Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Zirconocene dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconocene dichloride is an organozirconium compound composed of a zirconium central atom, with two cyclopentadienyl and two chloro ligands. It is a colourless diamagnetic solid that is somewhat stable in air.

Preparation method of silicon carbide/zirconium carbide composite ceramic

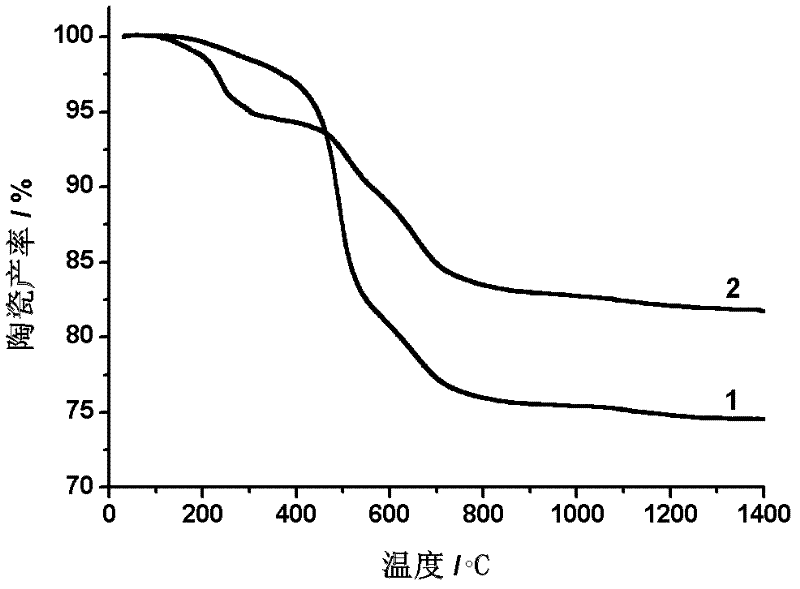

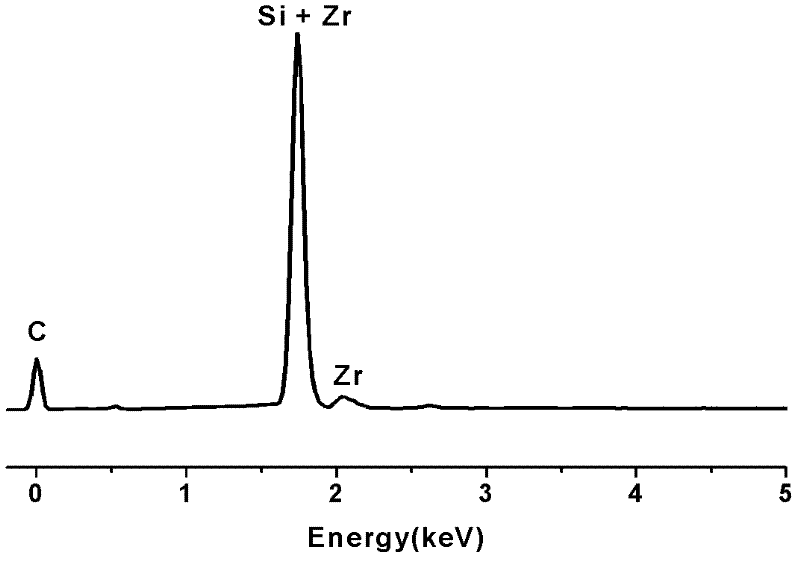

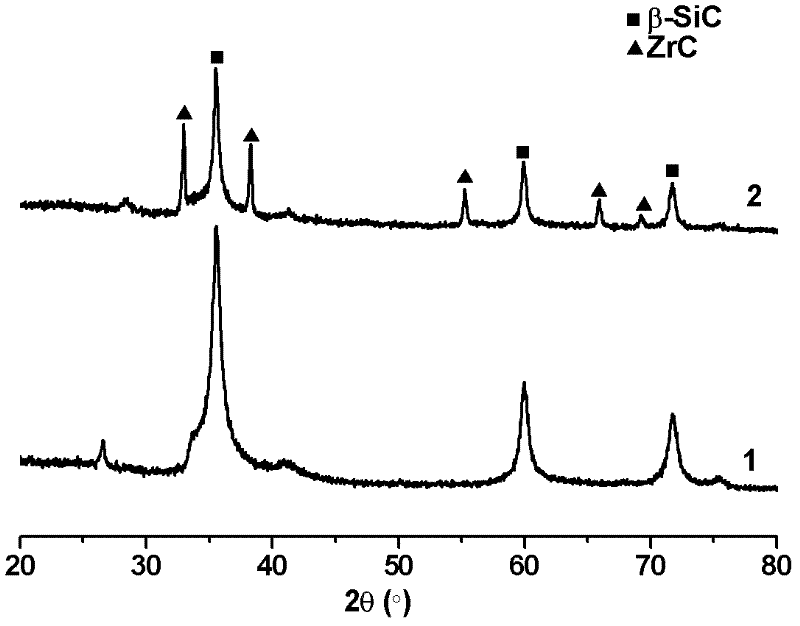

The invention relates to a preparation method of silicon carbide / zirconium carbide composite ceramic, and relates to inorganic nonmetal material composite ceramic. The preparation method comprises the steps of: dissolving bis(cyclopentadienyl) zirconium dichloride with a solvent under the protection of inert atmosphere, and adding liquid hyperbranched polycarbosilane to obtain a mixture A; and distilling the mixture A under reduced pressure under the protection of inert atmosphere to remove the solvent, and carrying out cracking reaction in inert atmosphere to obtain the silicon carbide / zirconium carbide composite ceramic. According to the invention, bis(cyclopentadienyl) zirconium dichloride is used as a zirconium source, and is used for catalyzing the crosslinking reaction of liquid hyperbranched polycarbosilane, so as to increase ceramic yield; zirconium carbide can inhibit the growth of silicon carbide microcrystal grains, and improve high-temperature resistance and oxidation resistance of the composite material; the zirconium content in the composite ceramic can be controlled by controlling the content of bis(cyclopentadienyl) zirconium dichloride in a hybrid precursor; the liquid hyperbranched polycarbosilane / bis(cyclopentadienyl) zirconium dichloride hybrid precursor is free of oxygen, thus the gas escaped in the high-temperature cracking process is reduced; the ceramic has high compactness; and the preparation method is simple to operate, and is easy for engineering.

