Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Nephelinite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nephelinite is a fine-grained or aphanitic igneous rock made up almost entirely of nepheline and clinopyroxene (variety augite). If olivine is present, the rock may be classified as an olivine nephelinite. Nephelinite is dark in color and may resemble basalt in hand specimen. However, basalt consists mostly of clinopyroxene (augite) and calcic plagioclase.

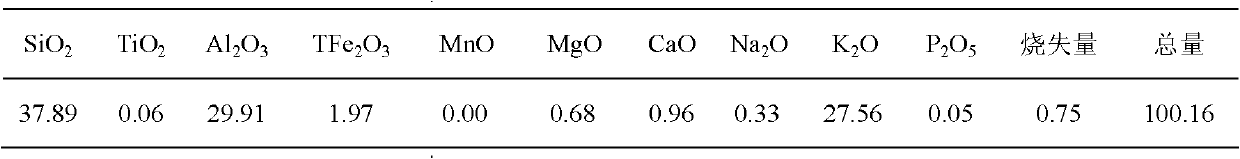

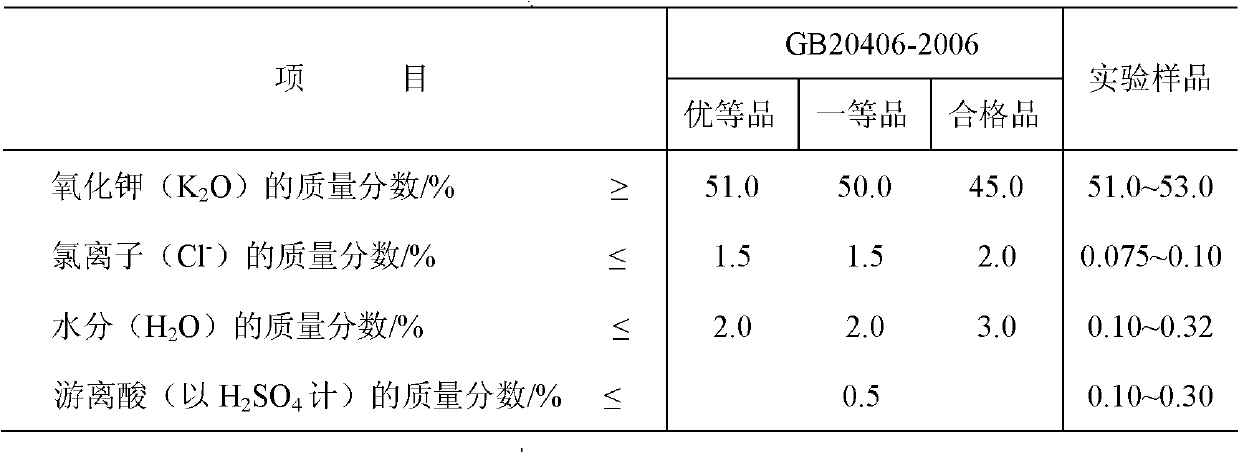

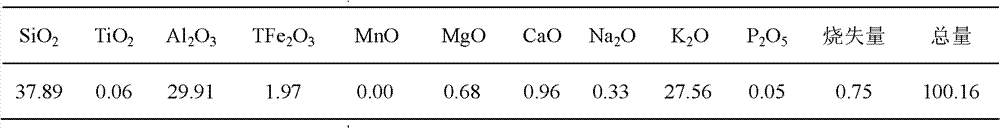

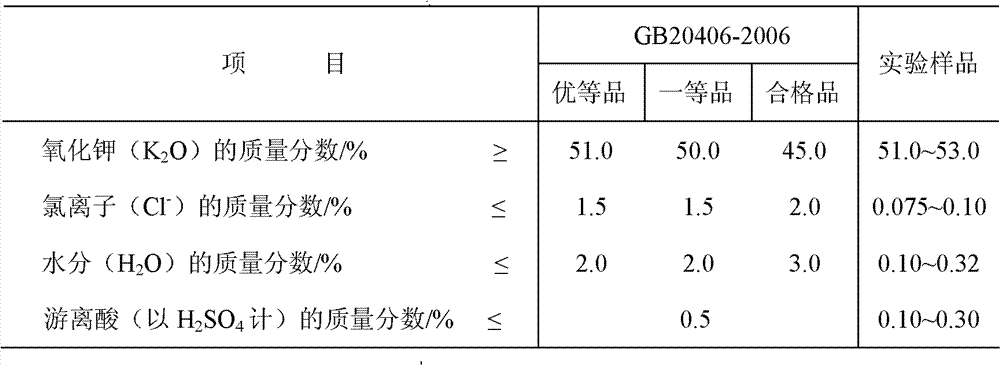

Technique for preparing agricultural potassium sulfate by utilizing kaliophilite powder

ActiveCN102167365ASimple processMild reaction conditionsSilicaAluminium silicatesEvaporationDistilled water

Owner:SHAANXI DAQIN POTASSIUM CO LTD

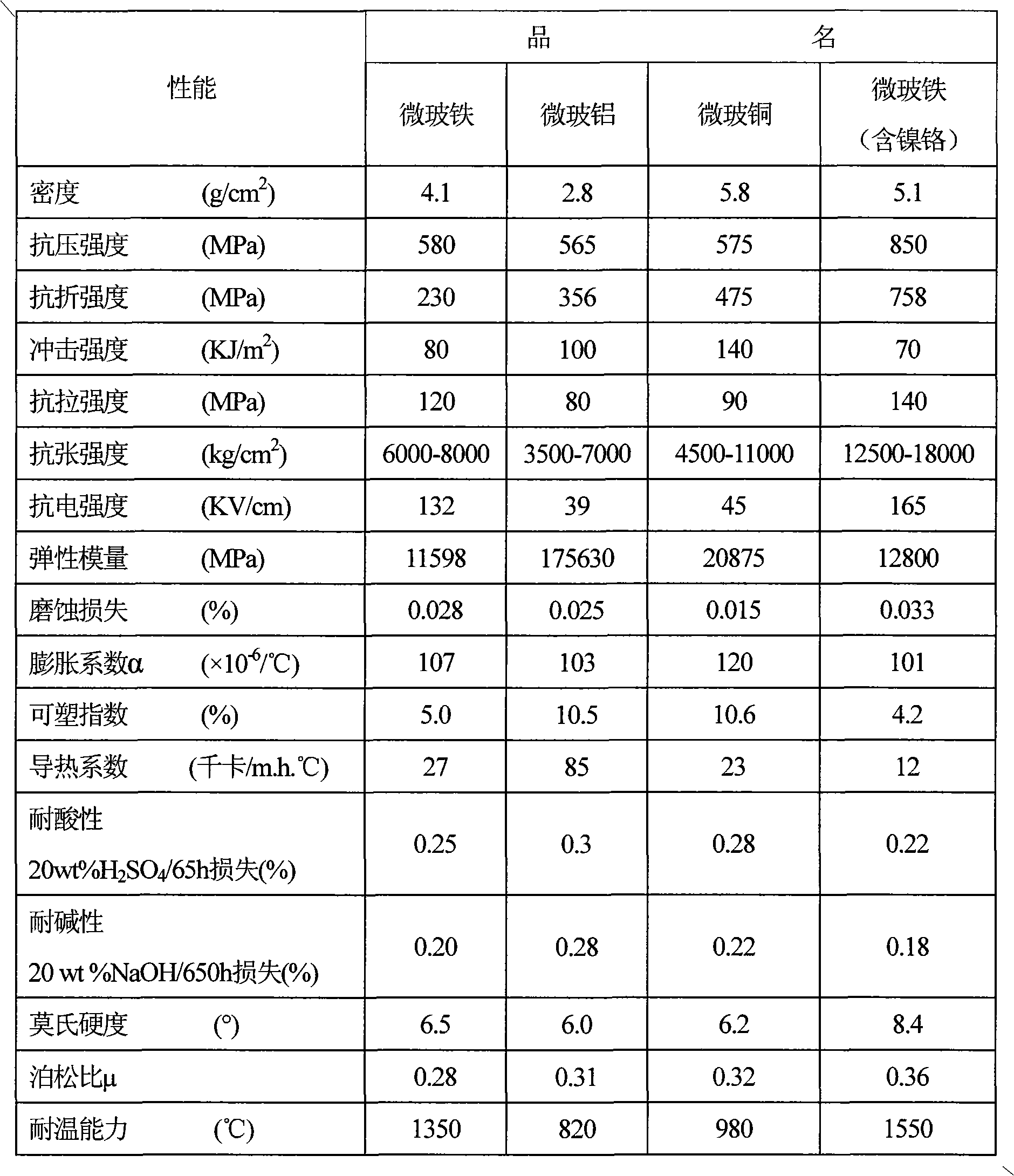

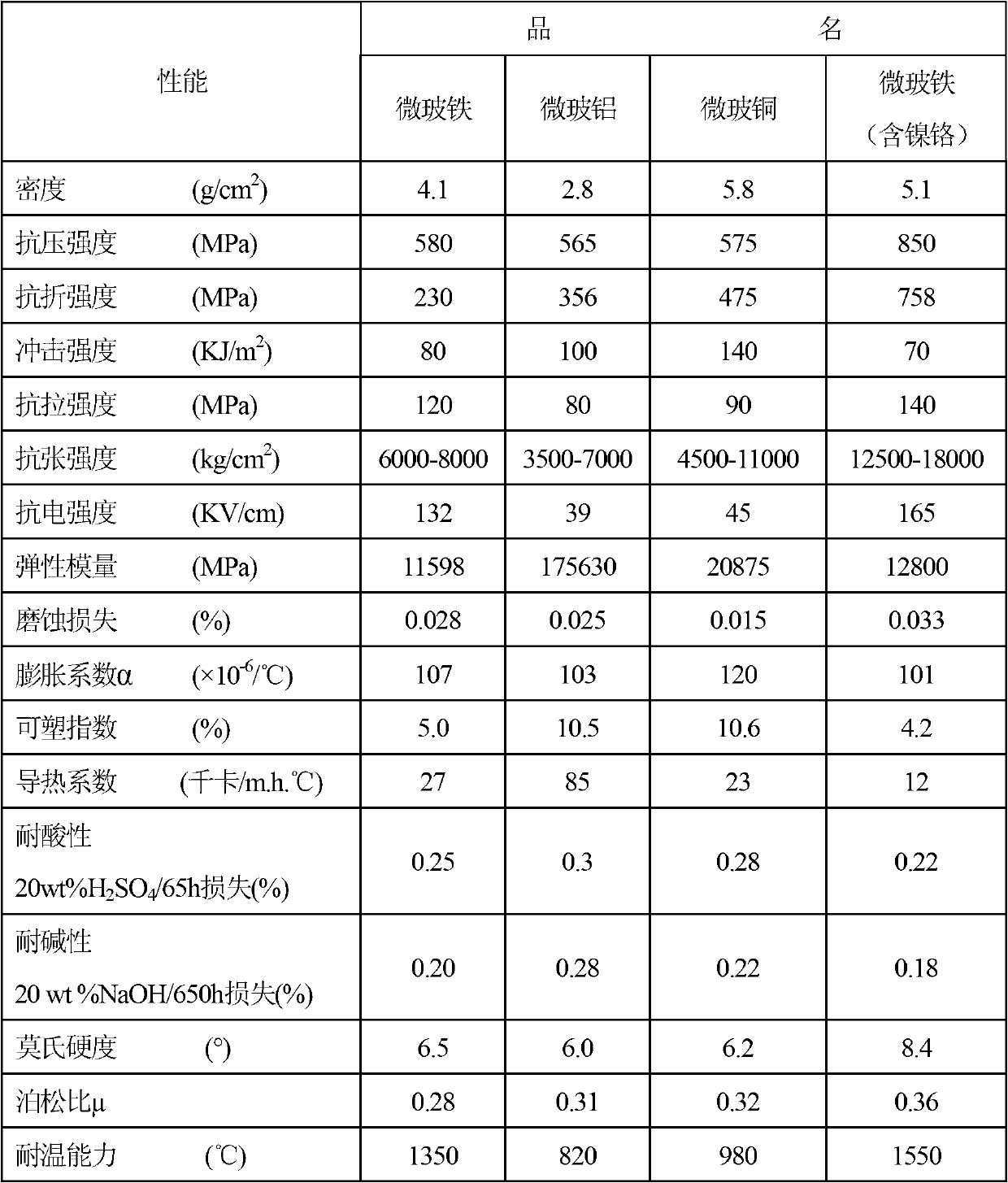

Nepheline glass ceramic and metal powder composite material and preparation method thereof

ActiveCN101927341ASolve the shortcomings of low physical and chemical propertiesExpand the marketTougheningFine powder

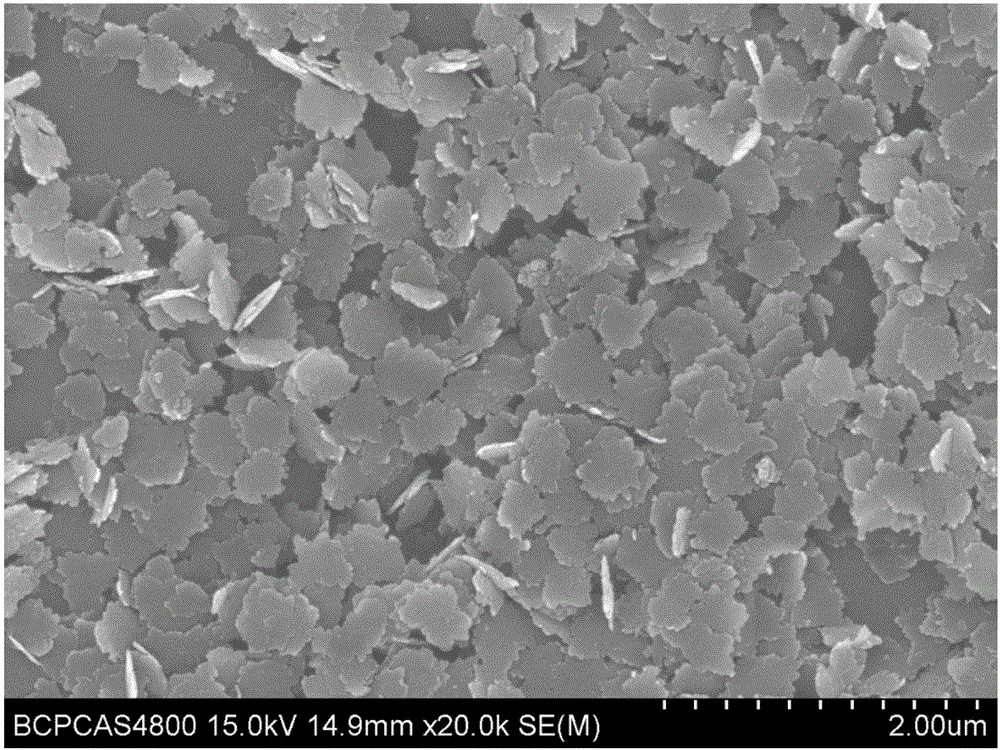

The invention relates to novel technology for producing novel silicon-based composite material by mixing nepheline glass ceramic and metal, in particular to a nepheline glass ceramic and metal powder composite material and a preparation method thereof. Nepheline glass ceramic powder and the selectively matched metal powder are prepared into novel iron-based, copper-based and aluminum-based composite materials. The glass ceramic powder is mixed with the metal powder, and a whisker is added to realize regrowth so as to improve the toughness; therefore, a novel high-strength composite material is obtained. The preparation method comprises the following steps of: crushing the selectively matched nepheline glass ceramic powder into fine powder with the particle size of 100 to 300 meshes, mixing with the selected metal powder, pressing into a blank, sintering and crystallizing in a crystallization furnace, forming by using a second hot extrusion mold, toughening by using a belt kiln, annealing, and finishing to prepare a high-strength product. The nepheline glass ceramic and metal powder composite material overcomes the defect of low physical and chemical properties of pure metal, and reduces the cost by 50 to 80 percent compared with a metallurgical product of pure metal powder.

