Handheld high-speed electric arc machining equipment and method

An arc machining, hand-held technology, applied in the field of hand-held high-speed arc machining equipment, can solve the problems of difficult operation, time-consuming clamping, and difficulty in clamping, so as to ensure the quality and performance of remanufactured products, maintain surface integrity, and process good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

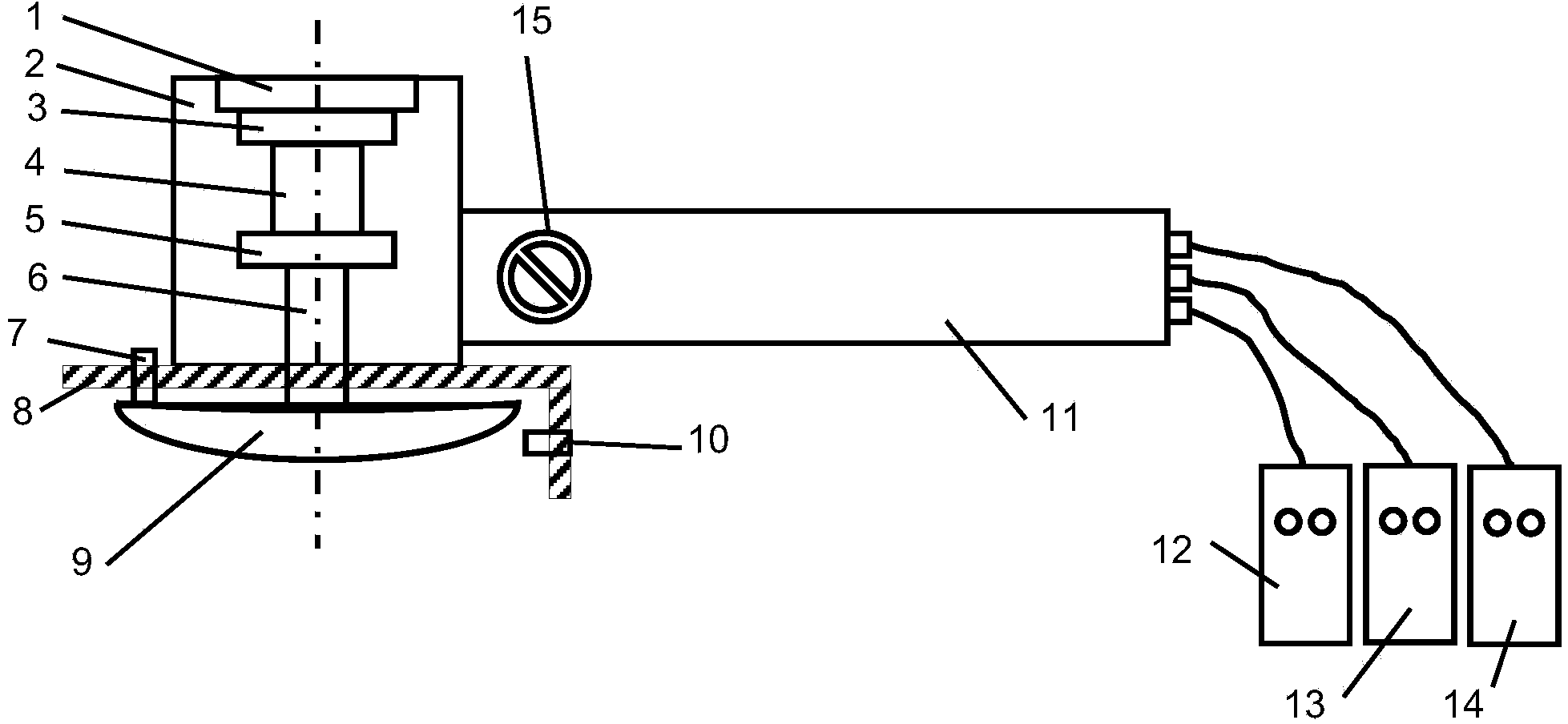

[0032] Such as figure 1 , The motor 1, the coupling 3, the main shaft 4, and the connecting flange 5 are all placed in the housing 2, and the motor 1 drives the main shaft 4 to rotate through the coupling 3. The main shaft 4 drives the horn 6 to rotate through the connecting flange 5 . The horn 6 passes through the lower end of the housing 2 and is fixedly connected to the conductive grinding wheel 9, and is insulated from each other. The conductive grinding wheel 9 is connected to the cathode of the arc processing control power supply 13 through the brush 7; the brush 7 is fixed on the protective cover 8 and is insulated from the protective cover. The rotation speed of the grinding wheel can be adjusted through the adjustment knob 15 of the rotation speed of the grinding wheel. The rotation speed of the grinding wheel is usually less than 50...

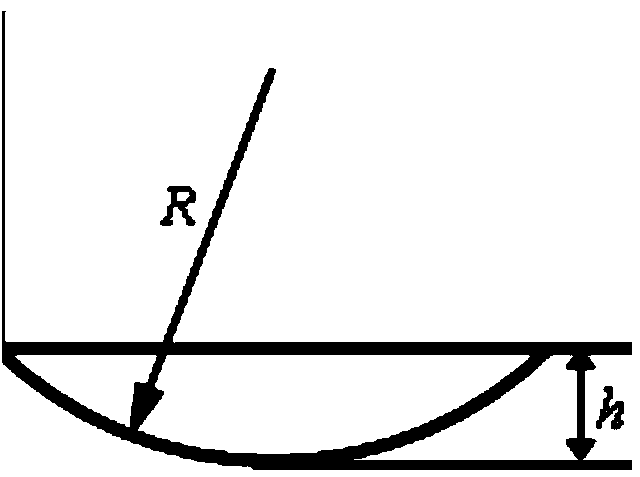

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com