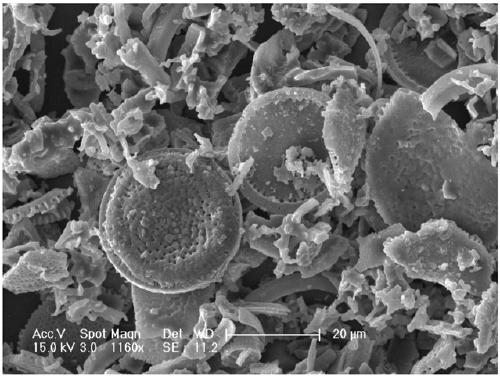

Diatomite-loaded metallocene catalyst as well as preparation method and application thereof

A technology of metallocene catalyst and diatomite, which is applied in the field of diatomite-supported metallocene catalyst and its preparation, can solve the problem that the use of metallocene carrier has not been greatly studied, and achieve the effect of low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

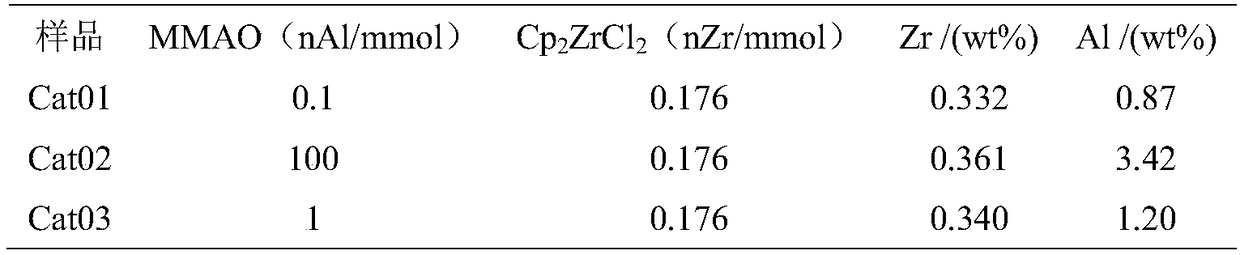

Embodiment 1

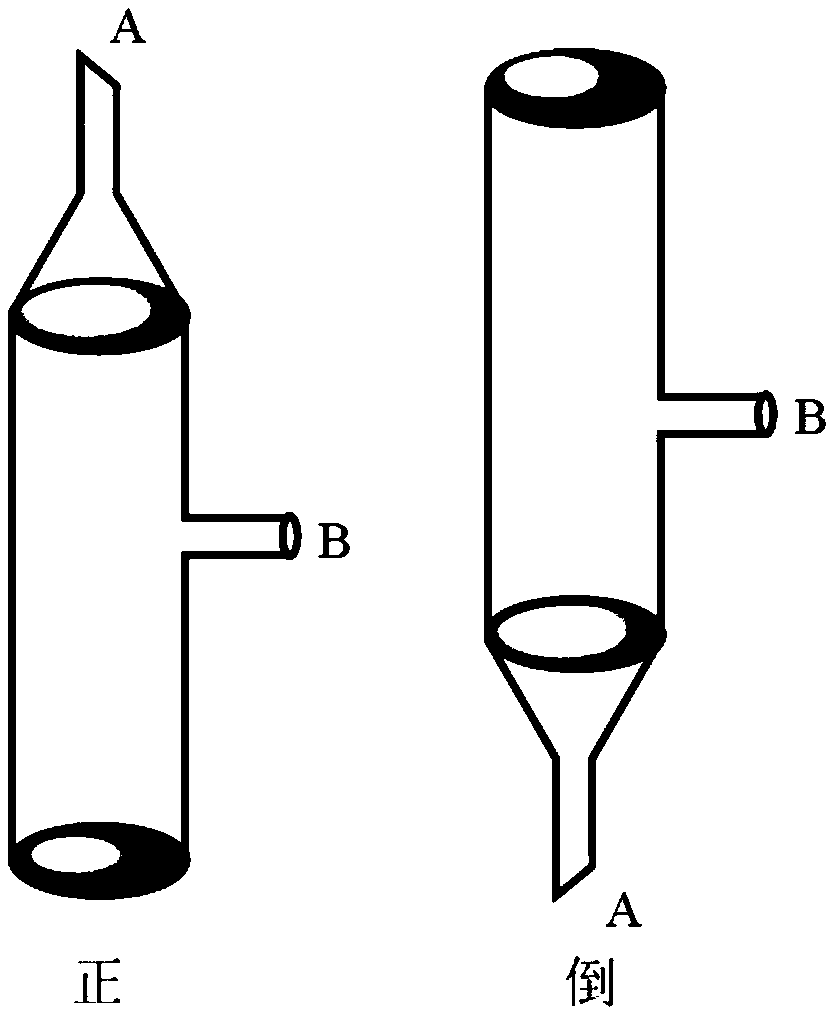

[0027] Catalyst loading

[0028] Using Diatomaceous Earth RS400 # to support metallocene catalysts. The specific loading process is as follows: under the protection of nitrogen, first add 0.5 g of the carrier to be loaded into a self-made filter Schlenk reactor, disperse it with 20 mL of toluene solvent, and then add 0.1 mL of MMAO through a syringe to remove trace water. The Al content is 0.1mmol, and then the Cp prepared in advance is added to the reactor with a syringe. 2 ZrCl 2 8.88 mL of the solution, in which the Zr content was 0.176 mmol, was stirred for 2 h, filtered, and the filter cake was dried to obtain 0.82 g of a diatomite-supported metallocene catalyst, which was labeled as Cat01.

Embodiment 2

[0030] Catalyst loading

[0031] Using Diatomaceous Earth RS400 # to support metallocene catalysts. The specific loading process is as follows: under nitrogen protection, first add 0.5 g of the carrier to be loaded into a self-made filter Schlenk reactor, disperse it with 20 mL of toluene solvent, and then add 100 mL of MMAO through a syringe to remove traces of water, in which Al The content is 100mmol, and then add the pre-prepared Cp to the reactor with a syringe 2 ZrCl 2 8.88 mL of the solution, in which the Zr content was 0.176 mmol, was stirred for 2 h, filtered, and the filter cake was dried to obtain 1.2 g of a diatomite-supported metallocene catalyst, which was labeled as Cat02.

Embodiment 3

[0033] Catalyst loading

[0034] Using Diatomaceous Earth RS400 # to support metallocene catalysts. The specific loading process is as follows: under the protection of nitrogen, first add 0.5 g of the carrier to be loaded into a self-made filter Schlenk reactor, disperse it with 20 mL of toluene solvent, and then add 1 ml of MMAO through a syringe to remove traces of water, in which Al The content is 1mmol, and then add the pre-prepared Cp into the reactor with a syringe 2 ZrCl 2 8.88 mL of the solution, in which the Zr content was 0.176 mmol, was stirred for 2 h, filtered, and the filter cake was dried to obtain 0.87 g of a diatomite-supported metallocene catalyst, which was labeled as Cat03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com