Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Ethoxypropionic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

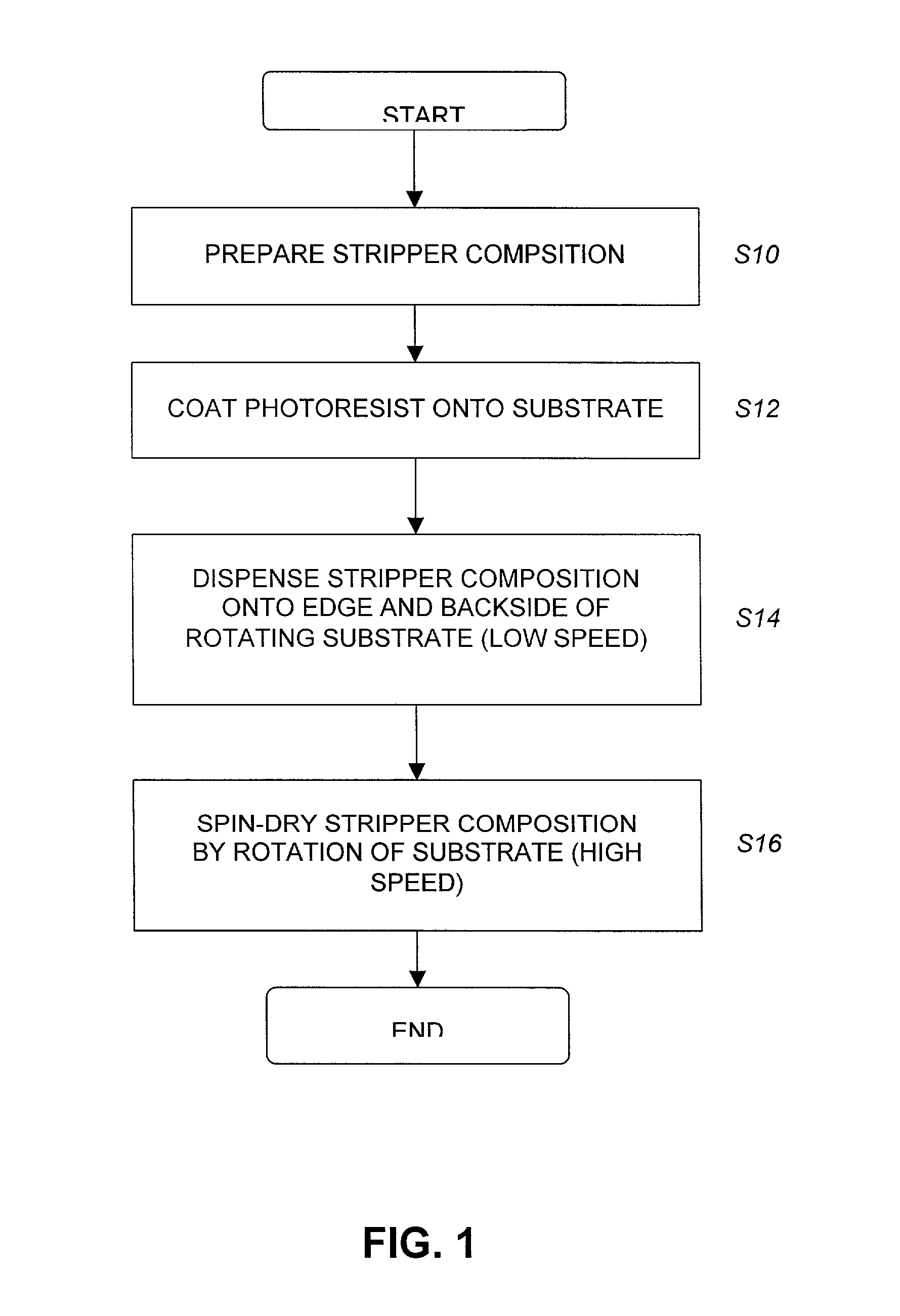

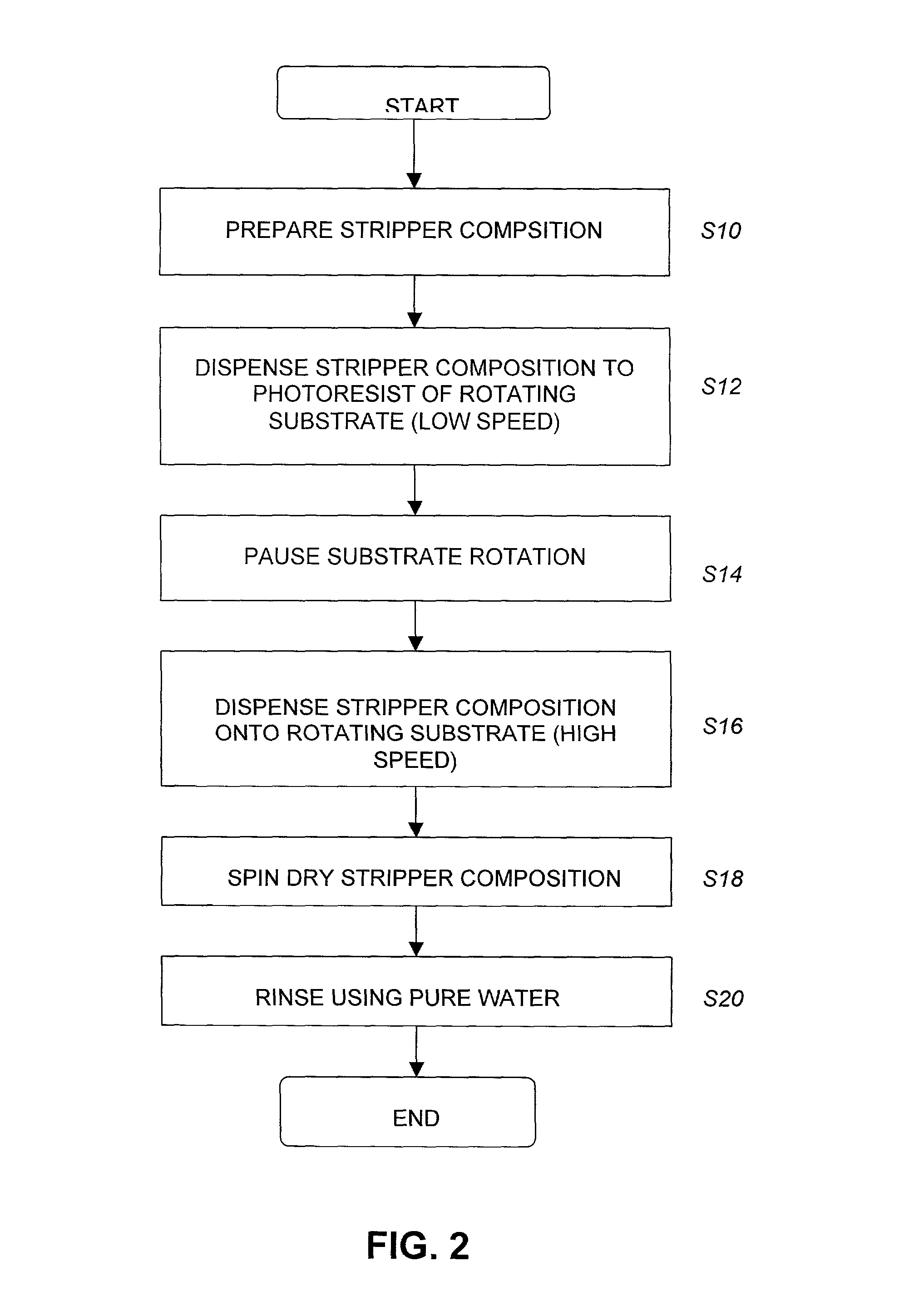

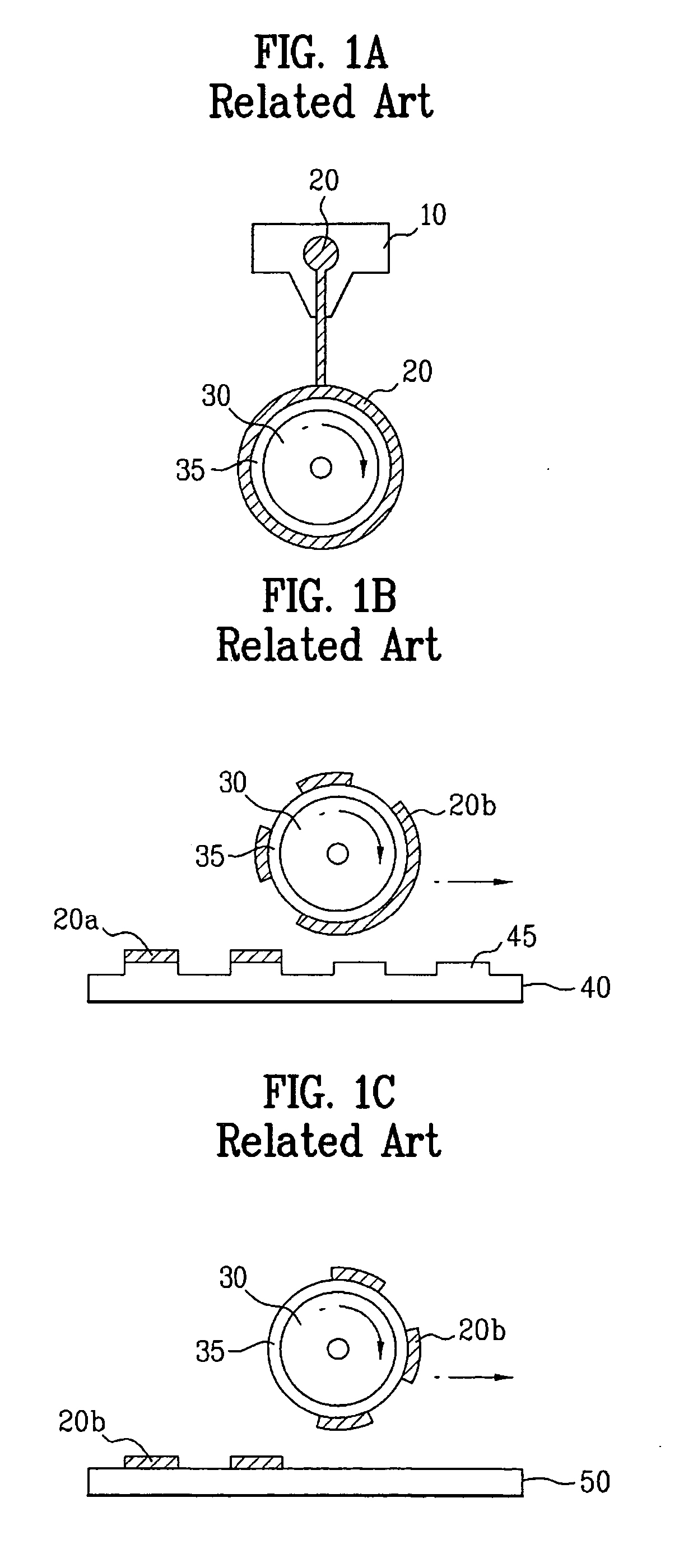

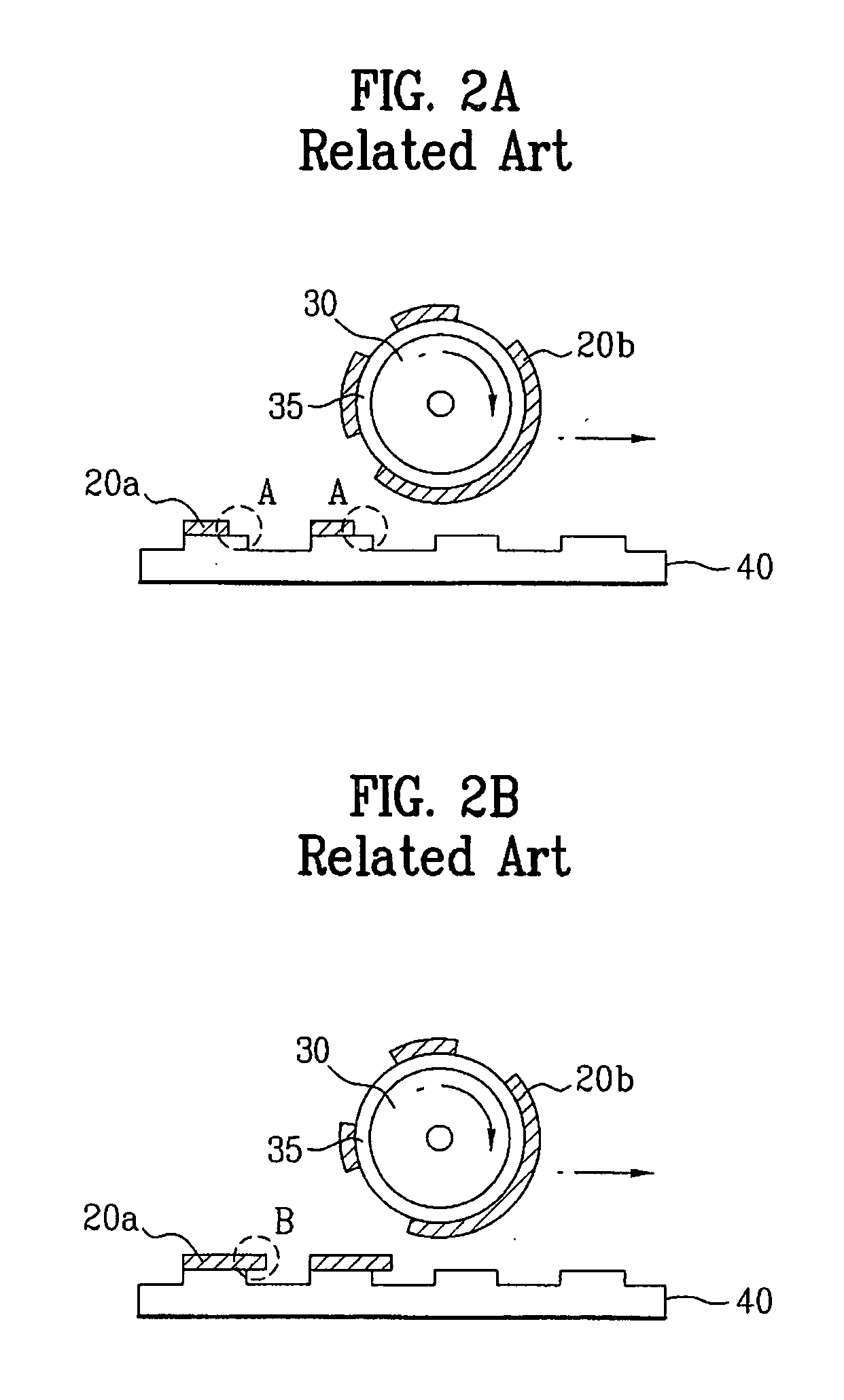

Photoresist stripper compositions

InactiveUS20030113673A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusAmyl acetateMethyl group

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

Particle size control for acetylenic agents useful in condition monitoring systems

ActiveUS7019171B1Improving quality performanceUrea derivatives preparationOrganic compound preparationNitrocelluloseRadiation Exposure Monitoring

Precipitation of polyacetylenic agents can be effected with control of a particle size parameter such as mean size or spread, by mixing a warm solution of the acetylenic agent with a cold precipitation fluid and appropriate selection of a constituent of the cold precipitation fluid and / or of the temperature conditions and collecting the precipitated acetylenic agent. Precipitation additives such as nitrocellulose or gelatin can usefully be employed. Solvents such as aqueous methanol and ethyl 3-ethoxypropionate can be useful. Polyacetylenic agents, e.g. substituted diacetylenics are useful to provide visual changes in condition-monitoring indicators such as time-temperature indicators, “TTIs”, useful as freshness indicators for radiation exposure monitoring and for other purposes. Controlled, small and / or consistent particle sizes of such polyacetylenic agents are helpful in providing consistent commercial properties, especially in inks in which they may be formulated.

