Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Ethyl 3-ethoxypropionate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ETHYL-3-ETHOXYPROPIONATE is an ester. Esters react with acids to liberate heat along with alcohols and acids. Strong oxidizing acids may cause a vigorous reaction that is sufficiently exothermic to ignite the reaction products.

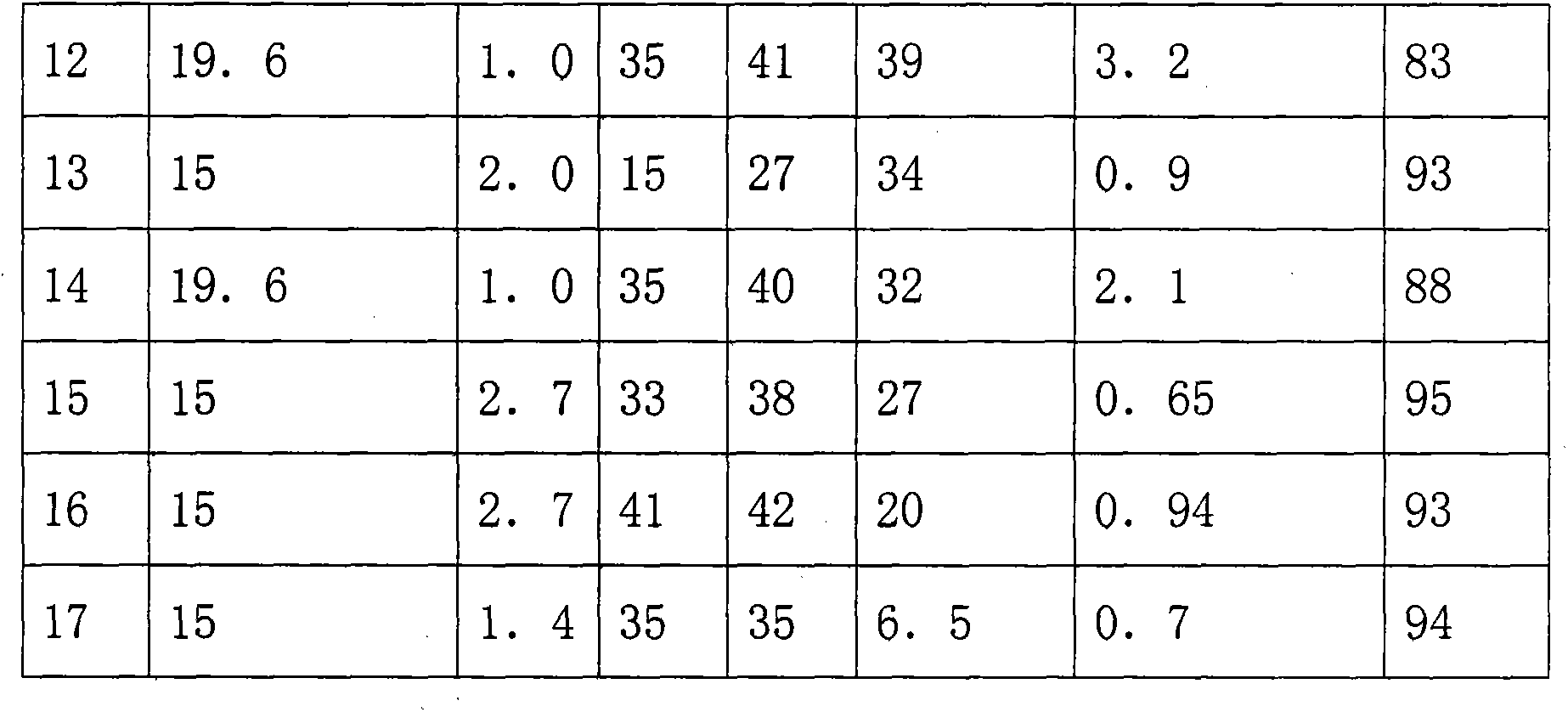

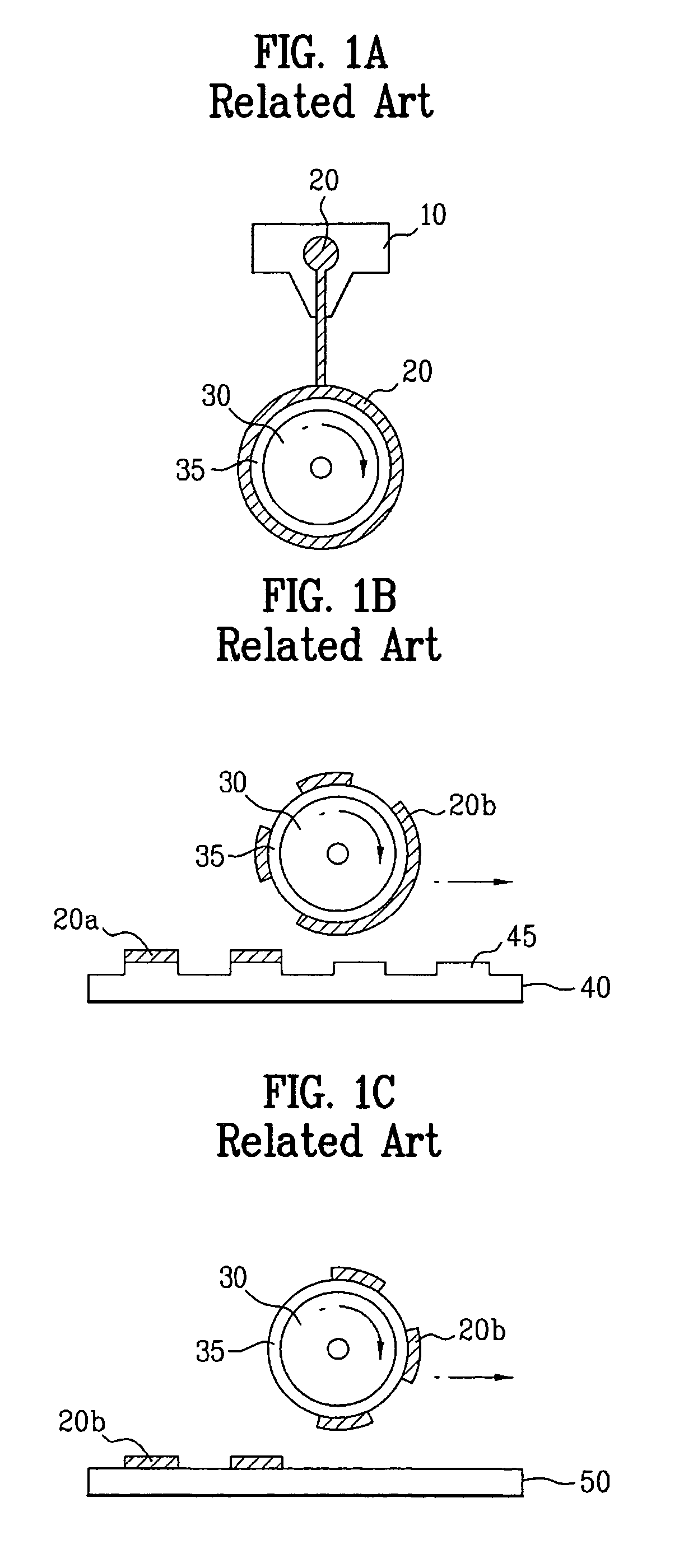

Particle size control for acetylenic agents useful in condition monitoring systems

ActiveUS7019171B1Improving quality performanceUrea derivatives preparationOrganic compound preparationNitrocelluloseRadiation Exposure Monitoring

Precipitation of polyacetylenic agents can be effected with control of a particle size parameter such as mean size or spread, by mixing a warm solution of the acetylenic agent with a cold precipitation fluid and appropriate selection of a constituent of the cold precipitation fluid and / or of the temperature conditions and collecting the precipitated acetylenic agent. Precipitation additives such as nitrocellulose or gelatin can usefully be employed. Solvents such as aqueous methanol and ethyl 3-ethoxypropionate can be useful. Polyacetylenic agents, e.g. substituted diacetylenics are useful to provide visual changes in condition-monitoring indicators such as time-temperature indicators, “TTIs”, useful as freshness indicators for radiation exposure monitoring and for other purposes. Controlled, small and / or consistent particle sizes of such polyacetylenic agents are helpful in providing consistent commercial properties, especially in inks in which they may be formulated.

Owner:TEMPTIME CORP

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS20070257235A1Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