Owner:XIAMEN UNIV

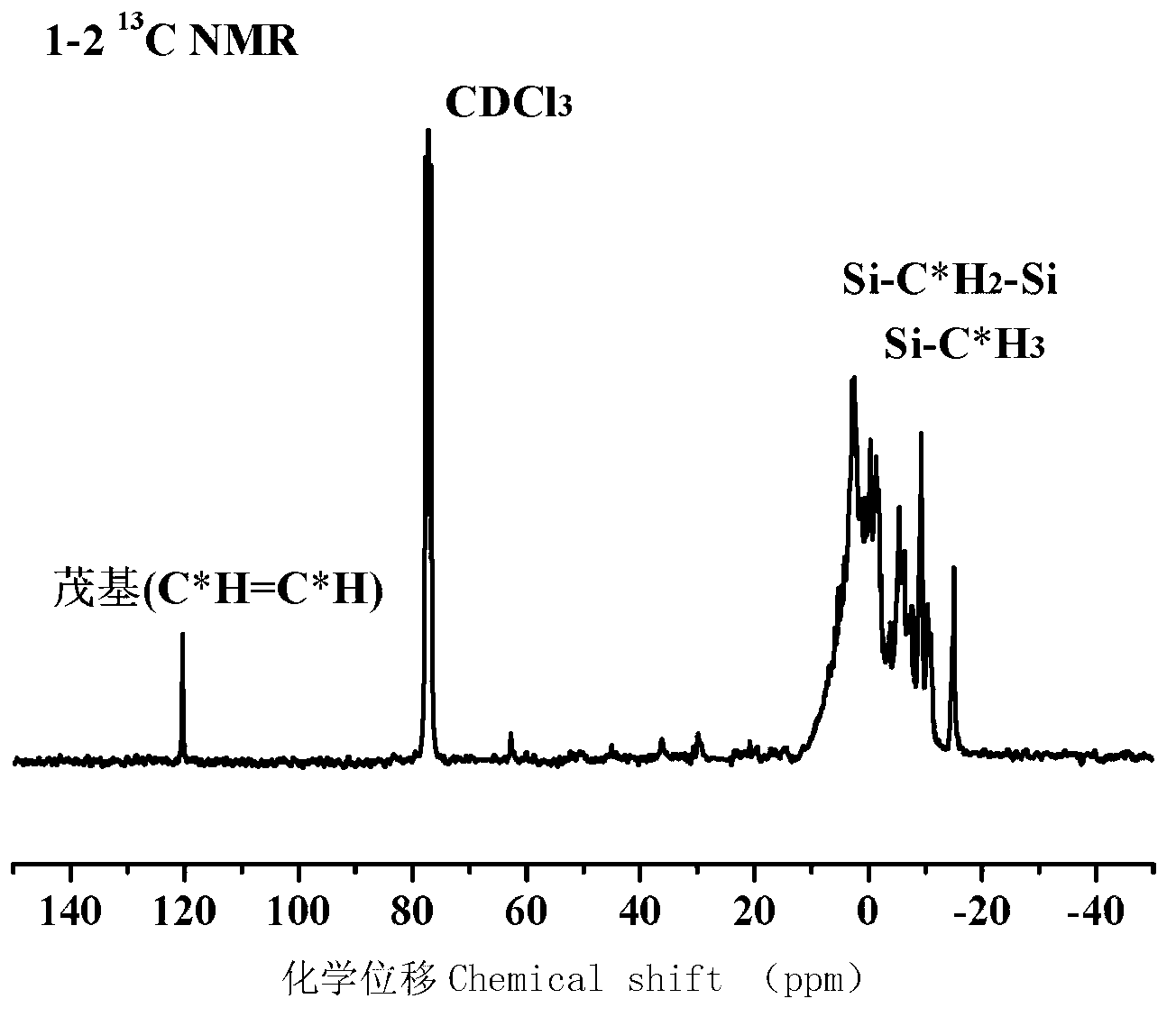

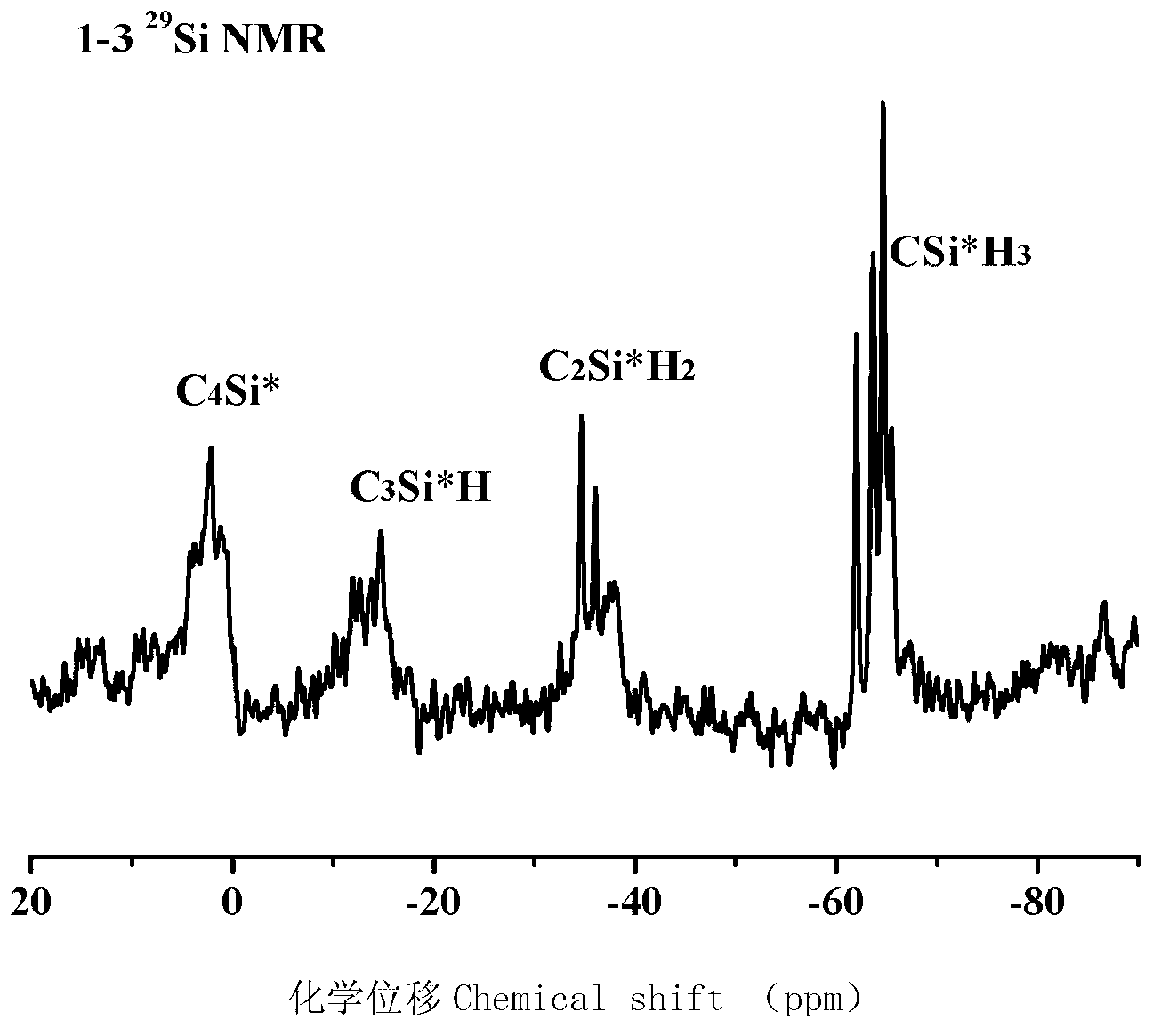

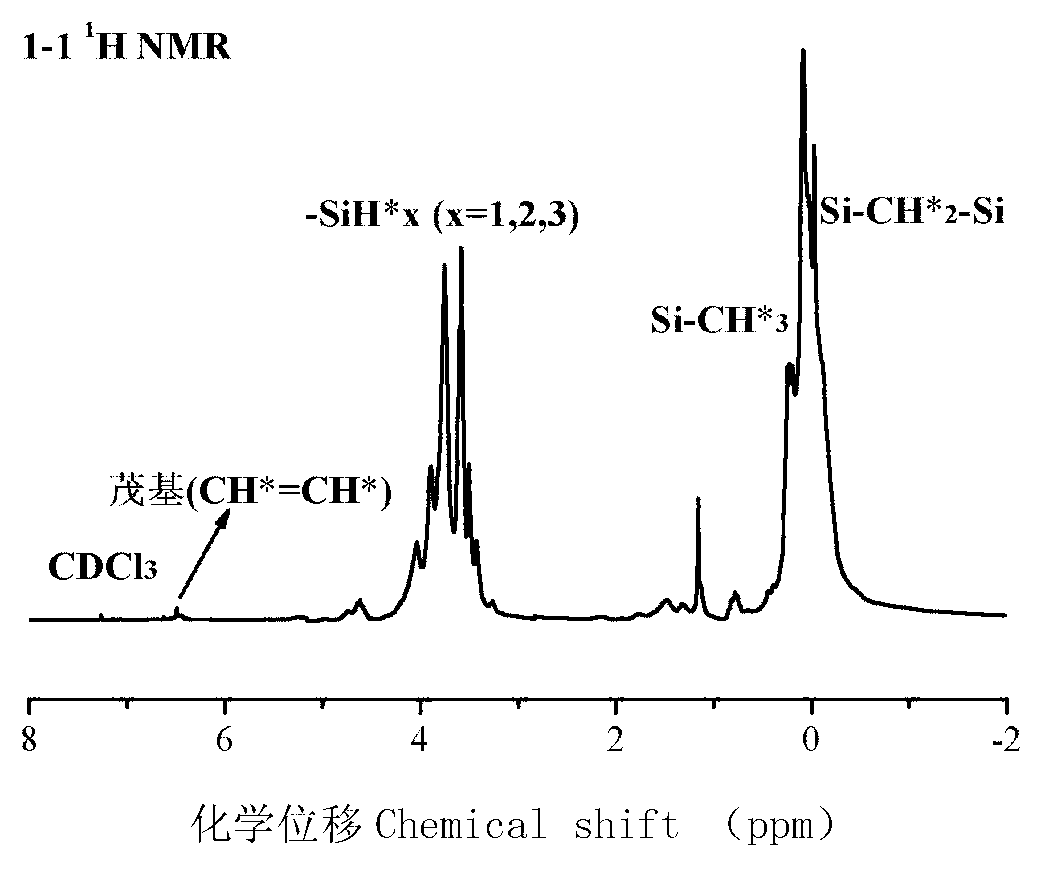

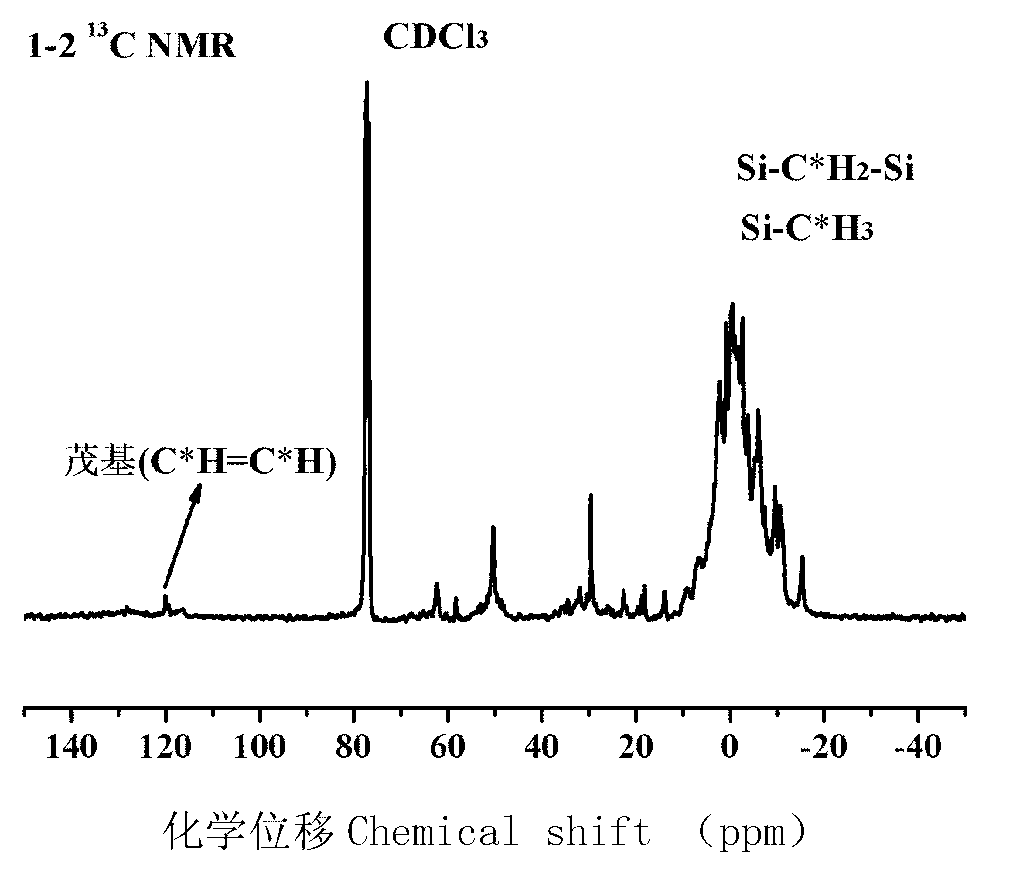

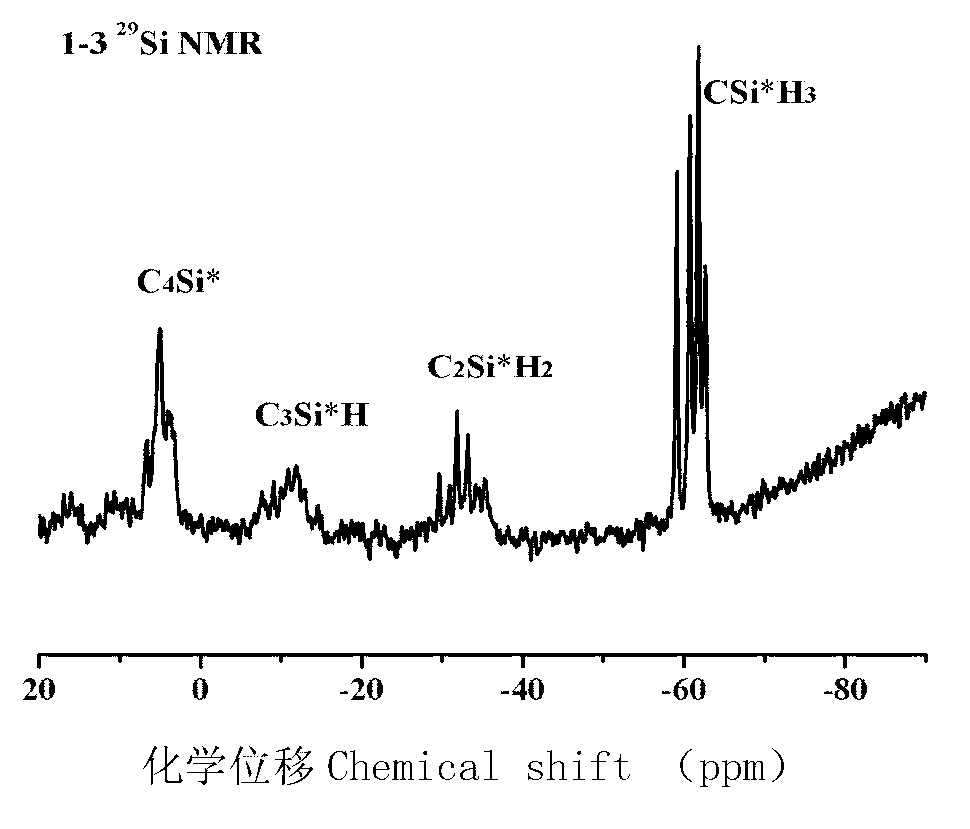

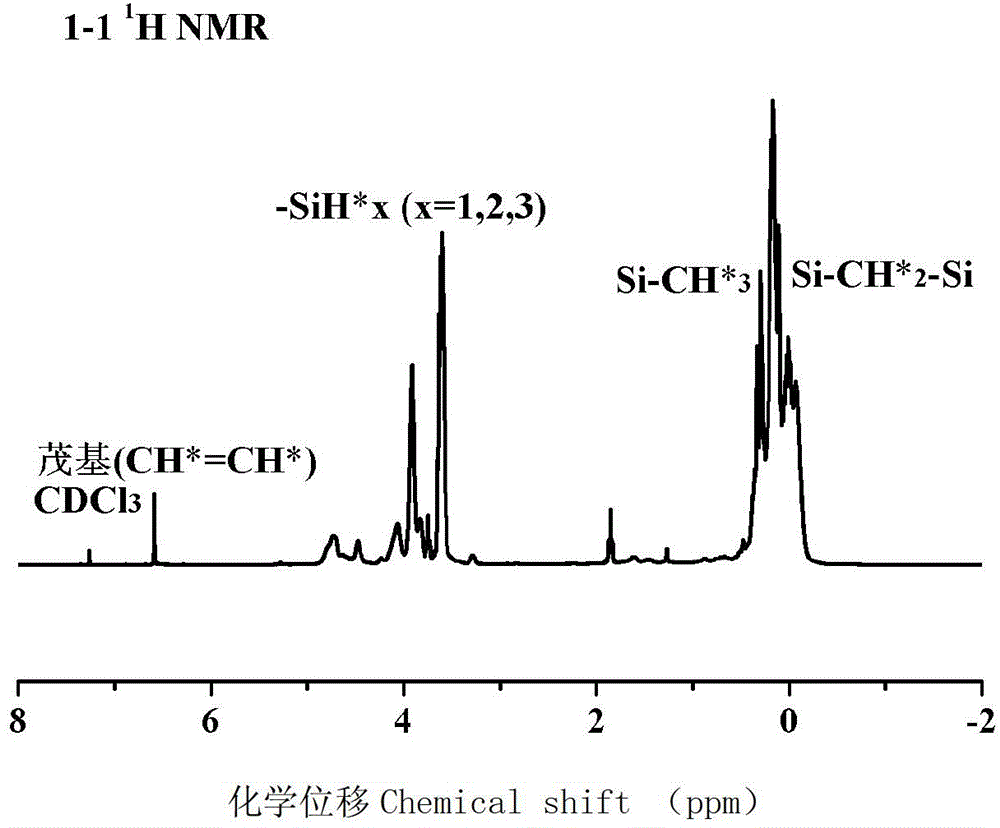

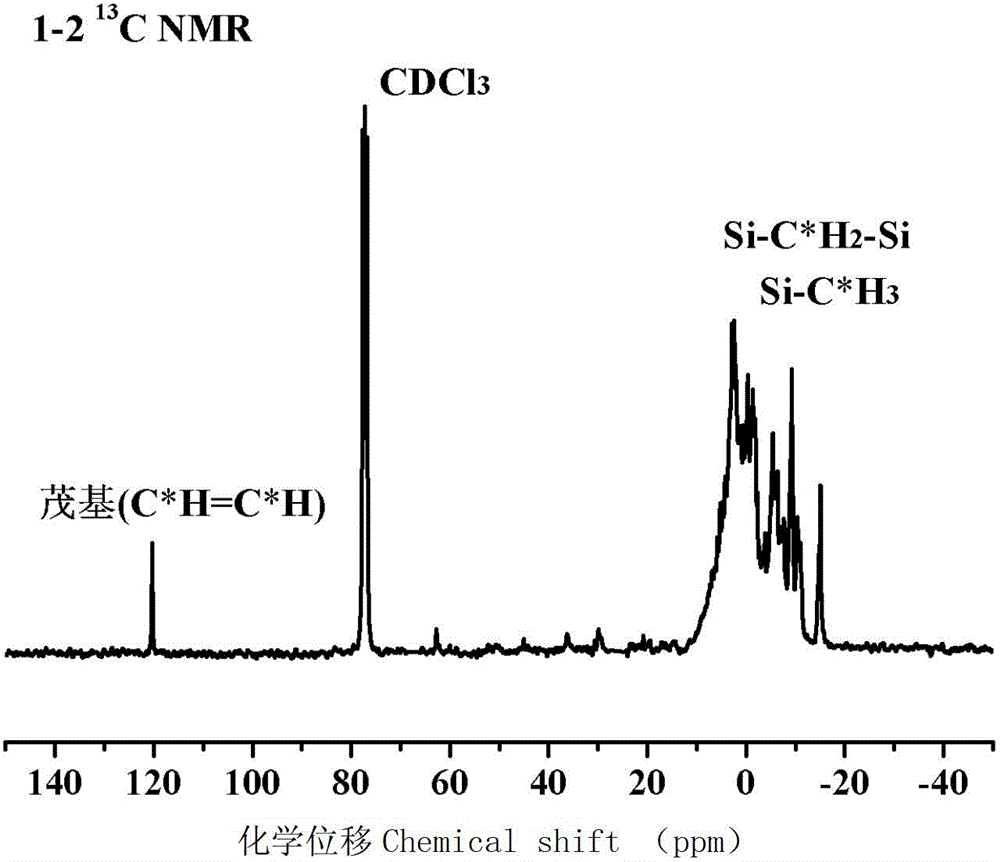

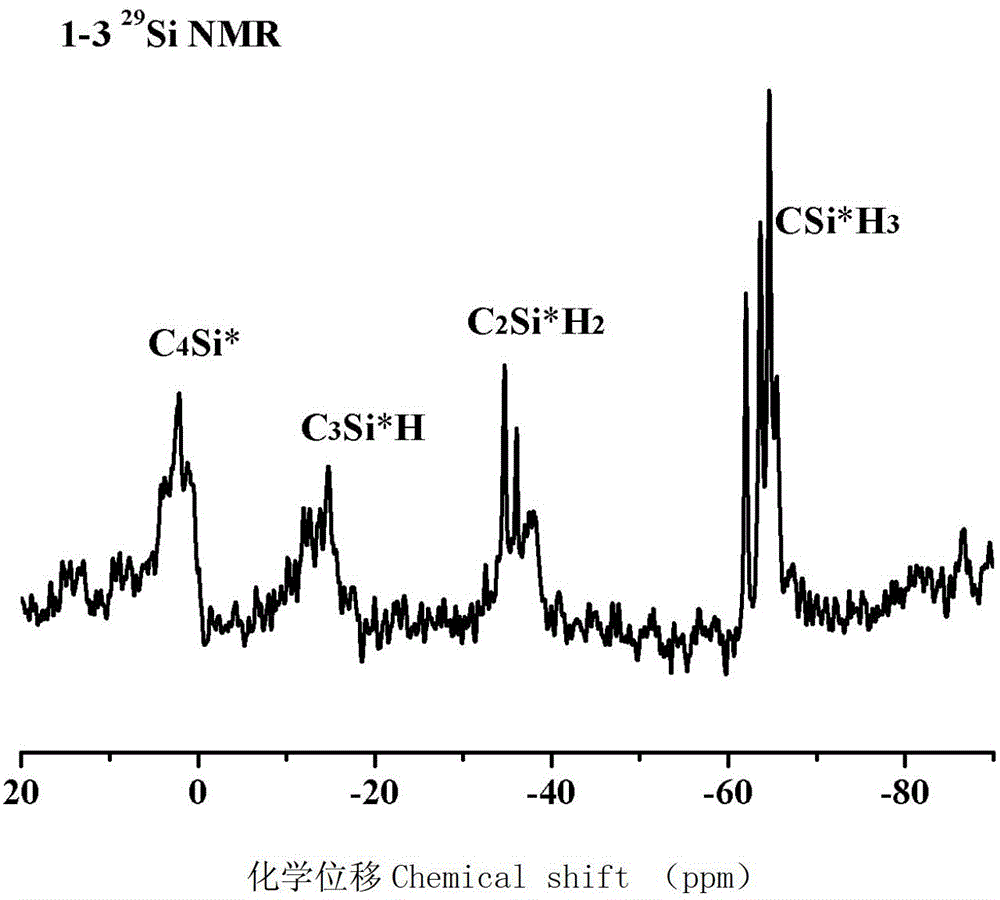

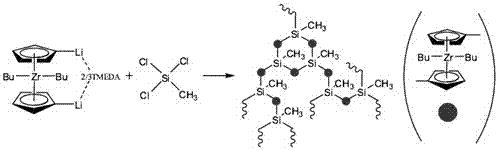

Method for preparing liquid anaerobic polyzirconocarbosilane

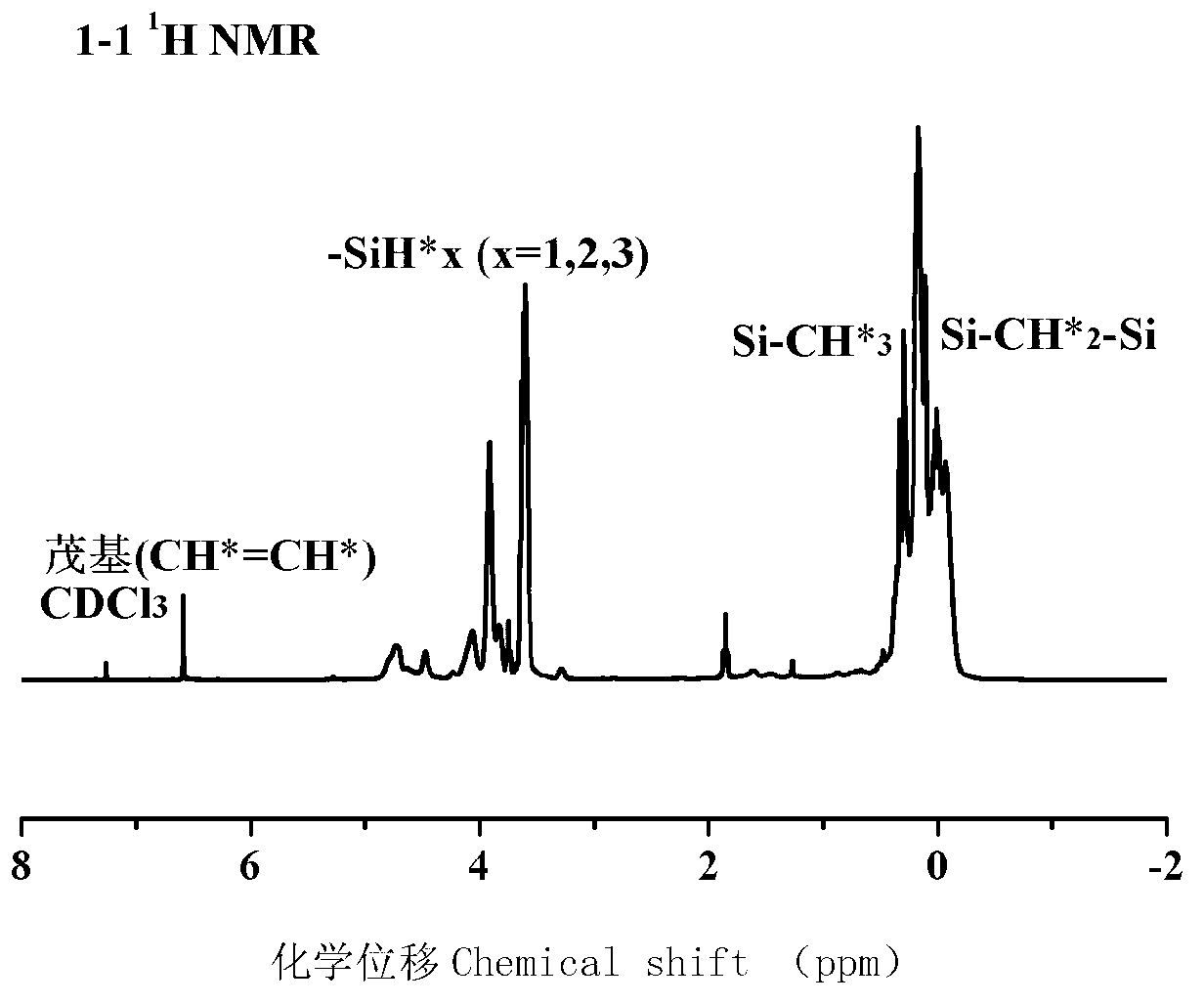

The invention relates to a preparation method of a compound, in particular to a method for preparing liquid anaerobic polyzirconocarbosilane, relates to a preparation method of a compound, and provides a method for directly preparing the liquid anaerobic polyzirconocarbosilane through binary or ternary polymerization of chloromethylsilane and zirconocene dichloride. The method comprises the steps as follows: 1), under the protection of an inert atmosphere, the chloromethylsilane and the zirconocene dichloride are mixed simultaneously and dissolved in absolute ether; 2), magnesium metals are added into a mixed solution obtained in the step 1) in batches for reaction; 3), under the protection of the inert atmosphere, a reducing agent is added in batches into a reaction mixed material obtained in the step 2) for reaction; and 4), under the protection of the inert atmosphere, an organic solvent is added into a reaction mixed material obtained in the step 3), an organic phase is extracted, standing is performed, an upper-layer organic phase is separated, the organic solvent is removed through filtration, and the liquid anaerobic polyzirconocarbosilane is obtained.

Owner:XIAMEN UNIV

Method for preparing liquid anaerobic polytitanocarbosilane

The invention discloses relates to a preparation method of a compound, in particular to a method for preparing liquid anaerobic polytitanocarbosilane, and provides a method for directly preparing the liquid anaerobic polytitanocarbosilane through binary or ternary polymerization of chloromethylsilane and zirconocene dichloride. The method comprises the steps as follows: 1), under the protection of an inert atmosphere, the chloromethylsilane and the zirconocene dichloride are mixed simultaneously and dissolved in absolute ether; 2), magnesium metals are added into a mixed solution obtained in the step 1) in batches for reaction; 3), under the protection of the inert atmosphere, a reducing agent is added in batches into a reaction mixed material obtained in the step 2) for reaction; and 4), under the protection of the inert atmosphere, an organic solvent is added into a reaction mixed material obtained in the step 3), an organic phase is extracted, standing is performed, an upper-layer organic phase is separated, the organic solvent is removed through filtration, and the liquid anaerobic polytitanocarbosilane is obtained.

