Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "No carcinogenic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

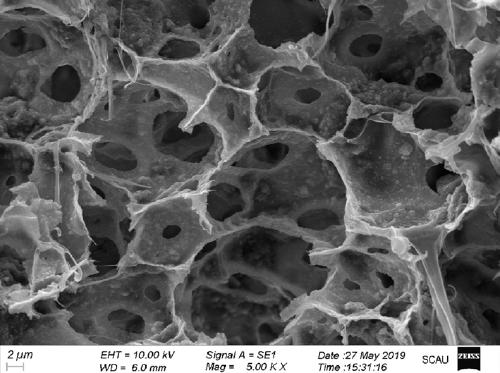

Preparation method for titanium alloy-hydroxyapatite salt biological ceramic porous material

PendingCN108950305ATake full advantage of performanceOvercome the performance mismatchAdditive manufacturing apparatusTransportation and packagingBiological propertyBone tissue

The invention discloses a preparation method for a titanium alloy-hydroxyapatite salt biological ceramic porous material. The preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material has the characteristics that the 3D printing technology is applied, and by means of the manner that the proportion value of hydroxyapatite salt powder to titanium alloy matrix powder of all fusion covering layers is dynamically adjusted, the titanium alloy-hydroxyapatite salt biological ceramic porous material with titanium alloy being a central layer and titanium alloy-hydroxyapatite salt being a transition layer is prepared. According to the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material, because the performance advantages of various materials are sufficiently utilized and the internal stress is further reduced, excellent mechanical and biological properties are exhibited, therefore, the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material is suitable for the field of bone tissue replacing or implant repairing.

Owner:SHANDONG JIANZHU UNIV

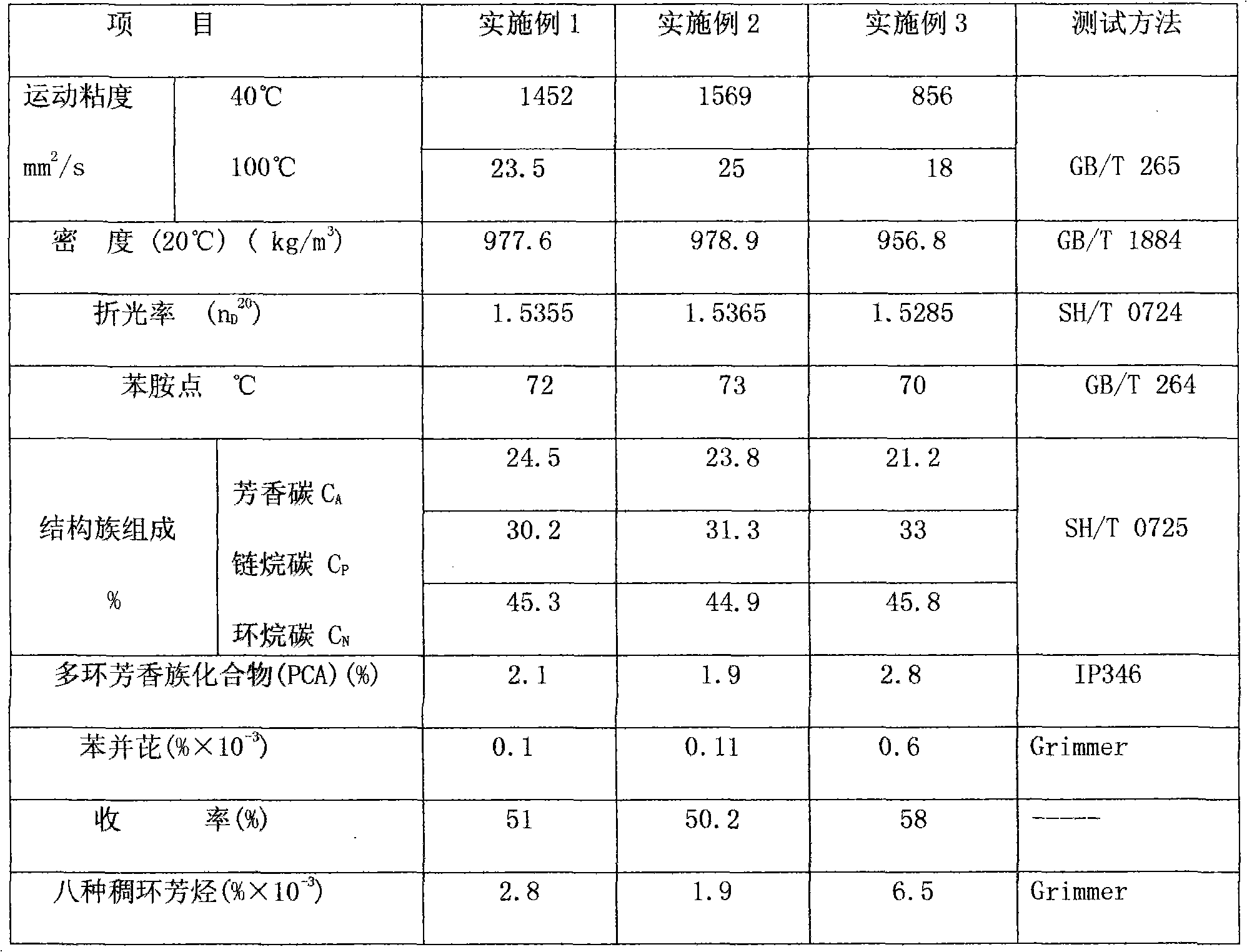

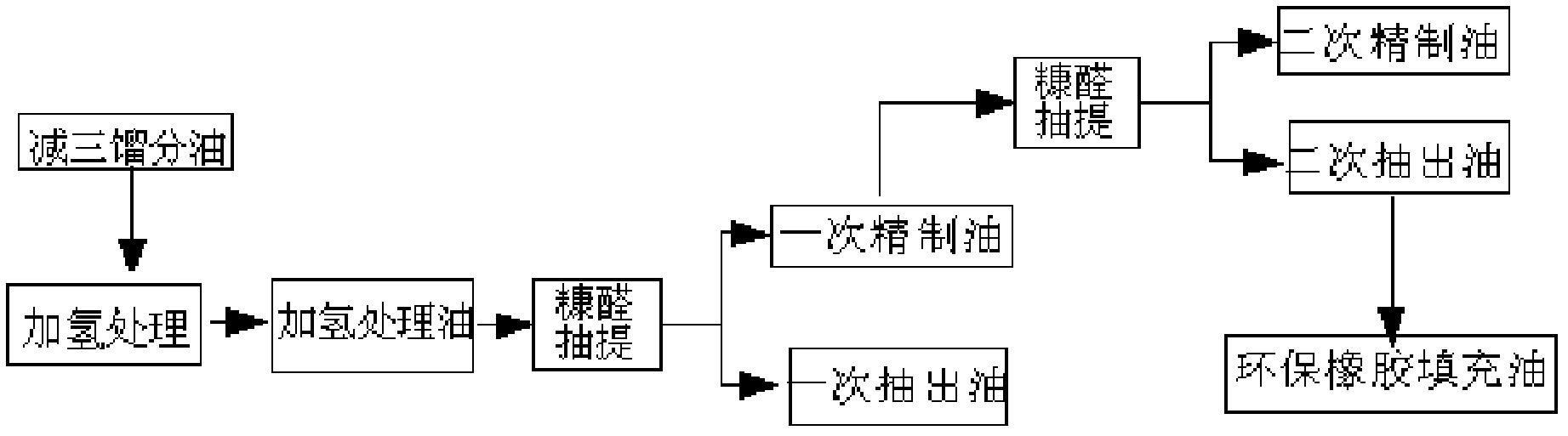

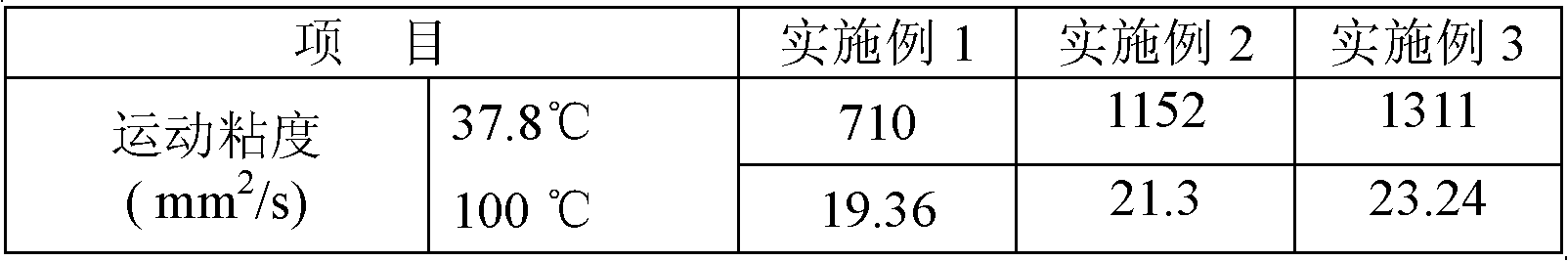

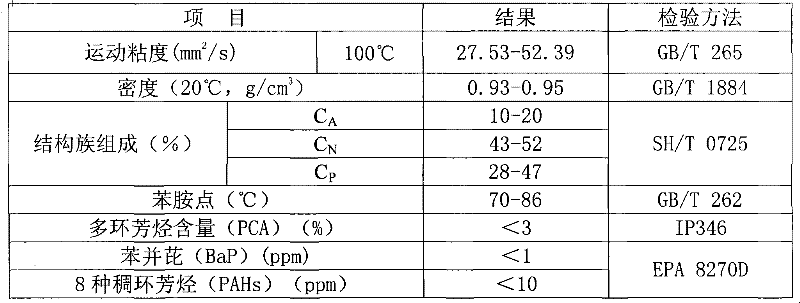

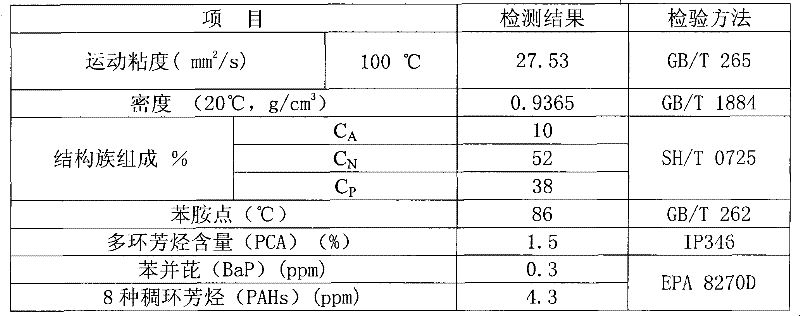

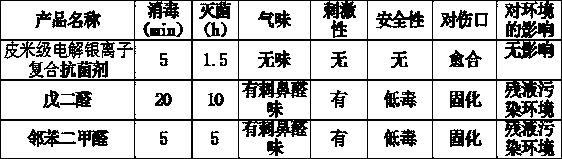

Environmental-friendly rubber filling oil and preparation method thereof

InactiveCN102604674AHigh aromatic contentImprove wet skid resistanceTreatment with hydrotreatment processesTowerAromatic hydrocarbon

