Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389 results about "Naphthalanic oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultralight high-elastic rubber sole material and preparation method thereof

InactiveCN103205026AIncrease elasticityImprove bending resistanceSolesSpecific gravityButadiene-styrene rubber

The invention discloses an ultralight high-elastic rubber sole material and a preparation method thereof. The ultralight high-elastic rubber sole material comprises the following raw materials in parts by weight: 40-60 parts of natural rubber, 30-40 parts of synthetic rubber, 10-20 parts of SEBS (Styrene-Butadiene-Styrene Block Copolymer) rubber, 10-20 parts of synthetic EVA (Ethylene Vinyl-Acetate Copolymer), 30-40 parts of ultralight white carbon black, 6-10 parts of naphthenic oil, 3-5 parts of high-activity zinc oxide, 3-5 parts of activating agents, 2-3 parts of vulcanization accelerators, 1-2 parts of stearic acid, 2-3 parts of diethylene glycol and 1-3 parts of anti-aging agents. The preparation method of the ultralight high-elastic rubber sole material comprises four steps. The ultralight high-elastic sole rubber prepared through the method disclosed by the invention has the advantages of scientificity in formula, low cost, simple preparation process and lighter specific gravity of the sole material and effectively enhances the elasticity and bending resistant degree of a sole.

Owner:南平市天时雨投资合伙企业(有限合伙)

Butadiene styrene rubber foaming plate and preparation thereof

The invention relates to a butadien styene rubber foamed sheet and preparation method. The butadien styene rubber foamed sheet comprises(by weight parts): the total sum of butadien styene rubber, natural rubber and polybutadiene being 100 parts, filler 70-180 parts, black factice or white factice 10-20 parts, naphthenic oil 20-60 parts, black carbon or carbon white 0-25 parts, olefin 1-4 parts, foaming agent 10-20 parts, blowing promoter2-8 parts, sulfur 0.5-3 parts, promoter 0.2-3 parts, antiager 1-4 parts, dispersant 1-4 parts, white titanium pigment 0-15 parts. The method comprises: raw roll milling, pressure type milling by preliminary refiner, milling by roll mixer, extruding by extruder, once foaming and sulphurizing, second foaming and sulphurizing, cooling. The butadien styene rubbr foamed sheet has good elasticity, high extension percentage, high intension, small compression permanent set, antifriction and limited slip, good damping effect, innocuity and vapidness, low price.

Owner:常州美利晟高分子科技有限公司

Heat-conduction and electric-conduction hot melt glue and preparation method thereof

InactiveCN103540280AGood compatibilityReduce the amount addedNon-macromolecular adhesive additivesElectrically-conducting adhesivesThermoplasticPolymer science

The invention relates to a heat-conduction and electric-conduction hot melt glue and a preparation method thereof. The hot melt glue is high in heat-conduction and electric-conduction properties under a precondition that the elasticity and bonding strength of the original hot melt glue; the heat conduction coefficient reaches more than 2.0w / m.k. According to the hot melt glue, base materials comprise styrene thermoplastic elastomers (SEBS) and styrene-butadiene-styrene thermoplastic elastomers (ESBS) modified by epoxidation; a thickening agent comprises two of hydrogenated rosin, terpene resin and C9 petroleum resin; a filler is graphene solid powder with heat-conduction and electric-conduction functions; the addition amount of the base materials accounts for 30-40%; the addition amount of thickening resin accounts for 30-50%; the addition amount of the solid graphene powder accounts for 1.5-3.5%; the addition amount of the other accessory ingredient naphthenic oil accounts for 15-18%; the addition amount of an antioxidant accounts for 1-2%; the heat-conduction and electric-conduction hot melt glue is prepared from the components of the hot melt glue through a melt blending method.

Owner:SHENYANG JIANZHU UNIVERSITY

Thermoplastic elastomer toughened epoxy resin, its preparation and its application

ActiveCN102516717AAdjustable elasticAdjustable plasticityOther chemical processesAnti-corrosive paintsElastomerPolymer science

The invention relates to a thermoplastic elastomer toughened epoxy resin, its preparation and its application, which belongs to the technical field of changing the physical index of epoxy resin. The raw materials possess the following weight proportion: 1) 100 parts of epoxy resin, 2) 15-40 parts of curing agent, 3) 2-20 parts of thermoplastic elastomer, 4) 5-100 parts of compatilizer and 0.5-5 parts of auxiliary agent; the compatilizer employs one or more selected from rosin and modified rosin, petroleum resin, coumarone indene resin, aromatic oil, naphthenic oil and solvent oil, the auxiliary agent employs one or more selected from calcium stearate, zine stearate and EBS. The method of the invention solves the compatibility of the thermoplastic elastomer and epoxy resin, and effectively improves the brittleness of epoxy resin, the property of a solidified substrate is capable of adjusting, and the manufacturability is capable of adjusting; the product of the invention has the advantages of environmental protection, good security and good economic applicability.

Owner:云南交投集团公路建设有限公司 +1

Synthetic resin and preparation method as well as application thereof

InactiveCN102174217AHigh molecular weightHigh softening pointBuilding insulationsPolyesterPentaerythritol

The invention provides a synthetic resin composition which consists of the following components in percentage by weight: 35 percent of component A and 65 percent of component B, wherein the component A is formed by polymerizing the following monomers in parts by weight: 20 parts of polyethylene, 20 parts of polypropylene, 15 parts of polyester, 8 parts of nylon, 10 parts of phthalic anhydride and 4 parts of pentaerythritol; and the component B is prepared from the following raw materials in parts by weight: 20 parts of pine tar, 8 parts of naphthenic oil, 10 parts of coumarone indene resin, 5 parts of 420 resin and 57 parts of rubber powder. In the resin composition, high molecular material waste can be effectively utilized and changed into things of value, and environmental pollution can be reduced. The invention also provides a preparation method and application of the resin composition.

Owner:方先明

Rubber composition

InactiveUS6939910B2Good loss characteristicHigh breaking strengthSpecial tyresPolymer scienceWear resistance

This invention provides a rubber composition comprising: a softening agent including a hydrogenated naphthenic oil of which an extract quantity of dimethylsulfoxide (DMSO) by IP 346 method is controlled to less than 3% by weight and blending at least one selected from a group of (1) a styrene-butadiene copolymer rubber with a bond styrene quantity in molecular of from 10% by weight to 60% by weight and with a vinyl bond quantity of the butadiene part of from 10% to 80% and (2) a butadiene rubber with a cis bond quantity of at least 30%. The rubber composition is superior in fracture characteristics, loss characteristic and wear resistance, and it is applicable to various rubber products, a pneumatic tire and, in particular, a tire tread.

Owner:BRIDGESTONE CORP

Compounded rubber racetrack and its processing method

The composite rubber runway is produced with styrene-butadiene rubber, EPDM, natural rubber, silica white, pot clay, stearic acid, spindle oil, naphthenic oil, antioxidant, ultraviolet absorbent, nano particle and promoter, and through weighing materials, cutting rubber materials, mixing, milling, calendering, kneading, sulfurizing in sulfurizing machine, sulfurizing and foaming in tunnel stove, washing, trimming and polishing. The present invention has excellent resilience, toughness and damping effect; is wear resistant, antiaging and ultraviolet resistant, and may be all-weather used.