Owner:XIAMEN UNIV

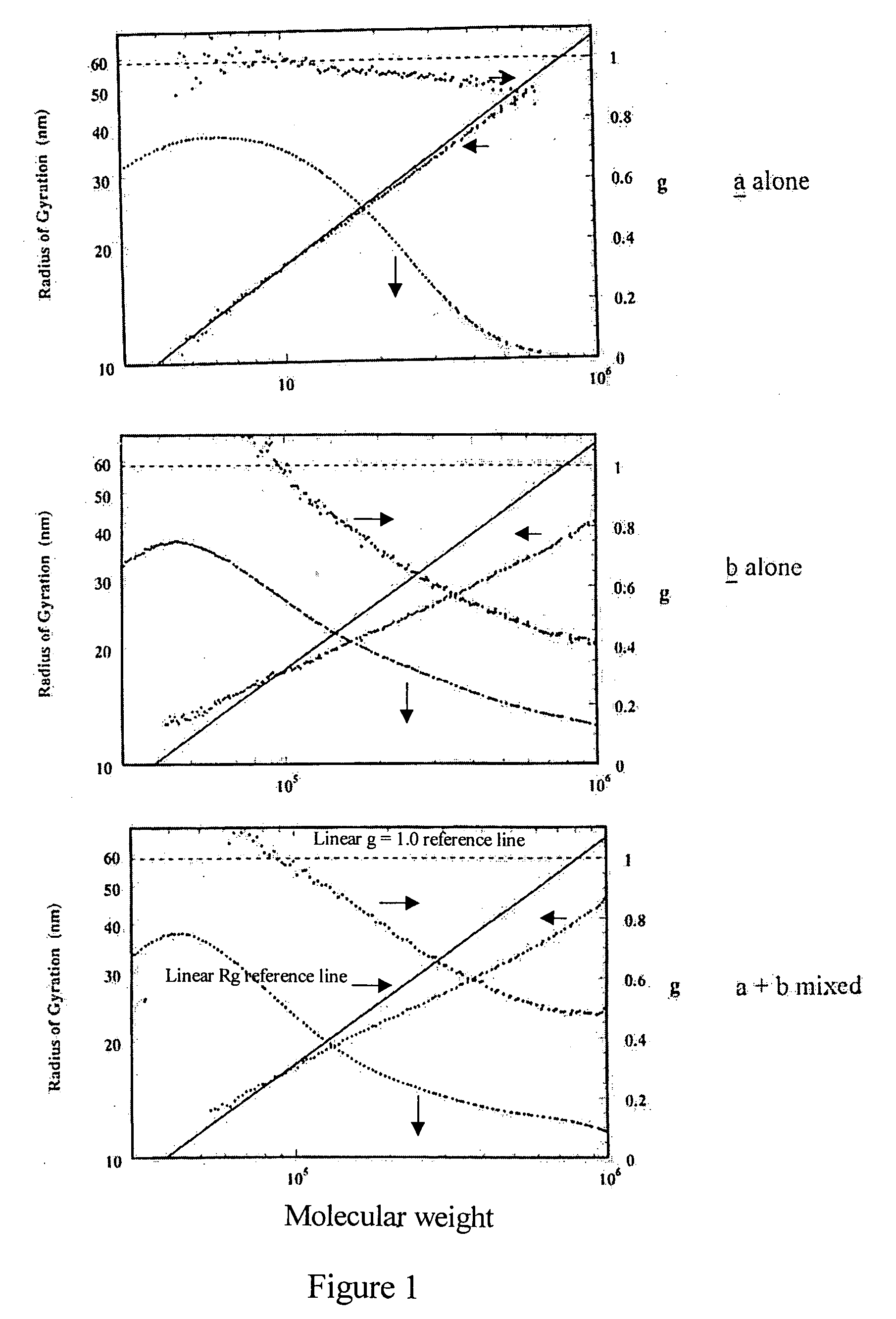

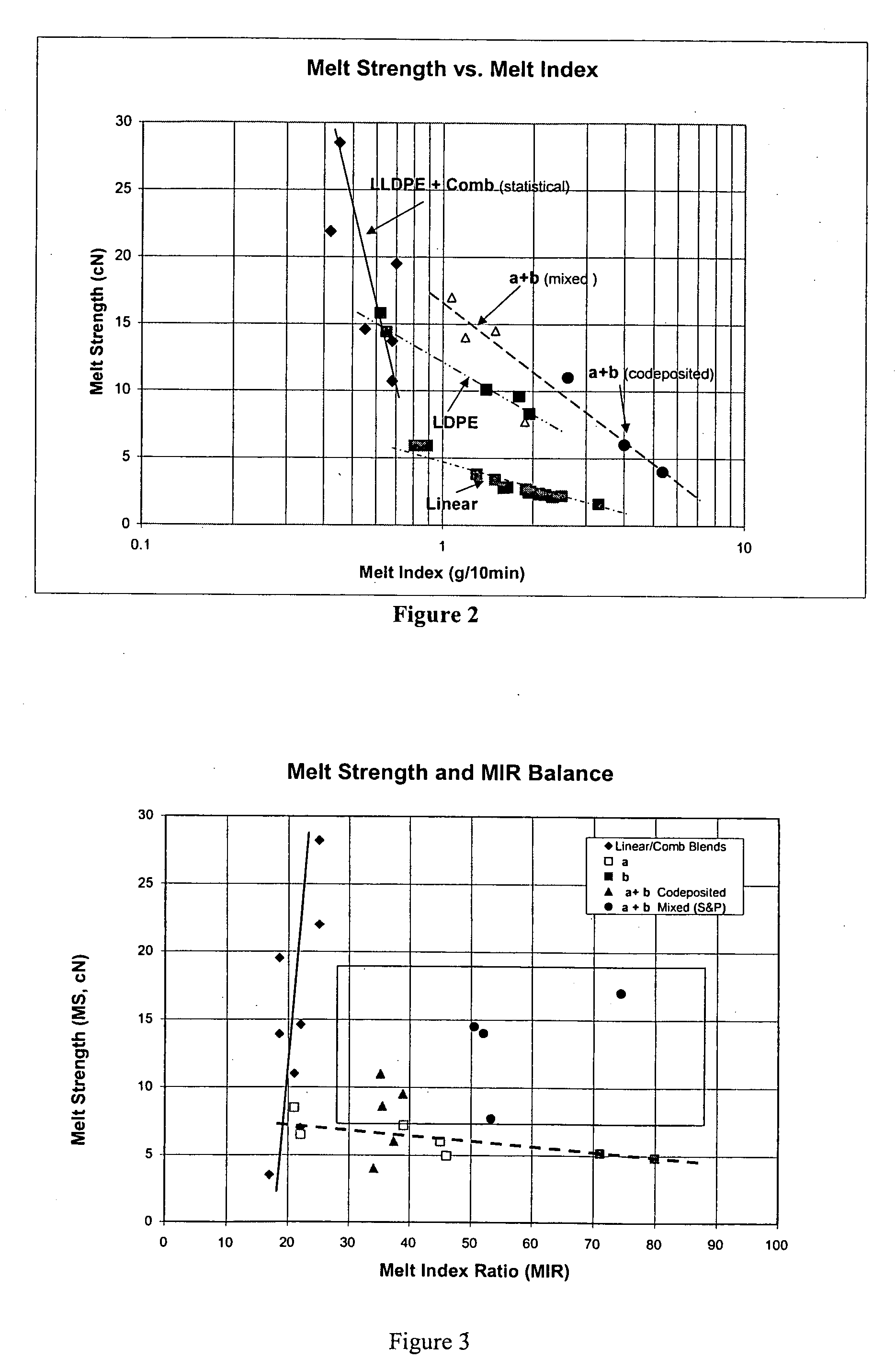

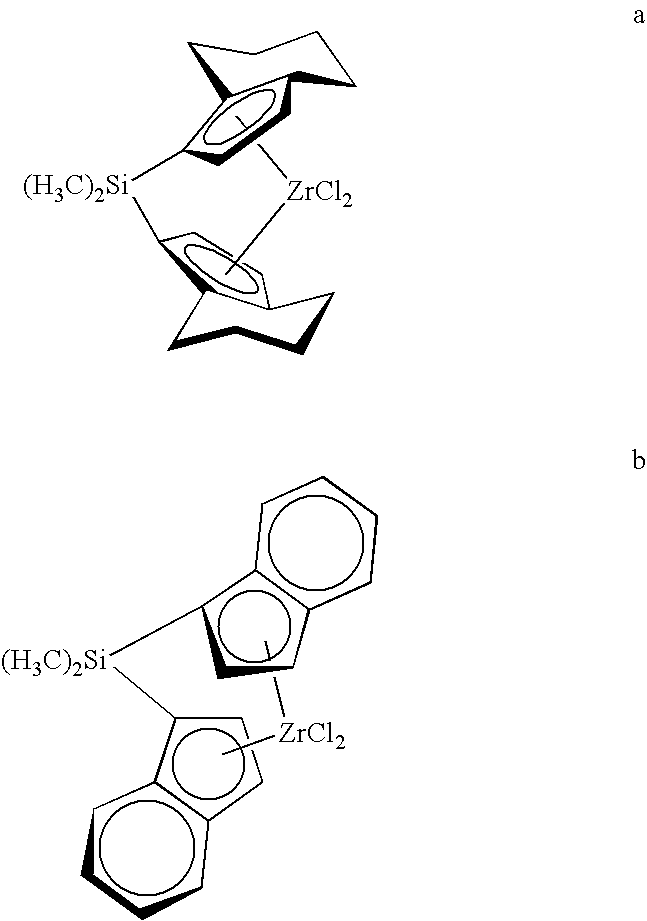

Linear low density polyethylenes with high melt strength and high melt index ratio

