Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Open treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Open treatment means treating for an open fracture, reduction is a type of surgical treatment for fracture whether close or open, you shouldn't correlate them as the same. open treatment is a broad term.

Product for and method of controlling odor in open waste water treatment environments

A product for substantially eliminating existing foul odors (such as those associated with materials such as hydrogen sulfide) and substantially preventing the production of new foul odors in matter, in open treatment environments is disclosed and comprises calcium nitrate and calcium carbonate.

Owner:WEGNER PAUL

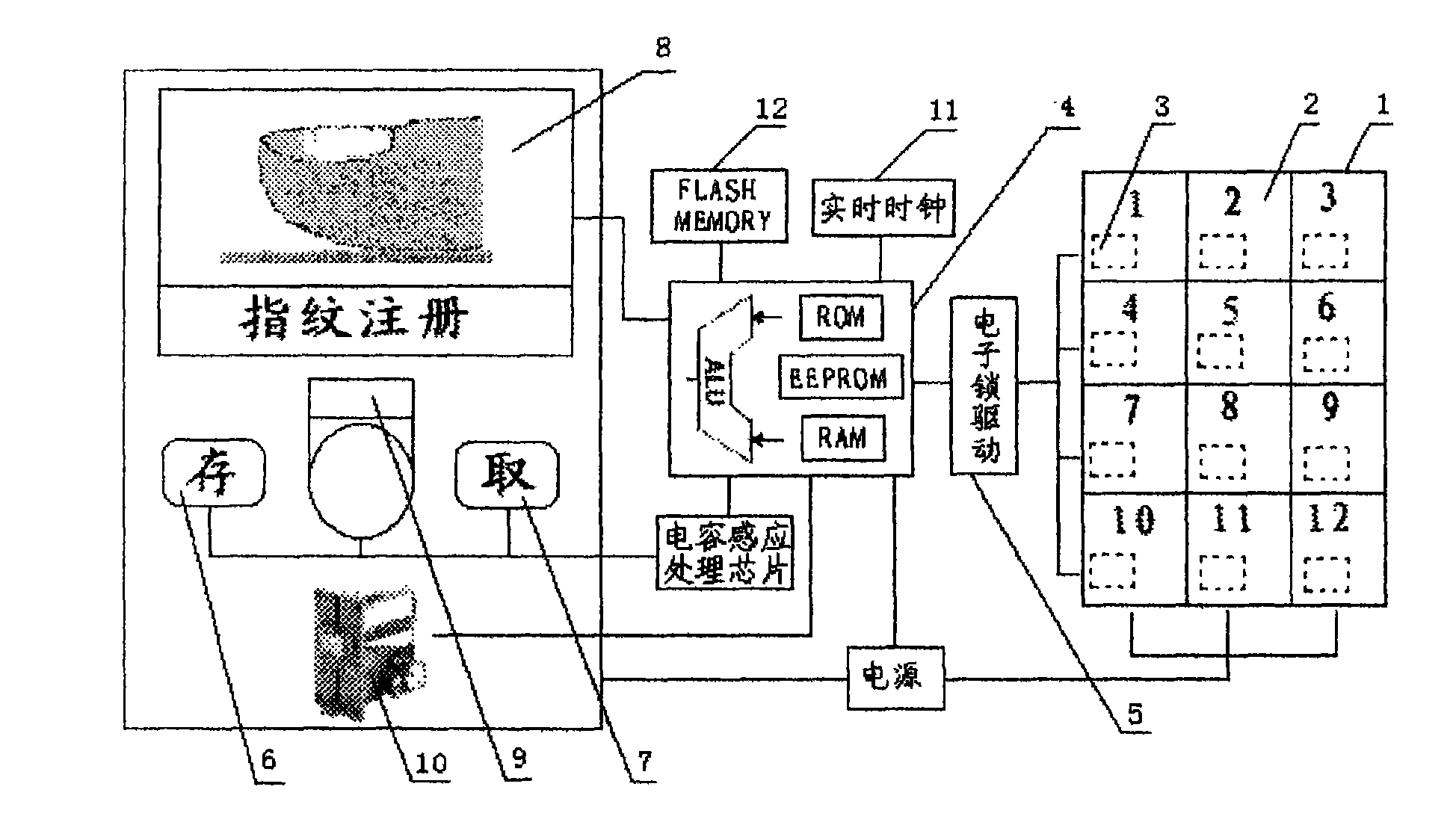

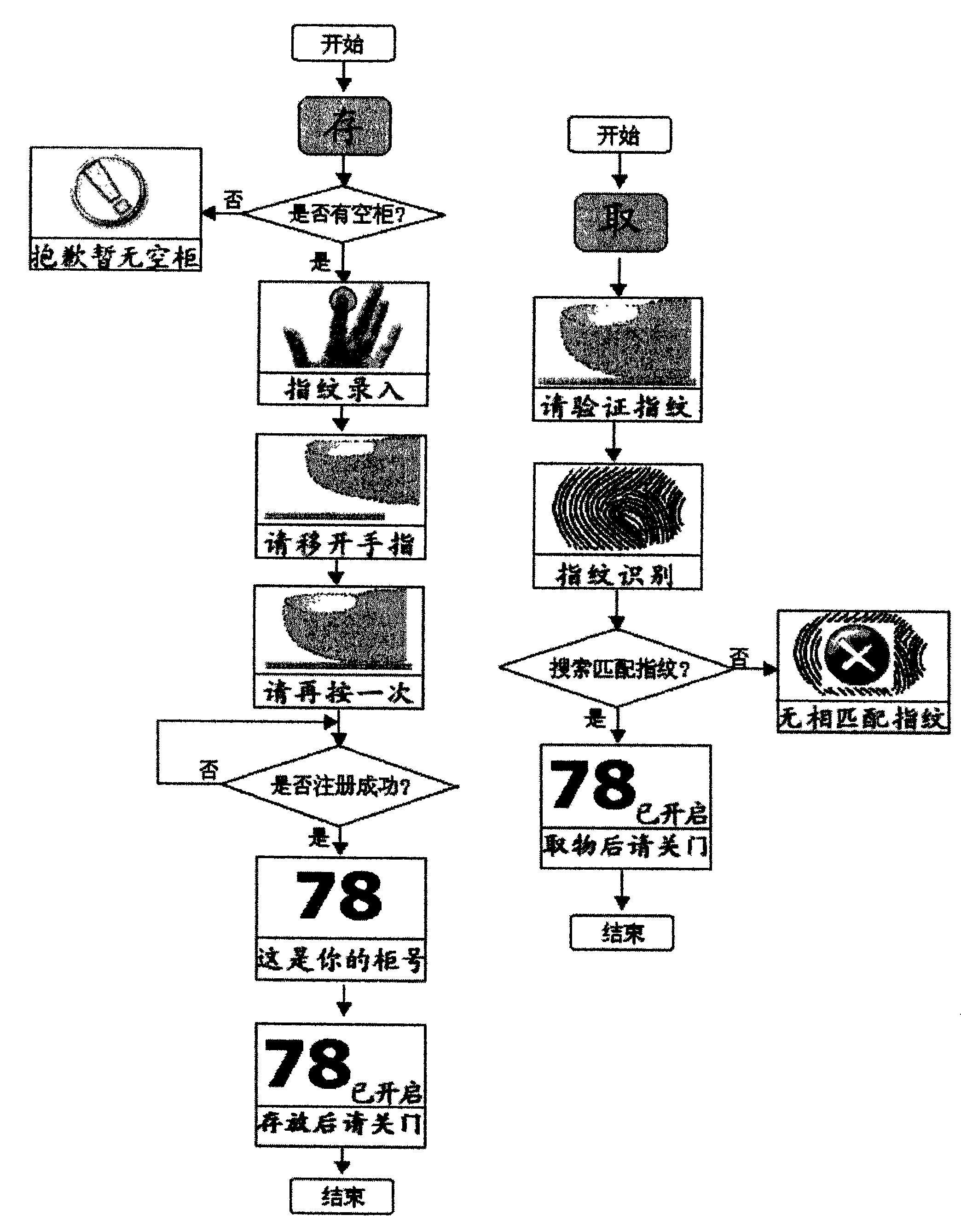

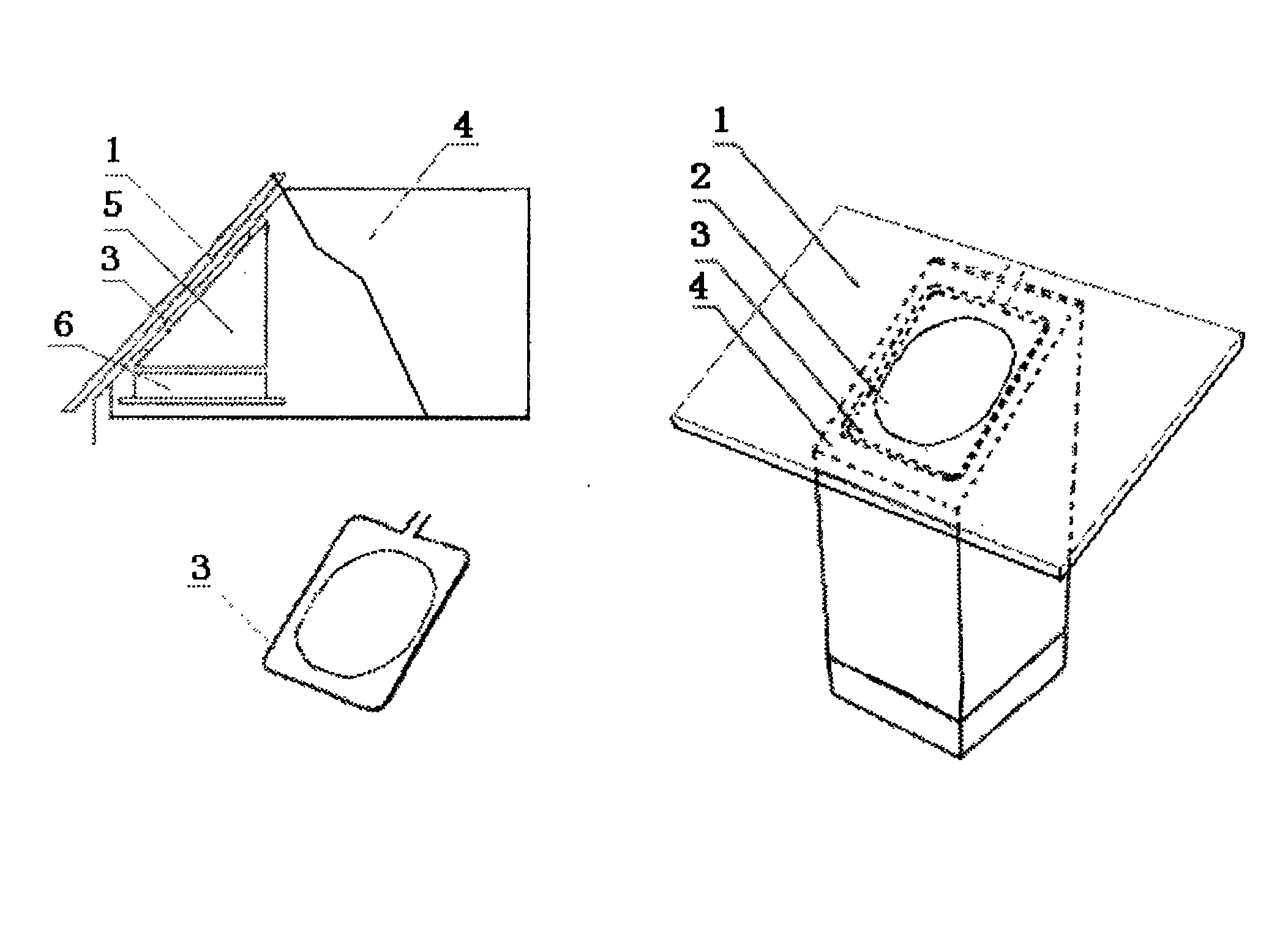

Man-machine interface technique for fingerprint locker and method for managing same

InactiveCN101625781AEasy to useQuality improvementApparatus for meter-controlled dispensingLiquid-crystal displayPublic place

The invention discloses a man-machine interface technique for a fingerprint locker and a method for managing the same. A system adopts the combination of the fingerprint identification technique in the biometric identification technology and the man-machine interface technique to complete the work for safe temporary storage of articles of people necessary in a public place. The technique is characterized in that: only 2 to 3 keys and display contents combining patterns and characters and displayed by an LCD form the interactive man-machine interface, and an intuition guide based mode is adopted to guide a user for routine access operation; and by the same man-machine interface, the equipment managing staff can quite conveniently complete the back-stage management operations of the equipment, such as time setting and correction, language setting of a user interface, fee rate setting, money withdrawing operation, locker opening treatment in an abnormal state, safety audit and the like, under a highly-safe safety restriction mechanism. The technique has the advantages of simple user interface and easy use of the same man-machine interface, easy management of the management interface,comprehensive management functions, and sound security mechanism.

Owner:黄涛

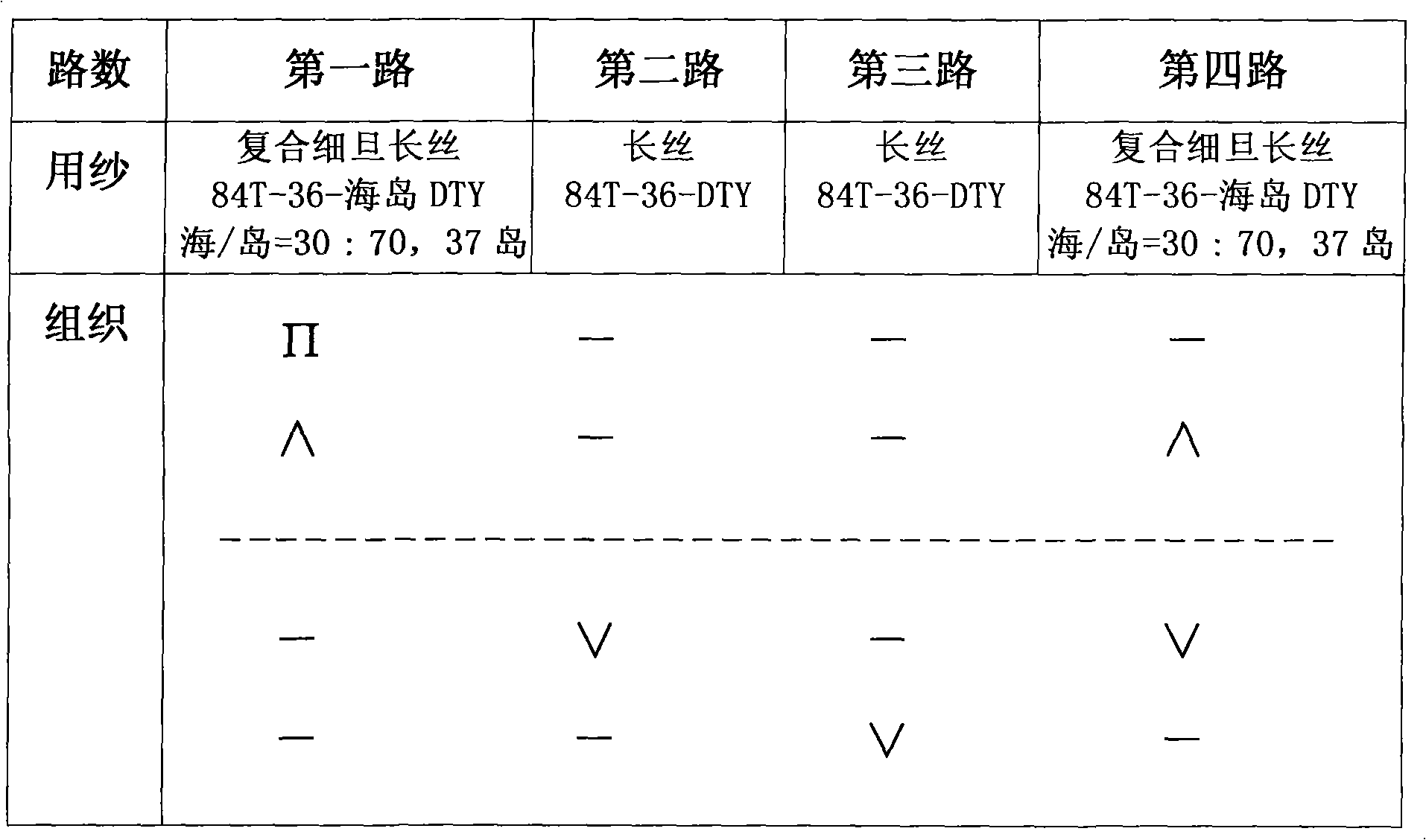

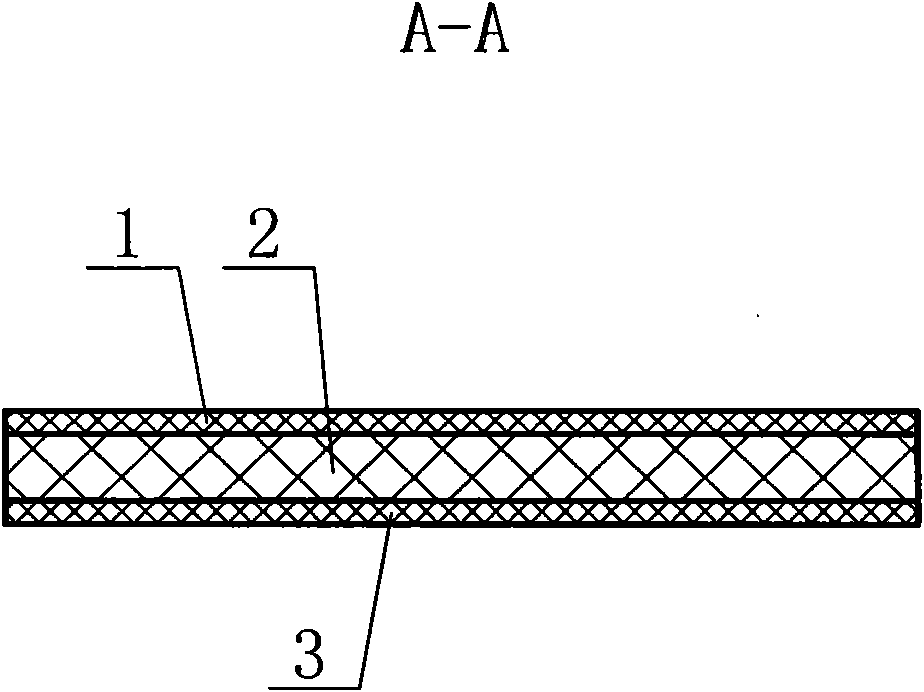

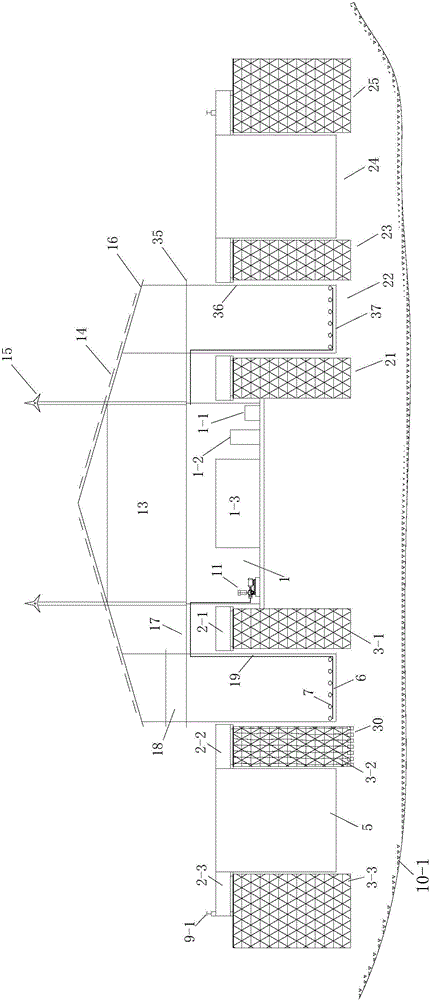

Cleaning wiping cloth with geometrical shape stability and manufacturing method and application thereof