Owner:绿茵天地体育产业股份有限公司

EPT rubber waterproofing paint and process for preparing the same

InactiveCN101113262AImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsVertical planePolymer science

The invention relates to an epdm rubber waterproof coating and a preparation method thereof. The total weight portions of dry raw material component of the waterproof coating are: epdm rubber 5-7, chlorinated polyethylene 10-15, reclaimed rubber 20-25, coumarone resin 2-3, naphthenic oil 5-10, carbon black 5-8, zinc oxide 0.5-0.7, stearic acid 0.1-0.3, sulfur 0.4-0.6, accelerator 0.5-0.9 and antioxidant 1-3. The waterproof coating adopts epdm rubber, reclaimed rubber and chlorinated polyethylene as film forming main bodies and also various modified promoter and fillings, which results in that the waterproof coating not only has excellent waterproof, ageing and cold resistance, but also has the advantages of convenient construction and low cost, and the components and construction thereof meet the requirements of national environmental standards. The invention has simple preparation process steps, is convenient to be widely industrially produced, and the store property and life service of the waterproof coating obtained is greatly prolonged. The waterproof coating can be widely applied to the waterproof construction in building, engineering, vertical plane and various waterproof datum planes.

Owner:北京立高科技股份有限公司

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

Industrial production method for ethylene propylene diene rubber molded sealed cell sponge rubber

ActiveCN101724172AProduction conditions are easy to controlStable productionPolymer scienceFoaming agent

The invention discloses an industrial production method for ethylene propylene diene rubber molded sealed cell sponge rubber and, relates to an industrial preparation method for a foaming material with a high foaming ratio. The method comprises the following steps of performing plastication, mixing, refining, and foaming and vulcanization molding on raw rubber, and is characterized in that carbon black, naphthenic oil, a blowing promoter, a vulcanization accelerator and an anti-aging agent are added in the mixing process to perform the mixing; a foaming agent Ac and a vulcanizing agent are added in the refining process to perform the refining; and the vulcanization conditions in the foaming and vulcanization molding process are that: the pressure is 15 to 20 MPa; the temperature is 160 to 180 DEG C; and the vulcanizing time is 3,000 to 3,500 seconds. The industrial production method is researched and developed based on market demands to turn laboratory researches to industrialized researches, ensure that the production condition can be controllable and the production process is stable. The industrial production method selects homemade rubber masses, selects the foaming agent Ac to replace the foaming agent H, and prepares an EPDM molded sponge rubber product in accordance with the requirements on the industrial production by adjusting the mixture ratio of various auxiliary agents in a formula and controlling process conditions.

Owner:连云港冠泰汽车配件有限公司

Stripping resistant self-adhered polymer modified asphalt membrane at low temperature and preparation method thereof

ActiveCN105419357AImproved viscosity retention at low temperaturesGood low temperature peeling resistanceSynthetic resin layered productsConstructions elementsPolymer modifiedAntioxidant

The invention provides a stripping resistant self-adhered polymer modified asphalt membrane at low temperature and a preparation method thereof. The modified asphalt membrane comprises a surface material, a modified asphalt layer and an isolating membrane. The thickness of the modified asphalt layer is 1.5mm. The modified asphalt layer is prepared from the following raw material components: petroleum asphalt, naphthenic oil, thermoplastic styrene-butadiene rubber, styrene-isoprene-styrene, styrene-butadiene rubber powder, coumarone resin, C5 hydrocarbon resin, terpene resin, an ultraviolet light absorber, an antioxidant, a silane coupling agent and light calcium carbonate. The stripping resistant self-adhered polymer modified asphalt membrane provided by the invention is good in stripping resistance at low temperature, good in holding power at low temperature, and the self-adhered construction at low temperature is realized.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Method for modifying waste rubber-adhesive powder and producing composite rubber waterproof curling material

The invention is concerned with waste rubber-rubber powder modifying, complex rubber waterproof rolled sheet made by the modified waste rubber-rubber powder and method. It is a comprehensive using for waste and old rubber. Step A is refining the modified rubber powder. Crush the waste and old rubber goods, remove impurity and take the part with over and equal to 40 mesh as fine rubber powder, then mix 100 fine rubber powder, 8 to 12 plasticizer and 0.5 to 1 modifier into fine mixing rubber powder, and modify the fine mixing rubber powder into highly shearing machine with 120+-5 degree. Step B is preparing the vulcanization rubber piece. The stuff is 100 synthetic rubber, 25 to 50 fine modified rubber powder, 2 to 8 zinc oxide, 0.5 to 2 accelerant M, 0.5 to 1.5 accelerant TT, 1 to 3 sulfur, 20 to 40 naphthene oil, 1 to 2 antioxidant A, 20 to 60 calcium carbonate, 40 to 80 carbon black. Mix and refine the synthetic rubber and fine modified rubber powder with the said stuff, except sulfidizing agent and accelerant. Add sulfidizing agent and accelerant with 80 to 90 degree and stop for 24 hours, and after refining again to get the molding piece. Step C is the production of un-vulcanization rubber piece. Mix and refine 100 butyl rubber, 8 to 10 polyisobutylene, 5 to 12 phenolic resin, 3 to 6 petroleum resin, 2 to 5 sodium oleate, 60 to 80 calcium carbonate and at 60 to 70 degree refine the mixture for 20 minutes again, then press or extrude the piece. Step D is complex vulcanization. Carry complex vulcanization on drum vulcanization machine to the vulcanization rubber piece without vulcanization and un-vulcanization rubber piece under the condition of 6 to 8 Mpa press to get the complex rubber waterproof rolled sheet. It uses for the waterproof layer to the underground building with high intention and extending nature, good dynamic capability.

Owner:天津市腾祥科技发展有限公司

Asphalt cold repairing binding material and its production process

InactiveCN1441004AImprove featuresGood compatibilityIn situ pavingsBuilding insulationsKeroseneRoad surface

The present invention relates to a kind of asphalt road cold repairing material. It is prepared with ehavy oil, C5 or C9 petroleum resin, C1-C10 solvent oil, styrene-butadiene rubber, diesel oil or kerosene or gasoline, thermoplastic styrene-butadiene rubber, naphthenic oil, RC-10 mineral oil and road petroleum asphalt. The preparation process includes preparing prepolymer A with heavy oil and petroleum resin; preparing prepolymer B with solvent oil and styrene-butadiene rubber; preparing prepolymer C with diesel oil or kerosene or gasoline, thermoplastic styrene-butadiene rubber and naphthenic oil; preparing cold repairing asphalt additive with prepolymer A, prepolymer B, prepolymer C and RC-10 mineral oil; and adding road petroleum asphalt.

Owner:袁永长

Elastomeric Compositions Comprising Hydrocarbon Polymer Additives Having Improved Impermeability

An elastomeric compositions having improved impermeability is disclosed. The cured elastomeric composition may comprise at least one C4-C7 monoolefin elastomer, a hydrocarbon polymer additive, and a clay. In some embodiments, the cured elastomeric composition has a permeation coefficient at 40° C. of 90 cc*mm / (m2-day) or less. In some embodiments, the elastomeric composition is substantially free of naphthenic oil.