Owner:赵凤宇

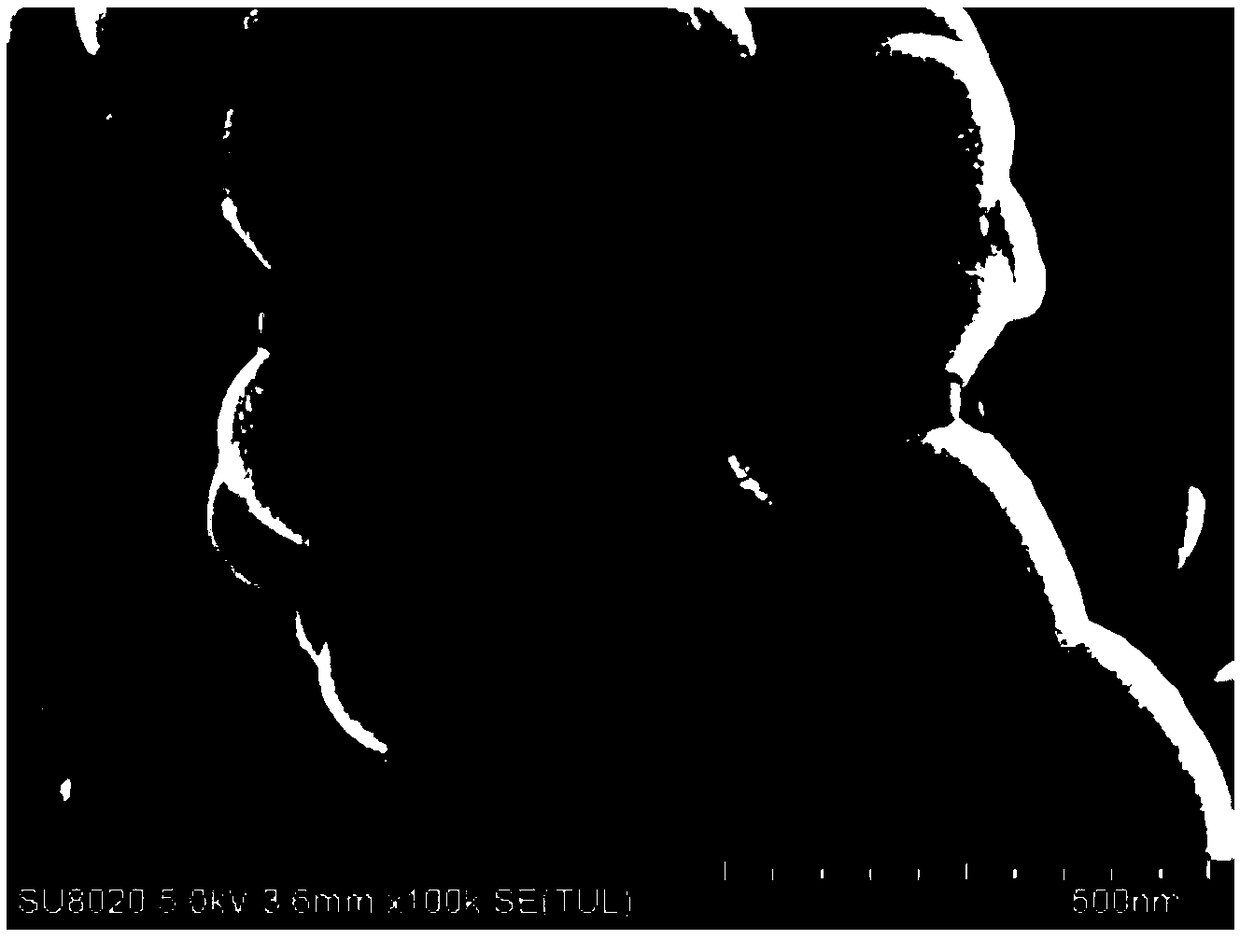

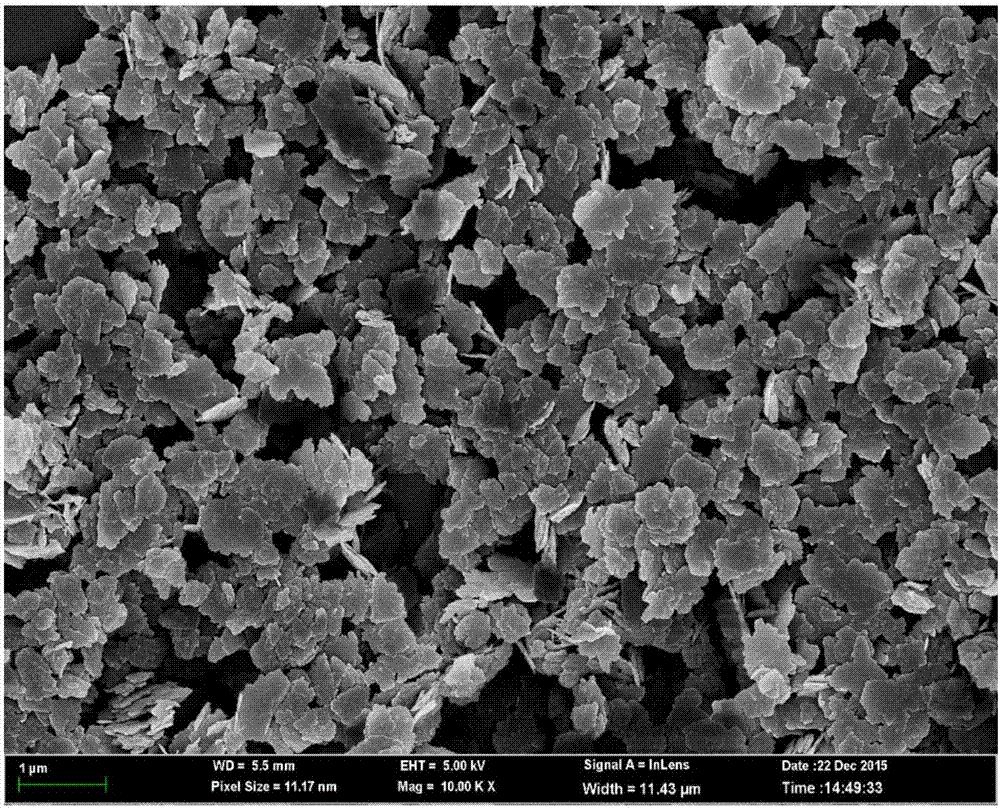

Method for preparing potassium nitrate and nanometer kaolinite with kaliophilite powder bodies

ActiveCN105776253AImprove resource utilizationSimple processNanotechnologyAlkali metal nitrate preparationResource utilizationFine chemical

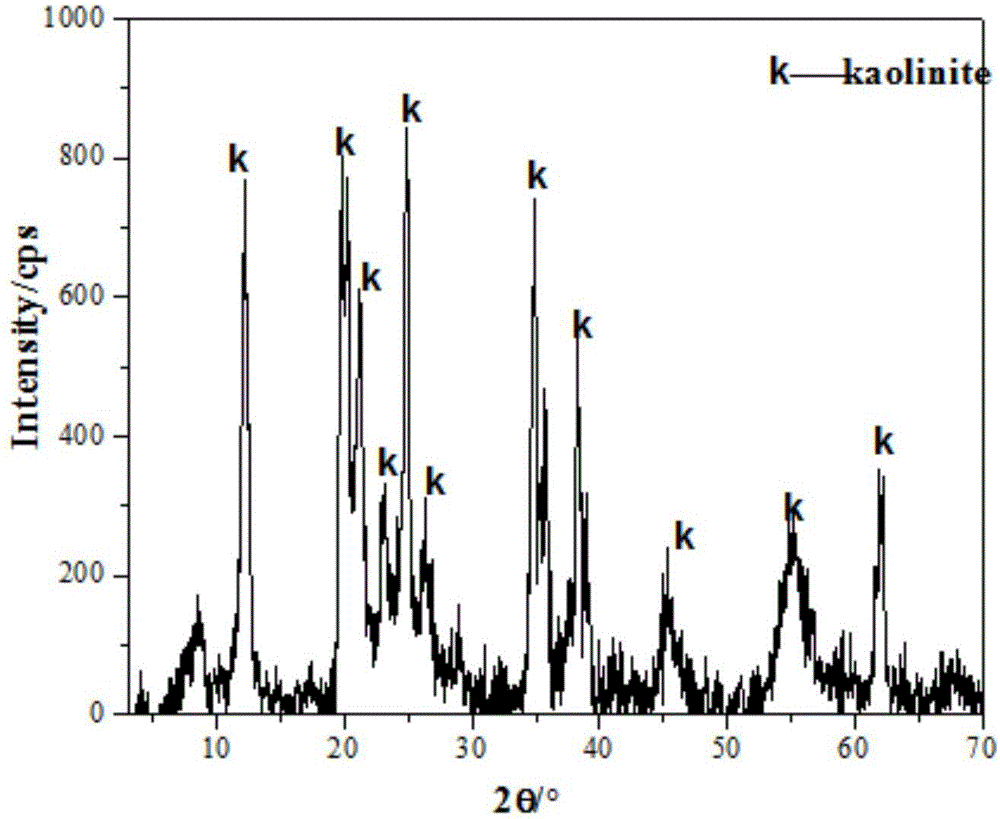

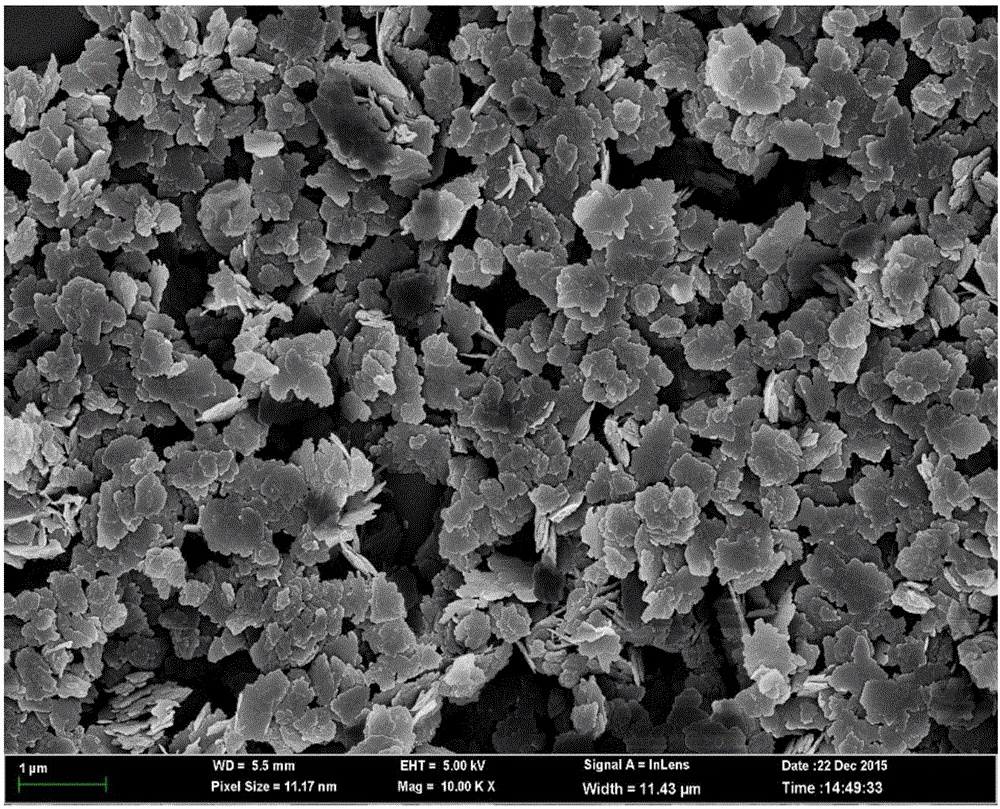

The invention relates to a method for synthesizing potassium nitrate as a by-product of nanometer kaolinite with kaliophilite powder bodies, and belongs to the field of preparation of fine chemical materials. The technology comprises the following steps: mixing the kaliophilite powder bodies with a nitric acid solution, performing a hydrothermal reaction under the condition of 210-250 DEG C for 12-36 hours, and performing synthesis so as to obtain a solid phase product, namely the nanometer kaolinite, and a liquid phase product, namely a potassium nitrate solution. According to the method disclosed by the invention, the kaliophilite powder bodies and the nitric acid are used as raw materials, the nanometer kaolinite and the by-product namely the potassium nitrate are synthesized, and components of potassium, aluminum and silicon in kaliophilite are fully utilized, so that the technology of the whole process is simple, modern industrial requirements of 100% resource utilization rate, zero discharge of waste gas, waste water and industrial residues, high efficiency, energy conservation and clean production can be met, and industrialized production is easy to realize.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for preparing phacellite by using coal ash as raw material

InactiveCN101602511AUniform chemical compositionImprove thermal stabilityAluminium silicatesSolid waste disposalResource utilizationPotassium hydroxide

The invention discloses a method for preparing phacellite by using coal ash as a raw material, which comprises the following steps: 1) drying the coal ash, and carrying out gradient magnetic separation of dry method; 2) mixing the magnetically-separated coal ash and potassium hydroxide according to a mass ratio of 1:0.1-0.3, adding the mixture into a crucible of a muffle furnace, heating the mixture, and baking the mixture at a constant temperature; 3) adding acid into a baked product of the coal ash according to a solid-liquid ratio of 1:1-5, dissolving the baked product in the acid for 1 to 2 hours, adding a chelating agent into the mixture according to a solid-liquid ratio of 1:0.1-0.5 during acid dissolution, and continually stirring the mixture; 4) after the acid dissolution is finished, filtering, washing and drying the filter residue to obtain a coal ash pretreatment sample; and 5) adding potassium hydroxide solution into the coal ash pretreatment sample according to a solid-liquid ratio of 1:2-5, adding the mixture into a stainless steel reaction kettle, heating the mixture to carry out hydrothermal reaction, and filtering, washing and drying a reaction product to obtain a phacellite product. The method overcomes the defects of the prior art such as high cost, uneven chemical components of the product and the like, achieves resource utilization of the solid waste coal ash, and has environmental and economic double benefits.

Owner:ZHEJIANG UNIV

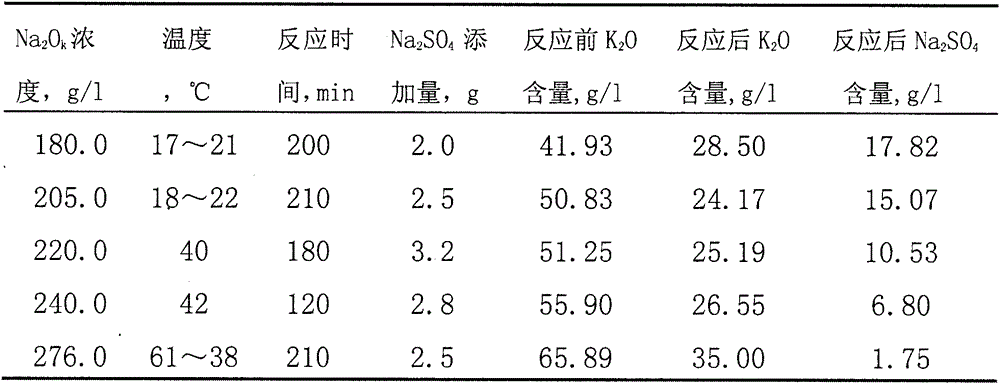

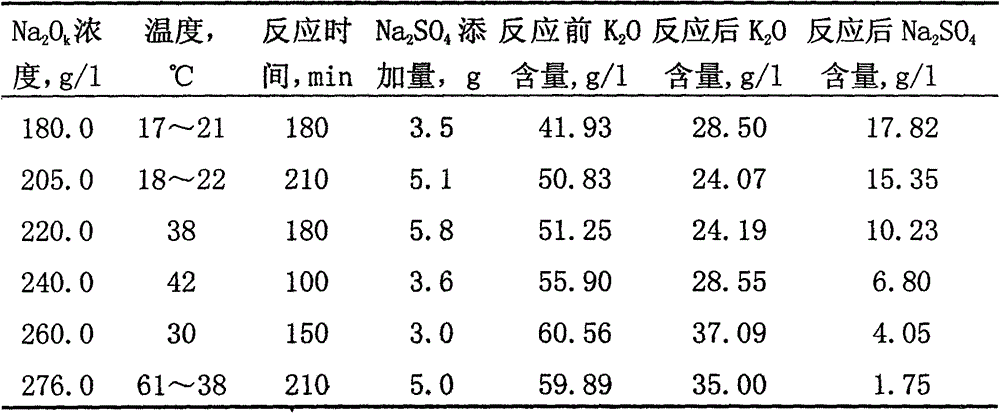

Method for separating potassium oxide from potassium-containing sodium aluminate solution

InactiveCN103818935AIncrease productionSolve the way outAlkali metal oxidesAlkali metal sulfites/sulfatesCombined methodSodium aluminate

The invention discloses a method for separating potassium oxide from a potassium-containing sodium aluminate solution, and relates to a method for separating potassium oxide from an evaporated sodium aluminate solution in an aluminum oxide production process. Potassium oxide is converted into potassium sulfate by adding sodium sulfate (or alunite for reaction to produce sodium sulfate) into the sodium aluminate solution and introducing SO4<2->, and is precipitated and separated in a form of aphthitalite, sodium sulfate and a little sodium carbonate mixture. The precipitation is performed under the condition of high caustic alkali and low temperature, and the residual of sodium sulfate in the solution can be avoided. A separation product can separate a potassium sulfate product according to a phase diagram, and sodium sulfate is recycled, or potassium chloride converts the mixture into pure potassium sulfate. The method achieves the output of sodium sulfate, and aluminum oxide and potassium sulfate can be co-produced by employing nepheline and alunite by a parallel serial method, and can be produced by employing high silicon ore such as nepheline and illite by an acid-alkali combined method.

Owner:赵凿元

Eucryptite microcrystal glass and preparation method thereof

InactiveCN109734322AImprove resource utilizationReduce manufacturing costResource utilizationAntimony trioxide

The invention provides eucryptite microcrystal glass and a preparation method thereof. The eucryptite microcrystal glass is prepared from, by weight, 45-70% of eucryptite, 1-5% of lepidolite, 20-38% of quartz sand, 2-8% of aluminum oxide, 3-5% of zirconium oxide and titanium oxide, 0.2-0.8% of talcum, 1-3% of barium carbonate, 0.2-0.7% of antimony trioxide and 0-1.5% of zinc oxide. The Sinkiang eucryptite is used as a main material, and the transparent eucryptite microcrystal glass with low expansion is prepared through synergistic effects of raw materials while indexes of strength, hardness,wear resistance and the like reach utilization standards; on the one hand, the resource utilization rate of domestic eucryptite is increased; on the other hand, microcrystal glass production cost is sharply reduced, getting rid of limitation of foreign imported resources on the industry of lithium-aluminum-silicon microcrystal glass is realized, and accordingly further development of the domesticindustry of lithium-aluminum-silicon microcrystal glass is effectively promoted.

Owner:WUHAN UNIV OF TECH

Spherical pellets containing common clay particulate material useful as a proppant in hydraulic fracturing of oil and gas wells

InactiveUS20140274818A1High compressive strengthLow raw material costFluid removalFlushingHydraulic fracturingResin coating

Ceramic propping agents include a plastic clay, aluminosilicate network modifier, strength enhancing agent, and binder. Usable strength enhancing agents can include nepheline materials having 0.1 to 5 percent iron oxide by weight. A resin coating can be used to encapsulate particles of the ceramic propping agent. The propping agent can be produced by grinding the components to the same approximate particle size, nucleating the particles by adding water, growing the resulting spherical pellets by adding additional particles that adhere to the surface of the spherical pellets, and vitrifying the pellets to form the propping agent.

Owner:BROWNWOOD CLAY HLDG

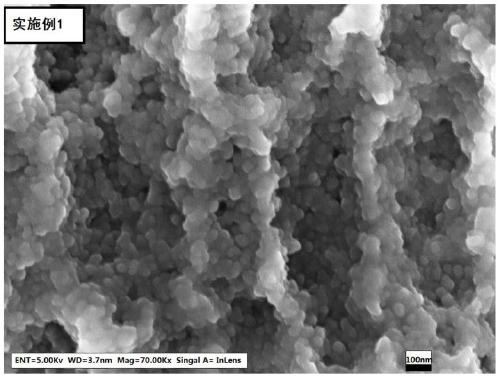

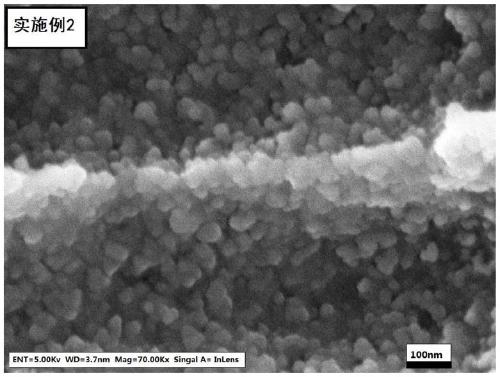

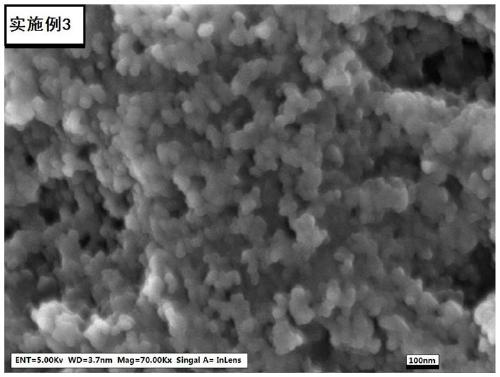

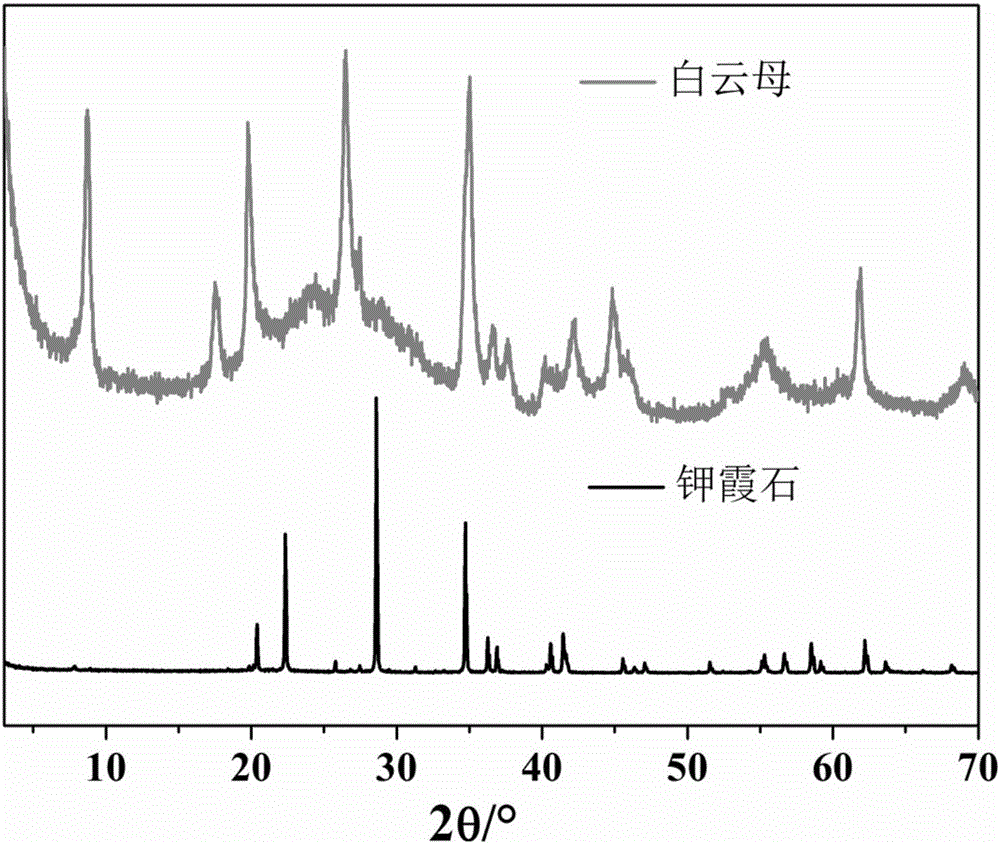

Method for synthesizing nano-white mica byproduct (potassium nitrate) by use of kaliophilite powder

ActiveCN107522208AImprove resource utilizationLow costAlkali metal nitrate preparationSilicon compoundsResource utilizationFine chemical

A method for synthesizing a nano-white mica (KAl2[Si3AlO10](OH)2) byproduct (potassium nitrate KNO3) by use of kaliophilite powder (KAlSiO4) and belongs to the field of preparation of fine chemical materials. The method is characterized in that white mica powder is mixed with nitric acid and an acetic acid solution, and a hydrothermal reaction is performed at 210-250 DEG C for 12-72 h to synthesize a solid-phase product (nano-white mica) and a liquid-phase product (a potassium nitrate solution). Kaliophilite powder and nitric acid are taken as raw materials to synthesize the nano-white mica byproduct (potassium nitrate), such components as potassium, aluminium and silicon in kaliophilite are fully utilized, the whole process is simple in technology, the modern industrial requirements for '100% resource utilization ratio' and 'three-waste zero emission' efficient energy-saving and clean production can be satisfied, and industrial production is easy to implement.

