Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74 results about "Yttrium compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium(III) sulfide (Y2S3) is an inorganic chemical compound. It is a compound of Yttrium and Sulfur. Lide, David R. (1998), Handbook of Chemistry and Physics (87 ed.), Boca Raton, Florida: CRC Press, pp. 4–95, ISBN 0-8493-0594-2.

Alkaline battery

InactiveUS6566009B1Good heavy-loading discharge characteristicImprove discharge characteristicsGel electrodesAlkaline accumulator electrodesZinc compoundsTitanium

The present invention provides an alkaline battery having good heavy-loading discharge characteristics even after long-term storage at high temperatures. The alkaline battery of the present invention comprises a positive electrode containing manganese dioxide and nickel oxyhydroxide as an active material, a negative electrode containing zinc as an active material, and an alkaline electrolyte. The positive electrode further contains at least one compound selected from the group consisting of an oxygen-containing zinc compound, an oxygen-containing calcium compound, an oxygen-containing yttrium compound, and an oxygen-containing titanium compound.

Owner:PANASONIC CORP

Alkaline battery

InactiveCN1322383AInhibition of self-discharge reactionsExcellent large load discharge characteristicsGel electrodesPrimary cell electrodesZinc compoundsTitanium

The present invention provides an alkaline battery having good heavy-loading discharge characteristics even after long-term storage at high temperatures. The alkaline battery of the present invention comprises a positive electrode containing manganese dioxide and nickel oxyhydroxide as an active material, a negative electrode containing zinc as an active material, and an alkaline electrolyte. The positive electrode further contains at least one compound selected from the group consisting of an oxygen-containing zinc compound, an oxygen-containing calcium compound, an oxygen-containing yttrium compound, and an oxygen-containing titanium compound.

Owner:PANASONIC CORP

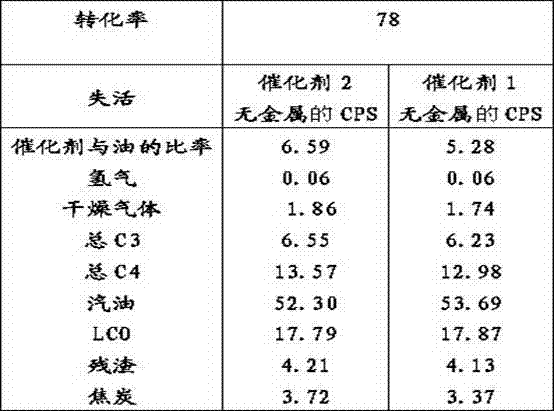

Process for making improved zeolite catalysts from peptized aluminas

This invention relates to a process of preparing a catalyst from zeolite and peptized alumina. The invention comprises adding a yttrium compound to the zeolite, either prior to, during, or after its combination with the peptized alumina. The yttrium compound can be added to the zeolite via exchange of yttrium onto the zeolite prior to addition of peptized alumina, or the yttrium can be added as a soluble salt during the combination of the zeolite and peptized alumina. In either embodiment, the zeolite catalyst is then formed from the zeolite, yttrium and peptized alumina, optionally containing other inorganic oxide. This invention is suitable for preparing fluid cracking catalysts.