InactiveCN101549344AExcellent geometry stabilityClean and wipe adequatelyWeft knittingCarpet cleanersYarnHigh density

The invention discloses a cleaning wiping cloth with geometrical shape stability and a manufacturing method and the application thereof. A cleaning mask of the cleaning wiping cloth has an organizational structure with convex-concave effect and is formed from fine filaments with the filament number of 0.01-1.0 dtex, and a supporting mask has an organizational structure with high density and is formed from filaments with the filament number of 1-10 dtex; the cleaning wiping cloth is difficult to extend and deform under the action of traction in the using process no matter being a knitted fabric or a woven fabric and has excellent geometrical shape stability. The manufacturing method of the cleaning wiping cloth comprises the following steps: raw material yarn selection and organizational design, fabric manufacture (weaving or knitting), hot water treatment, fiber opening treatment, heat setting, and the like; obtained cleaning wiping cloth is processed to a wind-shaped cleaning wiping belt which is arranged on automatic cleaning wiping equipment and can automatically clean mechanical parts following the transmission of the wind-shaped cleaning wiping belt, and the wind-shaped cleaning wiping belt is indirectly repeatedly used so as to prevent secondary pollution.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Preparation process of artificial leather shell material

A rpeparation process of imitation real leather shell fabric with excellent elasticity, air permeability, heat insulating ability, crease-resistance and buckskin effect includes the procedures of warp knitting, grey fabric, pretreatment, drying, raising, opening, dyeing, carding, shearing, grinding and foring, and is characterized by that its raw material is of "islands-in-sea" type fibre, and the technological condition of pretreatment is as follows: adding adjuvant at 120-130 deg.C, treatment time is 30-50 min., the technological condition of raising process is as follows: number of pin-rollers of raising machine is 24, model of card clothing is RA-91, and frame needling for three times; and the condition of opening treatment is that adding sodium hydroxide 10-15 g / l at 100-150 deg.C, heating time is 60-90 min., and the condition of grinding process is that grinding roller speed is 1200 rpm, pressing distance is 3mm and abrasive paper specification is 140-180 meshes.

Owner:JIANGSU HONGDA TEXTILE

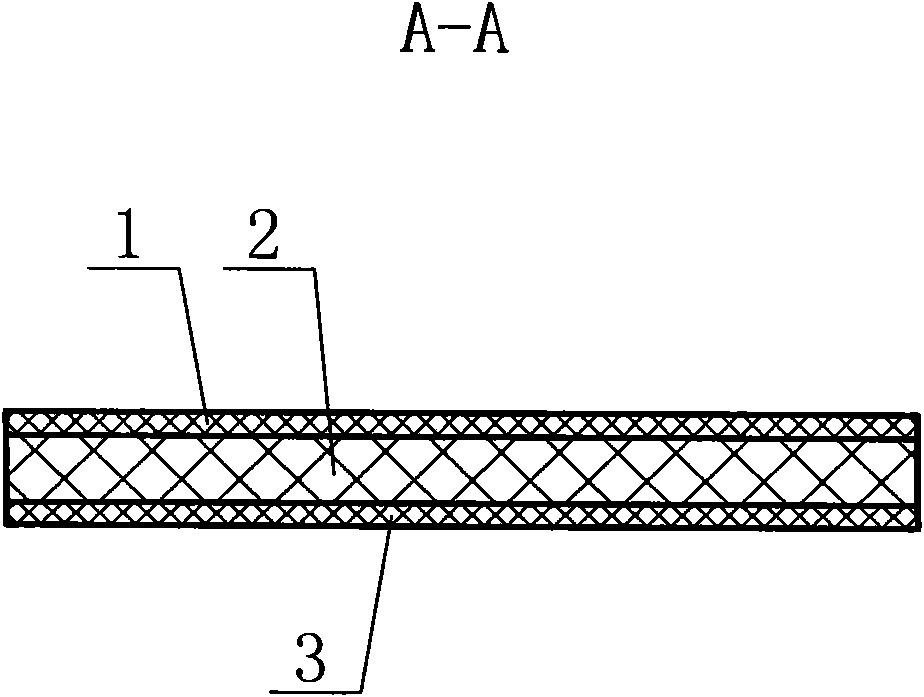

Production method of automobile interior trim panels made of natural fiber/thermoplastic resin composite materials

ActiveCN103465572AGuaranteed tensile strengthGuaranteed modulusSynthetic resin layered productsLaminationCompression moldingSurface layer

The invention discloses a production method of automobile interior trim panels made of natural fiber / thermoplastic resin composite materials. The method includes the steps of carrying out opening treatment on fiber in core-layer materials and fiber in surface-layer materials respectively, mixing and spreading out the fiber to form fiber nets, carrying out heating and gluing preforming treatment, carrying out rolling preforming treatment, cutting the preformed fiber nets into rolls to obtain core-layer fiber mats and surface-layer fiber mats, carrying out preheating treatment on the core-layer fiber mats and the surface-layer fiber mats, carrying out hot compression molding on the core-layer fiber mats to obtain core panels, carrying out hot compression molding on the surface-layer fiber mats on the core panels to enable surface panels of the trim panels to be tightly integrated with the core panels of the interior trim panels, then placing one integrated trim panel below a punching and blanking die, and carrying out punching and blanking simultaneously on the integrated trim panel to obtain one automobile interior trim panel. The production method achieves integration of designing, manufacturing and forming of the composite materials, and provides a progressive hot compression molding process to manufacture the automobile interior trim panels made of the natural fiber / thermoplastic resin composite materials.

Owner:SHANDONG UNIV

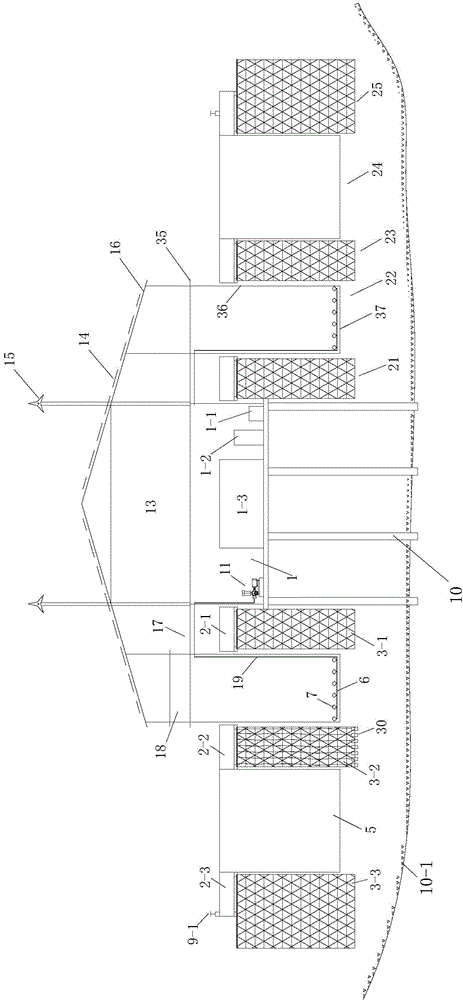

Opening treatment method for pipe-roofing continuous perforation

InactiveCN102561405AImprove the water-stop effectArtificial islandsProtective foundationEngineeringPre embedding

The invention relates to an opening treatment method for pipe-roofing continuous perforation. Pipe-roofing opening water-stopping is characterized in that a circular water-stop rubber seal board is disposed at each opening, and a sector rubber pressure board is connected and fastened to an underground structure of each hole through expansion bolts. The rubber seal boards are mutually tangent at the continuous openings and are mutually overlapped to form a whole. A grouting pipe is pre-embedded into an opening structure for water stopping at the juncture inside each opening, and the opening and the structural juncture are filled with grout for water stopping after entry of the grouting pipe into the hole. By the opening treatment method, impact on adjacent pipe roofs can be reduced greatly, the water-stop effect of the openings and the water-stop effect of the juncture of each opening with the pipe roof are enhanced, and the opening treatment method is superior to the traditional methods in terms of technical feasibility, operating efficiency and implementation effect. Presently, the opening treatment method is applied to underground channel pipe roofing at a source N0.33 in the Shanghai bund.

Owner:SHANGHAI FOUND ENG GRP

Filling cotton and preparation method thereof

InactiveCN101906700ALabor savingIncrease productivitySynthetic resin layered productsNon-woven fabricsProduction lineSurface layer

The invention discloses filling cotton and a preparation method thereof. The filling cotton comprises an upper needled surface layer and a lower needled surface layer, wherein a fiber web layer is arranged between the upper needled surface layer and the lower needled surface layer; and the upper needled surface layer, the fiber web layer and the lower needled surface layer are connected with one another through a strip-shaped needled band. The method comprises the following processing steps of: (1) needling raw materials of the upper needled surface layer and the lower needled surface layer by using a needling machine to prepare the upper needled surface layer and the lower needled surface layer; (2) putting raw materials of the fiber web layer into an opener for opening treatment; (3) carding the raw materials opened by the step (2) by using a carding machine to form planar netlike fibers; (4) laying the planar netlike fibers by using a lapping machine to form the fiber web layer and arranging the fiber web layer between the upper needled surface layer and the lower needled surface layer; and (5) needling the strip-shaped needled band by using the needling machine to obtain the filling cotton. The filling cotton is produced by a non-weaving process and can be produced on a large scale through a production line, and the elasticity and flexibility of a produced filling cotton product can meet market demands.

Owner:张延青

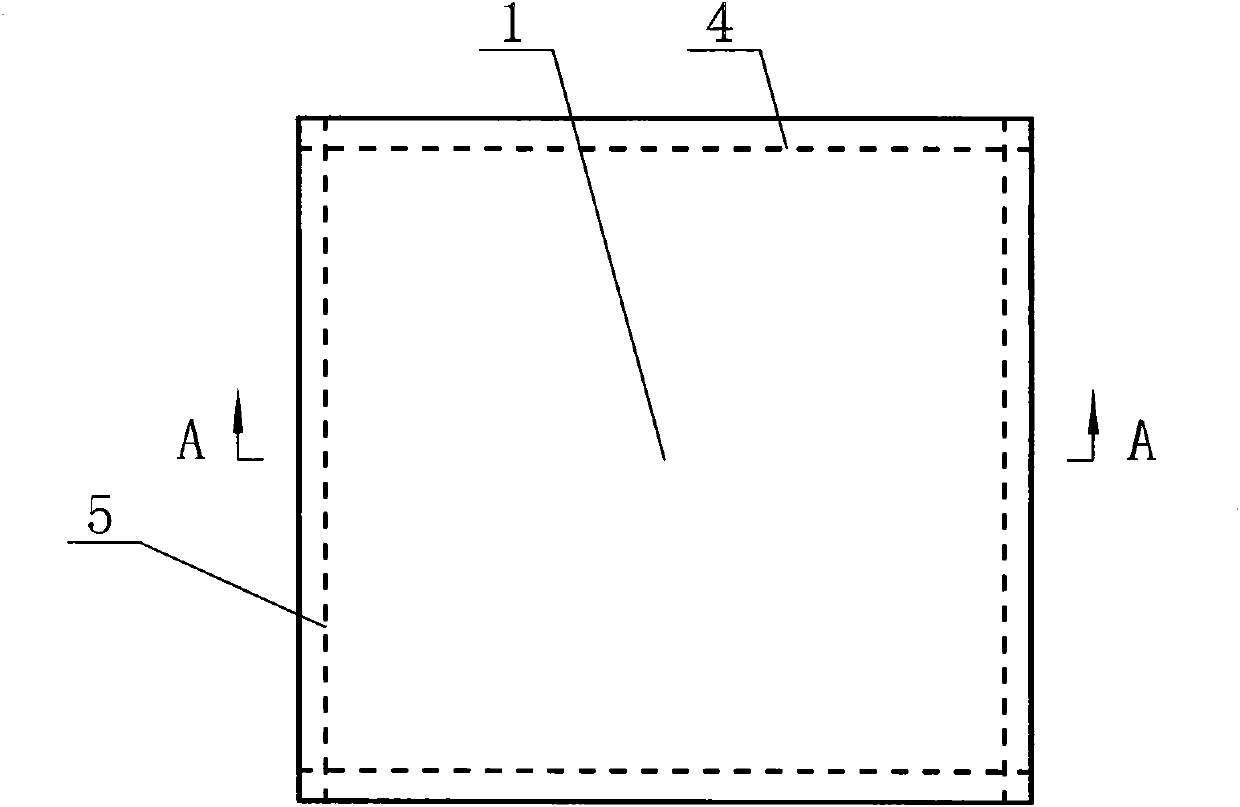

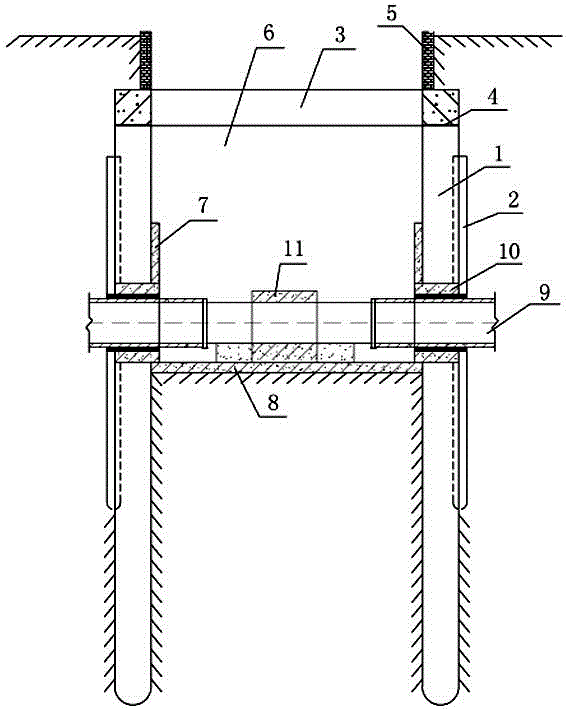

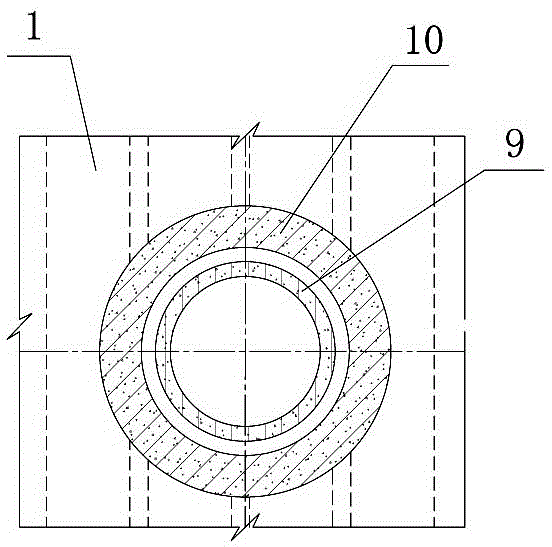

Small-size deep foundation pit supporting structure for pipe jacking construction

The invention discloses a small-size deep foundation pit supporting structure for pipe jacking construction. The supporting structure is constructed through the steps that firstly, bored perfusion pile rows are constructed around the determined foundation pit position, a high-pressure jet grouting pile row is constructed in a gap formed between every two adjacent bored perfusion pile rows, a side slope is excavated from the ground, an annular crown beam is poured on the tops of the bored perfusion pile rows, asphalt felt is laid between the crown beam and pile bodies, and then a brick wall is built on the top of the crown beam; secondly, a foundation pit is excavated after the crown beam reaches the required strength, and after the foundation building surface meets the construction requirement, the side wall of the foundation pit and an inner lining (the position where a jacking pipe is arranged in a penetrating mode is reserved) of a bottom plate are poured with reinforced concrete; lastly, opening treatment is conducted on the jacking pipe, a second-stage reinforced concrete layer is built on the dismantling face, and after the later-period pipe jacking construction requirements are met, overall supporting structure construction is completed. According to the small-size deep foundation pit supporting structure for pipe jacking construction, a conventional cantilever pile supporting method is broken through, and the supporting structure arranged in the foundation pit in a finite space meets the supporting requirement of a surrounding complex environment; meanwhile, by combining the construction characteristics of pipe jacking construction, basic guarantee conditions are provided for normal and safe construction of pipe jacking engineering.