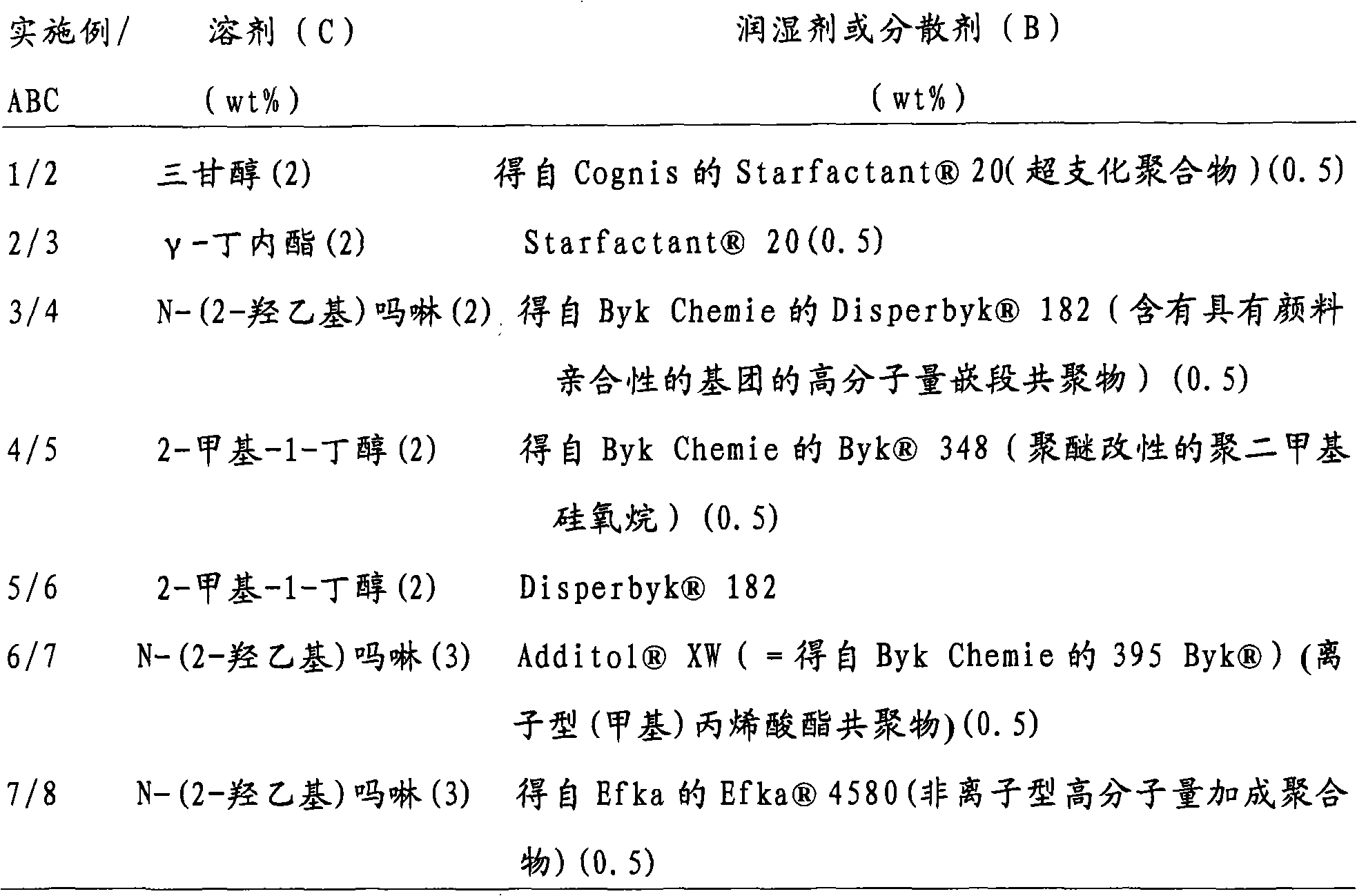

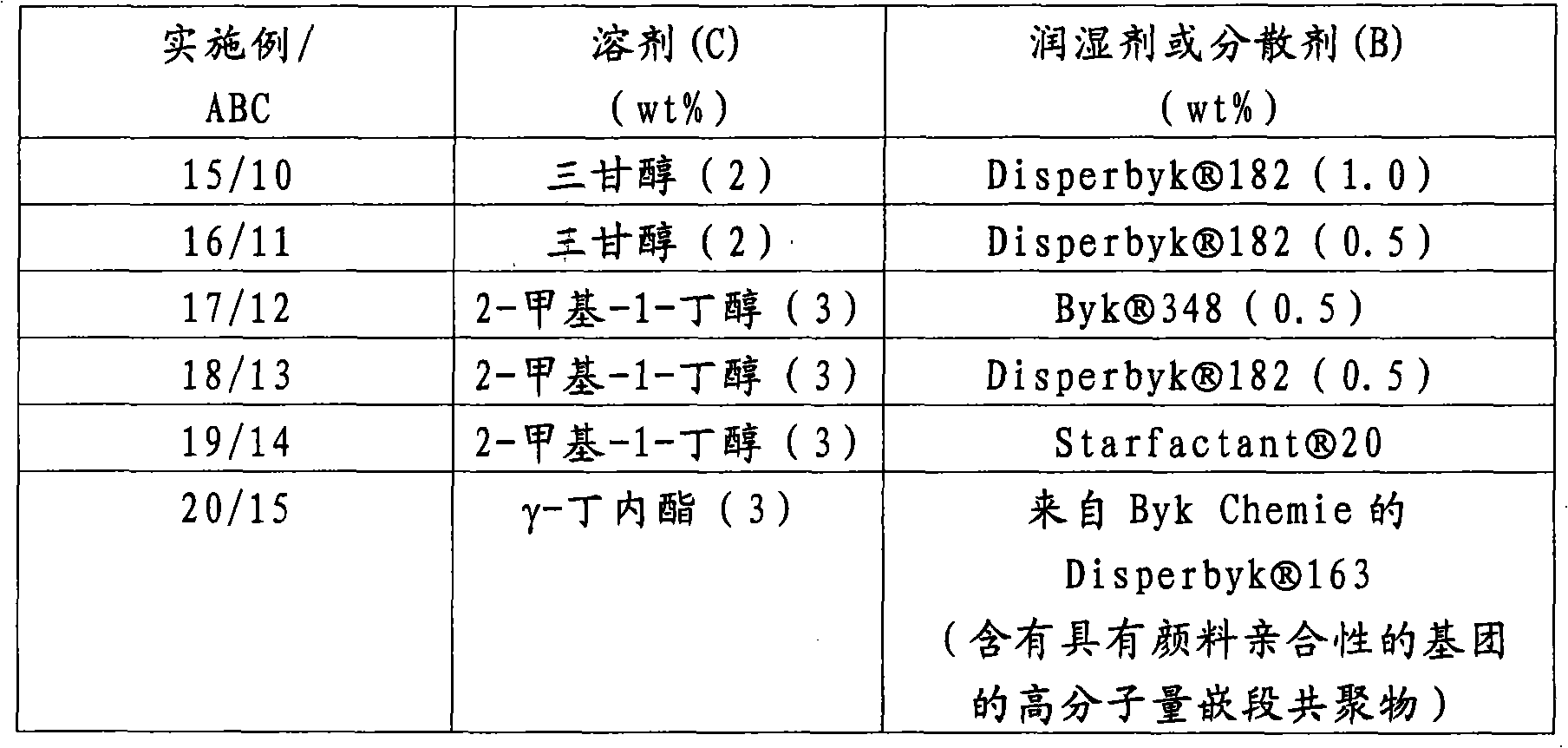

Aqueous coating material, method for the production thereof, and use thereof

ActiveCN101331196AEasy to manufactureLess spray cakingPolyurea/polyurethane coatingsSulfolane1-Pentanol

Disclosed is an aqueous coating material containing (A) at least one saturated and / or unsaturated polyurethane and / or an ionically and / or non-ionically stabilized polyurethane grafted with olefinically unsaturated compounds, (B) at least one wetting agent or dispersing agent, and (C) at least one organic solvent selected among the group comprising dimethylsulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexylglycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerin, trimethylolpropane solutions, pentaerythrite solutions, sorbit solutions, reactive polyether polyols having a number-average molecular weight of 110 to 6,000 Dalton and a hydroxyl number of 25 to 1,000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerin ethoxylate, ethyl-3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl); -piperidine, N-methylmorpholine, N-(2-hydroxyethyl)-morpholine, N-acetylmorpholine, N-cyclohexyl pyrrolidone, and N-octyl-2-pyrrolidone. Also disclosed are a method for producing said aqueous coating material and the use thereof.