Owner:WR GRACE & CO CONN

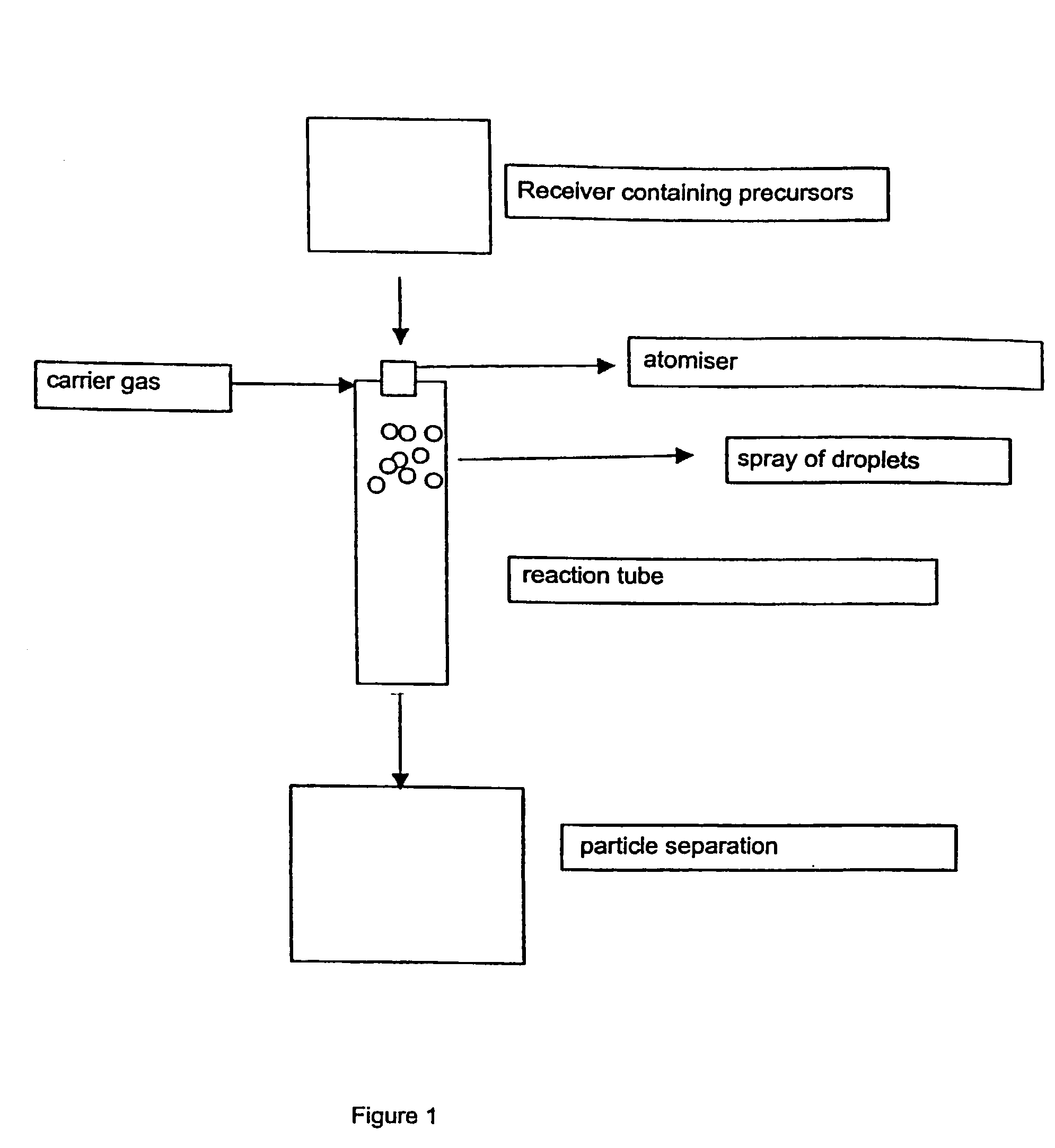

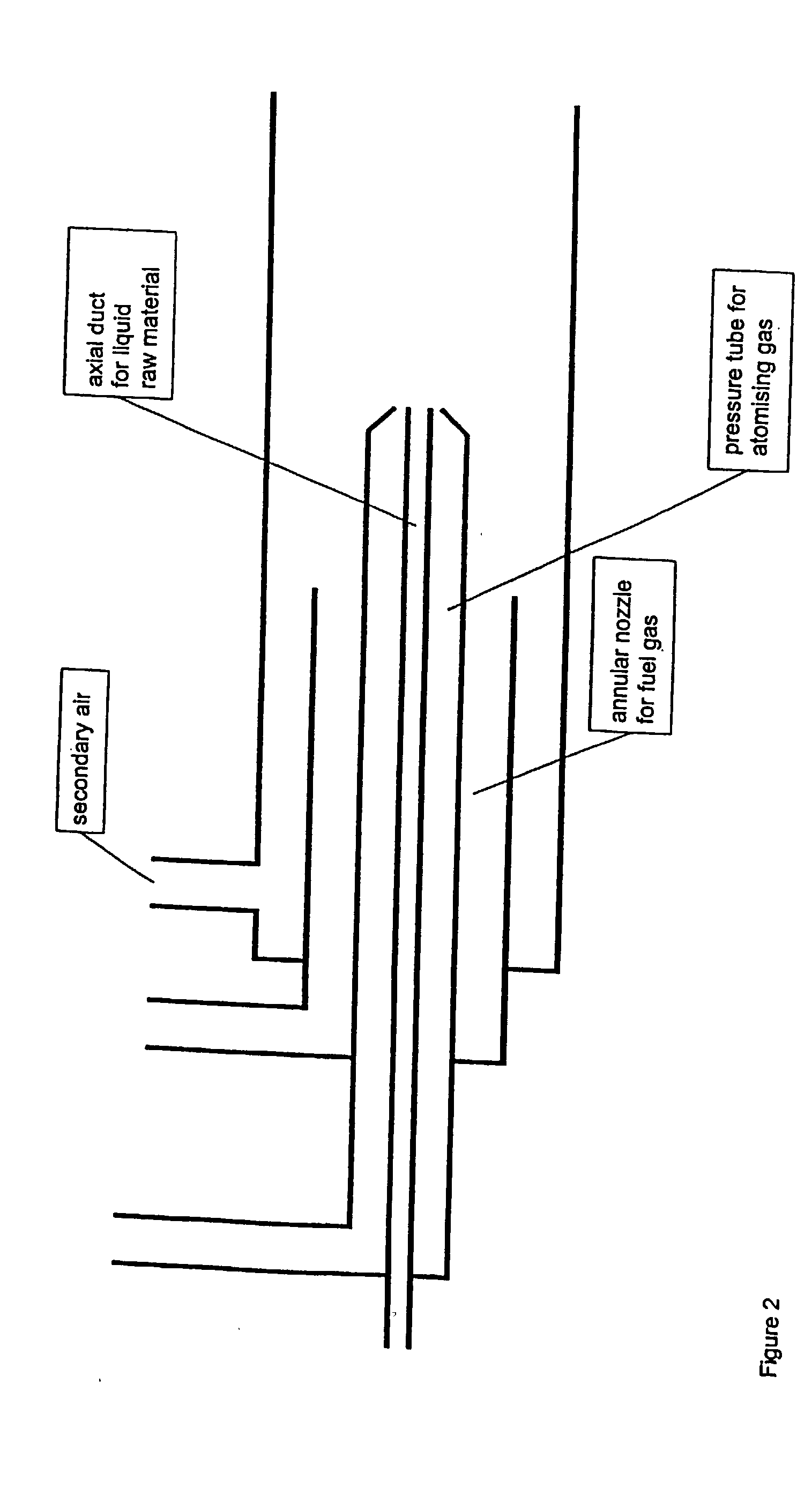

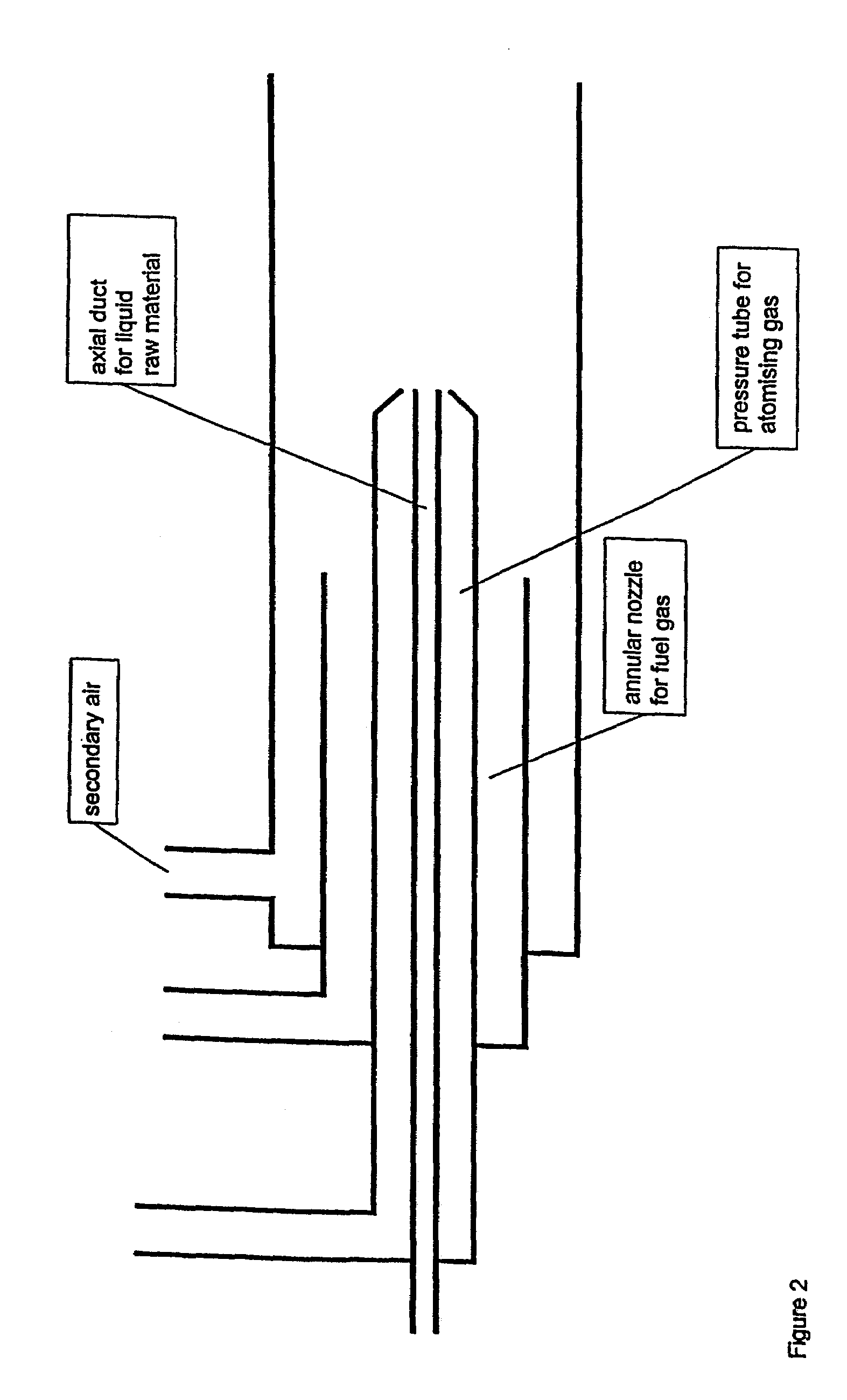

Nanoscalar pyrogenically produced yttrium-zirconium mixed oxide

Nanoscalar, pyrogenically produced yttrium-zirconium mixed oxide which has a BET surface area of between 1 and 600 m2 / g, a total chloride content of less than 0.05 wt. % and does not exhibit a conversion into the monoclinic phase during storage is produced by atomizing yttrium compounds and zirconium compounds and reacting them in a flame. The mixed oxide can be used as ceramic raw material.

Owner:EVONIK OPERATIONS GMBH

Ink composition

InactiveCN102105543AHard to clogImprove dispersion stabilityInksLuminescent compositionsVanadium CompoundsRare-earth element

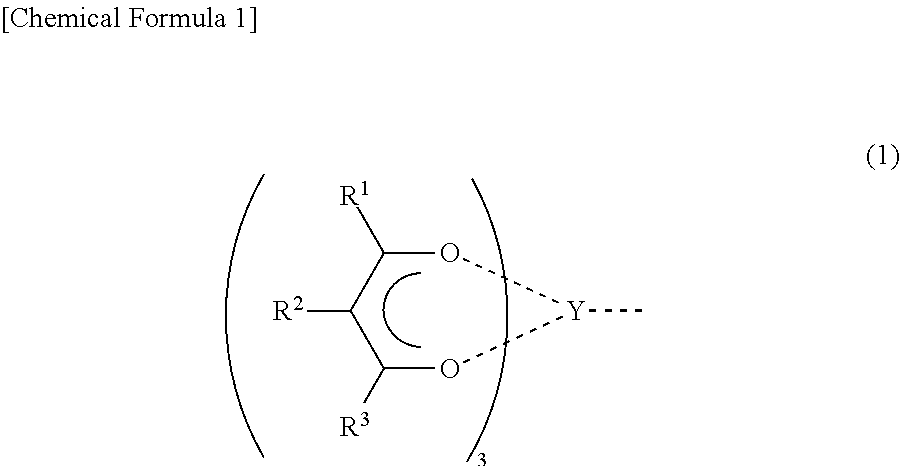

Disclosed is an ink composition comprising a microparticulate phosphor which can emit a high-brightness fluorescent light by ultraviolet ray and has a predetermined nanosize. The ink composition comprises a microparticulate phosphor represented by the formula: YVO4:A [wherein A represents a rare earth metal other than yttrium] and capable of emitting a fluorescent light upon the excitation with ultraviolet ray. The phosphor has an average primary particle diameter of 30 to 400 nm and is not burned. The phosphor can be produced by, for example, mixing and reacting a composition (I) comprising an yttrium compound, a compound of a rare earth metal other than yttrium and a complex-forming compound in water with a composition (II) comprising a vanadium compound in water.

Owner:KEIO UNIV +1

Member for plasma etching device and method for manufacture thereof

InactiveUS20080241412A1Molten spray coatingElectric discharge tubesSurface roughnessYttrium compound

A member for a plasma etching device, which comprises a device substrate comprising quartz glass, aluminum, alumite or a combination thereof and, formed on the surface thereof, a coating film of yttrium oxide or YAG having a film thickness of 10 μm or more and a variation in the thickness of 10% or less, and preferably a surface roughness (Ra) of 1 μm or less; and a method for manufacturing the member for a plasma etching device, which comprises a step of plasma-spraying yttrium oxide or YAG to the surface of said device substrate or a step of fusing yttrium oxide or YAG with an oxyhydrogen flame, followed by coating the surface with the fused product, or a step of applying a solution containing yttrium, a yttrium compound or YAG on the above surface, followed by heating to fuse the resultant coating, or a combination of the above steps, thereby forming a coating film of yttrium oxide or YAG having a film thickness 10 μm or more and a variation in the thickness of 10% or less, and preferably a surface roughness (Ra) of 1 μm or less. The member for a plasma etching device is capable of retaining high plasma resistance for a long period of time, is free from the occurrence of the abnormal etching owing to partial change of electric characteristics, and thus can be used for a long time, in particular, even in the treatment of a large semiconductor device of a 12 inch silicon wafer.

Owner:SHIN ETABU QUARTZ PRODS

Rare earth thick film circuit rare earth resistance pastes based on metal substrate and its preparation process

ActiveCN1972535AImprove electrical performanceImprove wettabilityNon-conductive material with dispersed conductive materialResistor manufactureOrganic solventRare earth

This invention discloses one rare earth thick film circuit resistance plasma and its process method based on metal baseboard, wherein, the plasma is composed of function phase and organic load with proportion as 65-85:35- 15; the function phase is composed of palladium-silver-yttrium compound power and micro crystal power with proportion as 75-55:25- 45; palladium-silver-yttrium weight as proportion as 75-59:15-40.5:10-0.5. The rare earth resistance plasma process comprises the following steps: a, micro crystal glass powder processing; b, palladium-silver-yttrium compound processing; c, matching organic solvent load; d, processing rare earth plasma.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Member for plasma etching device and method for manufacture thereof

A member for a plasma etching device, which comprises a device substrate comprising quartz glass, aluminum, alumite or a combination thereof and, formed on the surface thereof, a coating film of yttrium oxide or YAG having a film thickness of 10 μm or more and a variation in the thickness of 10% or less, and preferably a surface roughness (Ra) of 1 μm or less; and a method for manufacturing the member for a plasma etching device, which comprises a step of plasma-spraying yttrium oxide or YAG to the surface of said device substrate or a step of fusing yttrium oxide or YAG with an oxyhydrogen flame, followed by coating the surface with the fused product, or a step of applying a solution containing yttrium, a yttrium compound or YAG on the above surface, followed by heating to fuse the resultant coating, or a combination of the above steps, thereby forming a coating film of yttrium oxide or YAG having a film thickness 10 μm or more and a variation in the thickness of 10% or less, and preferably a surface roughness (Ra) of 1 μm or less. The member for a plasma etching device is capable of retaining high plasma resistance for a long period of time, is free from the occurrence of the abnormal etching owing to partial change of electric characteristics, and thus can be used for a long time, in particular, even in the treatment of a large semiconductor device of a 12 inch silicon wafer.

