Method for preparing liquid anaerobic polytitanocarbosilane

An oxygen-free polytitanocarbosilane technology, which is applied in the field of compound preparation, can solve the problems of uneven dispersion of titanium elements, low ceramic yield, high dielectric loss, etc., and achieve low resistivity, high dielectric loss, Ease of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Under the protection of an inert atmosphere, put 92.0g of chloromethyltrichlorosilane, 40.9g of (chloromethyl)methyldichlorosilane, 0.93g of titanocene dichloride and 500g of anhydrous tetrahydrofuran in a reaction flask 36.0g of magnesium was added in batches and mechanically stirred; after the magnesium was added, the reaction was kept at 100°C for 2h.

[0029] (2) Under the protection of an inert atmosphere, 15.2 g of lithium aluminum hydride was added in batches to the reaction material obtained in step (1), stirred mechanically, and reacted at 100° C. for 2 hours.

[0030] (3) Under the protection of an inert atmosphere, add about 1000g of n-hexane to the reaction material obtained in step (2), after mechanical stirring for 0.5h, let it stand for 0.5h, separate the upper organic phase, remove the organic solvent, and obtain light ink Green viscous liquid product, yield 83.4%.

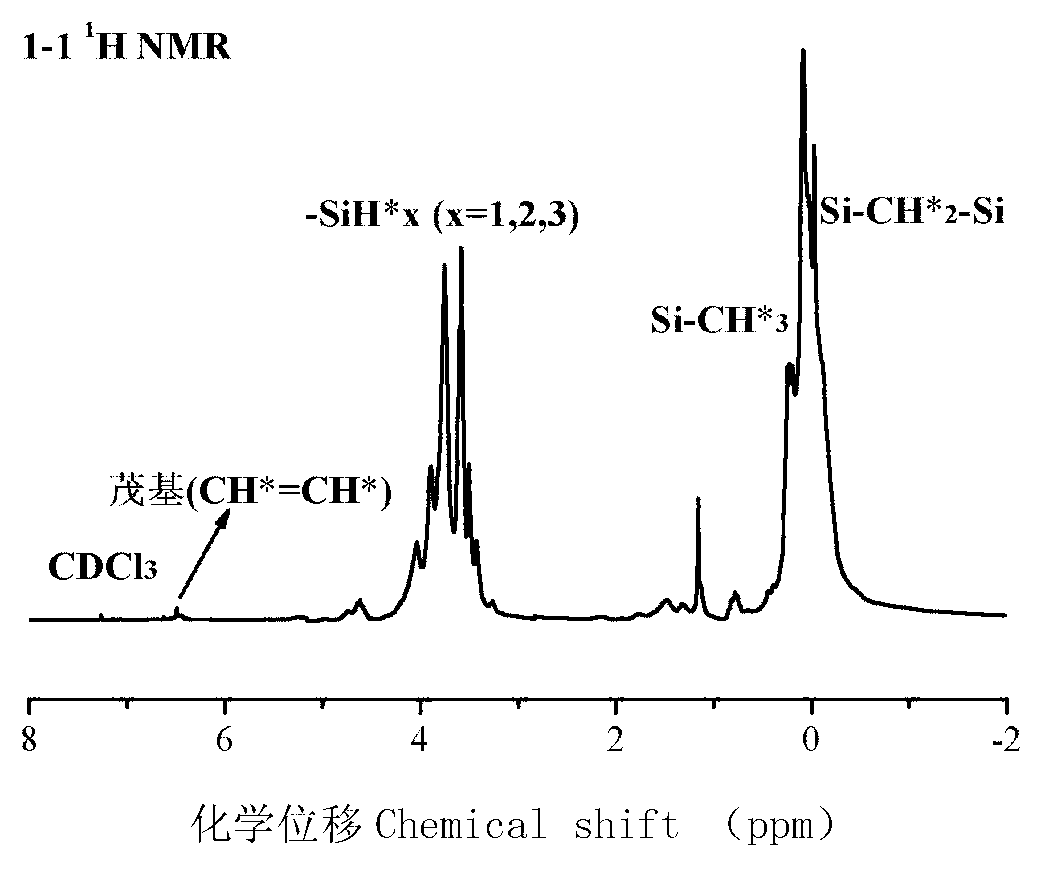

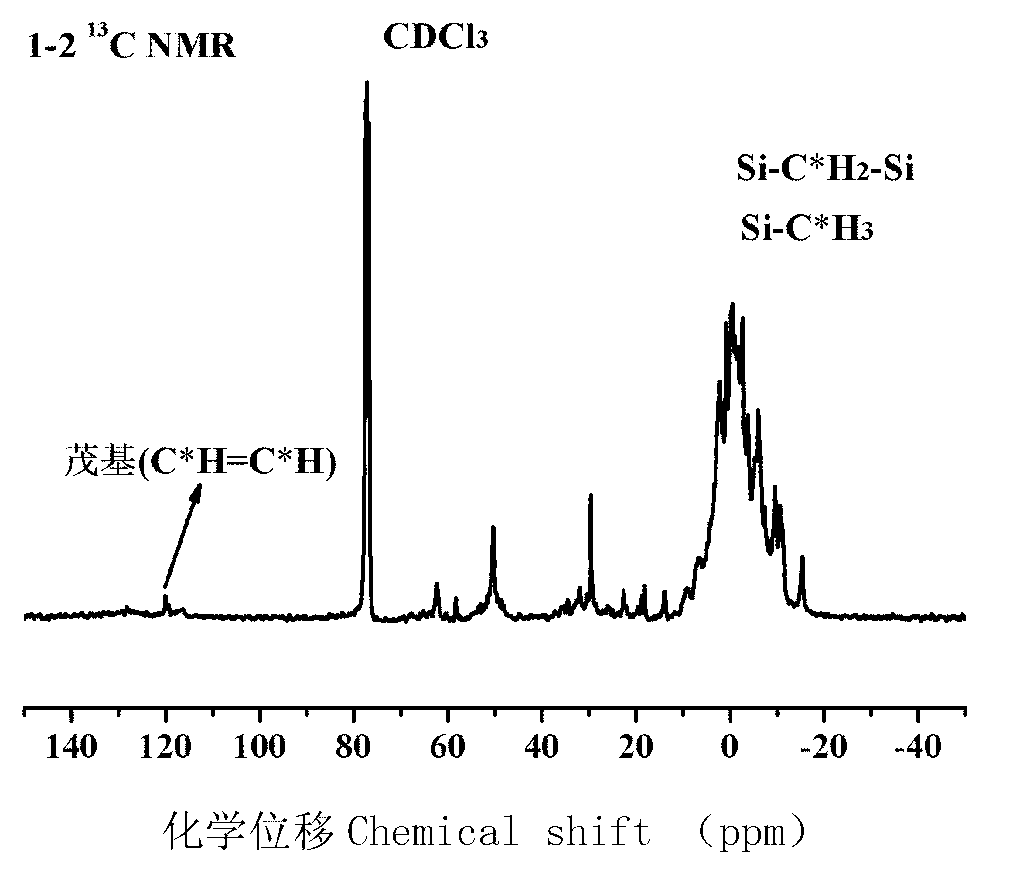

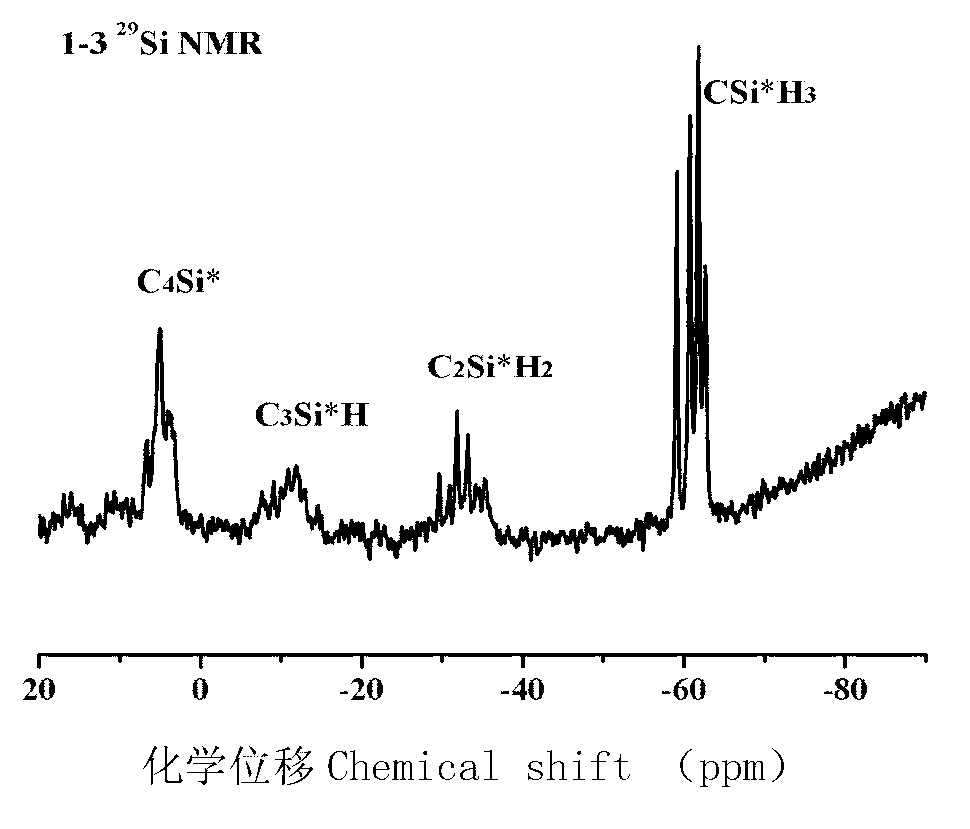

[0031] From the NMR spectrum ( 1 H-NMR, 13 C-NMR and 29 Si-NMR) to characterize ...

Embodiment 2

[0033] (1) Under the protection of an inert atmosphere, place 46.0g of chloromethyltrichlorosilane, 40.9g of (chloromethyl)methyldichlorosilane, 6.3g of titanocene dichloride and 500g of anhydrous ether in a reaction flask 18.0g of magnesium was added in batches and mechanically stirred; after the magnesium was added, the reaction was kept at 80°C for 36h.

[0034] (2) Under the protection of an inert atmosphere, 16.9 g of sodium aluminum hydride was added in batches to the reaction material obtained in step (1), stirred mechanically, and reacted at 60° C. for 12 hours.

[0035] (3) Under the protection of an inert atmosphere, add about 500g heptane to the reaction material obtained in step (2), after mechanical stirring for 0.5h, let it stand for 0.5h, separate the upper organic phase, remove the organic solvent, and obtain light ink Green viscous liquid product, yield 79.5%.

[0036] Through nuclear magnetic resonance data, it was confirmed that the liquid product was an ox...

Embodiment 3

[0038] (1) Under the protection of an inert atmosphere, mix 92.0g of chloromethyltrichlorosilane, 40.9g of (chloromethyl)methyldichlorosilane, 5.6g of titanocene dichloride and 1000g of anhydrous ethylene glycol dimethyl ether The solution was placed in a reaction bottle, and 19.2 g of magnesium was added in batches, and mechanically stirred; after the magnesium was added, the reaction was kept at 100° C. for 2 hours.

[0039] (2) Under the protection of an inert atmosphere, 18.5 g of lithium aluminum hydride was added in batches to the reaction material obtained in step (1), stirred mechanically, and reacted at 80° C. for 12 hours.

[0040] (3) Under the protection of an inert atmosphere, add about 500g of petroleum ether to the reaction material obtained in step (2), after mechanical stirring for 0.5h, let it stand for 0.5h, separate the upper organic phase, remove the organic solvent, and obtain light ink Green viscous liquid product, yield 80.3%.

[0041] Through nuclear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com