Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131 results about "Sorbitan monolaurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbitan monolaurate is a mixture of esters formed from the fatty acid lauric acid and polyols derived from sorbitol, including sorbitan and isosorbide. As a food additive, it is designated with the E number E493.

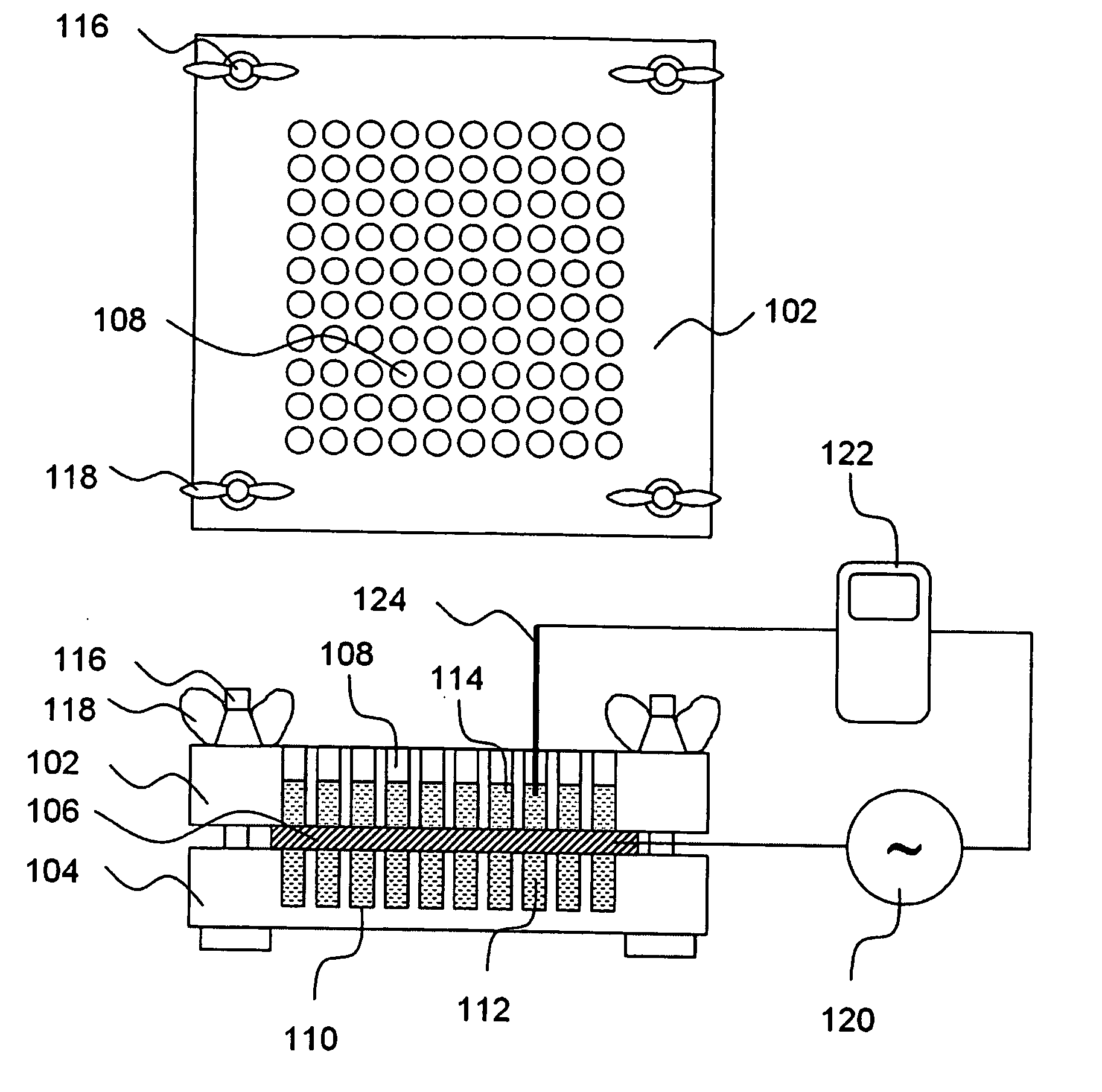

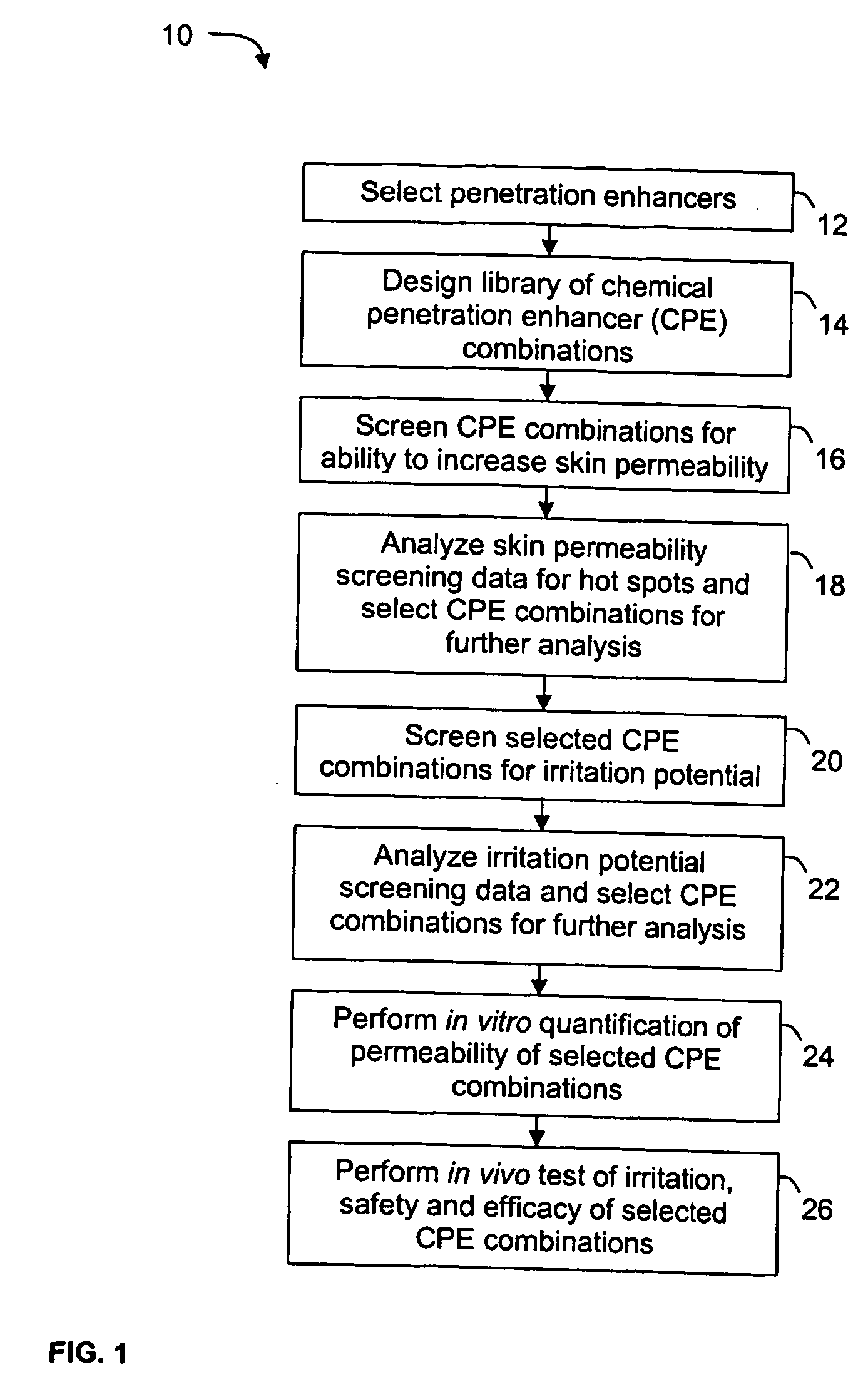

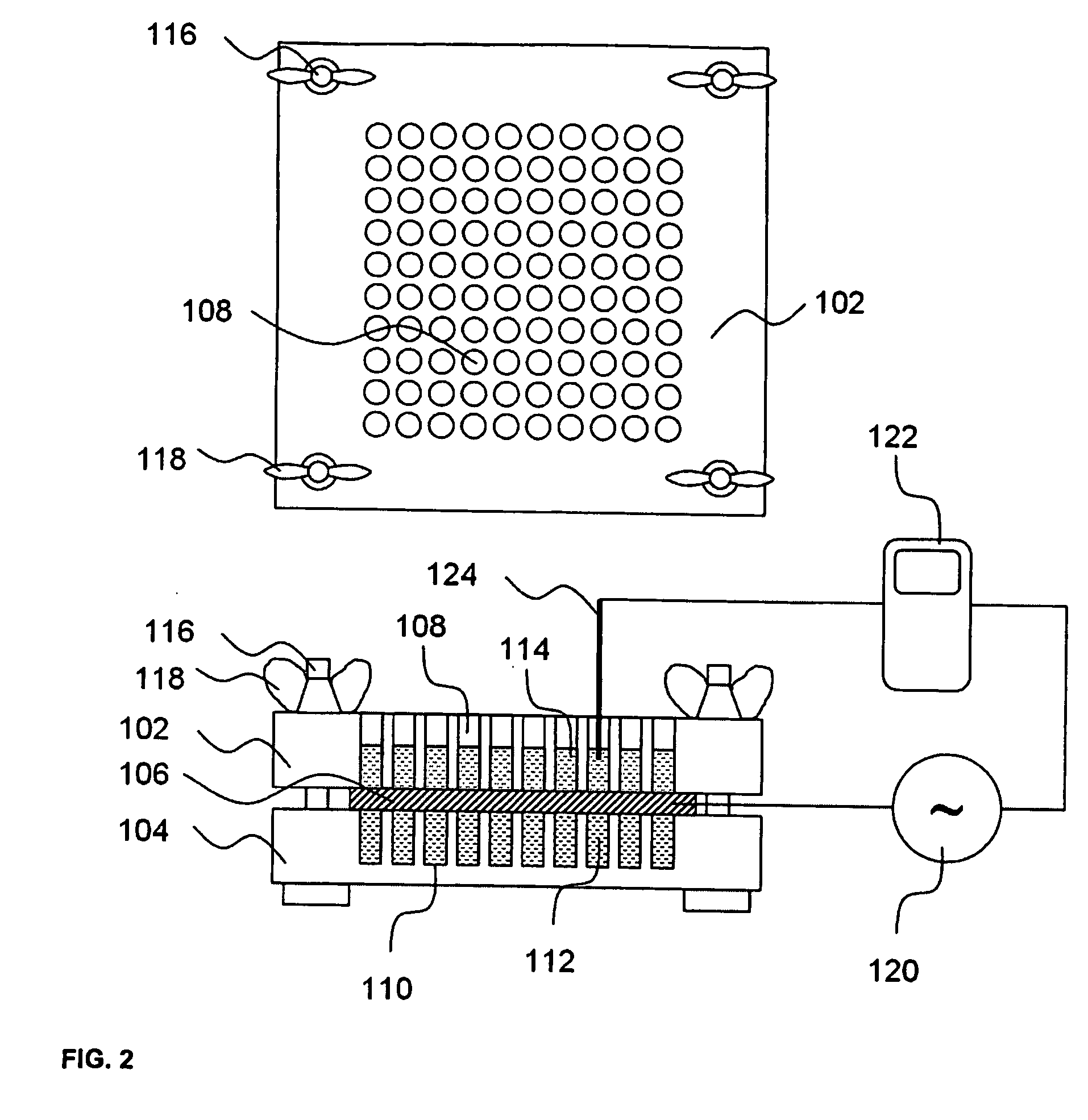

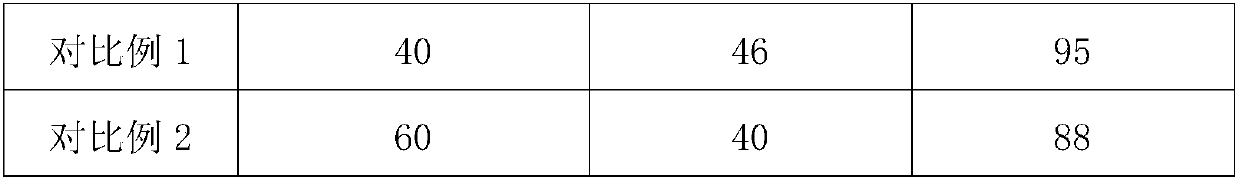

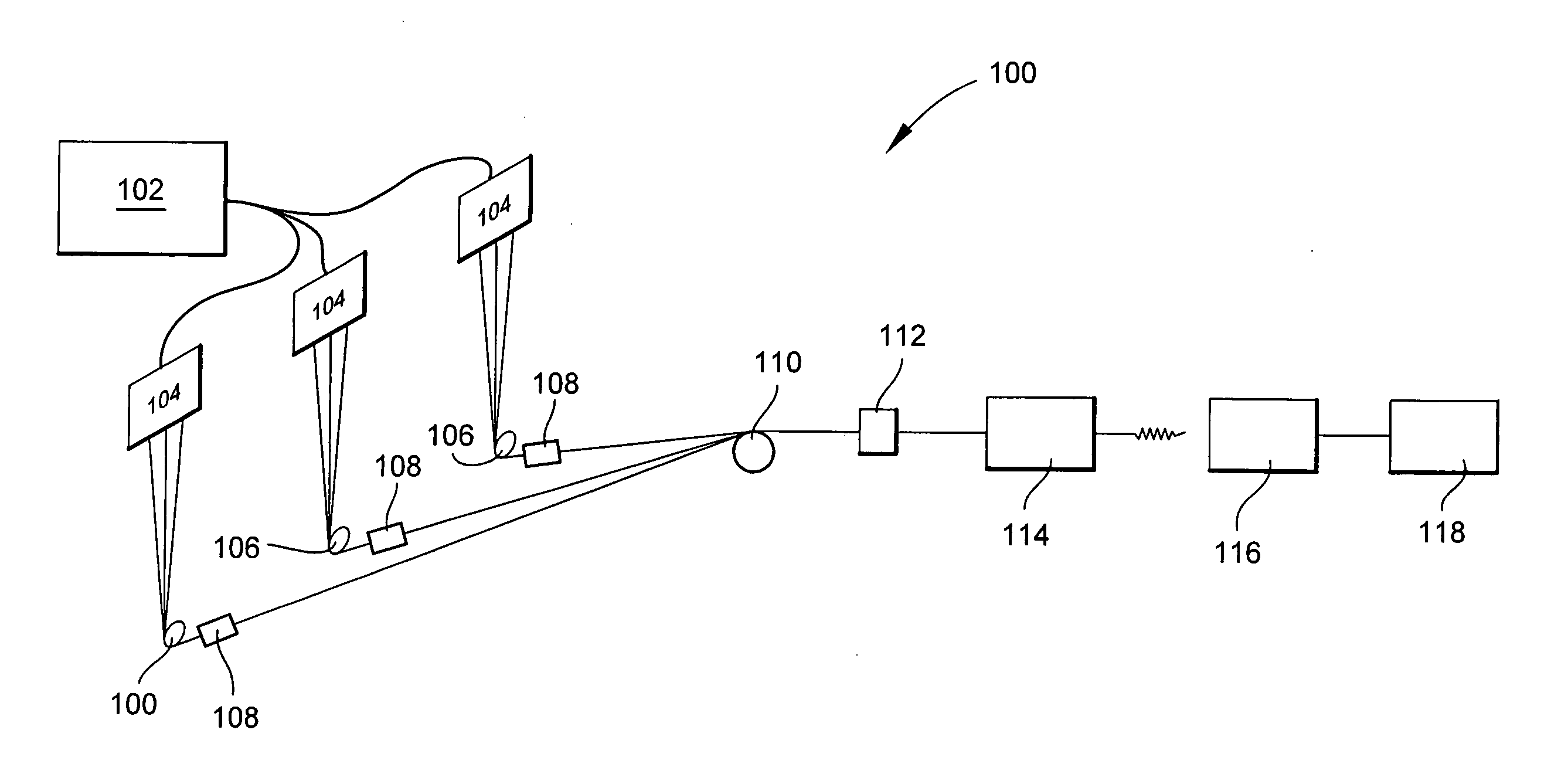

Penetration Enhancer Combinations for Transdermal Delivery

InactiveUS20070269379A1Easy to transportLess irritatingOrganic active ingredientsBiocideHigh-Throughput Screening MethodsIrritation

A high throughput screening and isolation system identifies rare enhancer mixtures from a candidate pool of penetration enhancer combinations. The combinations are screened for high penetration but low irritation potential using a unique data mining method to find new potent and safe chemical penetration enhancer combinations. The members of a library of chemical penetration enhancer combinations are screened with a high throughput device to identify “hot spots”, particular combinations that show higher chemical penetration enhancement compared to neighboring compositions. The irritation potentials of the hot spot combinations are measured to identify combinations that also show low irritation potential. A active component, such as a drug, is then combined with the combination in a formulation which is tested for the ability of the drug to penetrate into or through skin. It is then assessed whether the formulation can deliver the quantity of drug required, and animal tests are conducted to confirm in vivo the ability of the chemical penetration enhancer combinations to facilitate transport