Owner:SHIN ETABU QUARTZ PRODS

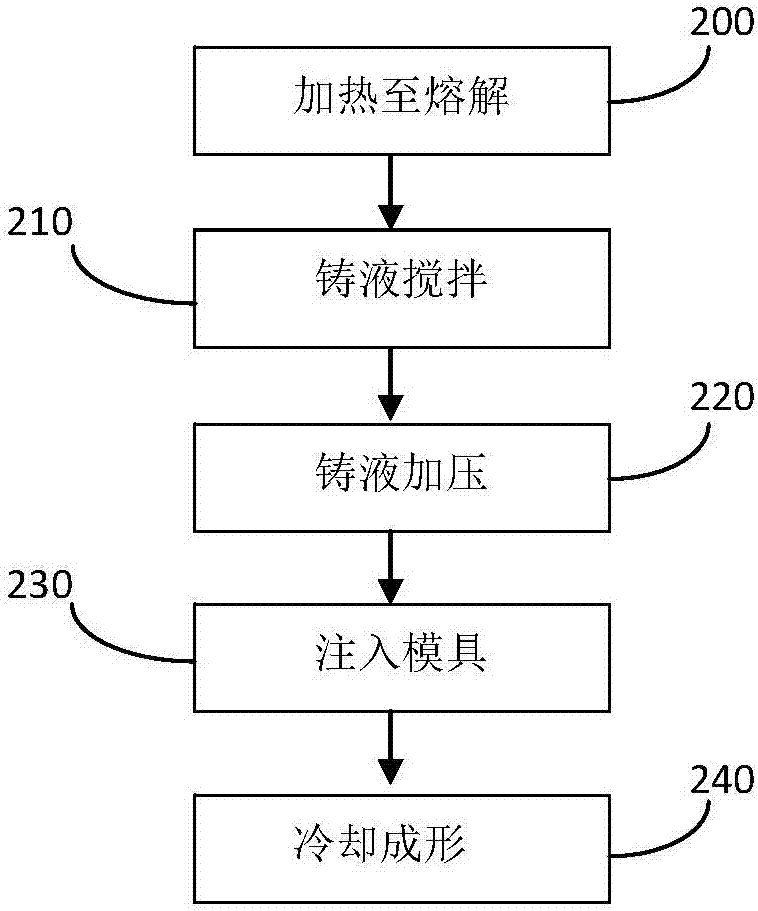

Mg-Gd-Y-Zr magnesium alloy refining flux and producing method thereof

The invention provides an Mg-Gd-Y-Zr magnesium alloy refining flux and a production method thereof. The chemical components of the flux are mixed according to the following mass percentages: potassium chloride of ranging from 30 to 50 percent, barium chloride of ranging from 5 to 20 percent, sodium chloride of ranging from 2 to 10 percent, calcium chloride of ranging from 10 to 20 percent, calcium fluoride of ranging from 2 to 8 percent, cryolite of ranging from 1 to 5 percent, gadolinium compound of ranging from 3 to 8 percent, yttrium compound of ranging from 3 to 8 percent, and zirconium compound of ranging from 2 to 8 percent, wherein, the gadolinium compound is gadolinium chloride, gadolinium carbonate or gadolinium fluoride, the yttrium compound is yttrium chloride, yttrium carbonate or yttrium fluoride, the zirconium compound is zirconium tetrachloride or potassium zirconium fluoride. The flux has good melting point, viscosity, wettability and the slag removing performance which is improved greatly. Because the flux does not contain magnesium chloride or react with the lanthanon such as gadolinium and yttrium, the chemical reaction loss of the lanthanon in the refining process is not caused, thereby being particularly suitable for the refining purifying process of the Mg-Gd-Y-Zr magnesium alloy and improving the refining effect of the magnesium fused mass.

Owner:SHANGHAI JIAO TONG UNIV

Electric melting method for manufacturing yttria stabilized zirconia

The invention discloses an electric melting method for manufacturing yttria stabilized zirconia. The method comprises the following steps: uniformly mixing 80-97 weight parts of monoclinic zirconia, 3-9 weight parts of yttrium compound, 0-3.4 weight parts of calcium compound and 0-3 weight parts of magnesium compound in a mixer to prepare mixing furnace charge, then putting into a arc furnace for melting, cooling a melt, and crushing. An yttria stabilized zirconia refractory material produced by the invention has a true density higher than 6.0g / cm<3>, a stabilization rate higher than 70%, compact material structure, good erosion resistance and thermal shock stability, so as to prolong service life of refractory material. In addition, the yttria stabilized zirconia can be applied to various zirconia ceramics, such as zirconia grinding medium, zirconia oxygen probe and plasma spraying.

Owner:郑州振中电熔新材料有限公司

Nanoscalar pyrogenically produced yttrium-zirconium mixed oxide

Nanoscalar, pyrogenically produced yttrium-zirconium mixed oxide which has a BET surface area of between 1 and 600 m2 / g, a total chloride content of less than 0.05 wt. % and does not exhibit a conversion into the monoclinic phase during storage is produced by atomizing yttrium compounds and zirconium compounds and reacting them in a flame. The mixed oxide can be used as ceramic raw material.

Owner:EVONIK OPERATIONS GMBH

Yttrium oxide-based laser ceramics with core-shell structure and preparation method thereof

The invention discloses yttrium oxide-based laser ceramics with a core-shell structure and a preparation method thereof, a core-layer of a crystalline grain of the laser ceramics is (Y, M) 2O3 phase, a shell-layer is (Y, N) 2O3 phase, wherein the M is a rare earth luminescent ion, and the N is a sintering assistant. The preparation process is as follows: first, mixing a yttrium compound with an M compound, calcining to obtain (Y, M) 2O3 powder, then mixing the yttrium compound with an N compound, calcining to obtain (Y, N) 2O3 powder, afterwards, mixing the two powder; or mixing the yttrium compound with the N compound and adding the (Y, M) 2O3 powder directly into the mixture to be mixed and calcined; performing isostatic pressure molding and vacuum sintering on the obtained mixed powder, then annealing after cooling. The preparation process provided by the invention is simple and controllable, a (Y, N) 2O3 thin layer with excellent sintering property is used to coat the (Y, M)2O3 phase, which can reduce crystal lattice distortion on the basis of ceramic sintering property improvement, thus obtaining excellent laser property.

Owner:CHINA JILIANG UNIV

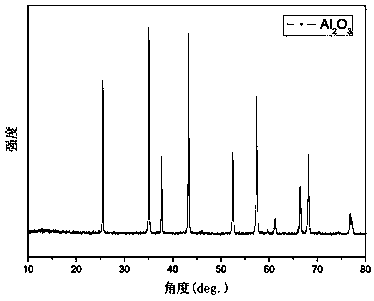

Fluorescent powder capable of promoting plant growth and preparation method thereof

ActiveCN109874803ALow priceWide variety of sourcesBiocidePlant growth regulatorsChromium CompoundsGrowth plant

The invention discloses fluorescent powder capable of promoting plant growth and a preparation method thereof. The fluorescent powder is prepared from Ce-doped oxide powder and Al2O3:Cr3+ powder whichare mixed, wherein the Ce-doped oxide powder has a garnet structure. The preparation method comprises the steps: a first aluminum compound and a chromium compound are weighed, and mixed and ground tothe micron grade, and first powder is obtained; the first powder is calcined at the high temperature, cooled and ground, and the Al2O3:Cr3+ powder is obtained; a second aluminum compound, a yttrium compound and a cerium compound are weighed, mixed, ground, calcined at the high temperature under the reducing atmosphere, cooled and ground, and YAG:Ce3+ powder is obtained; and the YAG:Ce3+ powder and the Al2O3:Cr3+ powder are mixed according to the mass ratio of 1:(1 to 20), and ground, and the fluorescent powder capable of promoting plant growth is prepared. The fluorescent powder can emit redlight beneficial to plant growth, the utilization rate of light energy can be increased, plant growth can be promoted, the cost is low, the efficiency is high, and electric energy is not consumed.

Owner:LANZHOU UNIVERSITY

Process for making improved catalysts from clay-derived zeolites

ActiveUS20120329639A1High retention rateCatalytic crackingMolecular sieve catalystsPtru catalystPhysical chemistry

This invention relates to a process of preparing an improved catalyst comprising a clay derived zeolite. In particular, the invention comprises combining an yttrium compound with a zeolite produced by treating clay with a silica source and under alkaline conditions. The clay derived zeolite can be further combined with conventional matrix and / or binder precursors to form particulates suitable for use as catalysts in fluid catalytic cracking (FCC). Alternatively, the clay that is treated with the silica source and alkaline conditions can be in particulate form having sizes suitable for use in FCC, and the zeolite is produced in situ within the particulate. Yttrium compound is then combined with the zeolite in the particulate, e.g., via impregnation. It has been shown that the addition of the yttrium compound improves zeolite surface area retention, and zeolite stability in catalysts comprising clay derived zeolites.

Owner:WR GRACE & CO CONN

Composition for negative electrode of alkaline electrolyte battery

InactiveUS20080070117A1Long life-timeLow self-dischargeAlkaline accumulatorsNon-aqueous electrolyte accumulator electrodesHydrogenManganese

The invention proposes a composition comprising: a) a hydrogen-fixing alloy of formula R1-tMgtNis-zMz in which: R represents one or more elements chosen from the group comprising La, Ce, Nd and Pr; M represents one or more elements chosen from the group comprising Mn, Fe, Al, Co, Cu, Zr and Sn; 0.1≦t≦0.4; 3.0≦s≦4.3; z≦0.5; b) a manganese compound in a proportion such that the mass of manganese represents from 1 to 5.5% of the mass of the alloy, c) an yttrium compound in a proportion such that the mass of yttrium represents from 0.1% to 2% of the mass of the alloy. The invention also relates to an anode comprising the composition according to the invention. The invention also relates to an alkaline electrolyte battery comprising said at least one anode.