Owner:EXXONMOBIL CHEM PAT INC

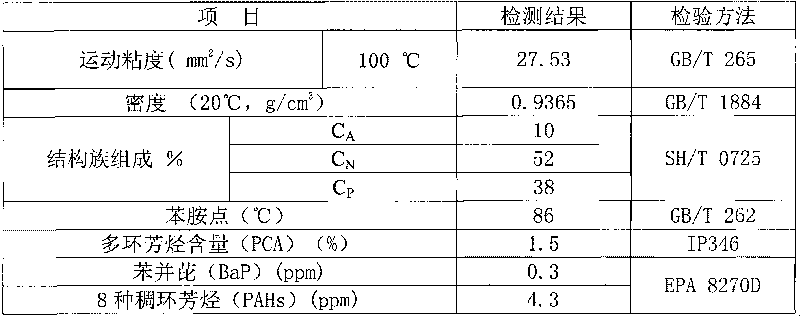

Blending-process method for producing environment-friendly rubber oil

ActiveCN101691427AImprove wet skid resistanceHigh aromatic contentTreatment with plural serial refining stagesResidual oilSolvent

The invention discloses a blending-process method for producing environment-friendly rubber oil. The method provided by the invention comprises the following steps: 1) performing solvent extraction on reduced-pressure residual oil to obtain deasphalted oil, wherein a solvent used for extraction is propane; the volume ratio of the solvent to the reduced-pressure residual oil is (6-8):1; and extraction conditions are tower-top temperature between 70 and 91 DEG C, tower-bottom temperature between 57 and 80 DEG C and pressure between 3.8 and 7.0 MPa; 2) performing solvent extraction on the deasphalted oil obtained in a step 1) to obtain heavy deasphalted oil, wherein the solvent used for extraction is propane; the volume ratio of the solvent to the deasphalted oil is (6-8):1; and the extraction conditions are tower-top temperature between 60and 80 DEG C, tower-bottom temperature between 50 and 70 DEG C and pressure between 2.8 and 3.9 MPa; and 3) mixing the heavy deasphalted oil obtained in a step 2) with naphthenic oil at a temperature between 70 and 90 DEG C for 30 to 120 minutes to obtain the environment-friendly rubber oil, wherein the mass ratio of the heavy deasphalted oil to the naphthenic oil is (0.3-0.7):(0.7-0.3). The environment-friendly rubber oil has the advantage of meeting the requirements of EU 2005 / 69 / EC environment-protecting directives, along with aromatic-carbon rate between 10 and 20 percent, PCA content of less than 3 percent, high aromatic hydrocarbon content, environment-protecting property, no toxicity and no carcinogenic effects. The environment-friendly rubber oil can be used as a substitute for the prior aromatic oil, and has significant economic value.