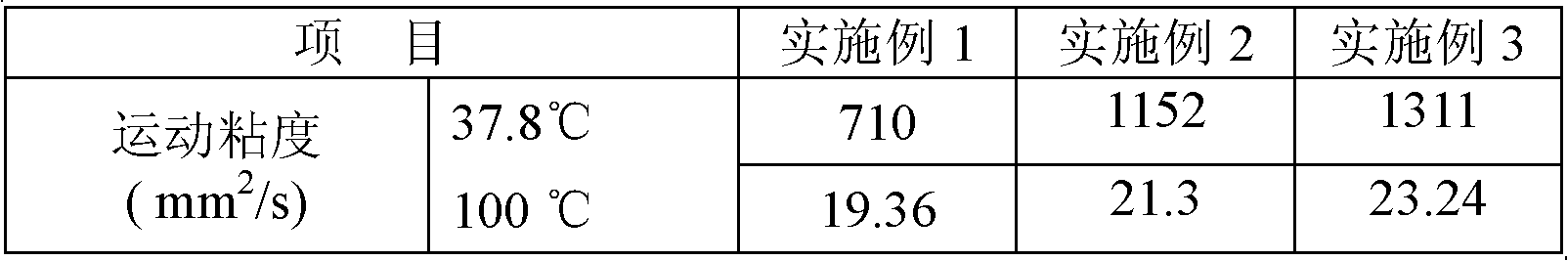

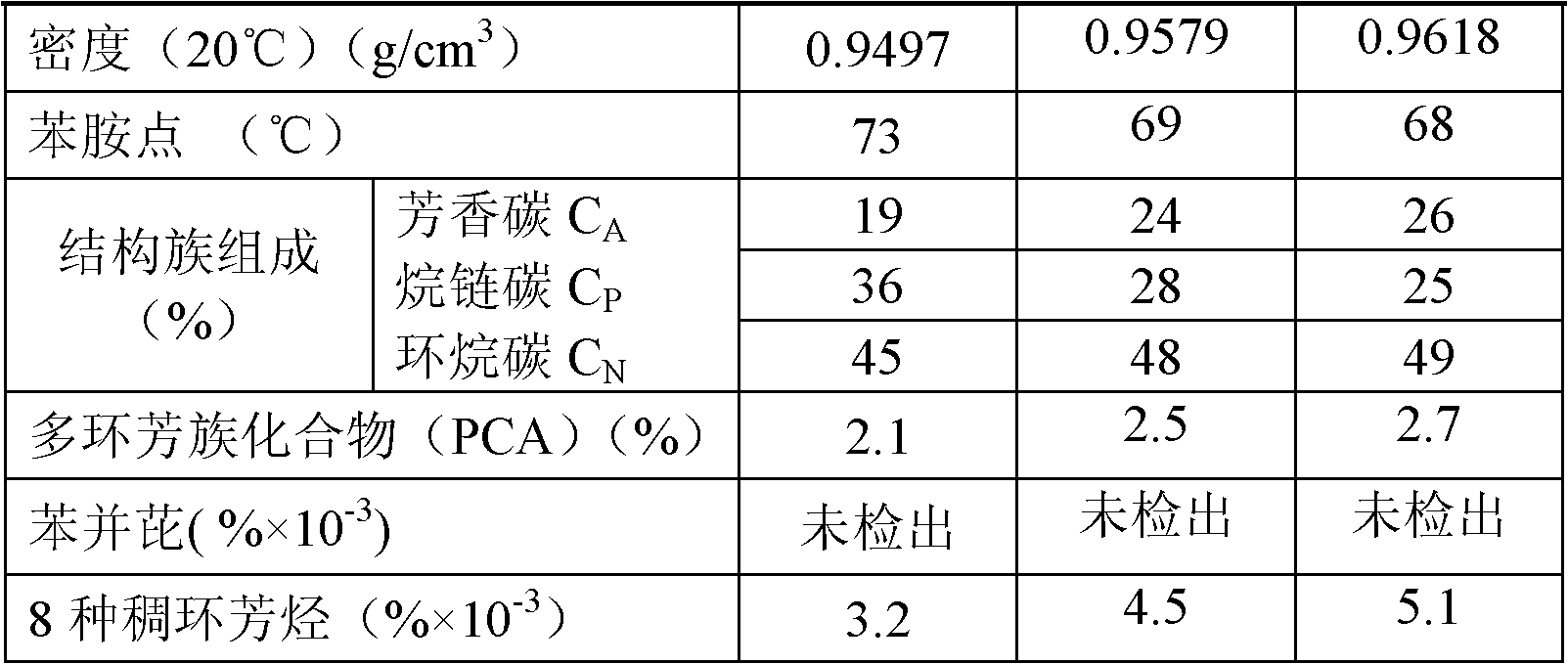

The invention discloses environmental-friendly rubber filling oil and a preparation method thereof. The method comprises the following steps of: (1) hydrotreating a vacuum cut 3 distillate to obtain hydrotreating oil; (2) extracting the hydrotreating oil in an extraction tower for the first time to obtain raffinate at the tower top of the extraction tower, and recycling a solvent to obtain primary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain primary extract oil; (3) extracting the primary refined oil into the extraction tower for the second time to obtain the raffinate at the tower top of the extraction tower, and recycling the solvent to obtain secondary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain secondary extract oil, that is to say, environmental-friendly rubber filling oil. The environmental-friendly rubber filling oil, provided by the invention, has the advantages of high aromatic hydrocarbon content, good compatibility with the rubber and excellent processing performance, the mass percentage composition of the aromatic hydrocarbon reaches 19-26%, the environmental-friendly rubber filling oil can be used in a tire manufacturing process, and excellent performances such as good wet traction and the like can be given.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Environment-friendly rubber oil and preparation method thereof

InactiveCN102585900AHigh aromatic contentImprove wet skid resistanceTreatment with hydrotreatment processesRaffinateAromatic hydrocarbon

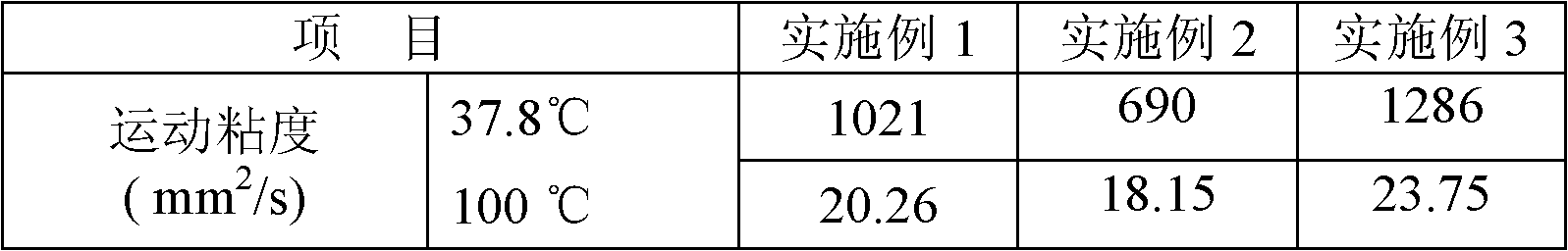

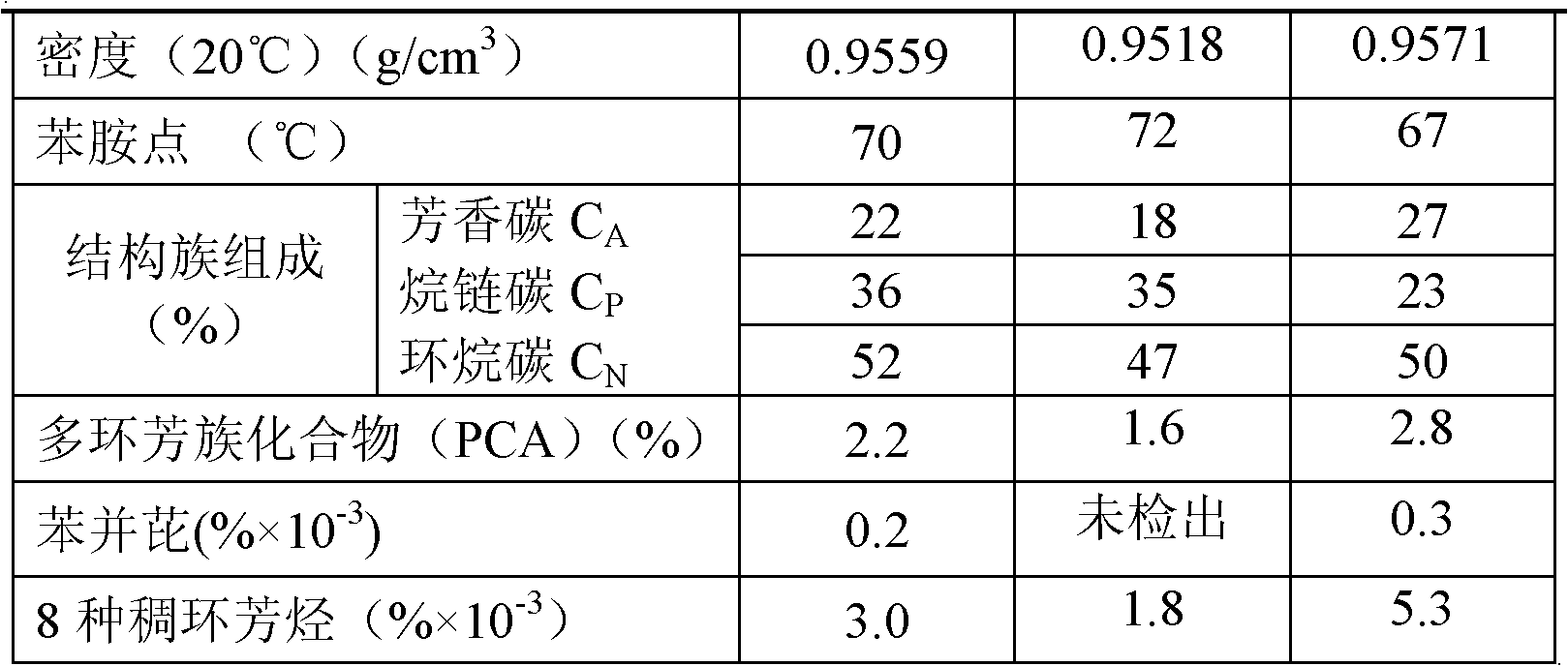

The invention discloses environment-friendly rubber oil and a preparation method thereof. The method comprises the following steps: (1) hydrotreating cut-3 distillate oil to obtain hydrotreated oil; (2) filling the hydrotreating oil into an extraction column for primary extraction to obtain raffinate on the top of the extraction column, recovering a solvent to obtain primary refined oil and obtain an extracting solution at the bottom of the extraction column, and recovering the solvent to obtain primary pumping oil; and (3) filling the primary pumping oil into the extraction column for secondary extraction to obtain the raffinate on the top of the extraction column, and recovering the solvent to obtain secondary refined oil namely the environmental-friendly rubber oil and obtain the extracting solution at the bottom of the extraction column, and recovering the solvent to obtain secondary pumping oil. The environment-friendly rubber oil provided by the invention has high aromatic hydrocarbon content, and the masses of aromatic carbon accounts for 18-27%. The environment-friendly rubber oil has good compatibility with rubber and excellent processing performance. The environment-friendly rubber oil can be used in the tyre manufacturing process and can endow excellent performances to the tyre, such as good slippery resistance.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Production technology of high-purity stevioside

ActiveCN102816192ANo carcinogenic effectRefreshing tasteSugar derivativesSugar derivatives preparationSide effectFiltration

The invention relates to a production technology of high-purity stevioside. The technology is characterized in comprising the steps of: an extraction step, a flocculation step, a membrane filtration step, an adsorptive separation step, a reverse osmosis concentration step, a desalting and de-coloring step, and a recrystallization step. The technology provided by the invention has advantages that: the stevioside is a completely safe foodstuff additive with no toxicity, no side effect, no teratogenic effect, no mutagenic effect, no carcinogenic effect, refreshing taste, good taste, high purity, and high sweetness. Therefore, requirements of people can be satisfied. During a production process of stevioside, no chemical method or chemical raw material is adopted, and no pollutant is discharged. A small amount of waste residual can be comprehensively used as a bio-fertilizer. Stevia leaf is a good organic fertilizer rich in organics, and can be used for improving and fertilizing soil. Therefore, a waste pollution problem is solved from the source.

Owner:NANTONG CHANGHAI FOOD ADDITIVE

Process for producing environment-friendly aromatic rubber oil

InactiveCN101928595AHigh aromatic contentGood compatibilityTreatment with plural serial refining stagesPolymer scienceSolvent

The invention relates to environment-friendly aromatic rubber oil used in the rubber industry. In the rubber oil, cyclohexane / petroleum ether / HVI150 and dimethyl sulfoxide are used as solvents, and PCA in the oil is extracted by using the selectivity of the dimethyl sulfoxide under a specific condition. The process aims to provide the rubber filling oil which is capable of exerting properties the same as the conventional aromatic oil, does not have the problem of carcinogenicity and has better safety, and a producing method thereof.