Owner:SAFT GRP SA

Titanium-based composite material and manufacturing method thereof

The invention provides a titanium-based composite material and a manufacturing method thereof. The titanium-based composite material is selected from alpha-phase pure titanium or titanium alloy parent metal, alpha-phase and beta-phase pure titanium or titanium alloy parent metal, beta-phase pure titanium or titanium alloy parent metal and Omega-phase mesoporous metal titanium parent metal; at least one ceramic powder enhanced composite material, which contains 10% of the components, of carbide, nitride, oxide or boride is added; or at least one ceramic powder enhanced composite material or one powder enhanced composite material composed of ferroelectric powder, which contains 10% of the components, of titanate, niobide, a barium compound, a strontium compound, a tantalum compound and a yttrium compound is added; or at least one magnetic powder enhanced composite material, which contains 10% of the components, of a neodymium-iron-boron compound or a samarium-cobalt compound is added; and the powder enhanced composite material and the titanium parent metal are mixed according to the total volume ratio of 10% to 70% and a mixture is processed in a casting, sintering or pressurizing manner to prepare the titanium-based composite material which has physical or chemical and electrical properties of the parent metal and the composite material.

Owner:BRILO TECH CO LTD

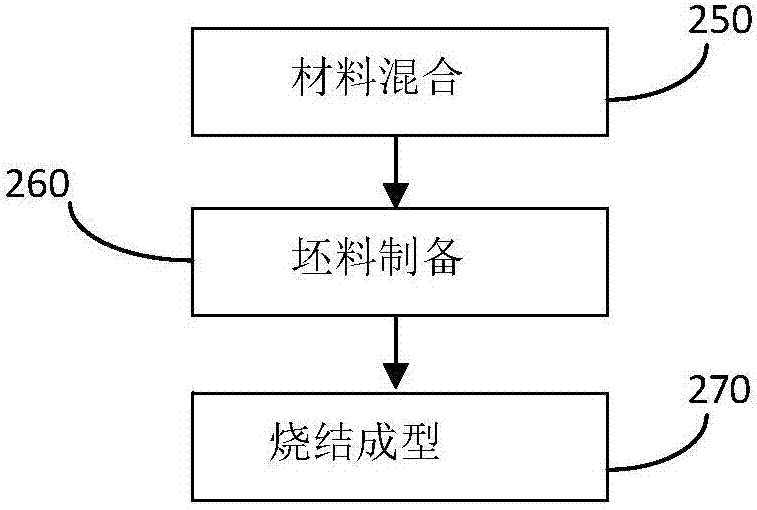

Preparation method of yttrium-containing lithium ion battery cathode material lithium titanate carbon-coated composite material

InactiveCN103579599AImprove uniformityImprove conductivityCell electrodesSecondary cellsCarbon compositesLithium compound

The invention provides a preparation method of an yttrium-containing lithium ion battery cathode material lithium titanate carbon-coated composite material. The preparation method is characterized in that the preparation method comprises following concrete steps: (1) weighing a soluble lithium compound, titanium dioxide (anatase type) and a yttrium compound according to a stoichiometric ratio of an target compound of Li[x]YpTi[y]Oz, adding into a ball milling jar, adding an organic micromolecule carbon source precursor and mixing, and performing ball milling in an uniform medium and drying, wherein the x is more than 0 and not more than 8, the p is more than 0 and less than 5, the y is more than 0 and not more than 6, the z is not less than 1 and not more than 12, and the ratio of x to y is not less than 1 / 2 and not more than 2; (2) maintaining the temperature of the dried powder in air or an inert gas at 300-600 DEG C for 2-20 h to obtain a sintering precursor; and (3) mixing the sintering precursor obtained in the step (2) and an organic macromolecule carbon source precursor, performing ball milling in an uniform medium and drying; and maintaining the temperature in air or the inert gas at 600-900 DEG C for 2-30 h to obtain a finished product of lithium titanate powder. The material shows excellent rate performance. The preparation method significantly improves the conductivity of the lithium titanate product, and the material shows the excellent rate performance and excellent cycle performance, and is suitable to be used in a power cell.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

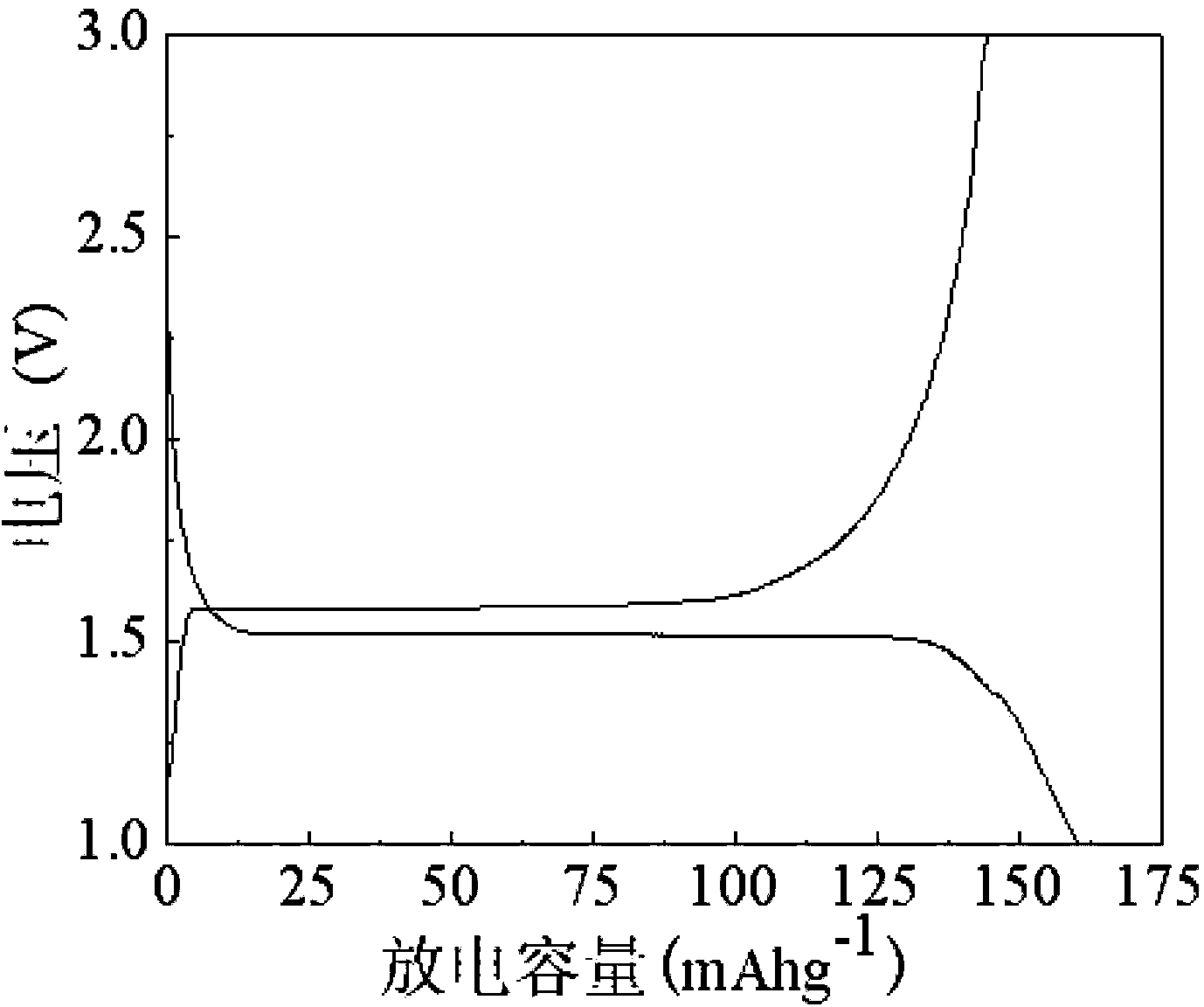

Method for preparing line shape or stick shape polycrystalline Ce0.6Zr0.3Y0.1O2 solid solution

InactiveCN101125302AImprove anti-poisoning performanceReduce poisonCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCeriumSurface-active agents

The invention relates to a preparing method for the linear or clubbed multi crystal Ce0.6Zr0.3Y0.1O2 sosoloid. The traditional method is hard to make the linear or clubbed multi crystal Ce0.6Zr0.3Y0.1O2 sosoloid. The invention takes the cetyl trimethylammonium bromide of a lower price as the surface active agent, obtain the Ce0.6Zr0.3Y0.1O2 avant garde via the water heating process, and then obtain the linear or clubbed multi crystal Ce0.6Zr0.3Y0.1O2 sosoloid by burning, wherein, the length of the linear or clubbed body is thirty nanometer to two micron. The invention can obtain cerium zirconium yttrium compound oxide and is the catalyst material in the material domain. The material has a wide applying potential in the multi catalyze, the storing and releasing of the oxygen, the solid fuel battery, the optical material, the solid electrolyte, the solid sensor and the high temperature heat proof refrigeration material.

