Method for modifying ultrafine light calcium carbonate and application of ultrafine light calcium carbonate in plastics

A technology of light calcium carbonate and nano calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, fibrous filler, dyed low molecular organic compound treatment, etc., can solve the problems of difficult uniform dispersion and poor compatibility of nano calcium carbonate, Achieve the effect of narrow particle size range, improved impact strength and reduced surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

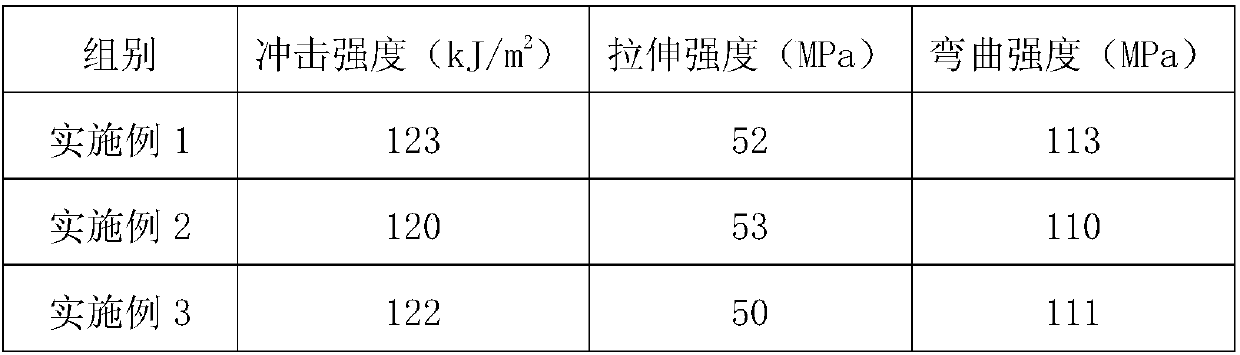

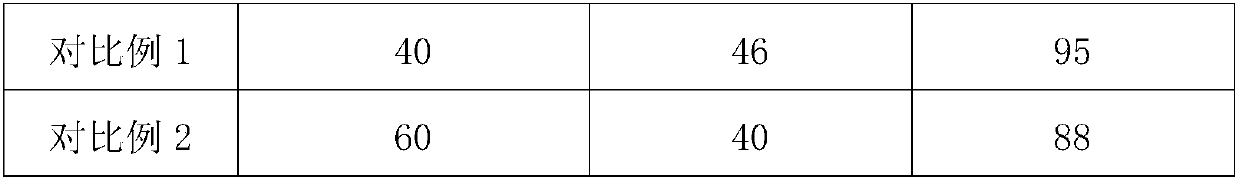

Examples

Embodiment 1

[0031] A modification method of superfine light calcium carbonate, comprising the following steps:

[0032] (1) pulping: it comprises the following steps:

[0033] A1. Preparation of Ca(OH) 2 Suspension: Put CaO into the digester and digest with water to obtain Ca(OH) 2 Suspension; when adding water for digestion, the mass ratio of water to CaO is 1:20, and the water temperature is 70°C.

[0034] A2. Add crystal form control agent: Ca(OH) prepared in step A1 2 A crystal form control agent is added to the suspension to obtain a mixed solution; the crystal form control agent is prepared from the following raw materials in parts by weight: 4 parts of sodium citrate, 5 parts of citric acid, 3 parts of glycolic acid, 1 part of propionic acid and lactic acid 1 part; the mass ratio of the crystal form control agent to the CaO is 1:50.

[0035] A3. Carbonization reaction: first, the mixed solution obtained in step A2 is added to a carbonization reactor with a stirring device; then...

Embodiment 2

[0045] A modification method of superfine light calcium carbonate, comprising the following steps:

[0046] (1) pulping: it comprises the following steps:

[0047] A1. Preparation of Ca(OH) 2 Suspension: Put CaO into the digester and digest with water to obtain Ca(OH) 2 Suspension; when adding water for digestion, the mass ratio of water to CaO is 1:15, and the water temperature is 80°C.

[0048] A2. Add crystal form control agent: Ca(OH) prepared in step A1 2 A crystal form control agent is added to the suspension to obtain a mixed solution; the crystal form control agent is prepared from the following raw materials in parts by weight: 8 parts of sodium citrate, 10 parts of citric acid, 5 parts of glycolic acid, 3 parts of propionic acid and lactic acid 3 parts; the mass ratio of the crystal form control agent to the CaO is 1:20.

[0049] A3. Carbonization reaction: first, the mixed solution obtained in step A2 is added to a carbonization reactor with a stirring device; t...

Embodiment 3

[0059] A modification method of superfine light calcium carbonate, comprising the following steps:

[0060] (1) pulping: it comprises the following steps:

[0061] A1. Preparation of Ca(OH) 2 Suspension: Put CaO into the digester and digest with water to obtain Ca(OH) 2 Suspension; when adding water for digestion, the mass ratio of water to CaO is 1:18, and the water temperature is 75°C.

[0062] A2. Add crystal form control agent: Ca(OH) prepared in step A1 2 A crystal form control agent is added to the suspension to obtain a mixed solution; the crystal form control agent is prepared from the following raw materials in parts by weight: 6 parts of sodium citrate, 8 parts of citric acid, 4 parts of glycolic acid, 2 parts of propionic acid and lactic acid 2 parts; the mass ratio of the crystal form control agent to the CaO is 1:35.

[0063] A3. Carbonization reaction: first, the mixed solution obtained in step A2 is added to a carbonization reactor with a stirring device; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com