Owner:王喜安 +1

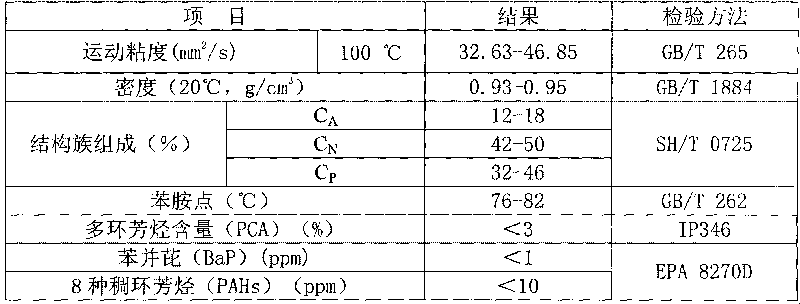

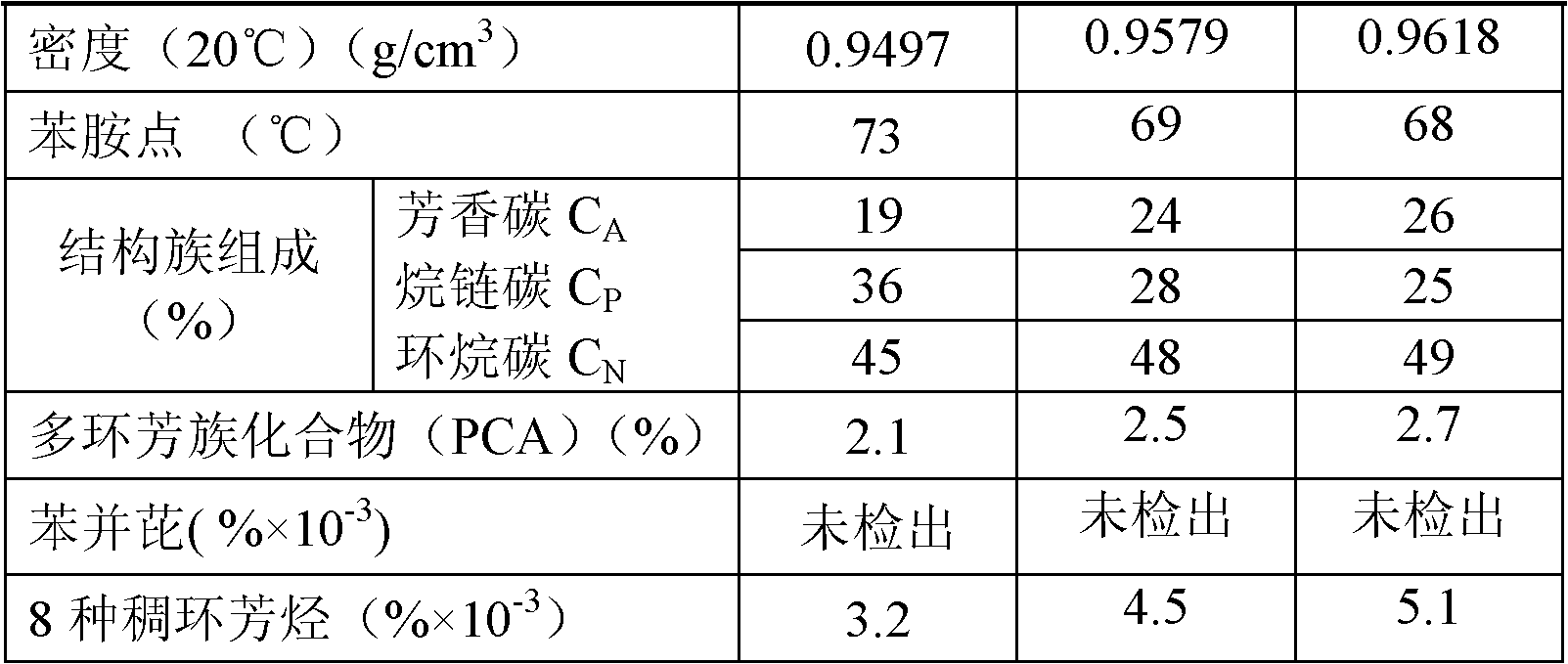

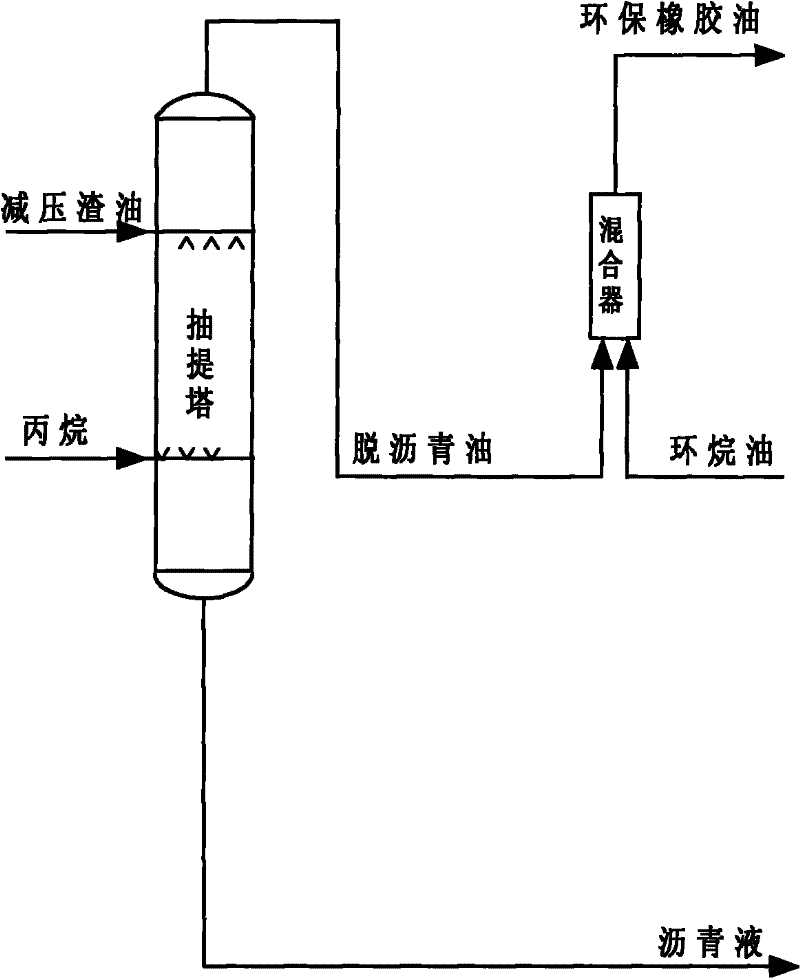

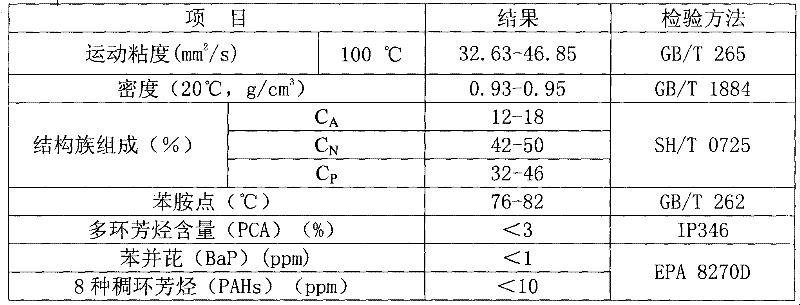

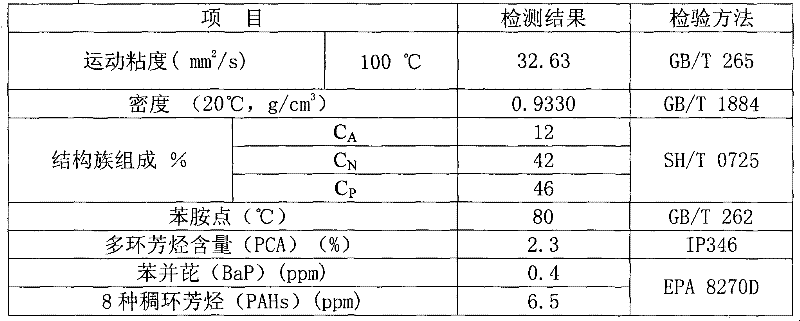

Method for producing environment-friendly rubber oil through blending method

ActiveCN101693772AImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the content of PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

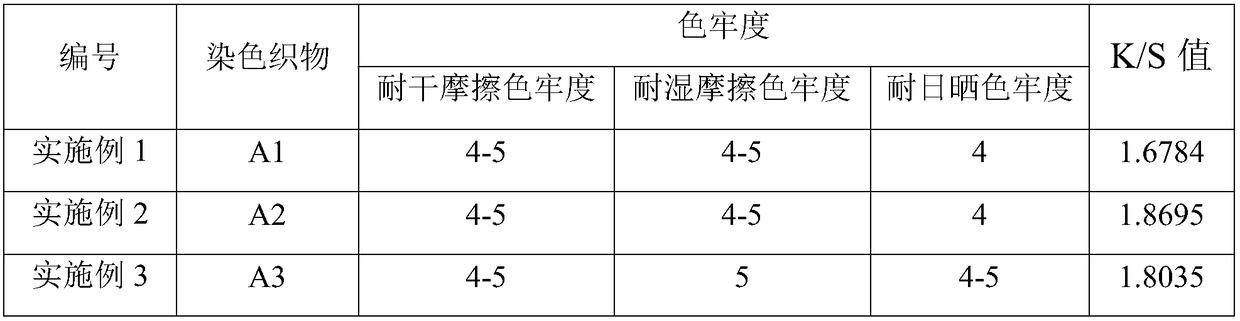

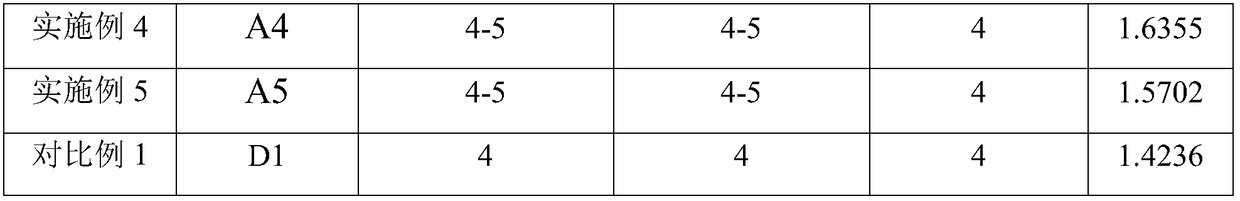

Method for extracting natural dye from rubia cordifolia as well as natural dye prepared by the method and dyeing method

InactiveCN108912729AHigh extraction rateImprove dyeing effectNatural dyesDyeing processDistillationFreeze-drying

The invention relates to the field of natural dye extracting and dyeing, discloses a method for extracting natural dye from rubia cordifolia as well as the natural dye prepared by the method and a dyeing method. The method for extracting natural dye from rubia cordifolia comprises the following steps: washing, drying and crushing rubia cordifolia roots, and extracting the obtained crushed materials in an alkaline aqueous solution; and sequentially performing suction filtration, distillation and freeze-drying on the obtained extracting liquor. The rubia cordifolia natural dye prepared by the method for extracting natural dye from rubia cordifolia has an obvious and relatively good dyeing effect; and specially, the dyed sample in deeper in surface color, and is better in color firmness.