Owner:TEMPTIME CORP

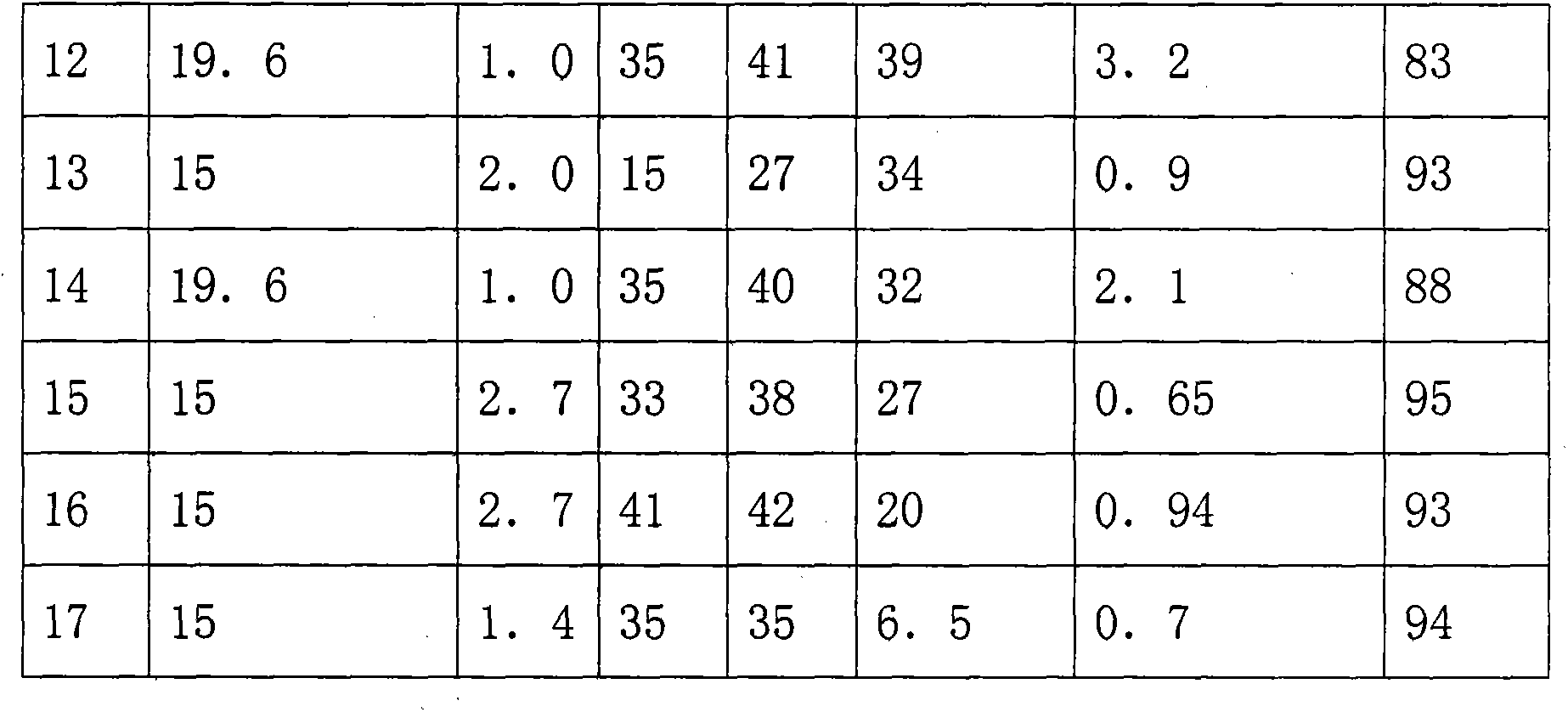

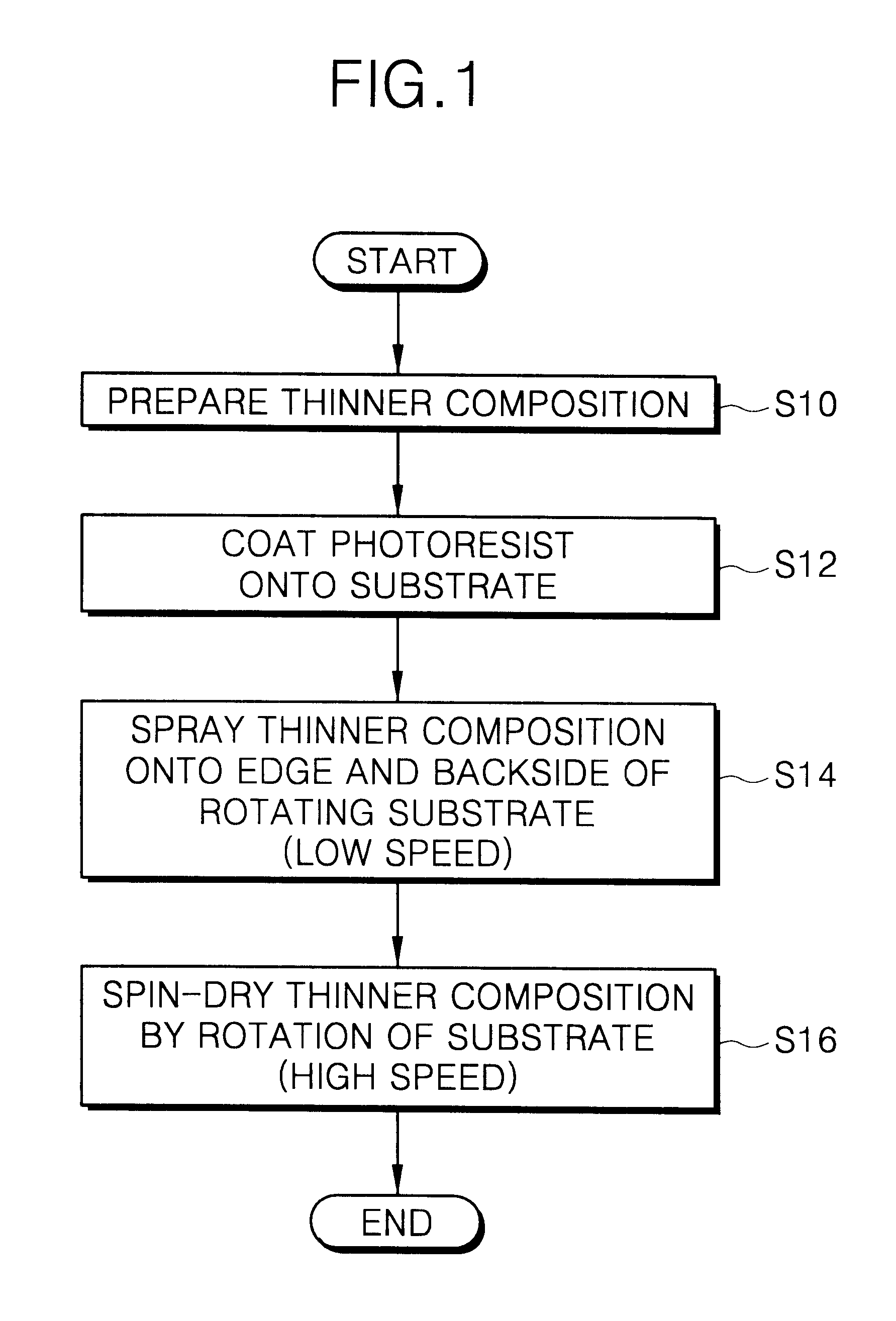

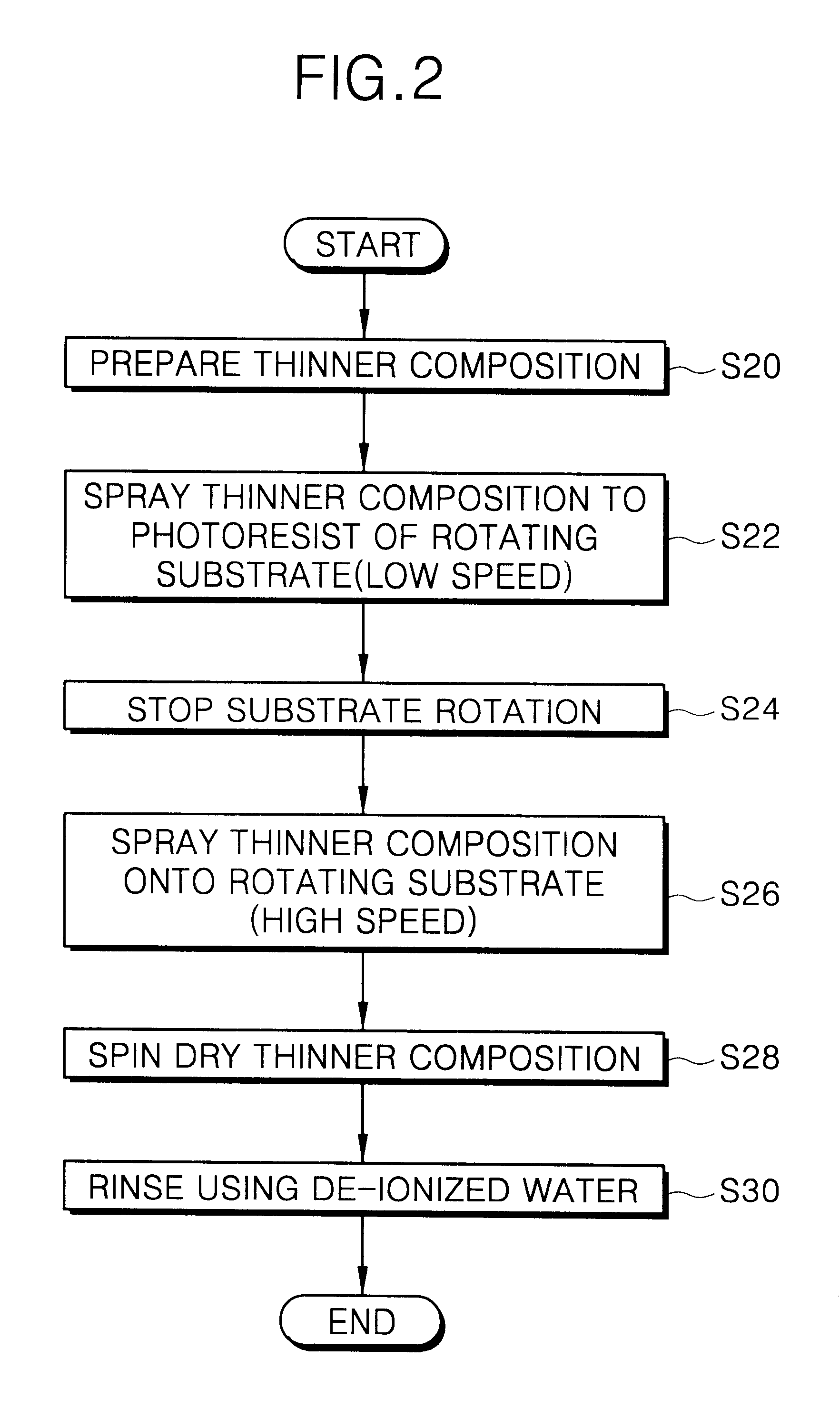

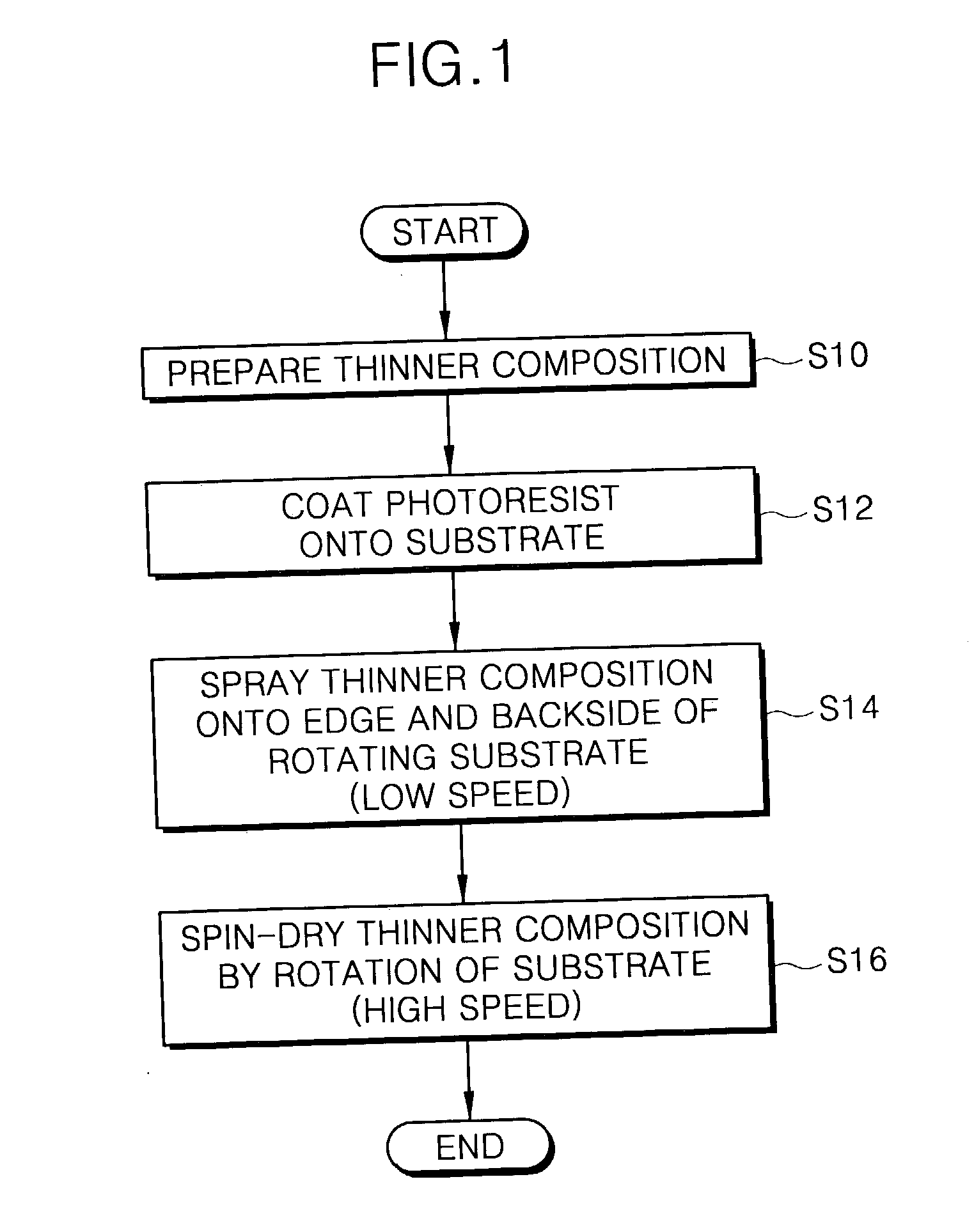

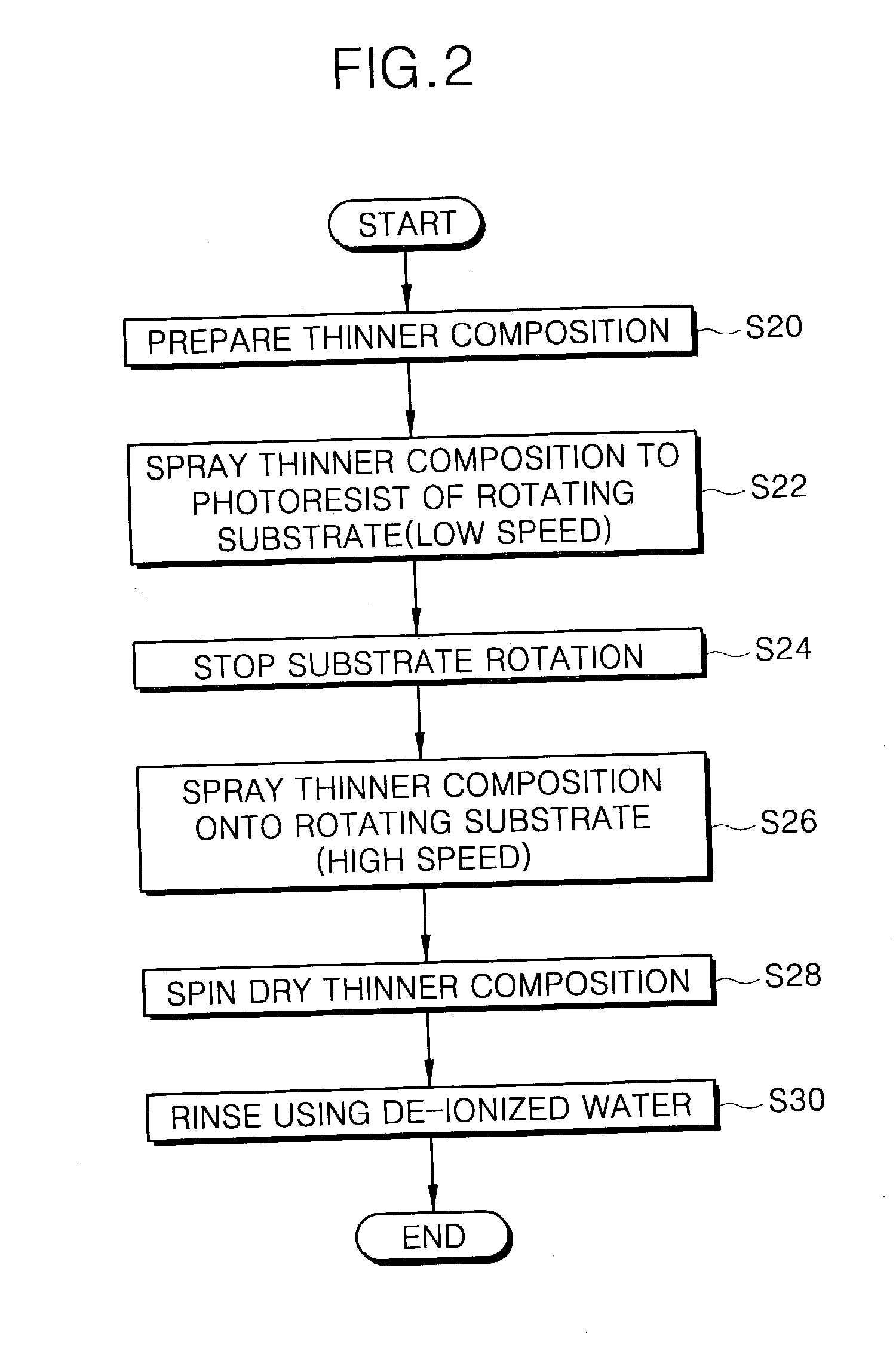

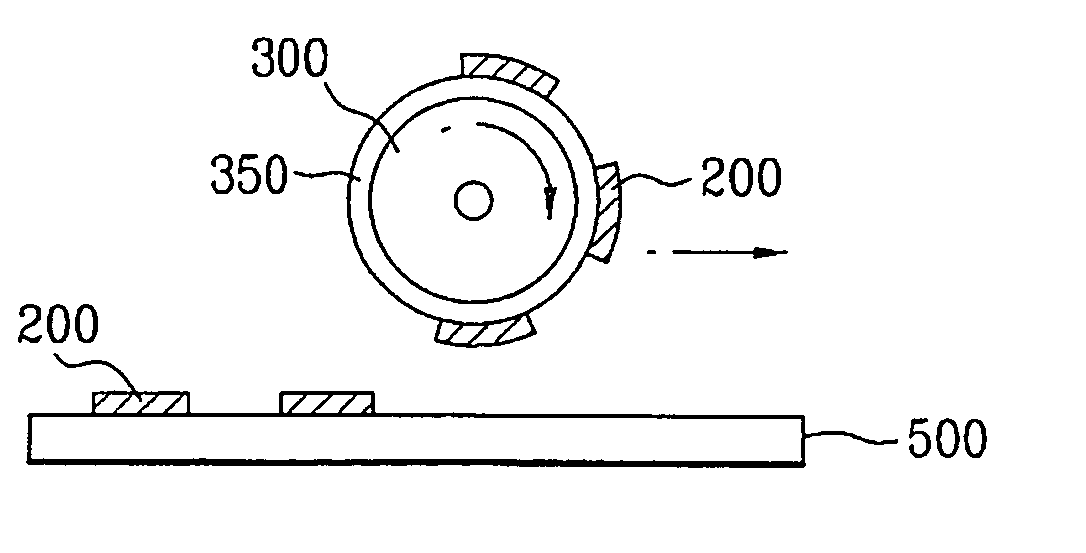

Thinner composition and method of stripping a photoresist using the same

InactiveUS20030157441A1Photomechanical coating apparatusPhotosensitive material processingPropionateResist