of sufficient active molecules across the skin to achieve therapeutic levels of the active molecule in the animal's blood. The invention provides specific unique and rare mixtures of chemical penetration enhancers that enhance skin permeability to hydrophilic macromolecules by more than 50-fold without inducing skin irritation, such as combinations of sodium laurel ether sulfate and 1-phenyl piperazine, and combinations of N-lauryl sarcosine and Span 20 / sorbitan monolaurate.

Owner:RGT UNIV OF CALIFORNIA

Pesticide emulsion and preparation method thereof

The invention provides a preparation method of a pesticide emulsion, which comprises the steps of preparing an avermectin molecular capsule system; preparing a water phase; preparing an oil phase; adding the oil phase into the water phase, adding the avermectin molecular capsule system after shear emulsion and carrying out the shear emulsion again, wherein, the avermectin molecular capsule systemis prepared by evenly mixing a capsule wall material, a cosolvent and the first part of water under the heating condition, adding avermectin and a first emulsifier for evenly mixing and cooling to the room temperature, the capsule wall material is beta-cyclodextrin and / or gamma-cyclodextrin, the first emulsifier is one or a plurality of fatty alcohol polyoxyethylene ether, sorbitan monooleate andpolyoxyethylene sorbitan monolaurate. Avermectin molecules in the pesticide emulsion containing avermectin molecular capsules prepared by the method greatly enhance the resistance of the avermectin molecules to oxygen, light, heat, acid, alkali and the like and simultaneously have the effects of sustained-release and solubilization, thereby solving the problem that the avermectin is instable to the light and further prolonging the effective period for prevention and treatment of the avermectin.