Owner:BEIJING UNIV OF TECH

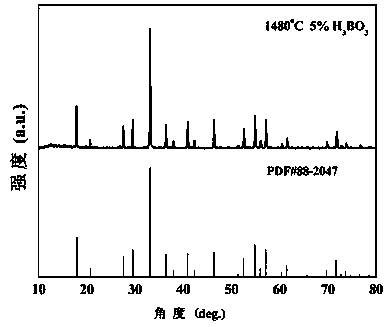

Method for preparing YAG-Ce fluorescent powder for white-light LED (light-emitting diode)

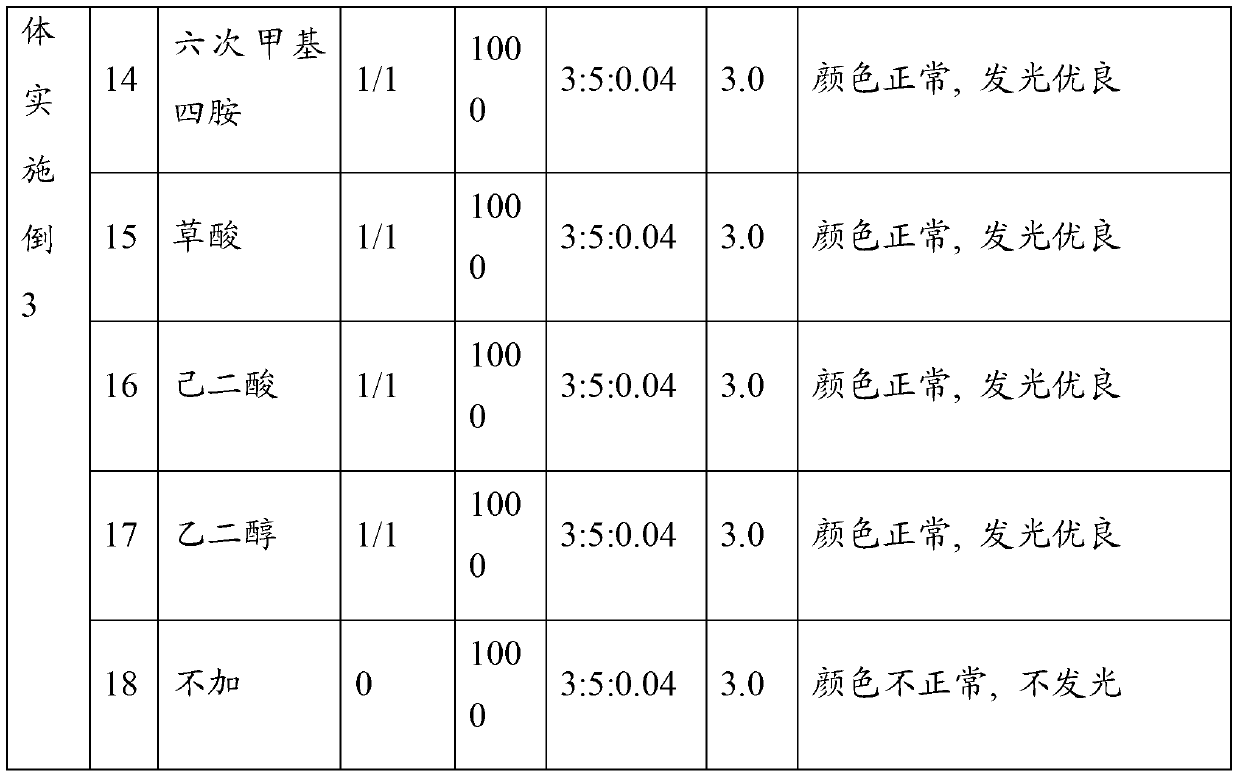

ActiveCN103343006AGood lookingLuminous intensityEnergy efficient lightingLuminescent compositionsCeriumReaction temperature

The embodiment of the invention discloses a method for preparing YAG-Ce fluorescent powder for a white-light LED (light-emitting diode). The method comprises the following steps of: weighing a combustion agent and raw materials comprising an aluminium compound, a yttrium compound and a cerium compound for preparing the YAG-Ce fluorescent powder; uniformly mixing and grinding the materials aforementioned, then starting to heat to 300-600 DEG C until a combustion phenomenon occurs, then heating, insulating and reacting for a period of time, then cooling to a room temperature to obtain yellow powder; and ball-milling and sieving the yellow powder to obtain the YAG-Ce fluorescent powder. According to the method disclosed by the embodiment of the invention, an organic matter is used as the combustion agent, and the YAG-Ce fluorescent powder used in a white-light LED device is manufactured by a combustion method; and because the combustion heat generated by a combustion reaction can be very high, the problems of high needed temperature, energy consumption, no environment friendliness and the like of the traditional high-temperature solid-state method can be effectively solved; a reaction temperature can be greatly reduced to about 1000 DEG C in the method disclosed by the invention from the traditional 1400-1700 DEG C, so as to achieve an effect of low-temperature synthesis, and the manufactured YAG-Ce fluorescent powder is excellent in appearance and light-emitting property; and because the temperature of a synthetic reaction is greatly reduced, the cost of energy is greatly reduced, and the total manufacturing cost is obviously reduced.

Owner:HUIZHOU UNIV

Conjugated diene polymer manufacturing method, polybutadiene, and rubber composition utilizing the same

InactiveUS8283401B2Maintain good propertiesImprove workabilitySpecial tyresPolymer scienceMooney viscosity

Provided by using a catalyst containing an yttrium compound is conjugated diene polymer with very low solution viscosity, improved workability, high degree of branching, and high content of cis-1,4 structures. Also provided is a rubber composition utilizing the polymer and allowing excellent dispersion of reinforcing agent. According to a method of manufacturing a conjugated diene polymer characterized by polymerizing a conjugated diene at 50 to 120° C. in the presence of a catalyst obtained from (A) an yttrium compound, (B) an ionic compound consisting of a non-coordinating anion and a cation, and (C) an organoaluminum compound, the conjugated diene polymer has the following characteristics that: (1) a ratio (Tcp / ML1+4) between a 5 wt % toluene solution viscosity (Tcp) measured at 25° C. and a Mooney viscosity (ML1+4) at 100° C. is 0.1 to 1.2; and (2) a content of cis-1,4 structures is 80% or higher, and a content of 1,2 structures is lower than 5%.

Owner:UBE IND LTD

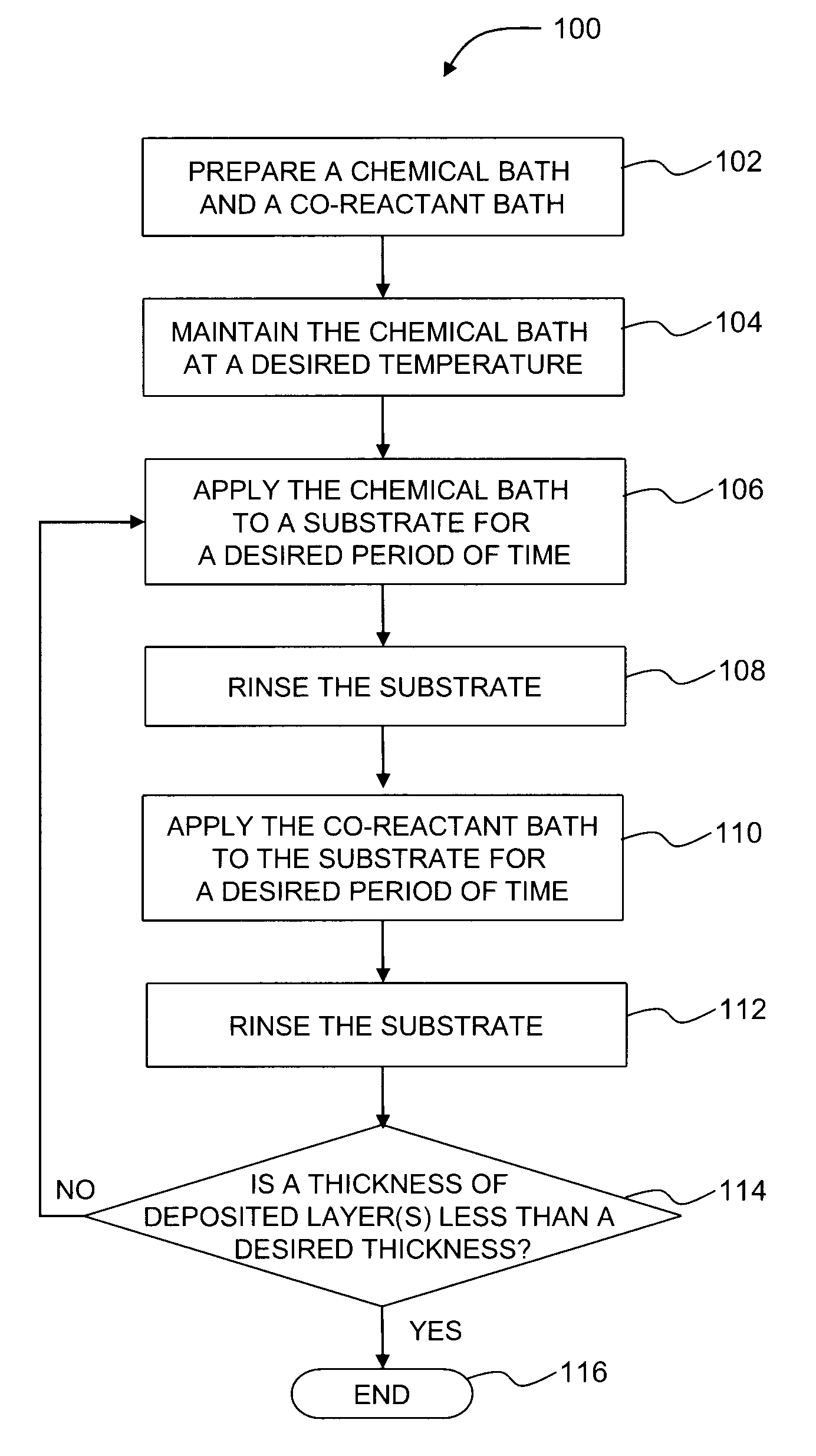

Deposition method for high-k dielectric materials

InactiveUS20090253270A1Pretreated surfacesSemiconductor/solid-state device manufacturingLanthanideTitanium

A method for depositing a high-k dielectric material on a semiconductor substrate is disclosed. The method includes applying a chemical bath to a surface of a substrate, rinsing the surface, applying a co-reactant bath to the surface of the substrate, and rinsing the surface. The chemical bath includes a metal precursor which includes at least a hafnium compound, an aluminium compound, a titanium compound, zirconium compound, a scandium compound, a yttrium compound or a lanthanide compound.