A thinner composition is effective in removing a variety of photoresists, and includes propylene glycol mono-methyl ether acetate, ethyl 3-ethoxy propionate and at least one of gamma-butyro lactone and propylene glycol mono-methyl ether. The thinner composition can selectively strip a photoresist coated on a backside and at an edge portion of a substrate, as well as a photoresist coated on a whole front surface of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

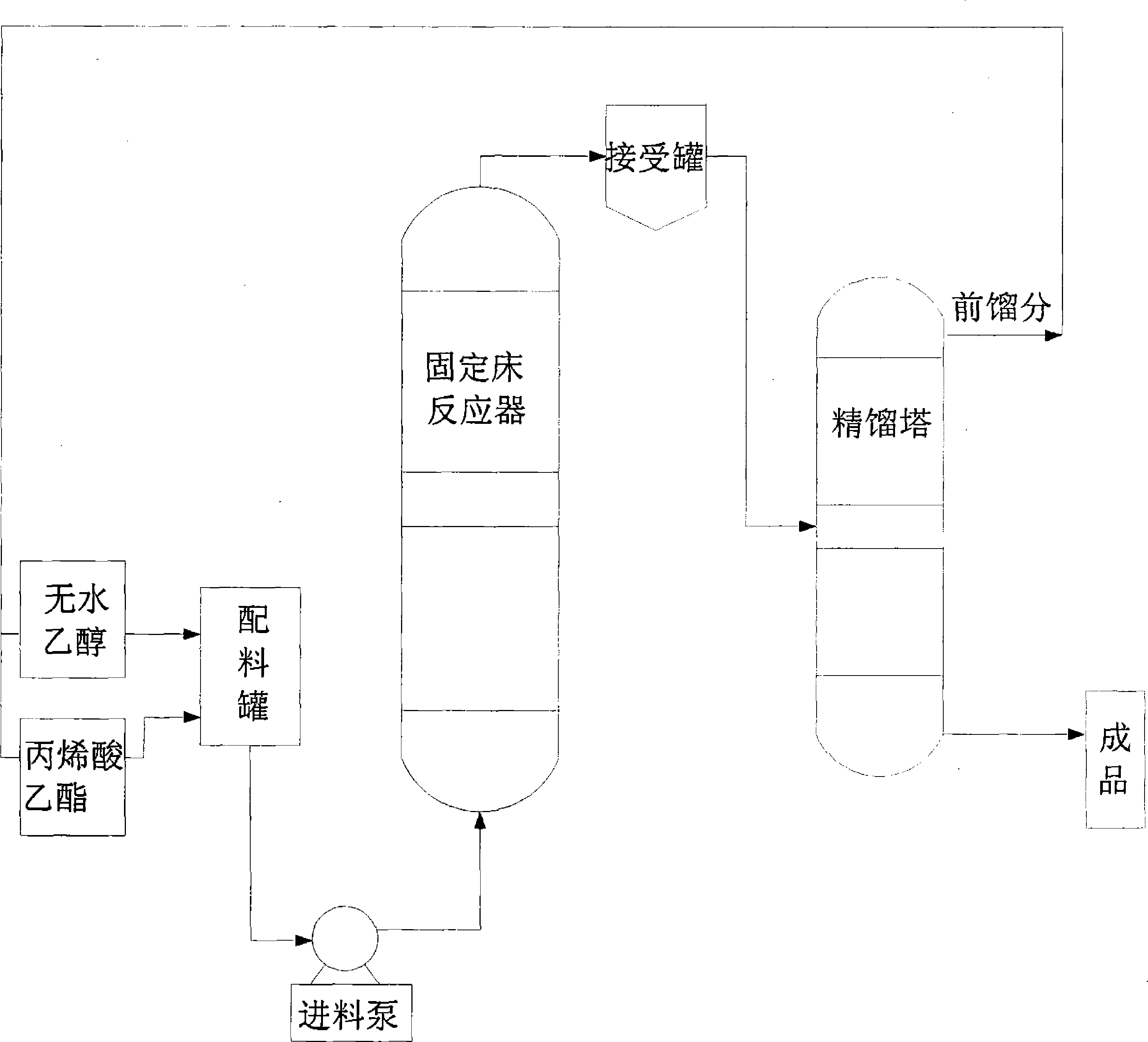

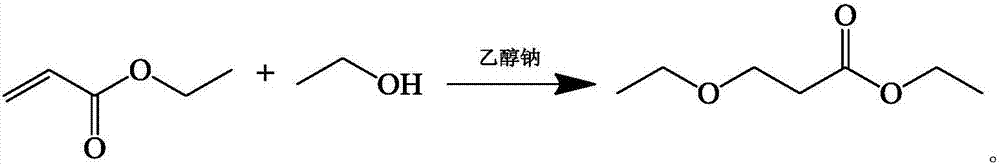

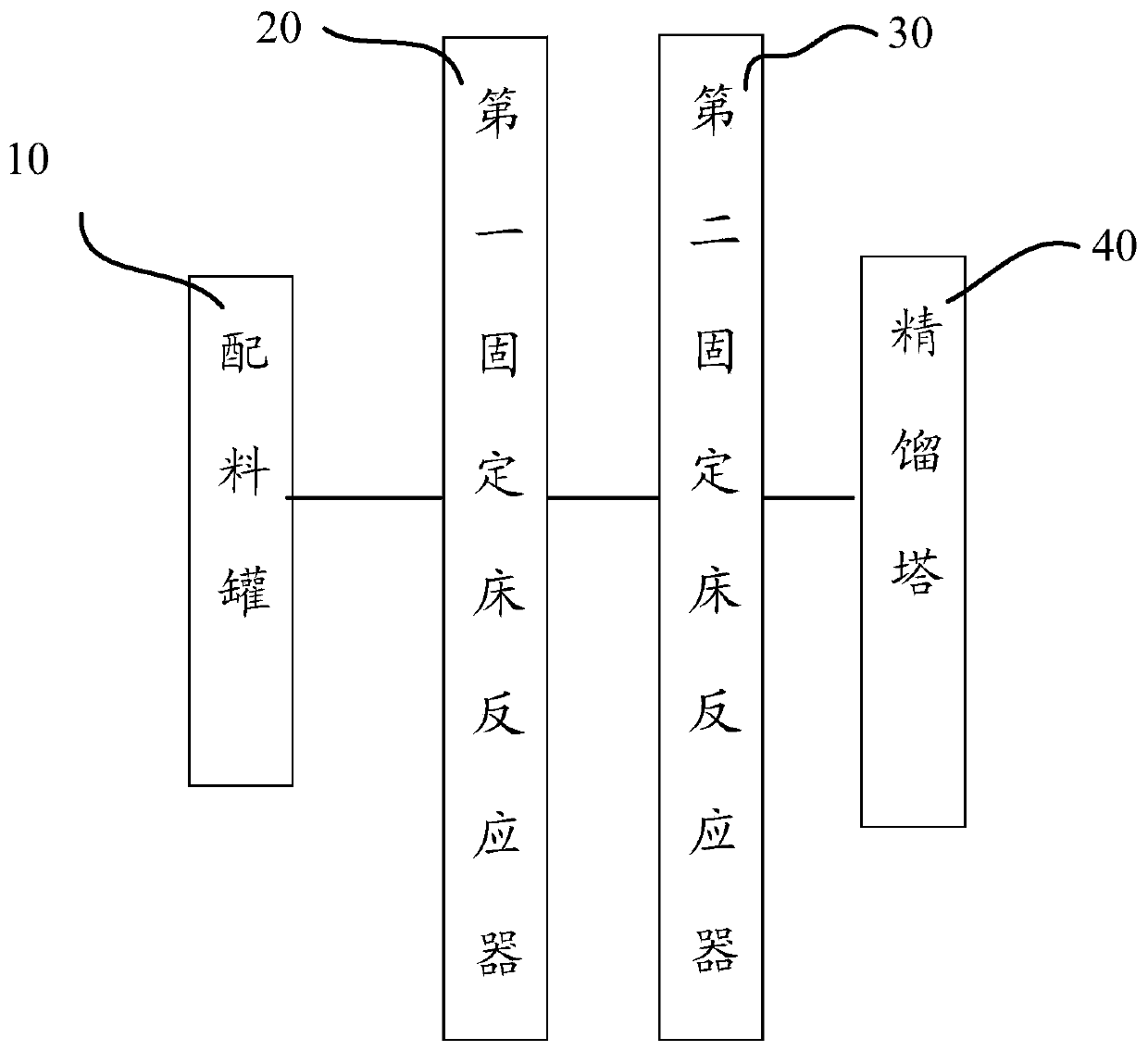

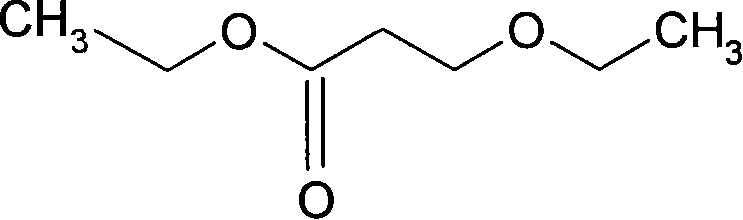

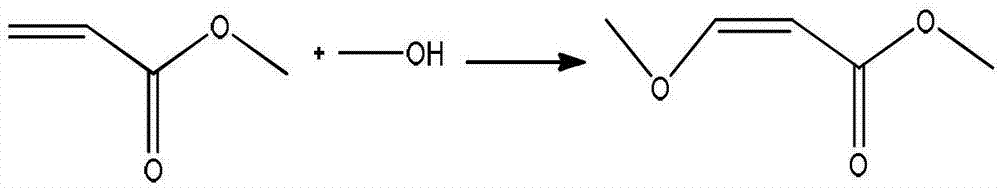

Preparation method of 3-ethoxyl ethyl propionate

ActiveCN101423475AReduce recyclingHigh yieldOrganic compound preparationCarboxylic acid esters preparationChemical synthesisDistillation