Owner:SHENZHEN NOPOSION AGROCHEM

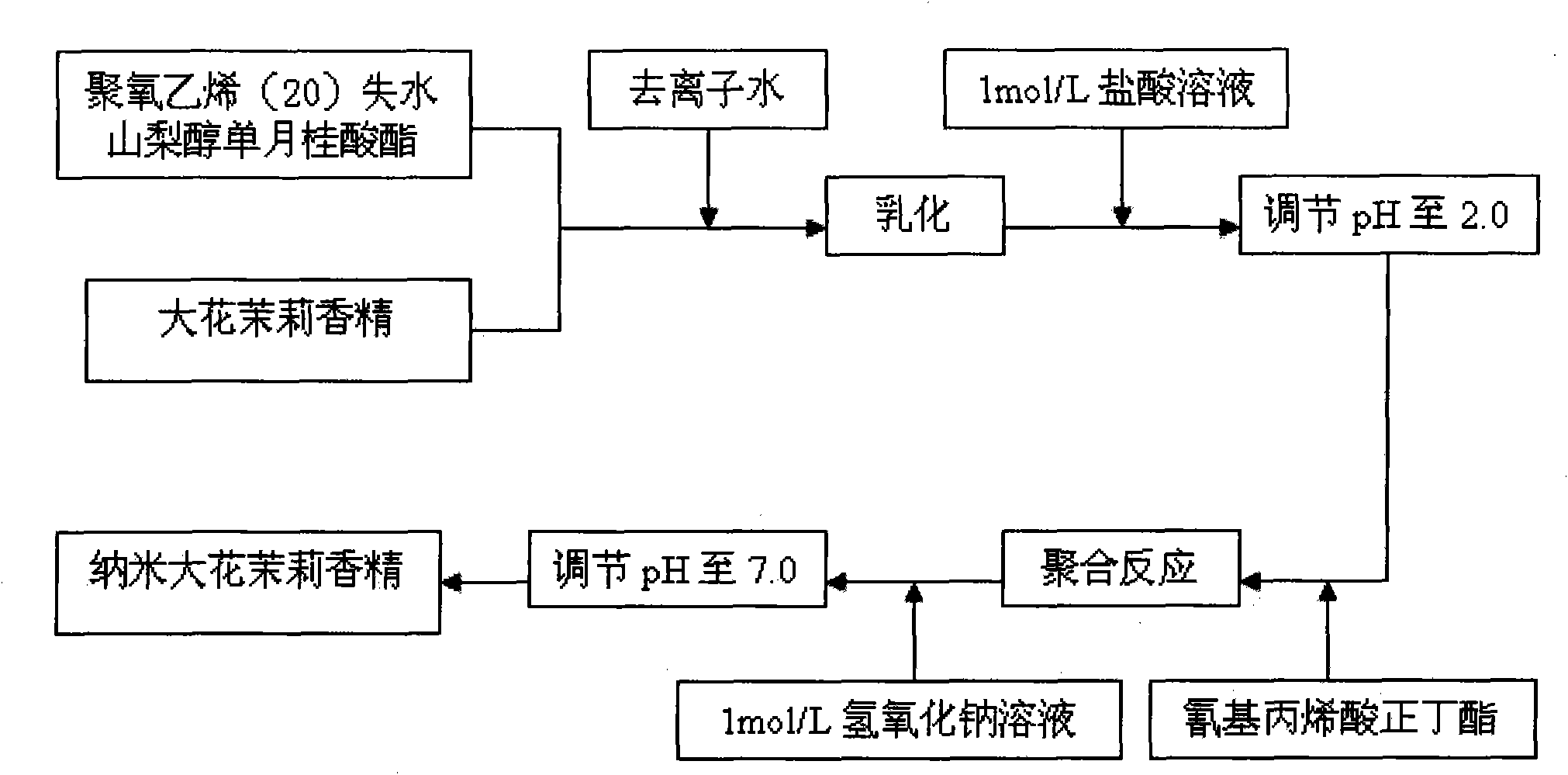

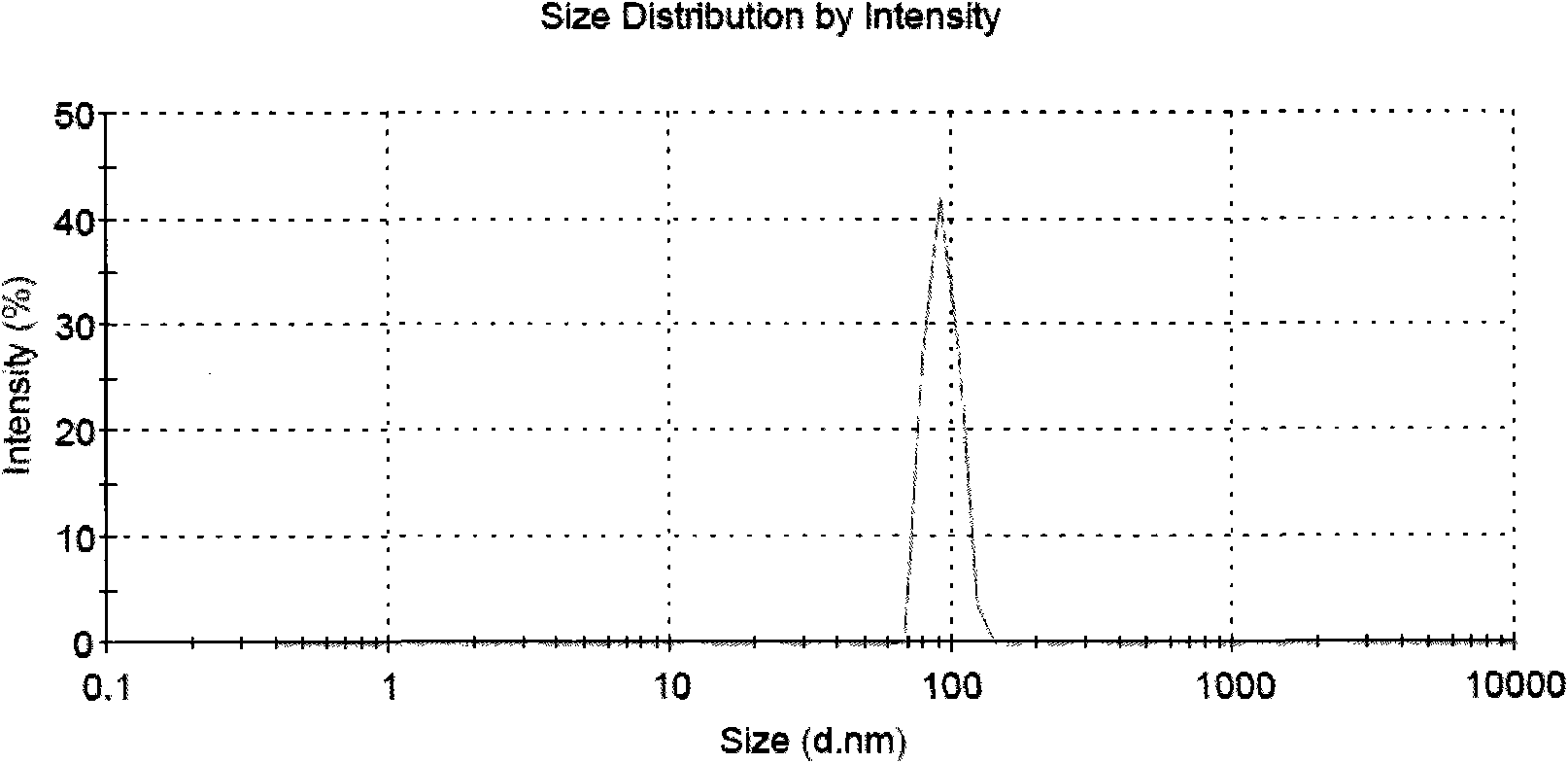

Preparation method of polybutylcyanoacrylate-encapsulated jasminum grandiflorum essence capsule

