Stripping resistant self-adhered polymer modified asphalt membrane at low temperature and preparation method thereof

A technology for modifying asphalt and polymers, which is applied in building thermal insulation materials, chemical instruments and methods, building components, etc., can solve the problems of self-adhesive construction of modified asphalt coils, etc., and achieves good low temperature peeling resistance, The effect of good heat resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

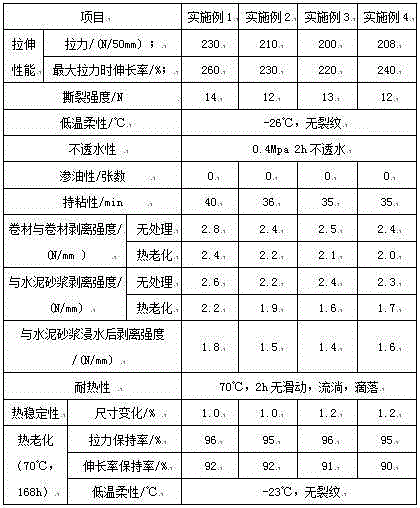

Examples

Embodiment 1

[0063] Embodiment 1 A kind of sticky polymer modified asphalt roll material of low temperature anti-peeling

[0064] The modified asphalt coil includes a surface material, a modified asphalt layer, and a separation film;

[0065] The surface material is a 45-degree strong cross film;

[0066] The thickness of the modified asphalt layer is 1.5mm;

[0067] The modified asphalt layer comprises the following components by weight:

[0068] Raw material components by weight

[0069] 42 parts of petroleum asphalt

[0070] 11 parts naphthenic oil

[0071] Thermoplastic styrene-butadiene rubber 4 parts

[0072] Styrene-isoprene-styrene 2.5 parts

[0073] 6 parts of powdered styrene-butadiene rubber

[0074] 2 parts coumarone resin

[0075] C5 hydrogenated petroleum resin 3 parts

[0076] 2 parts terpene resin

[0077] 0.05 parts of ultraviolet absorber

[0078] Antioxidant 0.03 parts

[0079] 0.22 parts of silane coupling agent

[0080] 27.2 parts of light calcium carbonat...

Embodiment 2

[0081] Embodiment 2 A kind of self-adhesive polymer modified asphalt membrane with low temperature resistance to stripping

[0082] The modified asphalt coil includes a surface material, a modified asphalt layer, and a separation film;

[0083] The surface material is PET reinforced metal aluminum foil;

[0084] The thickness of the modified asphalt layer is 1.5mm;

[0085] The modified asphalt layer comprises the following components by weight:

[0086] Raw material components by weight

[0087] 41 parts of petroleum asphalt

[0088] 12 parts naphthenic oil

[0089] 3 parts thermoplastic styrene-butadiene rubber

[0090] Styrene-isoprene-styrene 3.5 parts

[0091] 6 parts of powdered styrene-butadiene rubber

[0092] 2 parts coumarone resin

[0093] C5 hydrogenated petroleum resin 3 parts

[0094] 2 parts terpene resin

[0095] 0.05 parts of ultraviolet absorber

[0096] Antioxidant 0.03 parts

[0097] 0.22 parts of silane coupling agent

[0098] 27.2 parts of ligh...

Embodiment 3

[0099] Embodiment 3 A low-temperature anti-peeling adhesive polymer modified asphalt coil

[0100] The modified asphalt coil includes a surface material, a modified asphalt layer, and a separation film;

[0101] The surface material is a 45-degree strong cross film;

[0102] The thickness of the modified asphalt layer is 1.5mm;

[0103] The modified asphalt layer comprises the following components by weight:

[0104] Raw material components by weight

[0105] 50 parts of petroleum asphalt

[0106] 16 parts naphthenic oil

[0107] Thermoplastic styrene-butadiene rubber 10 parts

[0108] 1 part styrene-isoprene-styrene

[0109] 10 parts of powdered styrene-butadiene rubber

[0110] 1 part coumarone resin

[0111] C5 hydrogenated petroleum resin 1 part

[0112] Terpene resin 0.5 parts

[0113] 1 part UV absorber

[0114] Antioxidant 0.06 parts

[0115] 0.03 parts of silane coupling agent

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com