Owner:WUHAN TEXTILE UNIV

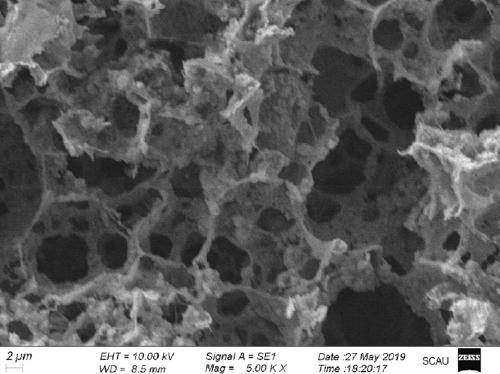

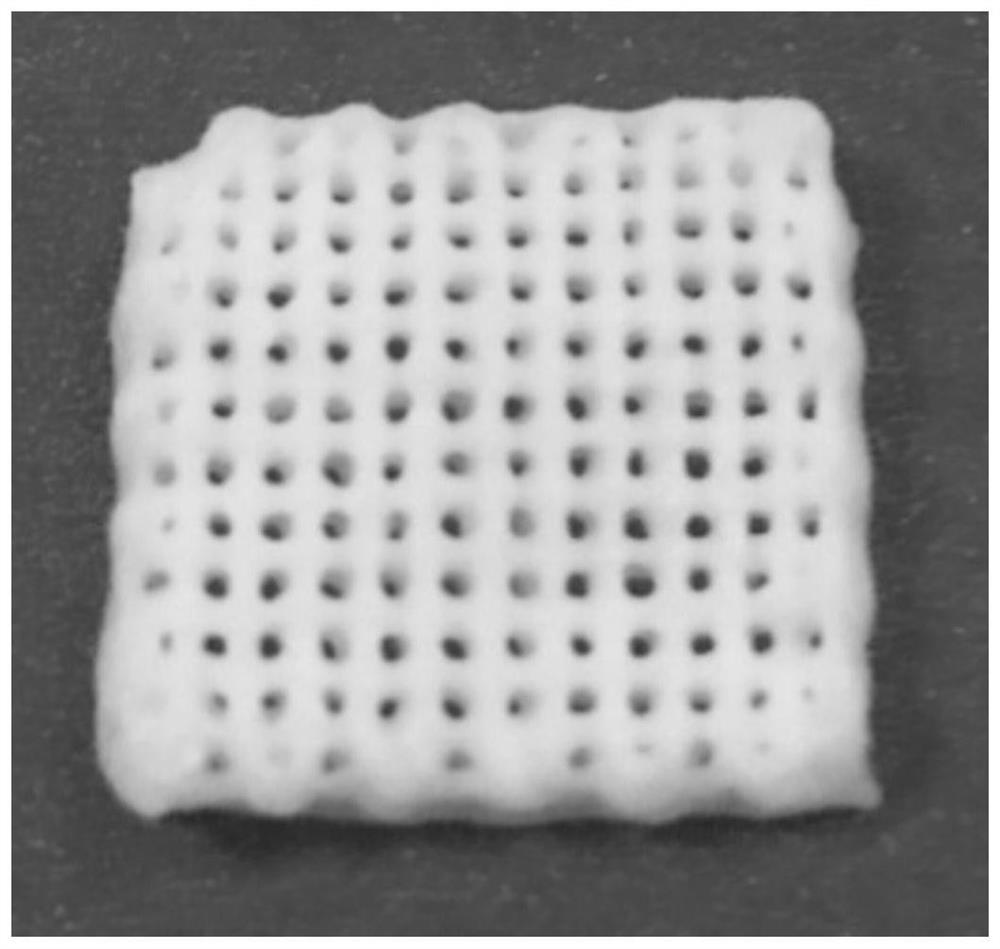

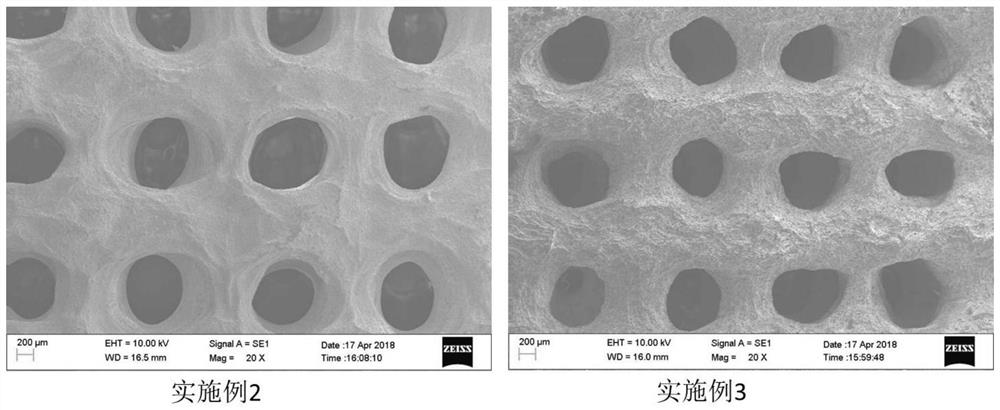

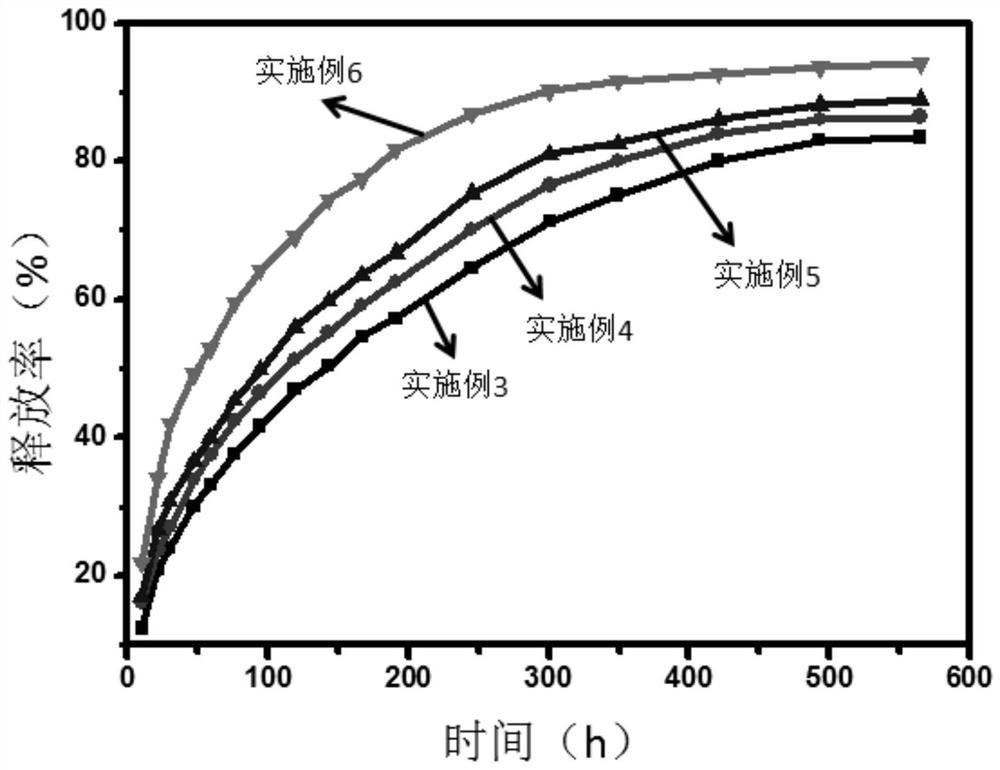

Pickering high internal phase emulsion, 3D printing porous support material and preparation method of Pickering high internal phase emulsion

ActiveCN110396205ANo carcinogenic effectImprove mechanical propertiesPharmaceutical delivery mechanismProsthesisPolymer scienceGenipin

The invention relates to a Pickering high internal phase emulsion, a 3D printing porous support material prepared from the Pickering high internal phase emulsion and a preparation method of the Pickering high internal phase emulsion. The method comprises the following steps: nano-hydroxyapatite particles are used as an emulsion stabilizer, gelatin, collagen and genipin are dissolved into deionizedwater to form a continuous phase of an emulsion, an organic solvent is used as a dispersion phase, emulsification treatment is performed, a cross-linking reaction is performed to form the oil-in-water Pickering high internal phase emulsion, the continuous phase of the emulsion is fixed, finally 3D printing is performed to obtain a gel support, the solvent is volatilized to remove the dispersion phase, and drying is performed to obtain the porous support material with communicating pores and adjustable pore diameters. According to the method provided by the invention, an emulsion template method is adopted, the emulsion template method is combined with a 3D printing technology, so that the prepared porous support material has the advantages of high porosity, communicating pores, adjustablepore diameters, good biocompatibility, no toxicity or harm to organisms and the like, and has a wide application prospect in the field of biomedical materials.

Owner:SOUTH CHINA AGRI UNIV +1

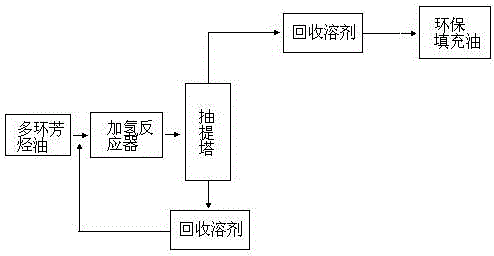

Environment-friendly filling oil preparation method

InactiveCN106675647AGood compatibilityImprove wet skid resistanceTreatment with hydrotreatment processesTowerPolyaromatic hydrocarbon

The invention relates to environment-friendly filling oil preparation method. The method comprises the following steps: performing hydrotreatment on polyaromatic hydrocarbon oil to obtain hydrotreatment oil; placing the hydrotreatment oil in an extracting tower for extracting a solvent, after the extraction is completed, a raffinate is obtained at the tower top of the extracting tower, the target product environment-friendly filling oil is obtained after the solvent is recovered, an extract is obtained at the tower bottom of the extracting tower, the extract oil is obtained after the solvent is recovered; the extract oil is subjected to hydrotreatment, and is placed at the extracting tower for solvent extracting, and the steps are repeated. The aromatic hydrocarbons content of the filling oil is high, the filling oil has good compatibility with the rubber, the processing property is excellent, while in use during a tire manufacture process, excellent performances such as good wet-skid resistance can be provided to the tire; the content of polyaromatic hydrocarbon compound in filling oil satisfies an EU export standard, wherein benzopyrene is undetected, so that the filling oil has no toxic and no carcinogenic effects.

Owner:SINOPEC YANGZI PETROCHEM +1

A kind of fiber dyeing and deepening agent and preparation thereof

The invention relates to the technical field of a textile finishing agent, and concretely discloses a fiber dyeing deepening agent. The textile finishing agent is prepared from the following formula raw materials in percentage by mass: 5.0.0 to 10.0 percent of emulsifiers, 10.0 to 20.0 percent of aliphatic amine, 25.0 to 35.0 percent of aliphatic amine derivatives, 3.0 percent of acid, 5.0 to 8.0 percent of aliphatic alcohol, 3.0 to 5.0 percent of urea and the balance deionized water. The fiber dyeing deepening agent has the advantages that the coloring effect on spandex (lycra) and nylon is extremely good; no allergy, no teratogenesis, no mutagenesis and no carcinogenesis are caused; no toxic and side effects are caused on the human body; the energy is saved; the environment is protected.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