Owner:河南省水利勘测设计研究有限公司

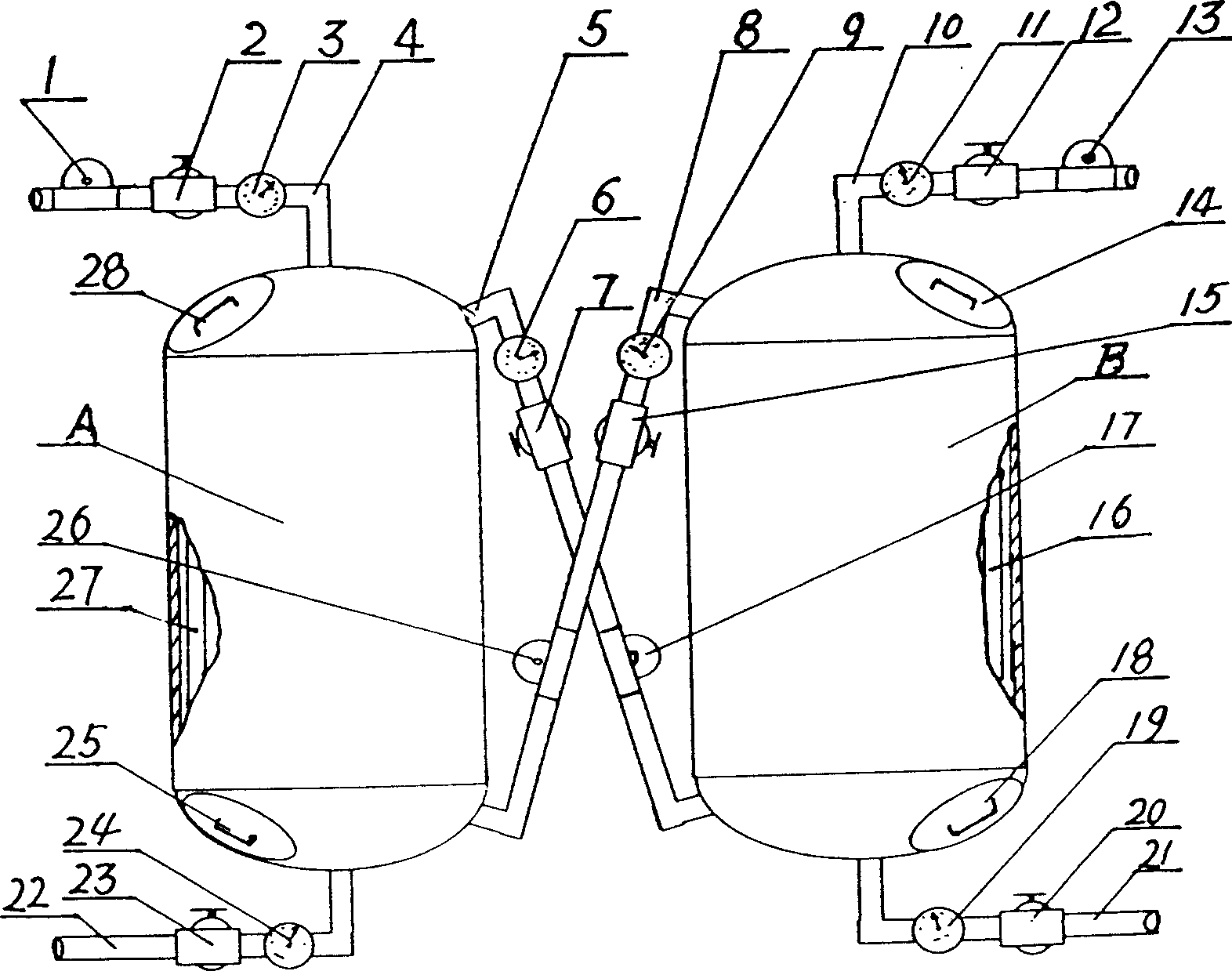

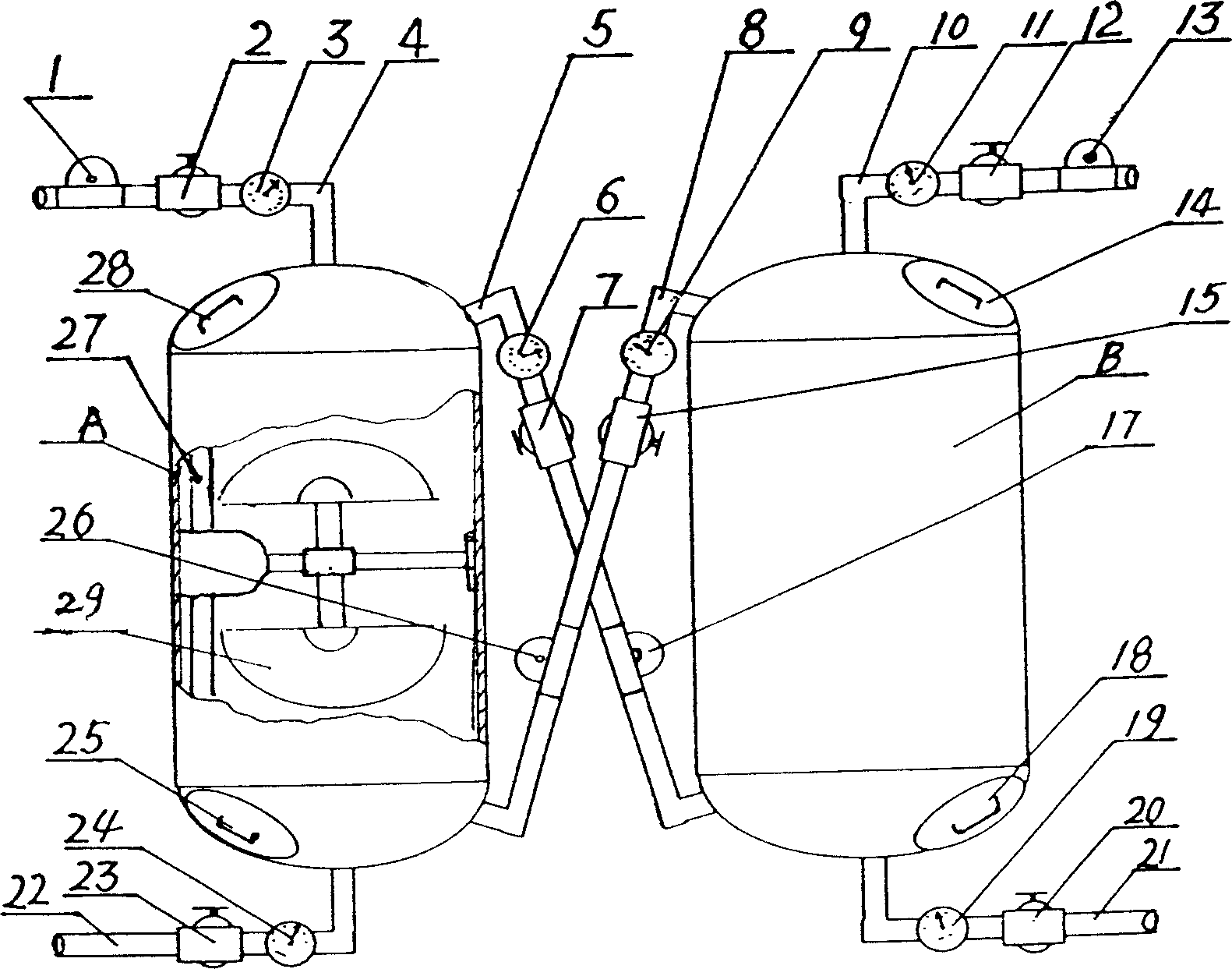

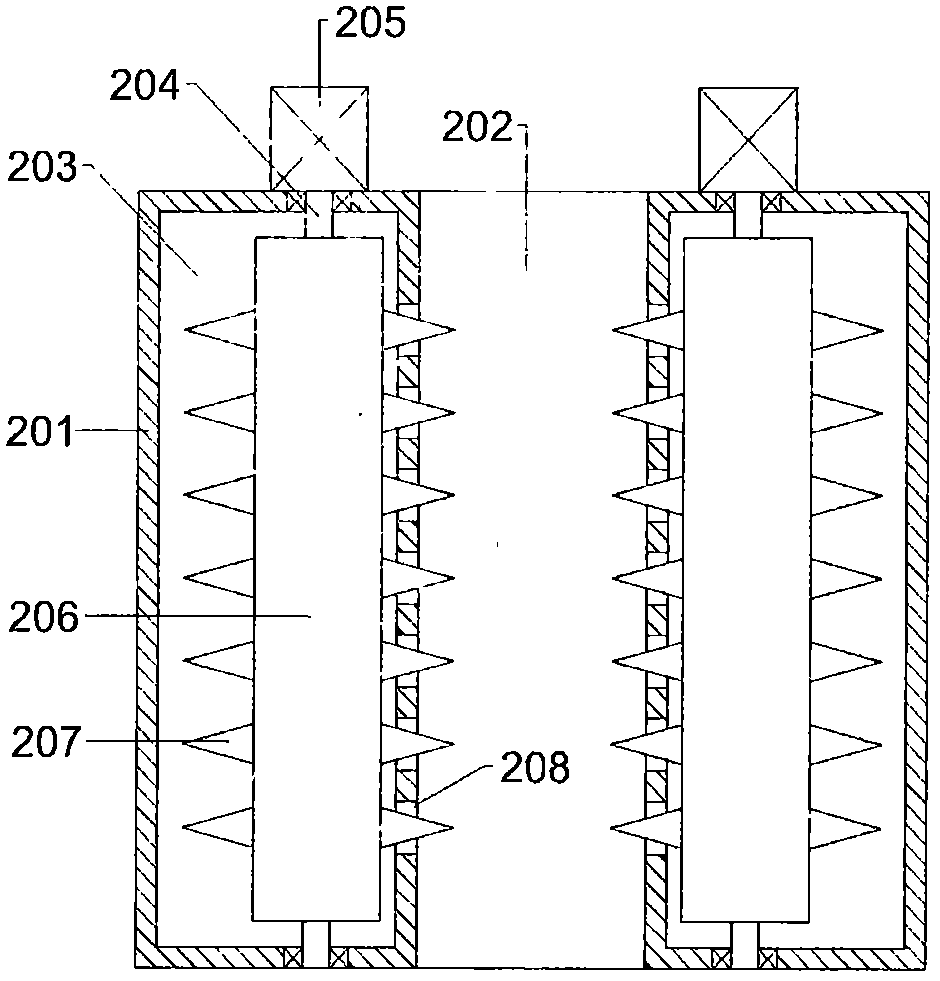

Production device of reclaimed white cotton from coloured cotton fabric an dits technology

InactiveCN1693568AUniform and thorough decolorizationGuaranteed concentrationBleaching apparatusLiquid/gas/vapor treatment of definite length materialsWater resourcesEngineering

The invention discloses a device for producing regenerated white cotton of colored cotton textile and its process, where there are two parallel reaction cylinders, there are top and bottom crosswise communicating tail gas pipes on the two reaction cylinders, and each tail gas pipe is installed with a valve, a flow meter and a vacuum pump; there is a UV lamp arranged in each reaction cylinder; another flow meter is installed on each air inlet pipe, and a pressure meter and another vacuum pump are installed on each air outlet pipe; the production process is: firstly humidifying the colored cotton textile to be processed, by steam, to make the water content of the colored cotton textile at 10-25%; making prophase decoloring treatment on the humidified cotton textile by ozone at a concentration of 5-25%; synchronously performing late UV decoloring treatment on the treated cotton textile in an ozone-containing environment to make the cotton textile turn white; and finally making cotton opening treatment on the white cotton textile to make the regenerated white cotton. The invention has the characters of simple process, high production efficiency, no pollution, no damage to cotton spinning material, saving water resources, and safety and reliability in production.

Owner:黄继理

Filter material containing polymer nanofiber, and preparation method thereof

ActiveCN102634930AReduce tanglingReduce adhesionFiltration separationNon-woven fabricsPolymer scienceNanofiber

The invention relates to a filter material containing polymer nanofiber, and a preparation method of the filter material, belonging to the field of textile material. The preparation method comprises the steps of: mixing the polymer nanofiber treated by opening and scutching through a grinder and organic fiber according to the mass ratio of (10-40): (60-90); carrying out mixing and opening treatment on the mixed fiber by an opener to form a mixed fiber layer; and treating the mixed fiber layer by an air lay technology and hot-press technology to prepare the filter material containing the polymer nanofiber. The filter material containing the polymer nanofiber has excellent filtering function; the preparation method of the filter material has the characteristic of being simple in technology; and the industrial production of the filter material containing the nanofiber can be easily realized, so that the filter material has high application potential in the field of cleaning material.