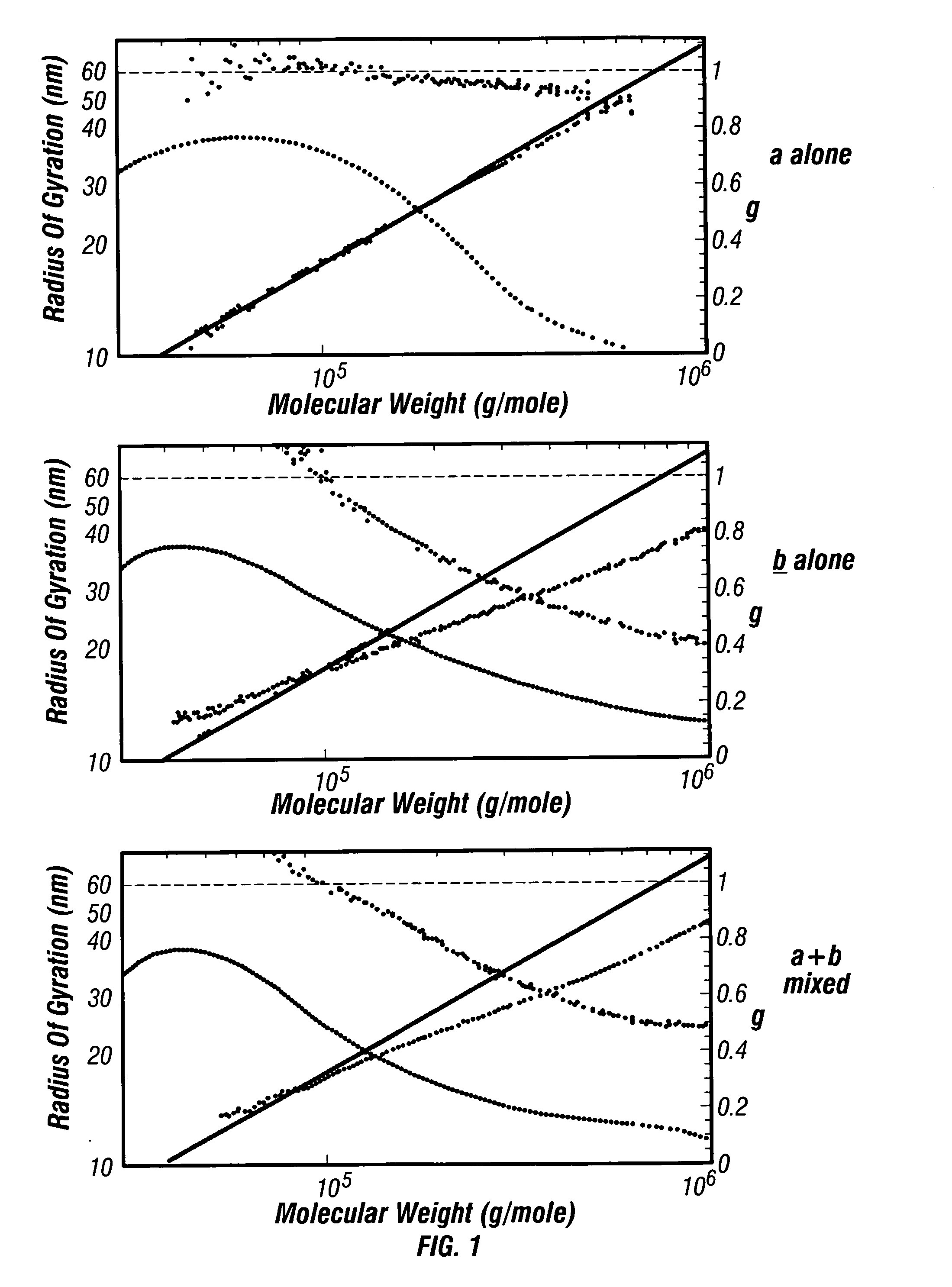

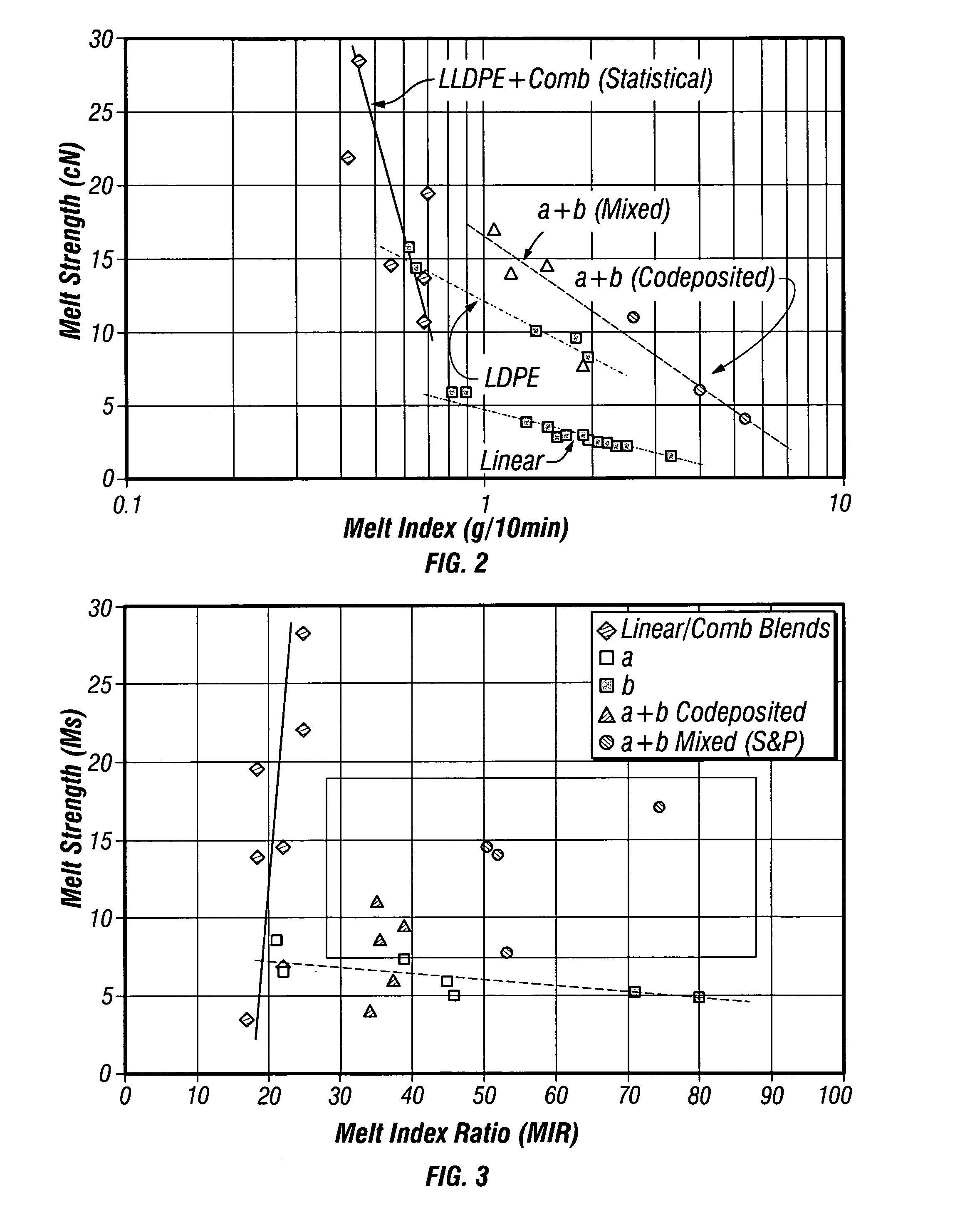

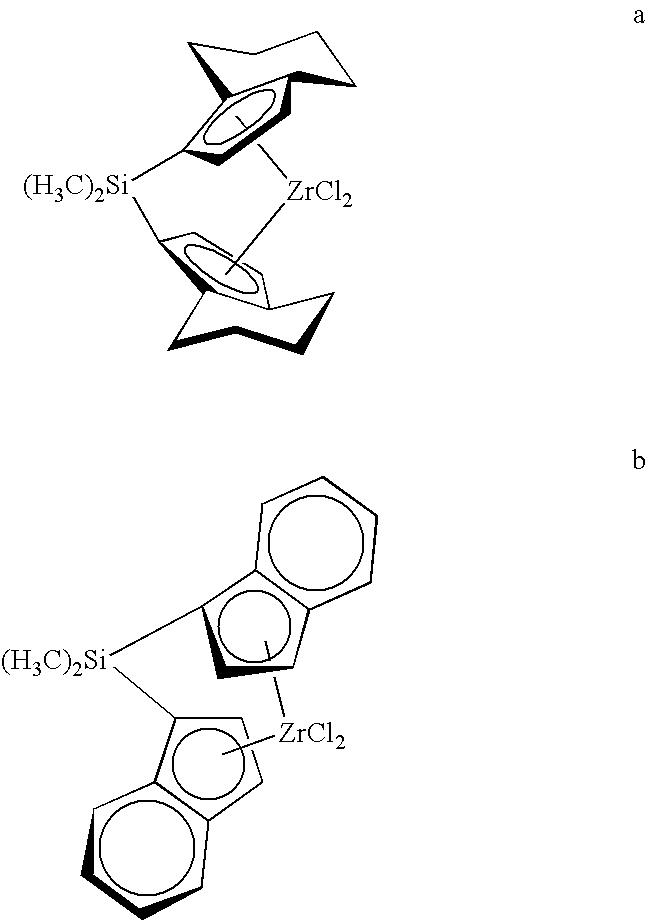

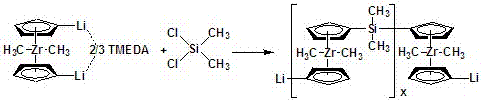

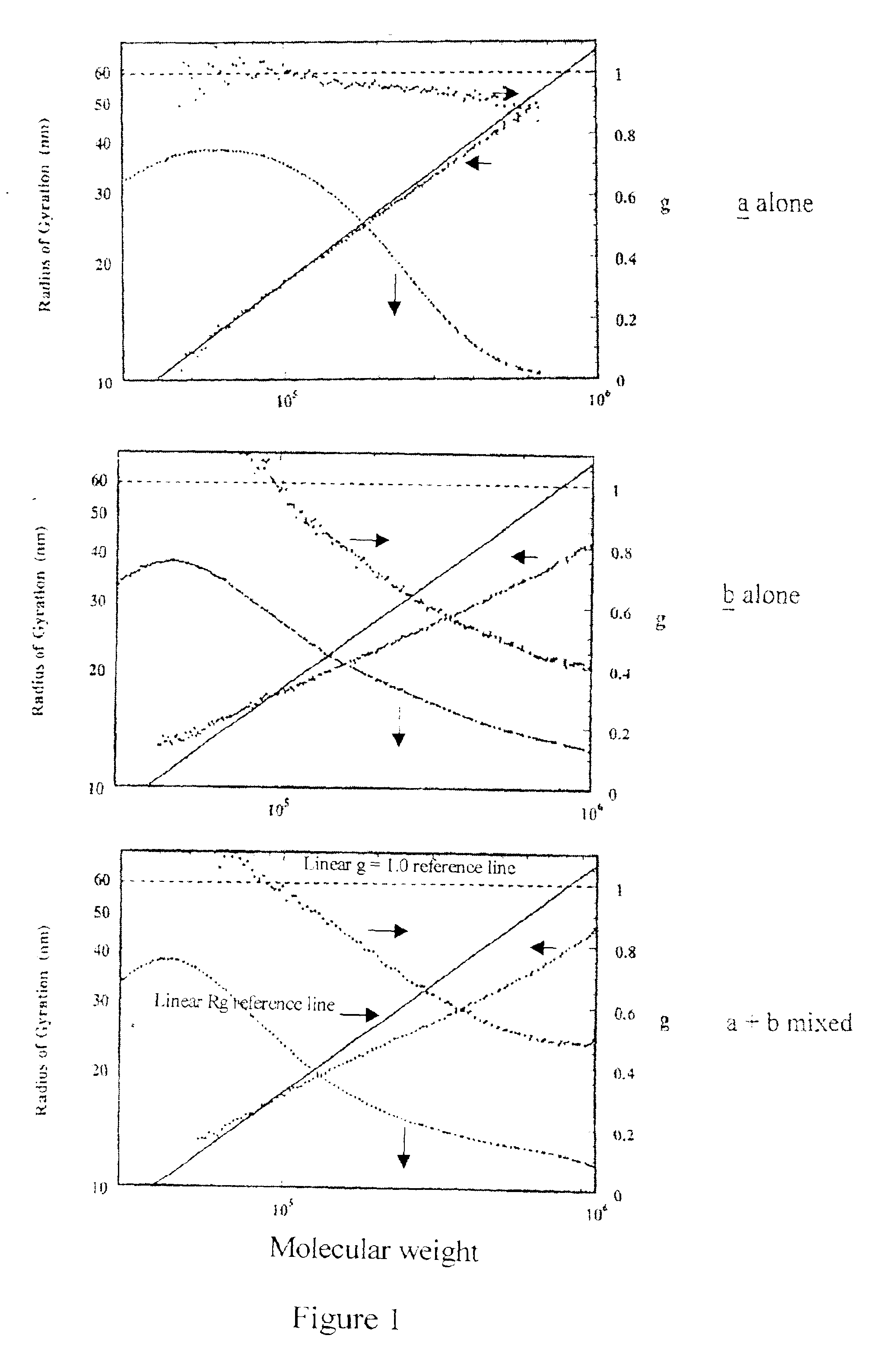

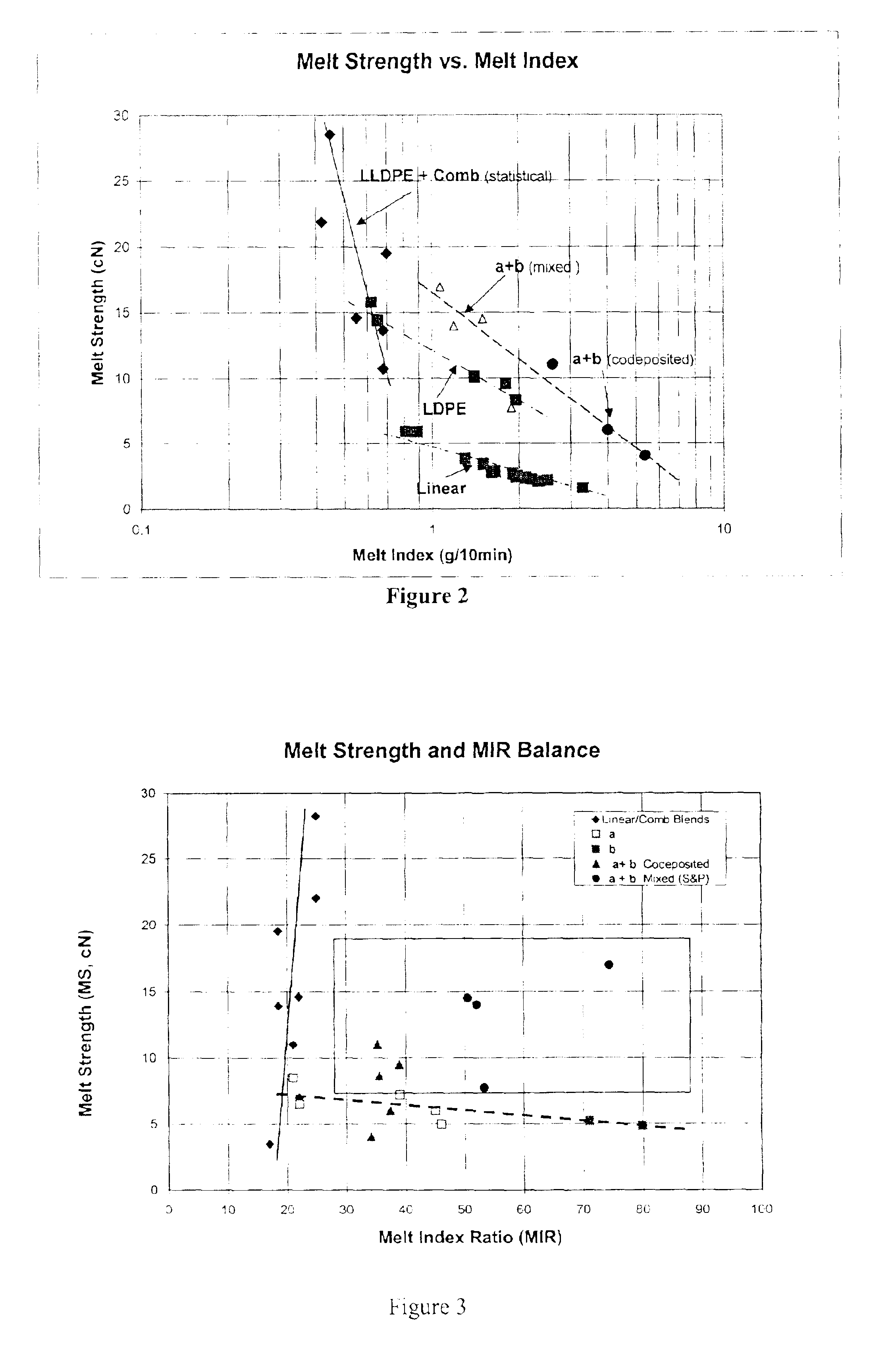

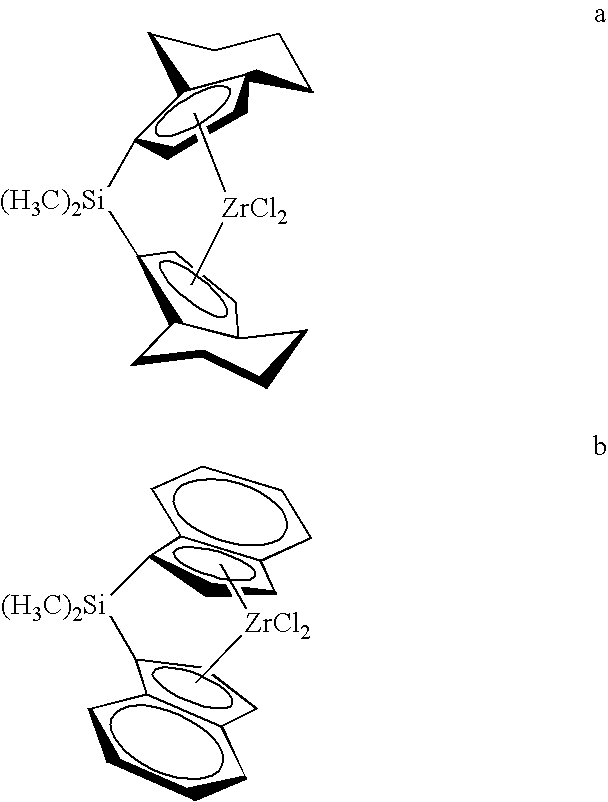

Linear low density polyethylenes (LLDPEs) that have relatively high melt index ratios (MIR) and relatively high melt strength (MS) are described. This combination of melt properties is achieved by a substantially non-blended LLDPE. Catalysts used to produce these polyethylenes are generally a blend of bridged bisindenyl zirconocene dichlorides, where one zirconocene contains saturated indenyls and the other unsaturated indenyls.

Owner:UNIVATION TECH LLC

Linear low density polyethylenes with high melt strength and high melt index ratio

Linear low density polyethylenes (LLDPEs) that have relatively high melt index ratios (MIR) and relatively high melt strength (MS) are described. This combination of melt properties is achieved by a substantially non-blended LLDPE. Catalysts used to produce these polyethylenes are generally a blend of bridged bisindenyl zirconocene dichlorides, where one zirconocene contains saturated indenyls and the other unsaturated indenyls.

Owner:UNIVATION TECH LLC

Method of promoting olefin polymerization

InactiveUS8188199B1High activityOptimal polymerization reaction temperatureOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinIn situ polymerization

The method of promoting olefin polymerization uses a nanoparticle filler to increase the activity of a metallocene catalyst for in situ polymerization of polyolefins. The filler may be nanoparticles of manganese, or nanoparticles of manganese-doped titanium dioxide. The method includes the steps of (a) mixing a metallocene catalyst, e.g., zirconocene dichloride, with nanoparticles of the filler in an organic solvent, e.g., toluene, in a reactor to form a reaction mixture; (b) immersing the reactor in a temperature bath for a period of time sufficient to bring the mixture to an optimal polymerization reaction temperature; (c) adding monomer to the mixture in the reactor; (d) adding methylaluminoxane (MAO) as a co-catalyst to the reaction mixture to initiate polymerization; and (e) quenching the polymerization, e.g., by adding methanol containing 5% hydrochloric acid by volume to the reactor.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

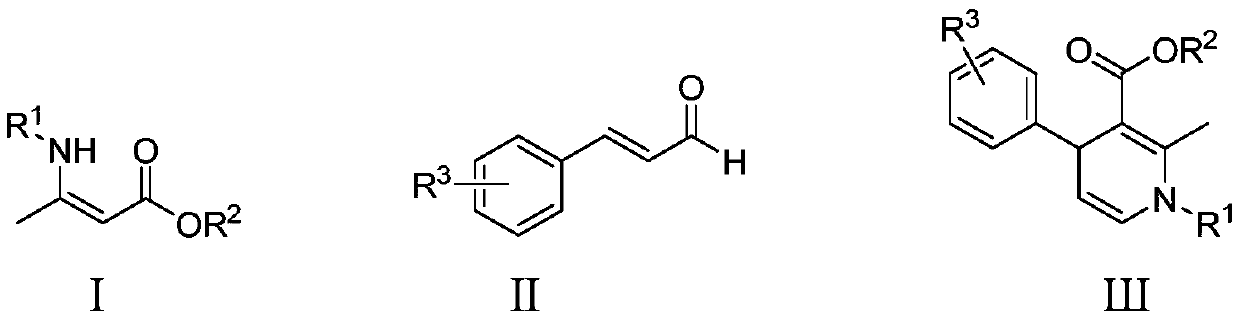

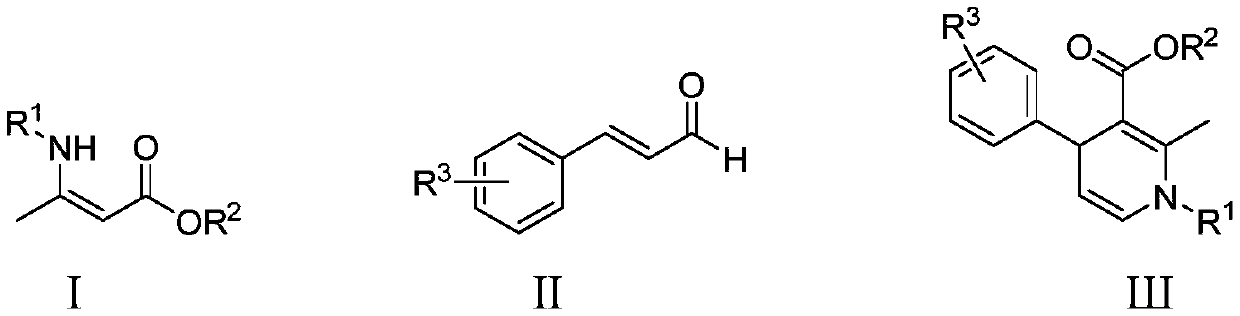

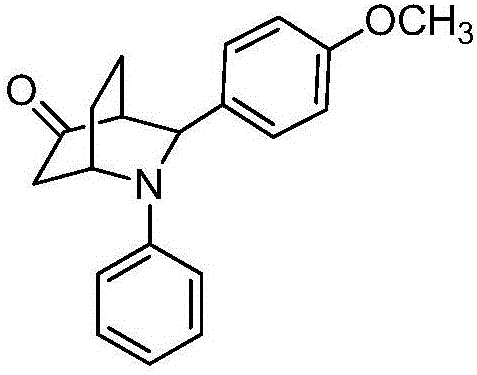

Method for catalytically synthesizing 1,4-dihydropyridine derivative through cooperation of zirconocene dichloride and benzoic acid ligands

PendingCN110003093AMild reaction conditionsEasy to operateOrganic chemistryChromatographic separationBenzoic acid

The invention discloses a method for catalytically synthesizing a 1,4-dihydropyridine derivative through cooperation of zirconocene dichloride and benzoic acid ligands. According to the method, with the zirconocene dichloride as a catalyst and 3-nitrophthalic acid, 4-nitrophthalic acid, 5-methoxysalicylic acid, 5-nitrosalicylic acid, 3,5-dinitrosalicylic acid and the like as the ligands, intermolecular ring closure is performed between enamine ester and cinnamaldehyde to produce the 1,4-dihydropyridine derivative. By the method, a reaction condition is mild, the operation is simple, the reaction time is short, a reaction product is single, the atomic economy is high, and after the reaction, the 1,4-dihydropyridine derivative with wide biological activity and a high medicinal value can be obtained at a relatively high yield only through simple column chromatographic separation of the product.

Owner:SHAANXI NORMAL UNIV

Method for preparing amorphous silicon-boron-carbon-nitrogen-zirconium-aluminum ceramic material

The invention relates to a method for preparing an amorphous silicon-boron-carbon-nitrogen-zirconium-aluminum ceramic material. The preparation method comprises the following steps: taking hexamethyl-disilazane, boron trichloride and trichlorosilane as raw materials, carrying out a condensation polymerization reaction to obtain light yellow liquid, adding trimethylamine-aluminum hydride and biszirconium dichloride to obtain a yellow precursor, and finally performing hot-pressing sintering, thereby obtaining the amorphous silicon-boron-carbon-nitrogen-zirconium-aluminum ceramic material. The method disclosed by the invention is simple, mild in conditions and low in cost; the prepared amorphous silicon-boron-carbon-nitrogen-zirconium-aluminum ceramic material is uniform in texture structureand high in chemical purity and has excellent high-temperature resistance and oxidation resistance, and the comprehensive performance of the ceramic material can be further regulated by regulating thecontent of Zr and Al in the amorphous silicon-boron-carbon-nitrogen-zirconium-aluminum ceramic material.