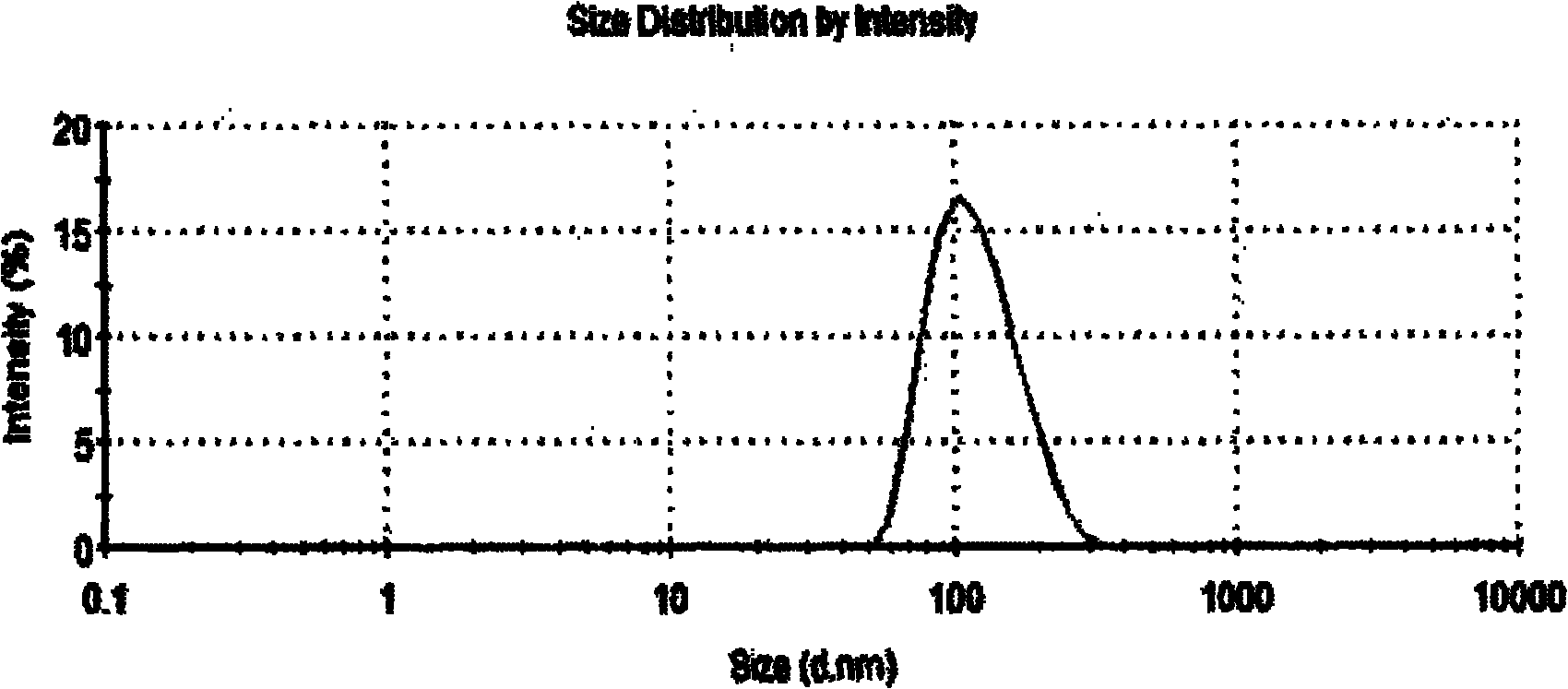

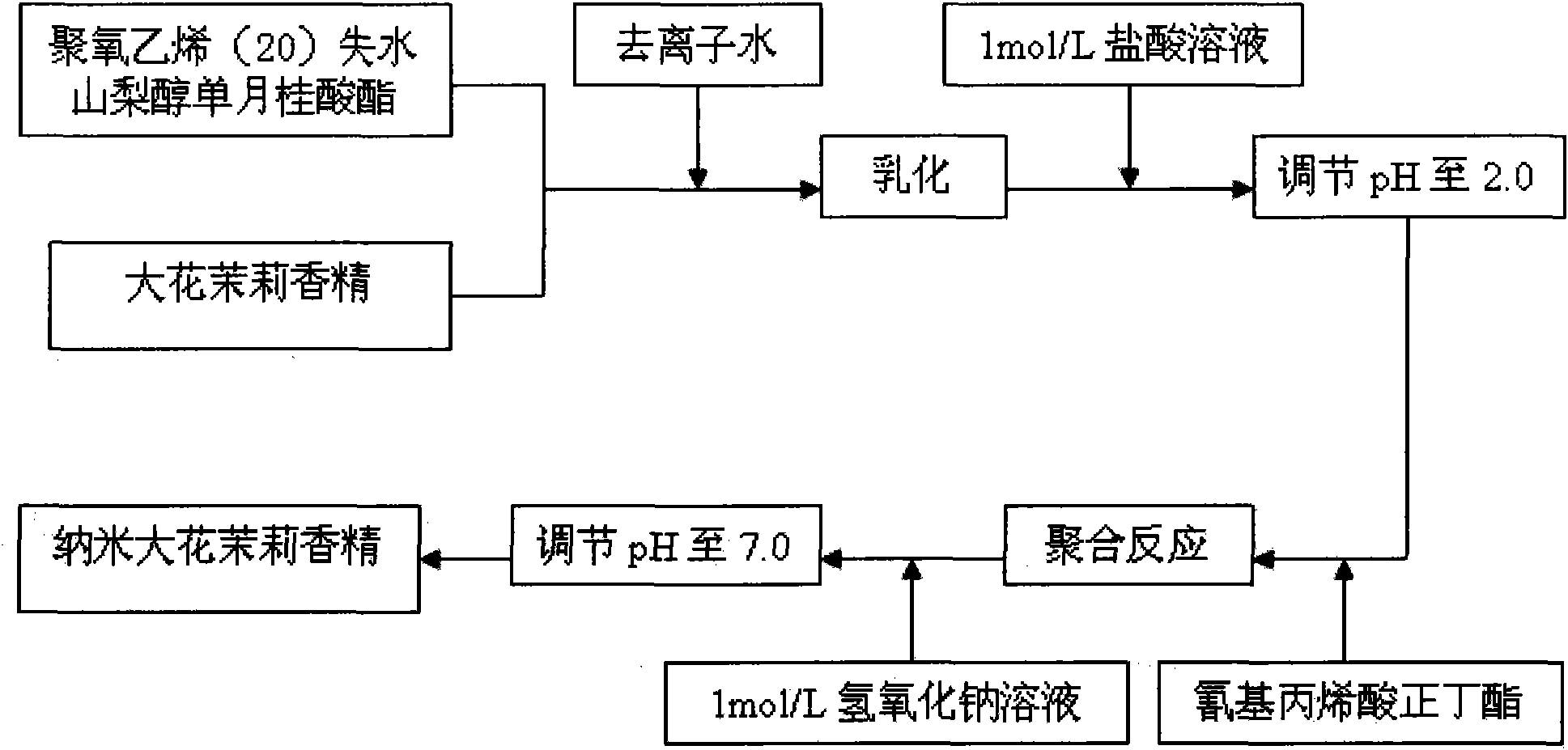

InactiveCN101818100ABiodegradableAdvantage thermal stabilityEssential-oils/perfumesJasminum grandiflorumGranularity

The invention discloses a preparation method of polybutylcyanoacrylate-encapsulated jasminum grandiflorum essence capsule, wherein the nano jasminum grandiflorum essence capsule is prepared by the following raw materials in parts by weight: 0.2-0.5 parts of jasminum grandiflorum essence, 1.0-2.3 parts of polyoxyethylene (20) sorbitan monolaurate, 0.4-1.0 part of butylcyanoacrylate monomer and 96-100 parts of deionized water. As tested by a dynamic laser particle sizer, the nano jasminum grandiflorum essence capsule prepared according to the method of the invention has the average particle diameter of 112nm, the particle size distribution coefficient of 0.104 and stable existence of system, and has the advantages of slow release of fragrance and long fragrance lasting time, etc.

Owner:SHANGHAI INST OF TECH

Pomalidomide nanoparticle and preparation and preparation method thereof

ActiveCN104224723ALarge specific surface areaHigh dissolution rateOrganic active ingredientsPowder deliveryPolyethylene glycolCyclodextrin

The invention relates to the technical field of medicines, and specifically relates to pomalidomide nanoparticle and preparation and a preparation method thereof. The pomalidomide nanoparticle comprises the following components in parts by weight: 0.5 to 1.5 parts of pomalidomide, and 10 to 100 parts of nano-carrier, wherein the nano-carrier comprises one or more of lecithin, povidone, polyalkylcyano-acrylate, acrylamide, N, N-methylene diacrylic acid amine, polysorbate, sorbitan monolaurate, lauryl alcohol polyoxyethylene, sodium dodecyl sulfate, poloxamer, polyethylene glycol, cyclodextrin and cyclodextrin derivates. The particle size of omalidomide nanoparticle is at nanometer level; on that basis, the prepared pomalidomide preparation is high in dissolution rate.

Owner:BEIJING COLLAB PHARMA

Roe and royal jelly tightening eye care gel and preparation method thereof

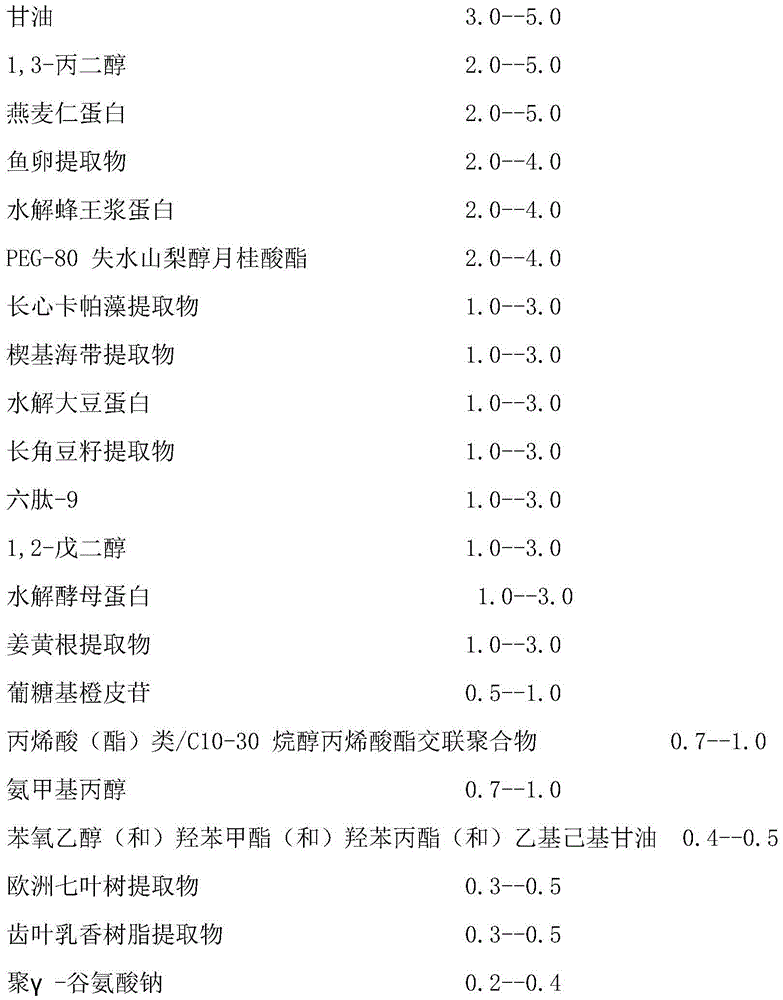

ActiveCN105640854AWrinkle smoothing effectElasticCosmetic preparationsToilet preparationsYeast ProteinsCeratonia siliqua

The invention relates to a roe and royal jelly tightening eye care gel, selecting oat kernel protein, roe extract, PEG-80 sorbitan monolaurate, hydrolyzed royal jelly protein, kappaphycus alvarezii extract, laminaria ochroleuca extract, hydrolyzed soybean protein, ceratonia siliqua seed extract, hexapeptide-9, 1,2-pentanediol, hydrolyzed yeast protein, turmeric root extract, glucosyl hesperidin and the like as raw materials. Simultaneously, the dosages of the raw materials are strictly limited, and the roe and royal jelly tightening eye care gel aims at the characteristics of eye skin, has strong pertinence to accurately supplement eye skin with nutrients, excites energy of eye skin cells to resist eye skin aging, thoroughly replenishes water and moisturizes eye skin to resist dryness, effectively relieves pressure and promotes blood circulation to resist injury.

Owner:QINGDAO CHENLAND MARINE BIOTECH CO LTD

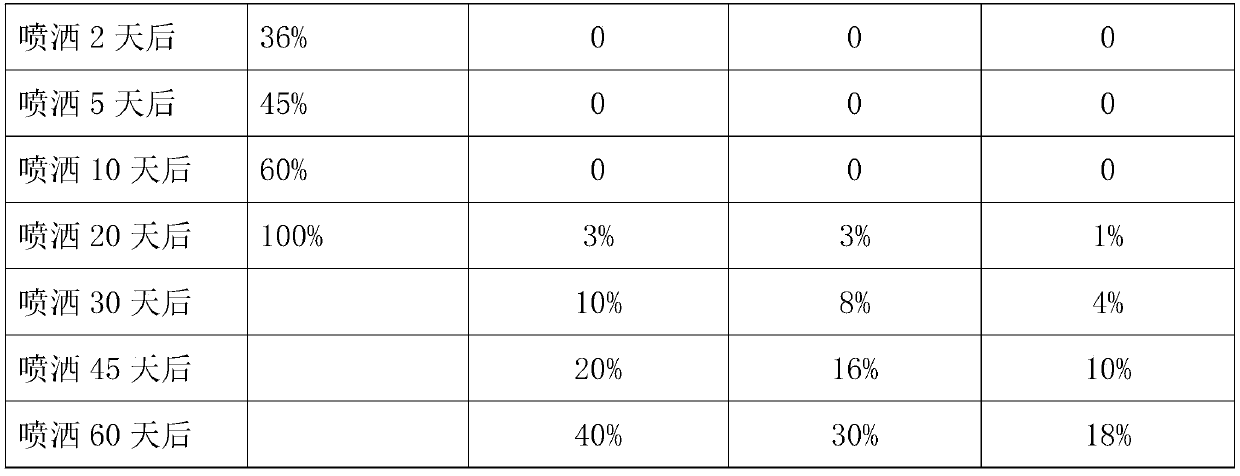

Environment-friendly bactericidal acaricide and preparation method thereof

InactiveCN111567575AAvoid harmWill not damage the structureBiocidePest repellentsBiotechnologyDioxyethylene Ether