Owner:CHINA NAT OFFSHORE OIL CORP +2

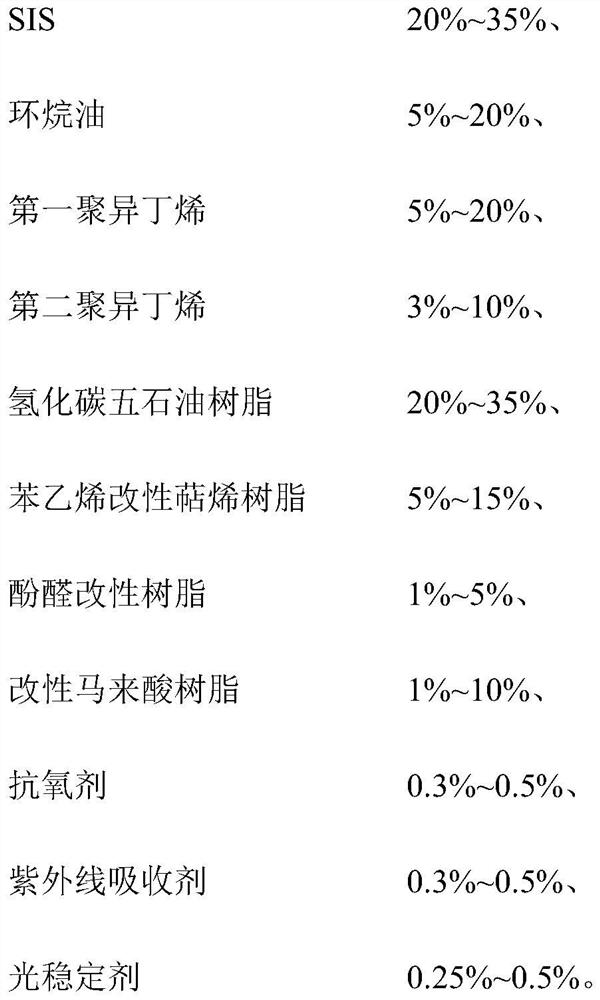

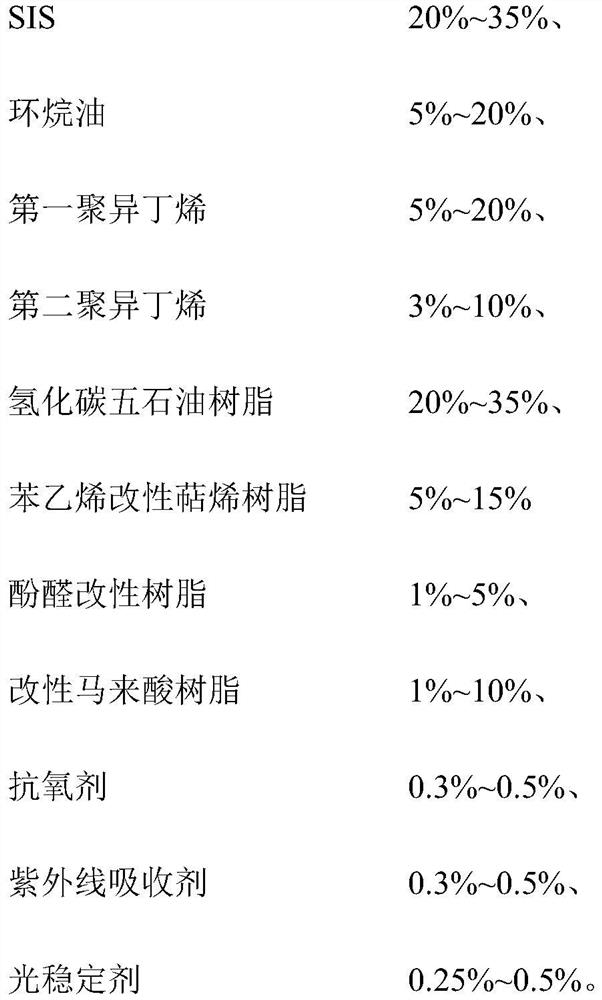

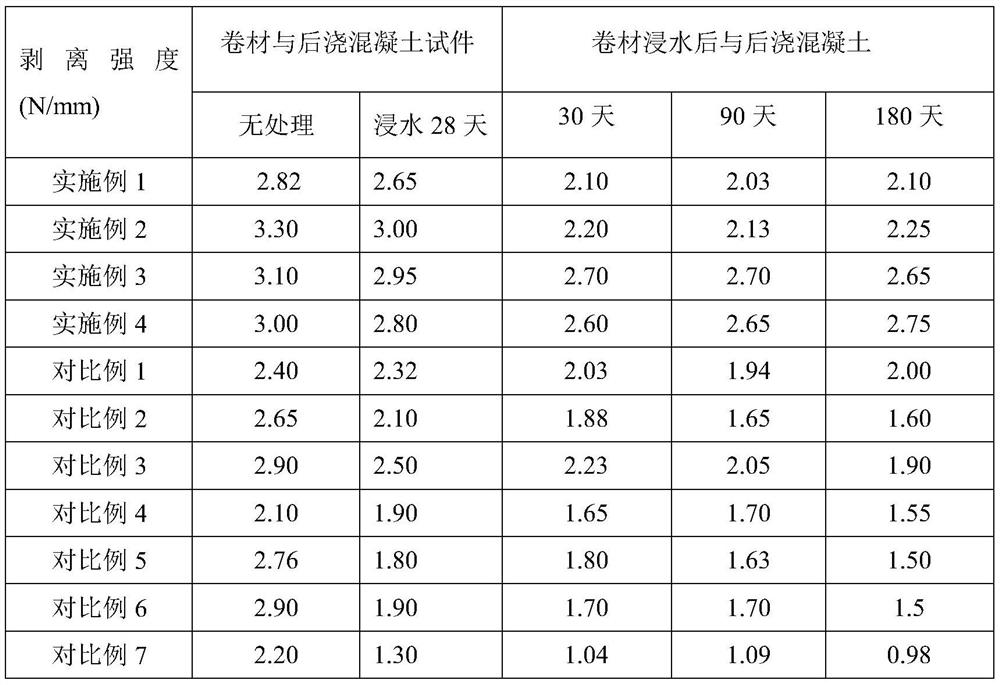

Non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and preparation method of non-asphalt-based pre-paved waterproof coiled material

ActiveCN112852359ALow water absorptionIncrease wetting angleMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceHydrolysate

The invention provides a non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and a preparation method thereof. The non-asphalt-based pre-paved waterproof coiled material comprises a polymer sheet layer, a polar hot-melt pressure-sensitive adhesive layer and a strong-hydrophobicity isolation sand layer, and the polar hot-melt pressure-sensitive adhesive comprises the following raw materials: SIS, naphthenic oil, first polyisobutene, second polyisobutene, hydrogenated C5 petroleum resin, styrene modified terpene resin, phenolic modified resin, modified maleic resin, an antioxidant, an ultraviolet light absorber and a light stabilizer. The high-hydrophobicity isolation sand is inorganic mineral particles treated by coupling agent hydrolysate. The prepared non-asphalt-based pre-paved waterproof coiled material has the characteristic of excellent water soaking resistance, after being soaked in water for 180 days, the isolation sand covered on the coiled material is still not easy to fall off, and the bonding surface at the lap joint can still keep a good bonding state, so that the good construction application performance of the coiled material is ensured.

Owner:江苏雨中情防水材料有限责任公司

Novel thermoplastic elastomer composite self-adhesion sport field paving coiled material and manufacture process thereof

The invention relates to a novel thermoplastic elastomer composite self-adhesion sport field paving coiled material. The coiled material comprises a main body layer made of thermoplastic elastomer, wherein a creep deformation self-adhesion layer is arranged on the bottom surface of the main body layer, and the thermoplastic elastomer is prepared by blending and modifying ethylene propylene diene monomer rubber and polyolefin resin. The manufacture process comprises the steps of: blending the ethylene propylene diene monomer rubber, the polyolefin resin and naphthenic oil in proportion, and carrying out twin-screw extrusion, so as to obtain the thermoplastic elastomer; adding an assistant agent and the naphthenic oil, heating and carrying out high-speed stirring and blending, carrying out compound extrusion by utilizing a pin extruder, then carrying out knurling, overlap edge profiling, microwave foaming, vulcanizing and double-roll gluing, and carrying out crimping to prepare the novel thermoplastic elastomer composite self-adhesion paving coiled material after cooling. According to the novel thermoplastic elastomer composite self-adhesion sport field paving coiled material, the shortage of the prior art can be improved, the performance index of the product is improved, and the manufacture process is simple; the controllable thickness is 4-13mm, and the novel thermoplastic elastomer composite self-adhesion sport field paving coiled material is mainly applied to the fields of athletic tracks in sport fields, basketball courts, tennis courts, badminton courts and the like.

Owner:高捷体育股份有限公司

Automobile buffer cushion block rubber preparation raw material and preparation method thereof

The invention belongs to the field of rubber material, and especially relates to an automobile buffer cushion block rubber preparation raw material and a preparation method thereof; the automobile buffer cushion block rubber preparation raw material includes, in parts by weight, 100 parts of a main material, 45-75 parts of carbon black, 3.1-4.9 parts of a vulcanization system, 1-3 parts of a plasticizing activity increasing agent, 4-6 parts of a reinforcement agent, 2-6 parts of an anti-aging agent, 1-3 parts of an internal lubricant, and 5-10 parts of naphthenic oil, wherein the main material includes 70-90 parts of ethylene-propylene-diene monomer, and 10-30 parts of high styrene rubber; the carbon black includes 20-35 parts of carbon black N220 and 25-40 parts of carbon black N550. With adoption of the special raw rubber system, a rubber material with high hardness and good fluidity is prepared; with adoption of the special anti-thermal oxygen aging system, the shortage of the anti-thermal oxygen aging performance of rubber is improved; with adoption of the special raw rubber material and the anti-ozone system, the ozone destruction resistant ability of the rubber is increased; and with adoption of the internal lubrication system, the frictional resistance of the rubber surface is reduced.