Owner:武汉维晨科技有限公司

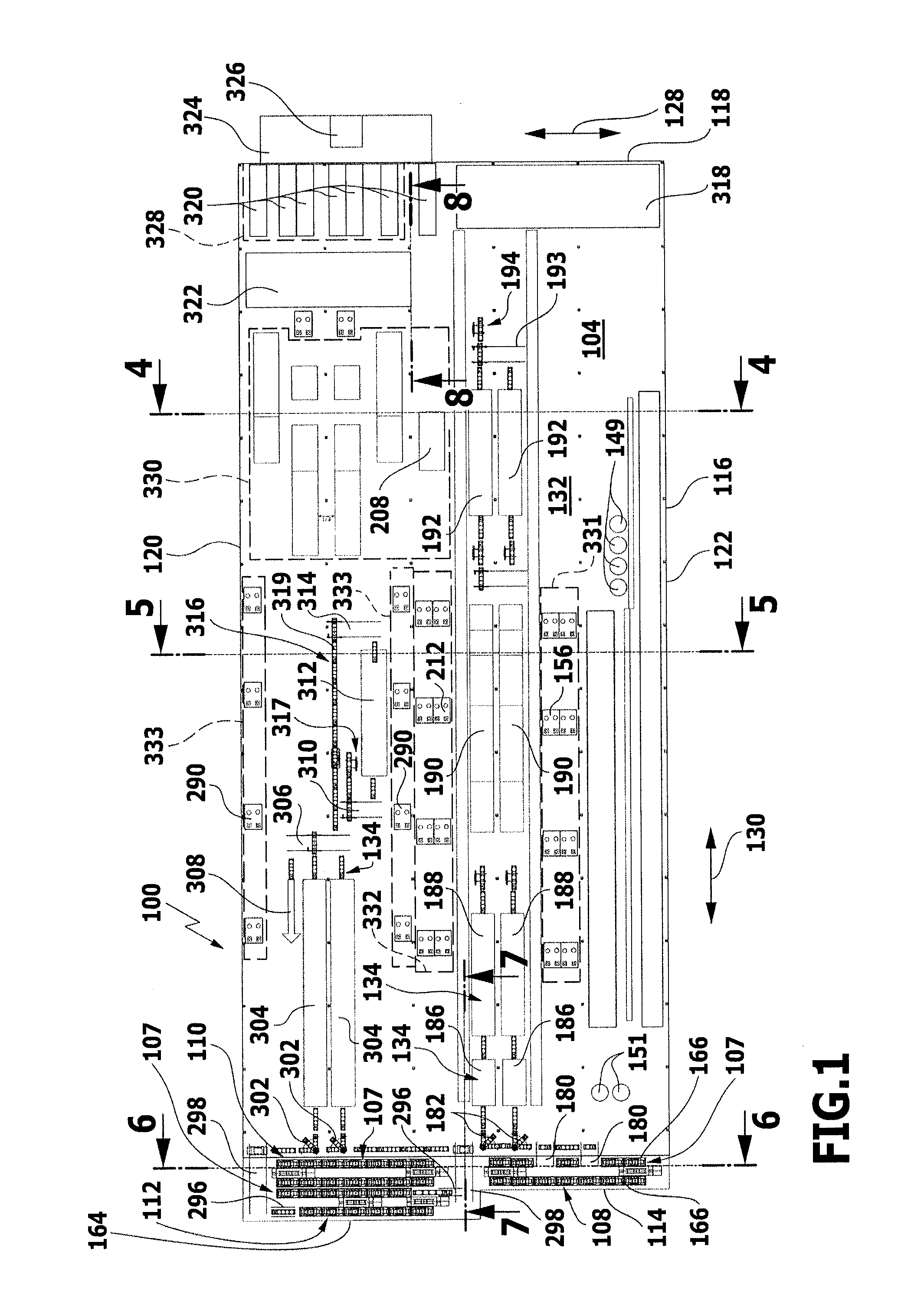

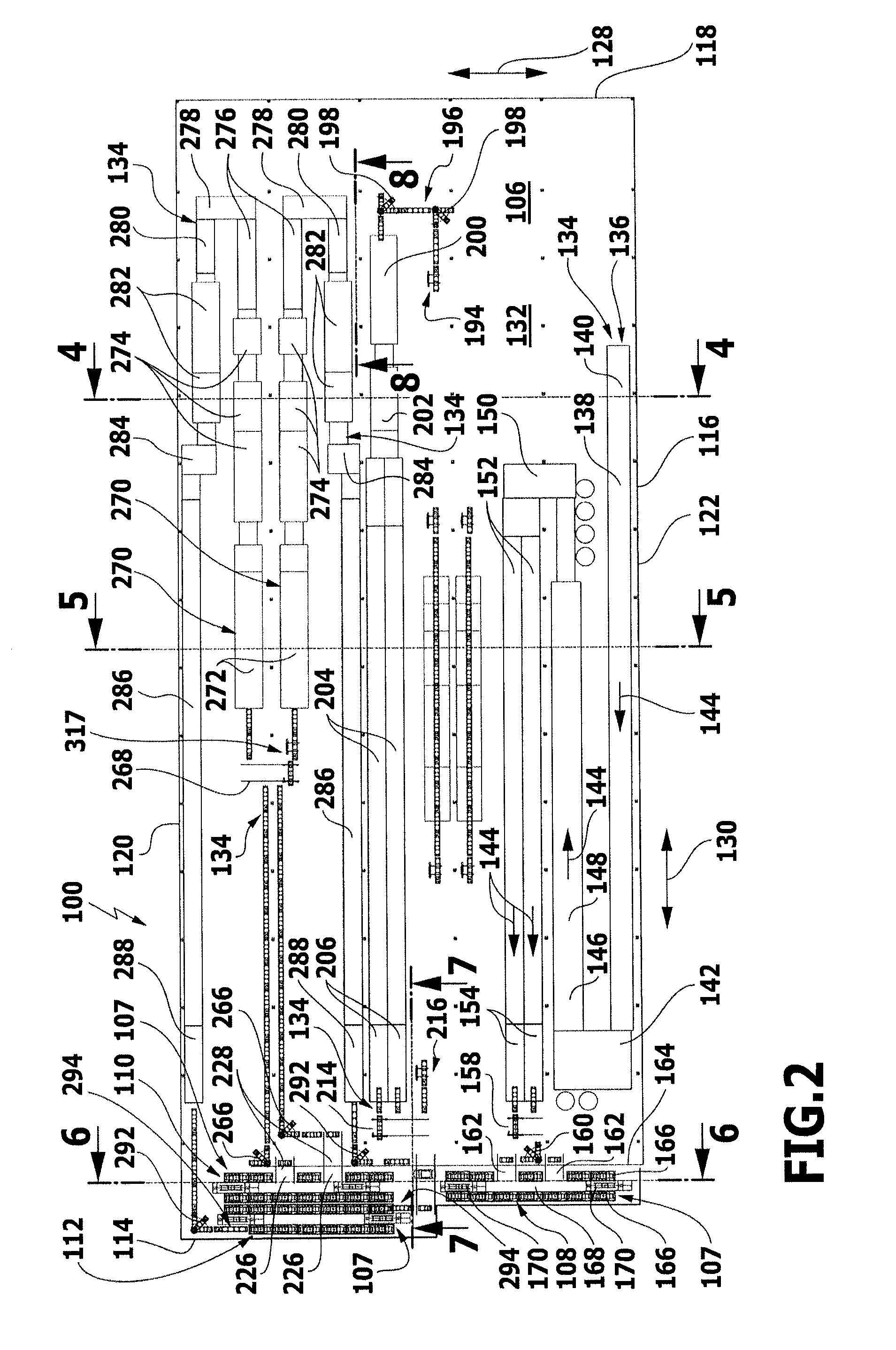

Paint shop for painting objects to be painted

ActiveUS20110162576A1Simple and clear structureFew installationSpray nozzlesPretreated surfacesPaint shopTransport engineering

To provide a paint shop for painting objects to be painted in the form of vehicle bodies and / or parts of vehicle bodies, there is proposed a paint shop for painting objects to be painted in the form of vehicle bodies and / or parts of vehicle bodies which comprises the following: a building shell, which encloses a building interior, in which are arranged at least one dip tank and at least one open treatment area, which is open in relation to the building interior; a first transport level, on which objects to be painted can be transported through at least one open treatment area; a second transport level, from which objects to be painted can be dipped into at least one dip tank; and at least one intermediate storage unit, wherein at least one object to be painted can be transported from one transport level of the paint shop into the intermediate storage unit and later can be transported out of the intermediate storage unit into another transport level of the paint shop.

Owner:DUERR SYST AG

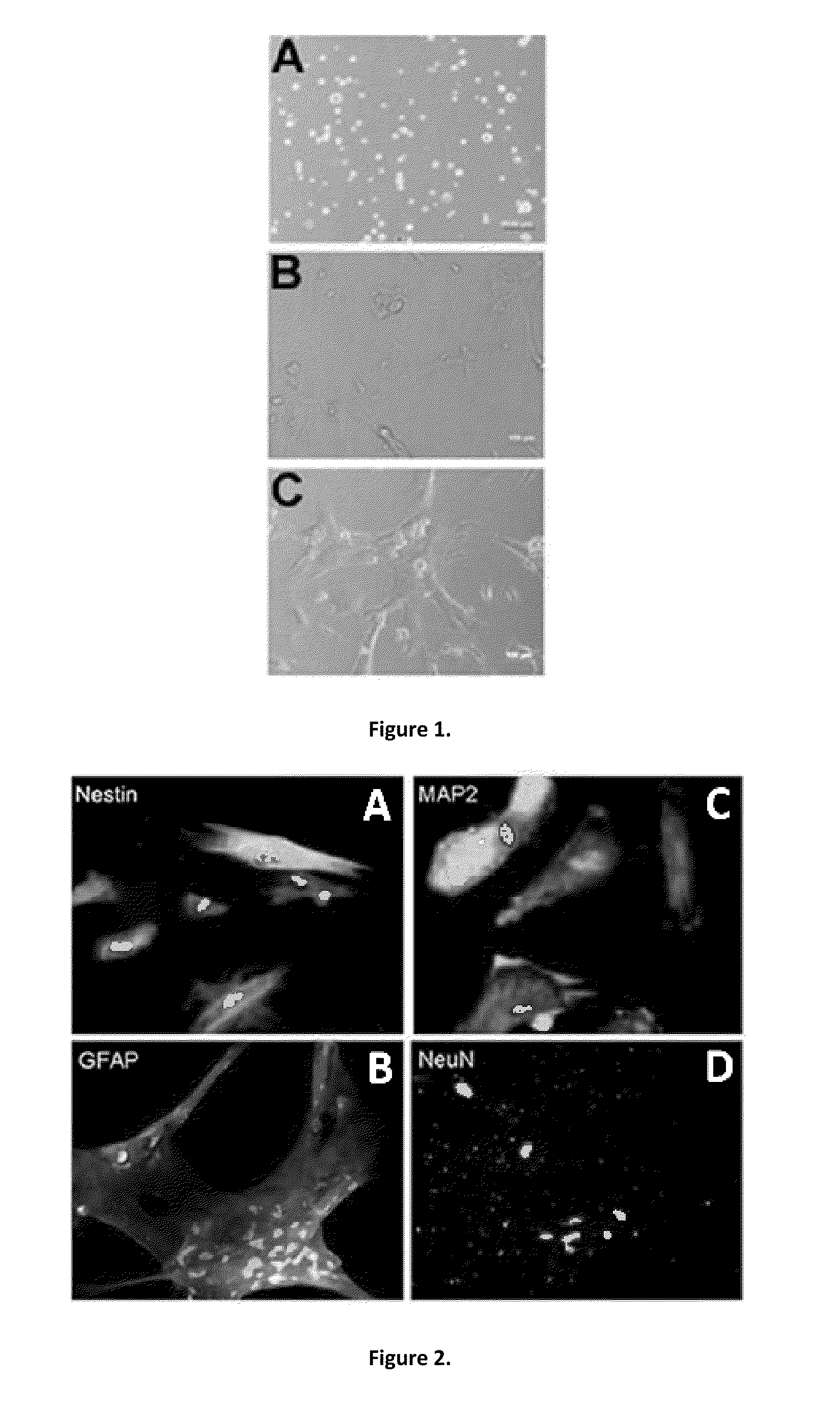

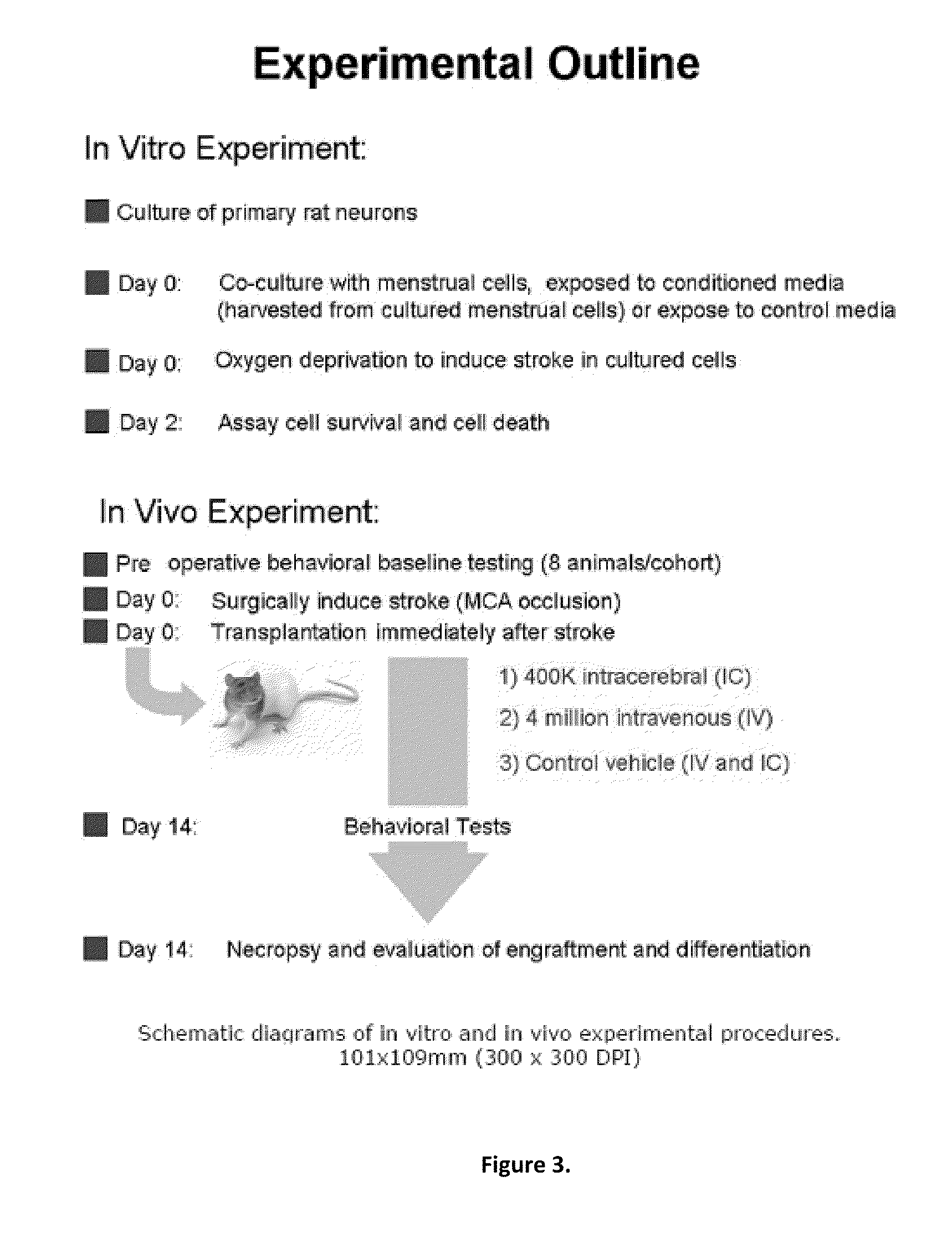

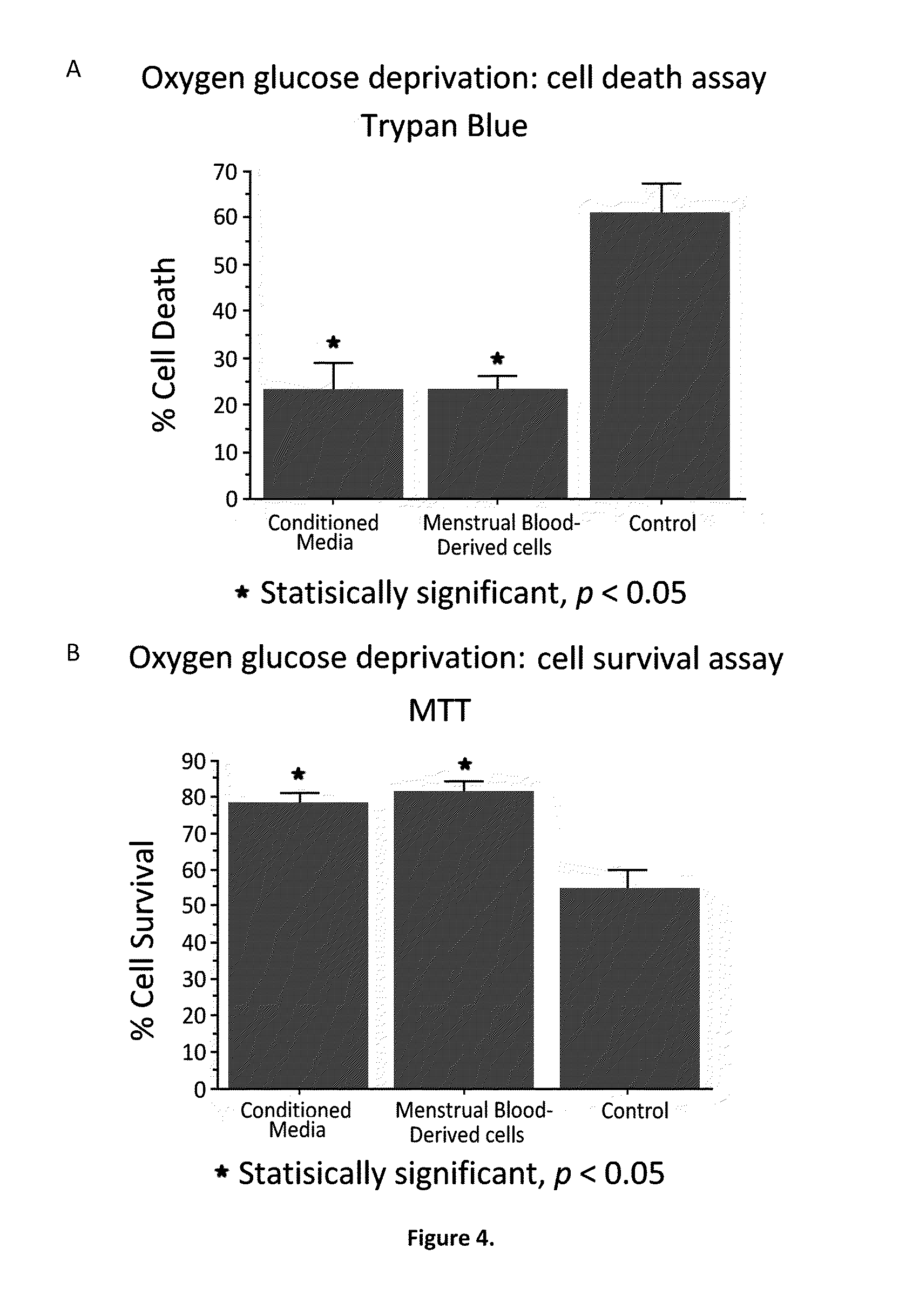

Methods of treating stroke using stem cell-like menstrual blood cells

InactiveUS20110268710A1Maintain potencyImprove proliferative abilityBiocideNervous disorderRisk strokeUmbilical cord

A cell type that is a complete match of the transplant recipient appears as an optimal scenario to open treatment options to a large patient population with minimal complications. The use of autologous bone marrow or umbilical cord blood has been proposed as a good source of stem cells for cell therapy. Menstrual blood is found to be another important source of stem cells. Assays of cultured menstrual blood reveal that they express embryonic like-stem cell phenotypic markers and neuronal phenotypic markers under appropriate conditioned media. Oxygen glucose deprivation stroke models show that OGD-exposed primary rat neurons, co-cultured with menstrual blood-derived stem cells or exposed to the media from cultured menstrual blood, exhibited significantly reduced cell death. Transplantation of menstrual blood-derived stem cells, either intracerebrally or intravenously, after experimentally induced ischemic stroke in adult rats also significantly reduced behavioral and histological impairments compared to vehicle-infused rats.

