Cleaning wiping cloth with geometrical shape stability and manufacturing method and application thereof

A technology of geometric shape and wiping cloth, applied in the field of textiles, can solve the problems of affecting the wiping effect of mechanical parts, large lateral shrinkage of the wiping belt, poor geometric shape stability of the wiping cloth, etc., and achieve the effect of excellent geometric shape stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 84T-144-DTY fine denier polyester filament is used for the warp yarn, 84T-24-FDY polyester filament is used for the weft yarn, the cleaning surface is designed as a dobby weave with concave-convex effect, and the supporting surface is designed as a high-density plain weave For the structure, please refer to Appendix 1 for the specific organizational chart. The fabric is woven by an air-jet loom. After the above-mentioned gray cloth is subjected to hot water treatment at 60-120°C for 30-120 minutes and physical fiber opening treatment with strong water flow impact, it is heat-set at 160°C for 120 seconds to obtain a finished wiping cloth. The supporting surface coverage factor of the obtained wiping cloth is 90%, and according to the Japanese Industrial Standard JIS L1096 8.14.1B method (constant load method elongation), the elongation in the warp and weft direction is measured to be less than 5%, that is, a stable geometric shape is obtained. Non-toxic cleaning wipes. ...

Embodiment 2

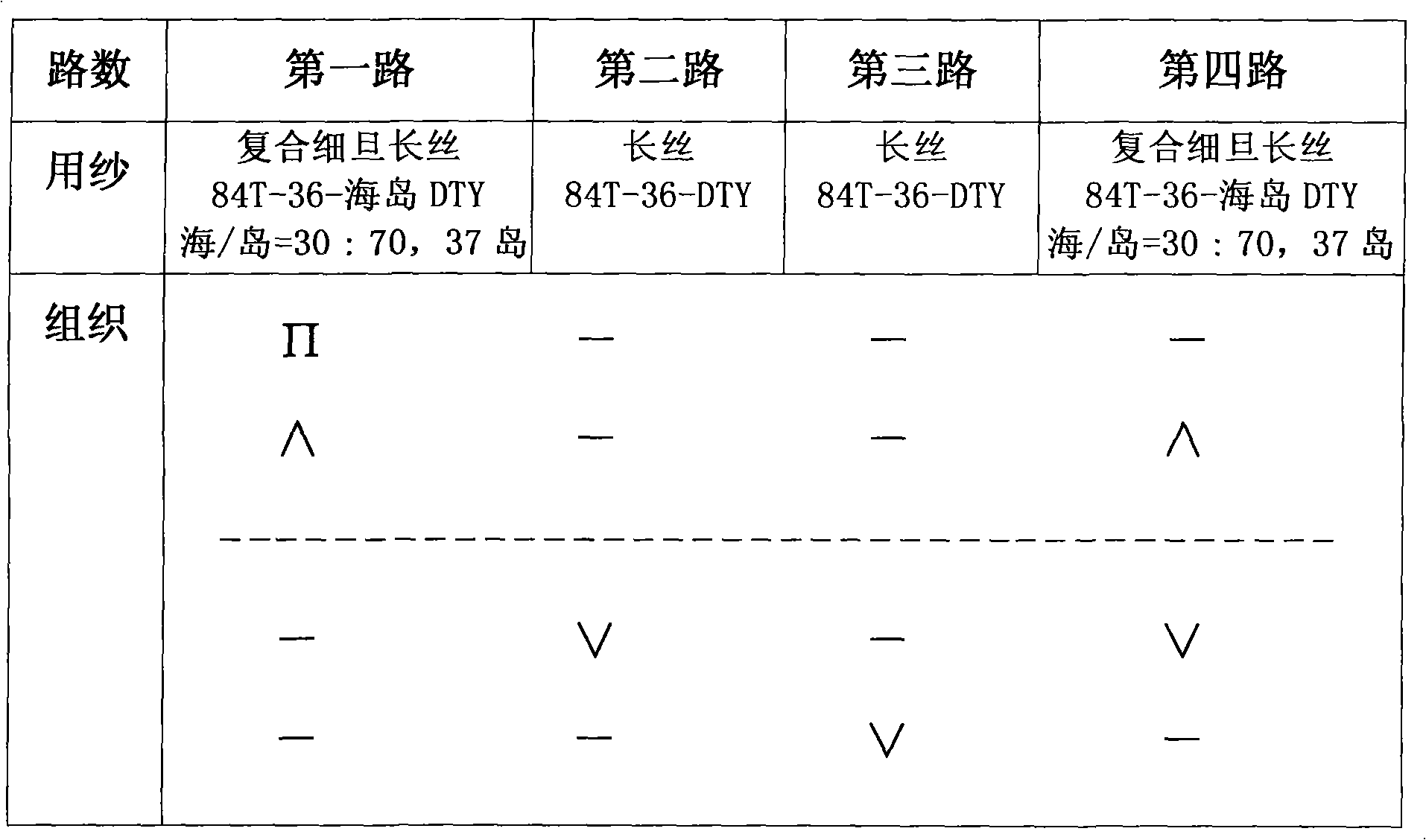

[0033] Select the following polyester yarns and weave structures, and use a tricot warp knitting machine to weave to make a gray cloth with a concave-convex effect on the clean surface;

[0034] Bar number

organize

GB1

56T-72-FDY

1-0 / 2-3 / 4-5 / 3-2 / /

GB2

56T-72-FDY

4-5 / 3-2 / 1-0 / 2-3 / /

GB3

84T-36-FDY

1-0 / 1-2 / /

[0035] The model of the warp knitting machine is HKS3 (130inch; E32 or E36, E40); in order to obtain a high-density support surface, the weaving longitudinal density is controlled at 18~22cpc.

[0036] After the above-mentioned gray cloth is subjected to hot water treatment at 60-130°C for 30-120 minutes and physical fiber opening treatment with high-pressure airflow impact, it is heat-set at 190°C for 45 seconds to obtain a finished wiping cloth. The cleaning surface is soft and has a concave-convex structure formed by mesh; the supporting surface coils are closely arranged and have high densit...

Embodiment 3

[0039] Select the following polyester yarns and structures, and weave them into gray fabrics with a weft knitting machine.

[0040]

[0041]The model of the weft knitting machine is a double-sided large circular knitting machine (34inch, 28G). The clean surface of the obtained gray cloth has the concave-convex effect of the mesh structure, and the supporting surface has a higher density.

[0042] After the above-mentioned gray cloth is treated with hot water at 60-140℃×20-120min, it is then subjected to chemical treatment for alkali weight reduction, and the weight reduction rate is controlled at about 35%, so that the sea-island composite fiber can be fully removed from the sea to obtain fine-denier polyester filaments . Then, through the impact of strong water flow, physical fiber opening treatment and heat setting at 180°C×60sec are carried out to obtain the finished wiping cloth. The supporting surface coverage factor of the obtained wiping cloth is 85%, and according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com