Owner:昊青薪材(北京)技术有限公司

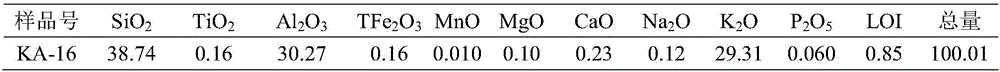

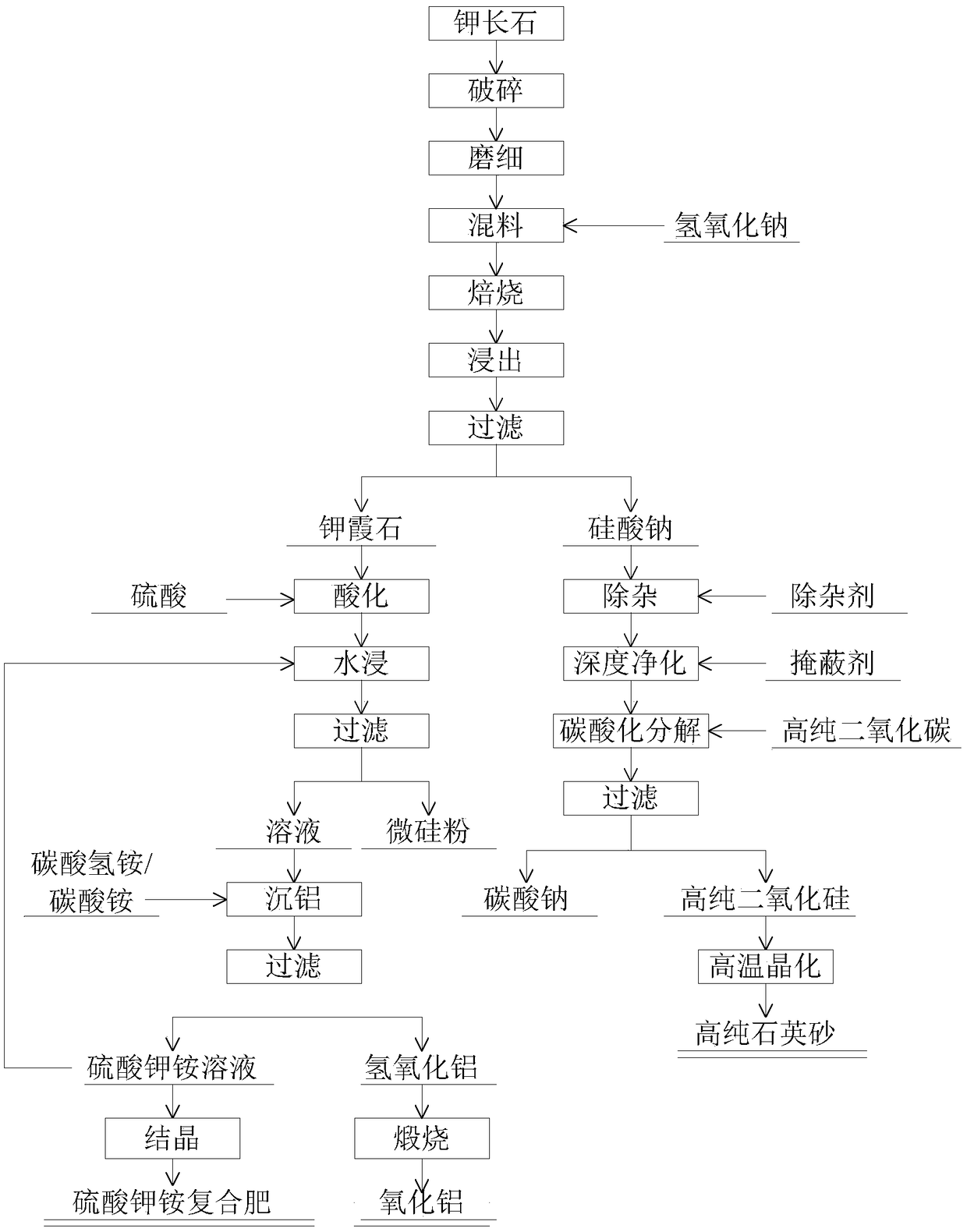

High value-added method for comprehensively utilizing silicon, aluminum and potassium in potassium feldspar ore

PendingCN109319792ASolve high value-added applicationsSimple methodSilicaSulfate/bisulfate preparationAluminium hydroxideDecomposition

The invention relates to a high value-added method for comprehensively utilizing silicon, aluminum and potassium in potassium feldspar ore. The method comprises the following steps: (1) crushing and grinding the potassium feldspar ore, then mixing the ground potassium feldspar ore with sodium hydroxide, and roasting; (2) leaching roasted clinker, and filtering to obtain a sodium silicate solutionand kaliophilite; (3) carrying out impurity removal, deep purification and carbonation decomposition on the sodium silicate solution to obtain high purity silicon dioxide; (4) carrying out high temperature crystallization to obtain high purity quartz sand; (5) acidizing the kaliophilite with sulfuric acid, dipping into water, and precipitating aluminum to obtain aluminum hydroxide powder; (6) calcining the aluminum hydroxide to prepare aluminum oxide; (7) crystallizing the solution subjected to aluminum precipitation to obtain potassium ammonium sulfate compound fertilizer. The method providedby the invention is simple in process, not high in requirements for equipment and lower in production cost, and realizes the high value-added comprehensive utilization of the silicon, the aluminum and the potassium in the potassium feldspar ore; the whole technological process does not cause secondary pollution to the environment, and meets the requirements of green industrial production.

Owner:BOHAI UNIV

High breaking resistant glass ceramic disc and preparation method thereof

The invention discloses a high breaking resistant glass ceramic disc and a preparation method thereof. The high breaking resistant glass ceramic disc is prepared from the following raw materials by weight part: 27-38 of broken glass, 15-25 of vesuvianite, 14-26 of kaliophilite, 10-15 of chromium slag, 17-29 of basalt, 4-6 of straw ash, 10-15 of titanaugite, 8-16 of dolomite, 9-18 of lazulite, 5-10 of magnesium zirconate, 3-6 of sodium carbonate, 2-3 of cobalt oxide, 3-5 of lithium silicate, and of 5-7 of an assistant. The glass ceramic disc prepared by the invention is prepared by compounding of vesuvianite, kaliophilite, chromium slag, basalt, straw ash, titanaugite, lazulite, magnesium zirconate, lithium silicate and other raw materials, has greatly enhanced mechanical properties, especially the breaking strength and fracture toughness, so that the glass ceramic disc has strong breaking resistance and durability, and is worthy of wide popularization and application.

Owner:安徽省德邦瓷业有限公司

Ceramic glaze and preparation method thereof

The invention discloses a ceramic glaze and a preparation method thereof. The ceramic glaze comprises the following raw materials in percentage by weight: 35-55% of nepheline, 15-25% of kaolin, 10-20%of quartz, 6-10% of modified flux, 5-9% of zinc oxide powder and 3-7% of cassiterite; the borax in the modified flux is heated to produce molten transparent glassy borax, making it easier to melt allkinds of heavy metal oxides, and sodium oxide produced in the reaction process of borax is combined with boric acid, and the boron glass is formed after heating treatment, at the same time, the boricacid reacts fully with the quicklime powder and forms calcium silicate crystal, while neither boron glass nor calcium silicate crystal can affect the flux effect and can be easily removed, it not only reduces the influence of effective intermediate products in the reaction process, but also further improves the fluxing and bonding properties. In the presence of excessive sodium oxide, it will affect the melting temperature and high temperature viscosity of the glaze, and then remove the sodium oxide to improve the quality of the glaze.

Owner:长沙集智创新工业设计有限公司

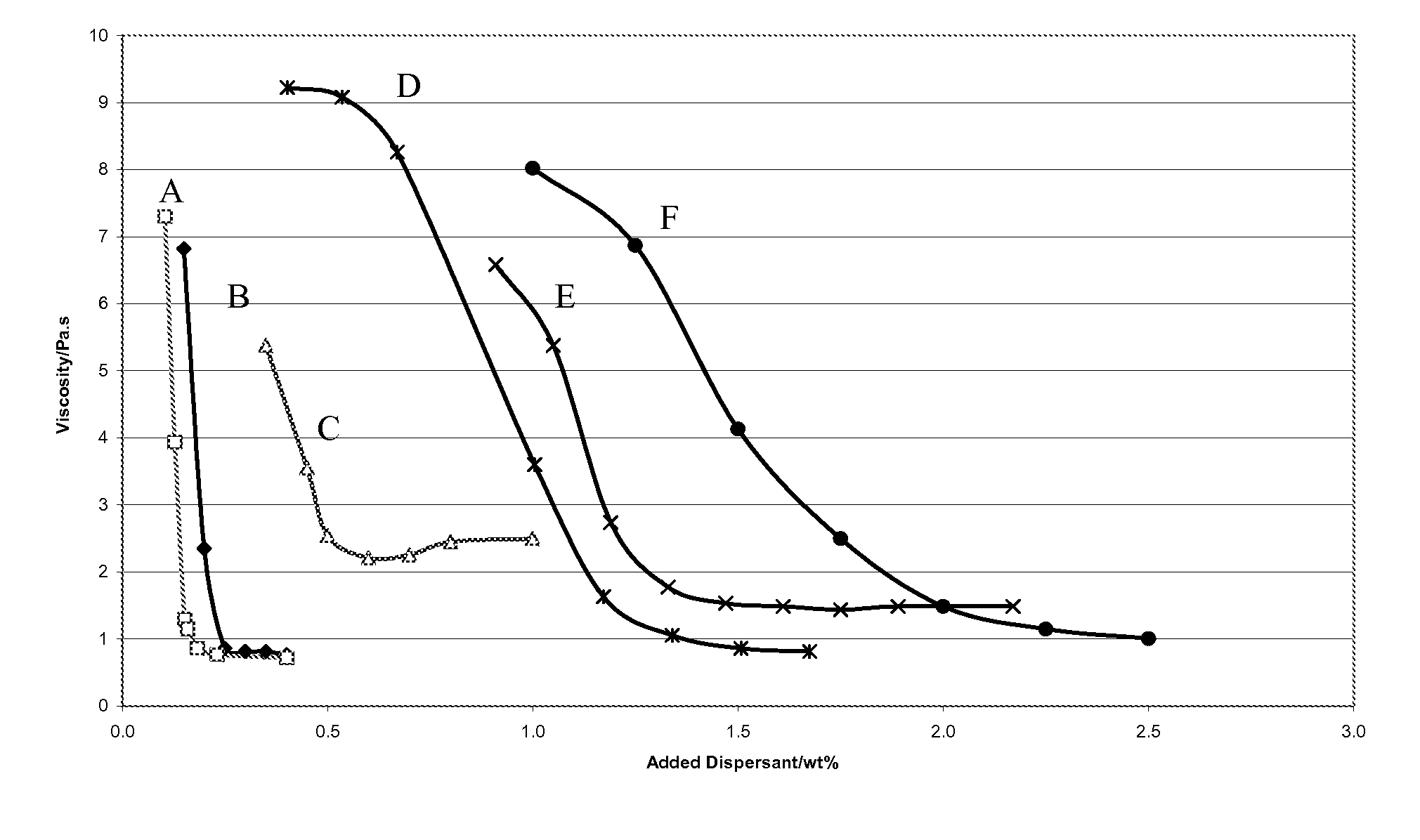

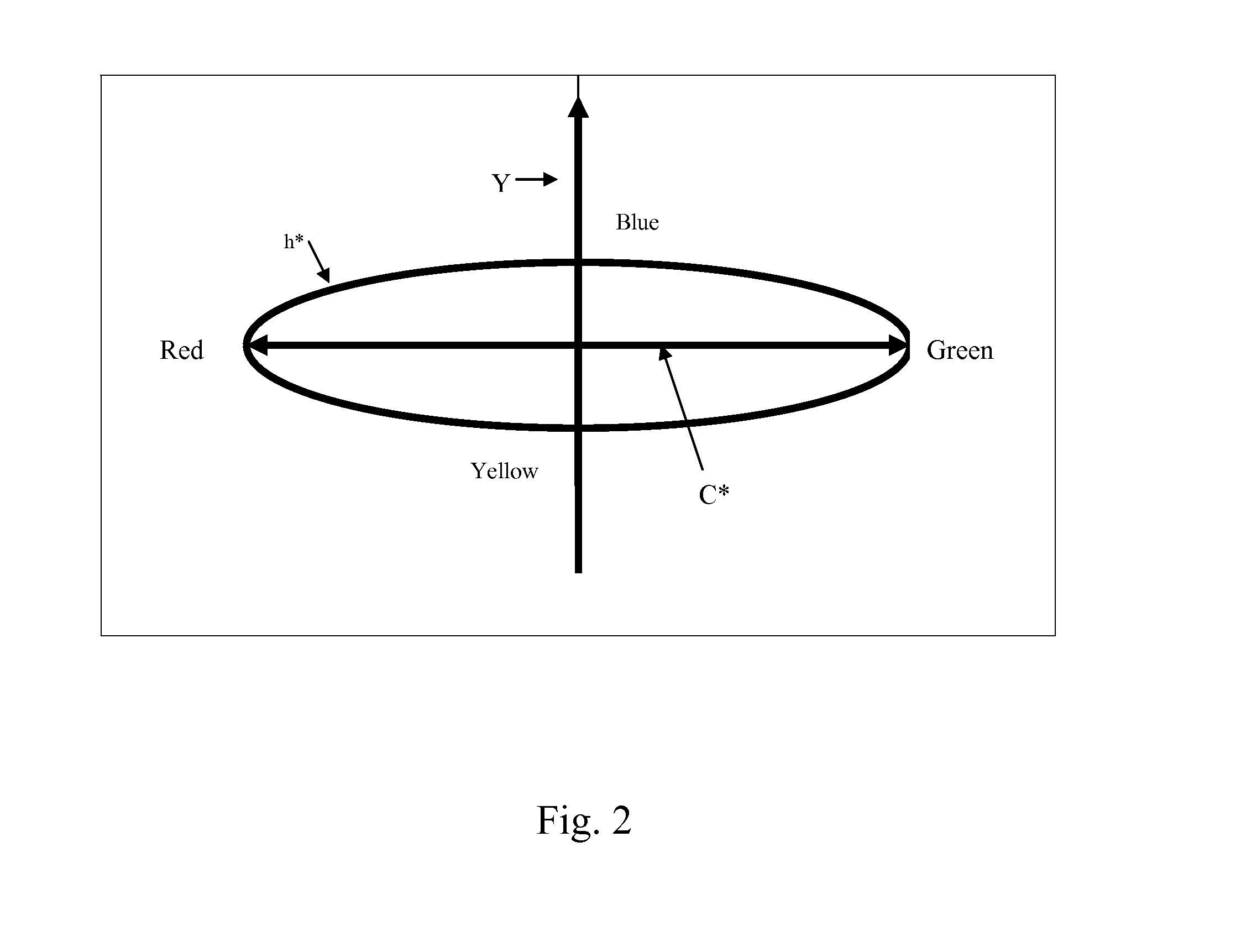

Low titanium dioxide coatings

Aqueous coating composition having a PVC from 78 to 85% and free of non-fugitive coalescing solvent, comprising, based on the total volume solids of the dry coating unless otherwise stated,a) opacifying pigment particles comprising from 3 to 10% titanium dioxide and from 0 to 20% of hollow polymeric particles;b) non-opacifying extender particles comprising calcium magnesium carbonate and / or calcium carbonate and / or nepheline syenite and / or kaolin;c) polymer binder particles of calculated Fox Tg of from 5 to 25° C. having an acid value of from 15 to 65 mg KOH / g of polymer;d) dispersant having weight average molecular weight of at least 3500 Daltons, and wherein the dispersant demand of a mixture of the opacifying pigment particles, other than the hollow polymeric particles, of a) and the extender particles of b) is greater than 0.35 wt %, calculated on the weight of the titanium dioxide and extender particles;e) fugitive coalescing solvent.