Owner:CRYO CELL INTERNATIONAL INC +3

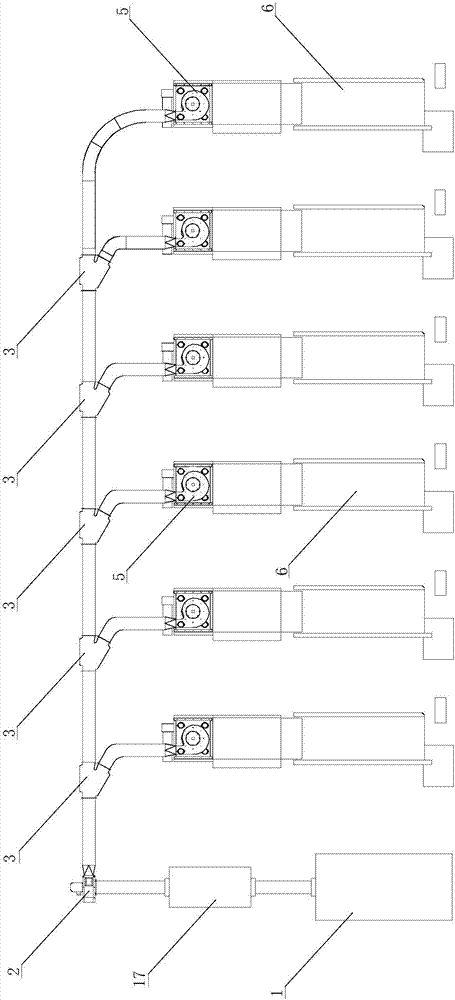

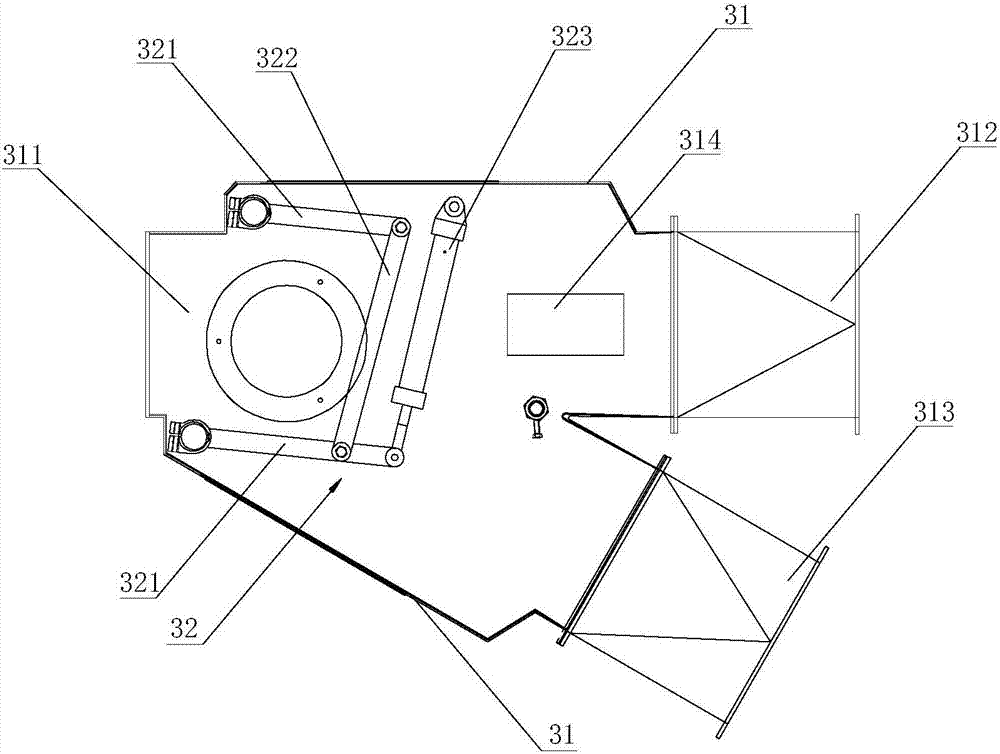

Wool spinning carding system capable of automatically controlling feeding

PendingCN107385574AImprove delivery efficiencyAvoid damageFibre cleaning/opening by toothed membersContinuous processingFiberEngineering

The invention discloses a wool spinning carding system capable of automatically controlling feeding. The system comprises a wool combining machine, a cotton feeding fan and a two-way cotton distributor set, and the wool combining machine is connected with the cotton feeding fan through a wool bin. The two-way cotton distributor set comprises a plurality of two-way cotton distributors, each two-way cotton distributor comprises a shell and a guide mechanism, each shell is provided with a feeding port and a discharging port, the side, located at the discharging port, of each shell is also provided with an distribution outlet, and each guide mechanism is arranged in the corresponding shell. All the two-way cotton distributor are sequentially connected end to end, and the feeding port of the first two-way cotton distributor is connected with the wind outlet end of the cotton feeding fan. The distribution outlet of each two-way cotton distributor is connected with an unpowered cotton condenser, and the discharging port of the last two-way cotton distributor is also connected with an unpowered cotton condenser. A carding unit is arranged below each unpowered cotton condenser. According to the wool spinning carding system capable of automatically controlling feeding, opening treatment is conducted in advance, the manual operation is reduced, the cost is saved, and the continuous production is achieved; by additionally arranging a wool pressing plate, the feeding efficiency and the capability of removing iron impurities are improved, and the damage to fibers is reduced.

Owner:青岛东佳纺机(集团)有限公司

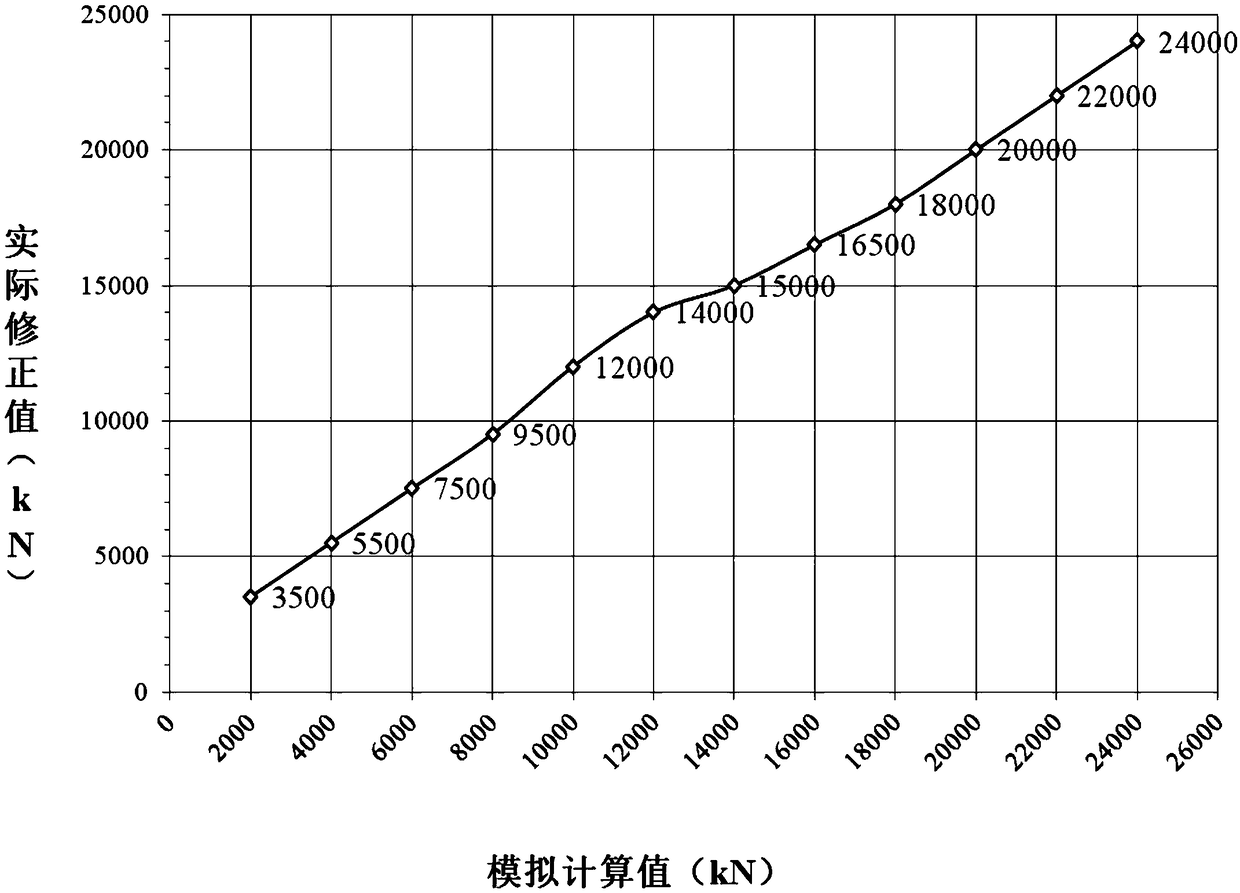

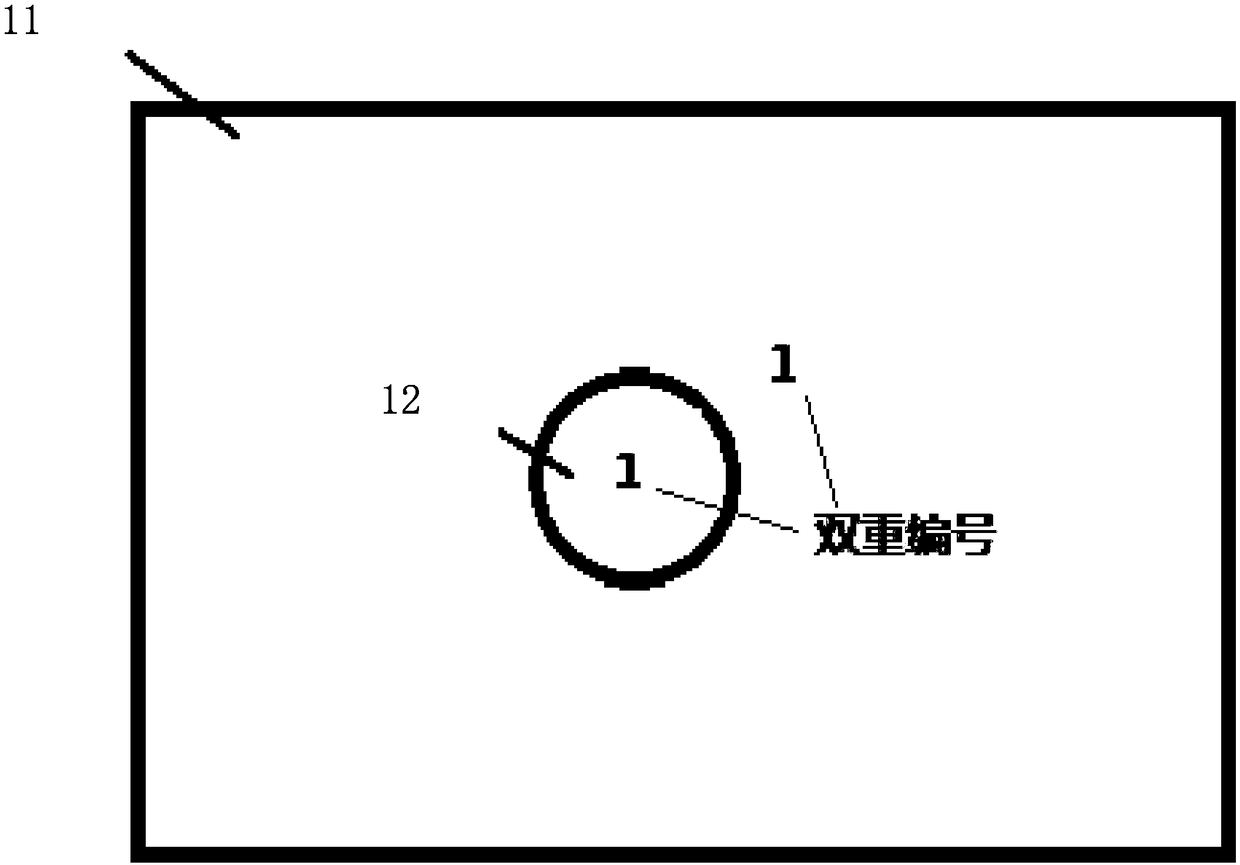

Measurement method of mould closing margin of stamping mould

ActiveCN109248939AImprove accuracyImprove reliabilityShaping toolsMetal working apparatusData treatmentMaterials science

The invention discloses a measurement method of a mould closing margin of a stamping mould. The method comprises the following steps that a mould blank holder state is checked and adjusted, a mould balance state is checked and adjusted, mould closing height is set, the to-be-measured mould is used for pressing a workpiece, opening treatment is conducted on the workpiece, all opened positions are subjected to double numbering, filler is prepared, the filler is prepared from industrial plasticine and soft steel wires, the workpiece is placed on the upper surface of a mould lower die, one group of filler is placed at each opened position, the soft metal wires, the industrial plasticine and the mould are stacked from top to bottom in sequence, the mould is closed, the filler is pressed, the thickness of an opened piece of the workpiece subjected to opening and the thickness of the soft metal wires subjected to pressing are measured, and for the opened positions, data processing is conducted on areas which need to be subjected to heavy coloring and light coloring separately, so that the mould closing margin of the stamping mould is obtained. Through the measurement method, the mould closing margin can be measured accurately and reliably.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Ultra-fine fibre adsorption face fabric and manufacturing method thereof

The invention relates to an adsorption material made of superfine fibers and widely used in the cleaning field and the manufacturing method thereof. The prior adsorption material has poor absorptivity and water absorbability and has snagging and aging problems. The invention provides a superfine fiber adsorption material and the manufacturing method thereof. The superficial loops of the inventive product are arranged in high and low rows alternately. The raw materials of high and low row loops are respectively superfine fiber / nylon composite yarn and elastic distorted polyester yarn, with a twist of 300-700. The manufacturing method comprises a twisting step in which the superfine fiber / nylon composite yarn and elastic distorted polyester yarn are twisted respectively in opposite directions; and a dyeing step which includes opening treatment and addition of hydrophilic softener. The inventive product has strong water absorbability and adsorptivity, is easy to clean after dirt cleaning, and has good anti-aging property.

Owner:HAINING LIDA WARP KNITTING CLOTH IND CO LTD

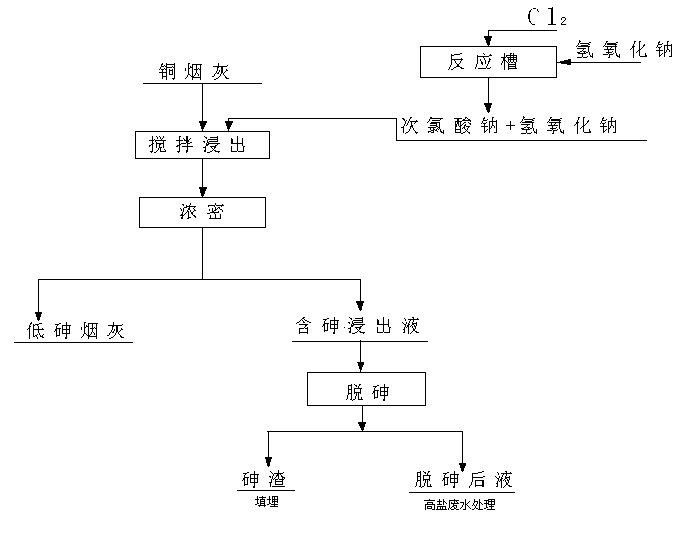

Wet-process open treatment method of arsenic in copper ashes

ActiveCN103233129AHigh recovery rateSolve the open circuit problemProcess efficiency improvementLiquid wasteImpurity

The invention discloses an open treatment method of arsenic in copper ashes and relates to a method for open pre-treatment of harmful arsenic impurities in intermediate material ashes in a copper smelting process. The wet-process open treatment method is characterized in that the treatment process comprises the following steps of: adding copper ashes to a solution containing sodium hypochlorite and sodium hydroxide; carrying out arsenic leaching reaction and filtering to obtain arsenic-removed slag and arsenic-removed solution; and recycling valuable metals including copper, lead, zinc and bismuth of the arsenic-removed slag. The wet-process open treatment method disclosed by the invention can be used for carrying out open treatment on the arsenic in the copper ashes before recycling the valuable metals, so that the subsequent recycling process of valuable metals is facilitated. Meanwhile, a utilization way for residual chlorine absorption liquid waste is found, so that the secondary pollution is avoided. Besides, the wet-process open treatment method for arsenic in the copper ashes is low in process cost and high in arsenic removal rate, and has great significance of improving environment protection, resource control and economical benefits.

Owner:JINCHUAN GROUP LIMITED

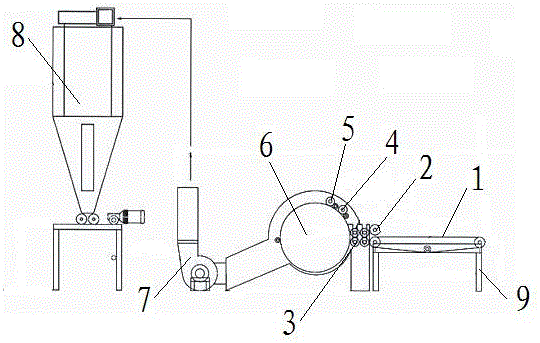

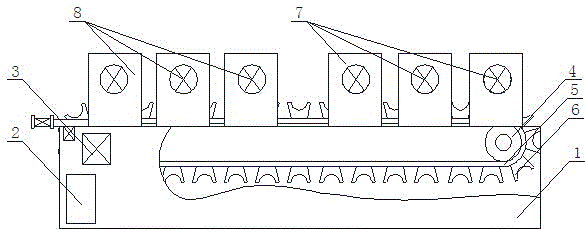

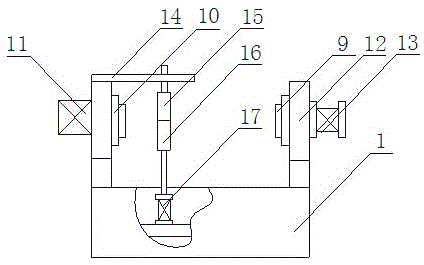

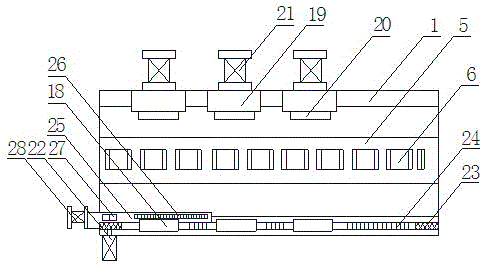

Non-woven fabric opener

InactiveCN105839233AQuick openingAvoid wastingTextile disintegration and recoveryFibre disintegrationEngineeringNonwoven fabric

The invention relates to the technical field of non-woven fabric, in particular to a non-woven fabric opening machine. The non-woven fabric opening machine is characterized in that a conveying device is arranged on a supporting frame; a press roll is arranged on one end of the conveying device; cotton feeding rollers are arranged at the left side of the press roll; a cylinder device is arranged at the rightleft side of all the cotton feeding rollers; the cylinder device is connected with a draught fan; the draught fan is communicated with a cotton coagulation box. When the non-woven fabric opening machine disclosed by the invention is in use, opening treatment on leftover materials of non-woven fabric can be rapidly completed, recyclinge treatment can be carried out, a waste of materials can be avoided, and the using demands are met.