The invention discloses an environment-friendly bactericidal acaricide and belongs to the technical field of daily chemical sterilization. The environment-friendly bactericidal acaricide is prepared from the following raw materials: eucalyptus leaf essential oil, folium artemisiae argyi essential oil, citronella essential oil, lemon essential oil, mint essential oil, orange essential oil, a rosemary extract, a fructus cnidii extract, a radix sophorae flavescentis extract, a sweet orange flower extract, a lavender extract, small molecular alcohol, deionized water, sorbitan monolaurate polyoxyethylene (20) ether and water-soluble polymer slow-release agent starch. According to the environment-friendly bactericidal acaricide of the invention, the durability of the product can be improved while the product is ensured to be rapidly applied for sterilization and acarus killing; main active substances in the product are natural plant extracts, and therefore, the product has the advantages ofgood environmental protection performance, freshness, naturalness, no toxic or side effect, mildness and no irritation to human skin, no harm to infants and young children, and good use experience; magnetic stirring and the ultrasonic treatment of an ultrasonic oscillator are adopted in a preparation process, and repeated cyclic staggered operation is carried out, and therefore, the bactericidal effect of the bactericidal acaricide can last longer, and the bactericidal acaricide has a good raw material combination effect and has a long shelf life.

Owner:WUXI HUOBAN COSMETIC TECH

Composition and method for reducing incidents of hot flashes in females

InactiveUS7179494B1Reduce morbidityReduce frequencyCosmetic preparationsBiocideButter cocoaMenopause present

A composition is provided for reducing incidents of hot flashes experienced by menopausal women, the composition comprising a mixture of water, a thickener, sorbitan monolaurate, cocoa butter or shea butter, polysorbate 20, dimethicone 200, bacteriacide, a pH adjuster and an effective amount of Chinese black cohosh. A method is also provided for preparing the composition and its use by menopausal women in need of treatment of hot flashes.

Owner:MARCHE IMAGE CORP

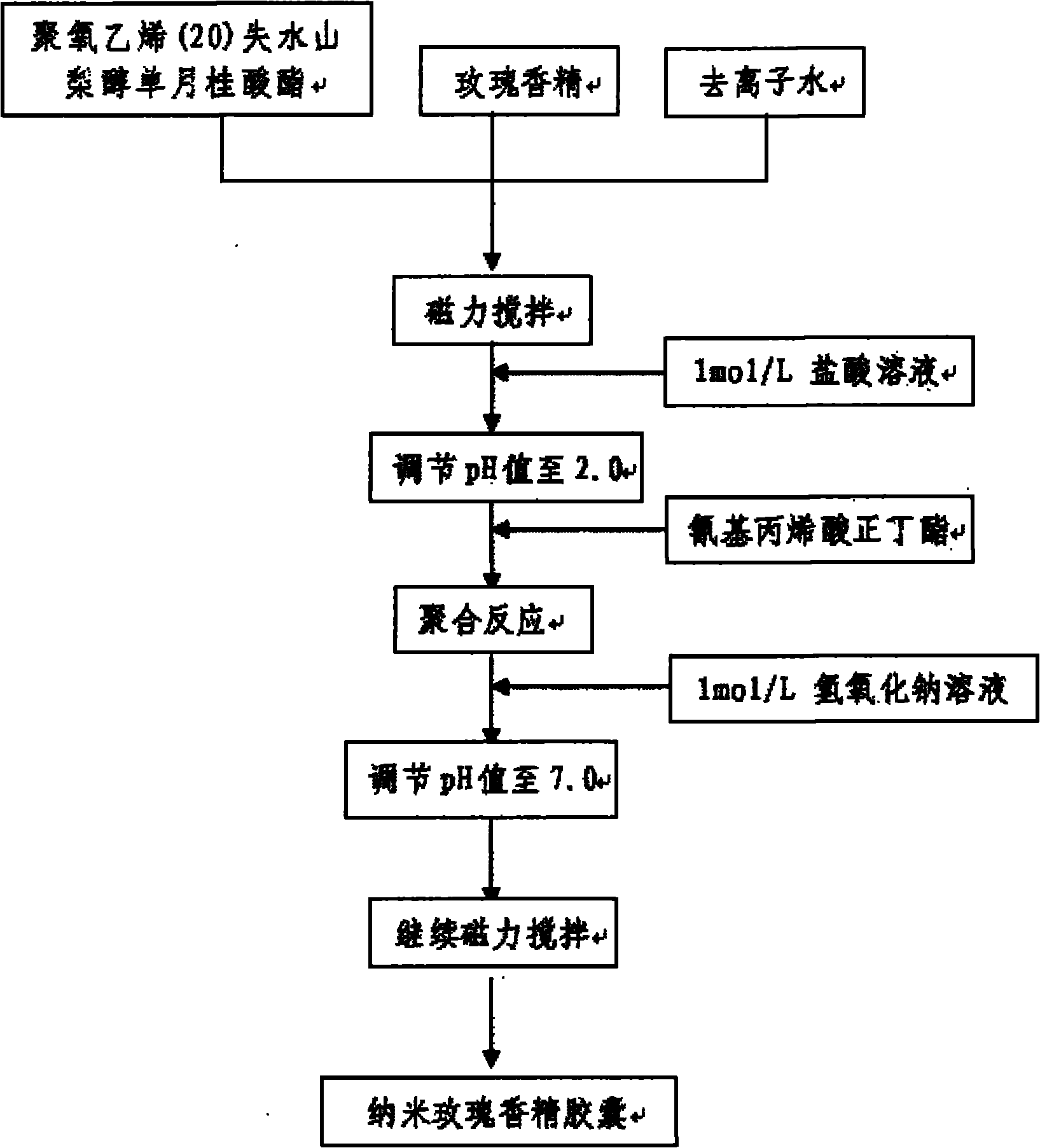

Method for preparing nano rose essence capsules

InactiveCN101816911AParticle size controllableUniform particle sizeEssential-oils/perfumesMicroballoon preparationEmulsionEmulsion polymerization

The invention discloses a method for preparing nano rose essence capsules, which comprises the following steps of: a, mixing 0.3 to 0.8 weight percent of rose essence and 2.0 to 3.2 weight percent of polyoxyethylene (20) sorbitan monolaurate, stirring the mixture at the rotation speed of 1,100rpm, adding deionized water into the mixture and stirring to form a uniform emulsion; and b, dripping 0.6 to 1.6 weight percent of N-butyl cyanoacrylate into the emulsion, reacting for 2 to 4 hours, adjusting the pH value of the system with 1mol / L solution of sodium hydroxide to 7.0, and continuously reacting for 0.5 hour until the reaction is completed. The nano rose essence capsules prepared by the emulsion polymerization method of the invention have an average particle size of 91nm and a peak width of 16.8nm, have uniform particle size distribution and can be applied to goods for everyday consumption, such as textiles, cosmetics and detergents and the like.

Owner:SHANGHAI INST OF TECH

Phosphorite flotation collecting agent

The invention discloses a phosphorite flotation collecting agent and belongs to the technical field of ore froth flotation collecting agents. The phosphorite flotation collecting agent comprises, by weight, 25-30 parts of amphoteric malic acid derivatives, 5-8 parts of a surface active agent, 1-3 parts of sorbitan monolaurate, 1-3 parts of emulsifier and 40-50 parts of water. The amphoteric malic acid derivatives are obtained in a manner that after malic acid and organic amine react, the product reacts with sulfamic acid and N,N-Dimethyl-N-dodecyl(2-hydroxy-3-chloropropyl)ammonium chloride. The prepared flotation collecting agent can be used for carrying out flotation on phosphate at the temperature ranging from 5 DEG C to 35 DEG C and is good in selectivity for middle-low grade phosphorite, high in collecting capacity and small in amount of usage, and meanwhile, flotation froth is good, non-stick and stable at the low-temperature condition.

Owner:嘉兴市南湖区翊轩塑料五金厂(普通合伙)

Long-acting wood fungicide

A long-acting wood fungicide comprises the following raw materials by weight: 6-10 parts of organic silicon, 3-5 parts water glass, 3-8 parts walnut green seedcase, 4-9 parts of sodium chloride, 6-8 parts of pinellia ternata, 7-9 parts of chitosan, 6-10 parts of hydroxyethyl urea, 6-8 parts of sodium dodecyl benzene sulfonate, 6-10 parts of ethylene-vinyl acetate copolymer, 4-8 parts of graphite, 3-5 parts of a drier, 4-9 parts of p-phenylenediamine, 4-6 parts of N-methylpyrrolidone, 4-7 parts of glycerol and 6-11 parts of dehydrated sorbitan monolaurate. The beneficial effects are that: the long-acting wood fungicide can well inhibit bacterial and microbial growth, and is non-toxic and harmless.