Owner:柳州日高汽车减振技术有限责任公司

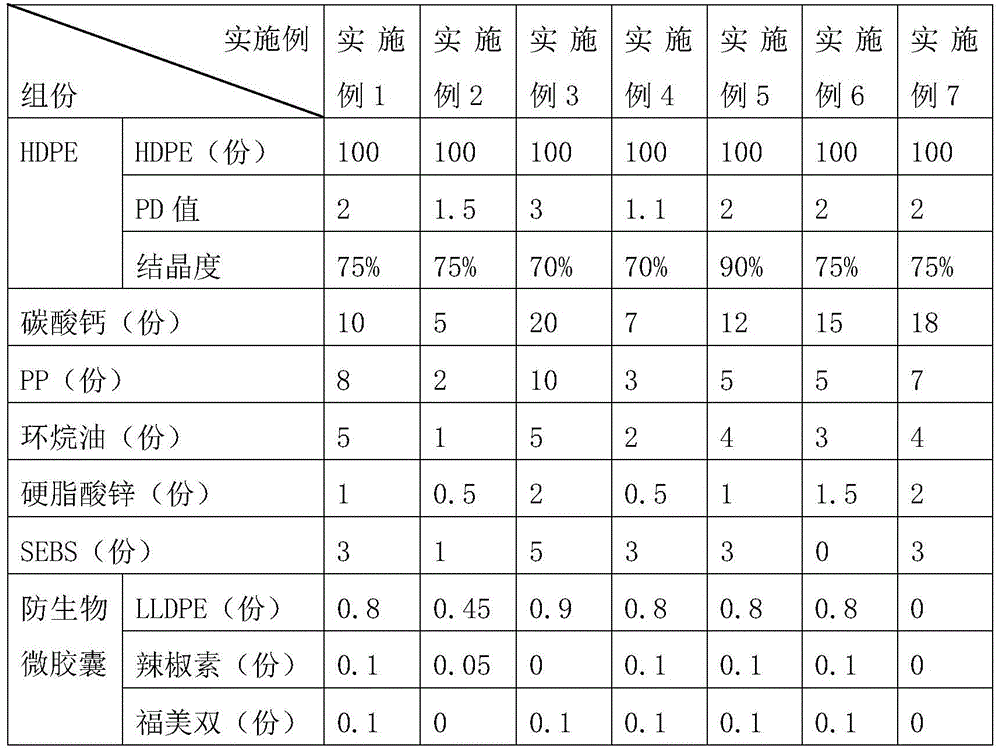

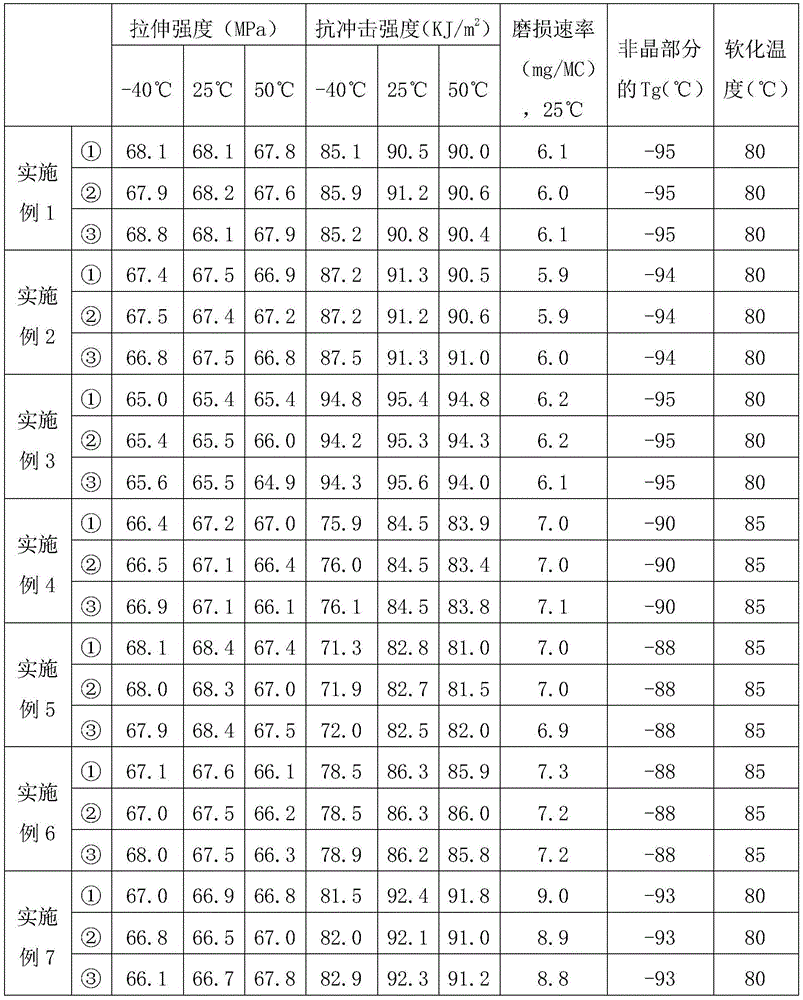

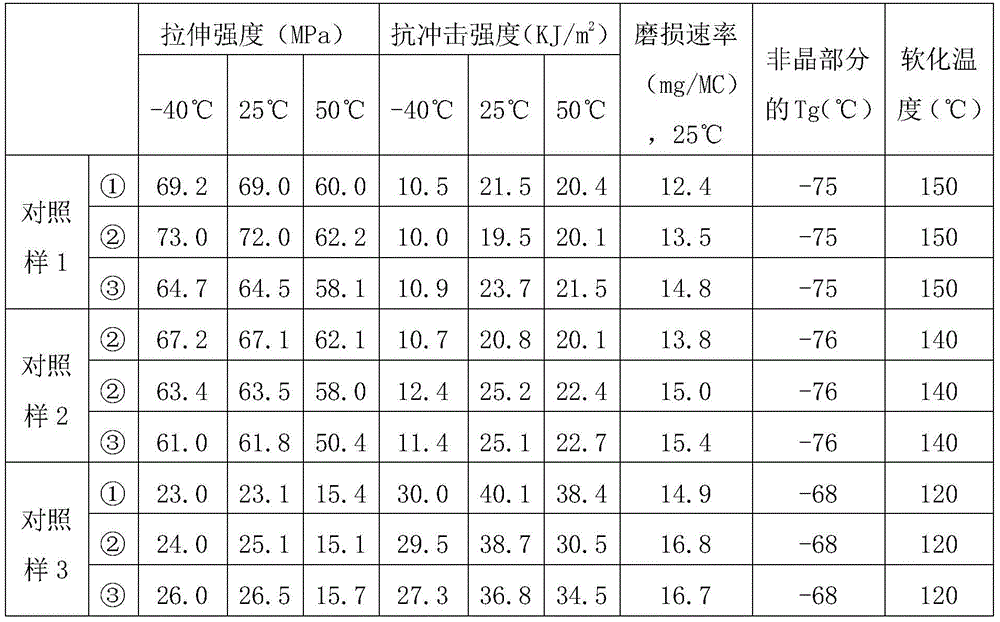

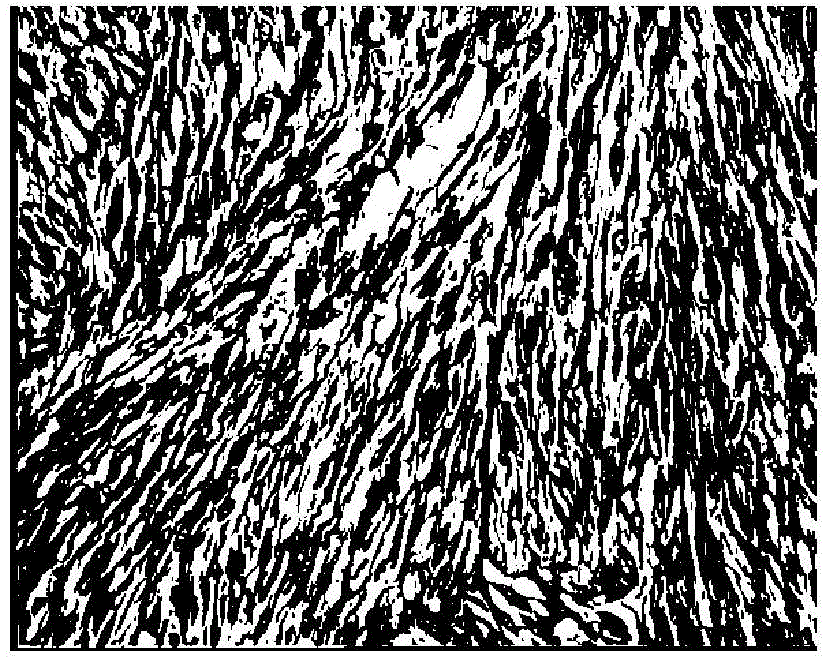

Septic tank special material and preparation method thereof

ActiveCN105542284AImprove processing fluidityImprove toughnessLow-density polyethyleneLinear low-density polyethylene

The invention discloses a septic tank special material with good processing fluidity. The septic tank special material is prepared from the following components in parts by weight: 100 parts of HDPE (high-density polyethylene); 5 to 20 parts of calcium carbonate; 1 to 10 parts of PP (propene polymer); 1 to 5 parts of naphthenic oil; 0.5 to 2 parts of zinc stearate. The invention also discloses a preparation method of the septic tank special material. The preparation method comprises the following steps: S1, mixing the HDPT, the calcium carbonate, the PP, the naphthenic oil, the zinc stearate and the SEBS, softening and fusing; S2, smashing an anti-bio agent and spraying on LLDPE (linear low density polyethylene) flux, and cooling to room temperature, so as to obtain an anti-bio microcapsule; S3, adding the anti-bio capsule obtained in S2 into the fusant of S1, and performing injection molding.