Owner:DONGHUA UNIV

Preparation method of indole-3-methanol

InactiveCN106243011AImprove adsorption capacityHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPotassium borohydrideMontmorillonite

The invention provides a preparation method of indole-3-methanol. The method comprises the following steps: 1, carrying out a reaction on zirconium chloride and cyclopentadiene in a mixed solvent through a diethylamine technology to prepare zirconocene dichloride; 2, modifying montmorillonite with cystine to obtain modified montmorillonite; 3, compounding the modified montmorillonite with zirconocene dichloride to obtain montmorillonite supported zirconocene dichloride; 4, compounding the modified montmorillonite with potassium borohydride to obtain montmorillonite supported potassium borohydride; 5, carrying out an acylation reaction on indole and toluidine under the action of the montmorillonite supported potassium borohydride to obtain indole-3-formaldehyde; and 6, reducing the indole-3-formaldehyde by the montmorillonite supported potassium borohydride to prepare the indole-3-methanol. The method has the advantages of high yield and low preparation cost.

Owner:叶芳

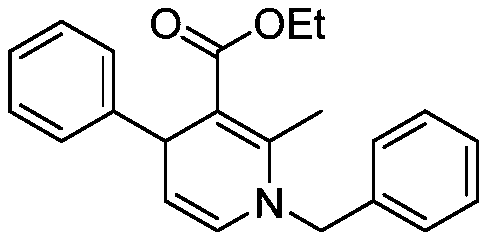

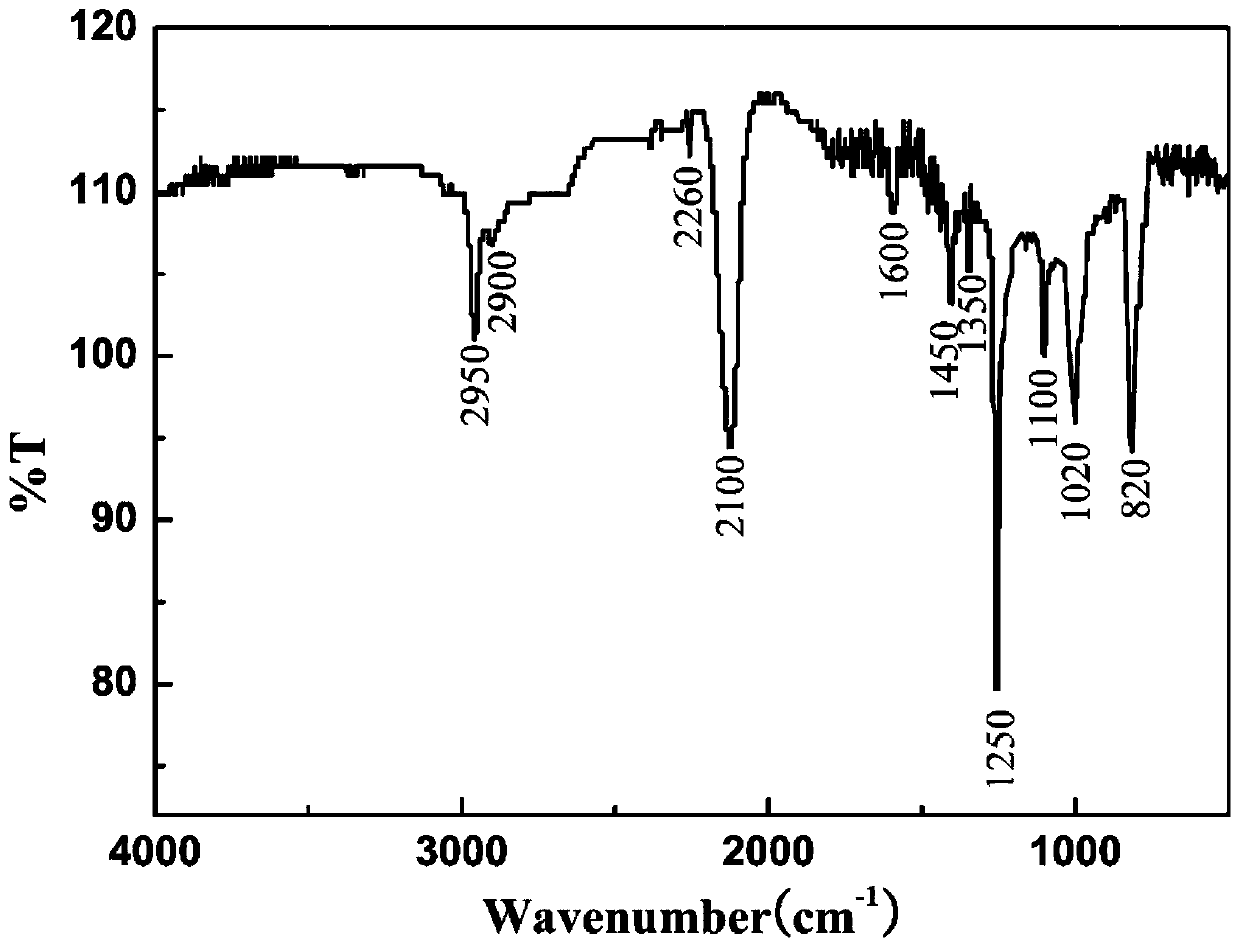

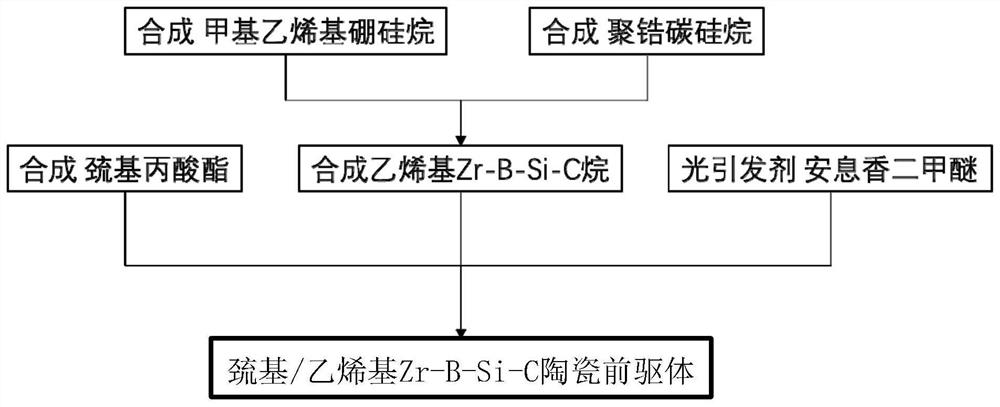

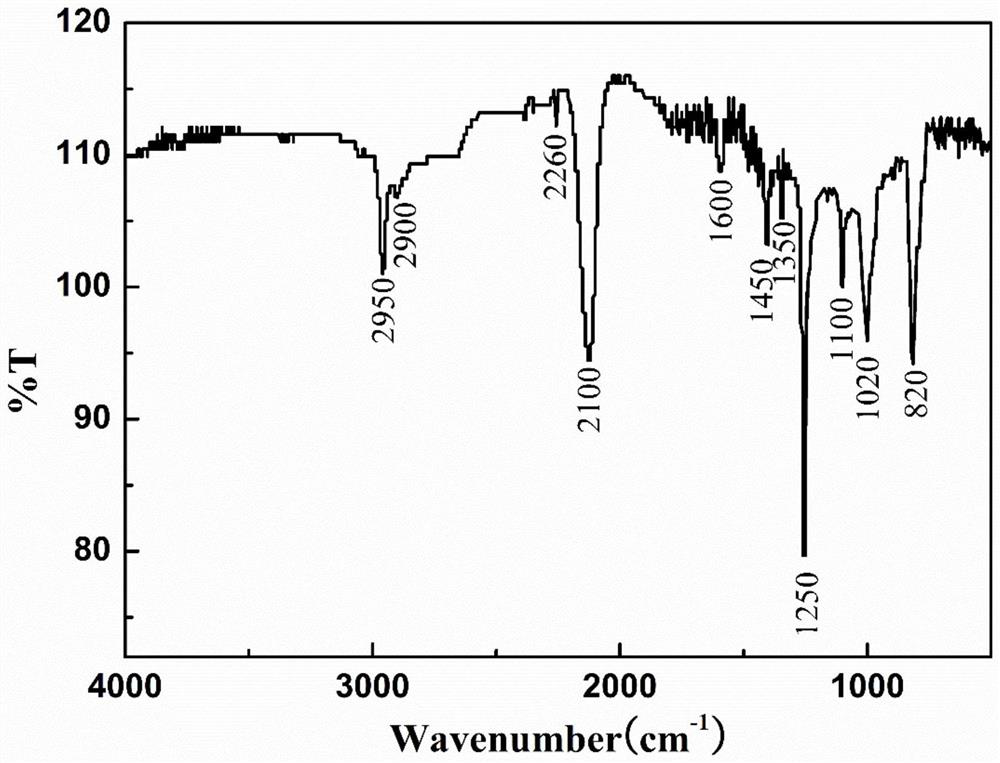

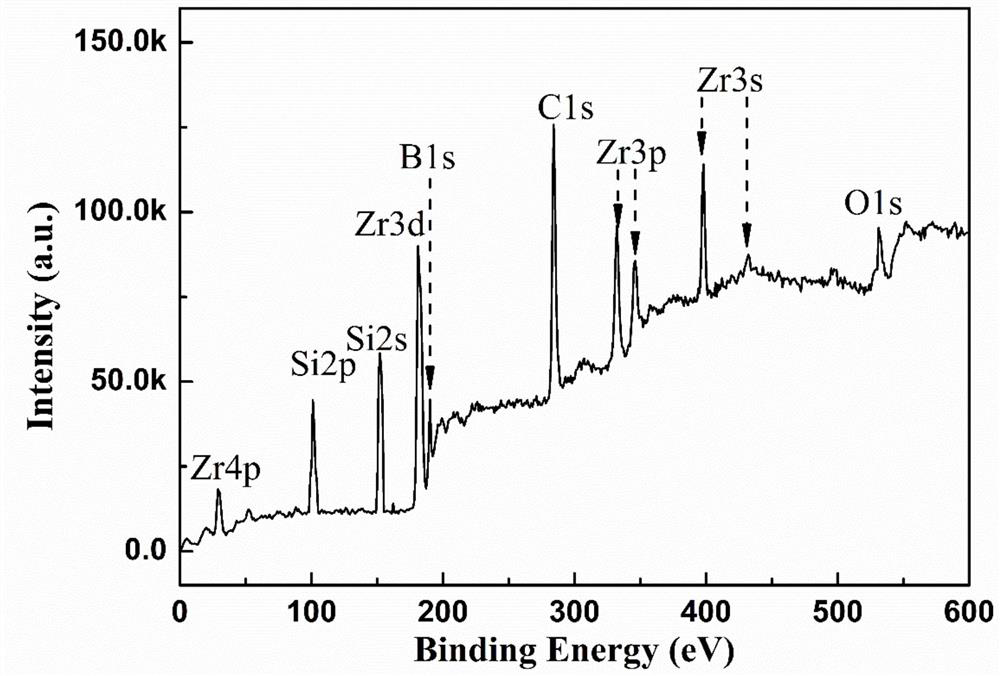

Light-sensitive Zr-B-Si-C ceramic precursor and in-situ preparation method thereof

The invention relates to a light-sensitive Zr-B-Si-C ceramic precursor and an in-situ preparation method thereof. The method comprises the following steps: uniformly mixing methylvinyldichlorosilane and a borane dimethyl sulfide complex, and then adding metal sodium for dechlorination to obtain methylvinyl borosilane; uniformly mixing chloromethyltrichlorosilane, methylchloromethyldichlorosilane and bis(cyclopentadienyl)zirconium dichloride, then adding metal magnesium to carry out a first heat preservation reaction, and then adding a reducing agent to carry out a second heat preservation reaction to obtain polyzirconocarbosilane; uniformly mixing methylvinyl borosilane and polyzirconocarbosilane to obtain vinyl Zr-B-Si-C alkane; and uniformly mixing the vinyl Zr-B-Si-C alkane with mercaptopropionate, and then adding a photoinitiator to initiate a polymerization reaction to prepare the ceramic precursor. The problems of high viscosity, high thermal stress, structural member mechanicalproperty attenuation and the like of a traditional photocuring system are solved, and a high-quality raw material is provided for photocuring 3D printing of an ultrahigh-temperature ceramic structuralmember.

Owner:XIAMEN UNIV OF TECH

High-temperature-resistant and ageing-resistant cable sheath material and preparing method thereof

InactiveCN105623007AExtended service lifeImprove high temperature resistanceHydrogenated Palm Kernel OilChlornitrofen

The invention discloses a high-temperature-resistant and aging-resistant cable sheath material. The high-temperature-resistant and aging-resistant cable sheath material is prepared from, by weight, 60-80 parts of nitrile butadiene rubber, 25-35 parts of methyl vinyl silicone rubber, 3-8 parts of zinc oxide, 2-7 parts of magnesium stearate, 12-18 parts of diethylene glycol monoethyl ether acetate, 10-16 parts of 2,2,2-trichloroacetamide benzyl ester, 11-18 parts of ethopabate, 4-10 parts of acetazolamide, 3-7 parts of magnalium zirconium oxide, 4-7 parts of zirconocene dichloride, 1-4 parts of hydrogen-chlorine ferrocene, 10-15 parts of bifenox and 12-18 parts of hydrogenated palm kernel oil. According to the high-temperature-resistant and aging-resistant cable sheath material, at the high temperature of 150 DEG C, changes of all performances are small, aging resistance is high, and the performance is stable.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Heat-conducting wear-resisting plastic material and preparation method thereof

The invention discloses a heat-conducting wear-resisting plastic material. The heat-conducting wear-resisting plastic material comprises components in parts by weight as follows: 20-30 parts of asbestos fibers, 25-30 parts of ceramic fibers, 10-15 parts of polytetrafluoroethylene, 8-12 parts of nylon, 2-6 parts of magnesium oxide, 8-14 parts of polycarbonate, 7-13 parts of ethyl carbamate, 6-9 parts of meprobamate, 2-4 parts of zirconocene dichloride, 1-3 parts of potassium fluoromagnesate, 1-3 parts of huntite, 2-4 parts of zinc phosphinate, 6-10 parts of ethyl methyl cellulose, 9-12 parts of solketal and 3-5 parts of N-oleoylethanolamine. The plastic material can integrate good heat conductivity and good wear resistance, and the service life of the plastic material is prolonged.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