Owner:QINGDAO KELIKE INFORMATION TECH

Environment-friendly pavement dust suppressant and preparation method thereof

InactiveCN103450852AQuick condensationAvoid flyingOther chemical processesSorbitan monostearateSODIUM PYRROLIDONE CARBOXYLATE

The invention provides an environment-friendly pavement dust suppressant and a protection method thereof. The dust suppressant is prepared from the following raw materials in parts by mass: 4 to 18 parts of sorbitan monolaurate, 5 to 24 parts of sorbitan monostearate, 2 to 6 parts of sodium lactate, 3 to 5 parts of sodium pyrrolidone-carboxylate, 3 to 7 parts of glycerin, and 150 to 160 parts of water. By adopting the environment-friendly pavement dust suppressant, the dust particles which are easy to fly can be quickly conglomerated into large particles to sink, thus the flying of dust on a pavement can be effectively prevented, and the acting efficiency is high; the dust suppressing effect can last for more than 6 days; the dust suppressing rate is up to 95%.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

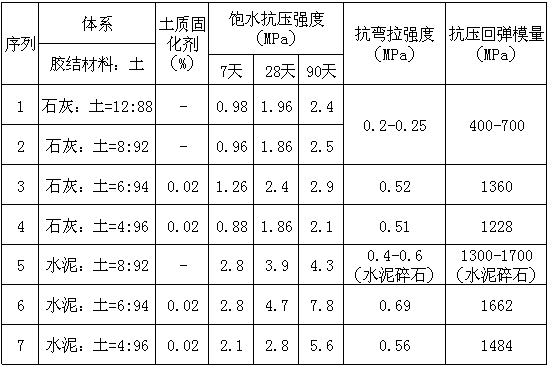

Water conservancy dike, dyke soil curing agent and preparation method thereof

The invention discloses a water conservancy dike, a dyke soil curing agent and a preparation method thereof. The water conservancy dike comprises a soil curing agent comprising the following components by weight percentage: 15%-20% of amino sulfonic acid, 5%-25% of water-soluble organic silicon, 5%-8% of triethanolamine, 2%-6% of poly carboxylic acid compound, 4%-6% of Na2SO4, 10%-30% of aliphatic sulfonate, 2-6% of nonylphenol polyoxyethylene ether, 1-3% of sorbitan monolaurate and 20-40% of water. The soil curing agent provided by the invention has high compressive strength and less construction consumption, the amount only accounts for ten thousandth to thirty thousandths of the total amount of limb soil in normal circumstances, the transportation cost is low, and the impact on the project cost is small. A dike crown, the dike and a road built by the soil curing agent has compression resistance, water durability, waterproofing and high adaptability. Under the condition of no cover, the dust can be reduced by about 60%, and the soil curing agent is an environment-friendly material.

Owner:吉林中路新材料有限责任公司

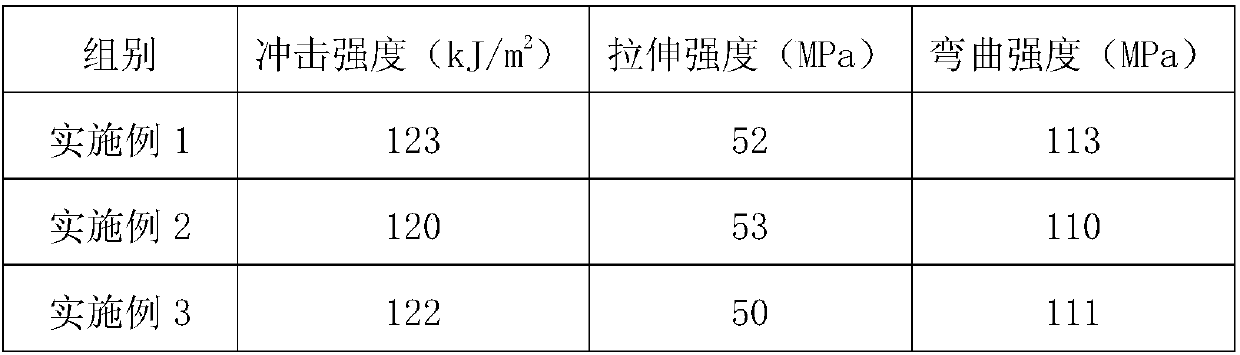

Method for modifying ultrafine light calcium carbonate and application of ultrafine light calcium carbonate in plastics

ActiveCN107629487AComplete crystal formNarrow particle size rangeCalcium/strontium/barium carbonatesPigment treatment with non-polymer organic compoundsDiethylene glycol monobutyl etherPropanoic acid

The invention discloses a method for modifying ultrafine light calcium carbonate and application of the ultrafine light calcium carbonate in plastics, and belongs to the technical field of calcium carbonate manufacture. The modifying method comprises the steps of pulping, treating surface and preparing a finished product, wherein the pulping step comprises the steps of preparing Ca(OH)2 suspension, adding crystal form controlling agent and performing carbonization reaction; the crystal form controlling agent is prepared from the following raw materials in parts by weight: 4-8 parts of sodium nitrate, 5-10 parts of citric acid, 3-5 parts of glycolic acid, 1-3 parts of propionic acid and 1-3 parts of lactic acid; a surface activation coating agent is prepared from the following raw materialsin parts by weight: 14-20 parts of phthalic acid ethylene glycol monobutyl ether ester sodium salt, 2-6 parts of isopropyl alcohol, 3-7 parts of diethylene glycol monobutyl ether, 8-12 parts of octadecylamine, 4-8 parts of lauryl amine and 5-9 parts of sorbitan monolaurate. The ultrafine light calcium carbonate can be used for improving the toughness and strength of PVC, and solving the problemsof uniform dispersing difficulty and poor compatibility with PVC when traditional nano-calcium carbonate is mixed with PVC.

Owner:广西华洋矿源材料有限公司

Cellulose acetate tow and method of making same

ActiveUS20050283959A1Increases fly (fluff)Improve the level ofArtificial filaments from cellulose derivativesChain sawsEmulsionCellulose acetate

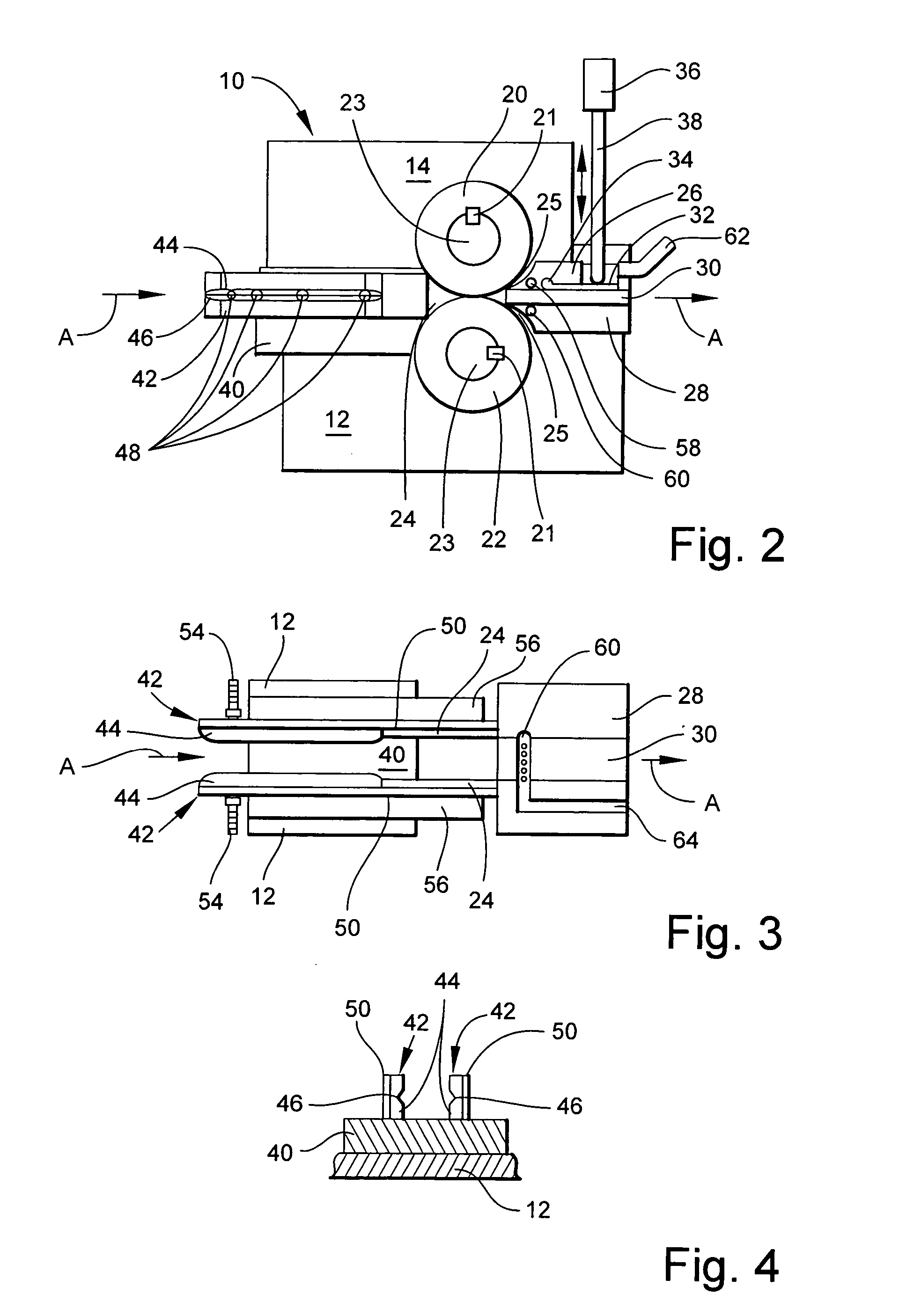

An apparatus and process for making a cigarette tow comprising: means for spinning a dope comprising a solution of cellulose acetate and solvent; means for taking-up the as-spun cellulose acetate filaments; means for lubricating the cellulose acetate filaments; means for forming a tow from the cellulose acetate filaments; means for crimping the tow, the means for crimping comprising a stuffer box crimper comprising a pair of nip rollers adapted to engage the tow, a pair of cheek plates juxtaposed to the pair of nip rollers adapted to keep the tow between the pair of nip rollers, a pair of doctor blades adjacent to an exit end of said pair of nip rollers, and a stuffer box having a stuffer channel adjacent the pair of doctor blades adapted to receive the tow into the channel from the pair of nip rollers, a flapper located at a distal end of the channel adapted to bearingly engage the tow; means for drying the crimped tow; and means for baling the dried crimped tow. The apparatus and process further comprises at least two of the following: A. wherein the means for crimping further comprising one roller of the pair of nip rollers being adapted to induce crimp into the tow; B. wherein the means for crimping further comprising one roller of the pair of nip rollers being made of a solid ceramic material; C. wherein the means for crimping further comprising a pair of tow edge lubricators adapted to lubricate lateral edges of the tow immediately prior to contact with the pair of nip rollers and being ahead of and in contact with the pair of cheek plates; D. wherein the means for crimping further comprising a steam injector being in communication with the channel; E. further comprising a means for plasticizing the tow being located after means for forming the tow and before the means for crimping the tow; F. wherein means for lubricating the filaments further comprises a finish comprising an emulsion of 62.0 to 65.0 weight percent of mineral oil; 27.0 to 28.0 weight percent of emulsifiers, the emulsifiers being a mixture of 50.0 to 52.0 weight percent sorbitan monolaurate, and 48.0 to 50.0 weight percent POE (20) sorbitan monolaurate; and the balance being water.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

Hemp yarn softening agent

A hemp yarn softening agent comprises components in parts by mass as follows: 5-15 parts of limonene, 12-20 parts of dimethyl distearylammonium chloride, 5-10 parts of mineral oil, 4-10 parts of a Gemini cation softening agent, 2-5 parts of an emulsifying agent and 20-35 parts of water, wherein the Gemini cation softening agent is a hydroxypropyl Gemini cation surface active agent; and the emulsifying agent is sorbitan monolaurate or oil-based sodium amino acid. The components are mixed proportionally and uniformly and added in the hemp yarn spinning process, so that the span yarn is uniformly coated with a protection film, the fast softening effect is realized, and the hand feeling of a hemp article can be remarkably improved.