Owner:INTEL CORP

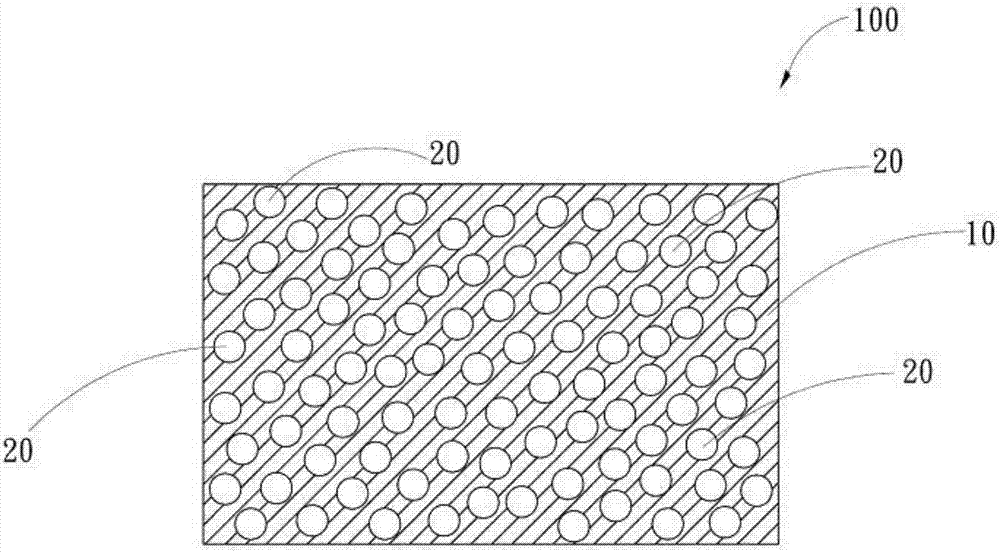

Plasma-resistant member

A plasma-resistant member according to the present invention includes a base member formed of a silicon nitride sintered body, an aluminum nitride sintered body, an alumina sintered body, or a silicon carbide sintered body; and a thin film formed on a surface of the base member and composed of an yttrium compound or a spinel, wherein the thin film has, in a surface of the thin film, a plurality of projections for supporting a wafer, and a ratio a2 / a1 of a film thickness a2 of portions of the thin film that include the projections to a film thickness a1 of portions of the thin film that do not include the projections satisfies 1<a2 / a1<1.6.

Owner:NGK INSULATORS LTD

Process for making improved zeolite catalysts from peptized aluminas

This invention relates to a process of preparing a catalyst from zeolite and peptized alumina. The invention comprises adding a yttrium compound to the zeolite, either prior to, during, or after its combination with the peptized alumina. The yttrium compound can be added to the zeolite via exchange of yttrium onto the zeolite prior to addition of peptized alumina, or the yttrium can be added as a soluble salt during the combination of the zeolite and peptized alumina. In either embodiment, the zeolite catalyst is then formed from the zeolite, yttrium and peptized alumina, optionally containing other inorganic oxide. This invention is suitable for preparing fluid cracking catalysts.

Owner:WR GRACE & CO

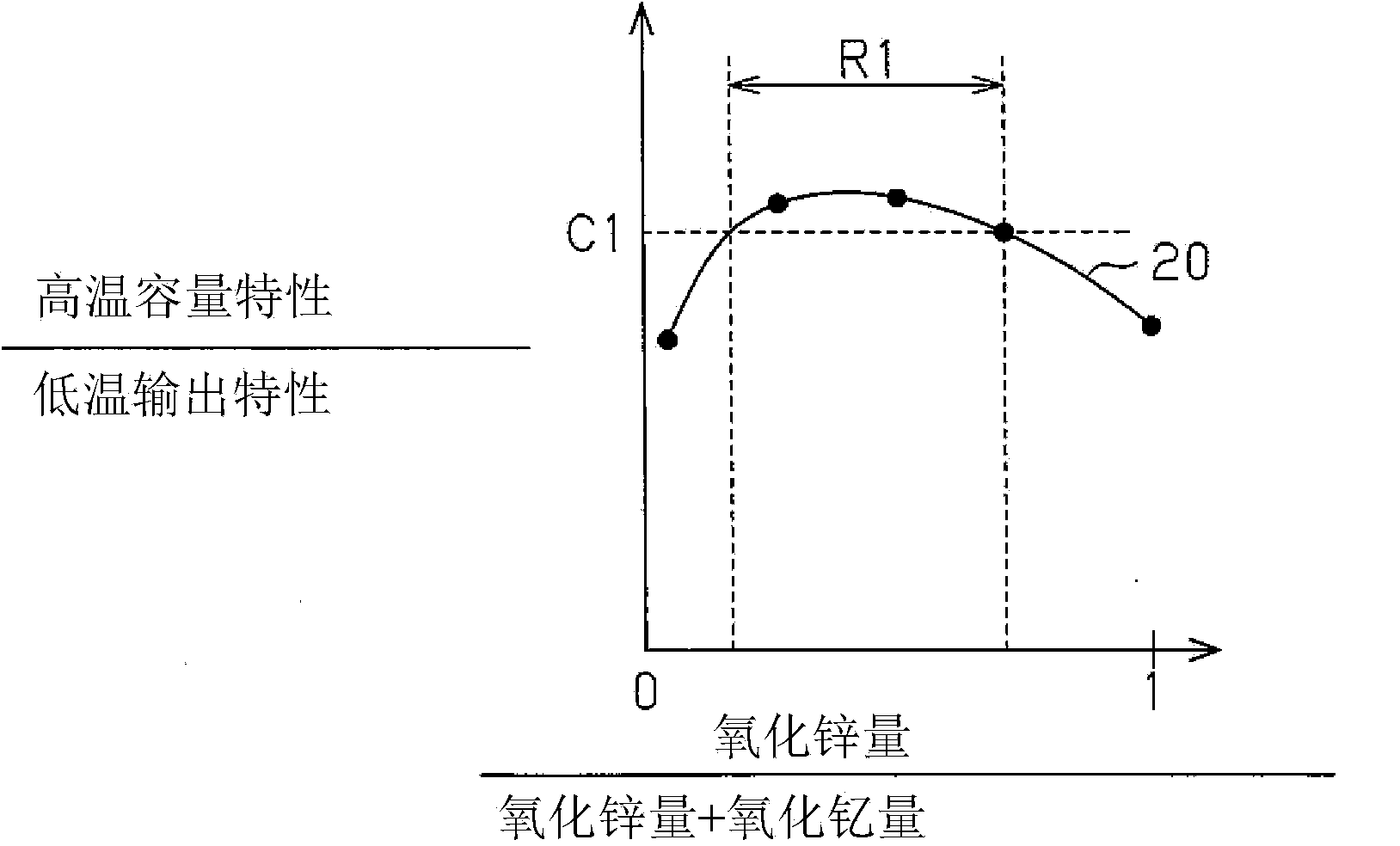

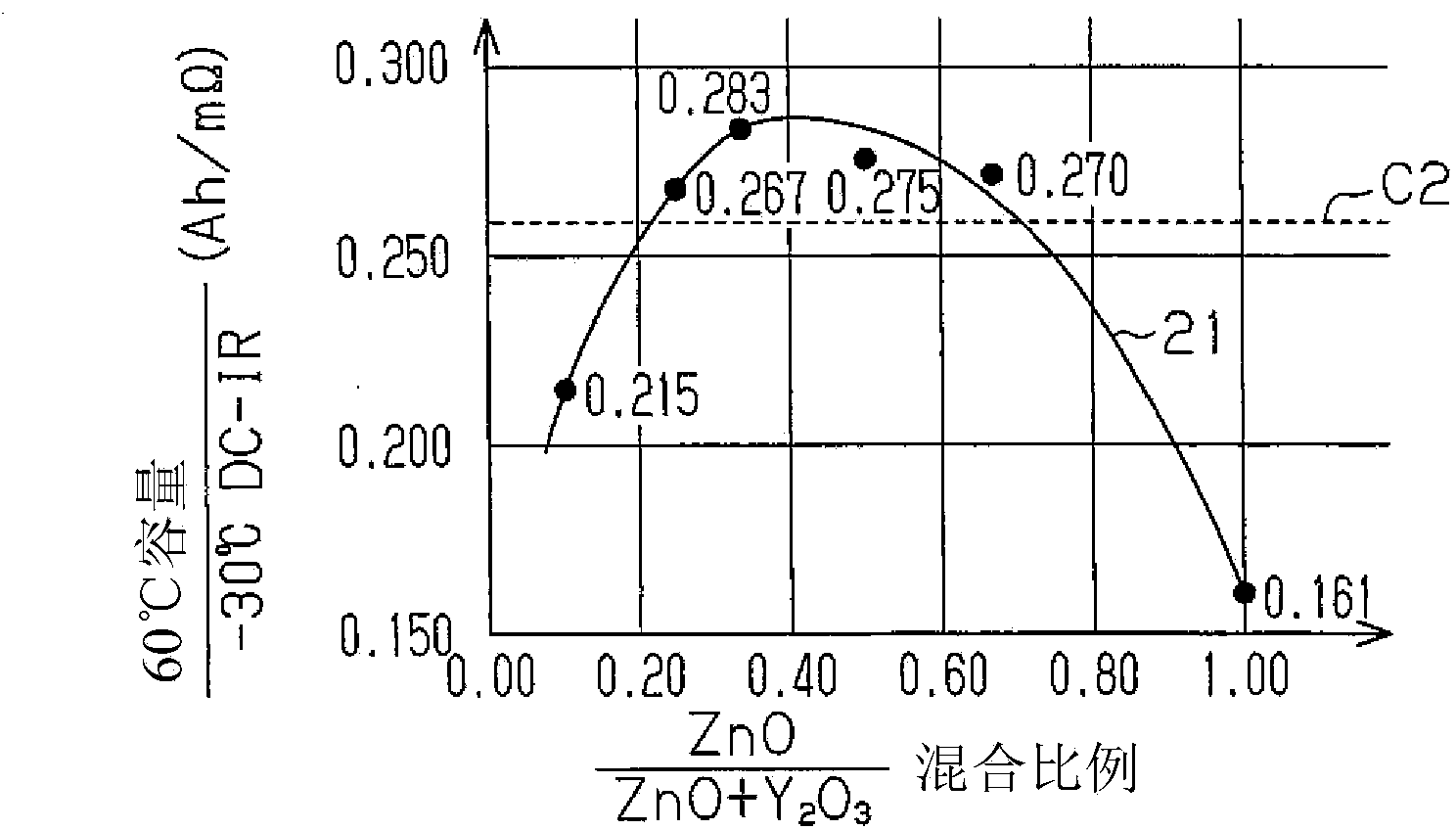

Alkaline storage battery anode, method for producing alkaline storage battery anode, alkaline storage battery, method for producing alkaline storage battery, anode active material for alkaline storage battery, method for producing anode active material for alkaline storage battery

InactiveCN103477471AAdjust usageLittle environmental dependencePositive electrodesAlkaline accumulator electrodesZinc compoundsPhysical chemistry