Owner:BASF COATINGS GMBH

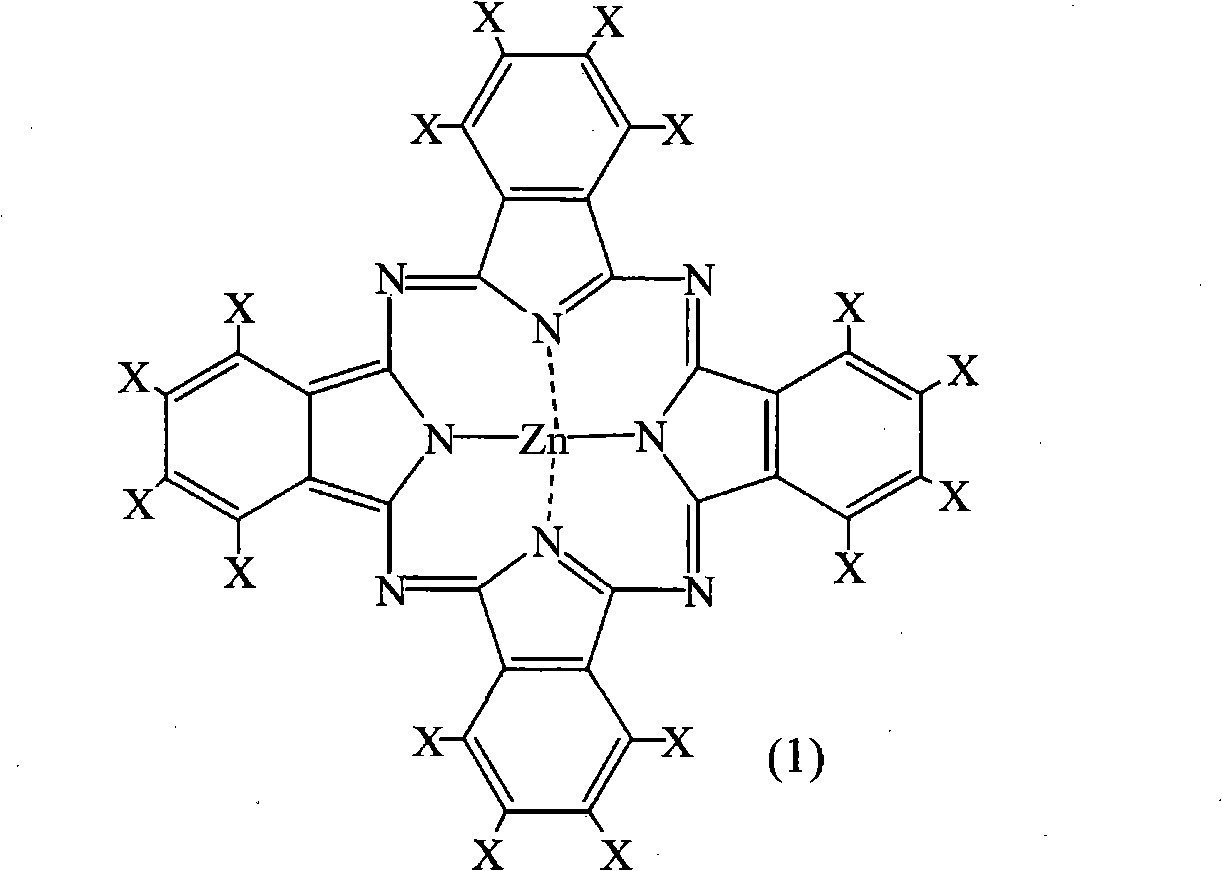

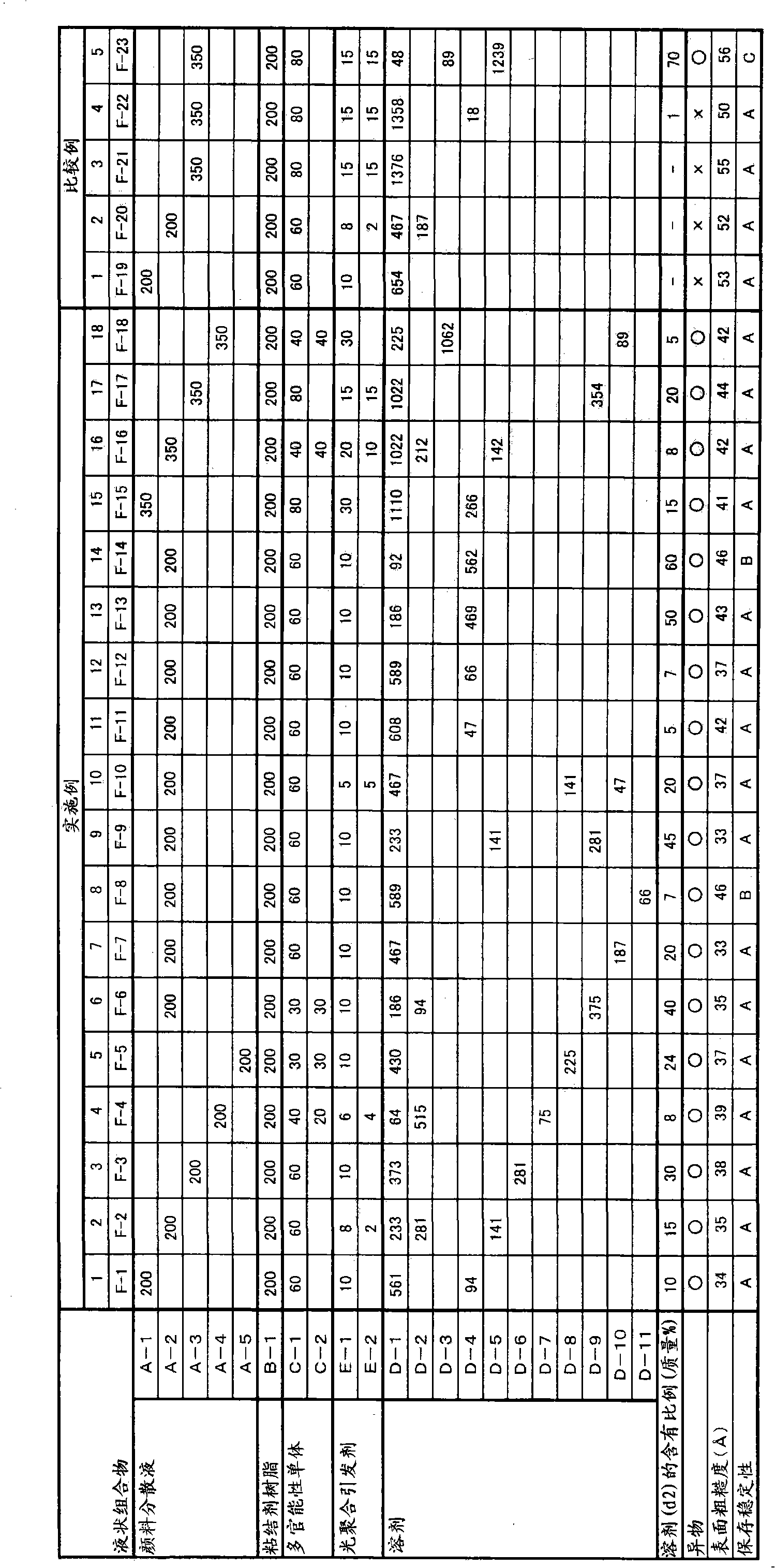

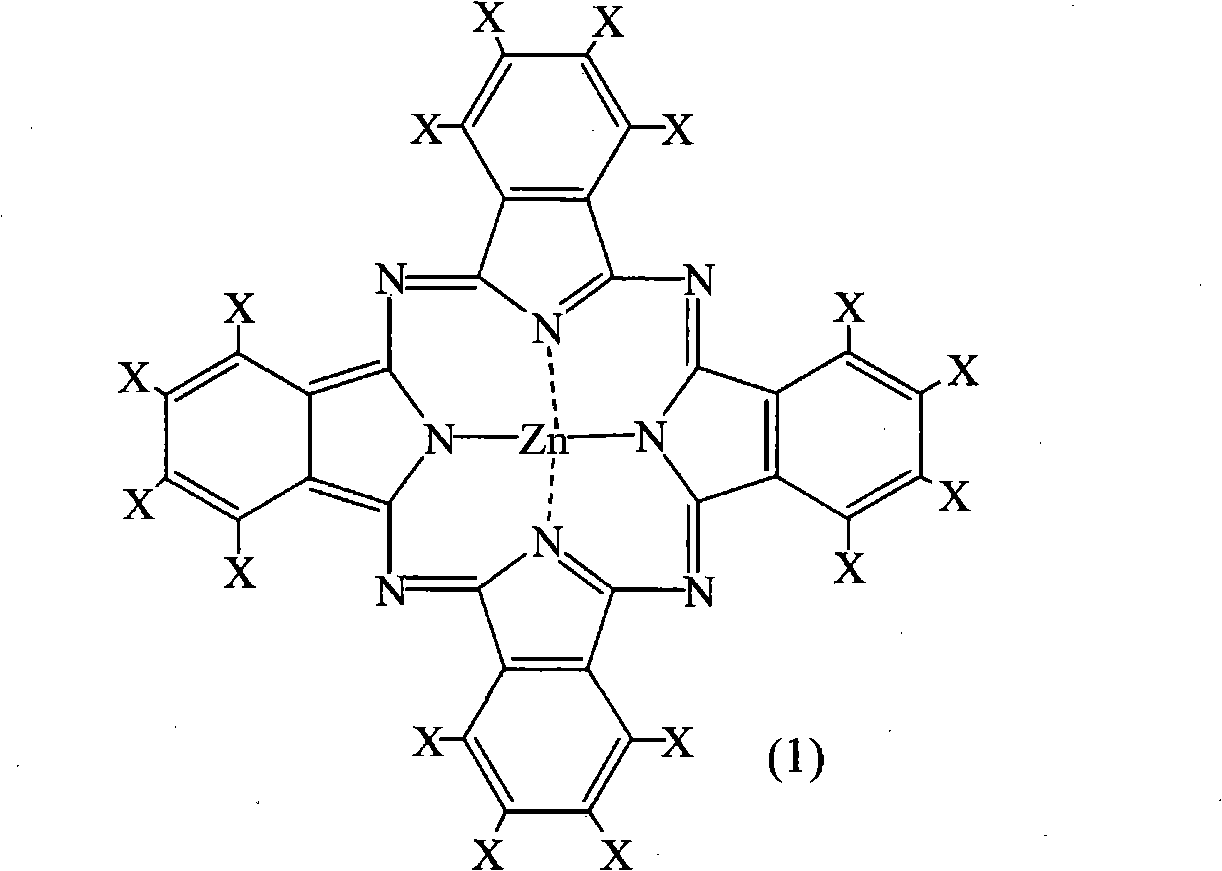

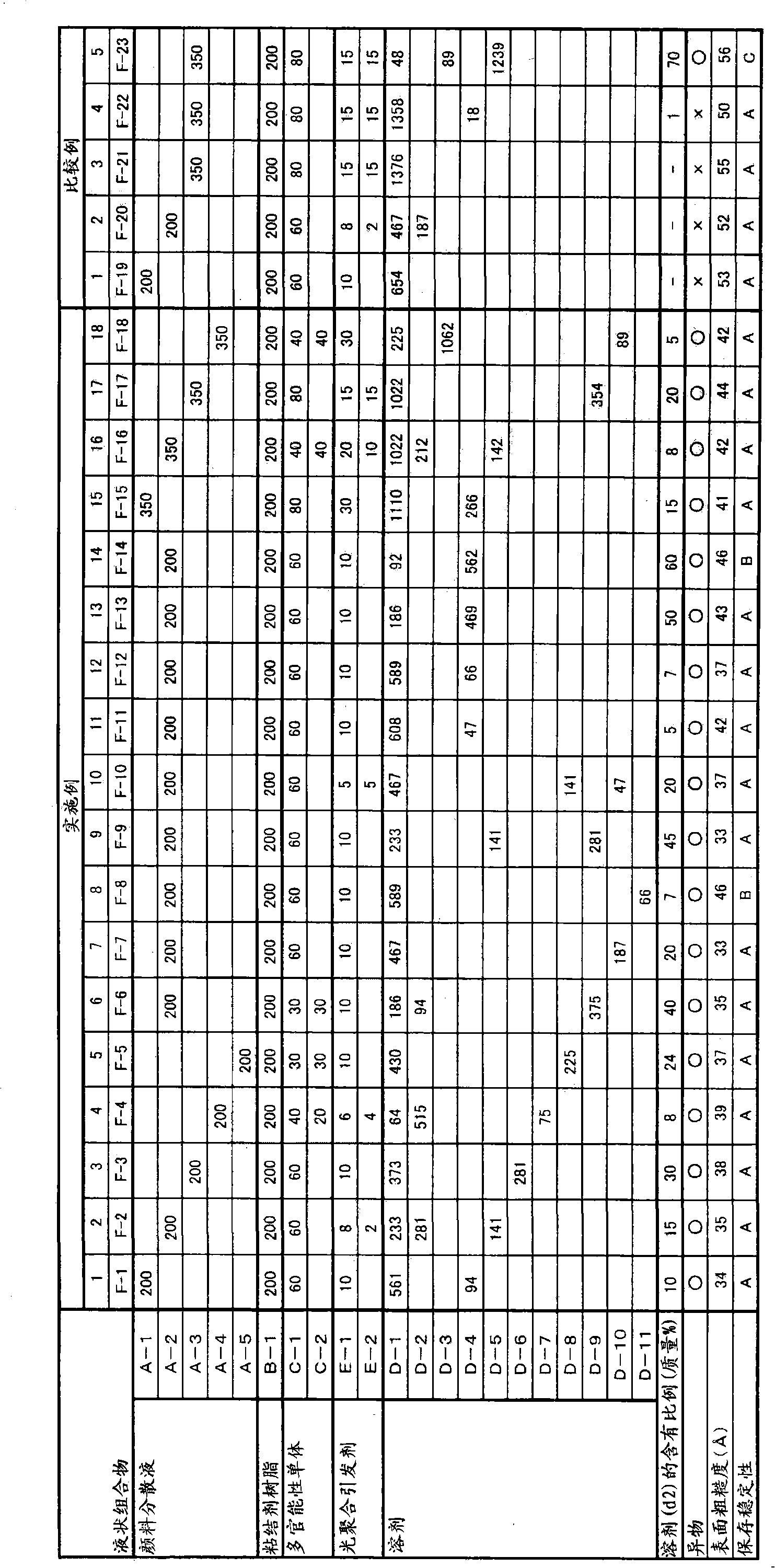

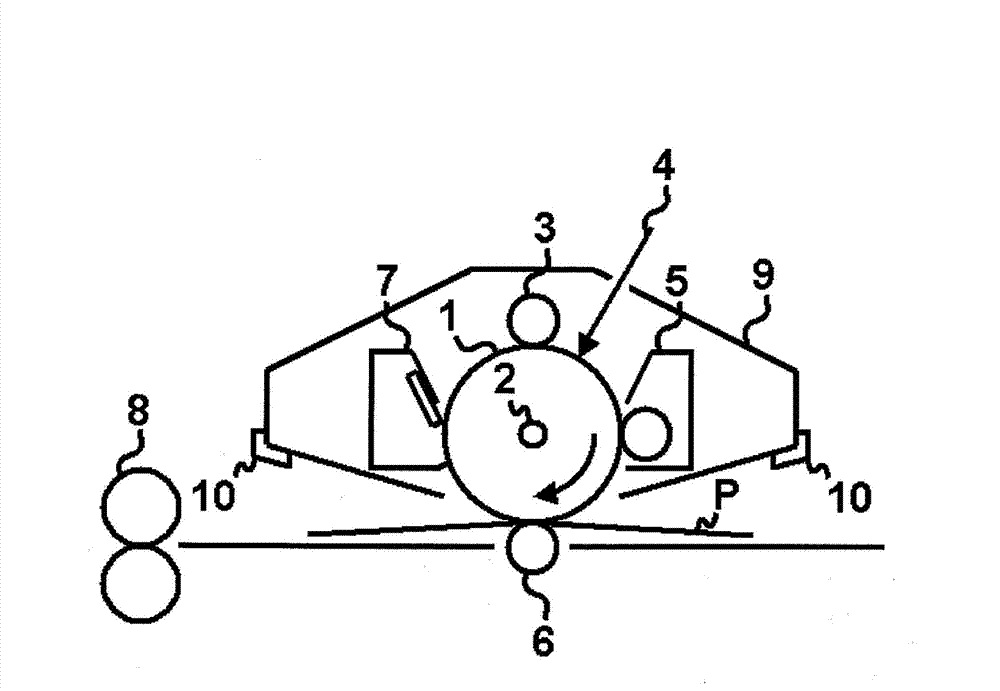

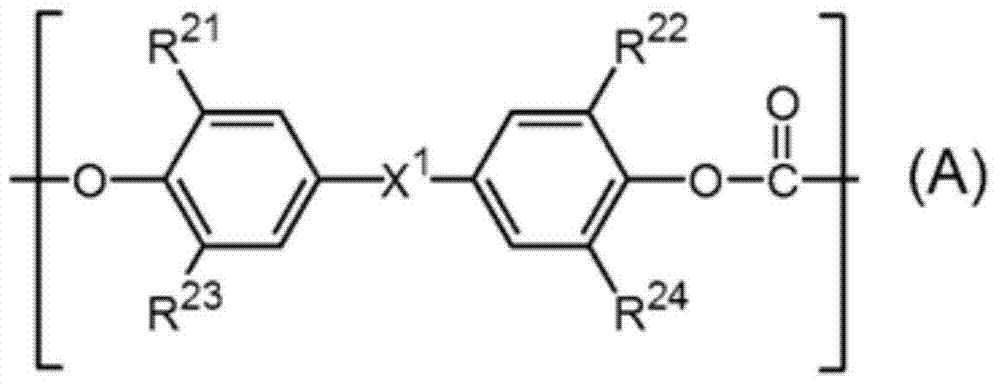

Coloring composition, color filter and color liquid crystal display device

ActiveCN101930177AImprove surface roughnessSuitable for makingOptical filtersPorphines/azaporphinesSolubilityPhthalocyanine

The invention relates to a coloring composition, color filter and color liquid crystal display device. The invention provides the coloring composition, which is suitable for the mass production of the color filter and contains a halogenated phthalocyanine zinc pigment. The coloring composition contains a colouring agent (A), a binder resin (B), a multifunctional monomer (C) and a solvent (D), characterized in that the colouring agent (A) contains halogenated phthalocyanine zinc, the solvent (D) contains at least one of propylene glycol methyl ether acetate, ethyl 3-ethoxypropionate and 3-Methoxybutyl acetate (d1) and a solvent with the solubility higher than that of the ethyl 3-ethoxypropionate (d2), and the solubility of the (d2) is higher than that of 5 to 60% by weight of the ethyl 3-ethoxypropionate in the total solvent.