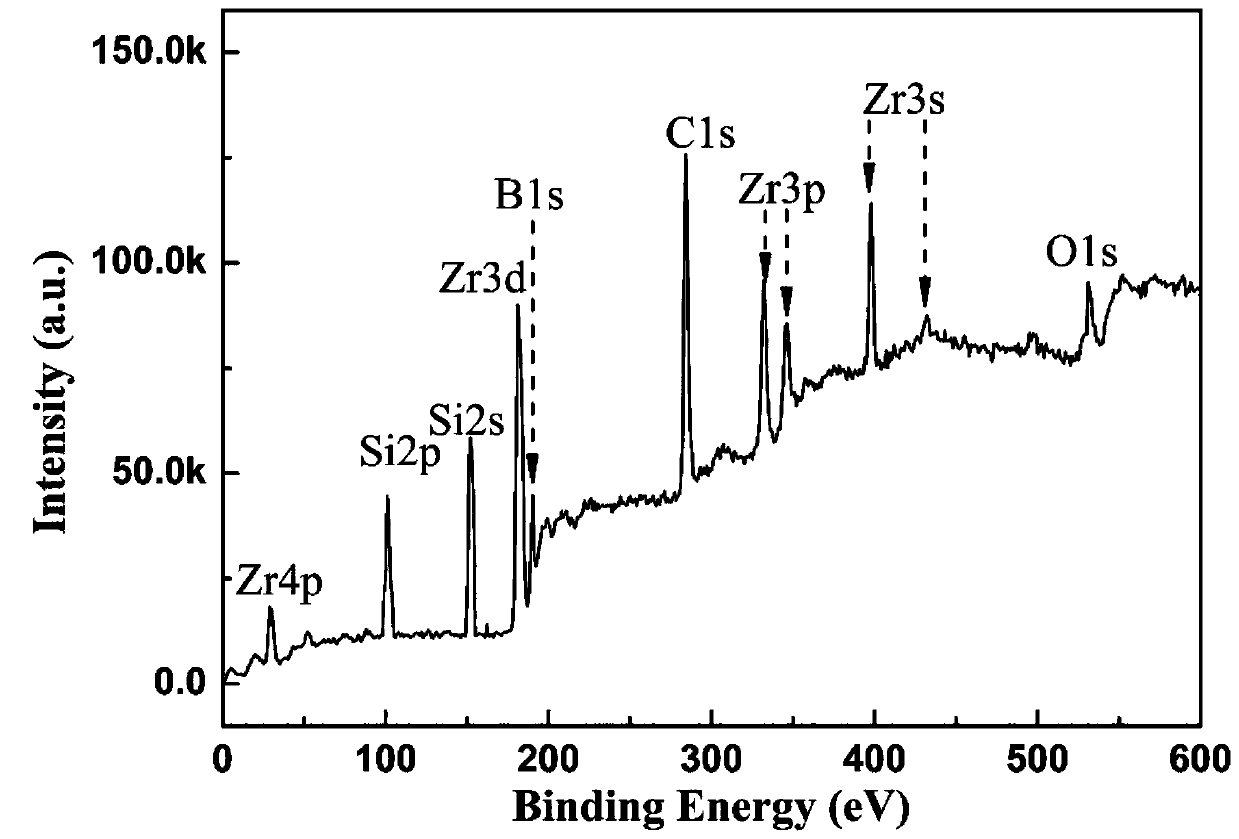

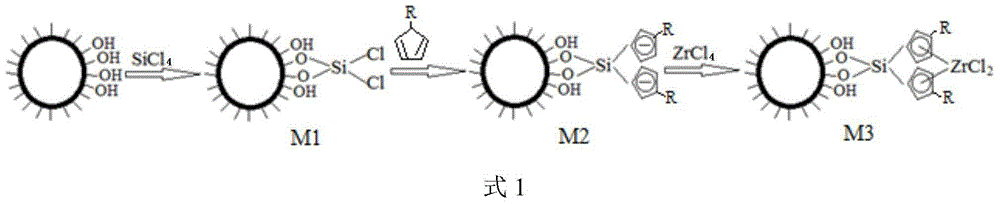

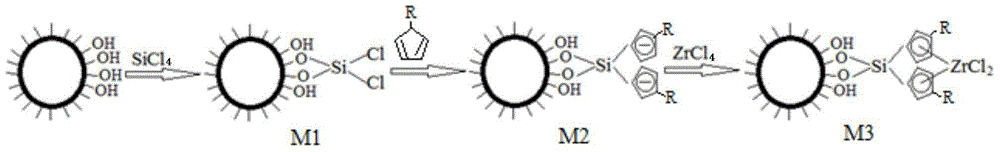

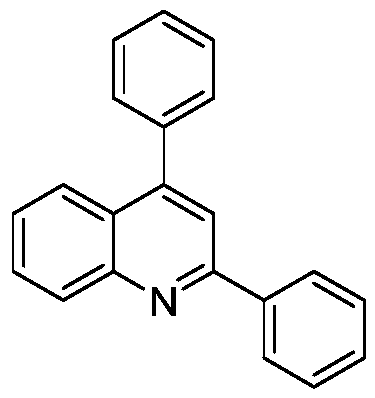

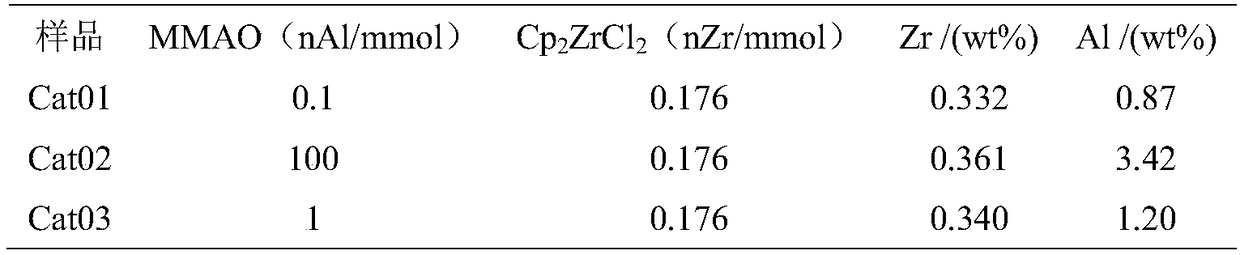

Catalyst for olefin polymerization and preparation method thereof

The invention discloses a load-type metallocene catalyst for olefin polymerization and a preparation method thereof. The preparation method comprises the following steps: performing silicon tetrachloride modification on the surface of an activated silica gel carrier, and performing bis-cyclopentadienyl-zirconium dichloride in-situ synthesis on the surface of the silicon tetrachloride modified silica gel to obtain the product, wherein the catalyst is a solid granule with the particle size distribution scope of 20-30 microns, the structure is stable when the environment temperature is under 300 DEG C, the surface metallocene modification rate is 45.7-47.3%, and the zirconium element content on the surface of the catalyst is 0.093-0.095 mmol / g. When the catalyst and the cocatalyst methylaluminoxane are compounded for catalyzing the homopolymerization of the olefin, the catalytic activity of the catalyst is higher than that of the catalyst obtained by loading zirconocene dichloride with the silica gel under the existence of methylaluminoxane, and the obtained polymerizate is white without caking. When the catalyst and the cocatalyst are compounded for the catalysis of the olefin homopolymerization, the catalytic activity of the catalyst is high and the obtained polymerizate product is white without caking.

Owner:BEIJING UNIV OF CHEM TECH

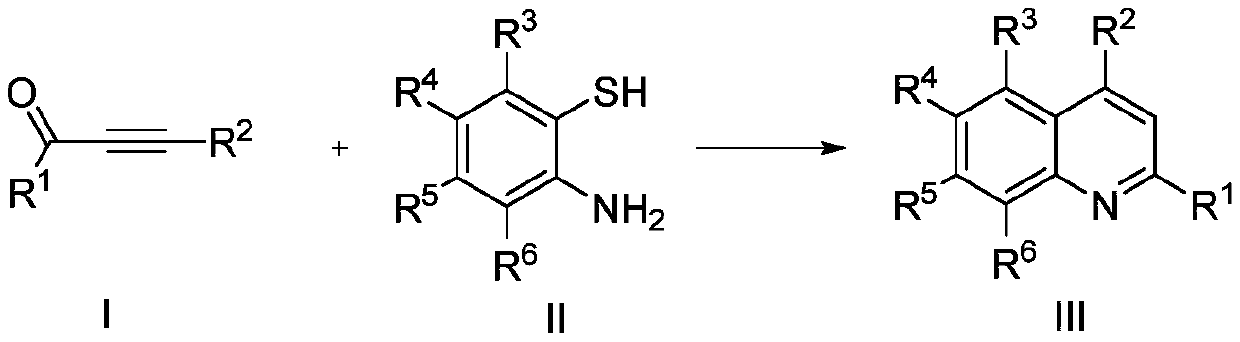

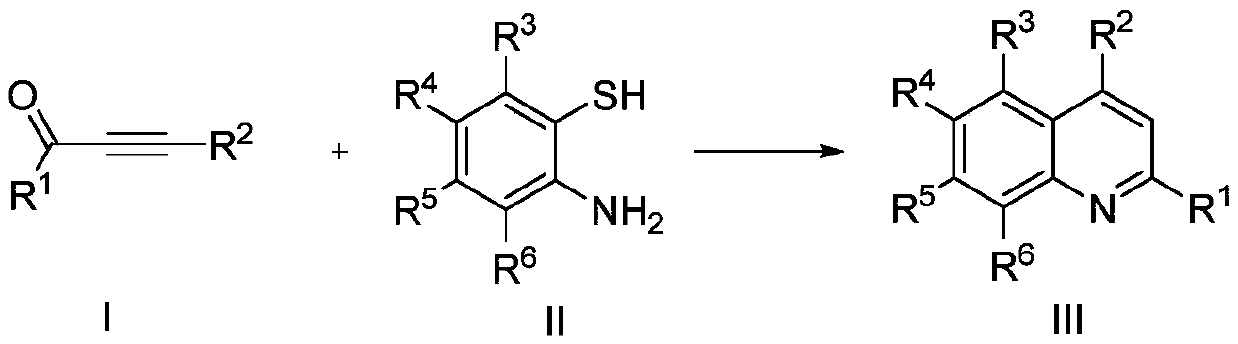

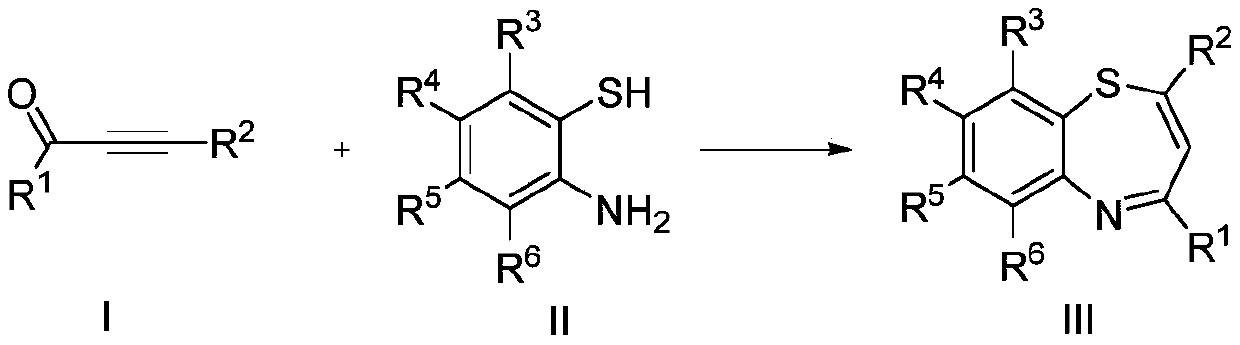

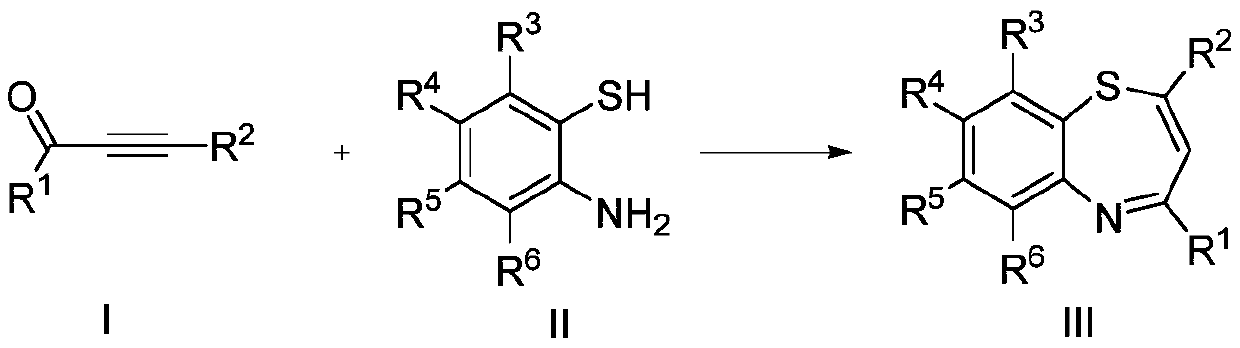

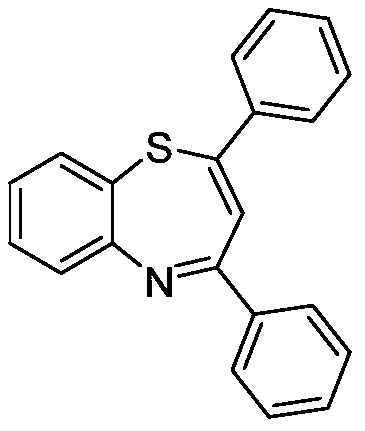

Method for preparing quinoline compounds under catalysis of zirconocene dichloride

ActiveCN110156673AReduce dosageMild reaction conditionsOrganic chemistryN dimethylformamideQuinoline

The invention discloses a method for preparing quinoline compounds under catalysis of zirconocene dichloride. According to the method, 3-butyne-2-one compounds and an o-aminophenylmercaptan compound are taken as raw materials, zirconium dichloride is taken as a catalyst, L-phenylalanine, tyrosine and the like are taken as catalyst ligands, and N,N-dimethylformamide is used as a solvent, and elemental iodine, hydrogen peroxide, peroxy tert-butyl alcohol and the like are used as oxidizing agents, so that the quinoline compound can be prepared in a high-efficiency and high-yield manner. The catalyst used in the method is less in use amount, low in cost and stable in air, reaction conditions are mild, and operation is simple. After the reaction is finished, the product is extracted and washed,simple column chromatography separation is carried out, and then the quinoline compound can be obtained. The method provides a low-cost efficient way for preparation of the quinoline compound and hasa wide application prospect.

Owner:SHAANXI NORMAL UNIV

Diatomite-loaded metallocene catalyst as well as preparation method and application thereof

The invention disclosed a diatomite-loaded metallocene catalyst. The diatomite-loaded metallocene catalyst is prepared by a method comprising the following steps: under the protection of an inert gas,dispersing diatomite in a solvent, then adding modified methylaluminoxane, stirring to remove trace water, then adding zirconocene dichloride, stirring for 1-3h, then filtering, and drying a filter cake to obtain the diatomite-loaded metallocene catalyst. The obtained diatomite-loaded metallocene catalyst can be applied to catalysis of ethylene polymerization. A carrier used by the diatomite-loaded metallocene catalyst is diatomite ore, and compared with a synthetic magnesium chloride or silicon dioxide carrier, the diatomite ore can reduce the cost of the catalyst under the premise of an equivalent effect.

Owner:HANGZHOU NORMAL UNIVERSITY

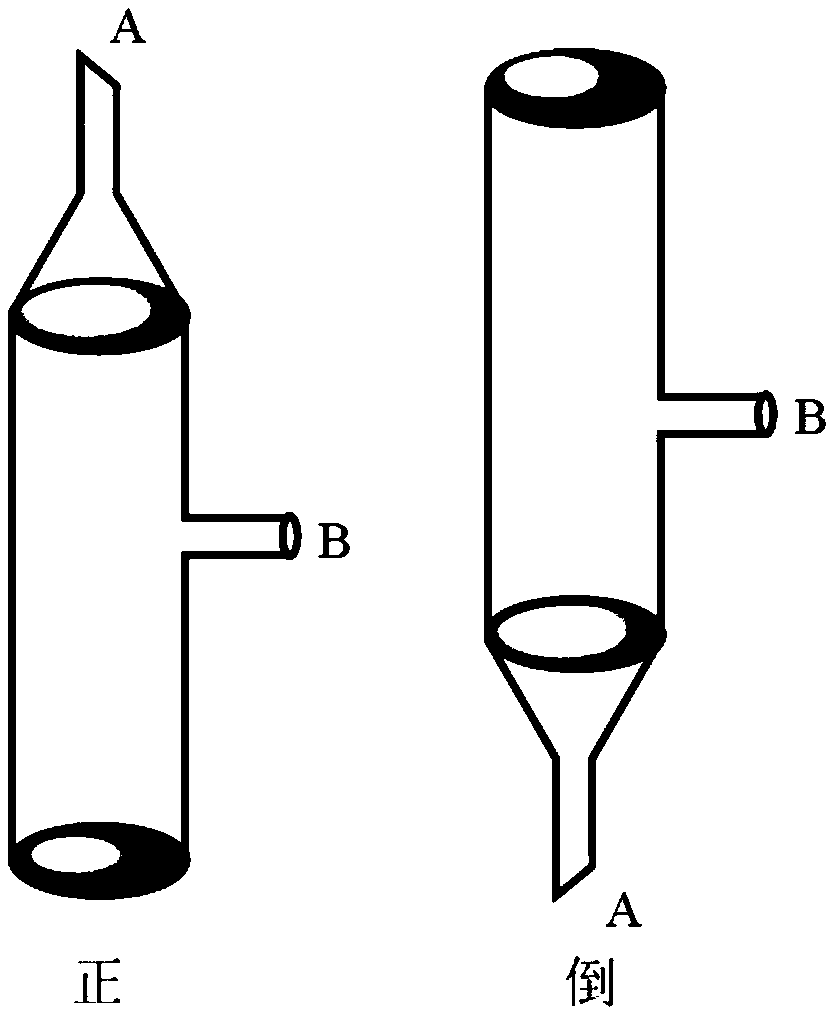

Method for synthesizing zirconocene dichloride

The invention relates to a method for synthesizing zirconocene dichloride, which comprises the following process steps: depolymerizing cyclopentadiene: depolymerizing the cyclopentadiene under inert atmosphere, and collecting cyclopentadiene monomers obtained by distillation for standby; heating a solvent of diglycol ether and sodium wires under the inert atmosphere, then dripping the cyclopentadiene monomers, and obtaining diglycol ether solution of cyclopentadienyl sodium; dripping the well prepared cyclopentadienyl sodium solution into alkane suspension of zirconium tetrachloride solids, and carrying out reaction at the temperature of 15-35 DEG C; removing alkane under one atmospheric pressure, further removing the diglycol ether, obtaining dark gray solids, carrying out extraction on the solids by using a Soxhlet extractor, filtrating extraction solution, depressurizing, removing the solvent by evaporation, cooling, then precipitating the solids, and obtaining a target product. The method for synthesizing the cyclopentadienyl sodium changes the reaction solvent and the reaction temperature, so that the sodium wires can be melted, thereby forming sodium sand to be evenly distributed in the solvent; meanwhile, the high temperature can also depolymerize the partial polymerized cyclopentadiene, basically quantitatively carry out the reaction and improve the reaction yield.

Owner:NANJING UNIV

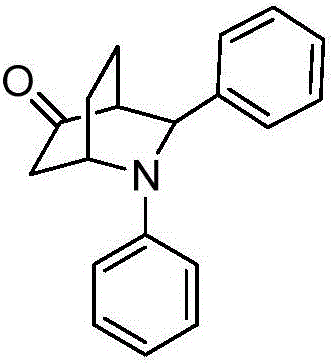

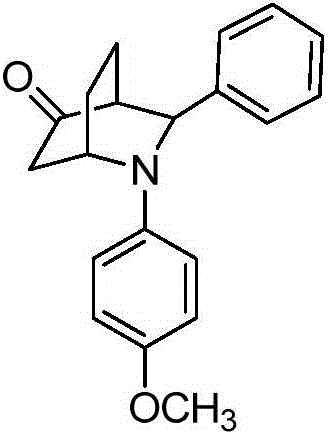

Method for preparing azabicyalo compound by efficient catalysis of o-aminobenzenesulfonic acid and zirconocene Lewis acid

InactiveCN106467536AReduce dosageBroad biological activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexeneAzabicyclo Compounds

The invention discloses a method for preparing azabicyalo compounds by efficient catalysis of o-aminobenzenesulfonic acid and zirconocene Lewis acid. The method takes 2-cyclohexene-1-ketone, aromatic aldehyde, and arylamine as raw materials, takes ethanol as a solvent, and takes zirconocene dichloride as a catalyst; under condition that Bronsted acid- o-aminobenzenesulfonic acid is added, the zirconocene dichloride can prepare a series of azabicyalo compounds with high efficiency and high yield. The catalyst has the advantages of little amount, low cost, no toxicity, stabilization on air, mild reaction condition, and high atom economy, after a reaction is complete, the product is subjected to simple separation and recrystallization to obtain the azabicyalo compound. The preparation of the azabicyalo compound opens up a novel approach of low cost, and environmental protection and high efficiency, and has wide application prospect.

