Process for making improved zeolite catalysts from peptized aluminas

一种氧化铝、胶溶化的技术,应用在物理/化学过程催化剂、分子筛催化剂、化学仪器和方法等方向,能够解决沸石结构塌陷表面积、损失、裂化活性损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

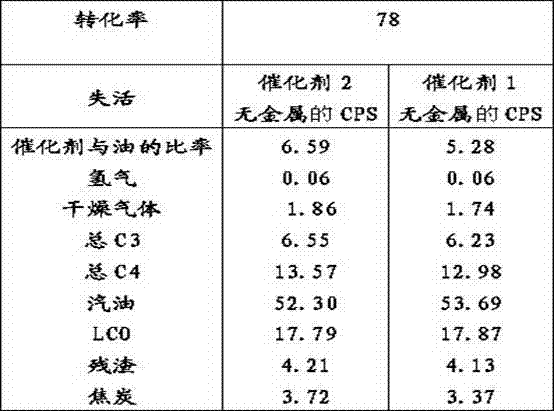

[0085] Catalyst 1 was prepared from the above yttrium solution and peptized alumina. Add 4735 grams (1141 g on a dry basis) of washed aqueous solution of USY zeolite, 9375 grams (1500 g on a dry basis) of peptized alumina, 625 grams (250 g on a dry basis) of colloidal dioxide Silicon, 2353 grams (2000 g on a dry basis) of clay, and 322 grams (73 g on a dry basis) of yttrium solution were mixed for about 10 minutes. The mixture was ground in a Drais mill to reduce particle size and spray dried in a Bowen spray dryer at an inlet temperature of 343°C. The spray dryer feed solids content was about 30% by weight. The spray-dried particles were calcined at 399°C. The calcined particles were then washed to reduce Na in the water bath 2 O, then filtered and rinsed with deionized water.

Embodiment 2

[0087] Catalyst 2 was prepared from the same lanthanum solution and peptized alumina as above. Add 4735 grams (1141 g on a dry basis) of washed aqueous solution of USY zeolite, 9375 grams (1500 g on a dry basis) of peptized alumina, 625 grams (250 g on a dry basis) of colloidal dioxide Silicon, 2353 grams (2000 g on a dry basis) of clay, and 389 grams (105 g on a dry basis) of the lanthanum solution were mixed for about 10 minutes. The mixture was ground in a Drais mill to reduce particle size and spray dried in a Bowen spray dryer at an inlet temperature of 343°C. The spray dryer feed solids content was about 30% by weight. The spray-dried particles were calcined at 399°C. Then, the calcined particles were washed to reduce Na in aqueous solution 2 O, then filtered and rinsed with deionized water.

Embodiment 3

[0089] Catalyst 3 was prepared from the yttrium solution described above and commercially available boehmite alumina. Add 5856 grams (1558 g, on a dry basis) of an aqueous solution of sodium subcarbonate USY zeolite, 3478 grams (800 g, on a dry basis) of polyaluminum chloride, and 947 grams (500 g, on a dry basis) of boehmite Alumina, 2471 grams (2100 g on a dry basis) of clay and 307 grams (70 g on a dry basis) of yttrium solution were mixed for about 10 minutes. The mixture was milled in a Drais mill to reduce particle size and spray dried in a Bowen spray dryer at an inlet temperature of 343°C. The spray dryer feed fixed content was about 38% by weight. The spray-dried particles were calcined at 593°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com