Blending-process method for producing environment-friendly rubber oil

An environmentally friendly rubber oil and production method technology, applied in the direction of only multi-stage serial refining process, etc., can solve the problems of difficult supply, high price, dependence on imports, etc., and achieve low product cost, low raw material cost, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

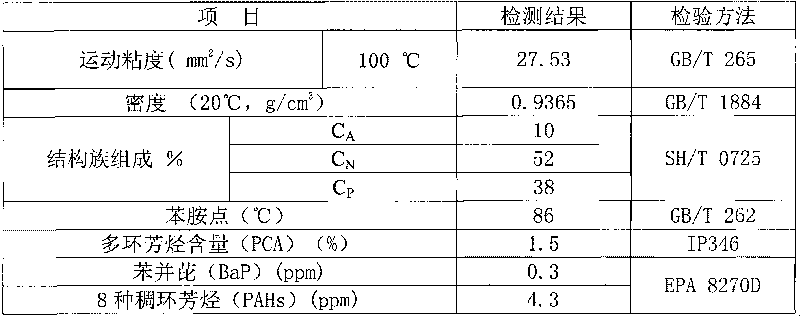

[0028] Embodiment 1, preparation and property determination of environment-friendly rubber oil

[0029] 1) Using Zhonghai Suizhong 36-1 vacuum residue as raw material, extract it in the first extraction tower to obtain deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 91°C, the temperature at the bottom of the tower is 80°C, The solvent is propane, the volume ratio of solvent and Zhonghaisuizhong 36-1 vacuum residue is 8:1, and the operating pressure is 3.8Mpa.

[0030] 2) The deasphalted oil obtained in step 1) is subjected to secondary extraction in the second extraction tower to obtain light deasphalted oil and heavy deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 80 ° C, the tower The bottom temperature is 70°C, the solvent is propane, the volume ratio of solvent and deasphalted oil is 6:1, and the operating pressure is 2.8Mpa.

[0031] 3) The heavy deasphalted oil and naphthenic oil obtai...

Embodiment 2

[0036] Embodiment 2, preparation and property determination of environment-friendly rubber oil

[0037] 1) Using Zhonghai Suizhong 36-1 vacuum residue as raw material, extract it in the first extraction tower to obtain deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 78°C, the temperature at the bottom of the tower is 68°C, The solvent is propane, the volume ratio of solvent and Zhonghaisuizhong 36-1 vacuum residue is 6:1, and the operating pressure is 4.8Mpa.

[0038] 2) The deasphalted oil obtained in step 1) is subjected to secondary extraction in the second extraction tower to obtain light deasphalted oil and heavy deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 70 ° C, the tower The bottom temperature is 60°C, the solvent is propane, the volume ratio of solvent and deasphalted oil is 6:1; the operating pressure is 3.1Mpa.

[0039] 3) The heavy deasphalted oil and naphthenic oil obtained ...

Embodiment 3

[0045] Embodiment 3, the preparation and property determination of environment-friendly rubber oil

[0046] 1) Using Zhonghai Suizhong 36-1 vacuum residue as raw material, extract it in the first extraction tower to obtain deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 70°C, the temperature at the bottom of the tower is 57°C, The solvent is propane, the volume ratio of solvent and Zhonghaisuizhong 36-1 vacuum residue is 8:1, and the operating pressure is 7.0Mpa.

[0047] 2) The deasphalted oil obtained in step 1) is subjected to secondary extraction in the second extraction tower to obtain light deasphalted oil and heavy deasphalted oil; the extraction conditions are: the temperature at the top of the tower is 60 ° C, the tower The bottom temperature is 50°C, the solvent is propane, the volume ratio of the solvent to the deasphalted oil is 8:1, and the operating pressure is 3.9Mpa.

[0048] 3) The heavy deasphalted oil and naphthenic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com