Owner:AKZO NOBEL COATINGS INT BV

Method for separating potassium oxide from potassium-containing sodium aluminate solution

InactiveCN104016390AIncrease productionRecycling by the wayAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali metal oxidesPotassium lowEvaporation

The invention discloses a method for separating potassium oxide from a potassium-containing sodium aluminate solution, relating to a method comprising the steps of in the production of aluminum oxide, introducing SO4<2-> by adding one or a mixture of more of sodium sulfate, aluminum sulfate (basic aluminum sulfate) and an alunite ore into seeded precipitation evaporation liquor, converting potassium oxide into potassium sulfate, and performing precipitation and separation in a form of sodium aphthitalite, wherein the precipitation is implemented under high-causticizing alkali and low-temperature conditions, so that residual sodium sulfate in the solution can be avoided, and the solution can be purified; sodium aphthitalite can be used for dissolving and separating out a potassium sulfate product by virtue of variable temperature, and sodium sulfate can be recycled; or a high-potassium low-sodium ore is used for generating a pure potassium aluminate solution by using a limestone sintering method, and then the pure potassium aluminate solution is subjected to a replacement reaction with sodium aphthitalite to generate potassium sulfate and sodium aluminate; potassium chloride also can be used for converting sodium aphthitalite into pure potassium sulfate. The method disclosed by the invention can be used for producing aluminum oxide and potassium sulfate by adopting nepheline and the alunite ore by virtue of a multiple process technology, and also can be used for producing chemicals namely aluminum oxide and potassium sulfate by adopting high-silicon ores such as potassium feldspar, lepidolite and illite by virtue of an acid-alkali combination method.

Owner:赵凿元

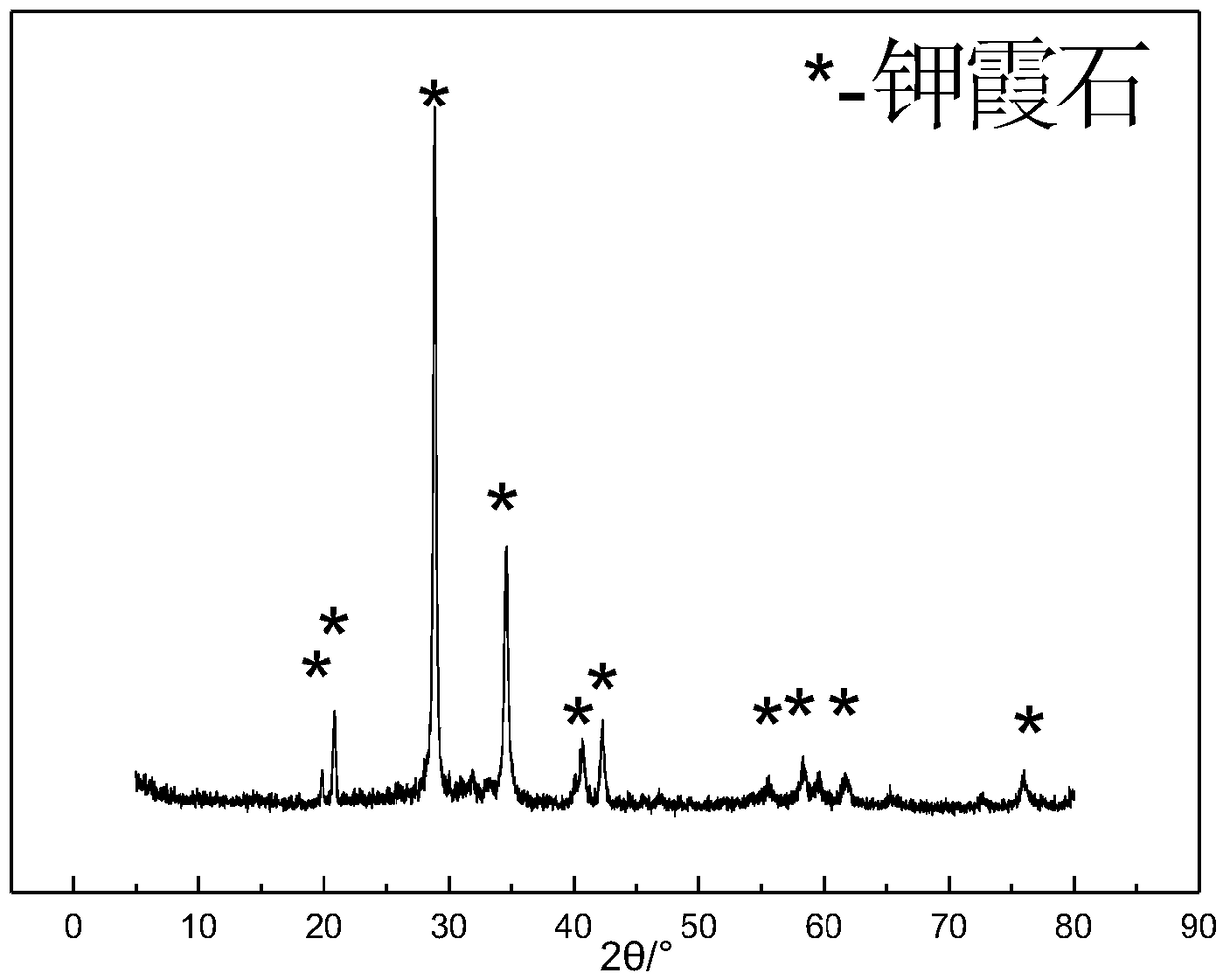

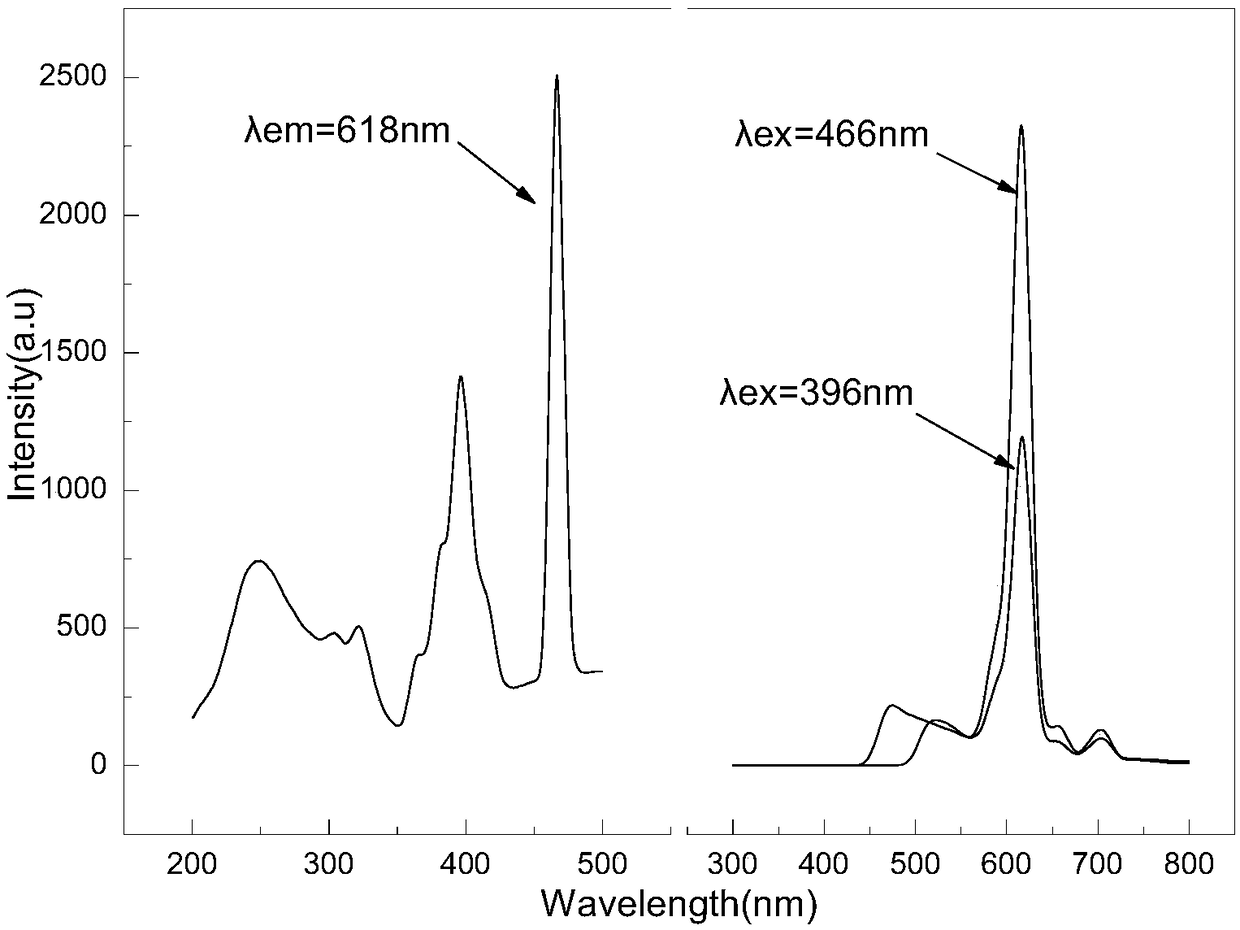

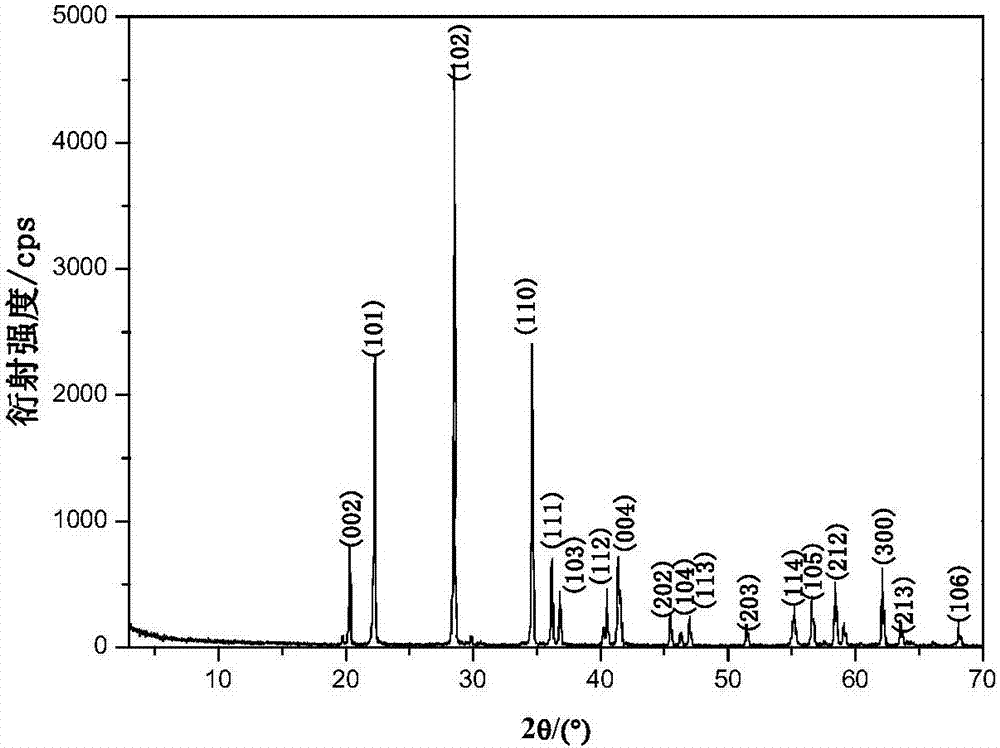

Method for synthesizing kaliophilite fluorescent material

PendingCN108841381AImprove luminous performanceSimple manufacturing processLuminescent compositionsSolubilityNitrate

Owner:JIANGXI UNIV OF SCI & TECH

A micropore composite fired brick tackified and modified with acrylic acid

InactiveCN106242632AHarm reductionImprove plasticityCeramic materials productionCeramicwareThermal insulationSludge

A micropore composite fired brick tackified and modified with acrylic acid is disclosed. The micropore composite fired brick is prepared from, by weight, 40-43 parts of municipal sludge, 8-9 parts of mesoporous silica, 22-25 parts of shale, 38-40 parts of gangue, 14-15 parts of rice hull, a proper amount of water, 6-7 parts of nepheline tailings, 7-9 parts of bamboo charcoal, 3-4 parts of acrylic acid, 2-3 parts of borax and 5-6 parts of hilly loess. The nepheline tailings and the hilly loess are compounded with the acrylic acid through a series of processes, thus playing a role of a filling material and increasing viscosity of mixed mud materials. Through mixing with other raw materials, the water content of a brick blank is increased obviously and the ratio of briquetting of brick blanks is increased. The fired brick is compact in appearance, comprises micropores inside, and is good in thermal insulation effects, good in toughness, high in strength and not liable to break. The raw materials are simple and easily available. A process is convenient in industrial control and suitable for large-scale production.

Owner:安庆太极新型建材开发有限公司

Smelting copper slag accretion agent and preparing method thereof

InactiveCN104928496ALow costWill not polluteRotary drum furnacesCrucible furnacesPyrophyllitePotassium

A smelting copper slag accretion agent is characterized by comprising, by mass, 74%-78% of perlite, 5%-12.0% of pyrophyllite, 3%-5% of calcium aluminate, 10%-14% of albite and 5%-15% of kaliophilite. A preparing method comprises the steps that firstly, weighing and mixing are carried out, raw materials are weighed according to the formula and weight, and the weighed raw materials are evenly mixed; secondly, crushing is carried out, the mixture obtained in the first step is placed in a crusher to be crushed, and the crushing granularity ranges from 80 meshes to 100 meshes; thirdly, packaging is carried out, powder obtained through crushing is bagged and packaged, and then a finished product is obtained. According to the smelting copper slag accretion agent, the vacancy of the domestic smelting copper industry in the field of the slag accretion field is filled up, the smelting copper slag accretion agent has the advantages of being low in cost, good in slag accretion effect, short in slag drossing time and small in copper loss, and in the using process, toxicity, dust and foreign smell do not exist, and the environment cannot be polluted.

Owner:万燕杰

Glass bead for outdoor advertisement reflective membrane and preparation method thereof

InactiveCN104965247AHigh mechanical strengthGood weather resistanceGlass shaping apparatusOptical elementsBetainePolymer science

The invention discloses glass beads for outdoor advertisement reflective membranes and a preparation method thereof. The glass beads are prepared from following raw materials by weight: 27-41 Yixing clay, 19-33 shell powder, 23-34 lamprophyllite, 18-30 cement slurry, 24-38 sunstone, 22-34 kaliophilite, 15-25 nahcolite, 5-10 1,3-butylene glycol, 4-7 potassiam polyoxyethylene laurylether phosphate, 6-8 nekal, 3-5 cocoamidopropyl betaine, 2-4 fatty methyl ester ethoxylates, and 6-9 additive. Yixing clay, lamprophyllite, cement slurry, sunstone, kaliophilite or the like are added to the raw materials, and the raw materials interact with each other, so the mechanical strength of the glass beads can be improved, and also the weatherability and endurance of the glass beads are substantially improved. The prepared glass beads have the good optical performance, are high in mechanical strength and long in service life, exhibit excellent weatherability and endurance, and fully meet use requirements of outdoor advertisement reflective membranes.

Owner:HEFEI DINGLIANG OPTICAL TECH

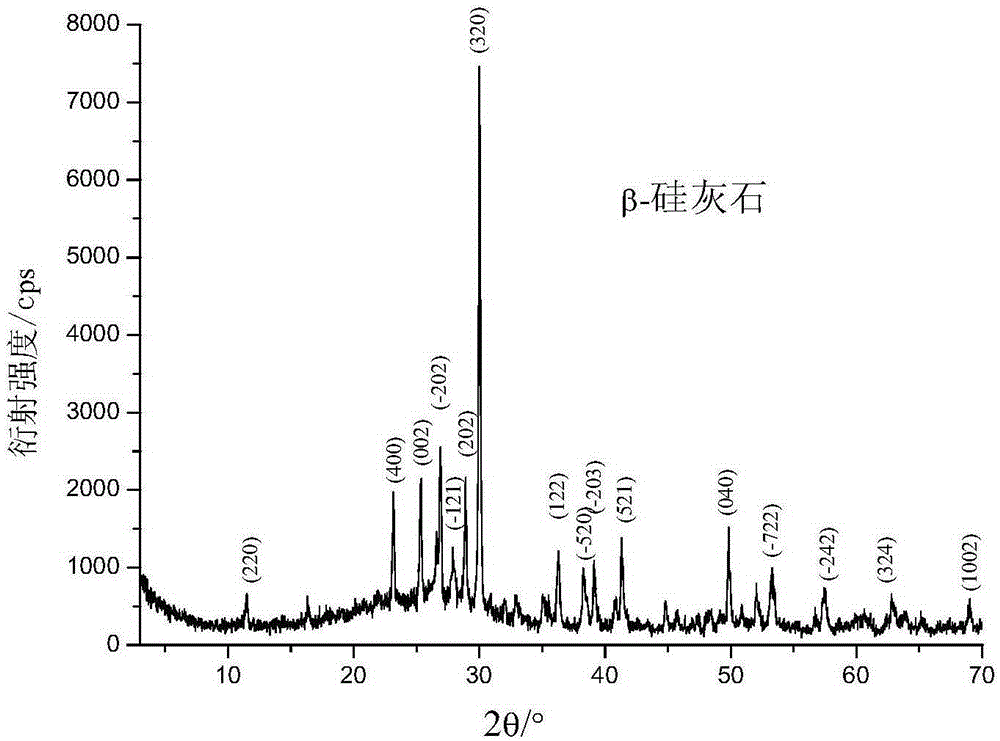

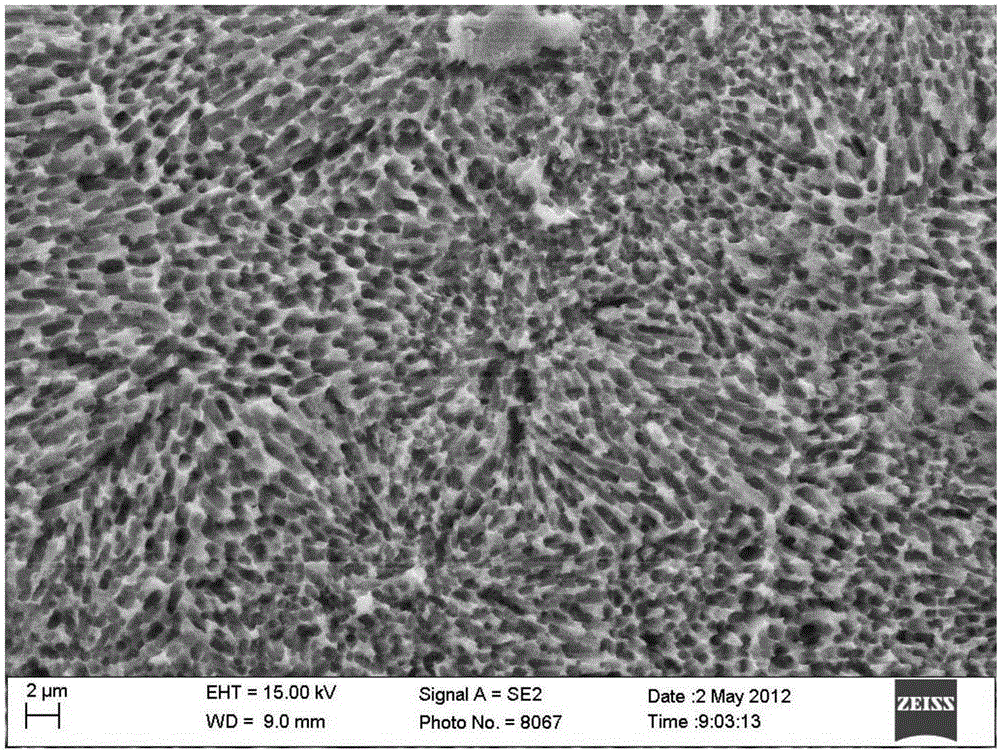

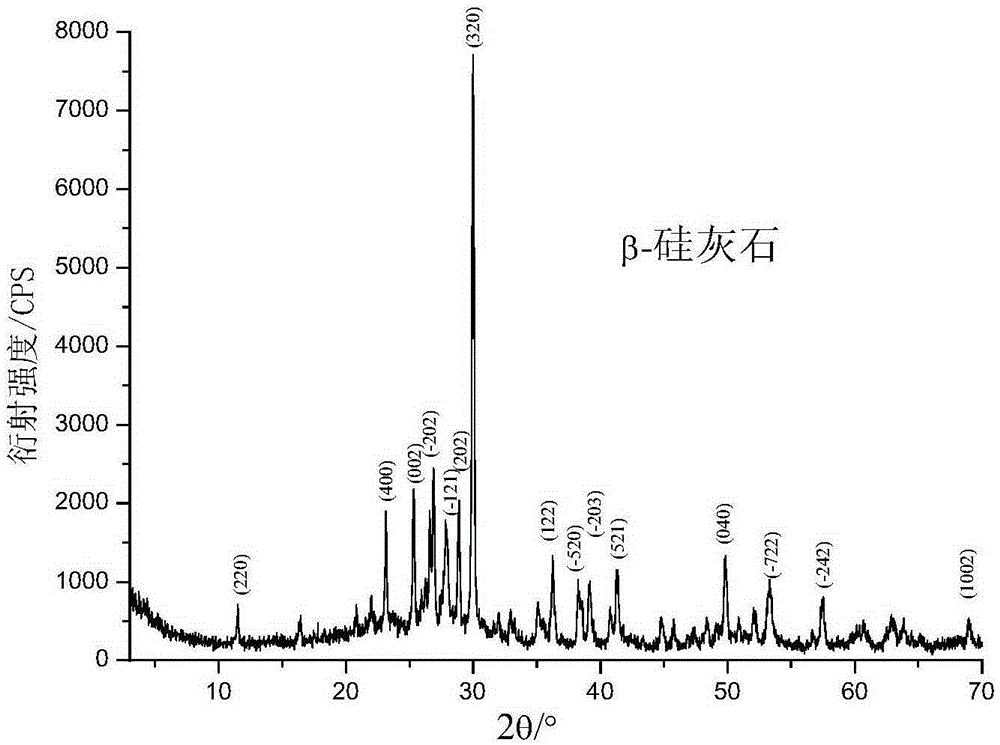

Process for producing beta-aedelforsite microcrystalline glass by using calcium silicate tailings