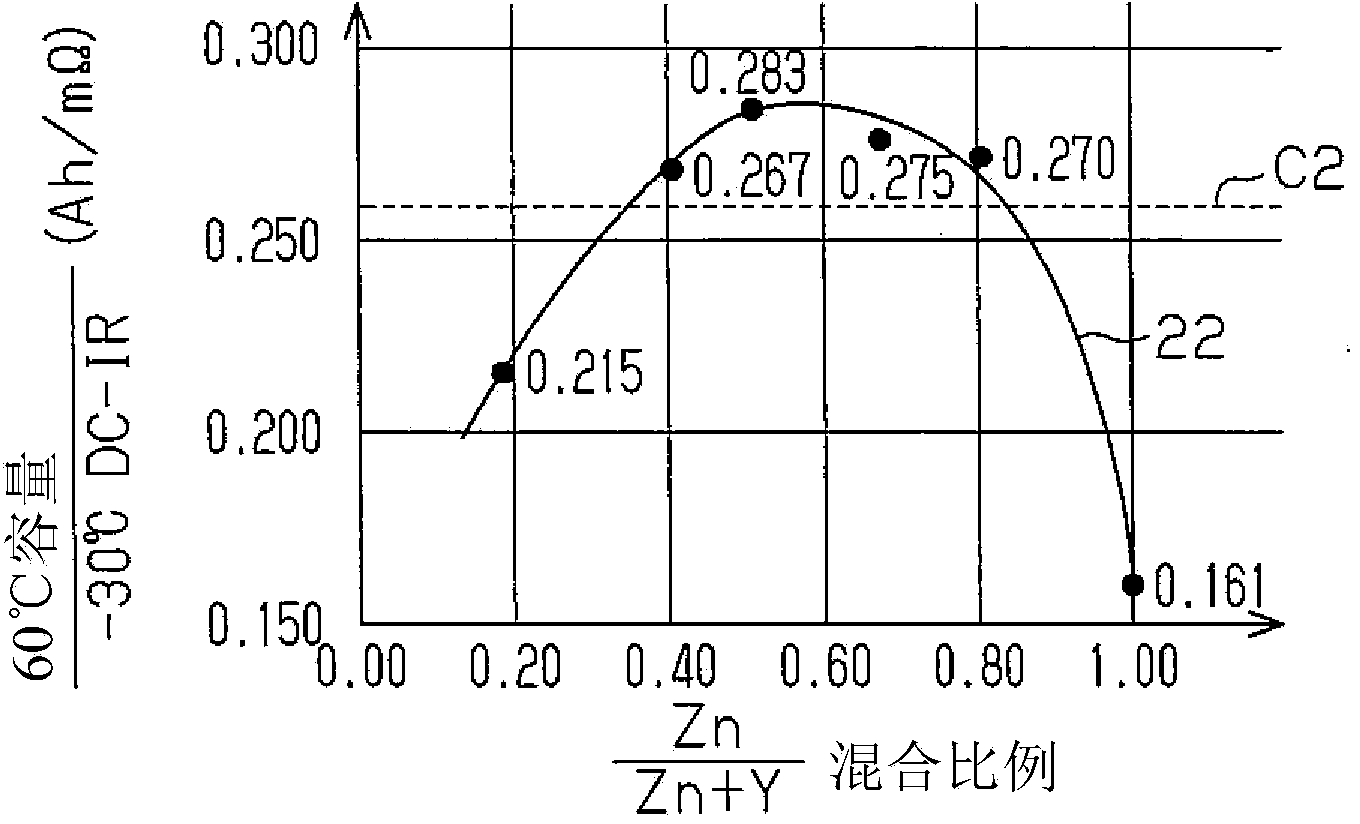

This alkaline storage battery anode is provided with: nickel hydroxide particles covered by a cobalt compound coating layer; a zinc compound; and an yttrium compound and / or an ytterbium compound. The zinc compound and the yttrium compound and / or ytterbium compound are blended at a blend ratio that is in accordance with the ratio of the capacitance characteristics of the alkaline storage battery and the output characteristics of the alkaline storage battery.

Owner:PANASONIC EV ENERGY CO LTD

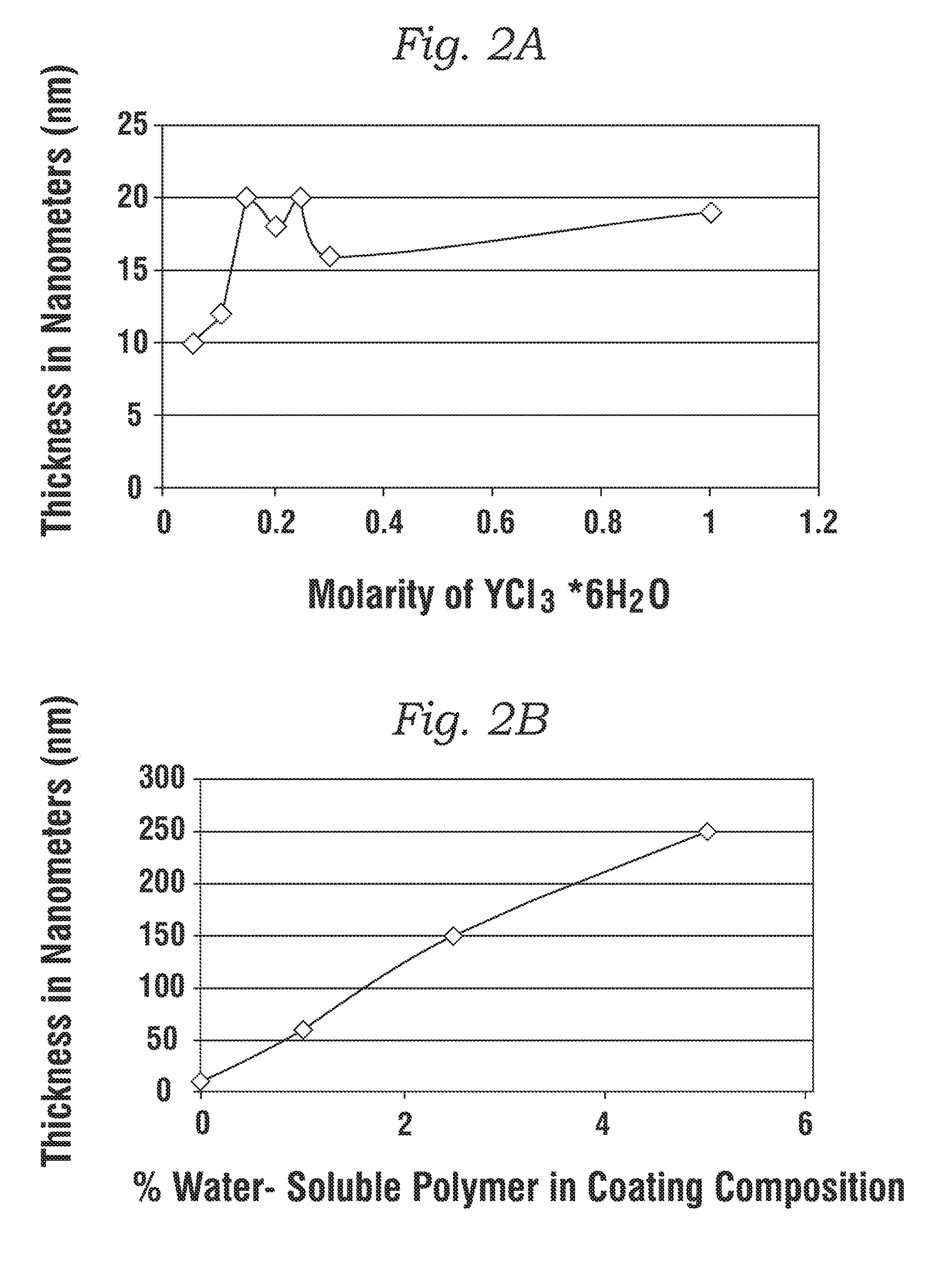

Transparent hydrophobic mixed oxide coatings and methods

A hydrophobic coating and a method for applying such a coating to a surface of a substrate. The method includes applying a coating composition to the surface and heating the coated surface at a cure temperature from about 450° C. to about 600° C. for a time from about 8 hours to about 48 hours. The coating composition is applied to the surface by an application method selected from the group consisting of flowing, dipping, and spraying. The coating composition comprises a yttrium compound, an additive selected from the group consisting of a cerium compound and a dispersion of yttrium oxide nanoparticles, a water-soluble polymer, and a solvent solution of de-ionized water and a water-soluble alcohol.