The invention belongs to the technical field of chemical synthesis, and in particular relates to a method for preparing 3-ethoxy ethyl propionate. The method comprises a synthesizing step and a refining step, wherein the synthesizing step adopts ethanol and ethyl acrylate as raw materials to carry out addition under the action of a catalyst, and the catalyst adopts alkali metal or alkali alcoholate. The method has the following advantages: 1, the method adopts one of the raw materials as solvent to react, so as to reduce solvent recovery and consumption in the production process; 2, the reaction catalyst uses basic catalyst such as sodium metal and the like, so as to improve reaction yield greatly; 3, the dosage of the reaction catalyst is reduced to about 2 percent, so as to lower amount of salt greatly after the reaction is finished, and reduce byproducts; 4, the reaction time can be shortened to 3 hours, so as to improve production efficiency; and 5, fore zeolite obtained in distillation can be used for next reaction, so as to achieve circular application, so that the proposal reaches green chemical requirement.

Owner:LINHAI LIANSHENG CHEM

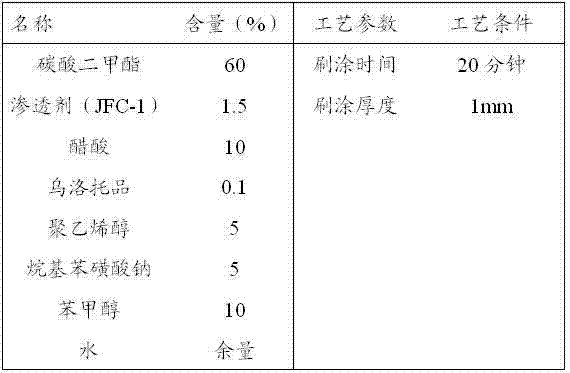

Degumming agent and preparation method and application thereof

The invention discloses a degumming agent and a preparation method and application of the degumming agent. The degumming agent mainly contains the following ingredients in percentage by weight: 40%-60% of main solvent, 1.5%-3% of penetrant, 6%-10% of activating agent, 0.1%-0.3% of corrosion inhibitor, 5%-15% of thickening agent, 5%-10% of emulsifier, 10%-15% of volatilization inhibitor and the balance of water, wherein the main solvent is one or a mixture of several of methyl carbonate, ethyl-3-ethoxy propionate, dibasic ester, alkoxy alcohol, alcohol amine or benzoic alcohol. The degumming agent is simple in using method, is free from being heated and can be used at normal temperature by either brushing or spraying, and the time for washing is short, so that the production efficiency can be greatly increased.

Owner:吉林中路新材料有限责任公司

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS20070257235A1Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

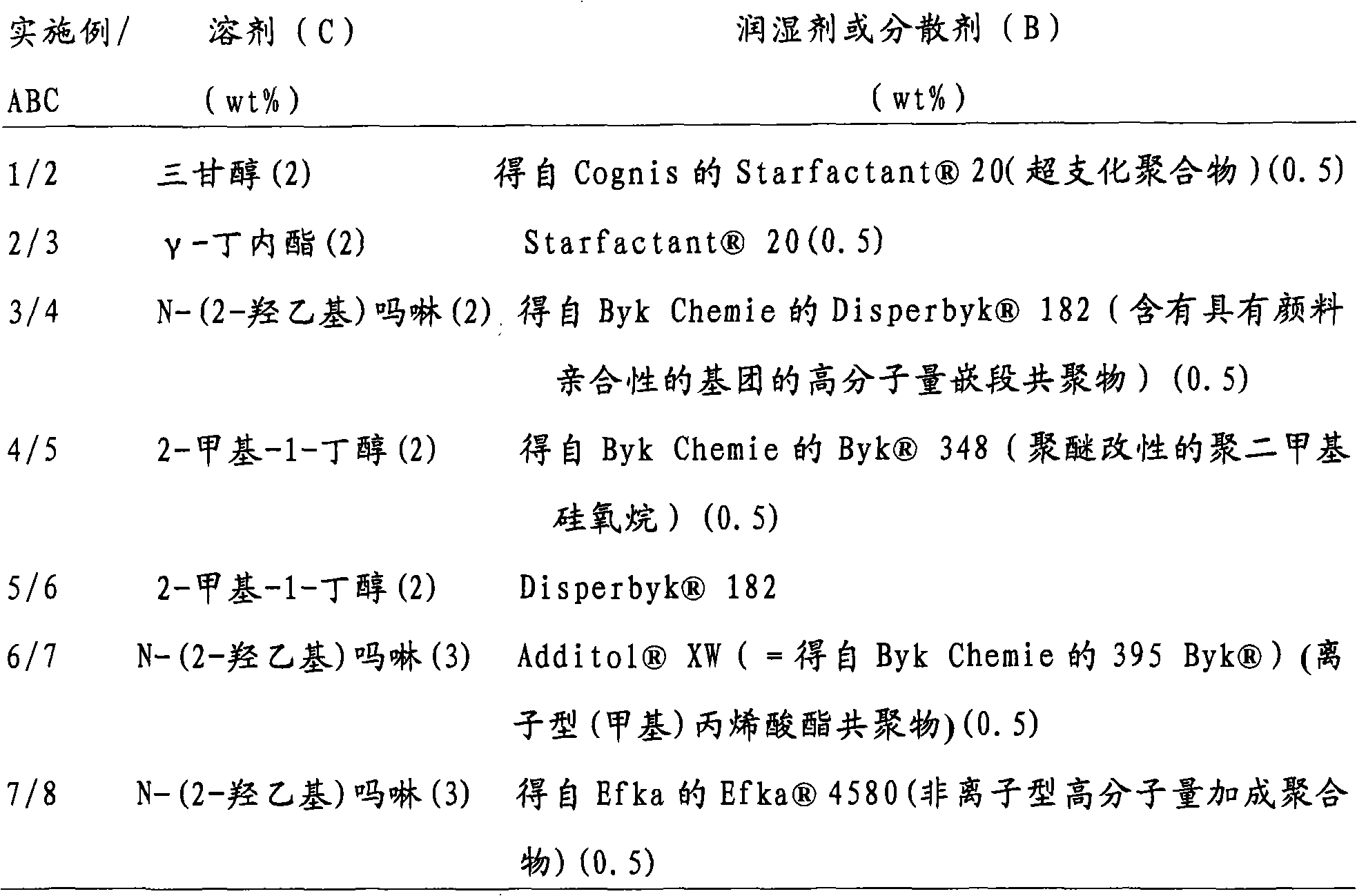

Aqueous coating material, method for the production thereof, and use thereof

ActiveCN101331196AEasy to manufactureLess spray cakingPolyurea/polyurethane coatingsSulfolane1-Pentanol

Disclosed is an aqueous coating material containing (A) at least one saturated and / or unsaturated polyurethane and / or an ionically and / or non-ionically stabilized polyurethane grafted with olefinically unsaturated compounds, (B) at least one wetting agent or dispersing agent, and (C) at least one organic solvent selected among the group comprising dimethylsulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexylglycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerin, trimethylolpropane solutions, pentaerythrite solutions, sorbit solutions, reactive polyether polyols having a number-average molecular weight of 110 to 6,000 Dalton and a hydroxyl number of 25 to 1,000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerin ethoxylate, ethyl-3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl); -piperidine, N-methylmorpholine, N-(2-hydroxyethyl)-morpholine, N-acetylmorpholine, N-cyclohexyl pyrrolidone, and N-octyl-2-pyrrolidone. Also disclosed are a method for producing said aqueous coating material and the use thereof.

Owner:BASF COATINGS GMBH

Photosensitive resin composition, thin film panel made with photosensitive resin composition, and method for manufacturing thin film panel

ActiveUS7338737B2Decorative surface effectsSemiconductor/solid-state device manufacturingQuinonePropionate

A photosensitive resin composition includes an alkali-soluble resin, a quinone diazide, a surfactant, and a solvent. The solvent includes a diethylene glycol dialkyl ether that includes an alkyl group including one to five carbon atoms, an ethyl 3-ethoxy propionate, an alkyl acetate that includes an alkyl group including three to eight carbon atoms, and an alkyl lactate that includes an alkyl group including one to six carbon atoms. The composition may be used to make high-quality display panels with uniformly-coated insulating layers.

Owner:SAMSUNG DISPLAY CO LTD

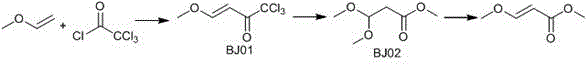

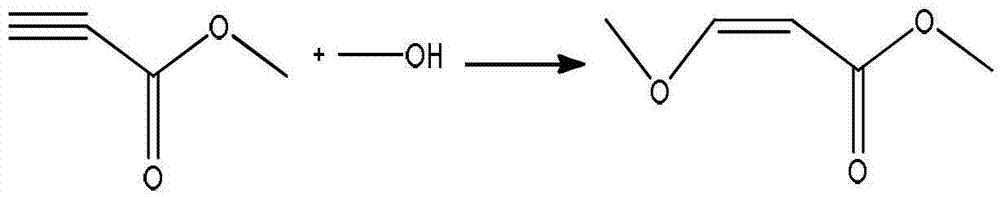

Synthesizing method for 3-methoxyacrylate

InactiveCN105418421AFew reaction stepsEasy to operateOrganic compound preparationCarboxylic acid esters preparationOrganic solventSolvent

The present invention relates to a synthesizing method for 3-methoxy-3-ethoxy methyl propionate, and belongs to the field of chemistry. The synthesizing step comprises the following steps: introducing methyl vinyl ether into trichloroacetyl chloride, and insulating until a reaction is completed; combining BJ01 with anhydrous methanol, adding an acid-binding agent I, and insulating until a reaction is completed; and mixing BJ02 with an organic solvent 2, adding a catalyst, and insulating until a reaction is completed to obtain the 3-methoxyacrylate. The synthesizing method for the 3-methoxyacrylate has the advantages of few reaction steps, easiness in operation, less waste gas, waste water and waste residues, high yield, high purity of products, and inexpensive and easily available raw materials. All the steps have no harsh conditions and are simple in operation and environmentally-friendly, and the solvent are easily recycled and reused, so that the synthesizing method is suitable for industrial production.