The invention relates to a process for producing beta-aedelforsite microcrystalline glass by using calcium silicate tailings. The process comprises a basic glass preparation process and a basic glass thermal treatment process. The process comprises the following steps: performing uniform ball milling on calcium silicate tailings, nepheline syenite, quartz sand and borax, melting the mixed powder at 1,300-1,500 DEG C for 2-5 hours to obtain glass metal, and pouring the glass metal into cold water to obtain basic glass particles; drying the basic glass particles, performing ball milling to obtain basic glass powder, and placing the basic glass powder into a steel die for pressure molding; nucleating a pressed blank at 500-900 DEG C for 30-120 minutes, and crystalizing at 500-1,200 DEG C for 30-150 minutes to obtain the beta-aedelforsite microcrystalline glass having a good decorating function. The process is wide in raw material source, and plays a good role in protecting the environment. The problem of emission of tailings in a process for extracting potassium from water-insoluble kali salt and the non-conventional process for extracting aluminum from aluminum-containing raw materials is solved effectively. Moreover, the process flow is simple, the production performance is excellent, and the additional value is high.

Owner:昊青薪材(北京)技术有限公司

Nepheline glass ceramic and metal powder composite material and preparation method thereof

ActiveCN101927341BSolve the shortcomings of low physical and chemical propertiesExpand the marketTougheningMaterials science

The invention relates to novel technology for producing novel silicon-based composite material by mixing nepheline glass ceramic and metal, in particular to a nepheline glass ceramic and metal powder composite material and a preparation method thereof. Nepheline glass ceramic powder and the selectively matched metal powder are prepared into novel iron-based, copper-based and aluminum-based composite materials. The glass ceramic powder is mixed with the metal powder, and a whisker is added to realize regrowth so as to improve the toughness; therefore, a novel high-strength composite material is obtained. The preparation method comprises the following steps of: crushing the selectively matched nepheline glass ceramic powder into fine powder with the particle size of 100 to 300 meshes, mixing with the selected metal powder, pressing into a blank, sintering and crystallizing in a crystallization furnace, forming by using a second hot extrusion mold, toughening by using a belt kiln, annealing, and finishing to prepare a high-strength product. The nepheline glass ceramic and metal powder composite material overcomes the defect of low physical and chemical properties of pure metal, and reduces the cost by 50 to 80 percent compared with a metallurgical product of pure metal powder.

Owner:赵凤宇

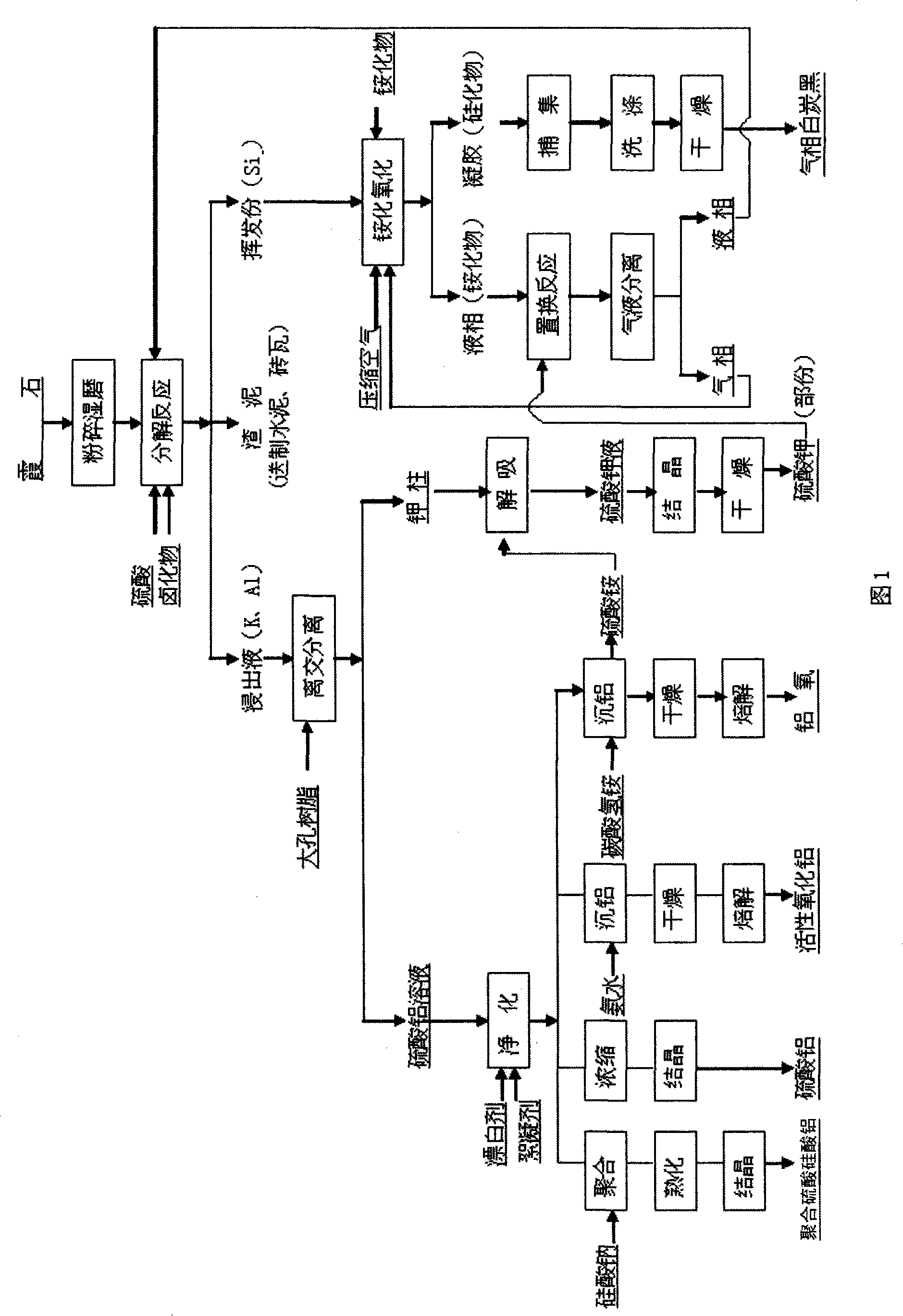

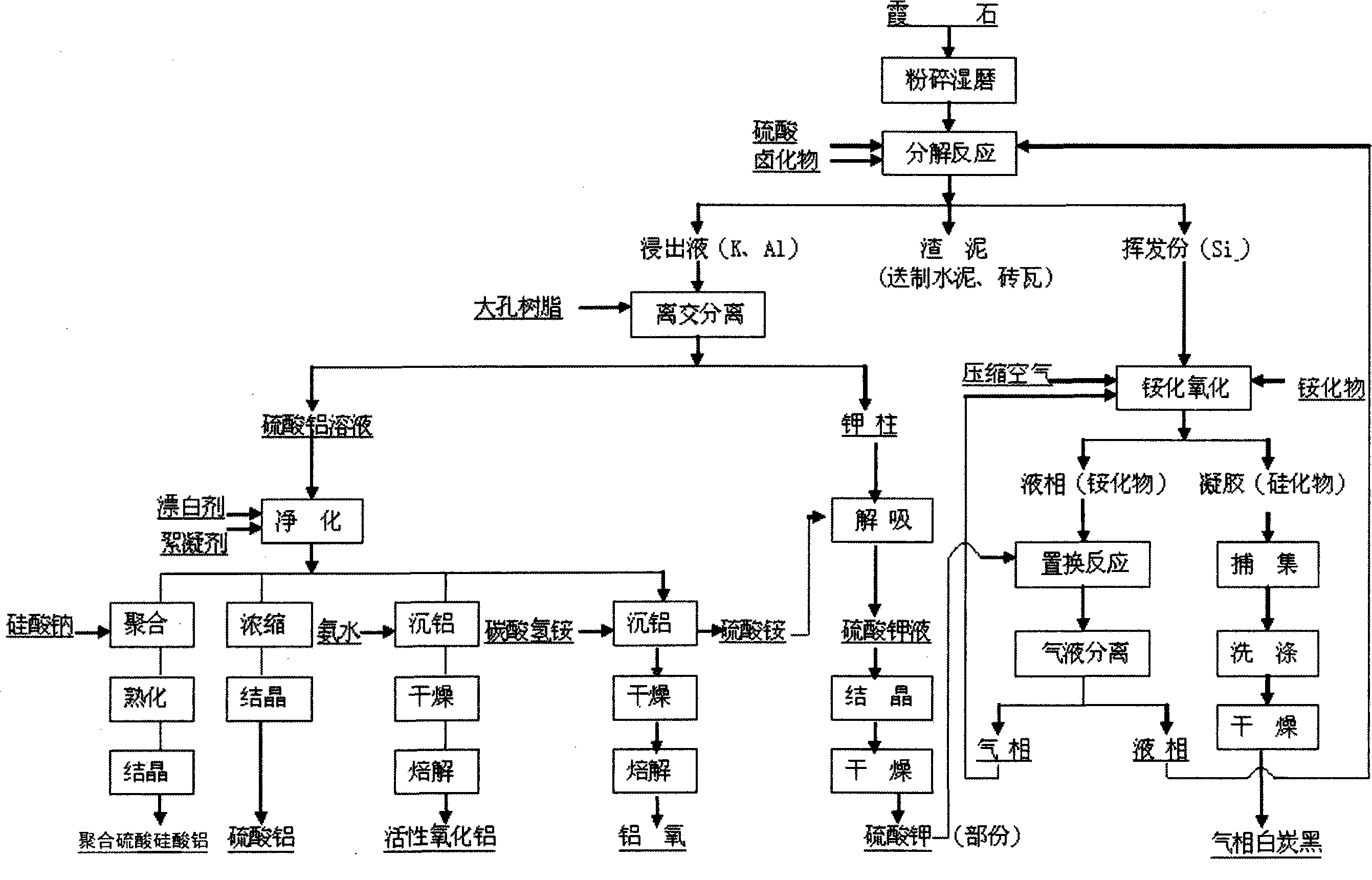

Chemical industry metallurgical comprehensive approach for nepheline ore by completely-wet method

ActiveCN101333597BIncrease valueAvoid pollutionProcess efficiency improvementChemical industryAluminum Ion

The invention provides a chemo-metallurgical technique taking nepheline ore as a raw material and adopting a whole wet method to prepare alumina and aluminum, potassium and silicon fine chemical products. The treatment method comprises: taking sulfuric acid as a leaching agent, and halide as an activator, making silicon in the nepheline ore be decomposed and run off in the form of gas phase halide, the aluminum and potassium enter a solution in the form of sulfate, the gas phase halide of silicon is oxidized into gas phase white carbon black products through ammoniation, a leaching solution containing potassium and aluminum ions realizes the potassium and aluminum separation through ion exchange, different aluminum-containing products are acquired by means of concentration, polymerizationor aluminum precipitation respectively, and potassium on a potassium post adopts an elution method for acquiring potassium-containing products. The technique has advantages of high recovery utilization rate of valuable elements and avoiding the pollution by the three wastes, and is particularly suitable for developing high potassium and high silicon type nepheline in the Gejiu area of China.

Owner:戴元宁

A method for preparing potassium nitrate and nano-kaolinite by using kalephine powder

ActiveCN105776253BImprove resource utilizationSimple processNanotechnologyAlkali metal nitrate preparationResource utilizationFine chemical

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

A kind of preparation method of cancryptite-red phosphorus synergistic flame retardant

The invention relates to a preparation method of a cannesite-red phosphorus synergistic flame retardant. The method comprises the steps of mixing cannonite and a certain amount of 0.1 mol / L NiCl2 solution, ion-exchanging at 60° C. for 30-180 min, and filtering , washed, dried, then placed in a quartz tube reactor, passed hydrogen at 400-450°C for 30-120min, then passed phosphine at 410-440°C for 2-10h, and finally put the sample in an air-isolated environment. The reaction vessel is heated and kept at 260-290° C. for 10-60 minutes to obtain a cannesite-red phosphorus synergistic flame retardant with 4-33% (mass ratio) of red phosphorus loaded in the pores. The preparation process of the invention is relatively simple, the deficiency of using the red phosphorus flame retardant alone is solved, and the prepared flame retardant has good flame retardant performance.

Owner:SHANDONG UNIV OF TECH

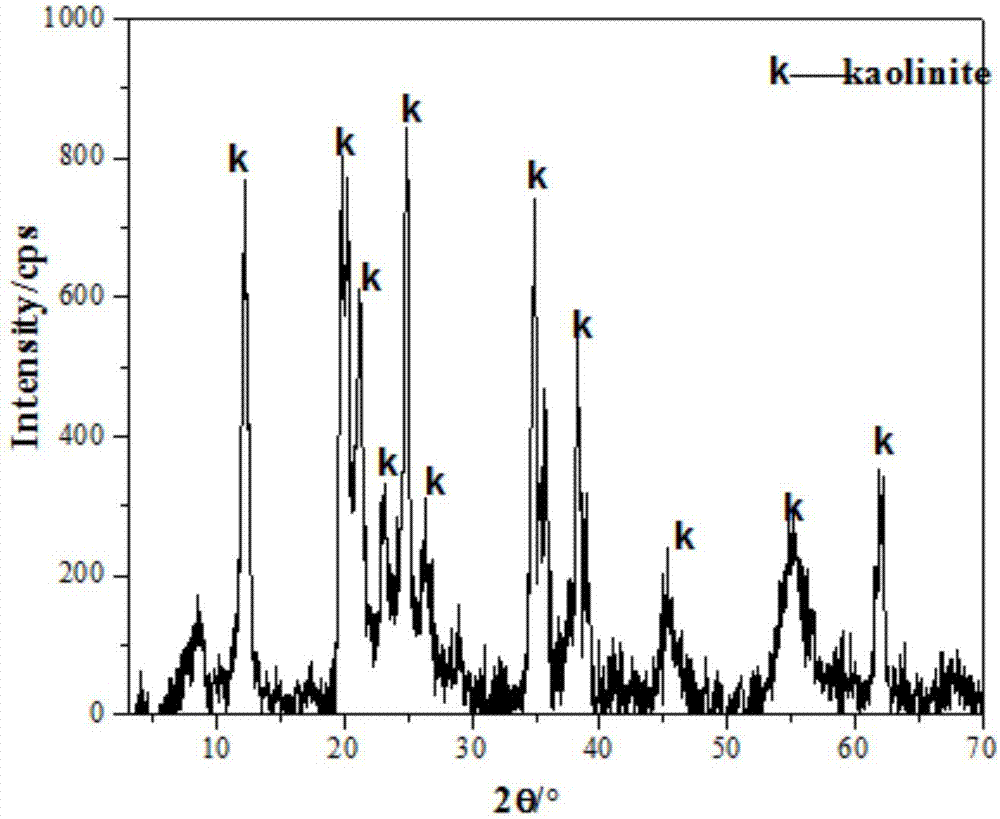

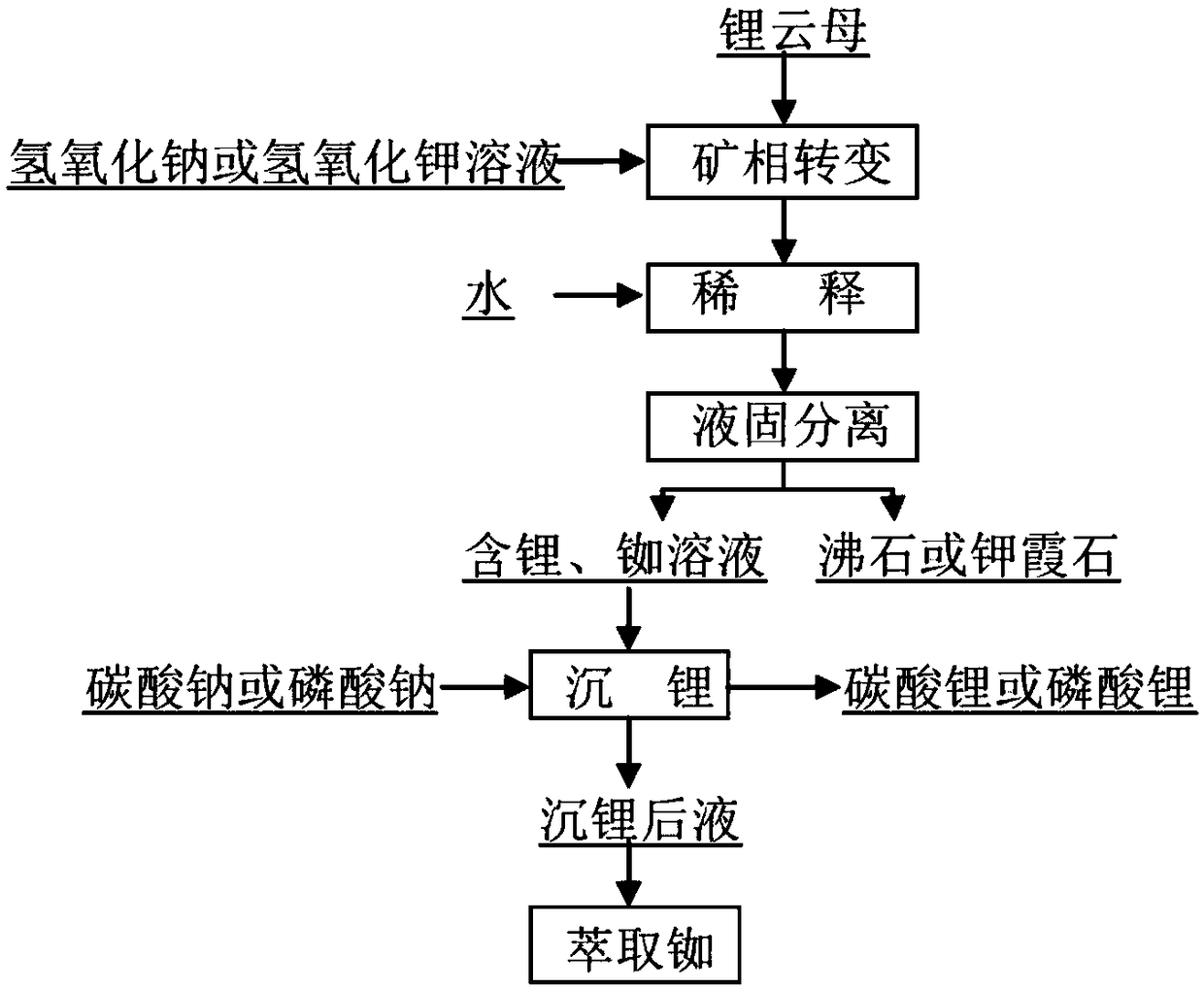

Method for extracting lithium, rubidium and co-producing zeolite or potassium nepheline from lithium mica ore