Owner:SHAANXI NORMAL UNIV

Anti-static polyethylene glycol monooleate halogen-free flame retardant

InactiveCN110305512ADoes not affect thermal conductivityImprove conductivityFireproof paintsElectrically-conductive paintsCross-linkPolymer science

The invention relates to the technical field of preparation of halogen-free flame retardants, and discloses an anti-static polyethylene glycol monooleate halogen-free flame retardant. The anti-staticpolyethylene glycol monooleate halogen-free flame retardant includes the following experiment raw materials of polyethylene glycol monooleate, an antioxidant complex, an organosilicon flame retardantauxiliary and a synergistic metallic and non-metallic catalyst, and the polyethylene glycol monooleate is a polymer of oleic acid and polyethylene glycol. According to the anti-static polyethylene glycol monooleate halogen-free flame retardant, the synergistic metallic and non-metallic catalyst is a complex of zirconocene dichloride and N-bromosuccinimide, through the zirconocene dichloride, the small amount of polyethylene glycol monooleate is coordinated to form a polyglyoxal monooleate compound, under catalysis of N-chlorosuccinimide, the polyglyoxal monooleate compound is chloridized intopolyoxalyl chloride monooleate, a cross-linking belt is formed between the polyethylene glycol monooleate polymer by the polyoxalyl chloride monooleate, and thus the polyethylene glycol monooleate polymer has stable conductive performance.

Owner:厦门芒娅贸易有限公司

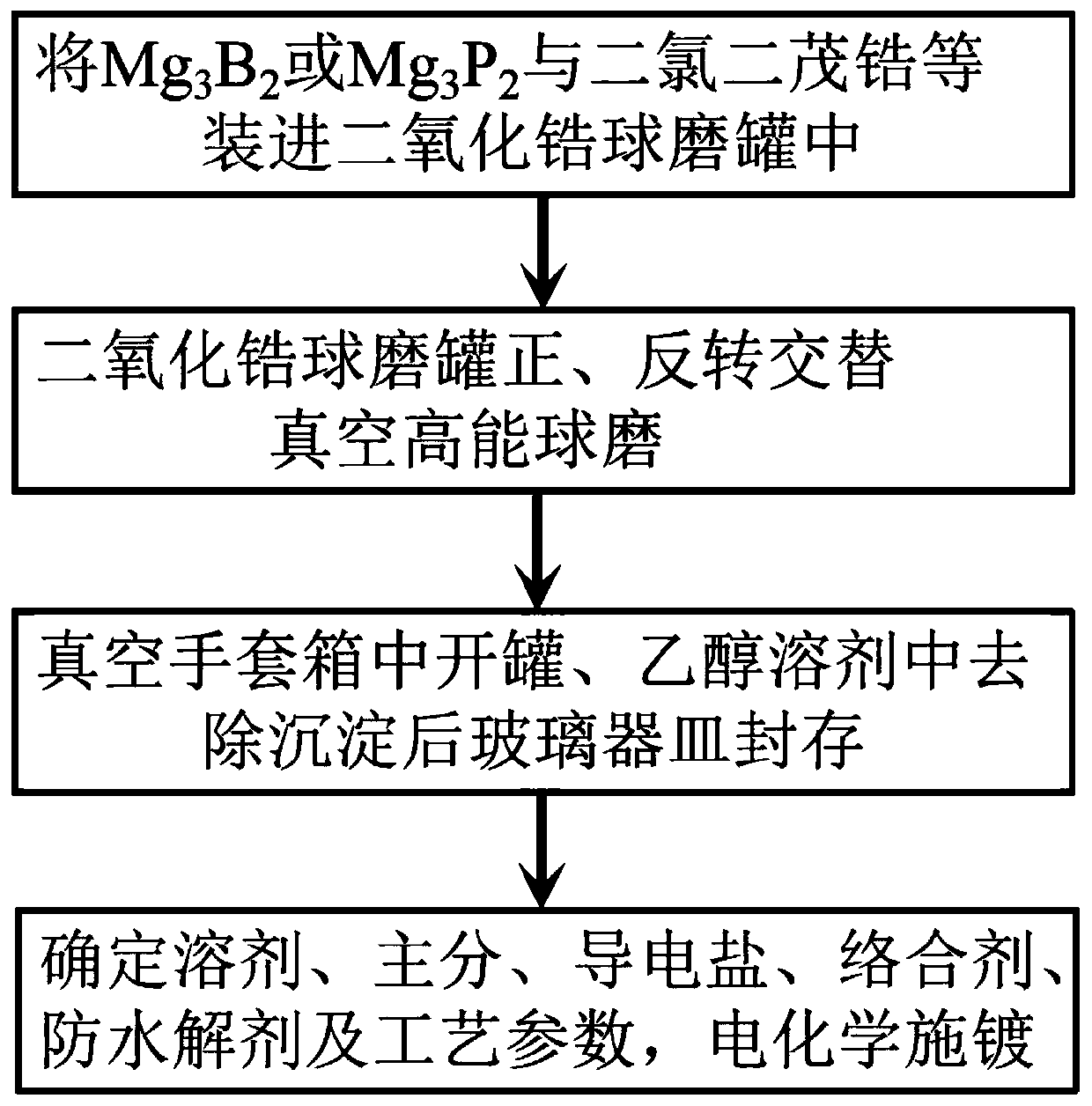

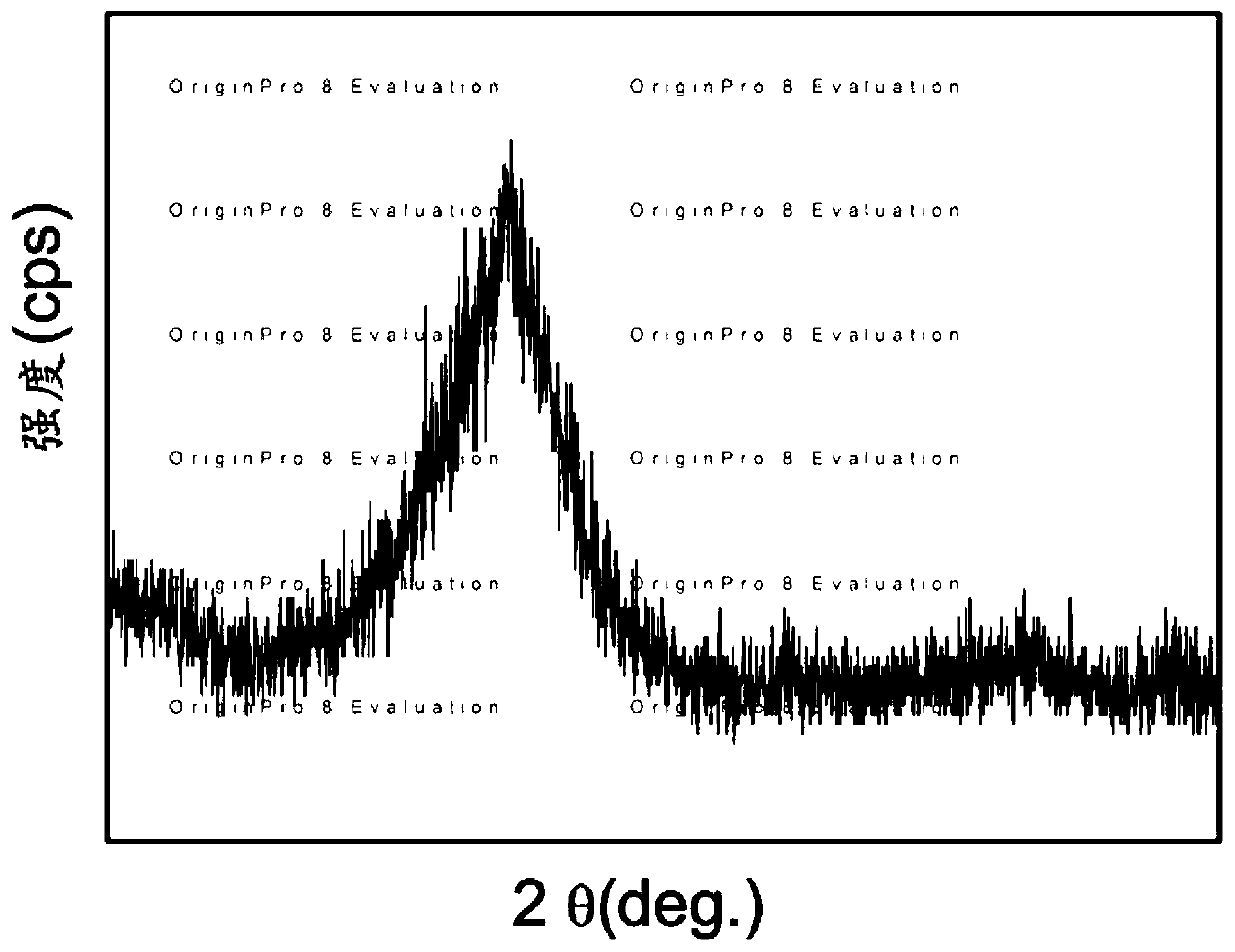

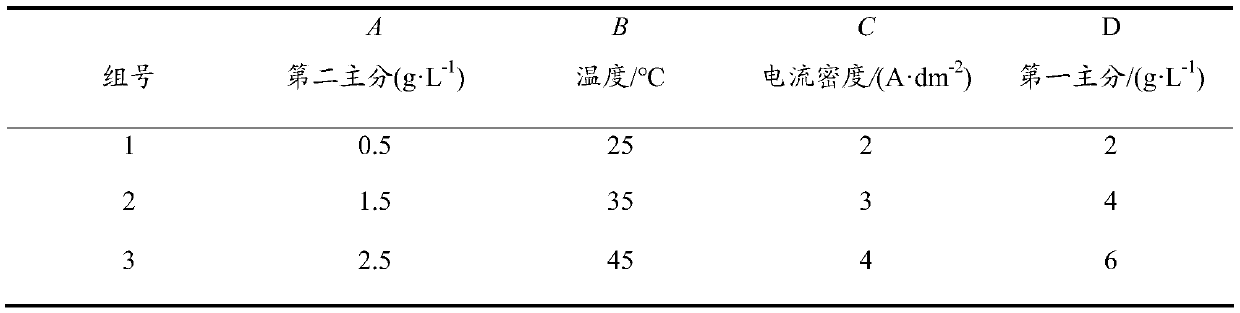

Rapid preparing method of Zr-based electrochemical amorphous alloy

InactiveCN110257737AReduce manufacturing costImprove efficiencyPhotography auxillary processesProcess efficiency improvementAlloySolvent

The invention provides a rapid preparing method of a Zr-based electrochemical amorphous alloy. The method comprises the following steps that firstly, Mg3B2, or Ca3P2 and zirconocene dichloride are put into a zirconium dioxide ball mill tank, then, benzene is used as an anti-bonding agent or diluting agent, and argon is inflated for sealing the tank; secondly, positive rotation and reverse rotation crossing is carried out for ball milling; thirdly, in a vacuum glove box, the tank is opened, and in an ethyl alcohol solvent, after sediment is removed, a glass ware is sealed for standby application; fourthly, the ethyl alcohol serves as the solvent, polycation salt serve as a first main salt main component, third-period later-transition group element acetate including Cu serve as a second main salt main component, tetra-n-butylammonium bromide serves as conductive salt, alkali metal oxalate, citrate, tartrate or ethylene diamine tetraacetic acid serves as a complexing agent, and under a certain current density, a selected steel workpiece base body is plated.

Owner:LIAONING TECHNICAL UNIVERSITY

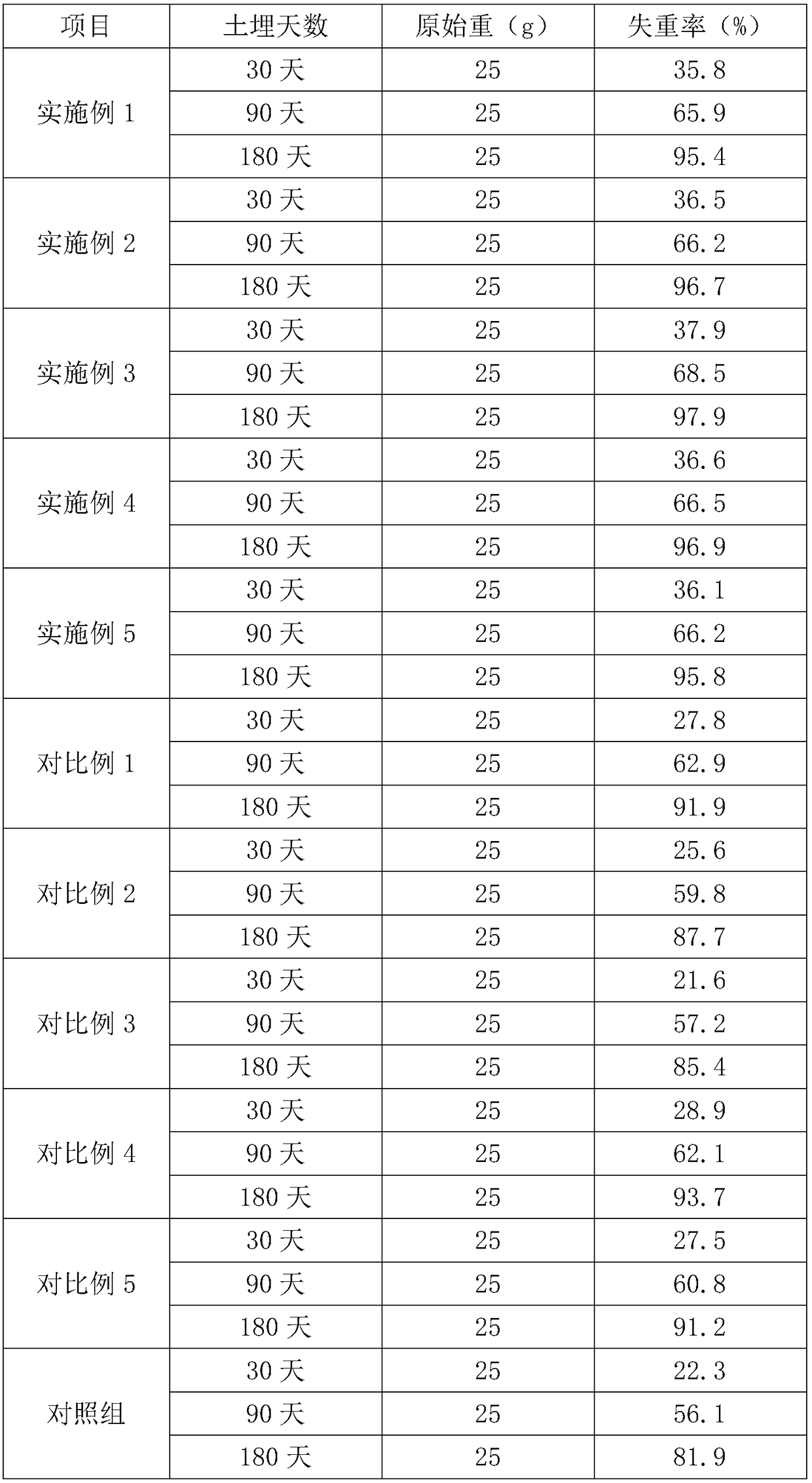

Degradable polyethylene plastic and preparation method thereof

InactiveCN108864551AImprove mechanical propertiesImprove degradation rateIpomoea cairicaEnvironmental resistance

The invention discloses a degradable polyethylene plastic and a preparation method thereof. The degradable polyethylene plastic is prepared from the following raw materials in parts by weight: 65 to 80 parts of polyethylene, 10 to 20 parts of mikania micrantha extract, 8 to 15 parts of bentonite, 5 to 8 parts of ipomoea cairica, and 1 to 5 parts of zirconocene chloride. The degradable polyethyleneplastic has the advantages that the raw materials are easy to obtain and are environment-friendly, so that the mechanical property and degrading speed are obviously improved; the preparation technology is simple, the industrialized production is easy, and the degradable polyethylene plastic is suitable for being popularized.

Owner:GANZHOU YANSHUNFEI TECH CO LTD

A photosensitive zr-b-si-c ceramic precursor and its in-situ preparation method

Owner:XIAMEN UNIV OF TECH

Method for preparing liquid anaerobic polyzirconocarbosilane

Owner:XIAMEN UNIV

A kind of synthesis method of ultra-high temperature resistant zrc/sic composite ceramic precursor

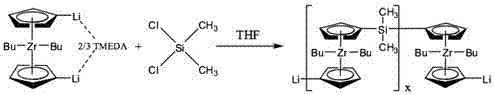

A method for synthesizing an ultra-high temperature resistant ZrC / SiC composite ceramic precursor, comprising the following steps: (1) under the protection of an inert gas atmosphere, dissolving zirconocene dichloride in an organic solvent, stirring and adding an organolithium compound, a compound (2) Under the protection of an inert gas atmosphere, add the halosilane monomer to the active component a obtained in the stirring step (1), and a polymerization reaction occurs to obtain component b, drop The reaction is terminated by adding a terminator, concentrated by filtration, purified by precipitation, and dried in vacuum to obtain the precursor of ultra-high temperature resistant ZrC / SiC multiphase ceramics. The present invention starts from the monomer and polymerizes step by step, the product chain length is controllable and uniform, and ZrC / SiC multi-phase ceramics with high purity and good uniformity can be further prepared; the two-step process is simple and can be reacted at normal temperature and pressure , the conditions are easy to control, the raw materials are easy to obtain, and are suitable for large-scale production.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing quinoline compounds by catalysis of zirconocene dichloride

ActiveCN110156673BReduce dosageMild reaction conditionsOrganic chemistryPhenylalanine+TyrosinePtru catalyst

The invention discloses a method for preparing quinoline compounds by catalyzing zirconocene dichloride. The method uses 3-butyne-2-ketone compounds and anthranilobenzenethiol compounds as raw materials, As a catalyst, L-phenylalanine, tyrosine, etc. are used as catalyst ligands, N,N-dimethylformamide is used as a solvent, and elemental iodine, hydrogen peroxide, tert-butanol peroxide, etc. are used as oxidants, The quinoline compounds can be prepared efficiently and in high yield. The catalyst used in the present invention is low in cost, stable to air, mild in reaction conditions, and simple in operation. After the reaction is completed, the product is extracted and washed and separated by simple column chromatography to obtain quinoline compounds, which are quinoline compounds The preparation of opens a low-cost and high-efficiency way, and has broad application prospects.