Owner:吴清来

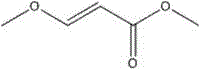

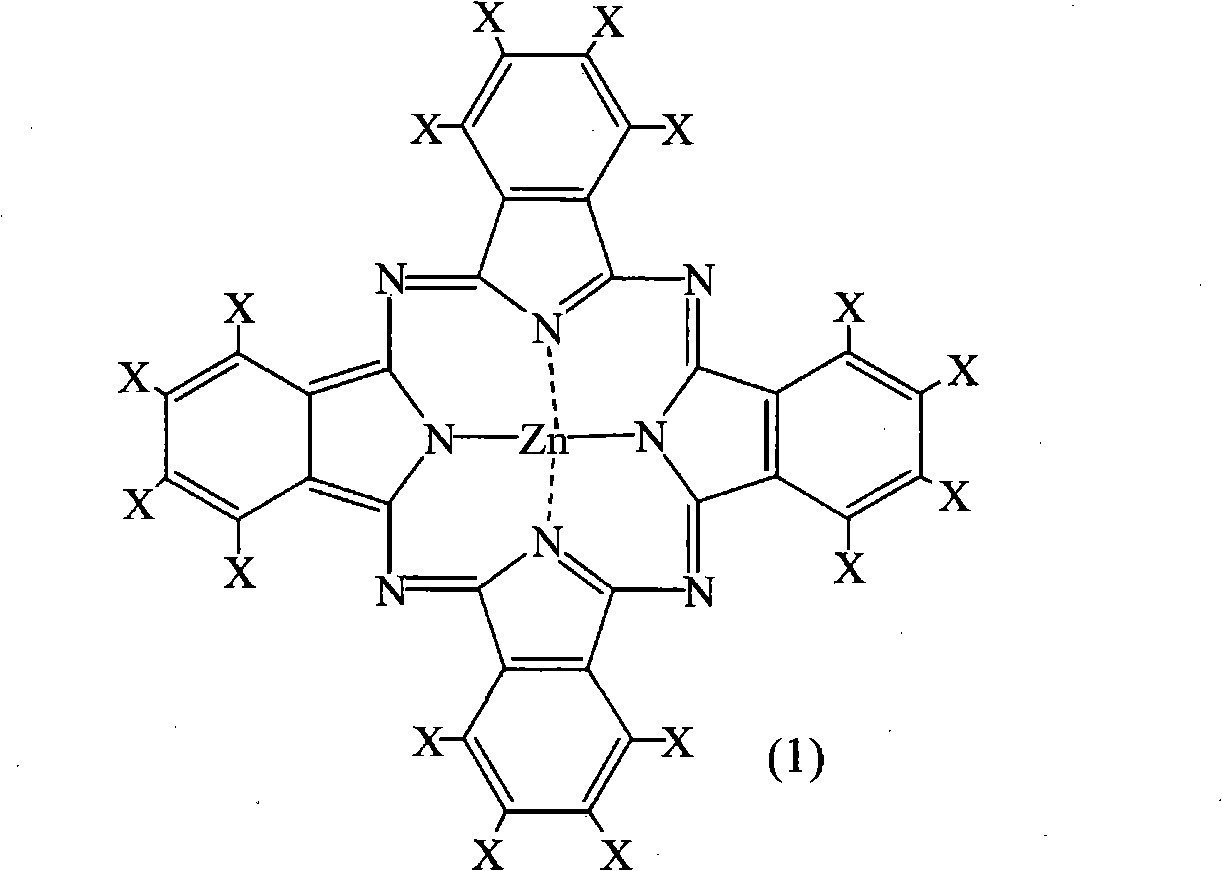

Coloring composition, color filter and color liquid crystal display device

ActiveCN101930177AImprove surface roughnessSuitable for makingOptical filtersPorphines/azaporphinesSolubilityPhthalocyanine

The invention relates to a coloring composition, color filter and color liquid crystal display device. The invention provides the coloring composition, which is suitable for the mass production of the color filter and contains a halogenated phthalocyanine zinc pigment. The coloring composition contains a colouring agent (A), a binder resin (B), a multifunctional monomer (C) and a solvent (D), characterized in that the colouring agent (A) contains halogenated phthalocyanine zinc, the solvent (D) contains at least one of propylene glycol methyl ether acetate, ethyl 3-ethoxypropionate and 3-Methoxybutyl acetate (d1) and a solvent with the solubility higher than that of the ethyl 3-ethoxypropionate (d2), and the solubility of the (d2) is higher than that of 5 to 60% by weight of the ethyl 3-ethoxypropionate in the total solvent.

Owner:JSR CORPORATIOON

Aqueous coating material, its preparation and use

ActiveUS20090270548A1Easy to prepareOutstanding performance propertyFilm/foil adhesivesPolyurea/polyurethane coatingsSulfolaneGlycerol

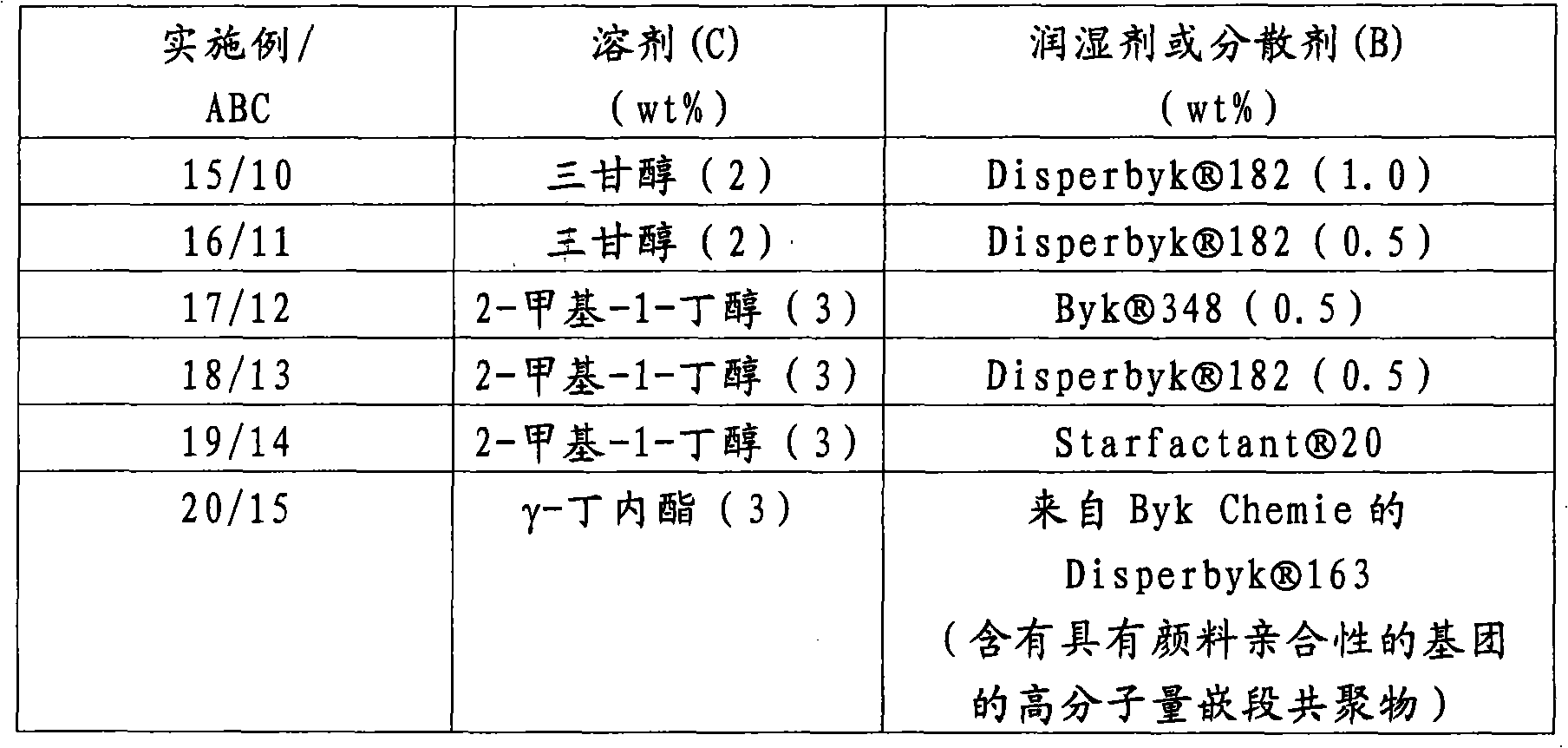

Disclosed herein is an aqueous coating material comprising (A) at least one polyurethane which is ionically stabilized, nonionically stabilized, or a combination thereof, and which is saturated, unsaturated, grafted with olefinically unsaturated compounds, or a combination thereof, (B) at least one wetting agent or dispersant; and (C) at least one organic solvent selected from the group consisting of dimethyl sulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexyl glycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerol, solutions of trimethylolpropane, solutions of pentaerythritol, solutions of sorbitol, reactive polyether polyols with a number-average molecular weight of 110 to 6000 daltons and a hydroxyl number of 25 to 1000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerol ethoxylate, ethyl 3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl)piperidine, N-methylmorpholine, N-(2-hydroxyethyl)morpholine, N-acetylmorpholine, N-cyclohexylpyrrolidone, N-octyl-2-pyrrolidone, and a combination thereof. Also disclosed is a process for preparing the foregoing aqueous coating material.

