Rigid-flex circuit board opening method

A combination of soft and hard, circuit board technology, applied in the direction of printed circuit, multi-layer circuit manufacturing, printed circuit manufacturing, etc., can solve the problems of large cost burden of circuit board manufacturers, high processing precision requirements, high skill requirements of employees, etc., to reduce pollution and energy consumption, reduce precision requirements, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

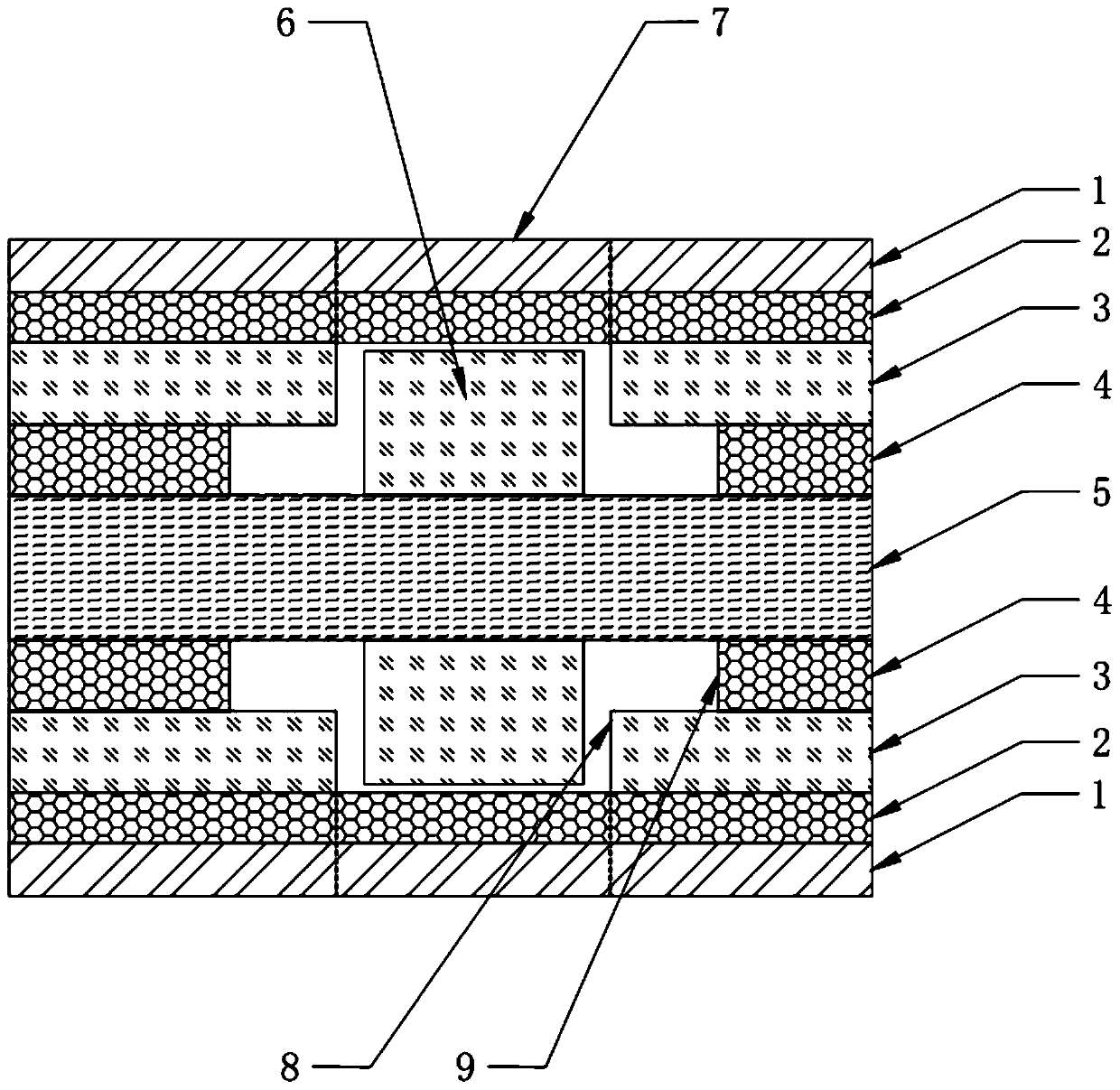

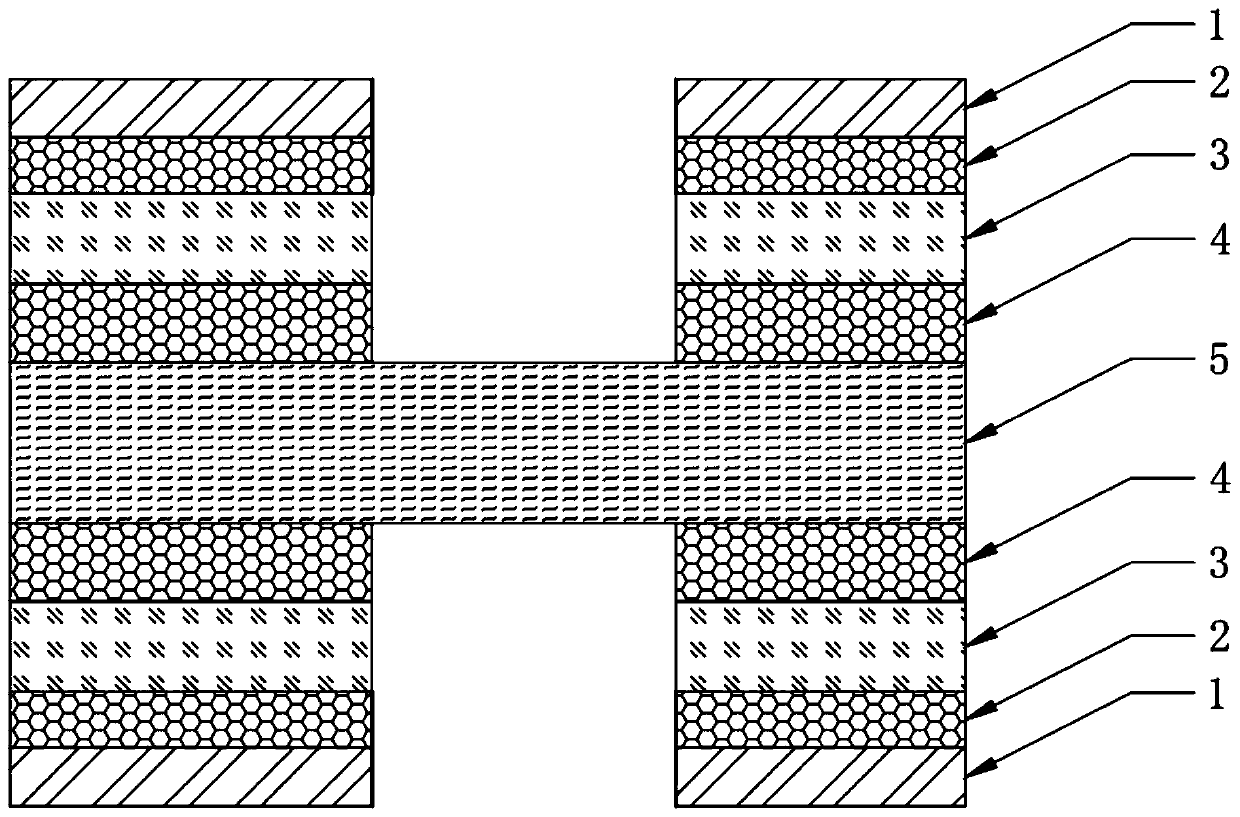

[0027] see figure 1 , this embodiment includes the following steps:

[0028] S1, prepare in advance the flexible board 5 laminated from the inside out, the second layer of non-flowing PP sheet 4, the FR4 light board 3, the first layer of non-flowing PP sheet 2 and the circuit layer 1, and the circuit layer 1 is provided with The opening area 7, the opening area 7 corresponds to the exposed flexible board area on the soft-rigid circuit board, and the position corresponding to the opening area 7 on the FR4 light board 3 is provided with a first window 8, the first window A spacer 6 is placed inside 8, and a second window 9 is opened on the position corresponding to the opening area 7 on the second layer of non-flowing glue PP sheet 4;

[0029] S2, the circuit layer 1 prepared in step S1, the first layer of non-flowing PP sheet 2, FR4 light board 3, the second layer of non-flowing PP sheet 4, the soft board 5, the second layer of non-flowing PP sheet 4, FR4 The light board 3, t...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] S1, prepare in advance the flexible board 5 laminated from the inside out, the second layer of non-flowing PP sheet 4, the FR4 light board 3, the first layer of non-flowing PP sheet 2 and the circuit layer 1, and the circuit layer 1 is provided with The opening area 7, the opening area 7 corresponds to the exposed flexible board area on the soft-rigid circuit board, and the position corresponding to the opening area 7 on the FR4 light board 3 is provided with a first window 8, the first window A spacer 6 is placed inside 8, and a second window 9 is opened on the position corresponding to the opening area 7 on the second layer of non-flowing glue PP sheet 4;

[0043] S2, the circuit layer 1 prepared in step S1, the first layer of non-flowing PP sheet 2, FR4 light board 3, the second layer of non-flowing PP sheet 4, the soft board 5, the second layer of non-flowing PP sheet 4, FR4 The light board 3, the first layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com