Owner:JSR CORPORATIOON

Aqueous coating material, its preparation and use

ActiveUS20090270548A1Easy to prepareOutstanding performance propertyFilm/foil adhesivesPolyurea/polyurethane coatingsSulfolaneGlycerol

Disclosed herein is an aqueous coating material comprising (A) at least one polyurethane which is ionically stabilized, nonionically stabilized, or a combination thereof, and which is saturated, unsaturated, grafted with olefinically unsaturated compounds, or a combination thereof, (B) at least one wetting agent or dispersant; and (C) at least one organic solvent selected from the group consisting of dimethyl sulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexyl glycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerol, solutions of trimethylolpropane, solutions of pentaerythritol, solutions of sorbitol, reactive polyether polyols with a number-average molecular weight of 110 to 6000 daltons and a hydroxyl number of 25 to 1000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerol ethoxylate, ethyl 3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl)piperidine, N-methylmorpholine, N-(2-hydroxyethyl)morpholine, N-acetylmorpholine, N-cyclohexylpyrrolidone, N-octyl-2-pyrrolidone, and a combination thereof. Also disclosed is a process for preparing the foregoing aqueous coating material.

Owner:BASF COATINGS GMBH

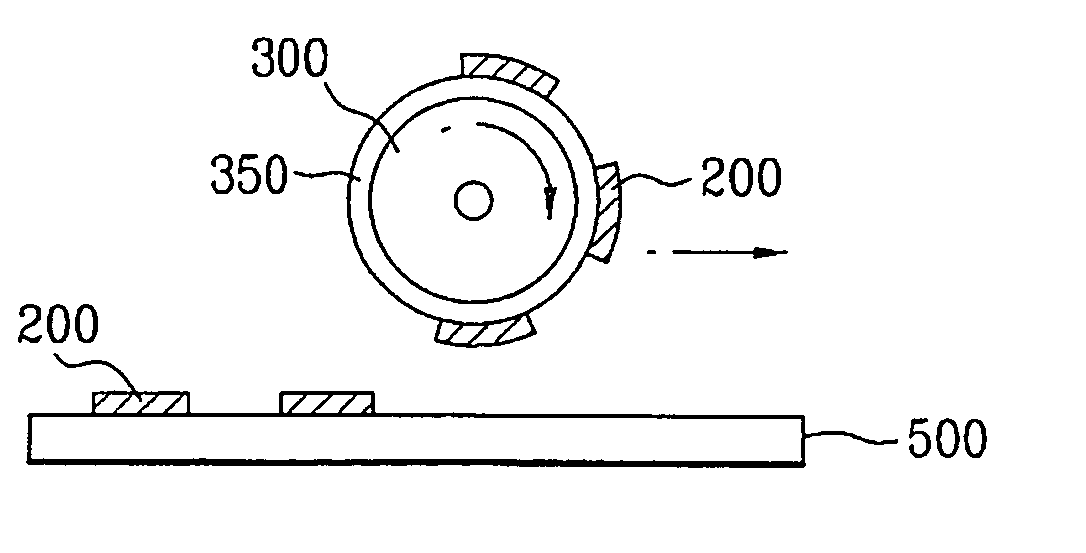

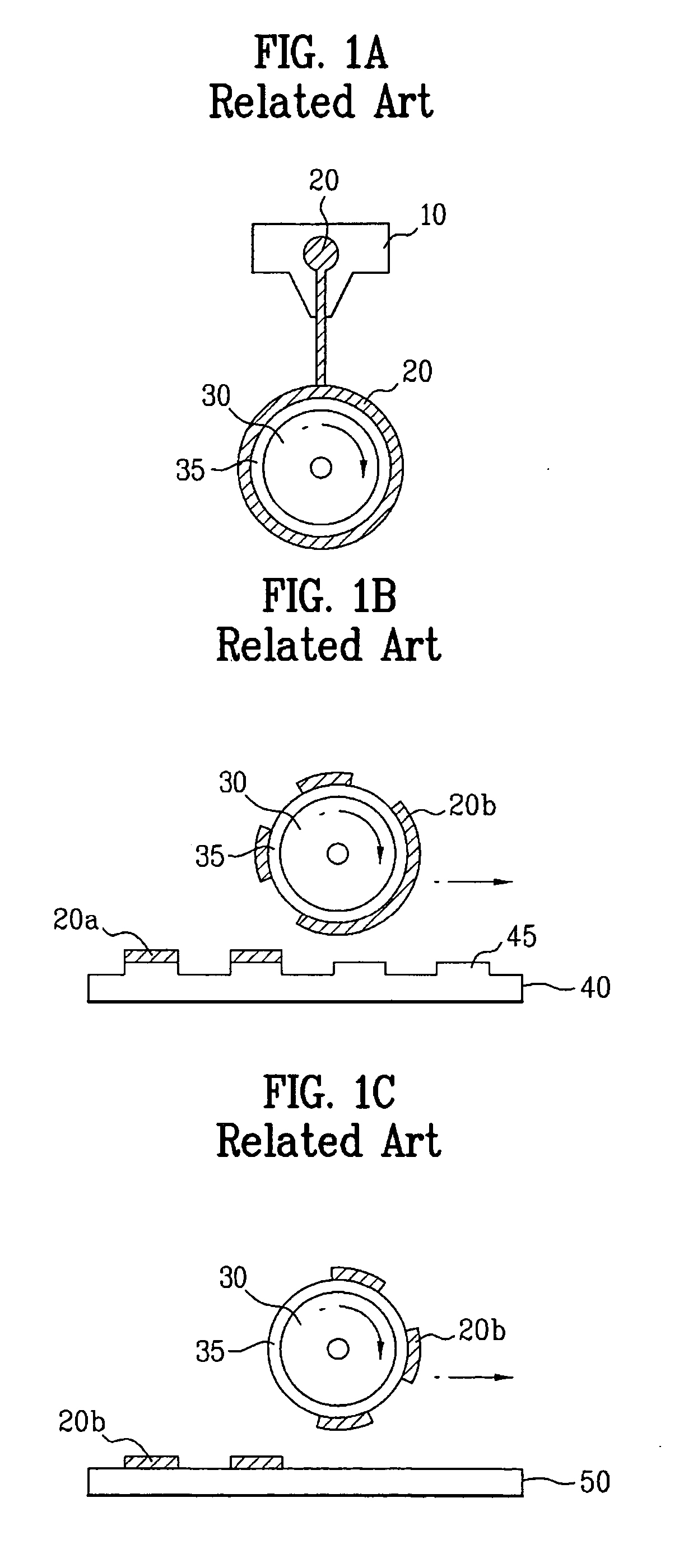

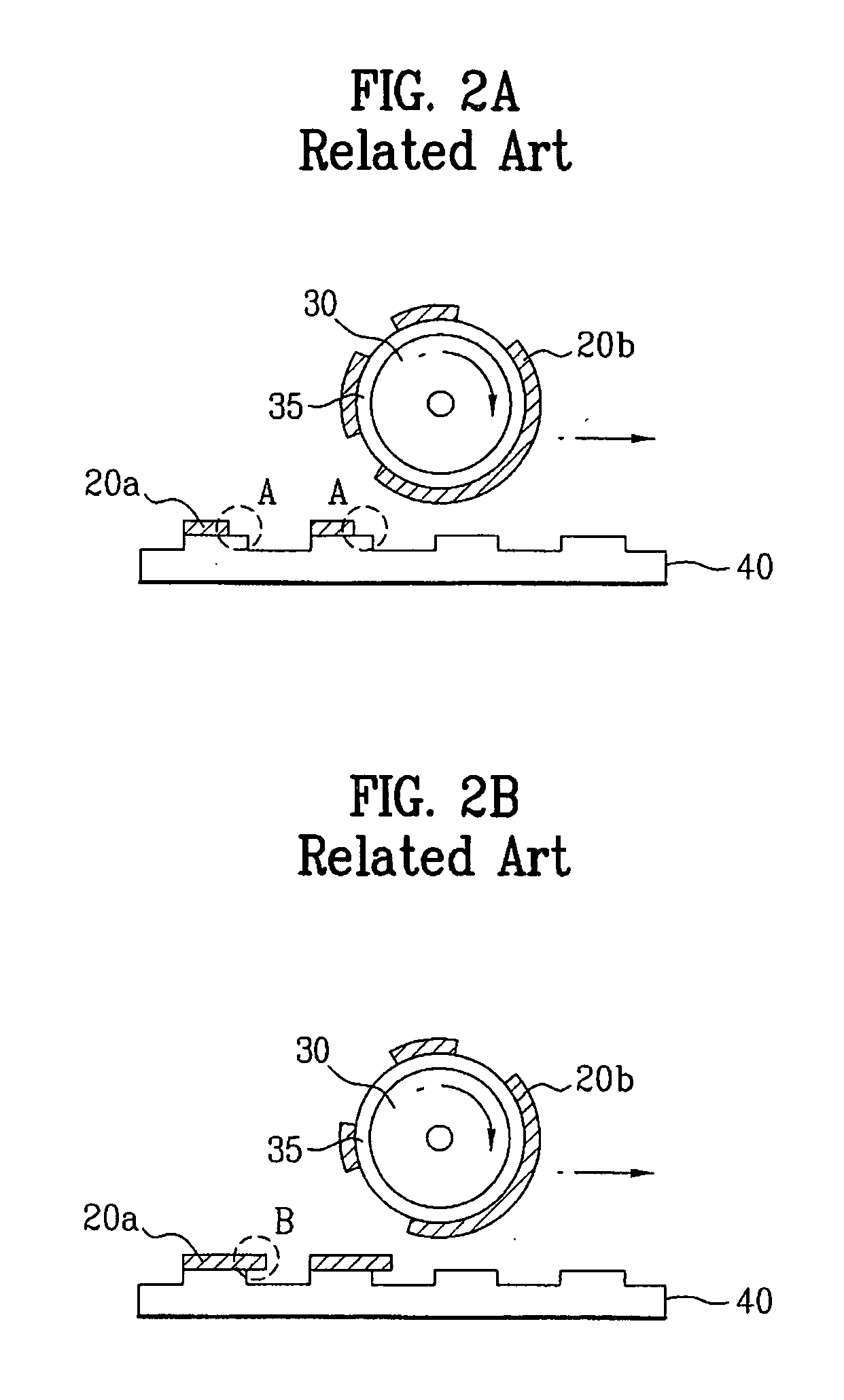

Solvent for printing, pattern composition for printing comprising the solvent, and patterning method using the composition

Disclosed is a solvent for printing which comprises a first solvent selected from the group consisting of acetone, methyl ethyl ketone, methyl acetate, ethyl acetate, methanol and mixtures thereof, and a second solvent selected from the group consisting of propylene glycol monomethyl ether acetate (PGMEA), propylene glycol monomethyl ether (PGME), isopropanol, butyl acetate, ethyl-3-ethoxypropionate and mixtures thereof. Further disclosed are a pattern composition for printing comprising the solvent for printing, and a patterning method using the composition. The use of the solvent for printing enables formation of an accurate pattern.