Owner:JIANGSU EAST GENIAL SPUNLACE NON WOVEN CO LTD

Method for manufacturing cellucotton felt applied to automobile hubcap sound insulation cushion

The invention discloses a method for manufacturing cellucotton felt applied to an automobile hubcap sound insulation cushion. The method comprises the process steps that a, 45 percent to 55 percent of PET short fibers, 30 percent to 45 percent of two-component PET short fibers, 10 percent to 15 percent of PP short fibers, by weight ratio, are placed in a mixer to be stirred; b, an opener carries out opening treatment; c, a carding machine carries out fiber carding treatment; d, a lapping machine carries out lapping treatment; e, a needle machine carries out same-position opposite-puncturing processing. Through the design of the process steps, the cellucotton felt has high strength and the good sound absorption and insulation effect and flame retarding effect, and can be suitable for the automobile hubcap sound insulation cushion well.

Owner:GUANGZHOU SANTAI AUTOMOTIVE TRIM MATERIALS

Dry comfortable skin-friendly anti-side-leakage hygienic product surface layer

The invention discloses a dry comfortable skin-friendly anti-side-leakage hygienic product surface layer which is prepared by blending ES fiber and pure cotton fiber according to a certain ratio, andthe ES fiber and the pure cotton fiber are mixed, then are in turn subjected to highly-disorder mixing treatment, netting, hydroentangled reinforcement treatment, two times of soft drying treatment, and finally rolled into a finished product. The dry comfortable skin-friendly anti-side-leakage hygienic product adopts the ES fiber and the pure cotton fiber as raw materials, the ES fiber has high curling degree, a produced non-woven fabric has the advantages of fluffiness, softness, skin-friendliness and good elasticity, the advantages of fluffiness and good elasticity of the fiber ensure the softness, skin-friendliness and dryness of the dry comfortable skin-friendly anti-side-leakage hygienic product surface layer; the natural plant cotton fiber is safe and unstimulating to skin, the cotton fiber can absorb water quickly, prevent side leakage of urine and menses; by two times of opening treatment, the highly-disorder mixing treatment, the hydroentangled reinforcement treatment and thetwo times of soft drying treatment, the uniformity of the non-woven fabric is improved, and the softness and skin-friendliness of the non-woven fabric can be ensured.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