Owner:SHANDONG WENYUAN BUILDING MATERIALS TECH

Pathological tissue transparentizing and dewaxing solution and preparation method thereof

ActiveCN104655460ANo irritating smellWon't become brittlePreparing sample for investigationAlkaneEther

The invention discloses a pathological tissue transparentizing and dewaxing solution and a preparation method thereof. The pathological tissue transparentizing and dewaxing solution comprises 92.5-98 parts by weight of highly branch chain saturated alkane, 0.5-5 parts by weight of a stabilizing agent and 0.1-2.5 parts by weight of synergist, wherein the highly branch chain saturated alkane is one or a mixture of more of naphthenic oil, quadricyclane, cis-1-isopropyl-4-methyl cyclohexane, and contra-1-isopropyl-4-methyl cyclohexane; the stabilizing agent is one or a mixture of more of epoxy soybean oil, trimethylolpropane, and epoxy butyl stearate; the synergist is one or a mixture of more of polyether modified heptamethyltrisiloxane, butyl ether polydimethylsiloxane, and dimethyl-3-hydroxypropyl methyl (siloxane and polysiloxane). The technical problems that a pathological tissue transparentizing and dewaxing solution is toxic and has pungent smell, and tissue becomes brittle and shrinks to be unfavorable for slicing after being soaked in the solution for a long time in the prior art are solved.

Owner:无锡市江原实业技贸有限公司 +1

Water-based non-cured rubber asphalt waterproof paint and production technology thereof

InactiveCN110643283AImprove waterproof qualityImprove creepConjugated diene hydrocarbon coatingsBituminous coatingsPolymer sciencePlasticizer

The invention discloses water-based non-cured rubber asphalt waterproof paint, and relates to the field of waterproof paint. The water-based non-cured rubber asphalt waterproof paint comprises the following components by weight: 2-12 parts of engine oil, 2-20 parts of aromatic oil, 3-7 parts of naphthenic oil, 1-5 parts of SBR, 1-3 parts of SBS, 25-40 parts of asphalt, 1-6 parts of tackifying resin, 0.5-2 parts of a plasticizer, 2-4 parts of an asphalt emulsifier, 30-40 parts of water, 3-10 parts of filler, 0.1-0.5 part of a dispersion agent, 5-25 parts of latex and 1-10 parts of tackifying emulsions. According to the technical scheme, when the water-based non-cured rubber asphalt waterproof paint is adopted for construction, heating is not needed, instantaneous forming is achieved, construction can be conducted on a wet substrate, and the water-based non-cured rubber asphalt waterproof paint has very excellent adhesive strength and self-healing performance, is energy-saving and environmentally friendly, and can improve the comprehensive waterproof quality of a building and can shorten a construction period; and a material has an excellent creep property and excellent stripping quality, adhesion and heat resistance.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Magnetic door seal made of thermoplastic polyolefin materials and for refrigerator and freezer and preparation method thereof

InactiveCN102936368AImprove low temperature resistanceLow environmental impactDomestic cooling apparatusLighting and heating apparatusElastomerPolymer science

The invention provides a magnetic door seal made of thermoplastic polyolefin materials and for a refrigerator and a freezer. The magnetic door seal comprises a thermoplastic polyolefin elastomer door seal rubber sleeve composed of polyolefin elastomer (POE) plastic, naphthenic oil, polypropylene, modifier, lubricant and filler. A preparation method is further provided. A product of the magnetic door seal is low temperature resistant and excellent in performance, and can be used even under -50 DEG C. Simultaneously, shore hardness is basically not affected by temperature change and is less affected by environment. The rubber sleeve is flexible and good in resilience under the -15 DEG C. The door seal and the method improve sealing performance of the door seal rubber sleeve, greatly reduce product energy consumption, improve mechanical performance of the door seal and prolong service life of the door seal.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Self-repairing safety tire

The invention discloses a self-repairing safety tire, which comprises a tire, wherein a leak-proof tight-fitting layer is arranged on the inner wall of the tire, and the leak-proof tight-fitting layeris adhered to the inner wall of the tire; the leak-proof tight-fitting layer consists of the following components in parts by weight: 35-45 parts of modified rubber polymers, 10-15 parts of terpene resin, 15-20 parts of petroleum resin, 10-15 parts of naphthenic oil, 20-25 parts of wax, 0.5 part of an antioxidant, 5 parts of pigments and 2 parts of coupling agents. The invention provides the self-repairing safety tire, when the tire is punctured by a sharp object in the running process of an automobile, the leak-proof tight-fitting layer tightly wraps the sharp object, and thus a leak-proof effect is achieved; and when the sharp object is pulled out, the breach of the leak-proof tight-fitting layer automatically close up, and the leak-proof tight-fitting layer at the breach is glued together depending on the viscosity, so that the tire not only can achieve the effects of puncture prevention and leak prevention, but also has the effect of buffering puncture.