Owner:BASF COATINGS GMBH

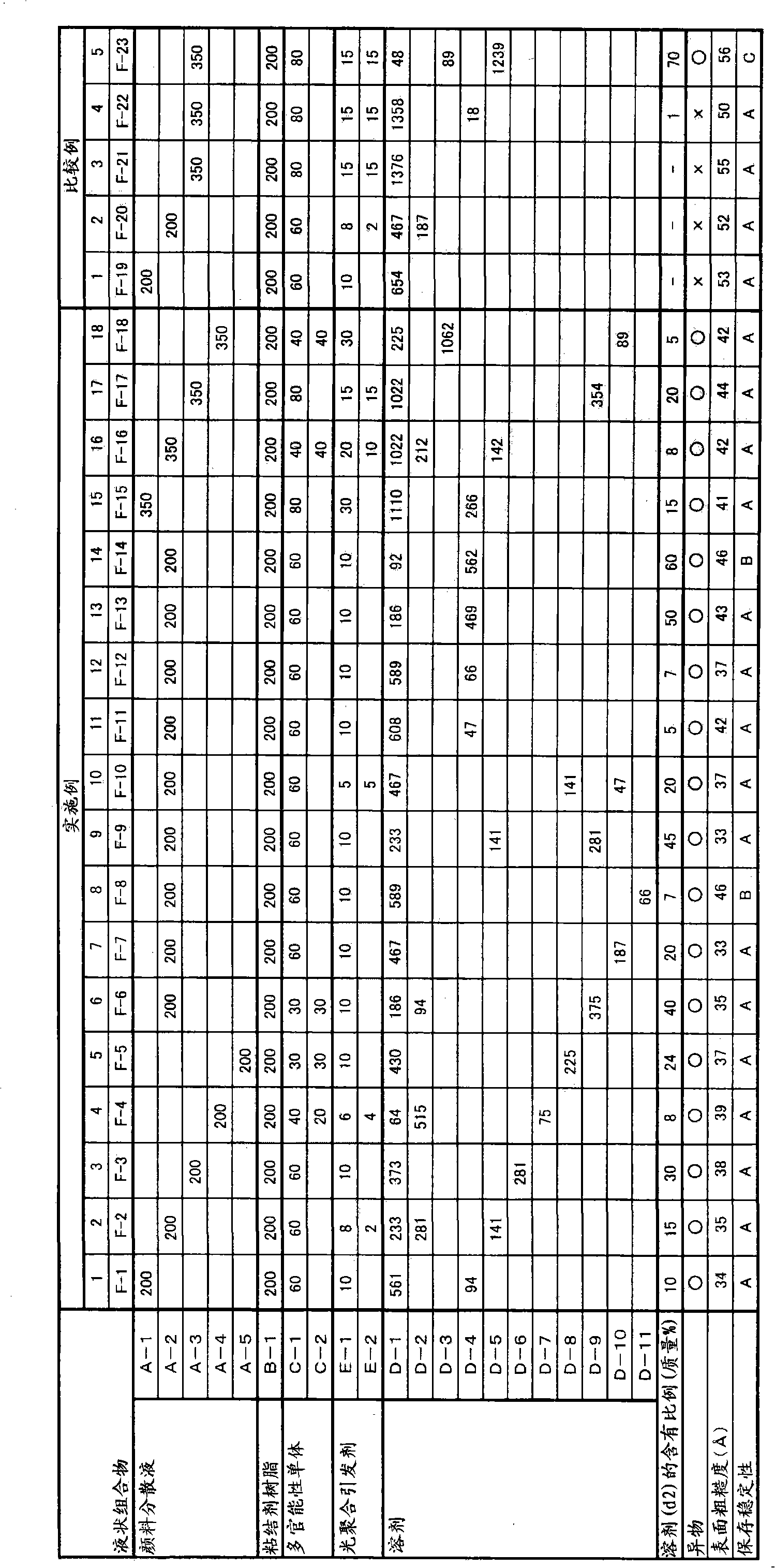

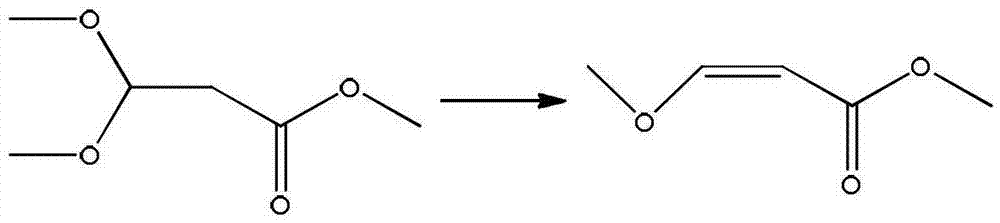

Preparation method of 3-methyl methoxyacrylate

ActiveCN103113227AWide variety of sourcesEasy to operateOrganic compound preparationCarboxylic acid esters preparationHydrogen SulfateChemical reaction

The invention discloses a preparation method of 3-methyl methoxyacrylate. 3-methyl methoxyacrylate is prepared in the presence of a catalyst potassium hydrogen sulfate or sodium hydrogen sulfate by adopting 3-methoxy-3-ethyoxyl methyl propionate and methanol as raw materials; and the chemical reaction formula is shown in the formula of the description. According to the preparation method of 3-methyl methoxyacrylate, provided by the invention, 3-methoxy-3-ethyoxyl methyl propionate and methanol which are easily prepared are adopted and used as the raw materials and are synthesized in the presence of the catalyst to obtain the target product. The method is simple and convenient, easy to operate, wide in raw material source, suitable for industrial production and higher in competitiveness, and is a preparation method with low cost and ideal yield.

Owner:HUNAN HAILI CHEM IND

Solvent for printing, pattern composition for printing comprising the solvent, and patterning method using the composition

Disclosed is a solvent for printing which comprises a first solvent selected from the group consisting of acetone, methyl ethyl ketone, methyl acetate, ethyl acetate, methanol and mixtures thereof, and a second solvent selected from the group consisting of propylene glycol monomethyl ether acetate (PGMEA), propylene glycol monomethyl ether (PGME), isopropanol, butyl acetate, ethyl-3-ethoxypropionate and mixtures thereof. Further disclosed are a pattern composition for printing comprising the solvent for printing, and a patterning method using the composition. The use of the solvent for printing enables formation of an accurate pattern.

Owner:LG DISPLAY CO LTD

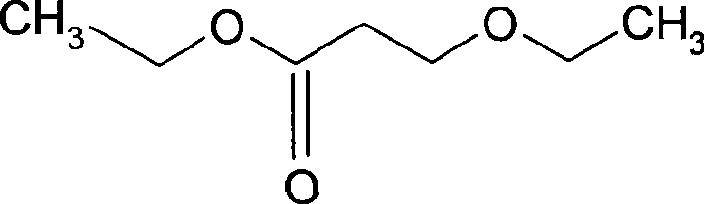

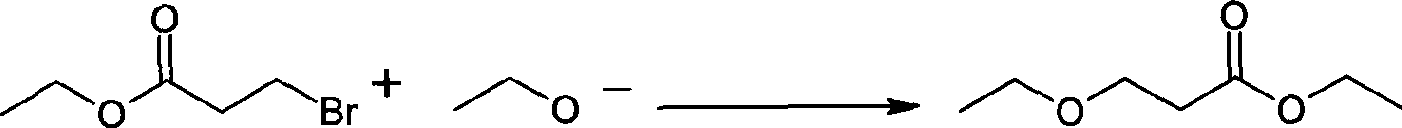

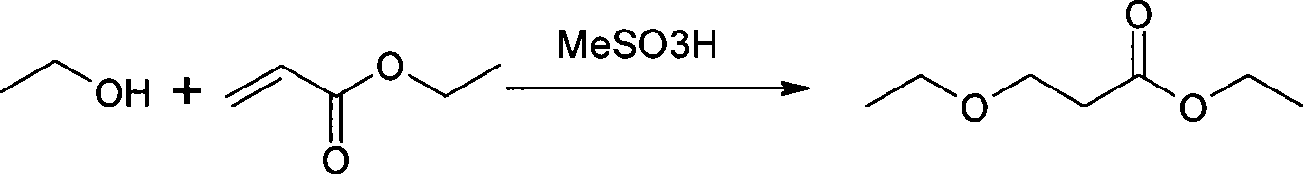

Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives

The present invention provides a process for the preparation of a compound of formula I in which a compound of formula II in which R is H or OR represents a protecting group for a carboxylic hydroxy group is reacted with a compound of formula III C6H13X III wherein X is a leaving group, in the presence of a base in the presence of an inert solvent at a temperature in the range −25° C. to 150° C. and optionally, when OR represents a protecting group, removal of the protecting group.

Owner:ASTRAZENECA AB

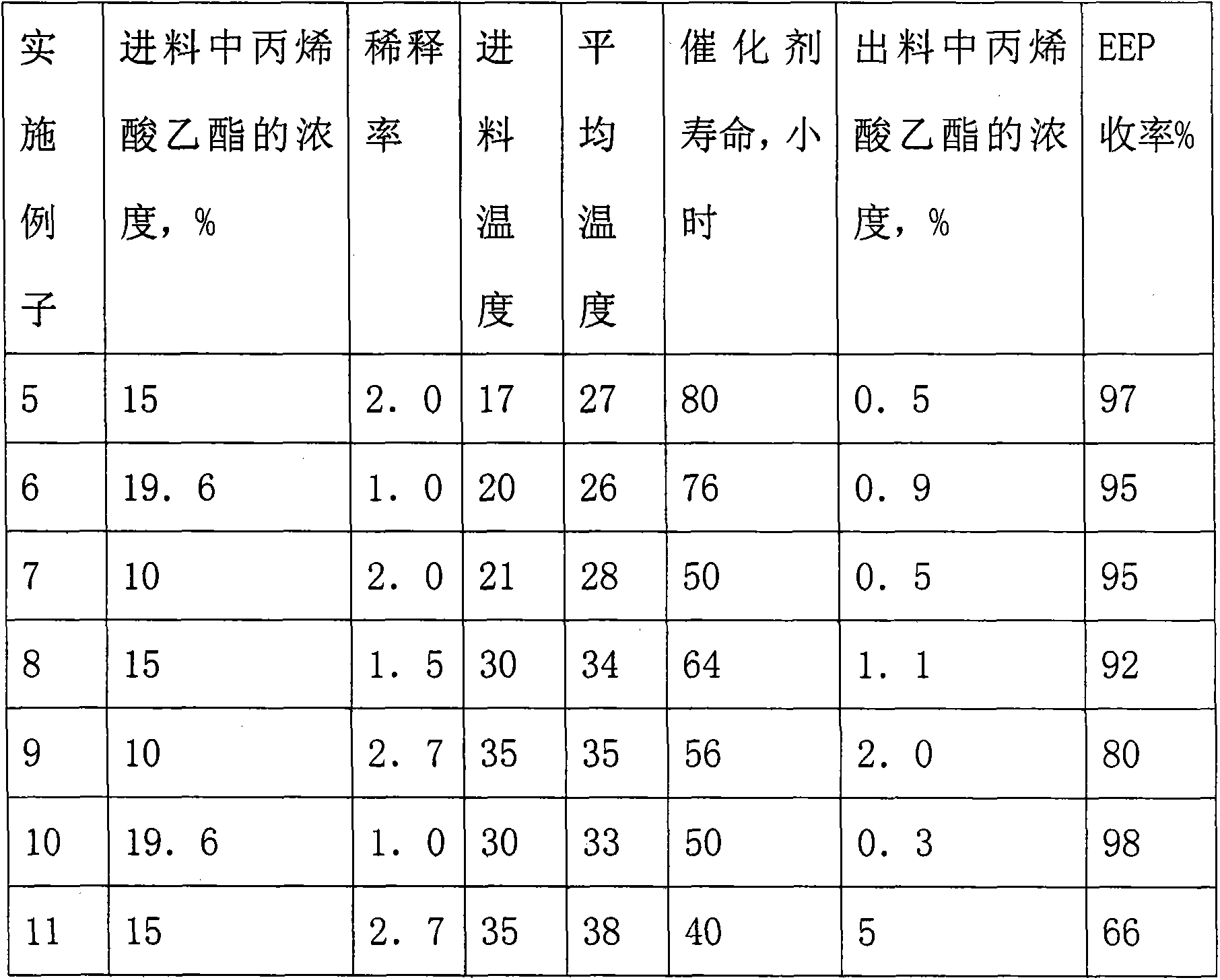

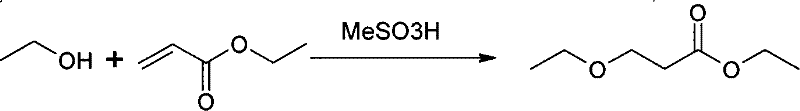

Preparation method for synthesis of ethyl 3-ethoxypropionate

InactiveCN104016861AEasy to separateFlexible operationOrganic compound preparationCarboxylic acid esters preparationChemical synthesisIon-exchange resin

The invention relates to the technical field of chemical synthesis, and particularly relates to a preparation method for synthesis of ethyl 3-ethoxypropionate; the ethyl 3-ethoxypropionate is synthesized by addition reaction of absolute ethanol and ethyl acrylate in the presence of a catalyst in a tubular reactor, the molar ratio of absolute ethanol to ethyl acrylate is 3: 1 to 100: 1, the catalyst weight accounting for 0.1% to 20% of the weight of the ethyl acrylate; the catalyst is anion exchange resin, and the method has the advantages of simple synthesis, mild condition, less side reaction, recycling and regeneration of the catalyst without damage, great simplification of the separation process, easy continuous production and the like.

