of D1, E, and E1 are basica...

Embodiment 3

[0045] Embodiment 3: The forming method of a certain type of protective cap.

[0046] (1) Premix preparation.

[0047]Adopt conventional preparation method: impregnate high-silica glass fiber cut-to-length yarn in aminophenol-formaldehyde resin (616#), prepare according to the following weight ratio: high-silica glass fiber cut-to-length yarn: phenolic resin = 60: 40 and repeatedly extrude , until the impregnation is uniform, then dry, loosen, and dry to make a fibrous premix, and then cut the premix according to the required length.

[0048] (2) Preform 5 equivalent slabs.

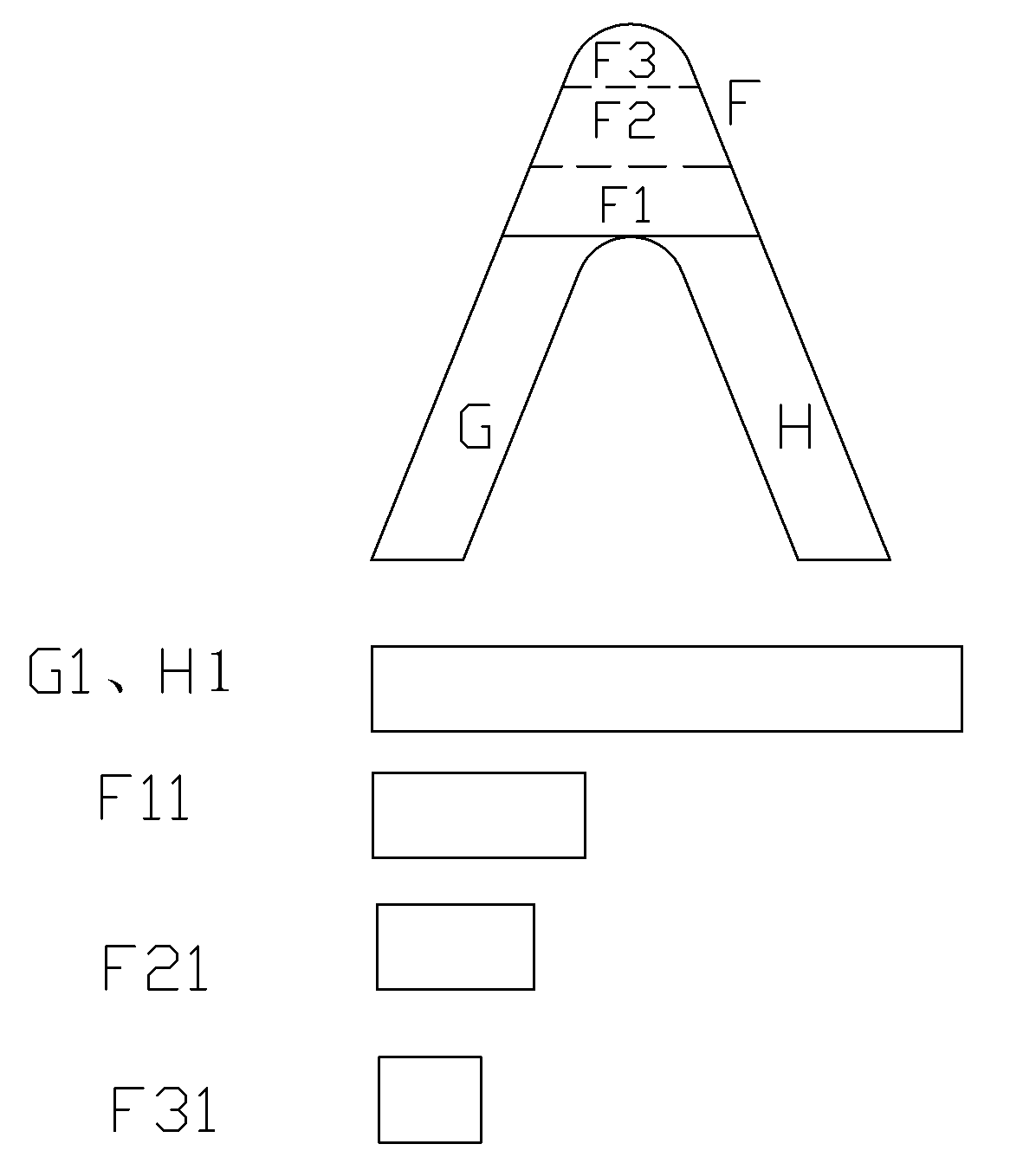

[0049] Divide the corresponding 5 equivalent plates first: determine the geometric size of the wave-transparent product according to the requirements and divide it into blocks, see figure 2 As shown, it is divided into five parts: F1, F2, F3, G, and H, and corresponds to five equivalent plates of F11, F21, F31, G1, and H1. The total thickness of F and F1+F2+F3, The thicknesses of G and G1, H and H1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com