Owner:SUZHOU QISHUO INFORMATION TECH CO LTD

Calcium carbonate surface-active agent

ActiveCN103432958AReduce surface tensionImprove workabilityTransportation and packagingMixingDiethylene glycol monobutyl etherActive agent

The invention provides a calcium carbonate surface-active agent and relates to a modifying agent used for calcium carbonate, and further provides a preparation method and using method thereof. The surface-active agent comprises the following components: stearic acid, isopropyl alcohol, ethylene-glycol, diethylene glycol monobutyl ether, isooctyl alcohol, aluminic acid ester, amino silicone oil, sorbitan monolaurate and polyoxyethylene sorbitan monolaurate. The activator modified calcium carbonate has an unprecedented effect; scagliola produced through filling of calcium carbonate is greatly improved in strength, rigidity, rigidity, especially shock resistance and scratch resistance, and is more compact and smoother. Meanwhile, the activator is low in cost; when the activator is added in a powder vertical mill for grinding the calcium carbonate to 600-mesh fine powder, 40 Yuan more is required for every ton of the calcium carbonate; and moreover, a DOP oil absorption value is smaller than 12, so that the economic benefit of the scagliola processing is greatly improved.

Owner:东莞市立信环保科技有限公司

Strawberry dual-proof polyethylene agricultural greenhouse film

InactiveCN103694538ANo-drip extended shelf lifeEasy to stretchClimate change adaptationGreenhouse cultivationLinear low-density polyethyleneHigh density

The invention discloses a strawberry dual-proof polyethylene agricultural greenhouse film. The strawberry dual-proof polyethylene agricultural greenhouse film comprises the following raw materials in parts by weight: 15-20 parts of vinyl acetate copolymer base material, 18-22 parts of high-density polyethylene base material, 15-20 parts of linear polyethylene base material, 10-15 parts of linear low-density polyethylene base material, 15-20 parts of metallocene polyethylene resin base material, 18-22 parts of sorbitan monolaurate, 1-3 parts of polyethylene wax, 0.05-0.15 part of antioxidant, 0.2-0.4 part of anti-oxygen agent, 0.01-0.015 part of ultraviolet absorption agent and 0.001-0.002 part of agricultural film color concentrate pigment. A preparation method comprises the following steps: mixing the raw materials, completing heating, then simultaneously feeding by three extruding machines, extruding into a machine head for discharge, cooling the discharged material with cooling wind, further performing secondary traction to primary traction, and finally winding and packaging to form a finished product. The effective service life of the agricultural greenhouse film produced by the method disclosed by the invention can achieve 3 years, and the antifog effective period can be prolonged to above 6 months; the tensile strength and the puncture strength are improved by 15%; and by using the product, the production of strawberry crops can be increased by 20%.

Owner:安徽大诚明农业科技股份有限公司

Glassware cleaning agent for laboratory detection and preparation method of glassware cleaning agent

InactiveCN104403854AStrong targetingEfficient removalSurface-active non-soap compounds and soap mixture detergentsEthylenediamineCellulose

The invention provides a glassware cleaning agent for laboratory detection and a preparation method of the glassware cleaning agent. The glassware cleaning agent comprises raw materials in parts by mass as follows: 32-45 parts of dioctylsodium sulfosuccinate, 6-15 parts of sorbitan monolaurate, 5-15 parts of sodium alkyl benzene sulfonate, 68-82 parts of ethylenebis (nitrilodimethylene) tetraphosphonic acid, 5-12 parts of sodium gluconate, 0.1-0.4 parts of trinitrotoluene, 3-5 parts of soap powder, 1-7 parts of borax, 2-8 parts of sodium hydrogen phosphate, 2-8 parts of tetrahydrofuran, 2-6 parts of hydroxypropyl methyl cellulose ether and 750-850 parts of water. The provided cleaning agent has high pertinence, can effectively remove residual chemical substances such as acid, alkali and the like, is rinsed easily and cannot cause secondary pollution.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Nutritional type deep-cleansing moisture-retention water

InactiveCN104207961ANon-irritatingNo greasy feelingCosmetic preparationsToilet preparationsPolyethylene glycolMoisture

Nutritional type deep-cleansing moisture-retention water comprises raw materials in parts by weight: 6.0 parts of propylene glycol, 15.0 parts of ethanol, 6.0 parts of 1,3-butanediol, 64.5 parts of deionized water, 6.0 parts of polyethylene glycol (400), proper amount of essence, 1.0 part of polyoxyethylene (20)sorbitan monolaurate, proper amount of a pigment, proper amount of an antiseptic, and 1.5 parts of polyoxyethylene-polyoxypropylene block copolymer. The usage amount and the physical and chemical properties of all raw materials give play to synergic effect, thereby realizing the effects of deeply cleaning skin, supplementing water, and retaining moisture of skin. The nutritional type deep-cleansing moisture-retention water has the pH value close to the pH value of human skin, has no stimulation on skin, enables a user to feel comfort and soft and have no greasy feeling, and has obvious deep-cleansing water-supplementing moisture-retention effects.

Owner:谢朝阳

Glass antifogging detergent

InactiveCN104479895AQuick cleanEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsO-Phosphoric AcidSodium sulfate

The invention relates to a glass antifogging detergent, belonging to the technical field of fine chemical engineering. The glass antifogging detergent is prepared from the following raw materials in parts by weight: 10-30 parts of sorbitan monolaurate, 15-25 parts of orthophosphoric acid, 9-18 parts of zinc chromate, 5-18 parts of sulfated castor oil, 5-18 parts of polypropoxybutyl ether sodium sulfate, 2-12 parts of quick-drying agent and 60-90 parts of water. By reasonably combining the sorbitan monolaurate and other raw materials, the detergent can quickly and effectively clean the glass, can be quickly dried, and can form an antifogging film on the glass surface to perform the antifogging function; and the antifogging efficacy time can reach one week and even longer.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Sleeping mask with efficacies of preserving moisture and soothing nerves and preparation method thereof

InactiveCN105168105AKeep dryRelieve symptoms of yang deficiency and night sweatsCosmetic preparationsNervous disorderPhysiologyCucumber juice

The invention relates to a sleeping mask with efficacies of preserving moisture and soothing nerves and a preparation method thereof. The sleeping mask is prepared from the following components in parts by weight: 12-24 parts of ethanol, 2.5-10 parts of beewax, 1.2-4.5 parts of sodium alginate, 5.5-11 parts of propylene glycol, 1-4 parts of sorbitan monolaurate, 1.5-6 parts of fatty alcohol-polyoxyethylene ether, 7-15 parts of cucumber juice, 5-12 parts of castor oil, 0.6-2.5 parts of tween, 0.5-3 parts of 2-hydroxy-4-methoxyl benzophenone, 0.1-0.4 part of sorbic acid, 0.2-0.5 part of essence, 72-85 parts of purified water, 3-9 parts of spina date seeds, 3-9 parts of tuber fleeceflower stem, and 1-4 parts of lucid ganoderma. The sleeping mask can effectively improve the problem of dry skin, enables the skin on the face to be soft, tender and white, also has the efficacy of soothing the nerves, and can relieve the symptoms of deficiency of yang and perspire during sleep to a certain extent.

Owner:JIANGSU QILIKANG SKIN PHARMA

Extraction preparation method of ganoderan for animals

The invention provides an extraction preparation method of ganoderan for animals. The method comprises the following steps: slicing and crushing ganoderma lucidum, performing Soxhlet extraction by using ethyl acetate to remove fat, performing filtering to obtain a precipitate, adding a surfactant sorbitan monolaurate for soaking, adjusting the pH value, performing ultrasonic extraction, performing centrifugal separation on an extracting solution, decoloring supernate with H2O2, removing proteins by a Sevage method, and performing concentrating, alcohol precipitation and freeze-drying to obtain the high-purity ganoderan. According to the invention, glycopeptide bonds of glycoprotein are broken through ultrasonic treatment and change of the pH value in the ultrasonic treatment process, in addition, the dissolution of the ganoderan is increased by adopting the surfactant sorbitan monolaurate, and the extraction rate of the ganoderan is remarkably increased. The synergistic effect of the two means increases the yield of the ganoderan. The method is simple and convenient to operate, takes less time, is nontoxic and pollution-free while efficiently extracting the ganoderan, can remarkably improve the immunity of the poultry and livestock and promote the growth of the poultry and livestock, can be widely applied to the poultry and livestock, and has a wide market prospect.

Owner:江西嘉博生物工程有限公司

Tea polyphenol containing anti-wrinkling and skin-moistening eye cream and preparation process thereof

InactiveCN104546543AStrong anti-aging effectImprove antioxidant capacityCosmetic preparationsToilet preparationsMethylisothiazolinoneGlycerol

The invention discloses a tea polyphenol containing anti-wrinkling and skin-moistening eye cream and a preparation process thereof. The eye cream comprises the following components in percentage by mass: 84.59-88.545% of deionized water, 5.0-6.0% of glycerol, 2.0-2.5% of isopropyl myristate, 1.5-2.0% of octyl decyl acid triglycerate, 1.0-1.5% of polyoxyethylene 20 sorbitan monolaurate, 0.5-0.8% of vitamin E, 0.5-0.8% of tea polyphenols, 0.5-0.8% of carbomer 940, 0.2-0.5% of triethanolamine, 0.1-0.2% of hyaluronic acid, 0.1-0.2% of 2,6-di-tert-butyl-4-methylphenol, 0.05-0.1% of essence, and 0.005-0.01% of methylisothiazolinone. Compared with the prior art, the eye cream has a good anti-wrinkling and skin-moistening effect, and can be used for alleviating eye fatigue, and improving the apparent level of dark eye circles.