Owner:SHAANXI NORMAL UNIV

A Hydrosilylation Reaction of Unsaturated Compound Catalyzed by Metallocene

The invention discloses an unsaturated compound hydrosilylation reaction taking metallocene as a catalyst. The catalyst comprises a metallocene coordination compound and metal powder, the molar ratioof the metallocene coordination compound to the metal powder is 1:1-1:3, the metallocene coordination compound is titanocene dichloride or zirconocene dichloride, and the metal powder is any of samarium, magnesium and aluminum or zinc. The prepared catalyst is a non-precious metal catalyst and has the advantages of low cost, simplicity in operation and the like, a new variety is increased for a hydrosilylation reaction catalyst, and the catalyst has excellent catalytic effects on hydrosilylation reaction of unsaturated olefins, can catalyze addition reaction of olefin, ketone and hydrogen-containing silane and is wide in applicability.

Owner:FOSHAN PULIDA TECH

Linear low density polyethylenes with high melt strength and high melt index ratio

InactiveUS6884747B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationLinear low-density polyethylenePtru catalyst

Linear low density polyethylenes (LLDPEs) that have relatively high melt index ratios (MIR) and relatively high melt strength (MS) are described. This combination of melt properties is achieved by a substantially non-blended LLDPE. Catalysts used to produce these polyethylenes are generally a blend of bridged bisindenyl zirconocene dichlorides, where one zirconocene contains saturated indenyls and the other unsaturated indenyls.

Owner:UNIVATION TECH LLC

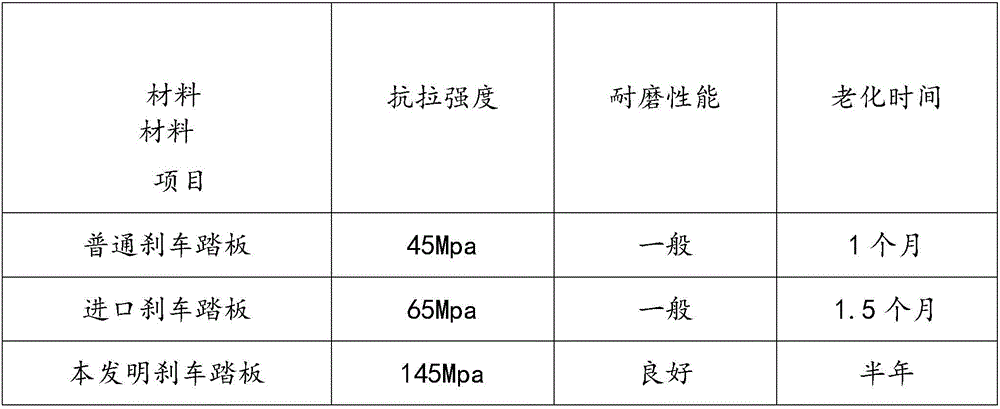

Material of automobile brake pedal and preparation method thereof

The invention discloses a material of an automobile brake pedal. The material is prepared from the following materials in parts by weight: 66-70 parts of polyamide, 12-14 parts of polyphenylene sulfide, 22-24 parts of glass fiber, 15-20 parts of carbon black, 11-14 parts of aluminum hydroxide, 7-12 parts of methylaluminoxane, 3-5 parts of zirconocene dichloride, 22-24 parts of p-phenylenediamine, 6-9 parts of ethoxyquinoline, 6-12 parts of maleic anhydride, 12-18 parts of polybutadiene latex, 1-2 parts of styrene-butadiene latex, 14-18 parts of borax, 3-8 parts of epoxidized soybean oil, 7-8 parts of ammonium polyphosphate, 11-14 parts of zinc borate, 20-22 parts of dioctyl phthalate, 7-10 parts of potassium titanate whisker and 11-16 parts of benzoyl peroxide. The material of an automobile brake pedal disclosed by the invention has the advantages of high structural strength, wear resistance, aging resistance and long service life.

Owner:芜湖天鸿汽车零部件有限公司

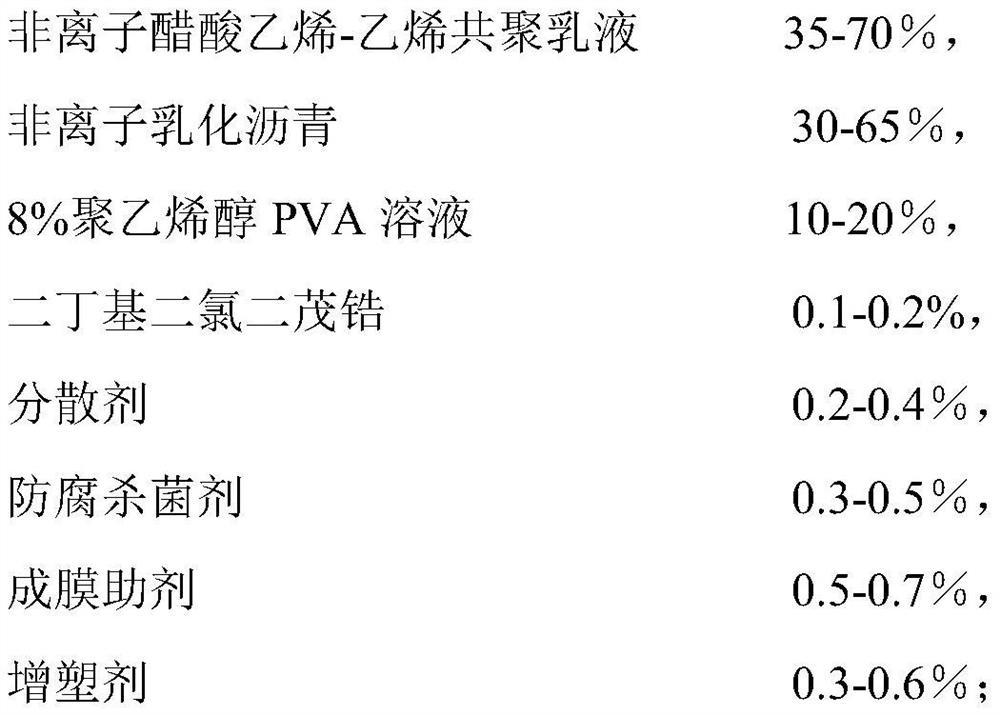

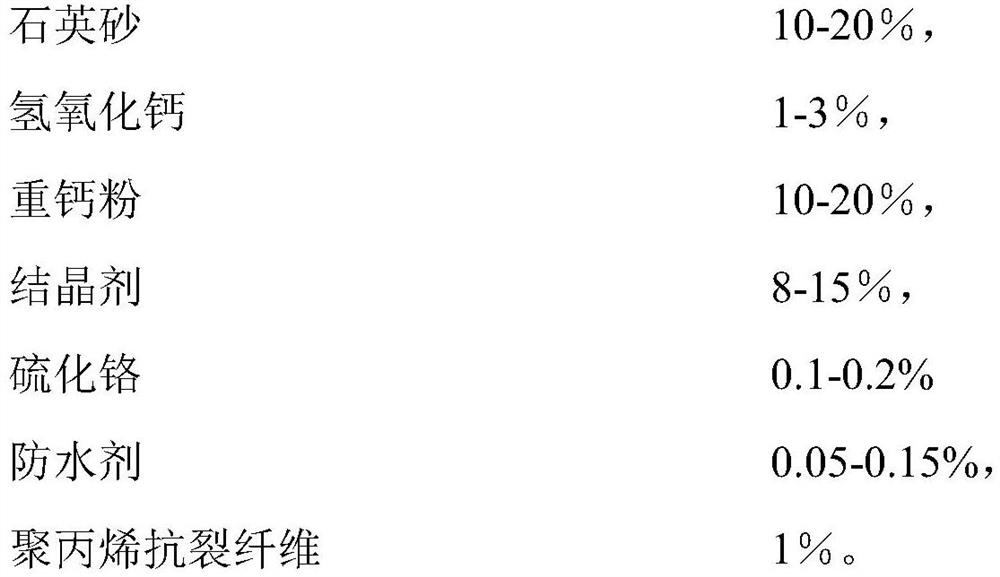

A kind of polymer cement-based waterproof coating and preparation method thereof

ActiveCN108707375BImprove self-waterproof performanceNo intervalAnti-corrosive paintsBituminous coatingsLap jointZirconocene dichloride

The invention provides a polymer cement-based waterproof coating. The polymer cement-based waterproof coating comprises a composition A and a composition B. The composition A is prepared from nonionicvinyl acetate-ethylene copolymer emulsion, nonionic emulsified asphalt and zirconium dibutyl zirconocene dichloride; the composition B is prepared from heavy calcium powder, chromic sulfide and JX-Iwaterproof agent, and the weight ratio of the composition A to the composition B is 1:(1-2.5). The invention further provides a preparing method of the polymer cement-based waterproof coating. The preparing method comprises the steps of firstly, uniformly mixing all the components of the composition A, continuously stirring the components, adding a uniform mixture of the composition B, and continuing to uniformly stir the mixture to obtain the polymer cement-based waterproof coating. After being molded and cured, the polymer cement-based waterproof coating is free of gaps, cracks or lap joint,is good in weather fastness, does not get cracked at minus 25 DEG C or deform at 100 DEG C, and has good surface hydrophobicity. Waterproof components permeating a base layer have the performance of enhancing self-waterproofing for the base layer; meanwhile, the function of self-restoring tiny fractures of the base layer is achieved.

Owner:常德市万福达环保节能建材有限公司

A kind of zrc/sic/c composite phase ceramic precursor material and preparation method thereof

The invention relates to a ZrC / SiC / C composite ceramic precursor material and a preparation method thereof; the precursor is pyrolyzed and converted into a composite ceramic at a temperature of 1600 DEG C, the zirconium content in the composite ceramic is not less than 50 wt%, and the silicon content in the composite ceramic is not less than 10 wt%. The preparation method of the precursor is characterized in that polysilylacetylene, zirconocene dichloride and n-butyllithium are subjected to a one-pot reaction under anhydrous and anaerobic conditions to synthesize the precursor, the zirconocenedichloride is used as a zirconium source, the polysilylacetylene is used as a silicon source, and the n-butyllithium is added at a low temperature to carry out a further reaction to prepare the precursor. The polymer precursor prepared by the method is expected to be used as a dipping matrix of a ceramic-based composite material and a carbon / carbon composite material so as to improve the ultrahigh-temperature oxidation resistance of the ceramic-based composite material and the carbon / carbon composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

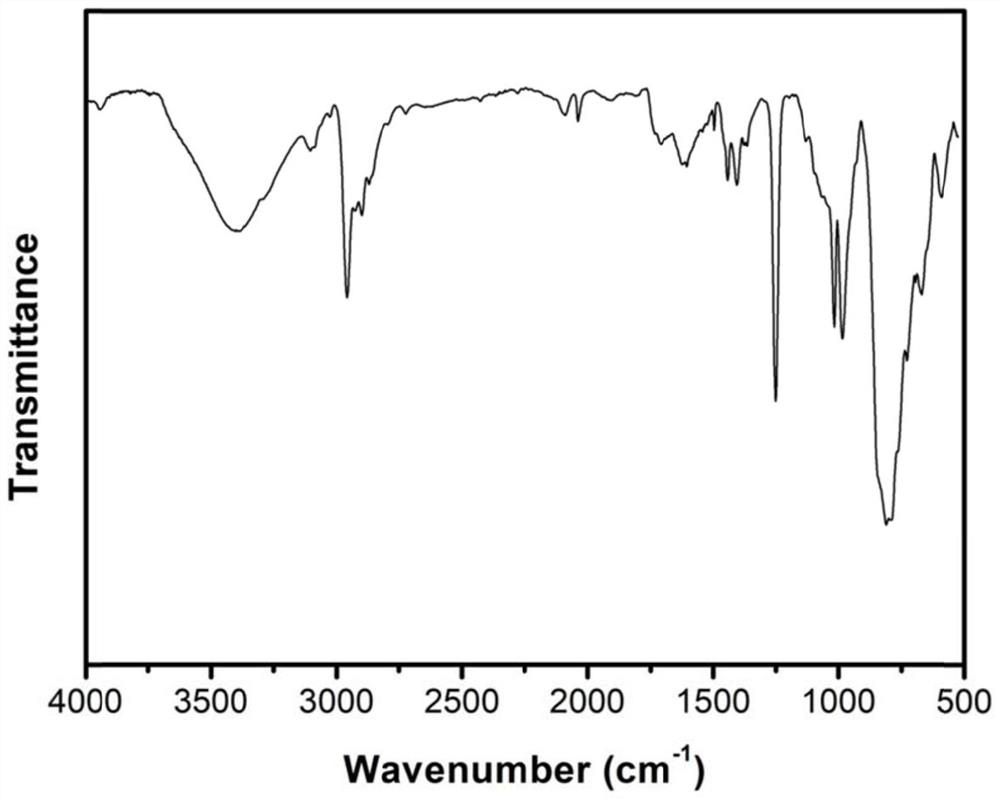

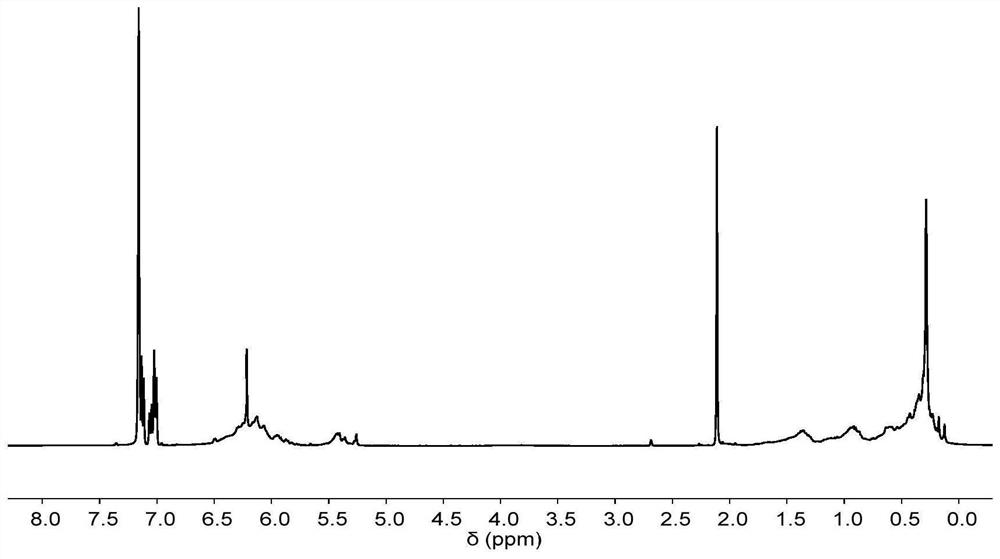

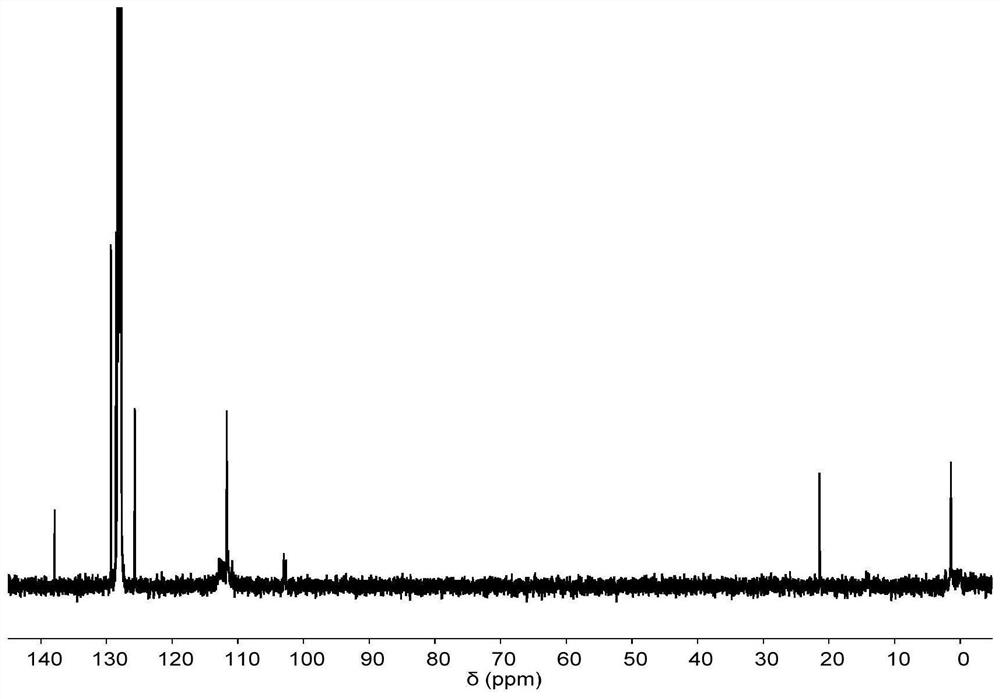

Method for preparing 1,5-benzothiazine compounds under catalysis action of zirconocene dichloride

ActiveCN110183397AReduce dosageMild reaction conditionsOrganic chemistryChemical recyclingKetonePhenylalanine

The invention discloses a method for preparing 1,5-benzothiazine compounds under the catalysis action of zirconocene dichloride. According to the method, 3-butyne-2-ketone compounds and o-aminobenzenethiol compounds are taken as raw materials, zirconocene dichloride is taken as a catalyst, and the 1,5-benzothiazine compounds are prepared efficient in a high-yield manner under the promotion actionof ligands such as L-phenylalanine, 3-nitrophthalic acid, 2-aminobenzene sulfonic acid and the like. According to the method, a few catalyst is used and is low in cost, non-toxic and stable to the air, the reaction conditions are mild, short time is consumed, operation is simple, the atom economy is high, all that is required is to perform simple column chromatography isolation on a product afterthe reaction ends, and the 1,5-benzothiazine compounds can be obtained. A novel, low-cost and efficient way is developed for preparation of the 1,5-benzothiazine compounds, and the method has broad application prospects.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com