Owner:江苏久祥科技有限公司

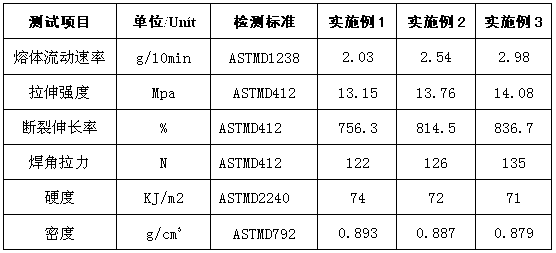

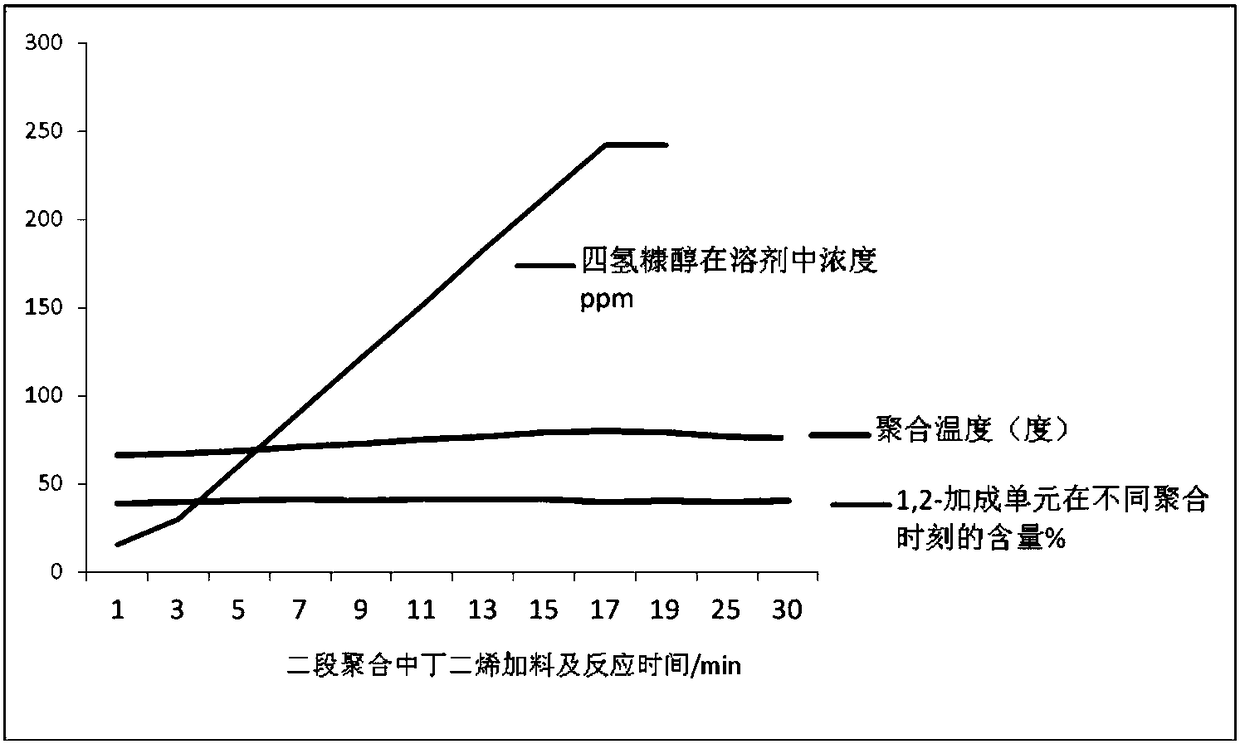

SBS containing 1,2 structure uniformly distributed butadiene block and hydride thereof and preparation and application method thereof

The invention discloses SBS containing a 1,2 structure uniformly distributed butadiene block and a hydride thereof and a preparation and application method thereof. According to the preparation process of the SBS, styrene reacts with an initiator under the action of an activator to initiate first-stage polymerization. During the second-stage polymerization process, a 1,2 structure regulator is dissolved in butadiene and the solution is uniformly added to a polymerization kettle within 16 to 18 minutes, and the reaction is further carried out for 8-12 min after the addition. During the third-stage polymerization, styrene can be used for the polymerization or a coupling agent can be adopted for coupling, the content of the 1,2-addition unit in the polybutadiene segment of the SBS is 38-42% and the 1,2-addition unit is uniformly distributed. SEBS obtained after hydrogenation has good compatible stability with naphthenic oil or white oil, and the oil has low mobility in SEBS and high lighttransmittance, and can be widely applied to transparent elastic materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

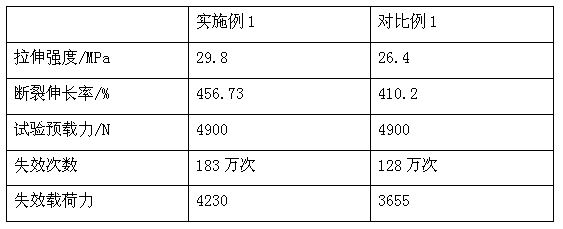

Fatigue-resistant rubber

ActiveCN103665459AImprove heat aging resistanceGood dynamic fatigue resistanceSodium stearateStearic acid

Owner:佛山市嘉翔新材料有限公司

Low-temperature hot melt adhesive

ActiveCN104559860ALarge fluctuationsLittle fluctuationMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesPolymer sciencePolyolefin

The invention discloses a low-temperature hot melt adhesive which is prepared from the following raw materials in percentage by mass: 10-40% of styrene-isoprene-styrene block copolymer (SIS), 10-30% of a tackifier, 5-18% of nitrile-butadiene rubber, 10-40% of polyethylene wax, 0.6-0.1% of an antioxidant, 10-30% of naphthenic oil and 20-30% of resin, wherein the tackifier is rosin resin or petroleum resin; the nitrile-butadiene rubber is powder nitrile-butadiene rubber with acrylonitrile content of 32-35%; the naphthenic oil is KN4010 naphthenic oil; the antioxidant is one or more of an antioxidant B225, an antioxidant 1010, an antioxidant 168, and an antioxidant DLTP, and has outstanding processing stability and long-term protective effect on polyolefin; the polyethylene wax is of an AC8 level, and shows very strong external lubricating property due to an irregular structure and low-viscosity homopolymer. The hot melt adhesive disclosed by the invention has viscosity of less than or equal to 1.5Pa.s at 150 DEG C, and the viscosity fluctuates little under a temperature changing condition, is relatively stable, and is more excellent at -10 DEG C.

Owner:竹林伟业科技发展(天津)股份有限公司

Stereoscopic colorful auto-bonded macromolecular waterproof roll

ActiveCN104369512AGood toughness strengthHigh tensile strengthSynthetic resin layered productsConstructions elementsElastomerPolymer science

The invention relates to a stereoscopic colorful auto-bonded macromolecular waterproof roll. The stereoscopic colorful auto-bonded macromolecular waterproof roll sequentially comprises a membrane layer, a first auto-bonded layer, a core layer, a second auto-bonded layer and a colorful mineral grain layer. The core layer is prepared by 100 parts of polyvinyl chloride resin, 15-25 parts of polyethylene terephthalate-1, 4-cyclohexane dimethanol ester, 10-20 parts of organic fibers and 3-5 parts of ABS high-adhesive powder by weight. Each auto-bonded layer is prepared by 100 parts of modified asphalt, 30-40 parts of naphthenic oil, 10-20 parts of butadiene styrene rubber, 25-35 parts of styrene thermoplastic elastomers, 20-30 parts of talcum powder, 1-2 parts of antioxidant and 3-5 parts of ultraviolet light absorber by weight.

Owner:LIAONING DAYU WATERPROOF TECH DEV

Transparent nylon elastomer and preparation method thereof

The invention discloses a transparent nylon elastomer, which is prepared from the following components in parts by weight: 35-80 parts of nylon, 8-50 parts of a polystyrene-b-poly(ethylene / ethylene / propylene)-b-polystyrene block copolymer, 1-20 parts of N,N-dimethyl-p-toluenesulfonamide, 1-35 parts of paraffin oil, 1-35 parts of naphthenic oil, 1-15 parts of maleic anhydride-grafted SEBS / SEEPS, 0.1-2 parts of an antioxidant 1098, 0.1-2 parts of a lubricant, 0.1-2 parts of a nucleating agent and 0.1-2 parts of a light stabilizer; the relative viscosity of the nylon is 2.1-4.0; the grafting rate of the maleic anhydride-grafted SEBS / SEEPS is 0.8% or more; and the lubricant is a lubricant EB-FF or polyethylene wax. The light transmittance of the transparent nylon elastomer is high, the elongation at break reaches 450 or over, the transparent nylon elastomer has the non-breaking characteristic in notch impact at -30 DEG C, and the harness reaches a relatively wide interval of 50-95 (shore A).