Owner:HANGZHOU SILIN BIOTECH

Gracilaria alga beauty mask

InactiveCN105232376ANon-irritatingAnti agingCosmetic preparationsToilet preparationsVitamin CIrritation

A gracilaria alga beauty mask is prepared from the following raw materials in parts by weight: 5.7 parts of mannitol, 3 parts of hydroxyethyl cellulose, 1.5 parts of sorbitan monolaurate, 11 parts of gracilaria alga extractive, 0.6 part of hyaluronic acid, 1 part of jojoba oil, 1 part of vitamin C, 1 part of vitamin E, 20 parts of a surfactant, proper amount of essence, proper amount of an antiseptic, and deionized water with the amount enabling the total weight fraction to be 100 parts. The raw materials with the usage amount and the physical and chemical properties give play to synergic effect, and therefore the effects of delaying ageing and improving skin quality are realized. The pH value of the mask is close to the pH value of human skin, and thus the mask does not stimulate skin. After the mask is used, people obviously feel comfortable, the skin is soft and grease-free, and the mask possesses obvious effects of moistening skin, resisting ageing and treating beauty.

Owner:刘艺鹏

Vortioxetine nanoparticles, preparation and preparation method thereof

InactiveCN106265523ALarge specific surface areaHigh dissolution rateOrganic active ingredientsPowder deliveryPolyethylene glycolCyclodextrin Derivatives

The invention relates to the technical field of medicines and particularly relates to vortioxetine nanoparticles, a preparation and a preparation method thereof. The vortioxetine nanoparticles comprise the following components in parts by weight: 1-5 parts of vortioxetine and 10-100 parts of nano carrier, wherein the nano carrier comprises one or more of lecithin, povidone, polyalkylcyanocraylate, acrylamide, N,N-methylene bisacrylamide, polysorbate, sorbitan monolaurate, polyoxyethylene lauryl ether, sodium lauryl sulfate, poloxamer, polyethylene glycol, cyclodextrin and cyclodextrin derivative. The vortioxetine nanoparticles provided by the invention are of nanoscale particle size; and on the basis, the prepared vortioxetine preparation has high dissolubility.

Owner:佛山市弘泰药物研发有限公司

Construction method for reducing surface bubbles of aluminum alloy formwork concrete

InactiveCN112171868AEasy to prepareLow costAuxillary shaping apparatusForming/stuttering elementsStructural engineeringSilicone fluid

The invention discloses a construction method for reducing surface bubbles of aluminum alloy formwork concrete. The construction method comprises the following steps that Tween20, sodium dodecyl sulfate and water are prepared into a first mixed solution, and simethicone and sorbitan monolaurate are uniformly stirred until the mixed solution is milky white to prepare a second mixed solution; the first mixed solution is slowly added into the second mixed solution, adding is carried out while stirring until the first mixed solution is completely added, then a compound modified additive is added,uniformly stirring and mixing are carried out to obtain a bubble eliminating release agent, the bubble eliminating release agent is directly sprayed on the surface of a formwork, and then concrete ispoured; and the surface tension of foam is changed through the bubble removing release agent, so that small bubbles are gathered into large bubbles, the bubbles are broken to achieve the defoaming effect. The preparation method of the bubble removing release agent is simple, the cost is low, and the problem that the surface bubbles of the aluminum alloy formwork concrete are too many is solved with low cost.

Owner:ANHUI TONGJI CONSTR GRP

Coating composition and uses thereof

InactiveUS20180244927A1Improve water-binding capacityIncrease ratingsSurgeryPharmaceutical delivery mechanismPVP polymerPyrrolidinones

The present invention provides a polymerizable coating composition comprising: (i) 1-vinyl-2-pyrrolidinone (NVP) and 2-hydroxyethylmethacrylate (2-HEMA) for forming a copolymer; (ii) a poly(vinyl pyrrolidone) (PVP) polymer having a molecular weight of at least 500,000 g·mol−1; (iii) a co-polymerizable crosslinker for crosslinking the 1-vinyl-2-pyrrolidinone (NVP) and the 2-hydroxyethylmethacrylate (2-HEMA); (iv) a co-polymerizable initiator for initiating co-polymerisation of the 1-vinyl-2-pyrrolidinone (NVP) and 2-hydroxyethylmethacrylate (2-HEMA); (v) a surfactant selected from non-ionic triblock copolymers of ethylene oxide / propylene oxide, nonionic triblock copolymers of poly(propylene oxide) (PPO) and poly(ethylene oxide) (PEO), tetrablock copolymers of PPO and PEO; Triton X-100 and derivatives thereof, polyethylene glycols and derivatives thereof, PEO derivatives of sorbitan monolaurate, and combinations of any two or more thereof; (vi) a solvent, wherein a vinyl component is 1-vinyl-2-pyrrolidinone for forming the copolymer and the PVP polymer, and an acrylate component is 2-hydroxyethyl methacrylate for forming the copolymer; wherein the vinyl and acrylate components are present at a molar ratio of between 10:1 and 1:10; and wherein 20-80% (w / w) of the vinyl component is PVP polymer.

Owner:QUEENS UNIV OF BELFAST

Salmon oil microcapsule cat food additive and preparation method thereof

InactiveCN107439801APrevent oxidationReduce bad smellAnimal feeding stuffAccessory food factorsFood additiveVegetable oil

The invention discloses a salmon oil microcapsule cat food additive and a preparation method thereof. The salmon oil microcapsule cat food additive is prepared from an oil core and a capsule shell, wherein the oil core is prepared by the following steps: taking salmon belonging to marine fishes as a raw material, carrying out cryogenic grinding and CO2 supercritical extraction to obtain fish oil taking fatty acid as a main ingredient, and then adding vegetable oil and a surfactant, wherein the vegetable oil is one or more of corn germ oil, peanut oil, rice bran oil, cinnamon oil and clove oil; the capsule shell is a natural high polymer material aqueous solution and is prepared from one or more of gelatin, cured corn starch, cured potato starch, chitin and alginate; the surfactant is one or more of polyoxyethylene (20) sorbitan monooleate, polyoxyethylene monoleate and polyoxyethylene (4) sorbitan monolaurate. The natural high polymer material is used to clad the salmon oil, and the problems of strong fishy smell of the salmon oil, the pollution to indoor air, high possibility of oxidation and short storage life are solved.

Owner:NANTONG XIANGJIA TEXTILE SCI & TECH CO LTD

Spreading oil coalescing agent

InactiveCN106070189ADiffusion fastEasy to useBiocidePlant growth regulatorsBULK ACTIVE INGREDIENTStearate

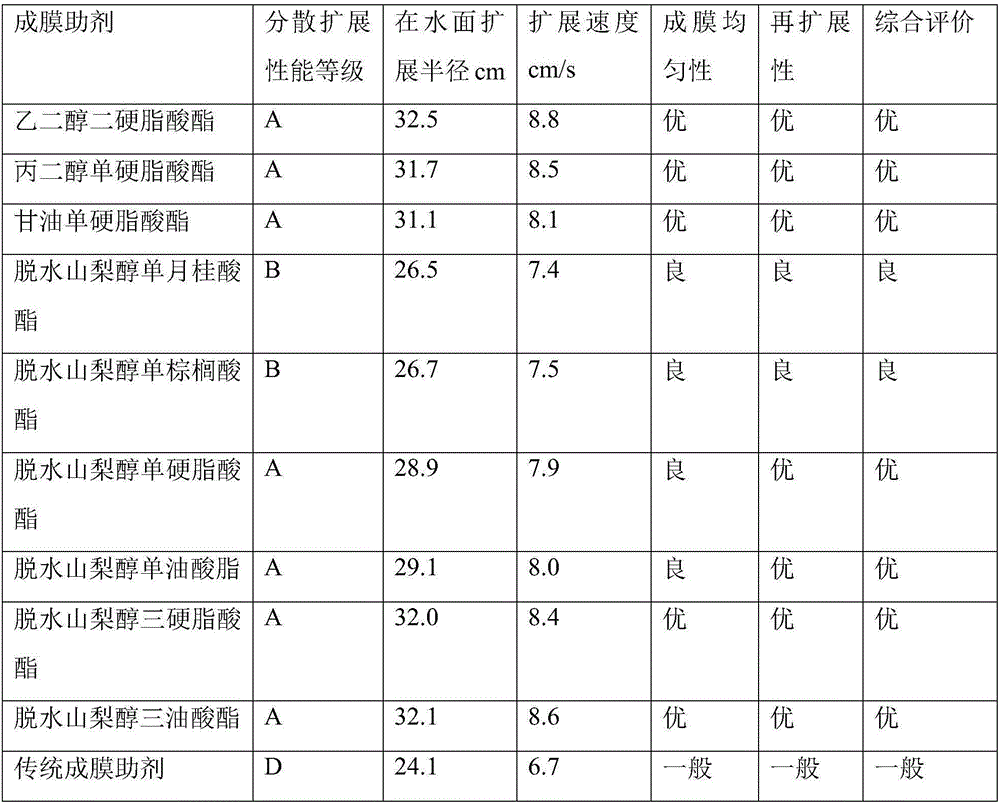

The invention relates to a novel spreading oil coalescing agent and an application of the oil coalescing agent in spreading oil, and belongs to the field of pesticide applications. One or more of ethylene glycol distearate, propylene glycol monostearate, glycerine monostearate, sorbitan monolaurate, sorbitan monopalmitate, sorbitan monostearate, sorbitan monooleate, sorbitan tristearate and sorbitan trioleate is or are active ingredients of the coalescing agent. The novel spreading oil coalescing agent can be used for preparing the coalescing agent for products such as a pesticide, a bactericide, a herbicide and a plant growth regulator in a paddy field.

Owner:JINGBO AGROCHEM TECH CO LTD

Nail patch

The present subject matter provides a nail patch comprising a backing layer and a pressure-sensitive adhesive layer disposed on at least one side of the backing layer, wherein the pressure-sensitive adhesive layer comprises a pressure-sensitive adhesive base, terbinafine and / or a pharmacologically acceptable salt thereof, and sodium acetate and / or sorbitan monolaurate as a solubilizer.

Owner:HISAMITSU PHARM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com