Owner:GKN AEROSPACE TRANSPARENCY SYST

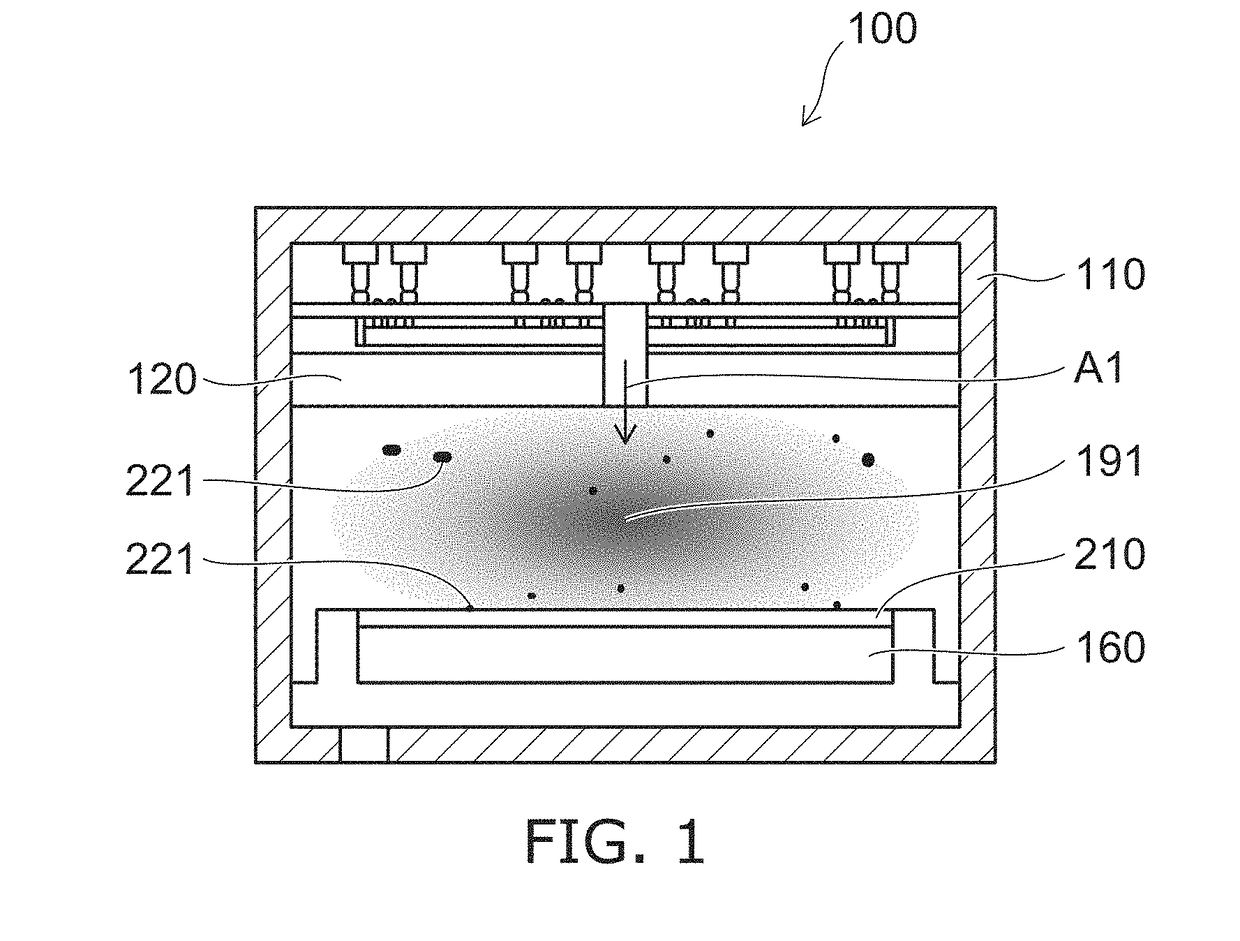

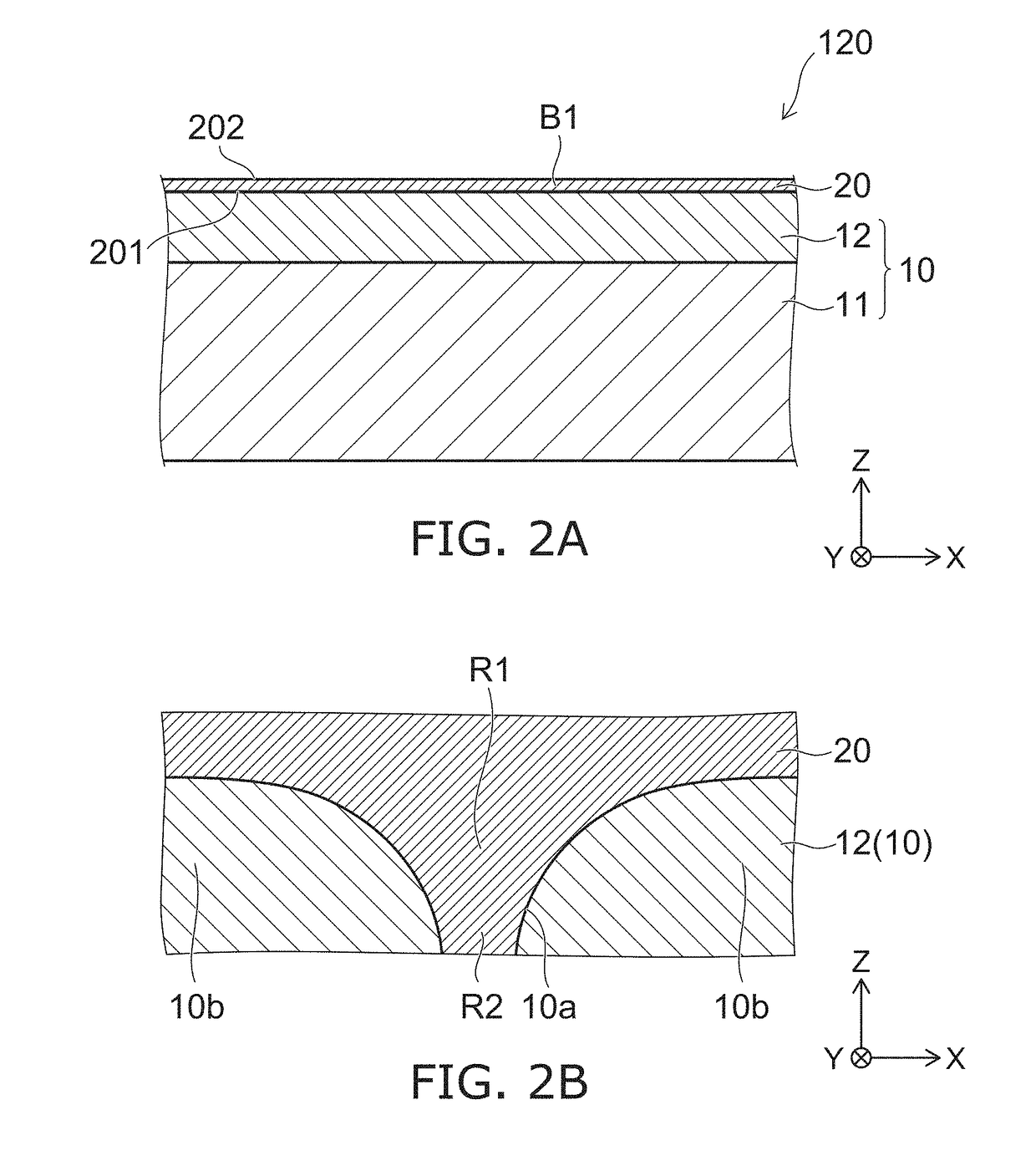

Member for semiconductor manufacturing device

ActiveUS20190027343A1Suppression widthReduce particlesElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringYttrium compound

According to one embodiment, a member for a semiconductor manufacturing device includes an alumite base material including a concavity, and a first layer formed on the alumite base material and including an yttrium compound. The first layer includes a first region, and a second region provided in the concavity and located between the first region and the alumite base material. An average particle diameter in the first region is shorter than an average particle diameter in the second region.

Owner:TOTO LTD

Nd-sensitized yttrium oxide-based laser ceramic and preparation method thereof

The invention discloses Nd-sensitized yttrium oxide-based laser ceramic. Each crystal particle of the laser ceramic is provided with a core-shell structure, a core layer is a (Y,Nd,M)2O3 phase, a shell layer is a (Y,N)2O3 phase, wherein M is rare earth luminescent ions, and N is a sintering aid. A preparation process comprises the following steps: firstly mixing a yttrium compound, a neodymium compound and an M compound, calcining to obtain (Y,Nd,M)2O3 powder, then mixing the yttrium compound with the N compound, calcining to obtain (Y, N)2O3 powder, and then mixing the two powders; or mixing the yttrium compound with the N compound, then directly adding the (Y,Nd,M)2O3 powder, mixing and calcining; carrying out isostatic pressing on the obtained mixed powder, carrying out vacuum sintering, cooling, and then annealing. The laser ceramic disclosed by the invention has the advantages that a (Y,N)2O3 thin layer with excellent sintering property is utilized for coating the (Y,Nd,M)2O3 phase, and the lattice distortion is reduced on the basis of improving the sintering property of the ceramic, so that excellent laser performance is obtained.

Owner:CHINA JILIANG UNIV

Sodium tolerant zeolite catalysts and processes for making the same

InactiveUS20130313164A1Reduce the impactHigh viscosityCatalytic crackingMolecular sieve catalystsYttrium compoundOrganic chemistry

This invention relates to a process of preparing a catalyst from zeolite having a relatively high content of sodium of 18.6 μg Na2O per zeolite surface area, or greater. The invention comprises adding yttrium compound to the zeolite, either prior to, during, or after its combination with precursors for catalyst matrix. This invention is suitable for preparing zeolite containing fluid cracking catalysts.

Owner:WR GRACE & CO CONN

Composition for negative electrode of alkaline electrolyte battery

The invention proposes a composition comprising:a) a hydrogen-fixing alloy of formula R1-tMgtNis-zMz in which:R represents one or more elements chosen from the group comprising La, Ce, Nd and Pr;M represents one or more elements chosen from the group comprising Mn, Fe, Al, Co, Cu, Zr and Sn;0.1≦t≦0.4;3.0≦s≦4.3;z≦0.5;b) a manganese compound in a proportion such that the mass of manganese represents from 1 to 5.5% of the mass of the alloy,c) an yttrium compound in a proportion such that the mass of yttrium represents from 0.1% to 2% of the mass of the alloy.The invention also relates to an anode comprising the composition according to the invention.The invention also relates to an alkaline electrolyte battery comprising said at least one anode.

Owner:SAFT GRP SA

Yttrium oxide-based powder with high sintering activity, and preparation method of yttrium oxide-based powder

InactiveCN106800411AAchieve seamless connectionLower sintering temperatureRoom temperatureYttrium compound

The invention discloses yttrium oxide-based powder with high sintering activity. The yttrium oxide-based powder has a core-shell structure, a core layer of the core-shell structure is a Y2O3 phase, and a shell layer of the core-shell structure is a (Y, La, Zr)2O3 phase; a preparation process of the yttrium oxide-based powder comprises the following steps: firstly, dissolving a yttrium compound into deionized water, then putting into a closed container, and heating up to 150-250 DEG C to obtain the core layer Y2O3 phase; cooling to room temperature, then adding compounds of Y, La and Zr, stirring for dissolving the compounds, and evenly mixing; after that, dropwise adding ammonia water while stirring so as to obtain a precipitate of the (Y, La, Zr)2O3-coated core layer Y2O3 phase; filtering the precipitate, then carrying out ball mill mixing, and drying; calcining an obtained product at the temperature of 900-1300 DEG C to obtain the yttrium oxide-based powder. The raw materials of the yttrium oxide-based powder are wide in source and easy to obtain, and the preparation technology of the yttrium oxide-based powder is simple and controllable; the Y2O3 phase is coated with the (Y, La, Zr)2O3 phase with excellent sintering performance, so that the yttrium oxide-based powder has the excellent sintering activity.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com