Small-size deep foundation pit supporting structure for pipe jacking construction

A deep foundation pit support, small size technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

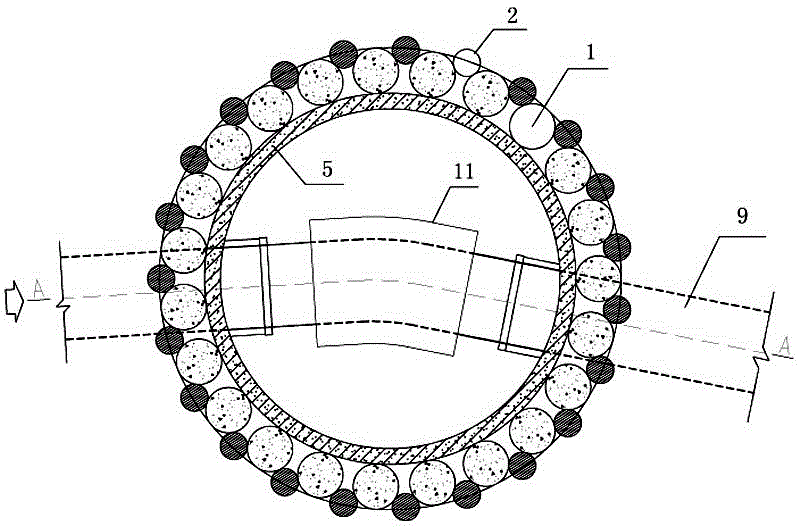

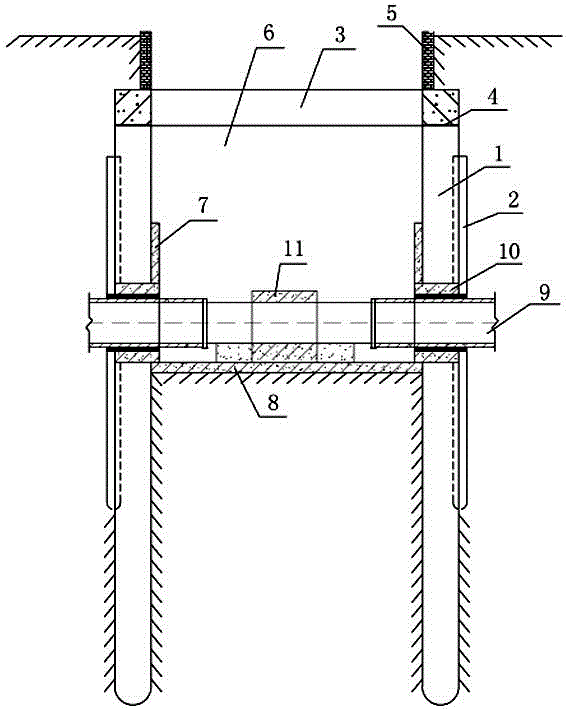

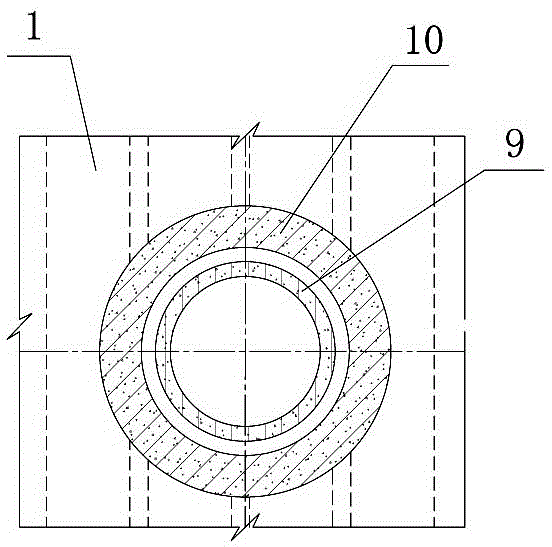

[0017] The small-sized deep foundation pit support structure used for pipe jacking construction according to the present invention is as follows: Figure 1-2 As shown, follow the specific steps below for construction:

[0018] The first step is to construct a plurality of bored piles 1 at intervals around the foundation pit determined on the ground to form a ring-shaped row of bored piles; during specific construction, the diameter and interval of the bored piles and the degree of support The depth is calculated and determined comprehensively based on the depth of the foundation pit, current geological conditions, surrounding loads, and groundwater characteristics. Under normal circumstances, the diameter of bored piles is generally initially planned to be 0.80m to 2m;

[0019] In the second step, according to the actually measured groundwater elevation, a high-pressure jet grouting pile 2 is constructed in the gap between two adjacent bored piles 1, wherein the pile body dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com