ActiveCN109321748AImplement extractionRealize comprehensive utilizationAluminium silicatesCrystalline aluminosilicate zeolitesRubidiumPotassium hydroxide

The invention provides a method for extracting lithium, rubidium and co-producing zeolite or potassium nepheline from lithium mica ore, and belongs to the technical field of hydrometallurgy. Accordingto the method, the lithium mica ore and sodium hydroxide solution or potassium hydroxide solution are added into a reactor to be stirred and mixed, and the appropriate temperature is controlled to carry out ore-phase transformation under the normal-pressure condition. The lithium-mica is converted into the zeolite or the potassium nepheline through the ore-phase transformation, and the lithium and the rubidium in the lithium mica are transferred into the solution, so that a solution containing the lithium and the rubidium is obtained; and a lithium product can be obtained from the solution through chemical precipitation, and the rubidium can be recovered from the solution through extraction. According to the method, the lithium mica ore is treated by adopting a full-wet-method technology,so that the valuable metal lithium and rubidium in the type of lithium ore is realized, and the zeolite and the potassium nepheline products with high added values are obtained through the ore phasetransformation, and the comprehensive utilization of resources is finally realized. In addition, the method has the characteristics of being short in flow, few in working procedures, low in energy consumption cost and the like, and the environmental protection requirements of clean production can be met.