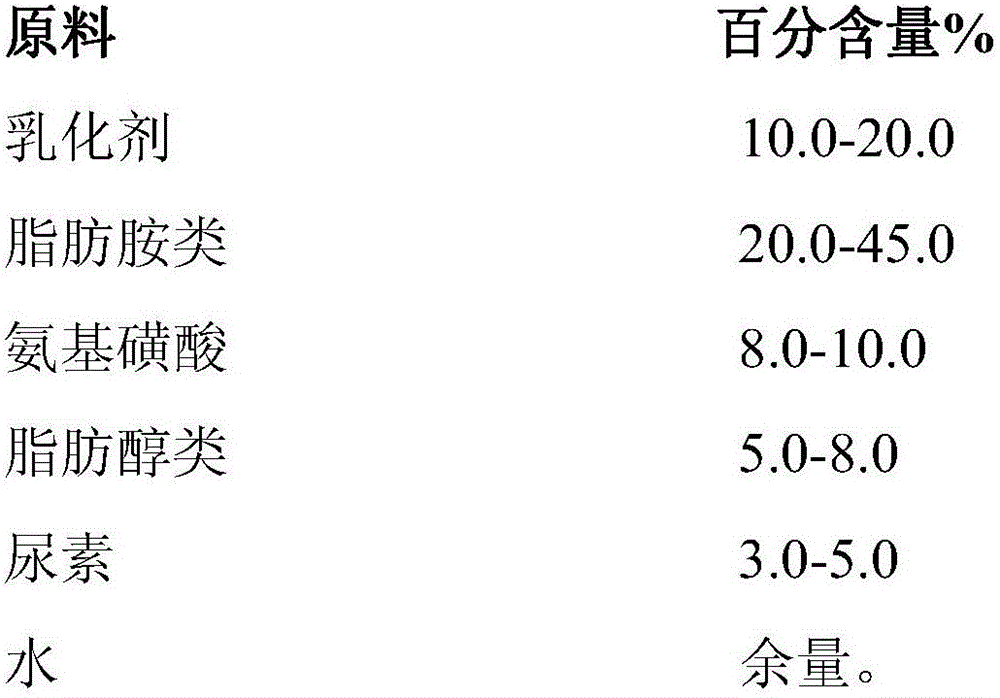

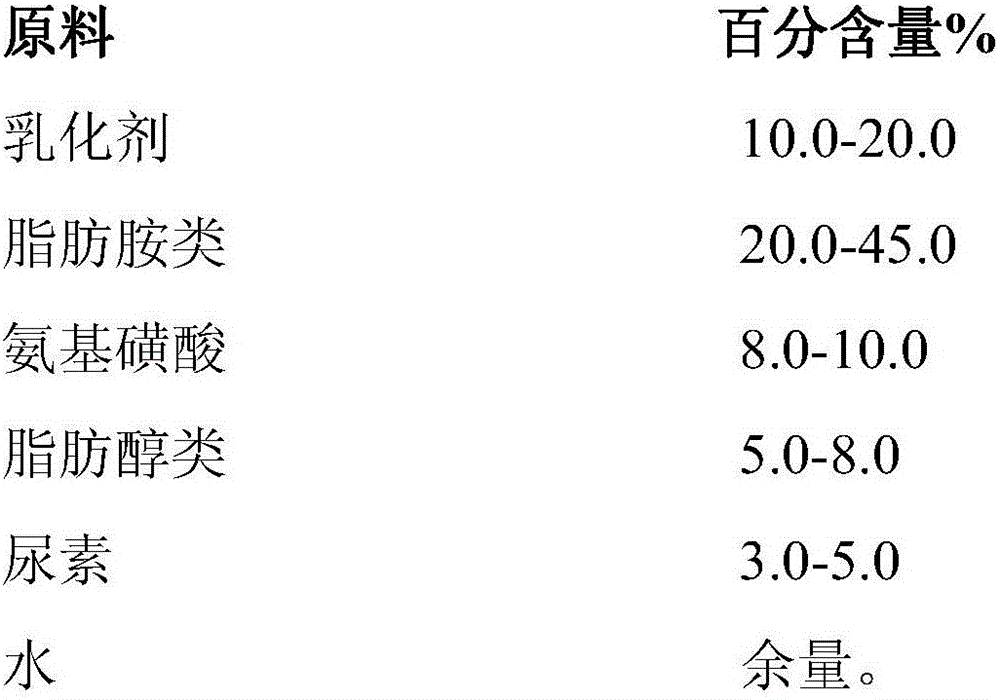

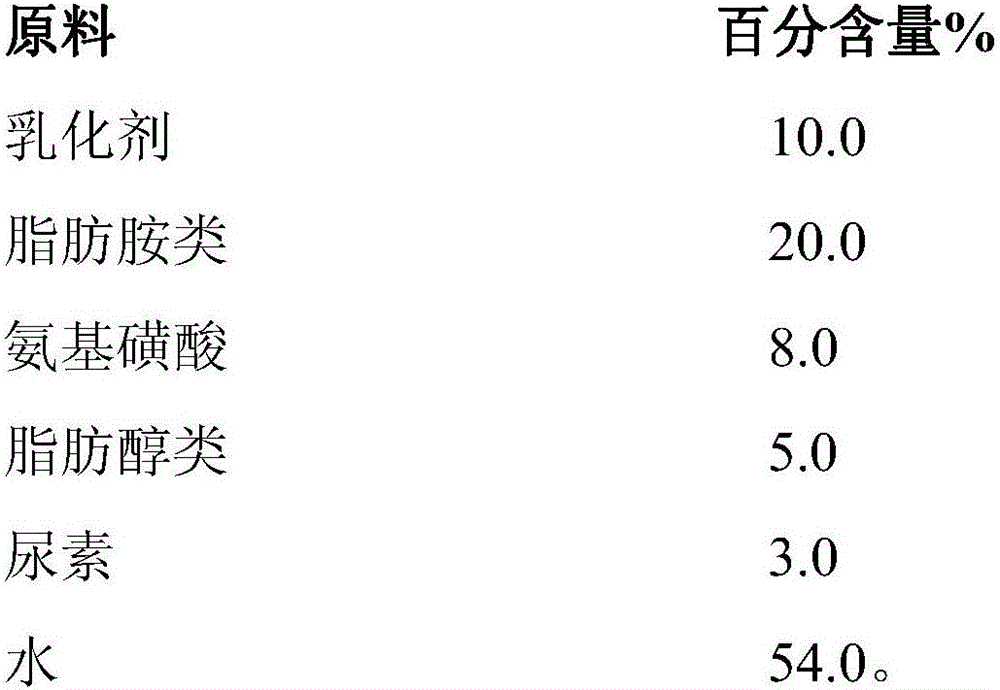

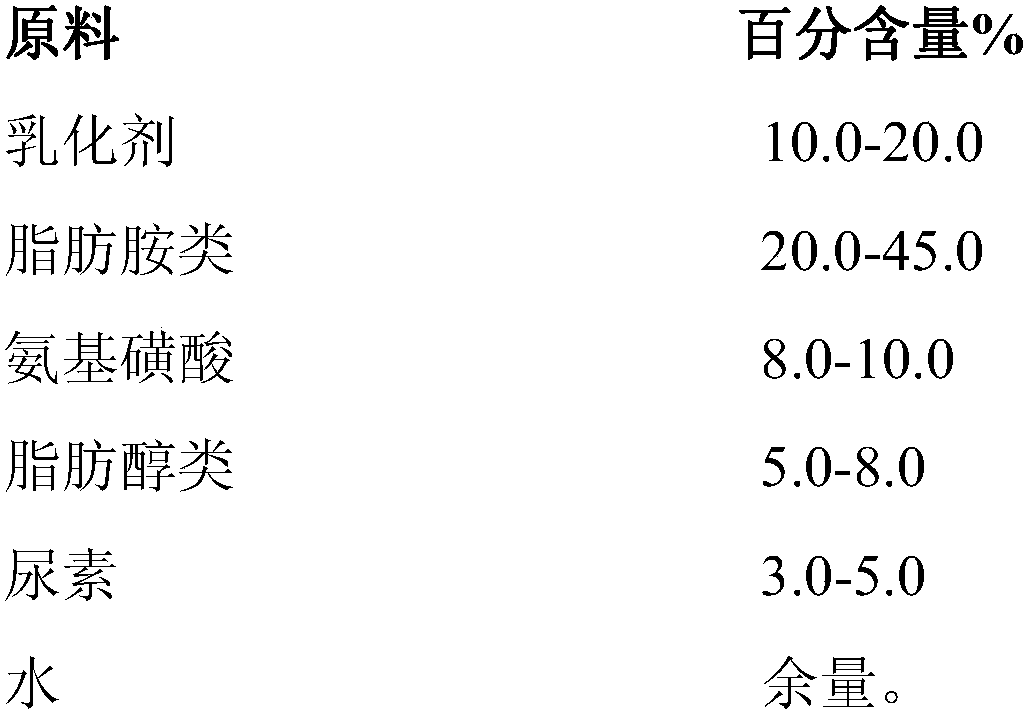

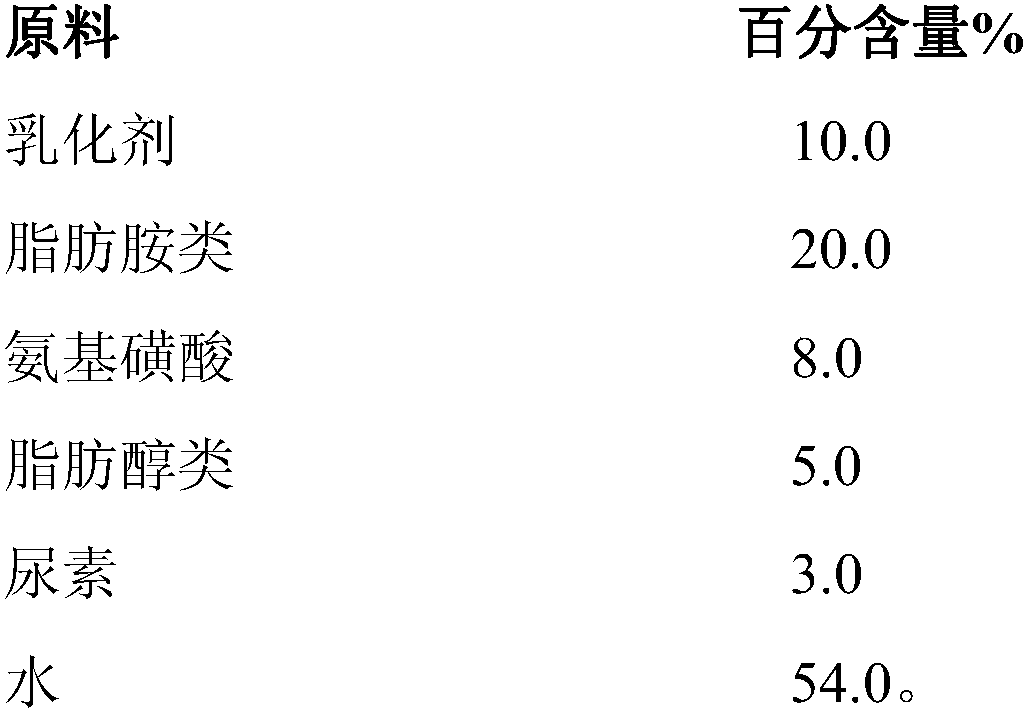

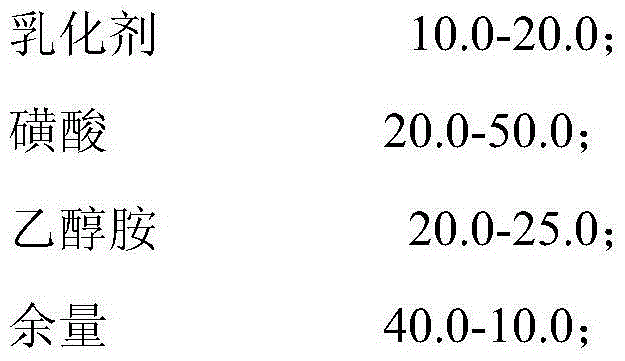

Acidic leveling agent and preparation method thereof

The invention relates to the technical field of textile printing and dyeing materials and particularly discloses an acidic leveling agent and a preparation method thereof. The acidic leveling agent is prepared from the following components by weight percent: 10.0%-20.0% of an emulsifying agent, 20.0%-45.0% of fatty amine, 8.0%-10.0% of sulfamic acid, 5.0%-8.0% of fatty alcohol, 3.0%-5.0% of urea and the balance of water. The preparation method comprises the following steps: adding the raw materials except water into a reaction kettle in sequence according to the formula and stirring; when adding each type of raw material, stirring for 20-25 minutes; weighing the water amount needed in the formula and adding into the reaction kettle; stirring and reacting for 1 hour; and after finishing, standing and filtering and discharging materials. The acidic leveling agent disclosed by the invention has extremely good diffusivity and mobility, so that dye molecules are uniformly combined with fiber molecules in a dyeing process; the acidic leveling agent is wide in applicability, good in effect and environmentally friendly; and compared with a traditional formula, the agent has the advantages that 10%-15% of the cost is reduced.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

Environmental-friendly rubber filling oil and preparation method thereof

InactiveCN102604674BHigh aromatic contentImprove wet skid resistanceTreatment with hydrotreatment processesProcess engineeringAromatic hydrocarbon

The invention discloses environmental-friendly rubber filling oil and a preparation method thereof. The method comprises the following steps of: (1) hydrotreating a vacuum cut 3 distillate to obtain hydrotreating oil; (2) extracting the hydrotreating oil in an extraction tower for the first time to obtain raffinate at the tower top of the extraction tower, and recycling a solvent to obtain primary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain primary extract oil; (3) extracting the primary refined oil into the extraction tower for the second time to obtain the raffinate at the tower top of the extraction tower, and recycling the solvent to obtain secondary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain secondary extract oil, that is to say, environmental-friendly rubber filling oil. The environmental-friendly rubber filling oil, provided by the invention, has the advantages of high aromatic hydrocarbon content, good compatibility with the rubber and excellent processing performance, the mass percentage composition of the aromatic hydrocarbon reaches 19-26%, the environmental-friendly rubber filling oil can be used in a tire manufacturing process, and excellent performances such as good wet traction and the like can be given.

