High-temperature resistant fibre non-woven filter cloth and manufacturing method thereof

A technology of high temperature resistant fiber and manufacturing method, applied in the field of filter cloth, can solve the problems of inability to withstand high temperature environment, short service life of filter cloth, rising production cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

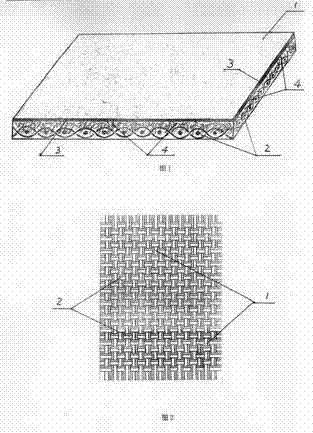

[0026] Embodiments of the invention are described in detail below, examples of which are shown in FIGS. 1 and 2 . The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0027] In the present invention, a kind of high temperature resistant fiber non-woven filter cloth and its manufacturing method are provided with monofilament woven net as base cloth, described filter cloth is made up of two-layer structure, namely: base cloth layer (accompanying drawing 2 in 1) and filter layer (4 in attached drawing 1). The base fabric layer is a woven net structure in which the warp and weft yarns of chemical fiber monofilament raw materials are interwoven (see attached figure 2 shown, with figure 2 1 in is the meridian direction, attached figure 2 2 in the latitudinal direction). The warp and weft interlaced woven net base cloth layer only plays the role of suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com