Owner:UNIV OF SCI & TECH BEIJING

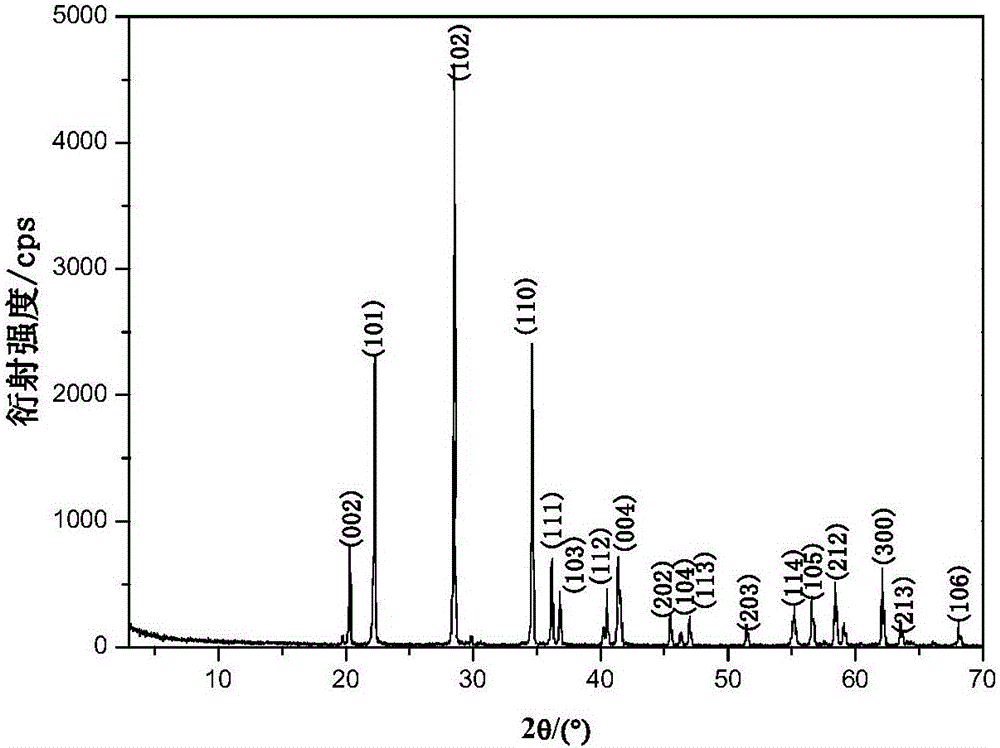

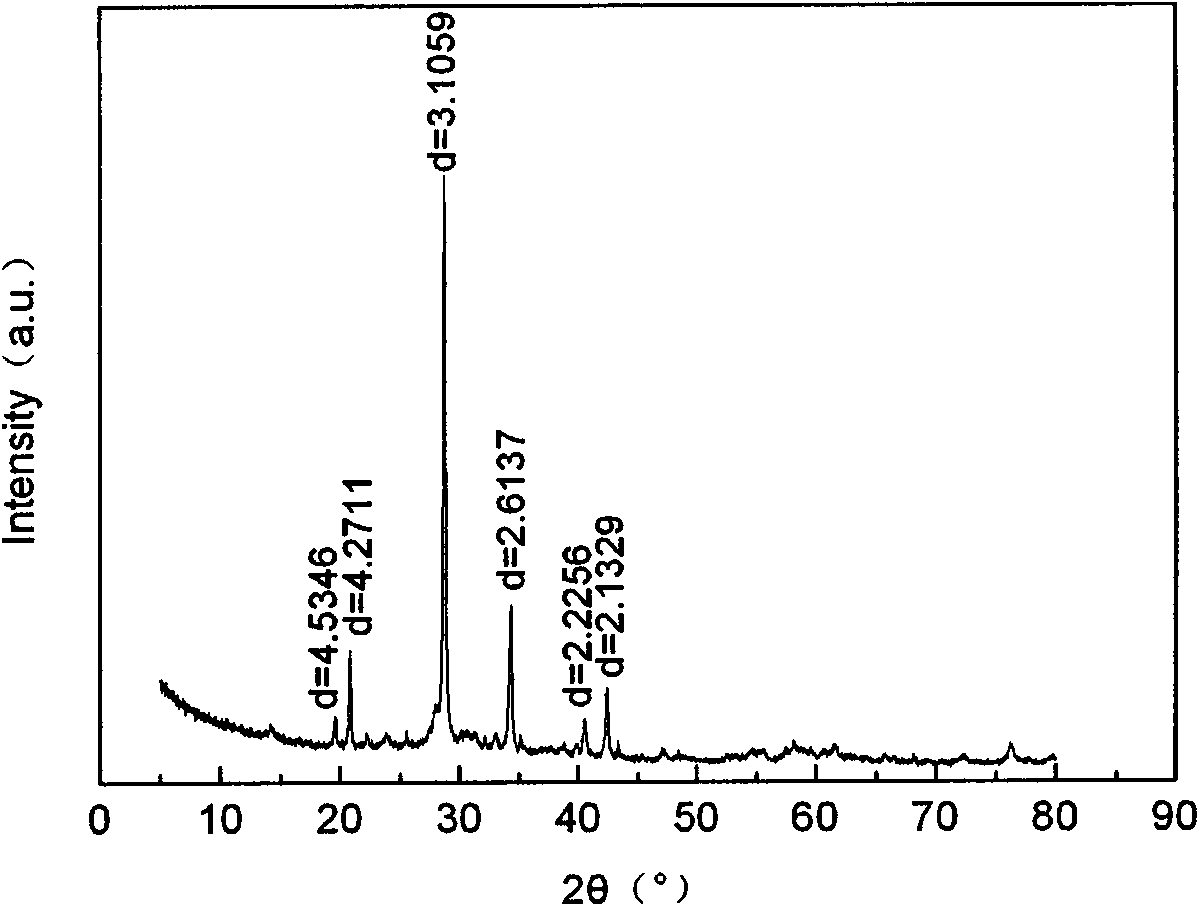

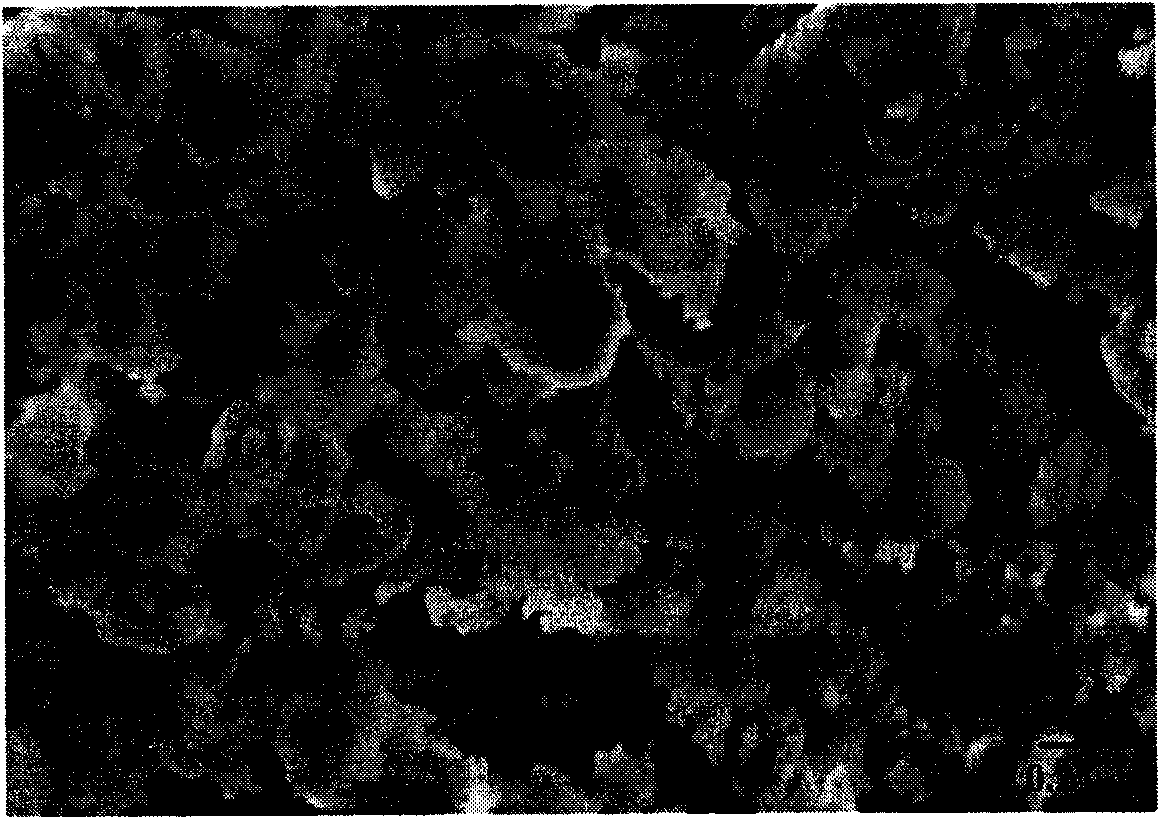

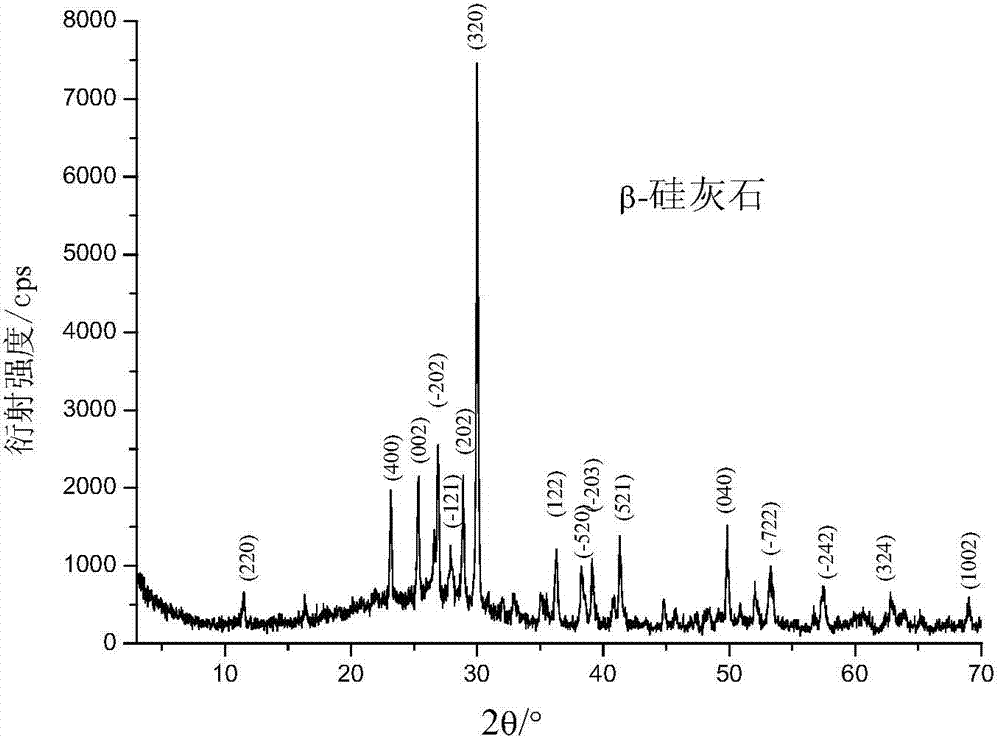

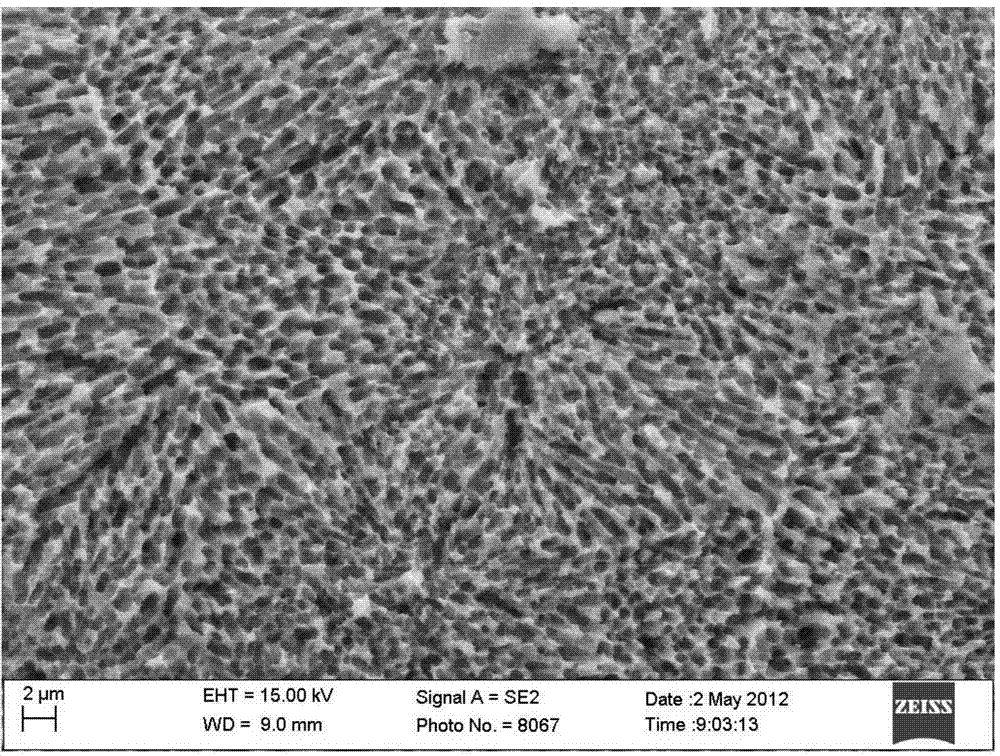

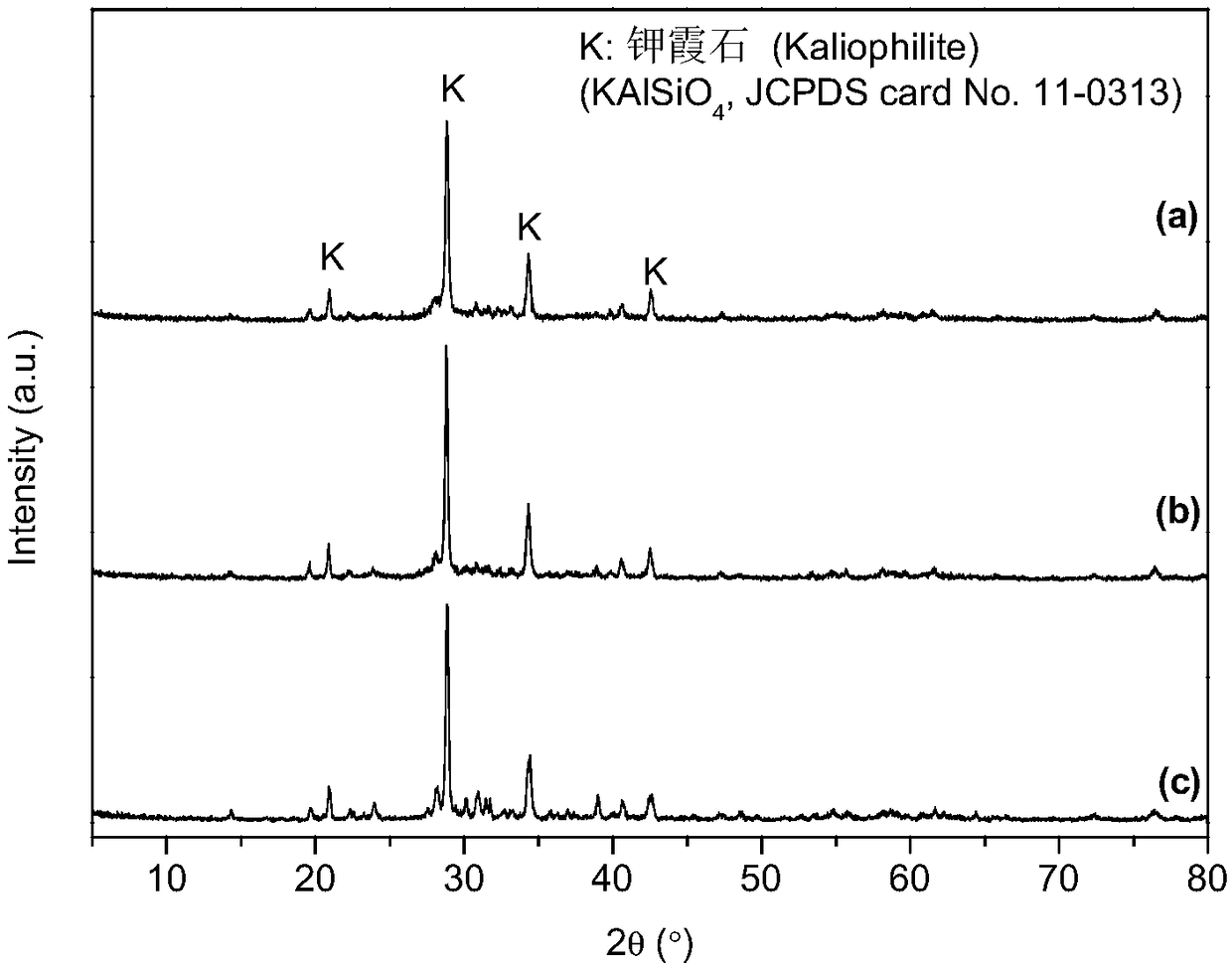

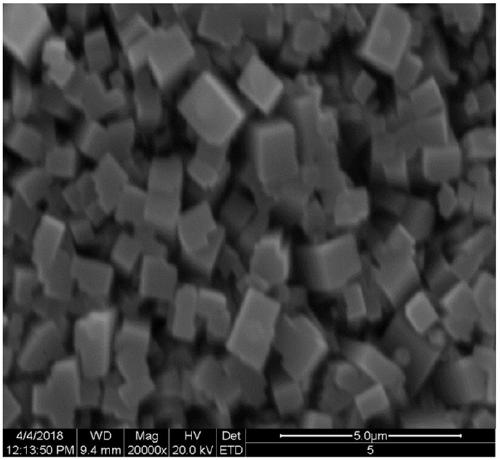

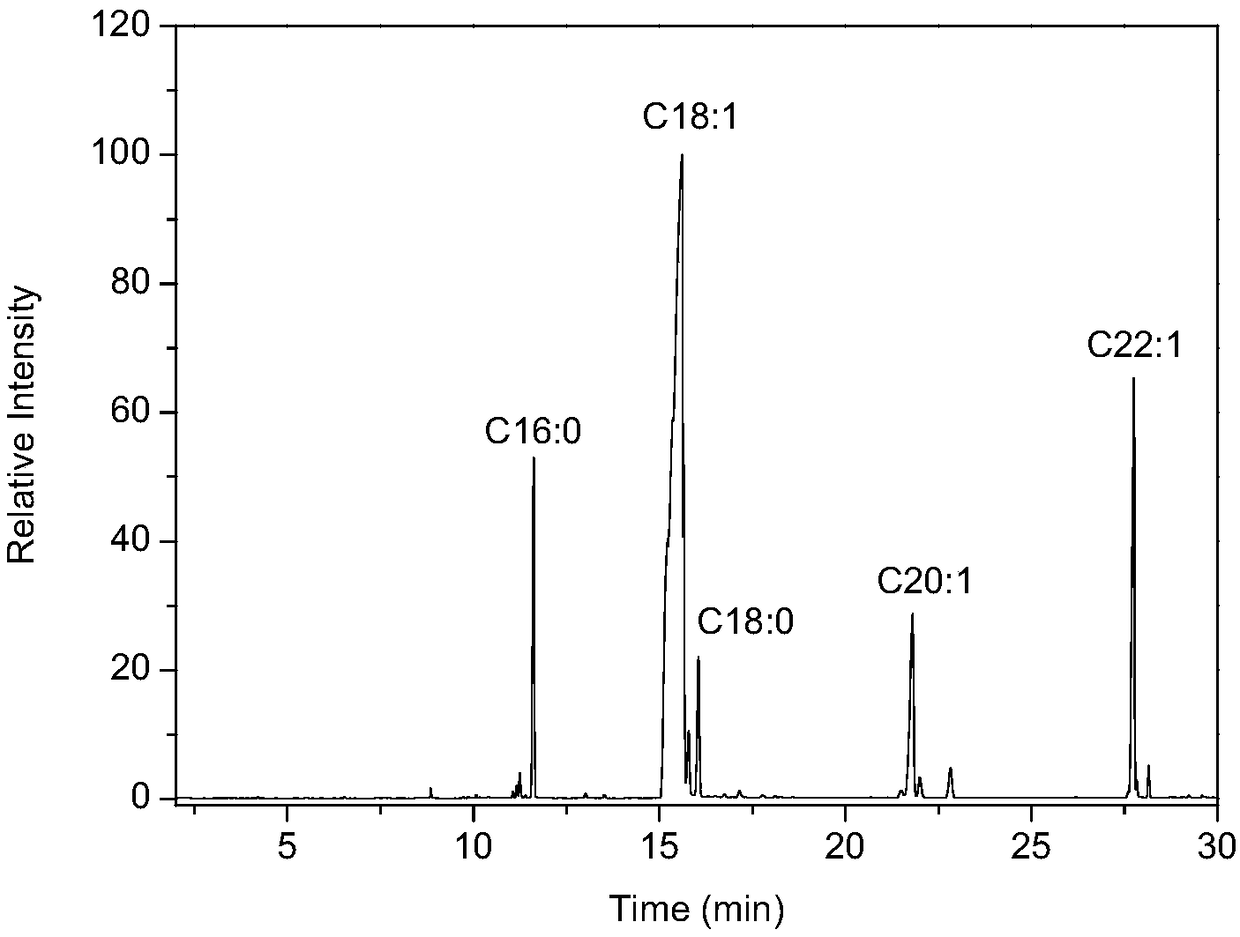

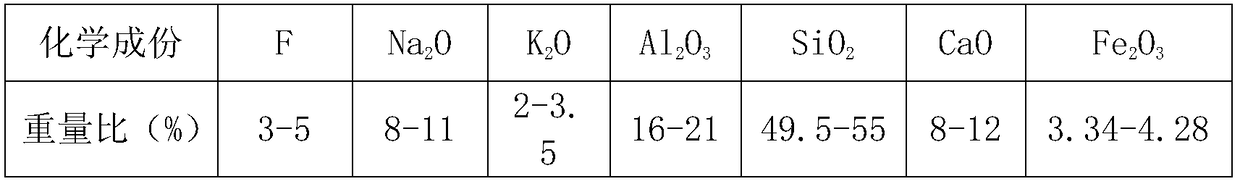

Low temperature synthesis method of kaliophilite catalyst used for preparation of biodiesel

ActiveCN109012646AReduce energy consumptionSynthesis temperature is lowPhysical/chemical process catalystsFatty acid esterificationBiodieselSynthesis methods

The invention discloses a low temperature synthesis method of a kaliophilite catalyst used for preparation of biodiesel and application of the kaliophilite catalyst to preparation of biodiesel. The preparation method comprises the following steps: mixing circulating fluidized bed fly ash, potash water glass and potassium hydroxide at the mass ratio of 1: 0.350-0.656: 0.112, directly synthesizing bulk kaliophilite through processes of moulding, maintenance, hydrothermal crystallization and the like, crushing the bulk kaliophilite, and screening bulk kaliophilite particles with particle size being 0.150-0.315 mm so as to obtain the catalyst for biodiesel. The catalyst has advantages of low reaction temperature, high catalytic activity, easy separation of products, high yield and the like, and has a potential industrial application prospect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Mineral based fillers used as a substitute for wood fillers in simulated wood products and simulated wood products containing the same

ActiveUS20130253098A1Competitive priceReduce moisture contentOther chemical processesNepheliniteNepheline syenite

A simulated wood product such as decking, fencing and architectural trim of the type heretofore made from a plastic with a natural wood powder as filler, wherein at least most, if not all, of the wood powder is replaced by a powder formed from a hard naturally occurring mineral, such as nepheline syenite or feldspar.

Owner:COVIA HLDG CORP

Method of preparing glass-ceramic with nepheline tailings being main raw material

PendingCN108821599AEfficient preparationImprove wear resistanceAdditional valuesCompressive strength

The invention discloses a method of preparing glass-ceramic with nepheline tailings being main raw material. The method includes: 1) raw material selection; 2) raw material mixing; 3) fusion of mixedraw material; 4) calendering shaping; 5) annealing; 6) crystallization. The glass-ceramic is 500-550 MPa in compressive strength and is 80-100 MPa in bending strength. The method can be used for preparing the high-additional value glass-ceramic with the nepheline tailings.

Owner:四川一名微晶科技股份有限公司

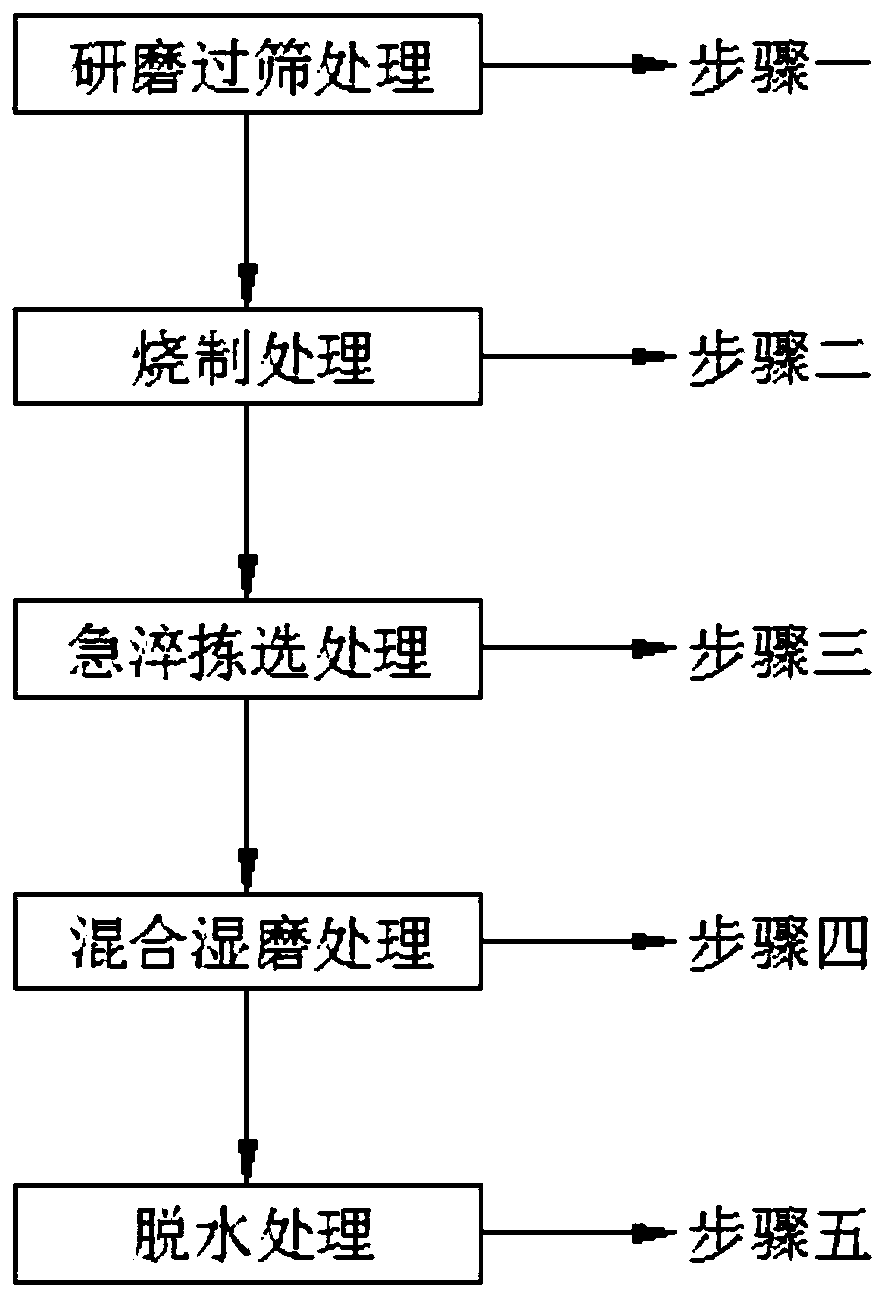

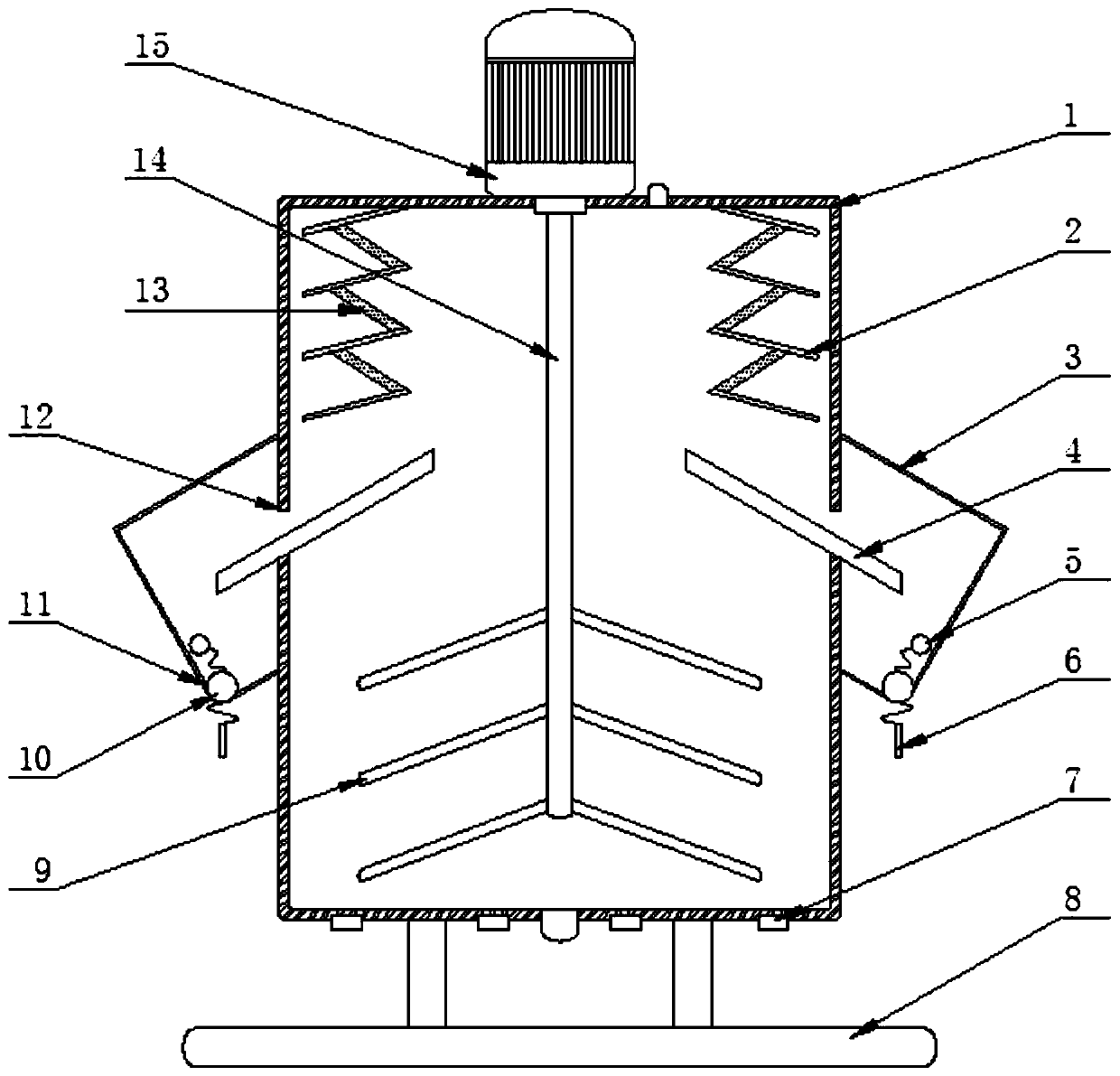

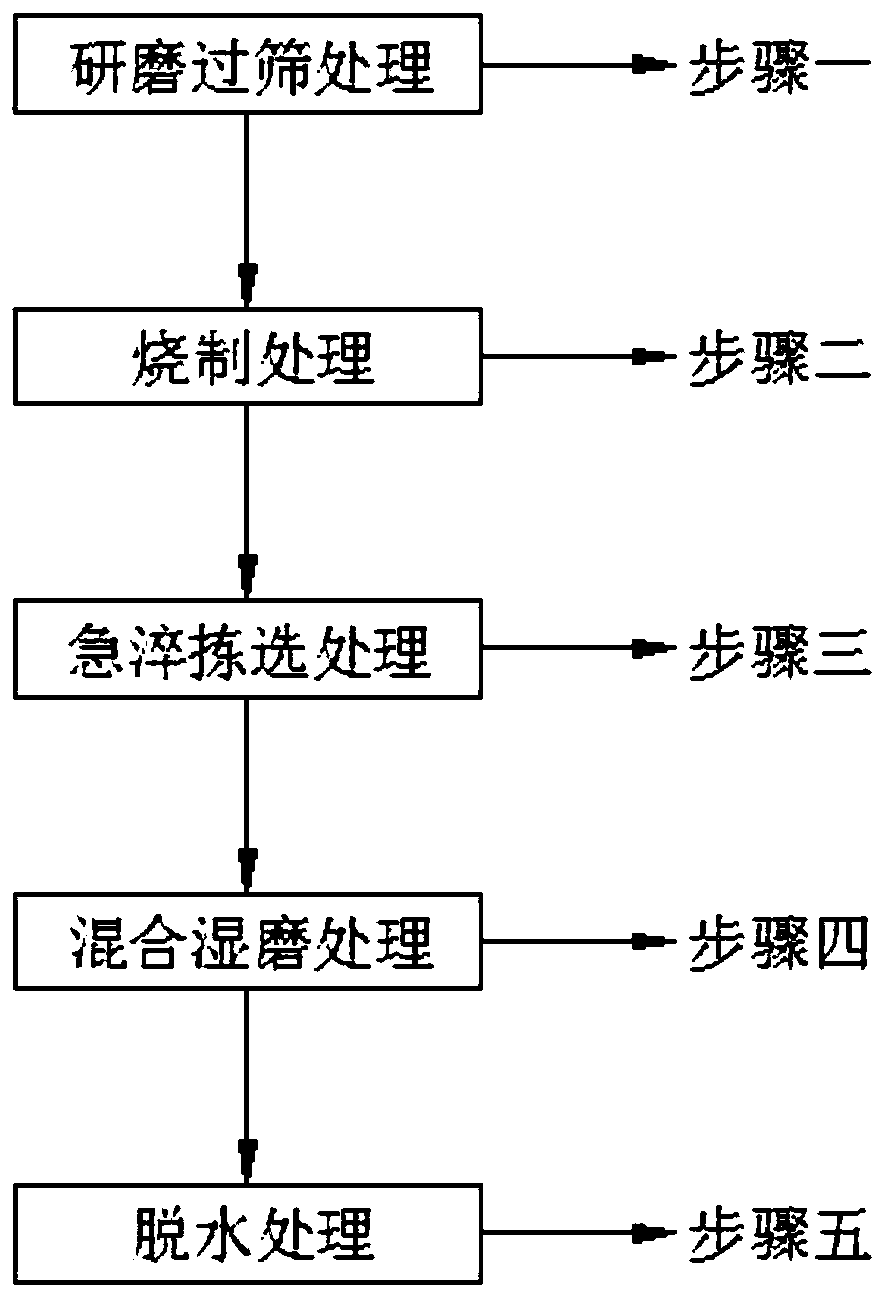

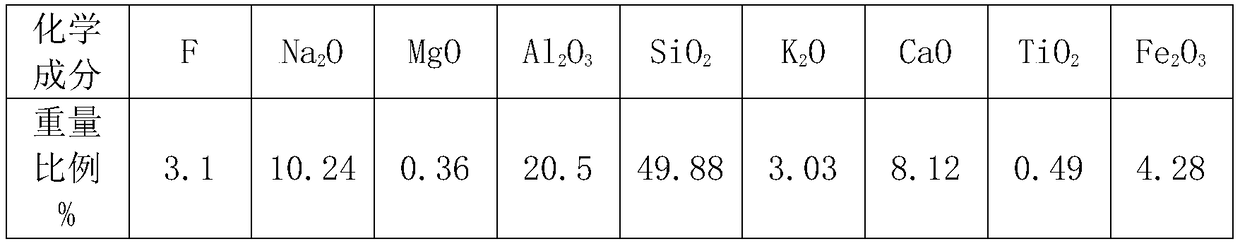

Nepheline syenite powder and production method thereof

ActiveCN103274763BHigh purityEnsuring particle size distribution rangeThermal expansionSilicon dioxide

The invention discloses nepheline syenite powder. The nepheline syenite powder comprises the following chemical components in parts by weight: 55-59 parts of silicon dioxide, 23-25 parts of aluminium oxide, 5.4-6.6 parts of potassium oxide, 9.5-10.5 parts of sodium oxide and 0.05-0.18 part of iron oxide. The produced product purity is high through adopting a double-level segmentation grinding, segmentation different magnetic field intensity multi-stage magnetic separator iron removal and segmentation multi-stage swirler classification purification technology, wherein the weight content of magnetic materials is less than 0.02%, the weight content of titanium dioxide is less than 0.01%, the weight content of the iron oxide is less than 0.18%, and the weight content sum of the potassium oxide and the sodium oxide is above 13.9%. The linear thermal expansion coefficient of the nepheline syenite powder is more than 9.1*10<-6> / DEG C, the limited internal exposure index IRa of radionuclide is not more than 0.80, and the external irradiation index Igamma is not more than 1.00; and the nepheline syenite powder is used for high-end ceramic glaze materials and can be substituted for imported products.

