Titanium-based composite material and manufacturing method thereof

A technology of titanium-based composite materials and manufacturing methods, which is applied in the field of titanium-based composite materials and their manufacturing, and can solve the problems of low wear resistance, low thermal conductivity, inability to apply wear resistance and high thermal conductivity vehicle components, etc. , to achieve the effect of increasing wear resistance and increasing the maximum surface hardness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

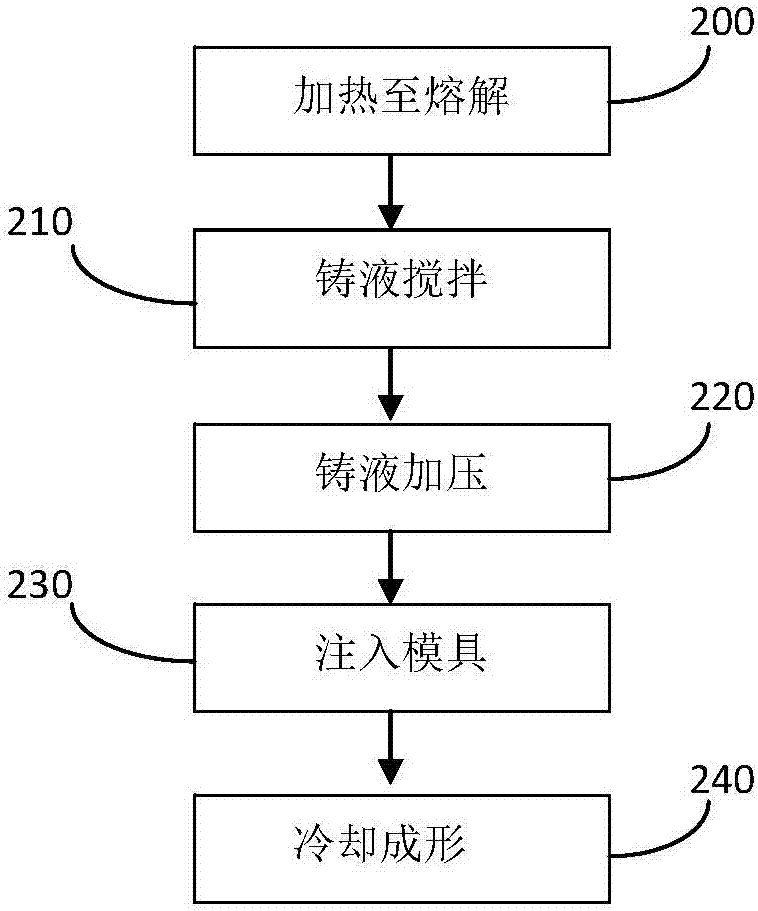

[0073] please cooperate figure 2 As shown, it is a flow chart of the first embodiment of the manufacturing method flow of the titanium-based composite material of the present invention, including steps 200-240, wherein:

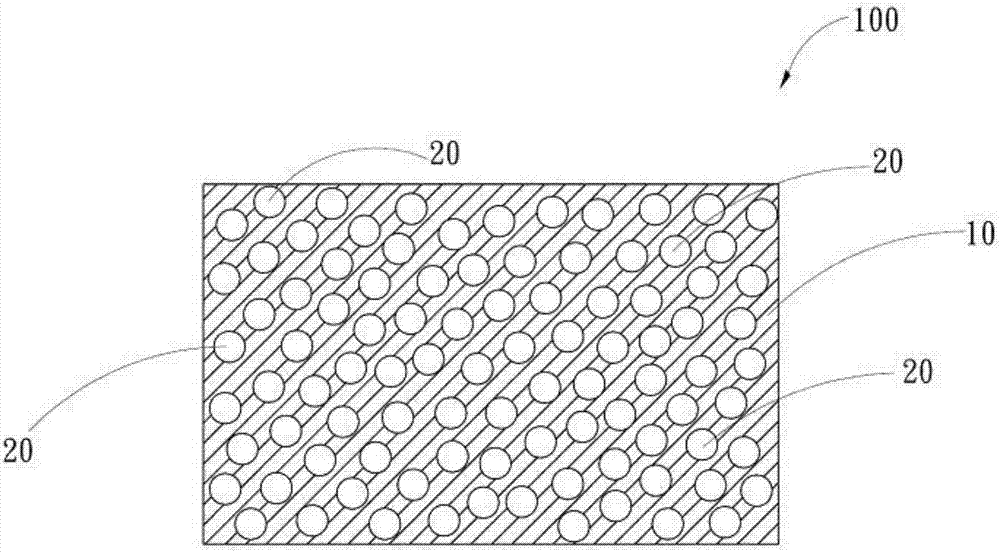

[0074] (200) Heating to melting, titanium alloys selected from α-phase pure titanium or titanium alloy base material, α-phase + β-phase pure titanium or titanium alloy base material, β-phase pure titanium or titanium alloy base material, or Omega interphase metals The metal base material 10 is heated to a powder reinforced composite material 20 with a ratio of 10% to 70% of the total volume to form a casting solution. The powder reinforced composite material 20 may be carbide, nitride, oxide, or At least one of ceramic materials such as borides or borides, or at least one of titanates, niobides, barium compounds, strontium compounds, tantalum compounds, yttrium compounds, or ferroelectrics containing more than 10% of the composition Composition, or at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com