Owner:LG DISPLAY CO LTD

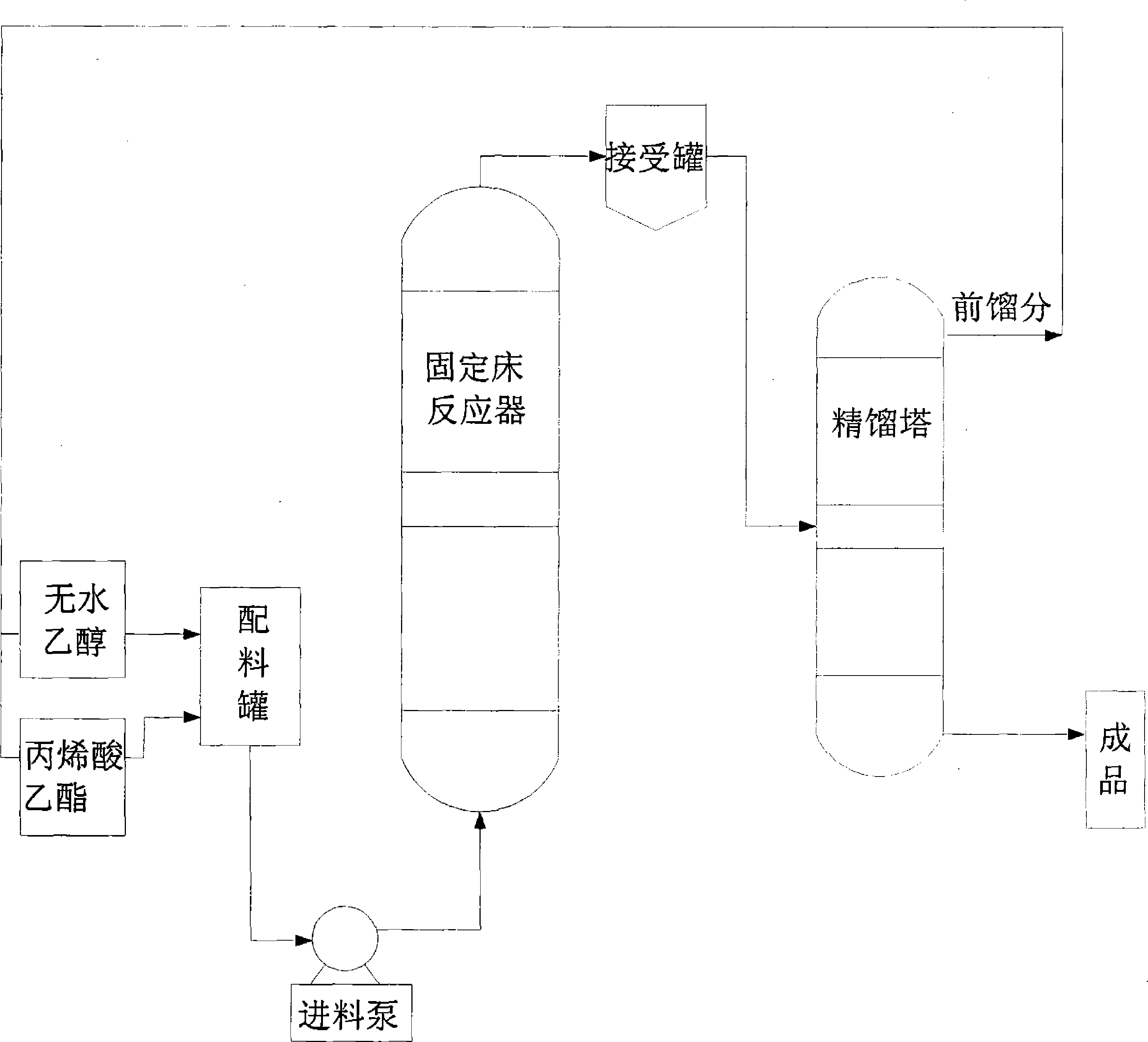

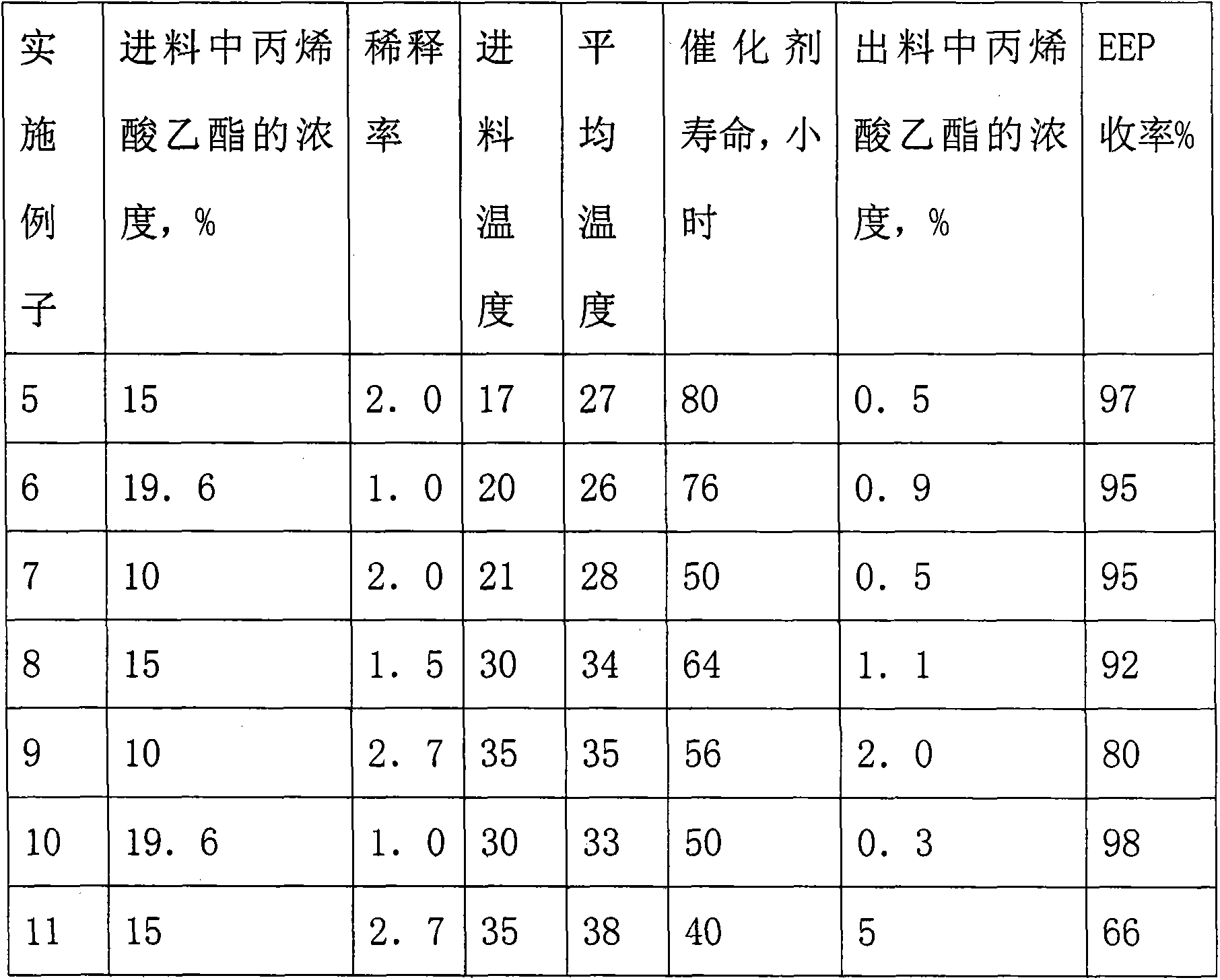

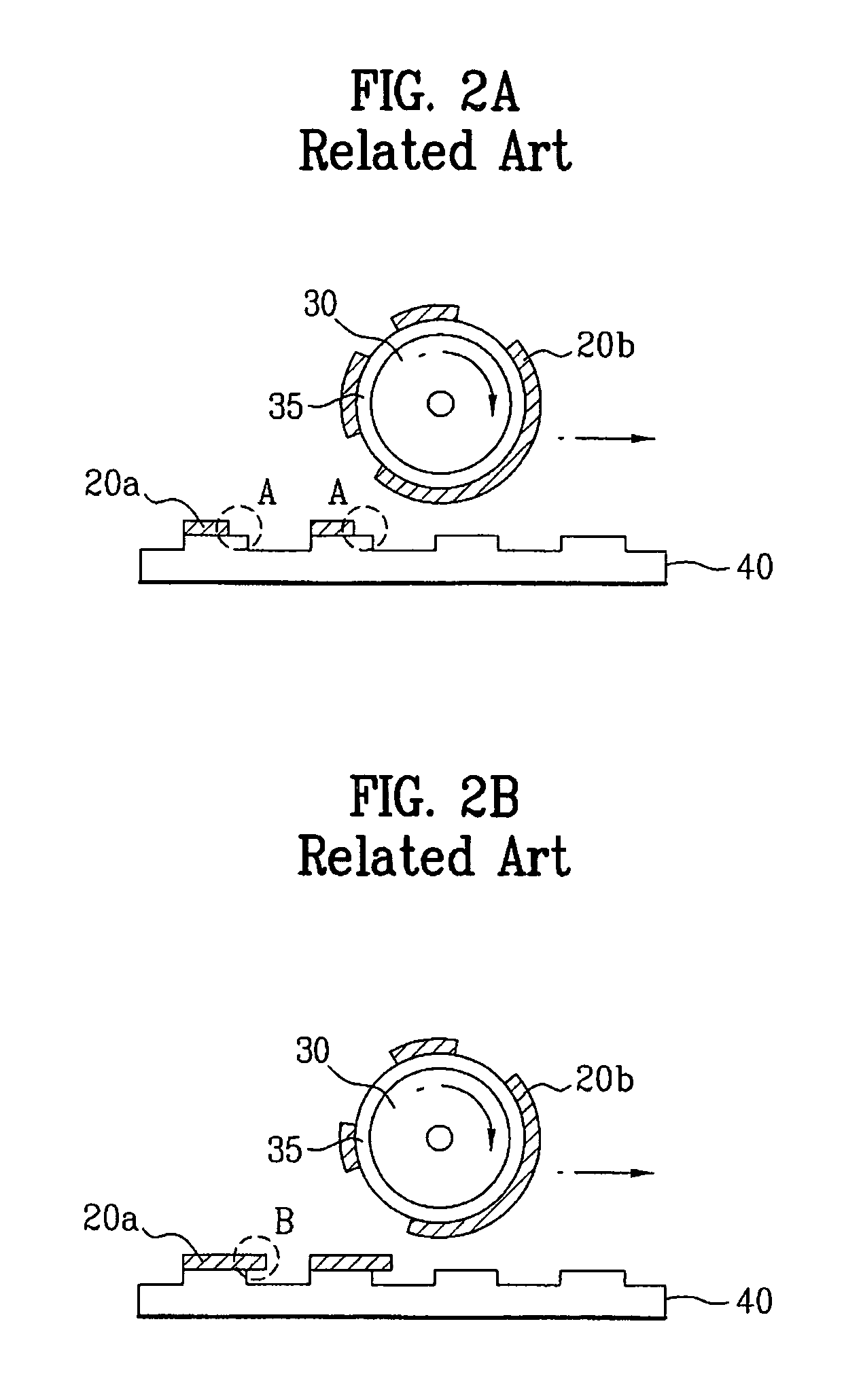

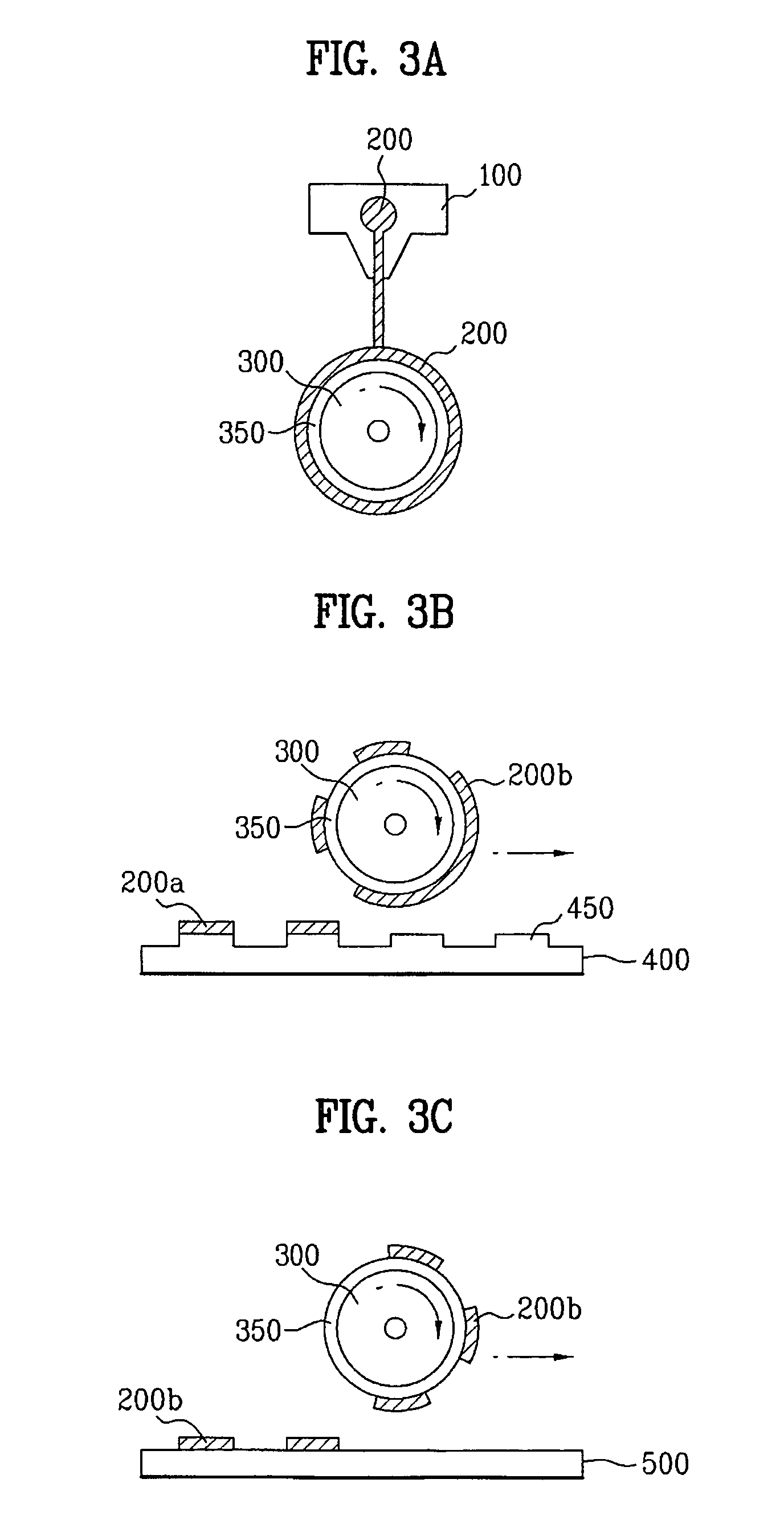

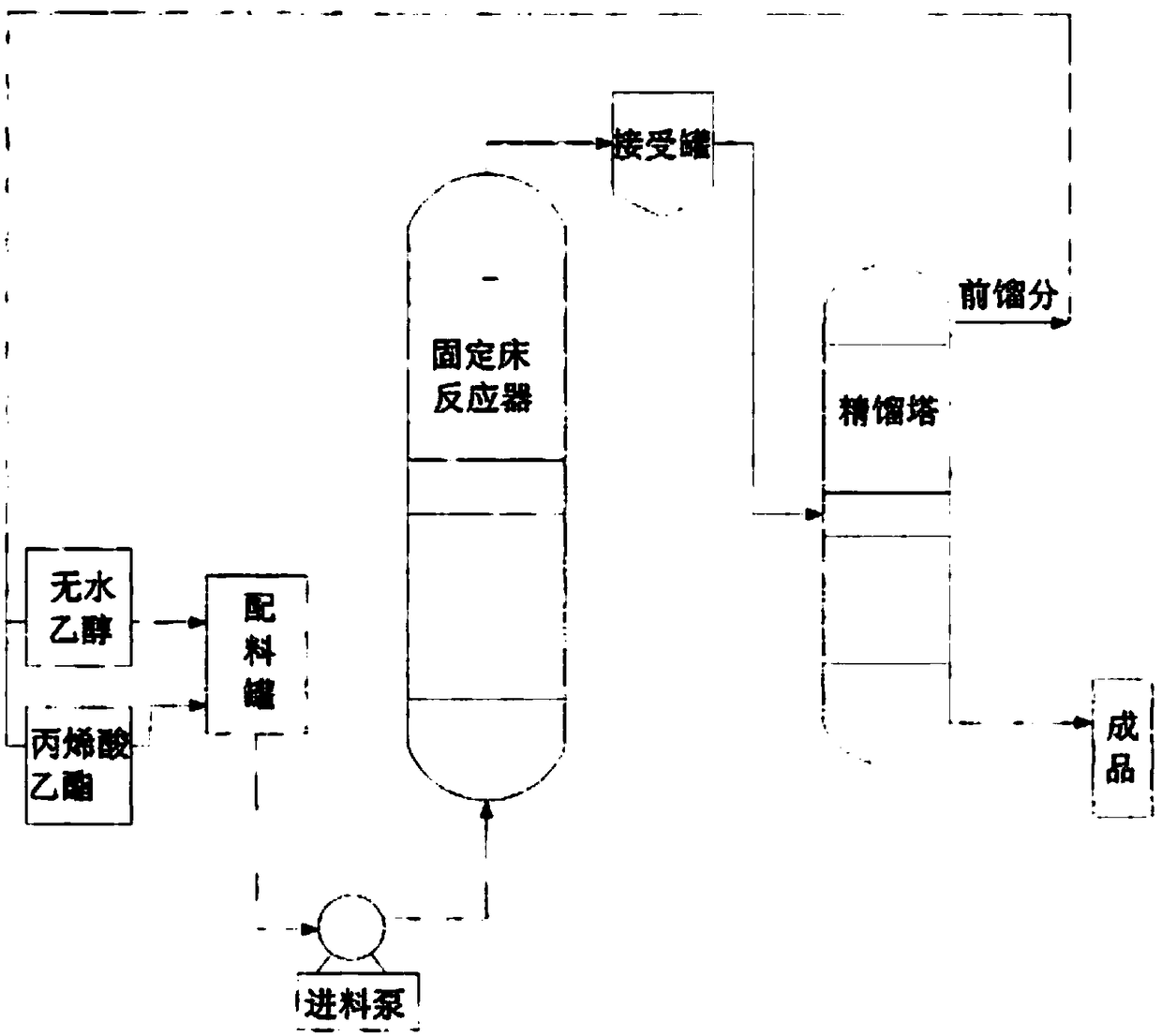

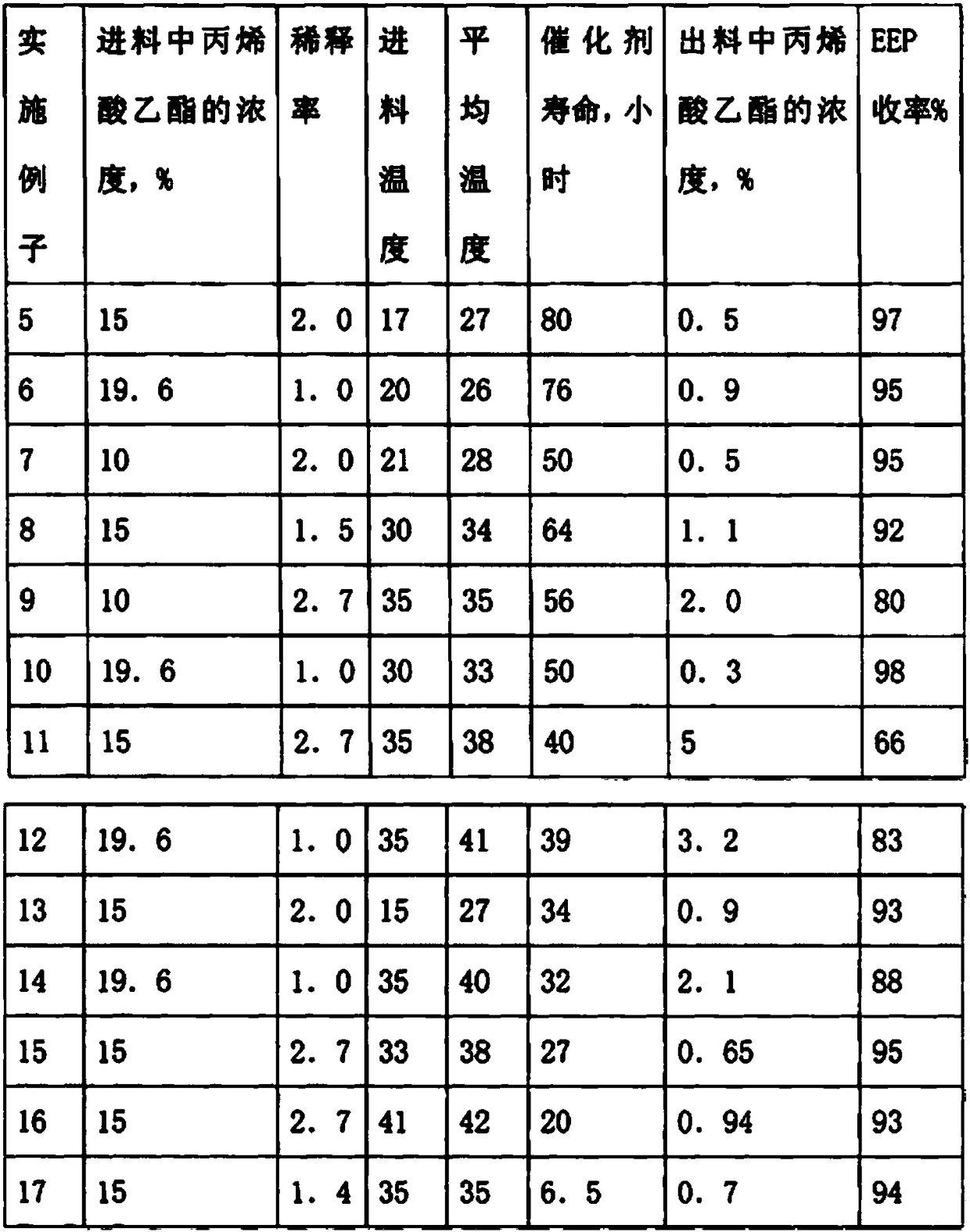

Preparation method for synthesis of ethyl 3-ethoxypropionate

InactiveCN104016861AEasy to separateFlexible operationOrganic compound preparationCarboxylic acid esters preparationChemical synthesisIon-exchange resin

The invention relates to the technical field of chemical synthesis, and particularly relates to a preparation method for synthesis of ethyl 3-ethoxypropionate; the ethyl 3-ethoxypropionate is synthesized by addition reaction of absolute ethanol and ethyl acrylate in the presence of a catalyst in a tubular reactor, the molar ratio of absolute ethanol to ethyl acrylate is 3: 1 to 100: 1, the catalyst weight accounting for 0.1% to 20% of the weight of the ethyl acrylate; the catalyst is anion exchange resin, and the method has the advantages of simple synthesis, mild condition, less side reaction, recycling and regeneration of the catalyst without damage, great simplification of the separation process, easy continuous production and the like.

Owner:SHENZHEN PRECHEM FINE CHEM CO LTD

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS7393474B2Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

Synergistic mixed solvents-based compositions for removal of paint, varnish and stain coatings