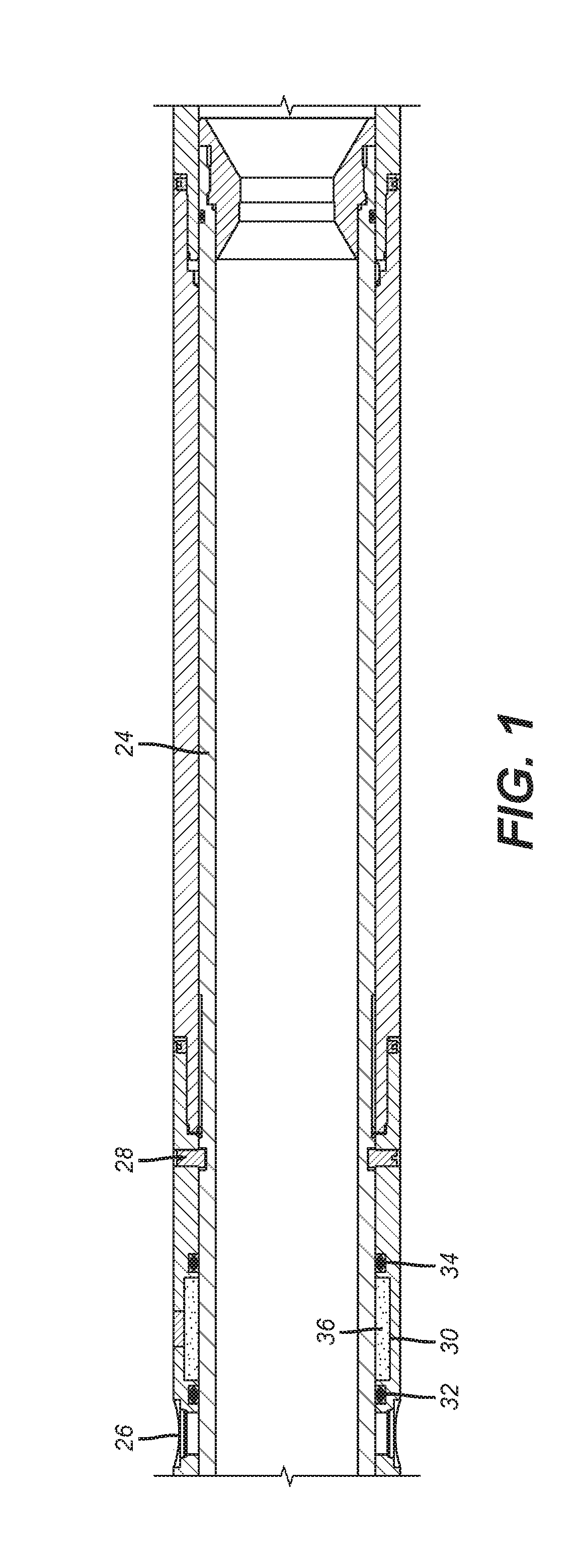

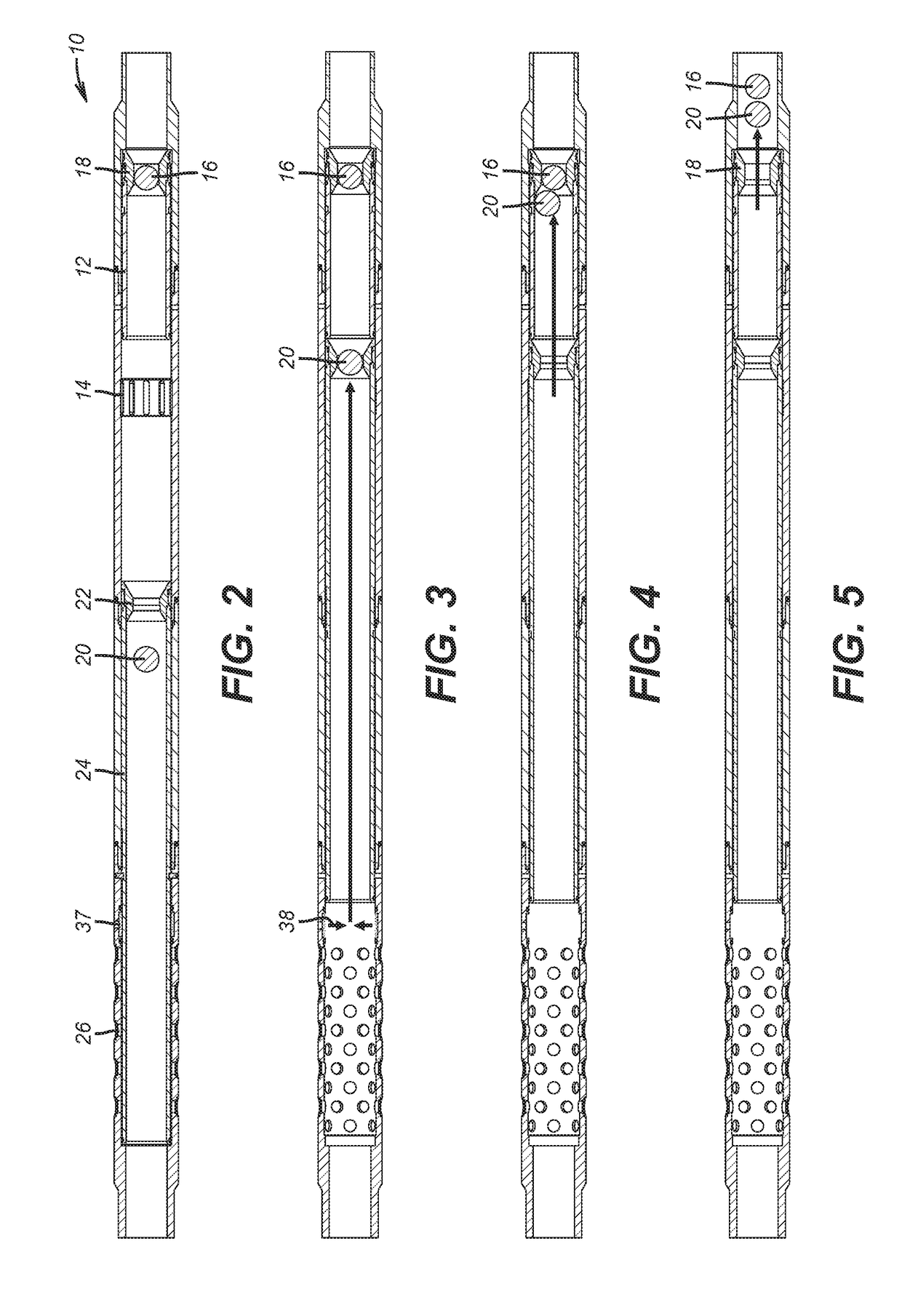

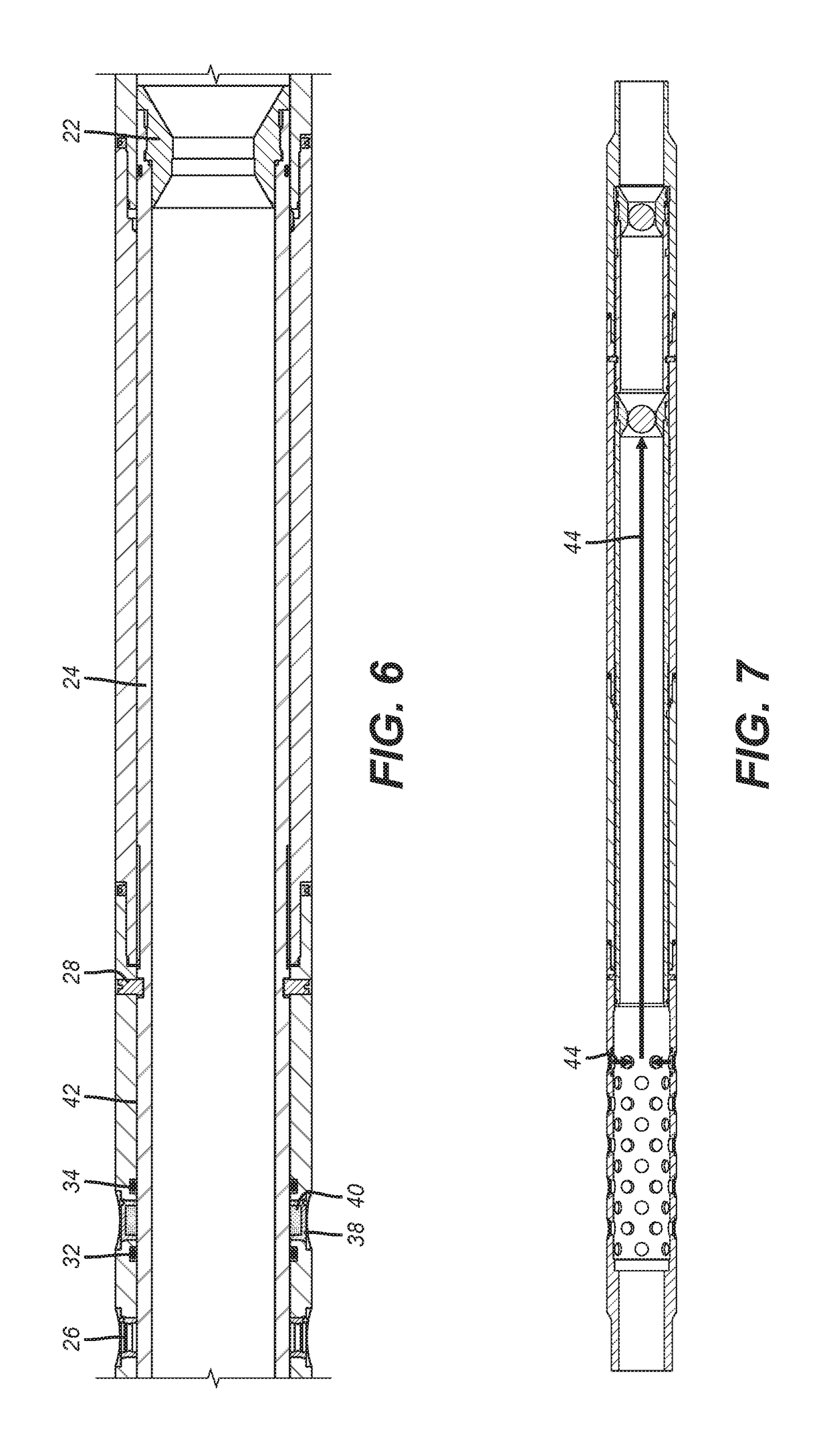

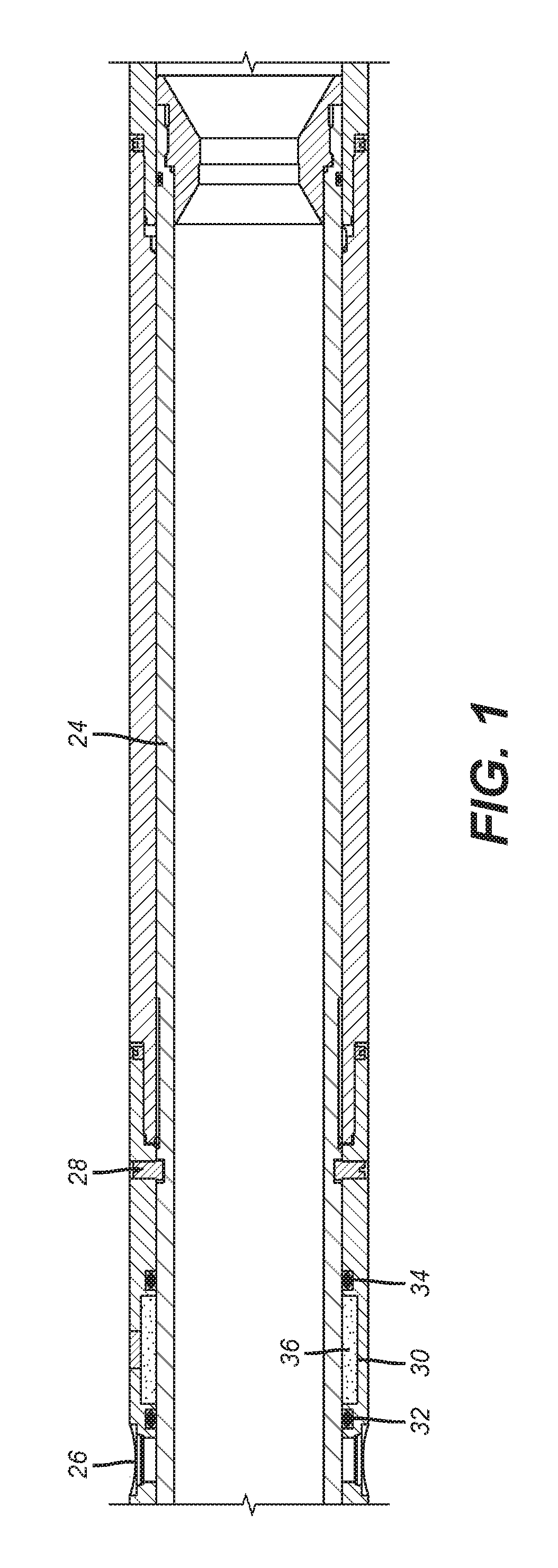

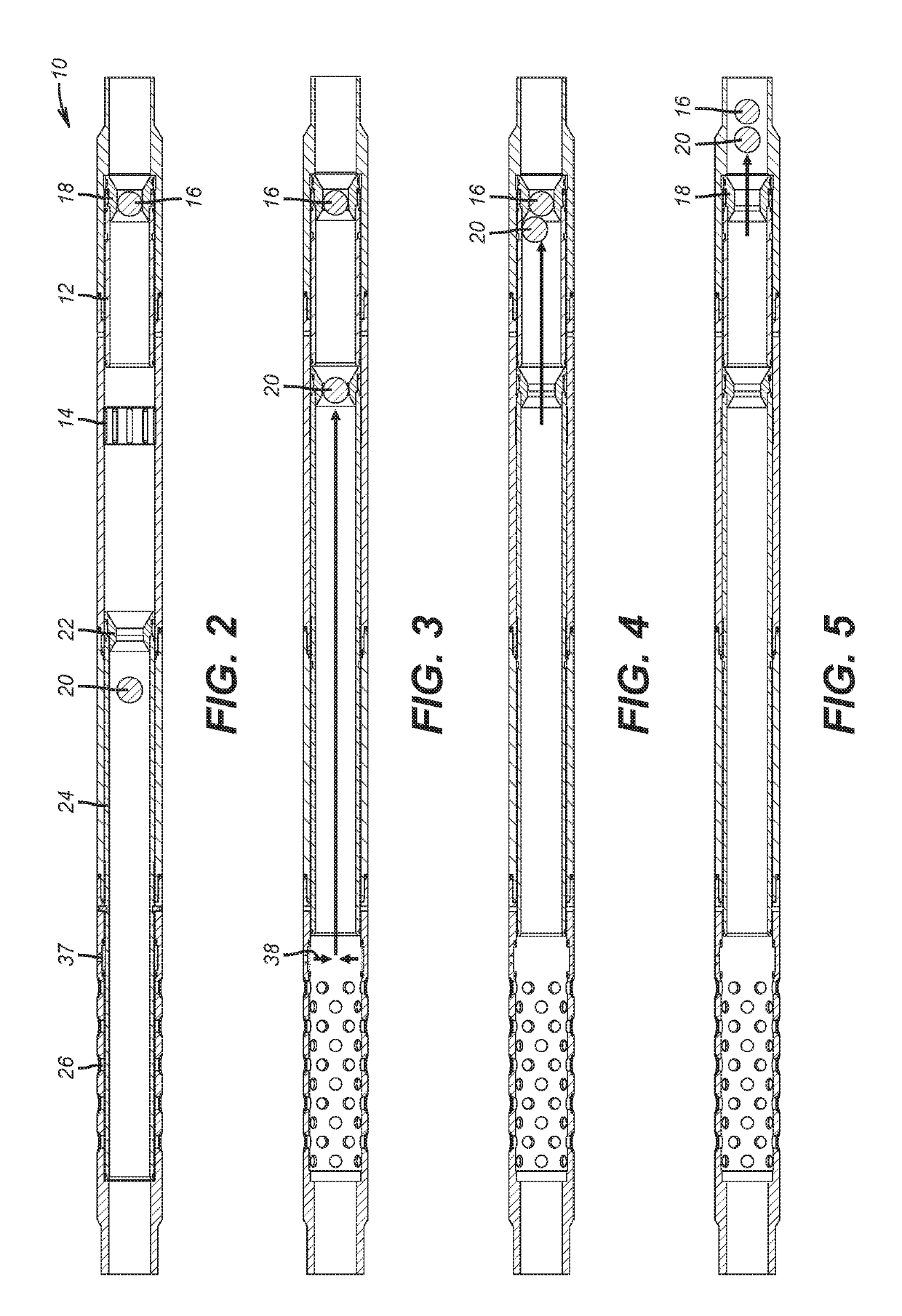

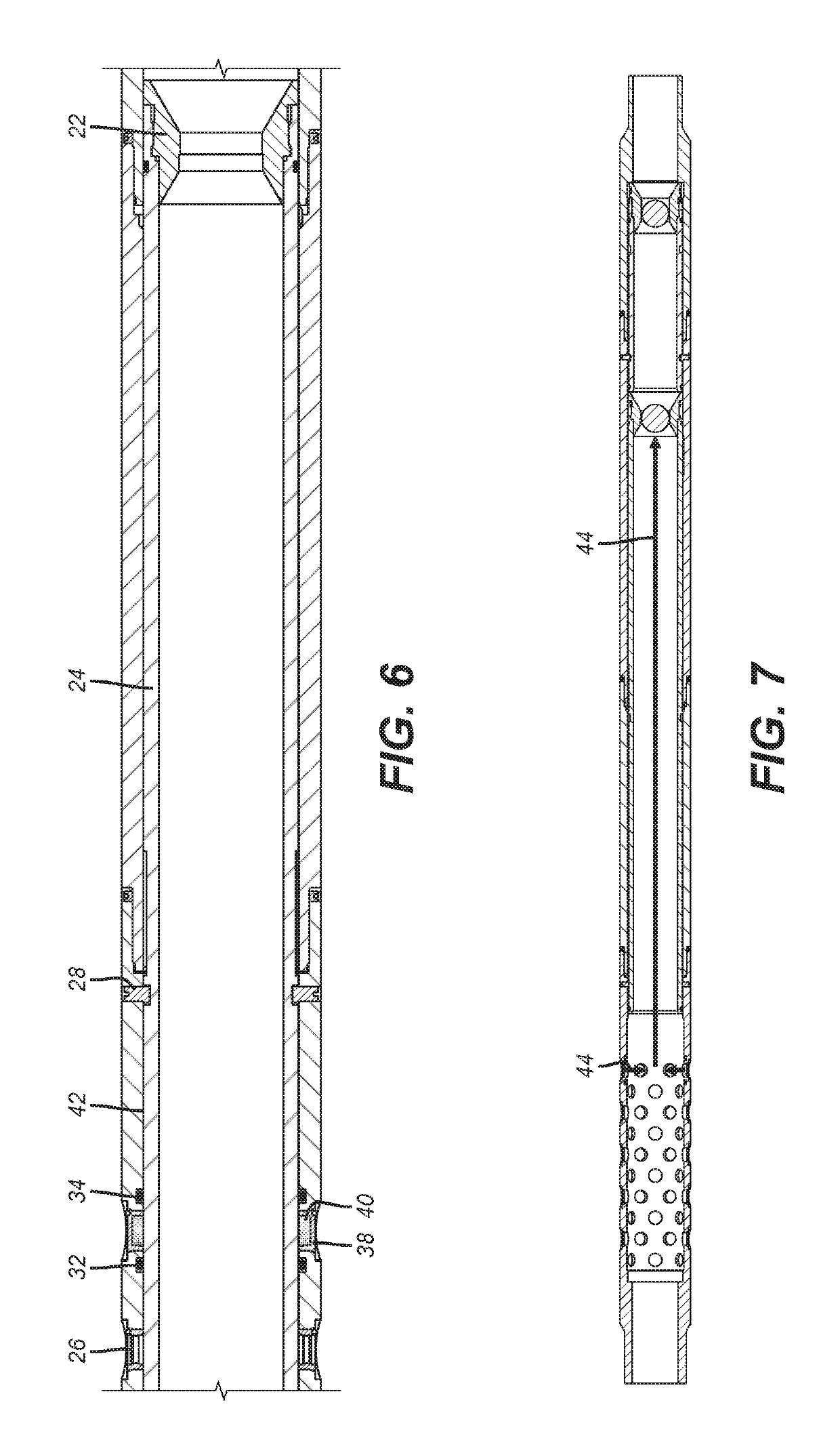

Sliding Sleeve Valve with Degradable Component Responsive to Material Released with Operation of the Sliding Sleeve

Salt or acid solution is stored inside a frac sleeve instead of being pumped from a surface location. A mechanically-actuated valve releases the stored salt or acid solution into the borehole to electrochemically degrade the frac ball and allow it to pass through the seat. The stored fluid can be immediately released upon mechanical actuation or released after a specified delay using an integrated timer. In multiple sleeve applications a first ball shifts a first sleeve to open treatment ports and a second ball shifts a second sleeve to close the treatment port and open screened production ports while releasing the stored material either between the seated objects or above one of the seated objects to initiate the disintegration that will allow objects on both seats to disintegrate and pass through.

Owner:BAKER HUGHES INC

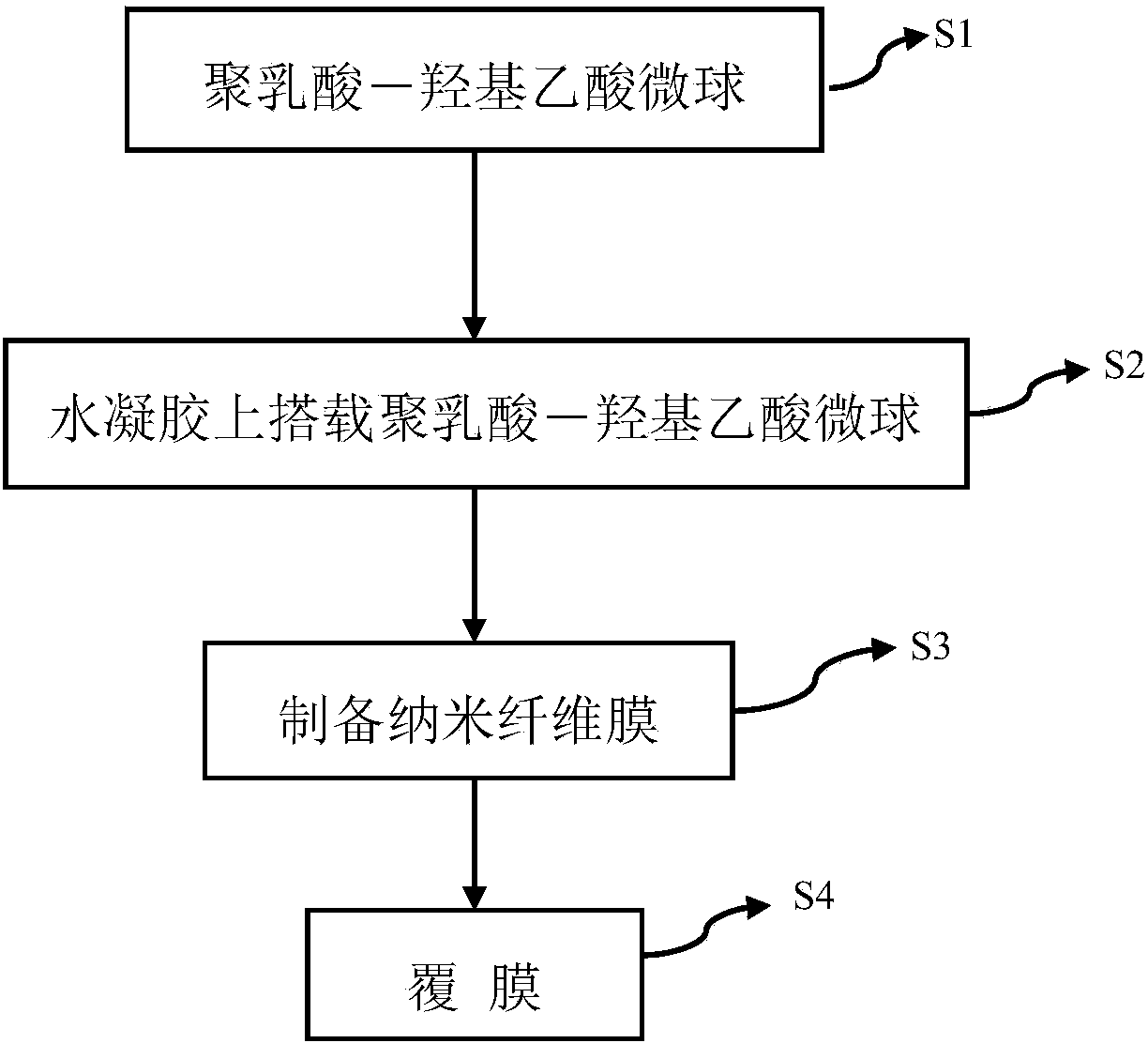

Biomimetic peritoneum for abdominal cavity open treatment and repairing, and preparation method thereof

The invention relates to a biomimetic peritoneum for abdominal cavity open treatment and repairing, and a preparation method thereof. The biomimetic peritoneum comprises hydrogel, polylactic acid-glycolic acid micro beads, which are carried on the hydrogel, and a nano fiber membrane that covers the hydrogel and the polylactic acid-glycolic acid micro beads. The polylactic acid-glycolic acid micro beads carried by the hydrogel are the origin of growth factors required by the wound healing. A layer of nano fiber membrane is covered on the micro beads to form a two-layer membrane so as to construct an artificial biomimetic peritoneum, which can be applied to abdominal cavity open wound repairing. The biomimetic peritoneum can protect the intestinal canals, can also be used a carrier for releasing micro beads, organically integrates the functions of wound protection and drug release, and promotes the wound healing. The mimetic peritoneum probably promotes the healing process by participating in the formation of newborn tissues through differentiation or secreting cell factors to promote the formation of newborn tissues through paracrine. The artificial peritoneum and the micro beads generate a synergetic effect, can directly participate in the regeneration of damage tissue, moreover, can trigger the self regeneration and repairing mechanism of athletes, and finally achieve the rapid repairing of abdominal cavity open wound.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

Sliding sleeve valve with degradable component responsive to material released with operation of the sliding sleeve

Owner:BAKER HUGHES INC

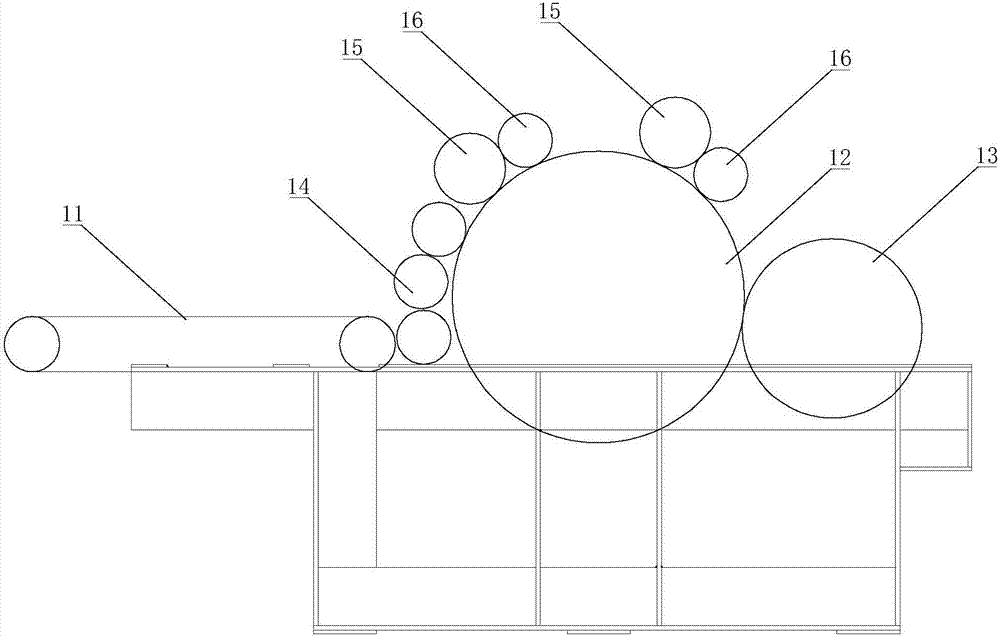

Full-automatic paper tube grinding and grooving device

ActiveCN105598754AImprove work efficiencySimple structureRevolution surface grinding machinesMetal working apparatusElectric machineryPulp and paper industry

The invention relates to a device for grinding and grooving treatment of paper tubes, in particular to a full-automatic paper tube grinding and grooving device and aims at providing a full-automatic paper tube grinding and grooving device which improves the working efficiency, reduces the labor intensity and can conduct grinding, grooving and opening treatment on three paper tubes at a time. The full-automatic paper tube grinding and grooving device comprises a machine frame, a control box, a motor I, two gears I, a chain I, arrangement blocks, grinding mechanisms and grooving mechanisms. The gears I are arranged at two ends of the machine frame respectively, the two gears I are connected to form a whole through the chain I, one gear I is connected with the motor I, multiple arrangement blocks are arranged on the chain I at intervals, an arrangement opening is formed in each arrangement block, the arrangement openings formed in the arrangement blocks face the outside, and accordingly the paper tubes can be arranged on the arrangement openings formed in the arrangement blocks and the like. The full-automatic paper tube grinding and grooving device has the advantages of being simple in structure, reasonable in design, convenient to use and the like.

Owner:浙江新凤鸣化纤有限公司

Method for preparing composite water-absorbing antibacterial material

ActiveCN107988702AGood broad-spectrum antibacterial propertiesStrong water absorptionNon-woven fabricsAlcoholNetwork structure

The invention provides a method for preparing a composite water-absorbing antibacterial material. The method comprises the following steps: step 1, using an antibacterial Chinese medicinal material asa natural fiber material, smashing and sieving, removing impurities from fibers and drying as standby application; step 2, mixing thermoplastic composite fibers with the natural fiber material driedin step 1, and performing opening treatment to form a fluffy network structure; step 3, preparing silver nitrate and sodium chloride reaction solution; step 4, centrifuging the reaction solution, washing with alcohol and drying to obtain nanocomposite antibacterial particles; step 5, adding polymer water-absorbent resin particles, the nanocomposite antibacterial particles and Foshi powder into meshes of mesh structures of mixed fibers, blowing hot air to the mesh structures and cooling to obtain the composite water-absorbing antibacterial material. According to the composite water-absorbing antibacterial material, the polymer water-absorbent resin particles, the antibacterial particles and the like are fixed in the meshes formed by means of intertwining the mixed fibers, so that the composite water-absorbing antibacterial material has excellent water absorption, and antibacterial and bactericidal properties.