Owner:CHINA NAT OFFSHORE OIL CORP +1

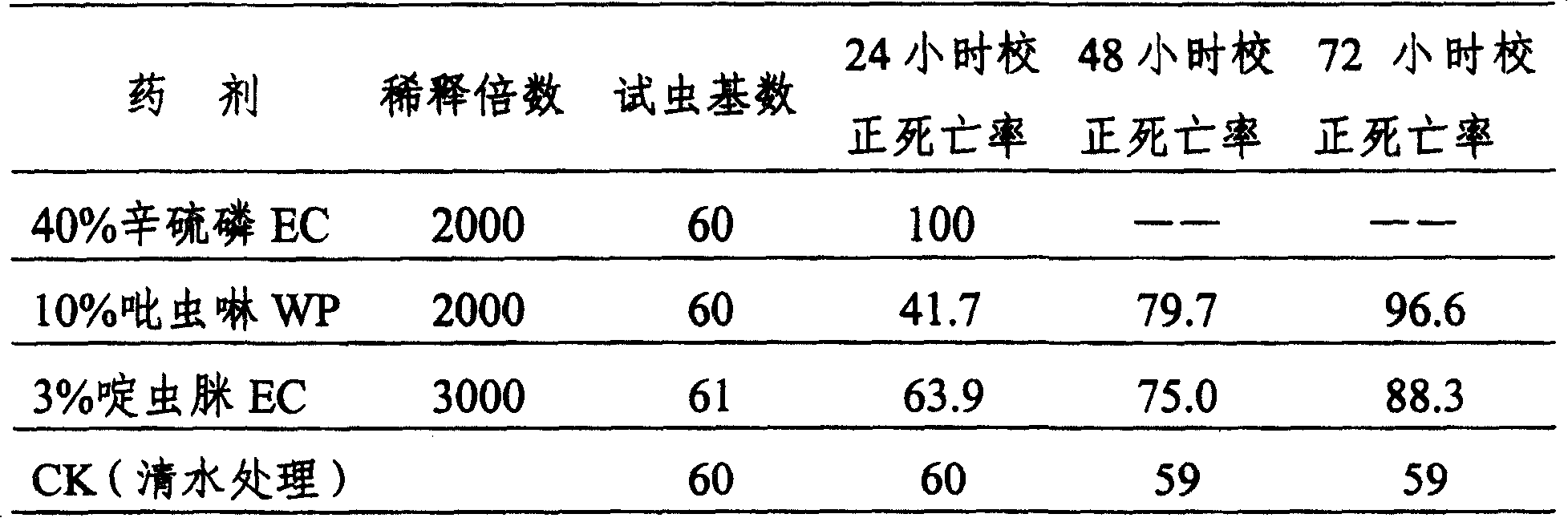

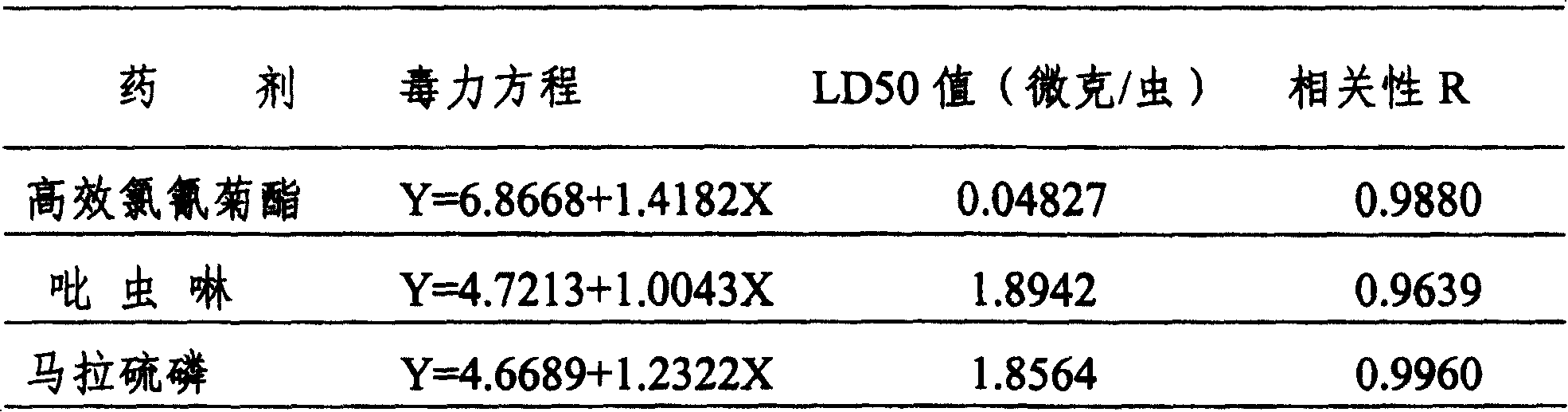

Imidacloprid oil solution and use thereof

InactiveCN1989811ASystemically activeLong durationBiocideAnimal repellantsAdditive ingredientGrasshopper

The invention discloses an oil solution of imidacloprid which comprises the following constituents (by weight portions): imidacloprid 0.5-15.5%, stabilizer 1-25%, and balancing dissolvent. The stabilizer being phenylcarbinol and / or isopropanol. The solution can be used for controlling grasshopper and Locusta migratoria manilensis (Meyen).

Owner:INST OF PLANT PROTECTION HEBEI ACAD OF AGRI & FORESTRY SCI

Blending-process method for producing environment-friendly rubber oil

ActiveCN101691427BImprove wet skid resistanceHigh aromatic contentTreatment with plural serial refining stagesResidual oilSolvent

The invention discloses a blending-process method for producing environment-friendly rubber oil. The method provided by the invention comprises the following steps: 1) performing solvent extraction on reduced-pressure residual oil to obtain deasphalted oil, wherein a solvent used for extraction is propane; the volume ratio of the solvent to the reduced-pressure residual oil is (6-8):1; and extraction conditions are tower-top temperature between 70 and 91 DEG C, tower-bottom temperature between 57 and 80 DEG C and pressure between 3.8 and 7.0 MPa; 2) performing solvent extraction on the deasphalted oil obtained in a step 1) to obtain heavy deasphalted oil, wherein the solvent used for extraction is propane; the volume ratio of the solvent to the deasphalted oil is (6-8):1; and the extraction conditions are tower-top temperature between 60and 80 DEG C, tower-bottom temperature between 50 and 70 DEG C and pressure between 2.8 and 3.9 MPa; and 3) mixing the heavy deasphalted oil obtained in a step 2) with naphthenic oil at a temperature between 70 and 90 DEG C for 30 to 120 minutes to obtain the environment-friendly rubber oil, wherein the mass ratio of the heavy deasphalted oil to the naphthenic oil is (0.3-0.7):(0.7-0.3). The environment-friendly rubber oil has the advantage of meeting the requirements of EU 2005 / 69 / EC environment-protecting directives, along with aromatic-carbon rate between 10 and 20 percent, PCA content of less than 3 percent, high aromatic hydrocarbon content, environment-protecting property, no toxicity and no carcinogenic effects. The environment-friendly rubber oil can be used as a substitute for the prior aromatic oil, and has significant economic value.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Digital printing white ink coloring brightener and preparation method thereof

InactiveCN110453515AImprove the coloring rate and display rateReduce chromatic aberration and stainsDyeing processDigital printingPolypropylene

The invention provides a digital printing white ink coloring brightener. The digital printing white ink coloring brightener is prepared from, by mass percentage, 5.0%-8.0% of pyridine and derivativesthereof, 1.0%-5.0% of polyacrylic acid and derivatives thereof, 0.1%-10.0% of polypropylene polymer and derivatives thereof, 1.0%-15.0% of benzyl compounds, 2.0%-8.0% of an emulsifier, 8.0%-10.0% of fatty amines and derivatives thereof, 0.1%-10.0% of polysilicon oxides, 1.0%-5.0% of fatty alcohols, and the balance water. By adopting the digital printing white ink coloring brightener, after printing of white and light inks, patterns are prominent, layers are distinct, the coloring rate and the display rate are increased, the color difference and stain after printing are reduced, the light fastness, washing and soaping fastness, rubbing fastness, perspiration fastness, ironing fastness, sublimation fastness and the like are improved, and the pass rate of finished products is increased.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

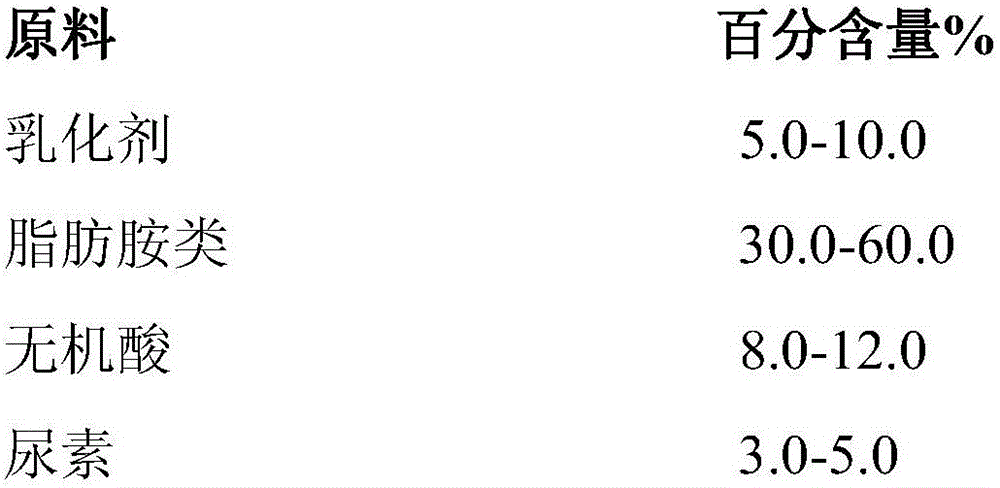

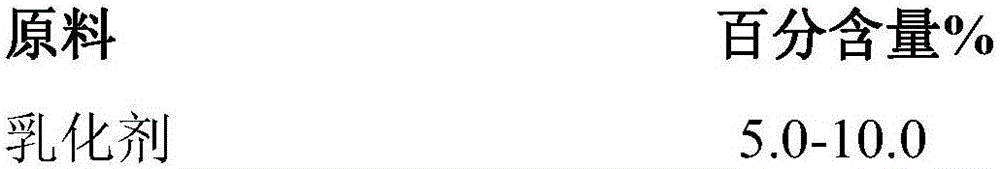

Acrylic dye-retarding agent and preparation method thereof

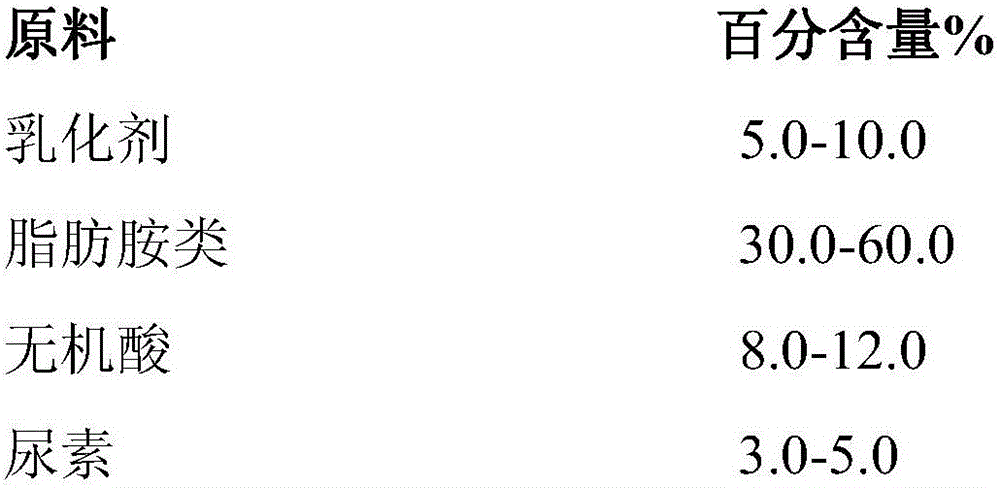

The invention relates to the technical field of weaving dye auxiliaries, in particular to an acrylic dye-retarding agent and a preparation method thereof. The acrylic dye-retarding agent comprises, by mass percentage, 5.0-10.0% of emulsifier, 30.0-60.0% of fatty amines, 8.0-12.0% of inorganic acid, 3.0-5.0% of urea, and the balance water. During the preparation, the emulsifier and the fatty amine in the formula are sequentially added into a reaction kettle, the stirring rotating speed is 300 rpm, 50% of the total water amount in the formula is added, and the inorganic acid and the urea are added; after a system is slowly heated to 70-80 DEG C and is subjected to heat insulation reaction for 3 h and then cooled to 50 DEG C, the balance water in the formula is weighed and added into the reaction kettle to be stirred for 20 min; and after the stirring is performed, the mixture stands and is filtered and discharged. The acrylic dye-retarding agent is environmentally friendly, has no toxic or side effect on the human body, and is low in cost, very good in dye-retarding effect and suitable for being popularized and applied.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