InactiveUS20160053203A1Less materialOrganic detergent compounding agentsChemical paints/ink removersSolvent basedStain

Compositions and methods are disclosed which are effective for removing or stripping varnish and paint or stains from surfaces such as wood or metal which comprises activating NMP and / or BLO with 1-20% by weight of ethyl 3-ethoxypropionate (EEP), preferably 2-15%, and optimally about 3-5%, and with 0.1-10% by weight of NOP / ALC EO, preferably 0.2-5%, most preferably 1 -3% by weight and / or 0.1-5% by weight of Silwett 77, preferably 0.2-3%, and most preferably 0.5-2% by weight,

Owner:NARAYANAN KOLAZI S

Temporary removable solvent based protective coating

InactiveUS20080268140A1Easy to disassembleEasy to wearTemporary coatingsPackagingDiacetone alcoholSucrose

This invention is for a composition of clear or pigmented coating that is temporary and removable. It is especially designed to protect the surface of an automobile from the damaging effects of the environment and also from damage caused by normal daily use. The coating is a composition of 40 to 80% of cellulose acetate butyrate ester, 15 to 60% of an acrylic polymer and 2 to 10% of a sucrose acetate isobutyrate. The remover is a combination of tetrahydrofurfuryl alcohol, dibasic ester, diacetone alcohol, ethyl 3 ethoxypropionate; 2,2,4 trimethyl-1,3 pentanoldiol monoisobutyrate, and white mineral oil.