Owner:中广核高新核材科技(苏州)有限公司

High-self-adhesive waterproof roll material of SBS (Styrene-Butadiene-Styrene) modified asphalt and production process thereof

InactiveCN101967868ARoof covering using flexible materialsBuilding insulationsPolymer scienceUltimate tensile strength

The invention relates to a high-self-adhesive waterproof roll material of SBS (Styrene-Butadiene-Styrene) modified asphalt and a production process thereof. The waterproof roll material comprises tire fabric, an oil-lubricated coating layer, a separating layer and a filming layer, wherein the oil-lubricated coating layer is prepared from the following materials in percentage by weight: 35-40 percent of alkyl asphalt, 10-13 percent of SBS binder, 3-5 percent of naphthenic oil, 5-13 percent of coumarone resin, 10-30 percent of sub-spherical silica micro powder and 10-29 percent of loess powder, wherein the sub-spherical silica micro powder and the loess powder are together used as a compound filler, and the addition of the two materials is 39-42 percent of the total material weight of the oil-lubricated coating layer. By adopting the sub-spherical silica micro powder and the loess powder as the compound filler, the invention can obviously improve the tensile strength and the elongation of the roll material, not only takes the effect of improving the adhesion, but also plays a role of resisting corrosion and radiation.

Owner:北京立高科技股份有限公司

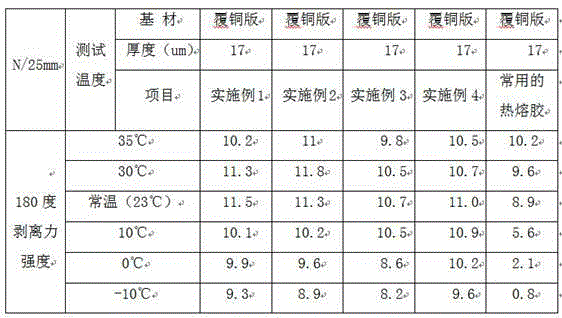

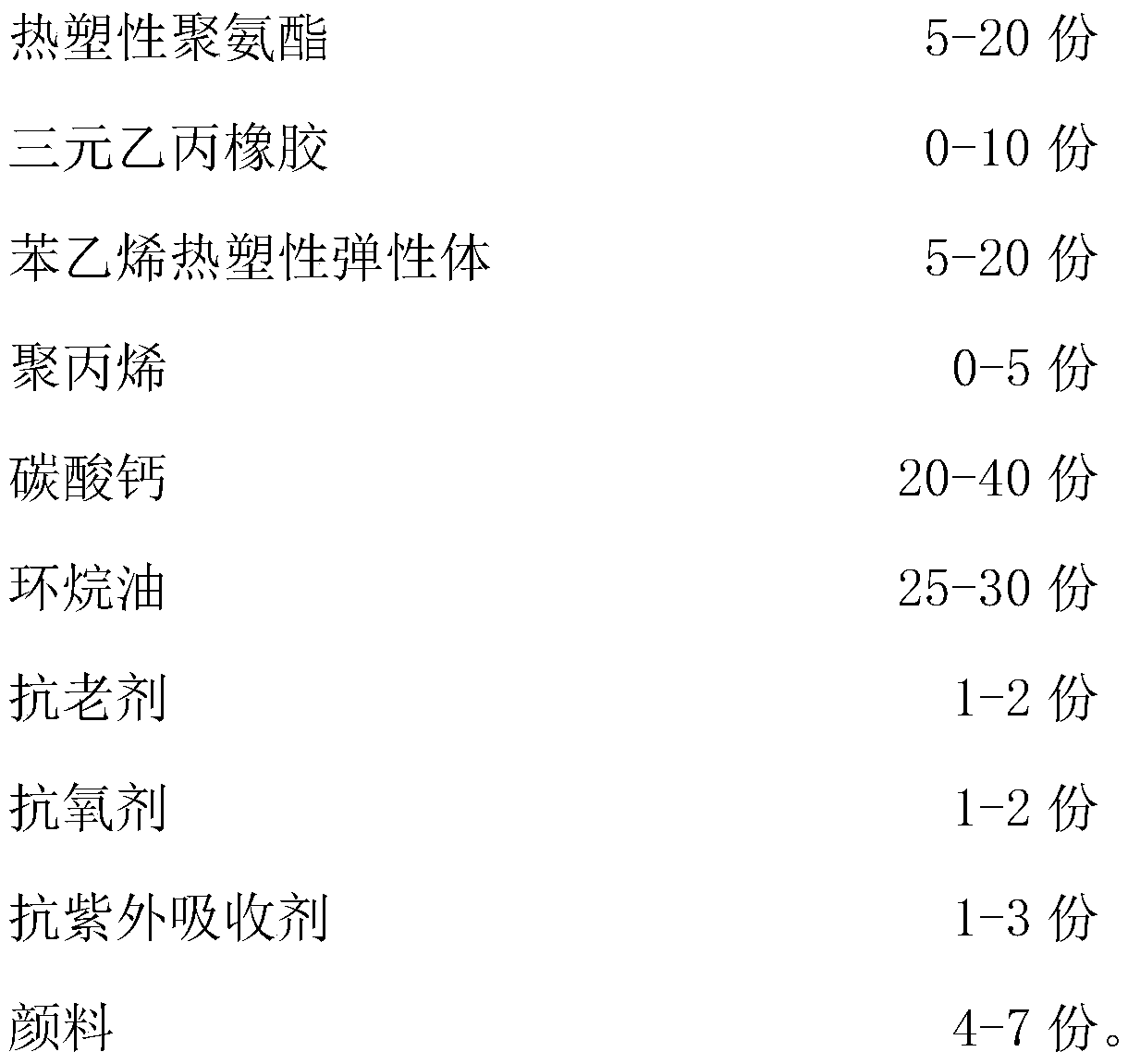

Environment-friendly odorless prefabricated plastic runway coiled material and preparation method thereof

The invention discloses an environment-friendly odorless prefabricated plastic runway coiled material. The coiled material is composed of the following components in parts by weight: 5 to 20 parts ofthermoplastic polyurethane, 0 to 10 parts of ethylene-propylene-diene monomer, 5 to 20 parts of a styrene thermoplastic elastomer, 0 to 5 parts of polypropylene, 20 to 40 parts of calcium carbonate, 25 to 30 parts of naphthenic oil, 1 to 2 parts of an anti-aging agent, 1 to 2 parts of an antioxidant, 1 to 3 parts of an anti-ultraviolet absorbent and 4 to 7 parts of a pigment. The invention furtherdiscloses a preparation method of the environment-friendly odorless prefabricated plastic runway coiled material. Compared with the traditional prefabricated runway coiled material, the prefabricatedrunway coiled material has the advantages of being low in production investment cost, simple in process, free of vulcanization, environmentally friendly, odorless, excellent in physical and chemicalperformance and high in cost performance, and the performance meets the requirements of the new national standard GB36246-2018.

Owner:HUNAN YOUGUAN SPORTS MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com