A kind of acid leveling agent and preparation method thereof

The invention relates to the technical field of textile printing and dyeing materials and particularly discloses an acidic leveling agent and a preparation method thereof. The acidic leveling agent is prepared from the following components by weight percent: 10.0%-20.0% of an emulsifying agent, 20.0%-45.0% of fatty amine, 8.0%-10.0% of sulfamic acid, 5.0%-8.0% of fatty alcohol, 3.0%-5.0% of urea and the balance of water. The preparation method comprises the following steps: adding the raw materials except water into a reaction kettle in sequence according to the formula and stirring; when adding each type of raw material, stirring for 20-25 minutes; weighing the water amount needed in the formula and adding into the reaction kettle; stirring and reacting for 1 hour; and after finishing, standing and filtering and discharging materials. The acidic leveling agent disclosed by the invention has extremely good diffusivity and mobility, so that dye molecules are uniformly combined with fiber molecules in a dyeing process; the acidic leveling agent is wide in applicability, good in effect and environmentally friendly; and compared with a traditional formula, the agent has the advantages that 10%-15% of the cost is reduced.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

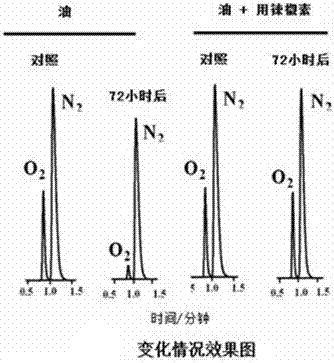

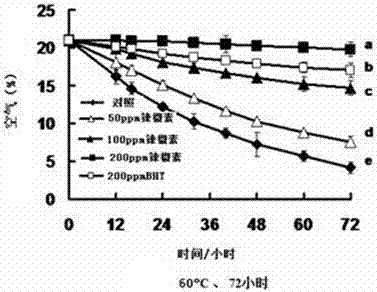

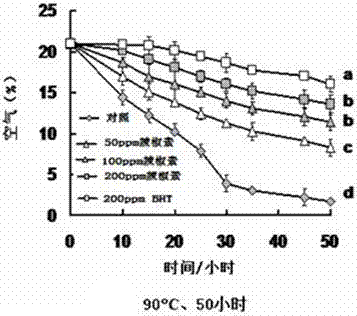

Edible oil taking natural capsaicine as antioxidant and application of natural capsaicine as antioxidant

InactiveCN106967506ANon-toxicImprove antioxidant capacityFatty substance preservation using additivesEdible oils/fatsPotential toxicityAntioxidant

The invention discloses the application of natural capsaicine as an antioxidant to edible oil. The addition amount of the natural capsaicine in the edible oil is 100 to 200ppm. Experiments show that the added natural capsaicine has good oxidation resistance in different temperature zones; by replacing synthetic antioxidants with the natural capsaicine, potential toxicity and carcinogenic effect do not exist, compounding is not required, and the application is easy to realize.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Colorless and transparent picometer-scale electrolytic silver ion composite antibacterial agent and preparation method thereof

The invention relates to a preparation method of a colorless and transparent picometer-scale electrolytic silver ion composite antibacterial agent. The composite antibacterial agent is prepared from the following components in parts by weight: 1-5 parts of an electrolytic silver ion solution, 2-8 parts of polyphosphate, 0.2-0.4 part of glacial acetic acid, 50-80 parts of hydrogen peroxide, 0.1-0.5part of glycerol, 25-40 parts of ultrapure water and an additional pH value regulator. The method adopts the hydrogen peroxide, the electrolytic silver ion solution and the ultrapure water as main sterilizing components, so that the prepared antibacterial agent has the characteristics of being broad in spectrum, high in efficiency, safe and environmentally-friendly; the shelf life of the composite antibacterial agent is up to 24 months; the product is widely applied to the fields such as medical treatment and public health, transportation, food and beverage, public environment, household life, personal products, air sterilization, livestock breeding, agricultural planting and water treatment, and has good economic and social benefits.

Owner:洛阳民康生物工程有限公司

A kind of preparation method of environment-friendly rubber filling oil

ActiveCN106467762BHigh aromatic contentGood compatibilityTreatment with hydrotreatment processesHydrocarbon oils refiningPolycyclic aromatic hydrocarbonResource utilization

The invention relates to a preparation method of environment-friendly rubber filling oil, which comprises the following steps: performing solvent extraction to high-aromatic oil in an extraction column, and recovering solvent from a product obtained in the top of the extraction column to prepare the environment-friendly rubber filling oil, and recovering solvent from a product obtained in the bottom of the extraction column to obtain extract oil; and (B) hydrogenating the extract oil to obtain hydrogenated treated oil, and feeding the hydrogenated treated oil back so as to mix the hydrogenated treated oil with the high-aromatic oil to perform the solvent extraction again, and repeating the steps in the manner hereinabove. By means of the method, the rubber filling oil has high aromatic hydrocarbon content and excellent compatibility with rubber, and has high processability, so that when being used in production process of tires, the rubber filling oil enables the tires to have excellent anti-slippery performance and the like. In the environment-friendly rubber filling oil, the content of polycyclic aromatic hydrocarbon compounds satisfies export European Union standard. The rubber filling oil is toxic-free and has no cancer causing effect, wherein the high-aromatic oil are all converted into the rubber filling oil, thus improving resource utilization rate and actually achieving green and environment protection in the whole process.

Owner:SINOPEC YANGZI PETROCHEM +1

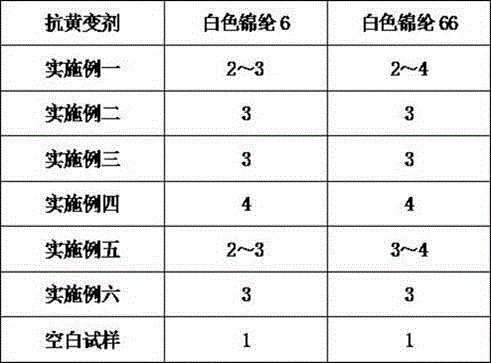

Anti-yellowing agent

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

A kind of acrylic fiber dye inhibitor and preparation method thereof

The invention relates to the technical field of weaving dye auxiliaries, in particular to an acrylic dye-retarding agent and a preparation method thereof. The acrylic dye-retarding agent comprises, by mass percentage, 5.0-10.0% of emulsifier, 30.0-60.0% of fatty amines, 8.0-12.0% of inorganic acid, 3.0-5.0% of urea, and the balance water. During the preparation, the emulsifier and the fatty amine in the formula are sequentially added into a reaction kettle, the stirring rotating speed is 300 rpm, 50% of the total water amount in the formula is added, and the inorganic acid and the urea are added; after a system is slowly heated to 70-80 DEG C and is subjected to heat insulation reaction for 3 h and then cooled to 50 DEG C, the balance water in the formula is weighed and added into the reaction kettle to be stirred for 20 min; and after the stirring is performed, the mixture stands and is filtered and discharged. The acrylic dye-retarding agent is environmentally friendly, has no toxic or side effect on the human body, and is low in cost, very good in dye-retarding effect and suitable for being popularized and applied.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

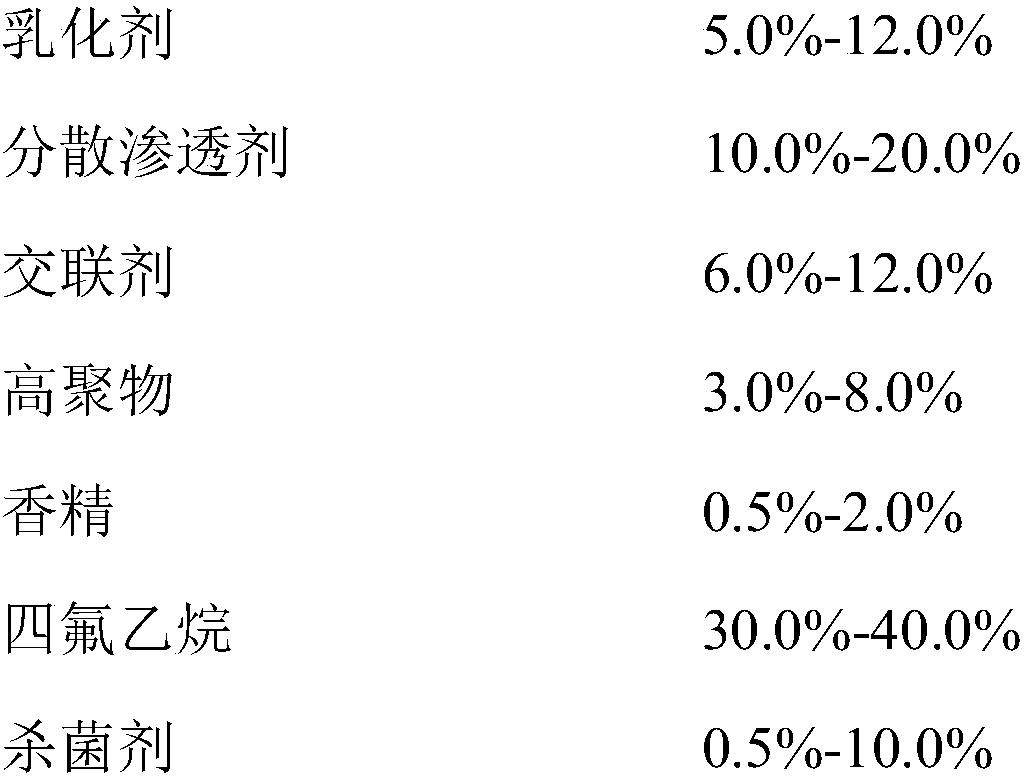

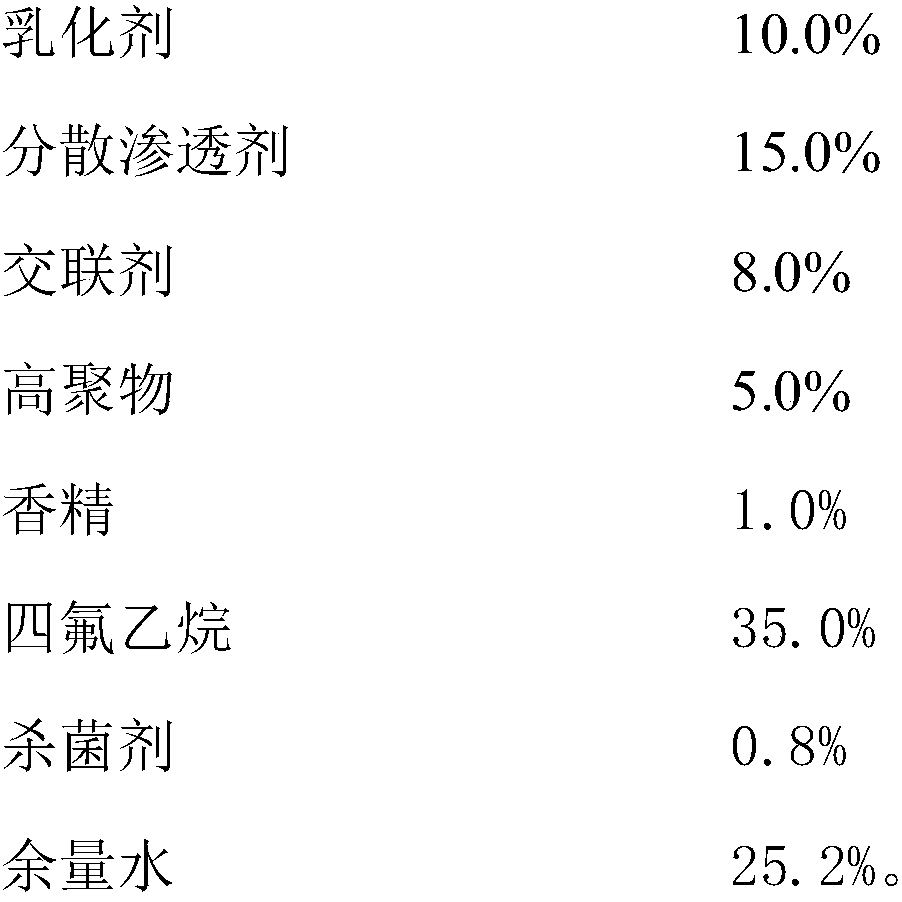

Deodorizing detergent and preparation method thereof

InactiveCN109370804AGood deodorizing effectReduce manufacturing costNon-ionic surface-active compoundsOrganic detergent compounding agentsCleanserWetting