Owner:北京安信乐布医疗用品有限公司

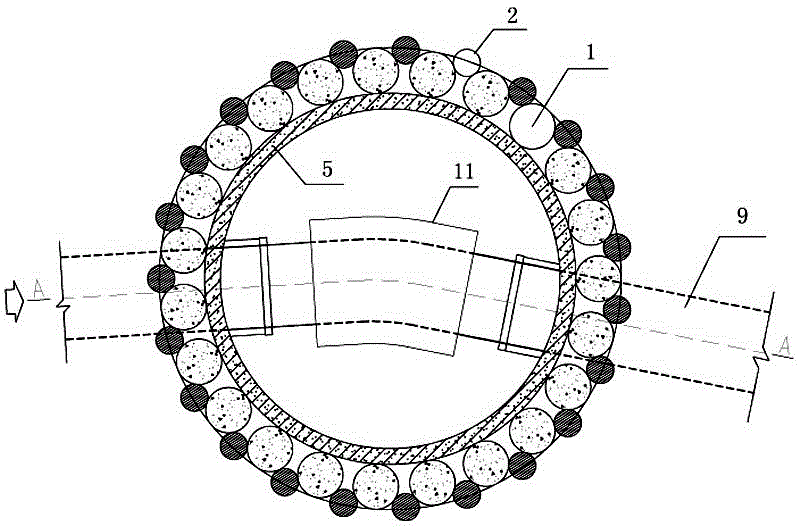

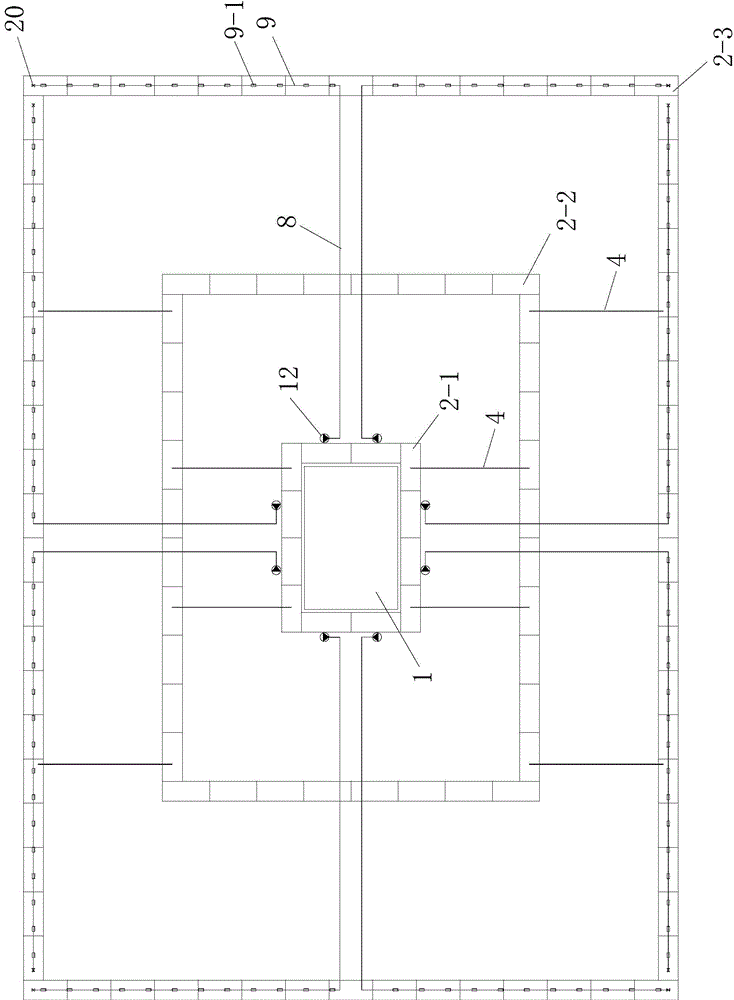

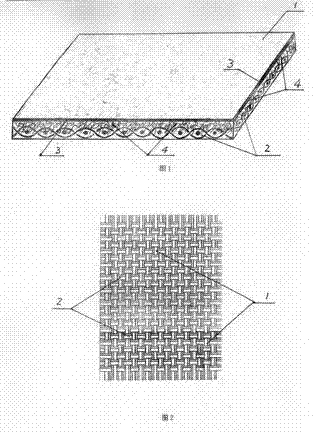

Open treatment system for air wash water type three-dimensional biologic chain membrane body for governing polluted water and building method of open treatment system

ActiveCN104478083AEfficient deliveryEffective proliferationBiological treatment apparatusTreatment with aerobic and anaerobic processesDry seasonWash water

The invention relates to an open treatment system for an air wash water type three-dimensional biologic chain membrane body for governing polluted water and a building method of the open treatment system. The system comprises a main carrier, a first circle of HY microbial membrane body region, a second circle of air wash water region, a third circle of HY microbial membrane body region, a fourth circle of aquatic swimming animal region, a fifth circle of HQY2 microbial membrane body region, a biological bacterium mixture sprinkling water repair region, a benthic shellfish region and an aquatic plant ecological purification region. The method comprises specific steps of respectively building the units. The open treatment system is energy-saving and environment-friendly, and does not occupy soil resources; a lot of building materials and energy consumption required for building sewage treatment plants can be saved; the open treatment system is capable of adjusting measures to local conditions, and governing polluted water on the spot, is free of limitation of the factors such as variation in water level in rainy seasons and dry seasons, and is maneuverable, flexible, fast, high in practicability, low in investment, fast in acting, low in operation management cost and the like; and both symptoms and root causes are treated.

Owner:郝新浦

High-temperature resistant no-woven filter cloth with monofilament-woven net as base cloth and manufacturing method thereof

InactiveCN103007629AHigh mechanical strengthHigh breaking strengthLamination ancillary operationsLaminationNylon 6Pulp and paper industry

The invention discloses a high-temperature resistant no-woven filter cloth with a monofilament-woven net as a base cloth and a manufacturing method thereof. The filter cloth is composed of a base cloth layer and a filter layer. A specific process route comprises the following steps of: selecting 100% of basalt short fibers for later use; selecting a woven net by taking nylon 6 filament fibers as warps and wefts for later use; placing the basalt short fibers into a cotton blender machine to be subjected to cotton blending, then carrying out opening treatment in an opening machine; then feeding raw material after opening into the cotton blender machine to be subjected to fine cotton blending; then feeding a carding machine to be carded into a net shape; then placing the carded net-like fibers into a lapping machine, and lapping to obtain a fibrous layer; combining the fibrous layer after lapping with woven net fabric into a whole by utilizing a needling machine; and then calendaring on the surface of a basalt short fibrous layer. The high-temperature resistant no-woven filter cloth with the monofilament-woven net as the base cloth disclosed by the invention has excellent high-temperature resistant property, and the contradictions and problems that the traditional single woven filter cloth is low in efficiency and easy to deform and a single non-woven filter cloth is insufficient in strength and easy to be broken are solved.

Owner:辽宁天泽产业集团纺织有限公司

Household article made from filler or batt containing down and production process of household article

InactiveCN102940319AFluffy and warmLightweight and environmentally friendlyNon-woven fabricsBed-coversFiberPolyester

The invention discloses a household article made from filler or batt containing down and a production process of the household article. The filler or the batt comprises the down, down silk, down velvet and fiber. The production process comprises the steps of washing and drying the down, the down silk and the down velvet, conducting mixing and opening treatment on the raw materials and the fiber, filling the opened mixture or manufacturing the opened mixture into batt rolling cotton through a machine, and finally obtaining the finished household article. The household article has the advantages that the household article is fluffy, light in weight, environment-friendly and keeps warm. The household article is simple in production process; the production cost of an enterprise is saved; the household article with antibacterial, mite removal and other functions can be manufactured by combining a polyester wadding treatment process; and the market competitiveness of the enterprise is improved.

Owner:VIOLET HOME TEXTILE TECH

Complete peeling and separation device with opening function for lotus seeds

The invention provides a complete peeling and separation device with an opening function for lotus seeds. The device includes a shell; a large-particle opening device is fixedly connected to the middle of the top of the shell; a screen is fixedly connected to the lower side of the large-particle opening device inside the shell; the screen is obliquely arranged towards the lower right, and the right part of the screen is provided with a falling through hole; the left side of the falling through hole on the screen is fixedly connected to a first flow guide plate; the first flow guide plate is obliquely arranged towards the lower left, and the left end of the first flow guide plate is connected to a small-particle opening device; the inner side wall of the shell is fixedly connected to a second flow guide plate below the small-particle opening device; the second flow guide plate is funnel-shaped; and a peeling device is fixedly connected to the middle part of the lower side of the secondflow guide plate. The device has the following beneficial effects: firstly: a first rotating shaft drives a first rotating cylinder to rotate, and the first rotating cylinder drives first opening teeth to rotate, and the first opening teeth are exposed from a through groove so as to carry out opening treatment on superficial shells of the lotus seeds.

Owner:何小平

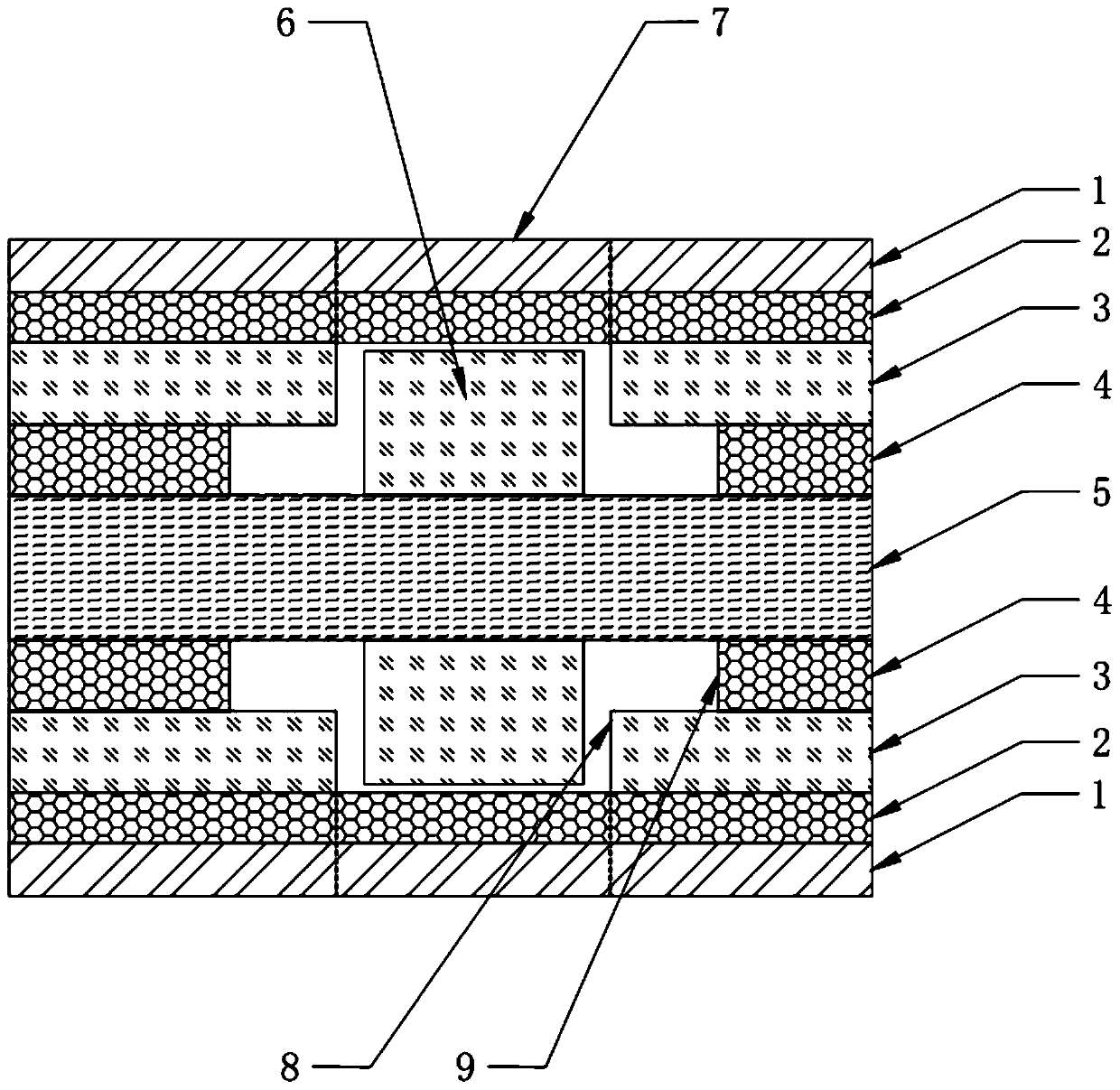

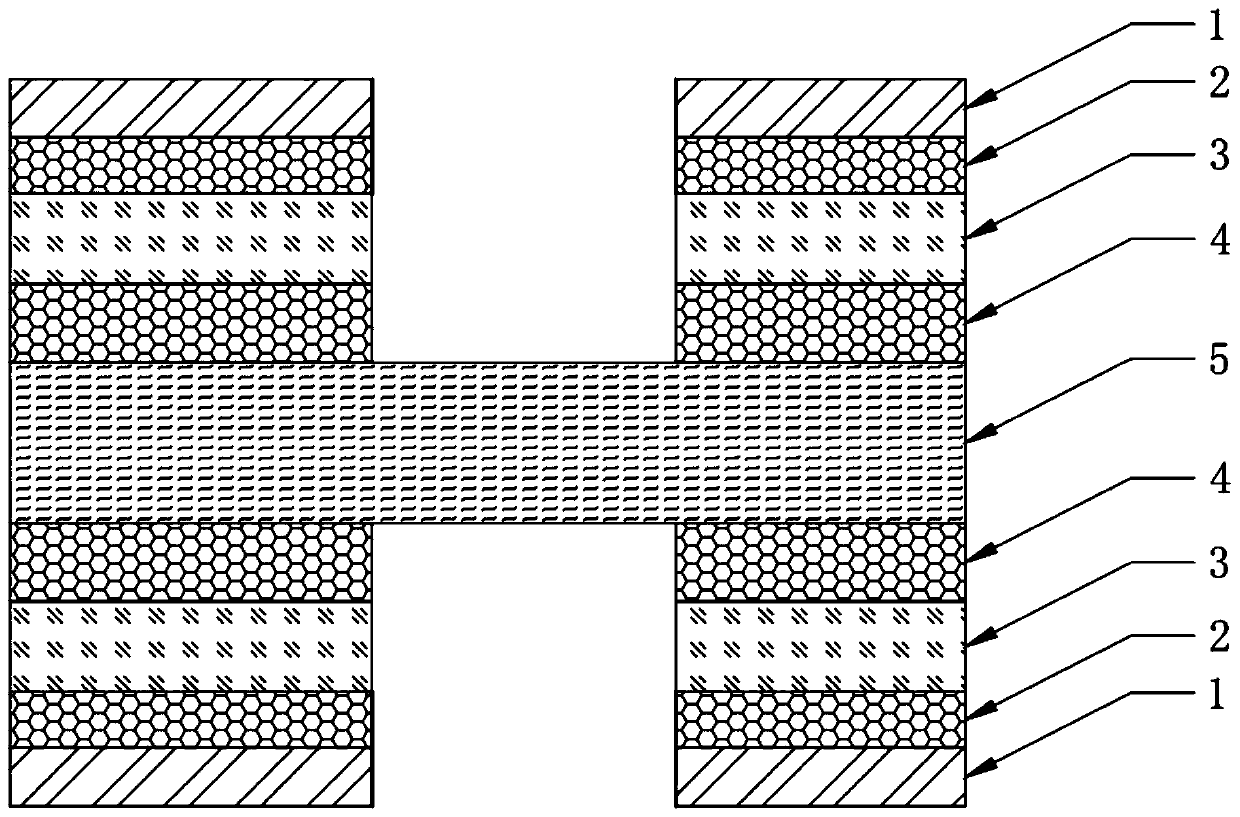

Rigid-flex circuit board opening method

InactiveCN110430673AReduce pollutionReduce consumptionMultilayer circuit manufactureNumerical controlWork in process

The invention discloses a rigid-flex circuit board opening method, which comprises the following steps: S1, a flexible board, a second-layer no-glue flow PP sheet, an FR4 light board, a first-layer no-glue flow PP sheet and a circuit layer which are arranged from inside to outside are prepared in advance; S2, the circuit layer, the first-layer no-glue flow PP sheet, the FR4 light board, the second-layer no-glue flow PP sheet, the flexible board, the second-layer no-glue flow PP sheet, the FR4 light board, the first-layer no-glue flow PP sheet and the circuit layer prepared in the step S1 are stacked in sequence and are laminated; S3, the laminated board prepared in the step S2 is subjected to drilling, electroplating, outer layer line and anti-welding process treatment; S4, a numerical control milling machine is used to perform opening treatment on an opening area of the laminated board prepared in the step S3, a pad is taken out, and a semi-finished product of a rigid-flex circuit board is obtained; and S5, the semi-finished product of the rigid-flex circuit board prepared in the step S4 is subjected to surface treatment, flexible board reinforcement and flying probe processes, and a rigid-flex circuit board is obtained. The opening processing depth precision requirements can be reduced, the production efficiency is improved, and the production cost is reduced.

Owner:AOSHIKANG TECH CO LTD

High-temperature resistant fibre non-woven filter cloth and manufacturing method thereof

InactiveCN103007630AHigh mechanical strengthHigh breaking strengthLamination ancillary operationsLaminationNylon 6Pulp and paper industry

The invention discloses a high-temperature resistant no-woven filter cloth and a manufacturing method thereof. The filter cloth is composed of a base cloth layer and a filter layer. A specific process route comprises the following steps of: selecting 100% of basalt short fibers for later use; selecting a woven net by taking nylon 6 filament fibers as warps and wefts for later use; placing the basalt short fibers into a cotton blender machine to be subjected to cotton blending, then carrying out opening treatment in an opening machine; then feeding raw material after opening into the cotton blender machine to be subjected to fine cotton blending; then feeding a carding machine to be carded into a net shape; then placing the carded net-like fibers into a lapping machine, and lapping to obtain a fibrous layer; combining the fibrous layer after lapping with woven net fabric into a whole by utilizing a needling machine; and then calendaring on the surface of a basalt short fibrous layer. The high-temperature resistant no-woven filter cloth disclosed by the invention has excellent high-temperature resistant property, and the contradictions and problems that the traditional single woven filter cloth is low in efficiency and easy to deform and a single non-woven filter cloth is insufficient in strength and easy to be broken are solved.

Owner:辽宁天泽产业集团纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com