Owner:广东奥胜新材料有限公司

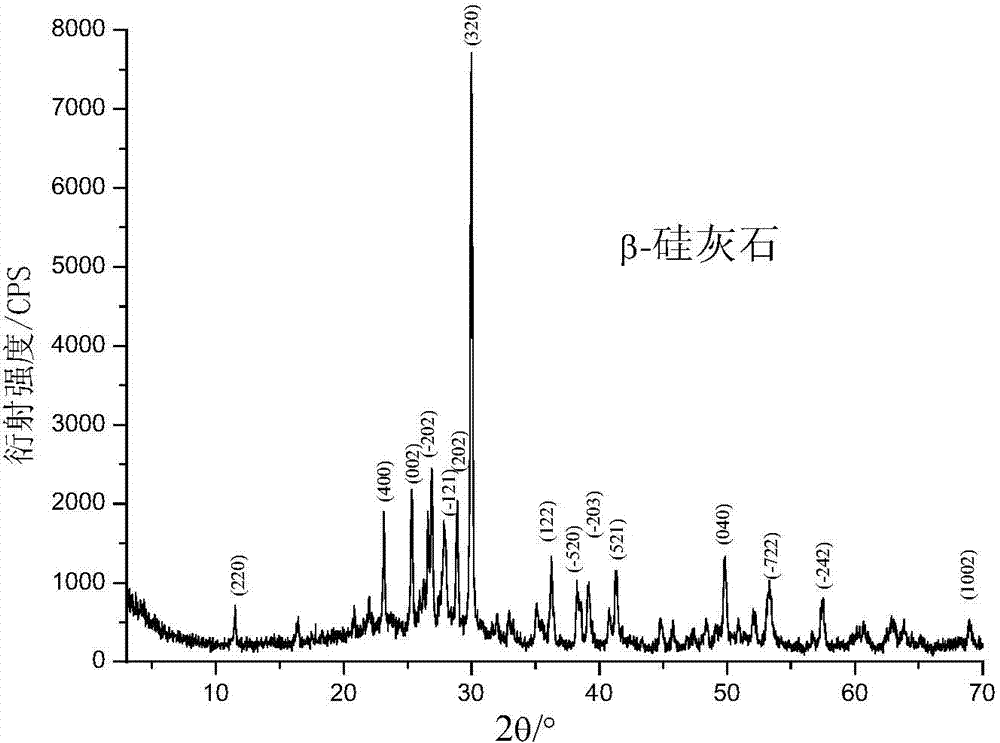

A process for producing beta-wollastonite glass-ceramic by utilizing calcium silicate tailings

The invention relates to a process for producing beta-aedelforsite microcrystalline glass by using calcium silicate tailings. The process comprises a basic glass preparation process and a basic glass thermal treatment process. The process comprises the following steps: performing uniform ball milling on calcium silicate tailings, nepheline syenite, quartz sand and borax, melting the mixed powder at 1,300-1,500 DEG C for 2-5 hours to obtain glass metal, and pouring the glass metal into cold water to obtain basic glass particles; drying the basic glass particles, performing ball milling to obtain basic glass powder, and placing the basic glass powder into a steel die for pressure molding; nucleating a pressed blank at 500-900 DEG C for 30-120 minutes, and crystalizing at 500-1,200 DEG C for 30-150 minutes to obtain the beta-aedelforsite microcrystalline glass having a good decorating function. The process is wide in raw material source, and plays a good role in protecting the environment. The problem of emission of tailings in a process for extracting potassium from water-insoluble kali salt and the non-conventional process for extracting aluminum from aluminum-containing raw materials is solved effectively. Moreover, the process flow is simple, the production performance is excellent, and the additional value is high.

Owner:昊青薪材(北京)技术有限公司

Technique for preparing agricultural potassium sulfate by utilizing kaliophilite powder

ActiveCN102167365BSimple processMild reaction conditionsSilicaAluminium silicatesEvaporationDistilled water

Owner:SHAANXI DAQIN POTASSIUM CO LTD

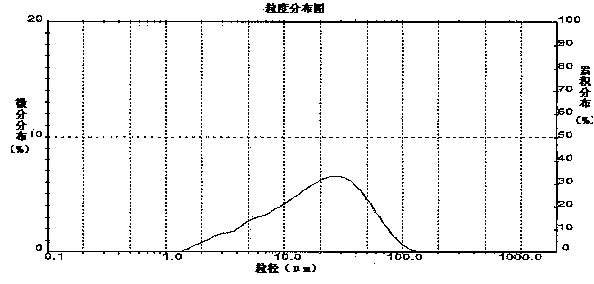

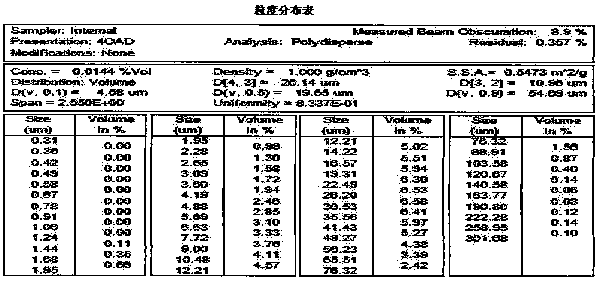

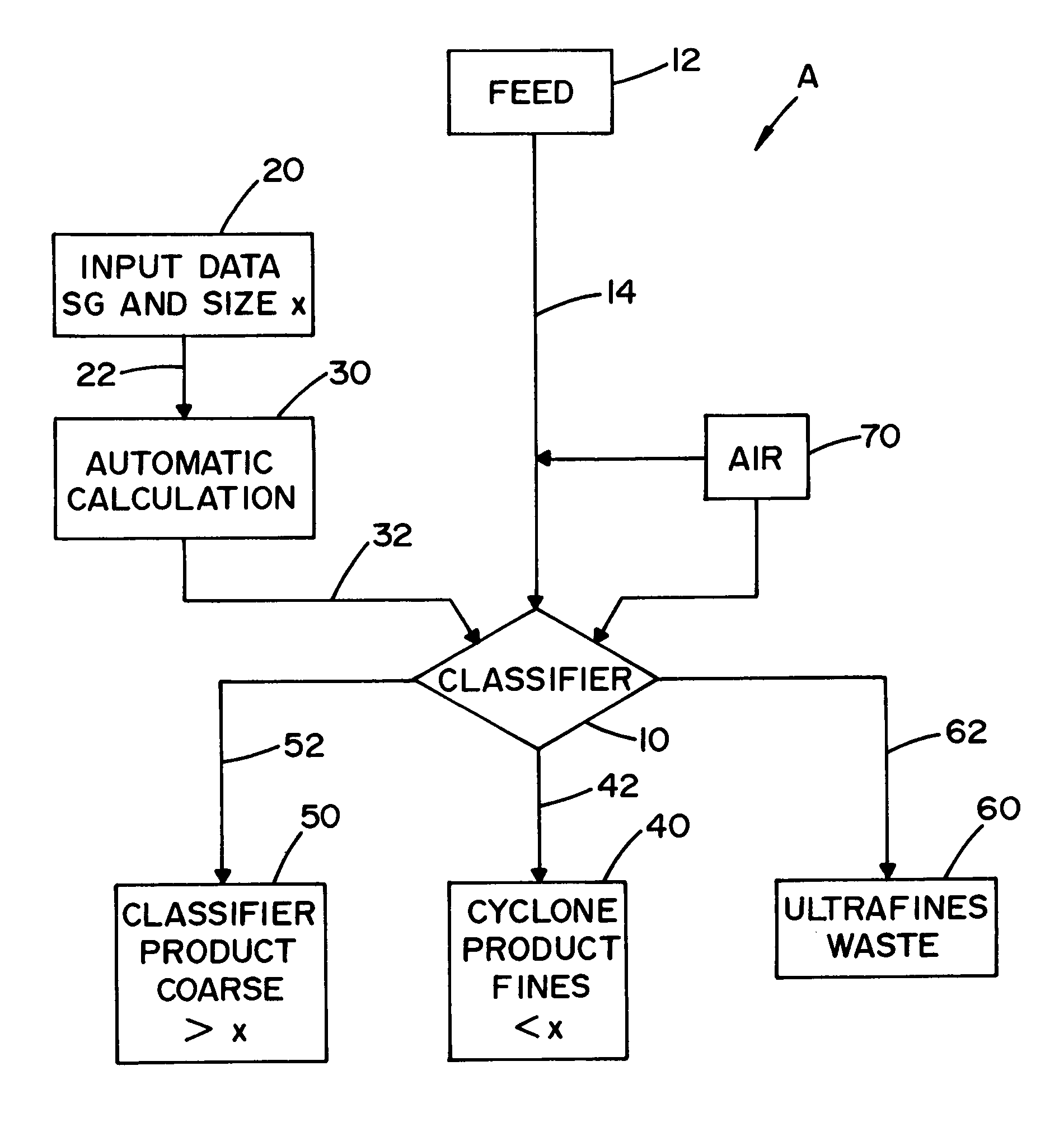

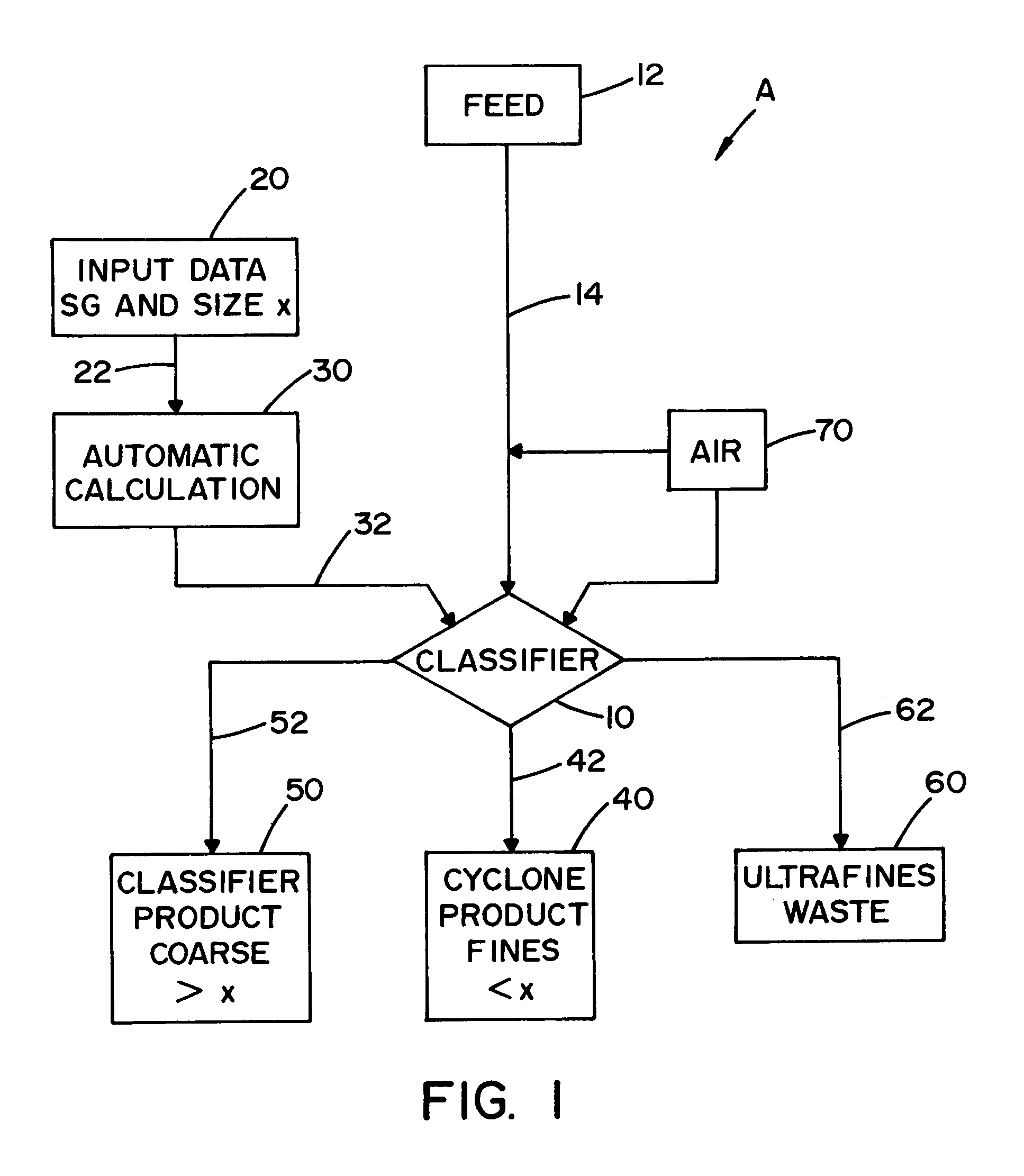

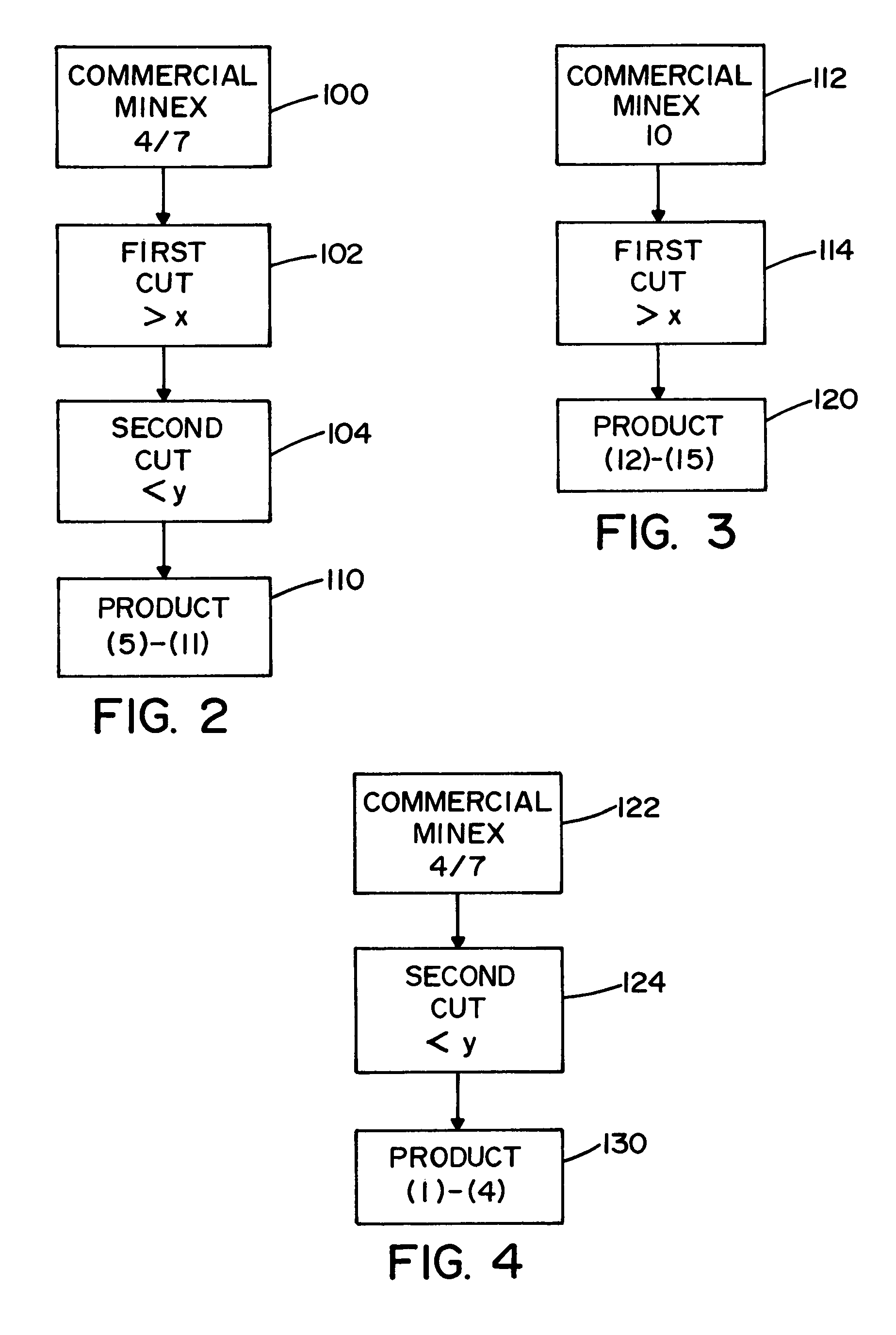

Nepheline syenite powder with controlled particle size and novel method of making same

ActiveUS9034096B2Reduce wearReduce glossOther chemical processesSolid separationUltra finePre treatment

An ultra-fine nepheline syenite powder produced from a pre-processed nepheline syenite powder feedstock. The powder having a “controlled” maximum grain size D95 or D99 of less than about 20 microns and a “controlled” minimum grain size D5 in the range of 2-8 microns with a particle size spread D5-D95 of less than about 12 microns.

Owner:COVIA HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com