The invention provides a deodorizing detergent and a preparation method thereof. The deodorizing detergent is prepared from the following components in parts by mass: 5.0%-12.0% of an emulsifier, 10.0%-20.0% of dispersion penetrant, 6.0%-12.0% of a crosslinking agent, 3.0%-8.0% of high polymer, 0.5%-2.0% of essence, 30.0%-40.0% of tetrafluoroethane, 0.5%-10.0% of fungicide, and the balance of water. According to the deodorizing detergent, the fungicide which is environmentally friendly and safe is used for sterilizing and the essence is used for deodorizing; compared with products of the samegrade, the preparation cost is reduced by 15.0-8.0% and the sterilizing, deodorizing and cleaning effect is improved by 5.0-8.0%; and the deodorizing detergent has excellent wetting power, penetration, emulsifying power, degreasing power and cleansing detergency, and good hard water resistance and acid and alkali resistance.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

Method for producing environment-friendly rubber oil through blending method

ActiveCN101693772BImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the contentof PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

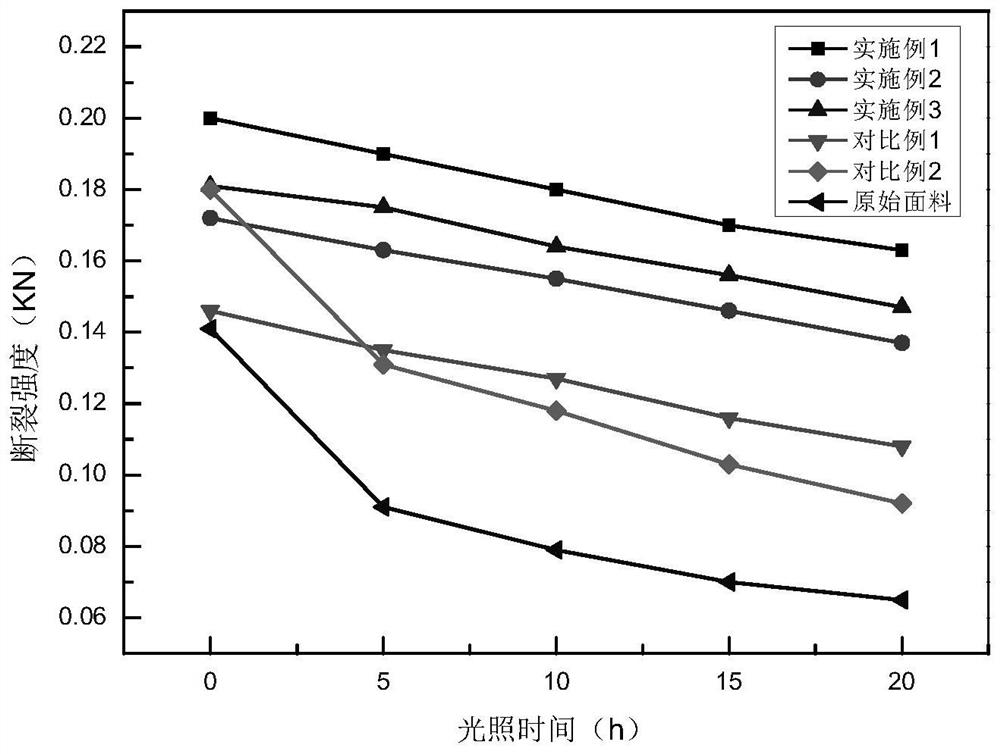

Preparation method of ultraviolet aging resistant textile fabric added with attapulgite

PendingCN114525675AEnhance toughening effectGood mechanical propertiesLight resistant fibresVegetal fibresPolymer scienceCotton fibre

The invention belongs to the technical field of textile fabrics, and particularly relates to a preparation method of an attapulgite-added anti-ultraviolet aging textile fabric. According to the preparation method, a composite material of attapulgite loaded nano CeO2 and nano ZnO is arranged on cotton fibers, so that the anti-ultraviolet aging textile fabric is prepared. According to the preparation method, not only can the prepared fabric have good mechanical properties, but also the fabric can have lasting and excellent ultraviolet aging resistance. Operation is simple and easy to control. The raw materials are nontoxic and have no carcinogenic effect, the prepared anti-ultraviolet aging fabric is woven by wrapping the surface of the fiber with the anti-ultraviolet aging agent, and the fabric has good anti-ultraviolet aging performance in all directions.

Owner:常州纳欧新材料科技有限公司

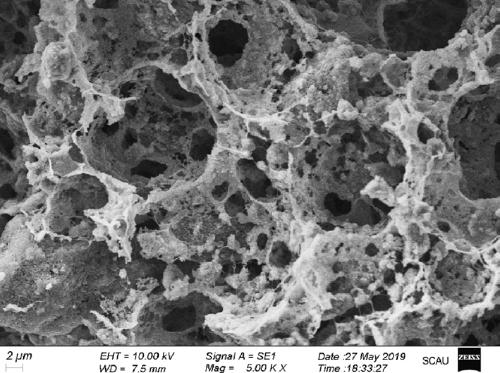

A porous grade composite medical gel scaffold constructed by 3D printing and its preparation method

ActiveCN109432505BGuaranteed performanceGood biocompatibilityAdditive manufacturing apparatusTissue regeneration3d printFormulary

Owner:SOUTH CHINA AGRI UNIV

Production technology of high-purity stevioside

ActiveCN102816192BNo carcinogenic effectRefreshing tasteSugar derivativesSugar derivatives preparationSide effectFiltration

The invention relates to a production technology of high-purity stevioside. The technology is characterized in comprising the steps of: an extraction step, a flocculation step, a membrane filtration step, an adsorptive separation step, a reverse osmosis concentration step, a desalting and de-coloring step, and a recrystallization step. The technology provided by the invention has advantages that: the stevioside is a completely safe foodstuff additive with no toxicity, no side effect, no teratogenic effect, no mutagenic effect, no carcinogenic effect, refreshing taste, good taste, high purity, and high sweetness. Therefore, requirements of people can be satisfied. During a production process of stevioside, no chemical method or chemical raw material is adopted, and no pollutant is discharged. A small amount of waste residual can be comprehensively used as a bio-fertilizer. Stevia leaf is a good organic fertilizer rich in organics, and can be used for improving and fertilizing soil. Therefore, a waste pollution problem is solved from the source.

Owner:NANTONG CHANGHAI FOOD ADDITIVE

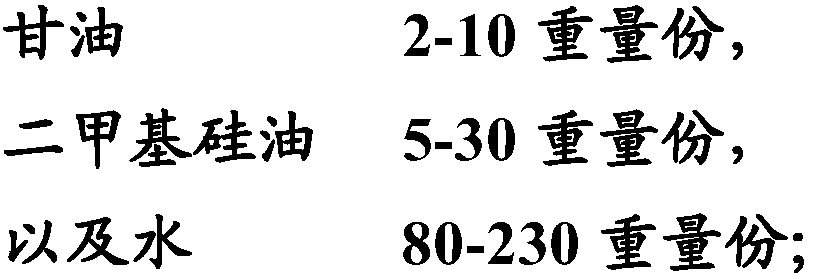

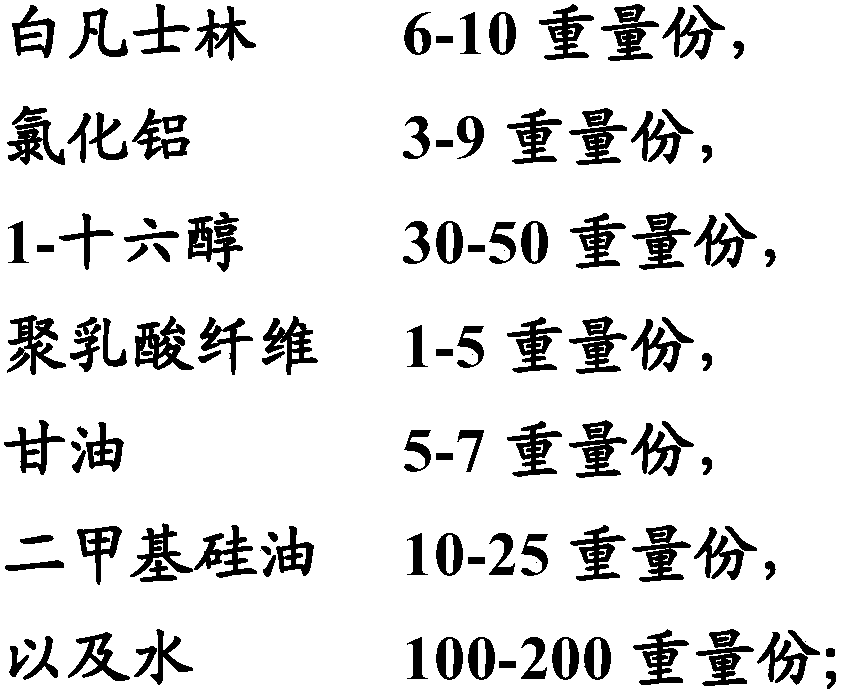

A whitening composition, its preparation method and use

ActiveCN106317952BNo carcinogenic effectNo pollution in the processFibre treatmentNon-macromolecular organic additionAluminium chlorideWhitening Agents

The invention belongs to the field of textile or papermaking, and relates to the whitening of textiles or paper, in particular to a whitening composition which comprises white vaseline and aluminum chloride. The invention also relates to a preparation method and use of the whitening composition. The whitening composition provided by the invention has advantages of low carcinogenicity, environmental protection, health and no pollution, and has a whitening effect approximate to that of the conventional ordinary whitening agent.

Owner:CHINA TOBACCO FUJIAN IND

Imidacloprid oil solution and use thereof

InactiveCN100401892CSystemically activeLong durationBiocideAnimal repellantsAdditive ingredientGrasshopper

The invention discloses an oil solution of imidacloprid which comprises the following constituents (by weight portions): imidacloprid 0.5-15.5%, stabilizer 1-25%, and balancing dissolvent. The stabilizer being phenylcarbinol and / or isopropanol. The solution can be used for controlling grasshopper and Locusta migratoria manilensis (Meyen).

Owner:INST OF PLANT PROTECTION HEBEI ACAD OF AGRI & FORESTRY SCI

A kind of bactericidal softener for pure cotton fabric

The invention discloses a bactericidal softener for pure cotton fabrics, which comprises components A and B, component A includes components A, B and C, and its components include the following components in parts by mass: component A: hard 67-75 parts of fatty acid, 21-23 parts of diethylenetriamine as polyamine, 11-15 parts of diethylenetriamine; Component B: 9-11 parts of dimethyl sulfate, 7 parts of diethyl sulfate ‑9 parts, 6‑10 parts of epichlorohydrin, 5‑9 parts of diethyl sulfate; C component: 4‑8 parts of glycerol monostearate, 7‑15 parts of Tween, fatty alcohol polyoxyethylene ether 2‑6 parts; component B: 17‑21 parts of sorbitan stearate, 7‑13 parts of fatty alcohol polyoxyethylene ether, 12‑16 parts of baking soda, 13‑15 parts of sodium tripolyphosphate, ethanol 18-22 parts; the product of the present invention is safe, reliable, green and environmentally friendly, non-toxic, harmless and non-irritating to the human body, and the manufacturing process is simple and easy to operate, the raw materials are easy to obtain, and the production cost is low.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com