Owner:NATHE HEINRICH W

Shock-absorption synthetic rubber and preparation method thereof

The invention discloses a shock-absorption synthetic rubber which is prepared from the following raw materials in parts by weight: 10.5-12.6 parts of methyl methacrylate, 2.3-5.7 parts of silver-coated glass microsphere core-shell composite particle, 2.6-4.8 parts of rosin polyoxyethylene sulfonate, 1.5-1.8 parts of polyethyleneglycol octyl phenyl ether, 5.3-7.8 parts of ethyl 3-ethoxypropionate, 4.3-5.2 parts of pine tar, 2.5-3.7 parts of magnesium oxide and 1.3-1.8 parts of coupling agent. The environment-friendly rubber material has the advantages of simple formula and technique, low production cost, high damping, high elasticity and favorable high / low temperature resistance, and can not release bromides or other harmful substances. The rubber product can not generate any corrosive action on electronic components after being used for a long time. The shock-absorption synthetic rubber is especially suitable for manufacturing shock-absorption sleeves and other products of disk drives and other electronic and electric products. The shock-absorption synthetic rubber has high damping capacity, and thus, still has high shock absorption effect under the condition of strong shocks when the automobile runs at high speed or passes over a deceleration strip.

Owner:张桂华

Particle size control for acetylenic agents useful in condition monitoring systems

ActiveCN101072750ASuitable for mass productionShorten the timeUrea derivatives preparationCarbamic acid derivatives preparationNitrocelluloseAcetylenic Compounds

Precipitation of polyacetylenic agents can be effected with control of a particle size parameter such as mean size or spread, by mixing a warm solution of the acetylenic agent with a cold precipitation fluid and appropriate selection of a constituent of the cold precipitation fluid and / or of the temperature conditions and collecting the precipitated acetylenic agent. Precipitation additives such as nitrocellulose or gelatin can usefully be employed. Solvents such as aqueous methanol and ethyl 3-ethoxypropionate can be useful. Polyacetylenic agents, e.g. substituted diacetylenics are useful to provide visual changes in condition-monitoring indicators such as time-temperature indicators, ''TTIs'', useful as freshness indicators for radiation exposure monitoring and for other purposes. Controlled, small and / or consistent particle sizes of such polyacetylenic agents are helpful in providing consistent commercial properties, especially in inks in which they may be formulated.

Owner:TEMPTIME CORP

Polymethacrylimide foam plastic and preparation method thereof

The invention provides a polymethacrylimide foam plastic which comprises methacrylic acid, methacrylonitrile, a foaming agent, an initiator, a nucleating agent, a coupling reagent and a pre-recovery agent, wherein the pre-recovery agent is selected from at least one of chlorinated polyethylene and ethyl3-ethoxypropionate. The invention further provides a preparation method of polymethacrylimide foam plastic. According to polymethacrylimide foam plastic provided by the embodiment of the invention, chlorinated polyethylene and ethyl 3-ethoxypropionate are added in the raw materials as the pre-recover agent, and due to existence of the pre-recover agent during production process, free radicals are formed nearby amino (-C-NH-C-) of the polymethacrylimide foam plastic during the reaction. During the recovering of the polymethacrylimide foam plastic, amino can be hydrolyzed into -CN and -COOH, so that high-molecule chain of the polymethacrylimide foam plastic can be broken into small molecules, so that the degradation of the material can be realized.

Owner:株洲觅渔渔具有限公司

Solvent for printing, pattern composition for printing comprising the solvent, and patterning method using the composition

Disclosed is a solvent for printing which comprises a first solvent selected from the group consisting of acetone, methyl ethyl ketone, methyl acetate, ethyl acetate, methanol and mixtures thereof, and a second solvent selected from the group consisting of propylene glycol monomethyl ether acetate (PGMEA), propylene glycol monomethyl ether (PGME), isopropanol, butyl acetate, ethyl-3-ethoxypropionate and mixtures thereof. Further disclosed are a pattern composition for printing comprising the solvent for printing, and a patterning method using the composition. The use of the solvent for printing enables formation of an accurate pattern.

Owner:LG DISPLAY CO LTD

Temporary removable solvent based protective coating

InactiveUS20140018280A1Easy to disassembleEasy to wearDetergent compounding agentsTemporary coatingsDiacetone alcoholAcetic acid

This invention is for a composition of clear or pigmented coating that is temporary and removable. It is especially designed to protect the surface of an automobile from the damaging effects of the environment and also from damage caused by normal daily use. The coating is a composition of 40 to 80% of cellulose acetate butyrate ester, 15 to 60% of an acrylic polymer and 2 to 10% of a sucrose acetate isobutyrate. The remover is a combination of tetrahydrofurfuryl alcohol, dibasic ester, diacetone alcohol, ethyl 3 ethoxypropionate; 2,2,4 trimethyl-1,3 pentanoldiol Monoisobutyrate, and White Mineral Oil.

Owner:OCONEE COATING TECH LLC

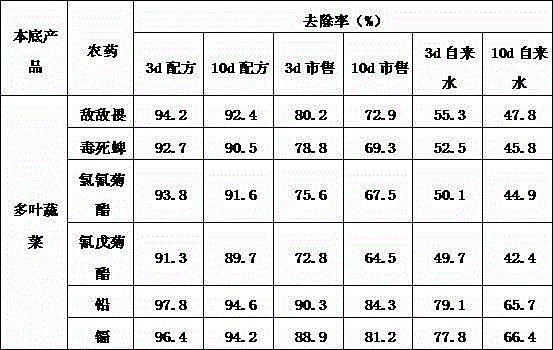

Leafy vegetable washing agent

InactiveCN104531405AEasy to cleanSurface-active non-soap compounds and soap mixture detergentsCyclohexene2-Ethylhexanoic acid

The invention relates to washing agents, in particular to a leafy vegetable washing agent. The leafy vegetable washing agent is formed by peroxide tertiary amyl-2-ethylhexoate, 4-methyl-1-(1-ethyl methyl)-3-cyclohexene-1-alcohol, diethylene glycol monovinyl ether, ethyl 3-ethoxypropionate, 2-(acetamido)-4-amino-4-ketobutyric acid, alpha-sulpho-omega-hydroxyl poly ethylene oxide-C10-16-alkyl ether, diethylene glycol dimethyl acrylic ester, 2,7-double [2-(diethyl amino) ethyoxyl]-9-fluorenone hydrochloride and polyquaternium-37. According to the leafy vegetable washing agent, cleaning is conduced according to the shape characteristics that holes and seams of leafy vegetables are numerous and leaves are overlapped, the surfaces of the vegetables are cleaned in an all-dimensional mode, and the cleaning effect is good. Meanwhile, the washing agent is mild in composition property, no stimulation can be generated to the skin of a human body, and people can clean the vegetables at ease.

Owner:烟台顺隆化工科技有限公司

Ethyl 3-ethoxypropionate preparation method

InactiveCN108569965AEasy to separateFlexible operationOrganic compound preparationCarboxylic acid esters preparationAnhydrous ethanolSide reaction

The invention discloses an ethyl 3-ethoxypropionate preparation method, wherein the raw materials comprise anhydrous ethanol and ethyl acrylate, and the catalyst is ethyl acrylate accounting for 0.1-20% of the weight. According to the present invention, the method has advantages of simple synthesis, mild conditions, less side reactions, substantially-simplified separation process, convenient continuous production and the like, wherein the catalyst can be recycled without the damage, and can be regenerated.

Owner:XIAN GERUIDE NEW CHEM MATERIALS CO LTD

Flame-retardant adhesive

InactiveCN109575862AImprove flame retardant performanceImprove securityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAcrylic resin

The invention discloses a flame-retardant adhesive. The flame-retardant adhesive is prepared from the following raw materials in parts by weight: 17 to 26 parts of aluminum oxide, 15 to 20 parts of halogen-free epoxy resin, 8 to 15 parts of ethyl 3-ethoxypropionate, 6 to 9 parts of alcohol soluble acrylic resin, 15 to 18 parts of an organic phosphorus compound, 3 to 6 parts of a curing promoter, 5to 8 parts of a flame retardant, 7 to 12 parts of a curing agent, 7 to 13 parts of a smoke suppressor and 4 to 9 parts of an ultraviolet absorbent. The flame-retardant adhesive is resistant to high temperature, good in flame-retardant effect, high in safety and stable in quality and contains a few of pollutants.

Owner:徐州铂蓝新材料科技有限公司

Preparation method of plastic flexible pipe material with strong wear resistance

The invention discloses a preparation method of a plastic flexible pipe material with strong wear resistance. The method comprises the steps: performing ultrasound and separation on high density polyethylene and polyvinyl butyral in mixed acid; treating hydroxyethyl cellulose by sulphuric acid and performing ultrasound and dilution on the treated hydroxyethyl cellulose with ethyl 3-ethoxypropionate and nano carbon sol; mixing magnesium hydroxide with calcium bisulfate and adding acrylic acid, methyl trichlorosilane and stannic maleate in batches; mixing products and dewatering and curing to obtain primary blank; modifying tris(nonyl phenyl) phosphate and polyglycerol ricinoleate to obtain a modified treatment mixture; finally, smelting the primary blank and the modified treatment mixture,stirring with perlite micropowder and dewatering, extruding and cooling to obtain a finished-product plastic flexible pipe material. The prepared plastic flexible pipe material with the strong wear resistance has excellent wear resistance and a good application prospect in the flexible pipe manufacturing industry.

Owner:苏州环亚软管塑业有限公司

Heat-conducting composite plastic with insulating function

InactiveCN106317751AEnhanced interactionImprove thermal conductivityDecabromodiphenyl etherDiethyldithiocarbamic Acid

The invention discloses heat-conducting composite plastic with an insulating function. The heat-conducting composite plastic is prepared from, by weight, 60-70 parts of ABS resin, 15-20 parts of BPS resin, 2-6 parts of alum, 14-20 parts of magnesium hypophosphite, 9-13 parts of melaMine cyanurate, 6-12 parts of silicon carbide, 3-7 parts of ammonium heptamolybdate, 2-9 parts of magnesium stearate, 12-25 parts of ethyl 3-ethoxypropionate, 1-3 parts of lactic acid, 23-29 parts of glass fibers, 12-23 parts of ceramic fibers, 23-27 parts of aluminum oxide, 1-3 parts of titanium dioxide, 3-7 parts of tetraethylthiuram disulfide, 4-10 parts of N-phenyl-alpha-naphthylamine, 3-7 parts of barium sulfate, 3-7 parts of phthalic acid ethyl caproic ester, 0.5-2 parts of antimonous oxide, 2-5 parts of decabromodiphenyl ether, 1-5 parts of simethicone and 1-2 parts of diethyldithiocarbamic acid. Unique molecular design is adopted, interaction force between thermoplastic plastic and filler is increased, a heat channel is formed through high-efficiency contact between the filler, and thermal conductivity is greatly improved.

Owner:桐城市弘业塑胶有限公司

Temporary removable solvent based protective coating

InactiveUS9290667B2Easy to disassembleEasy to wearTemporary coatingsPackagingDiacetone alcoholDibasic ester

This invention is for a composition of clear or pigmented coating that is temporary and removable. It is especially designed to protect the surface of an automobile from the damaging effects of the environment and also from damage caused by normal daily use. The coating is a composition of 40 to 80% of cellulose acetate butyrate ester, 15 to 60% of an acrylic polymer and 2 to 10% of a sucrose acetate isobutyrate. The remover is a combination of tetrahydrofurfuryl alcohol, dibasic ester, diacetone alcohol, ethyl 3 ethoxypropionate; 2,2,4 trimethyl-1,3 pentanoldiol monoisobutyrate, and white mineral oil.

Owner:OCONEE COATING TECH LLC

Coloring composition, color filter and color liquid crystal display device

ActiveCN101930177BImprove surface roughnessSuitable for makingOptical filtersPorphines/azaporphinesSolubilityPhthalocyanine

Owner:JSR CORPORATIOON

An adhesive used for rubber

InactiveCN109554142AImprove adhesionImprove reliabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholAdhesive

An adhesive used for rubber is disclosed. The adhesive is prepared from, by weight, 10-12 parts of titanium dioxide, 12-16 parts of ethyl acetate, 12-17 parts of vinyl acetate copolymerization emulsion, 12-25 parts of ethyl 3-ethoxypropionate, 12-17 parts of N,N-ethylene bis-stearamide, 5-10 parts of zinc oxide, 6-10 parts of an aqueous solution of polyvinyl alcohol, 5-10 parts of a filler, 13-16parts of ethanol, 12-16 parts of alumina, 3-7 parts of lemon acetic acid, 3-5 parts of a curing agent and 4-6 parts of modified resin. The adhesive has good adhesion effects, high reliability and highdurability.

Owner:徐州隆邦家具有限公司

Gasoline

InactiveCN108219866AImprove combustion efficiencyExtend your lifeLiquid carbonaceous fuelsFuel additivesSodium phosphatesTG - Triglyceride

The invention provides gasoline. The gasoline is mainly prepared from 20-30 parts of petroleum, 8-15 g of potassium, 5-11 g of talcum powder, 2-6 g of aluminum oxide, 1-6 g of silica gel, 1-7 g of calcium sorbate, 2-7 g of triglyceride, 1-3 g of white vanadium mint juice, 2-15 g of theophylline, 1-5 g of chondroitin sulfate, 3-7 g of collagen hydrolysate, bamboo charcoal fiber, 3-5 g of hydrogen peroxide, 4-10 g of alanine, 5-7 g of amyl alcohol, diethyl ether, butanol, 3-9 g of ethyl 3-ethoxypropionate, 1-3 g of sodium phosphate, ethyl ester, ethyl vinyl ether, 5-11 g of tricarboxylic triethylamine, 5-8 g of turpentine, 5-20 g of pearl powder, 3-9 g of yoghourt, 6-12 g of vanilla polysaccharide, 16-19 g of soy isoflavone, and 3-12 g of soy lecithin. The combustion efficiency of the gasoline is higher at the temperature of 20 DEG C below zero, and the energy is saved. The service life of an automobile is prolonged, and the wear of the automobile is reduced.

Owner:吕化

Permanganate dirt-removing method for printed-circuit board

InactiveCN1215746CGood decontamination effectOther chemical processesInsulating layers/substrates workingN-ethyl-2-pyrrolidoneSolvent

Owner:OMG ELECTRONICS CHEM INC

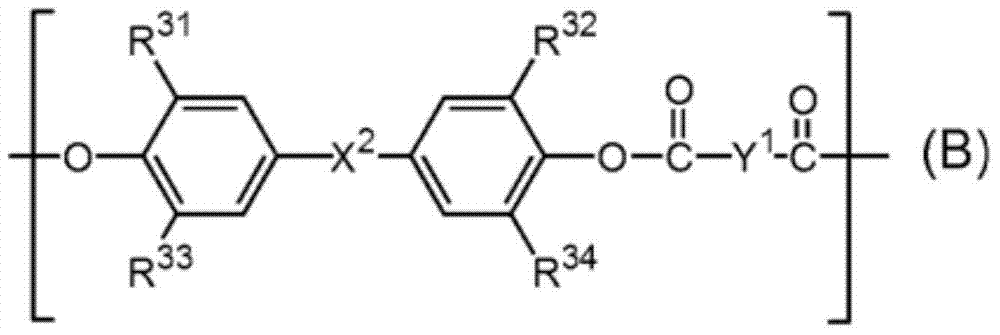

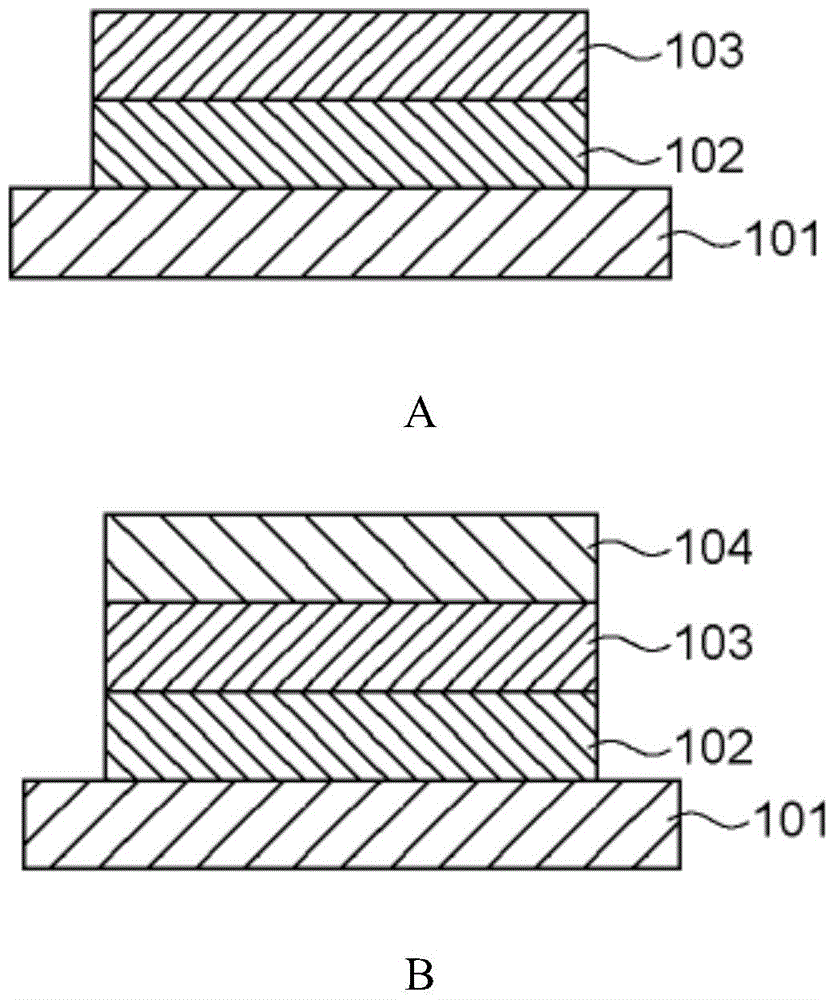

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveCN103718113ALower initial coefficient of frictionElectrographic process apparatusAcrylic resinBenzyl acetate

The electrophotographic photosensitive member includes a surface layer containing (alpha) a polycarbonate or polyester resin not having a siloxane structure at the end, (beta) a polycarbonate or polyester or acrylic resin having a siloxane structure at the end, and (gamma) a methyl benzoate, an ethyl benzoate, a benzyl acetate, ethyl 3-ethoxypropionate or a diethylene glycol ethyl methyl ether.

Owner:CANON KK

Manufacturing method of pipe clamp

InactiveCN108213847AQuality improvementExtended service lifeEngine componentsVolumetric Mass DensityBENZYL ALCOHOL/WATER

The invention discloses a manufacturing method of a pipe clamp. The manufacturing method of the pipe clamp comprises the following steps: performing decarburization and impurity removal treatment on 40 parts to 80 parts of iron-based alloy to obtain pure alloy; then performing upsetting to form cylindrical blank materials; unfolding a flat plate to ensure that the thickness is 2mm to 5mm; then beginning to align to each other and forging the blank materials to ensure that the density is 3 times of original density; then folding the blank materials and forging the blank materials to ensure thatthe density is 6 times of the original density; paving a layer of 30 parts to 99 parts of zinc oxide, 30 parts to 45 parts of carborundum, 3 parts to 7 parts of benzyl alcohol, 5 parts to 17 parts ofalanine, 2 parts to 15 parts of propyl pyruvate, 6 parts to 18 parts of dipropylene glycol monoalkyl ether, 6 parts to 19 parts of ethyl 3-ethoxypropionate and 21 parts to 40 parts of cocamide on thesurface at a moment of forging for the third time and directly and wholly hammering into a material; then manufacturing the blank materials of the pipe clamp; simmering for 20 seconds to 90 seconds at 200 DEG C to 239 DEG C; and finally, putting the blank material into an oxygen atmosphere and performing forging. The pipe clamp manufactured by the method disclosed by the invention is reliable inquality, long in service life, and can be used in many places; and therefore, a trouble of replacement of pipe clamps is reduced.

Owner:沈阳利泰自控技术有限责任公司

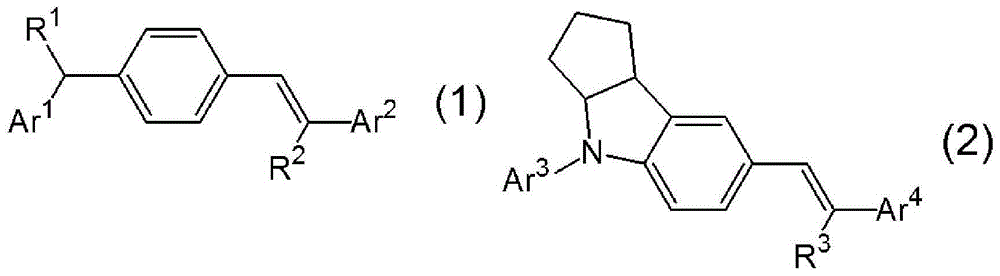

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveCN103941556AReduce coefficient of frictionElectrographic process apparatusSulfolaneNitrobenzene

The invention relates to an electrophotographic photosensitive member, a process cartridge and an electrophotographic apparatus. The charge transporting layer as the surface layer of an electrophotographic photosensitive member includes a charge transporting substances represented by any one of formulae (1) to (5), a specific compound, and a specific resin (binder resin). The specific compound is hexanol, heptanol, cyclohexanol, benzyl alcohol, ethylene glycol, 1,4-butanediol, 1,5-pentanediol, diethylene glycol, diethylene glycol ethyl methyl ether, ethylene carbonate, propylene carbonate, nitrobenzene, pyrrolidone, N-methylpyrrolidone, methyl benzoate, ethyl benzoate, benzyl acetate, ethyl 3-ethoxypropionate, acetophenone, methyl salicylate, dimethyl phthalate, or sulfolane.

Owner:CANON KK

Plastic for injection molding

The invention discloses plastic for injection molding is prepared from, by weight, 30 to 40 parts of ethyl 3-ethoxypropionate, 25 to 35 parts of epoxy resin, 10 to 14 parts of aluminum oxide, 10 to 14parts of silicon dioxide, 12 to 16 parts of glass fiber, 8 to 14 parts of titanium dioxide and 6 to 10 parts of anti-aging master batch. The plastic has the beneficial effects that a product finallyprepared from the plastic has good wear resistance and heat resistance, the preparation method is simple, and the cost is low; the plastic is easier to store, stable in physical property and chemicalproperty and long in storage time.

Owner:安徽鼎晟精密制造有限公司

Formula of film panel

InactiveCN103926793AImprove heat resistanceGood solvent resistancePhotosensitive materials for photomechanical apparatusAcrylic resinHeat resistance

The invention discloses a formula of a film panel. The film panel comprises the following components: acrylic resin, a surfactant, a solvent, bi-azide quinine, strong base and an etching control agent, wherein the solvent comprises ethyl 3-ethoxypropionate and trimethyl pentanediol isobutyrate; ethyl 3-ethoxypropionate takes up 20-30% of the total amount of the solvent; trimethyl pentanediol isobutyrate takes up 70-80% of the total amount of the solvent. The formula of the film panel, which is provided by the invention, has the beneficial effects that in the using process of the film panel prepared by the components, the heat resistance and the solvent resistance of photosensitive resin patterns for curing the film panel are improved; the film panel is stable in performance, and is scientific and reasonable in matching.

Owner:张洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com