Owner:SHENZHEN PRECHEM FINE CHEM CO LTD

Thinner composition and method of stripping a photoresist using the same

InactiveUS6682876B2Photomechanical coating apparatusPhotosensitive material processingPropionateResist

A thinner composition is effective in removing a variety of photoresists, and includes propylene glycol mono-methyl ether acetate, ethyl 3-ethoxy propionate and at least one of gamma-butyro lactone and propylene glycol mono-methyl ether. The thinner composition can selectively strip a photoresist coated on a backside and at an edge portion of a substrate, as well as a photoresist coated on a whole front surface of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Light shading resin composition for color filter and color filter

ActiveCN101045807AAdjust coatingAdjust storage stabilityOptical filtersPhotosensitive materials for photomechanical apparatusSolubilitySolid component

The invention relates to a light shading resin composition for color filter, the characteristic of which is that it contains 80~90 wt% of solvent and solid content; relative to solid content, it contains 8~35 wt% of acrylic acid series photosensitive resin, 45~65 wt% of black pigment, silicon surfactant or fluorin surfactant and initiator for photopolymerization whose HLB value is below 8. The viscosity of the resin composition is between 1.0 and 10.0mPa.s; relative to all solvents, it contains 30~50 wt% of the first solvent having a acetoxyl group in molecule, 0~25 wt% of propylene-glycol diacetate as the second solvent, 30~50 wt% of the third solvent having structure of 3-ethoxy propionic acid in molecule, 10~30 wt% of alicyclic compound having a carbonyl as the fourth solvent. Consequently, it has excellent evenness when coating, dryness of coating substrate and solid components' solubility.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

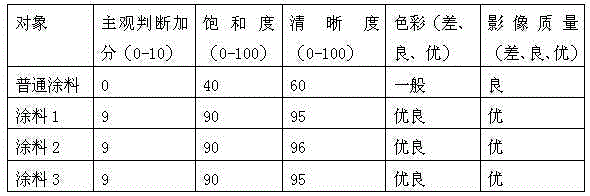

Paint for projection and preparation method of paint

The invention discloses paint for projection and a preparation method of the paint. The paint comprises the following components in parts by mass: 20-30 parts of crylic acid, 30-40 parts of resin, 1-2 parts of microcrystalline cellulose, 3-5 parts of cellulose ether, 1-2 parts of borosilicate, 0.3-0.8 part of nano-powder, 2-4 parts of titanium dioxide, 2-4 parts of aromatic polyimide fiber, 1-2 parts of alkyl cyclohexyl bromobenzene, 1-3 parts of 4-n-pentyl-4'-cyanobiphenyl, 0.2-0.3 part of a defoaming agent, 2-4 parts of a dispersing agent, 0.2-0.4 part of a flatting agent, 0.2-0.5 part of N,N-dimethylethanolamine and 10-15 parts of 3-ethoxypropionic acid ethyl ester. The paint for projection and the preparation method of the paint, provided by the invention, have the benefits as follows: the reflecting property of a wall body during projection can be improved by the paint, the viewing angle balance is improved, the gain is increased, the projection effect is further improved, and the pain is environment-friendly, wear-resistant, flame-retardant and has a better stability.

Owner:香山红叶集团有限公司

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS7393474B2Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

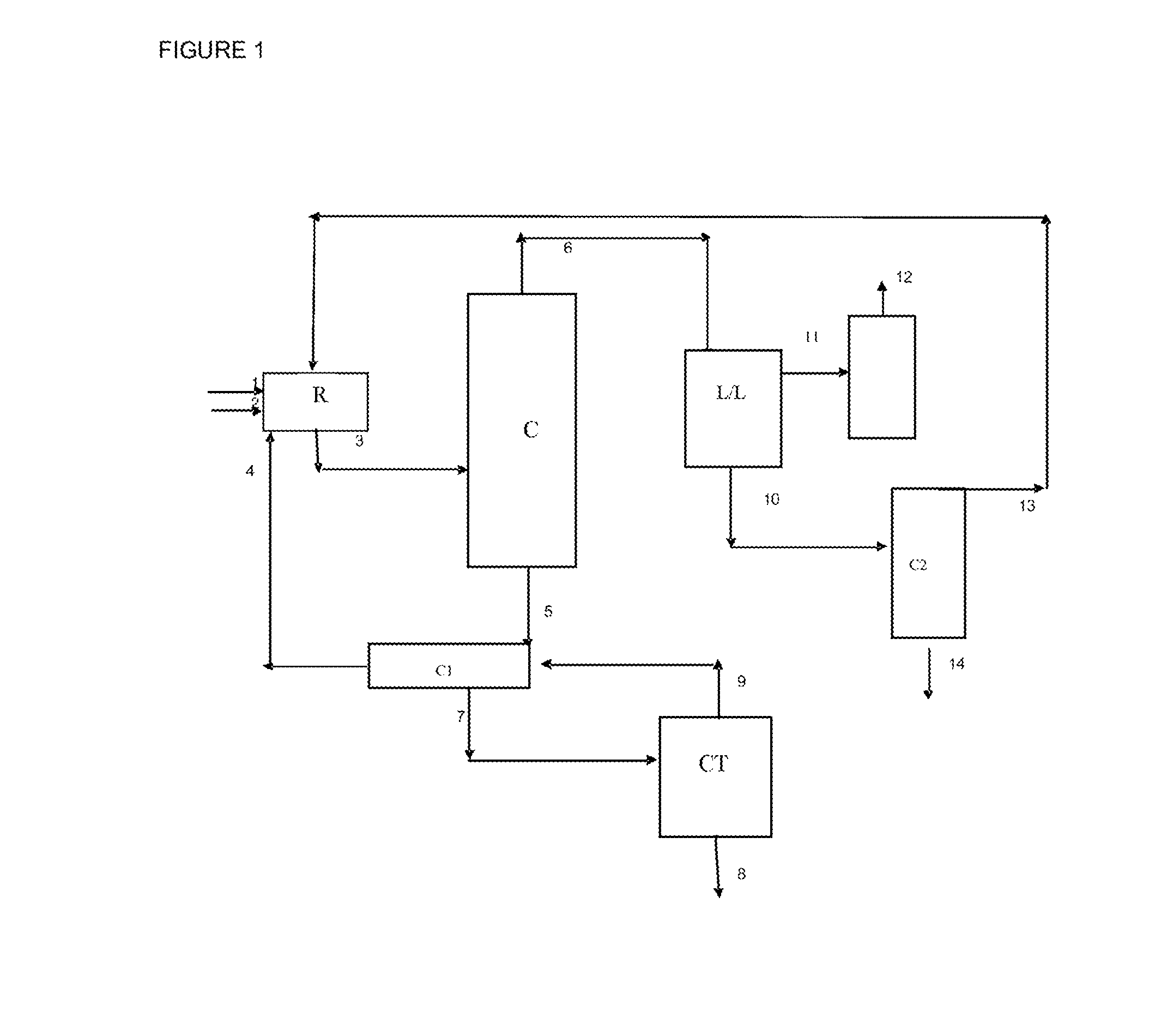

Process for producing light (METH)acrylic esters

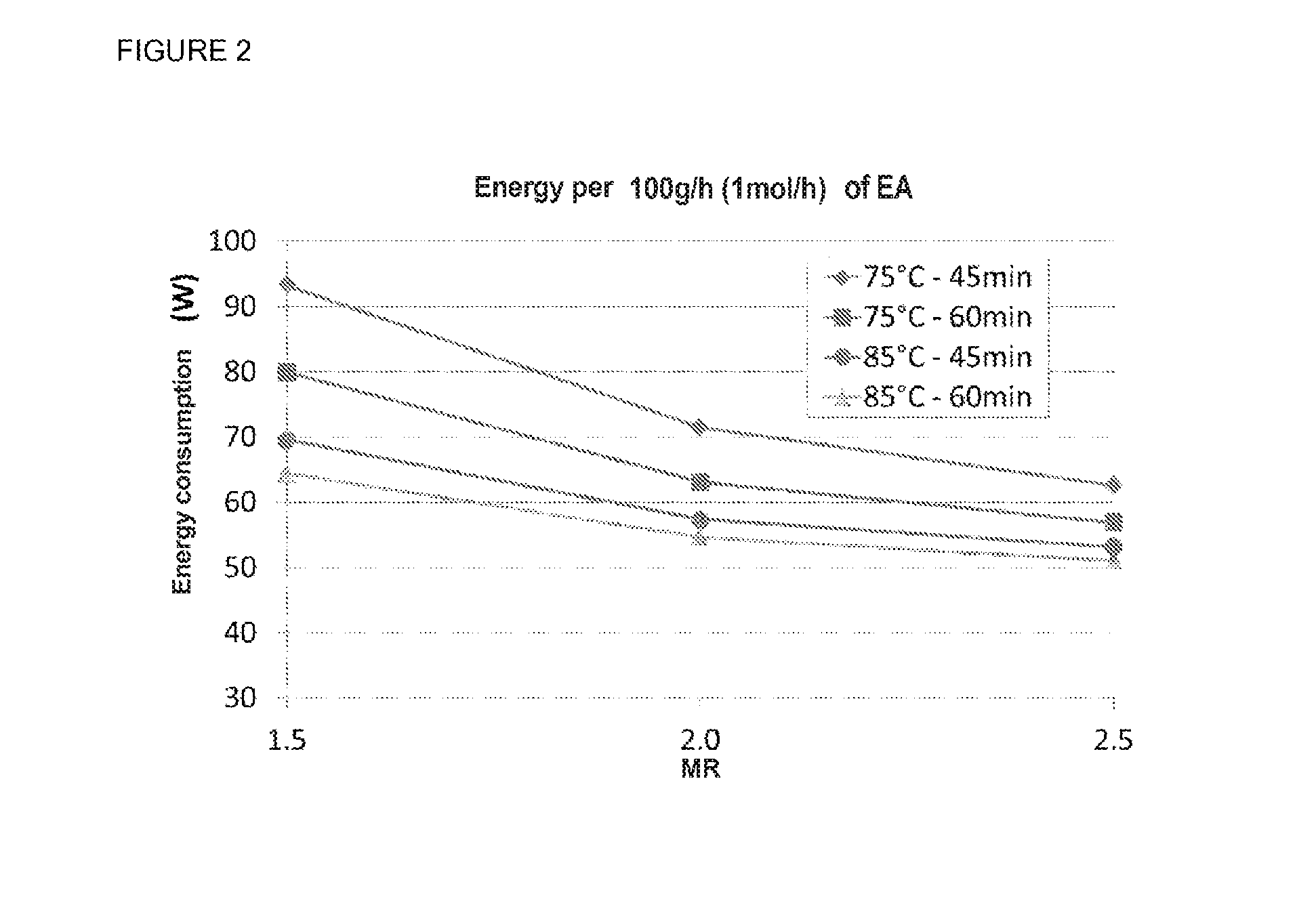

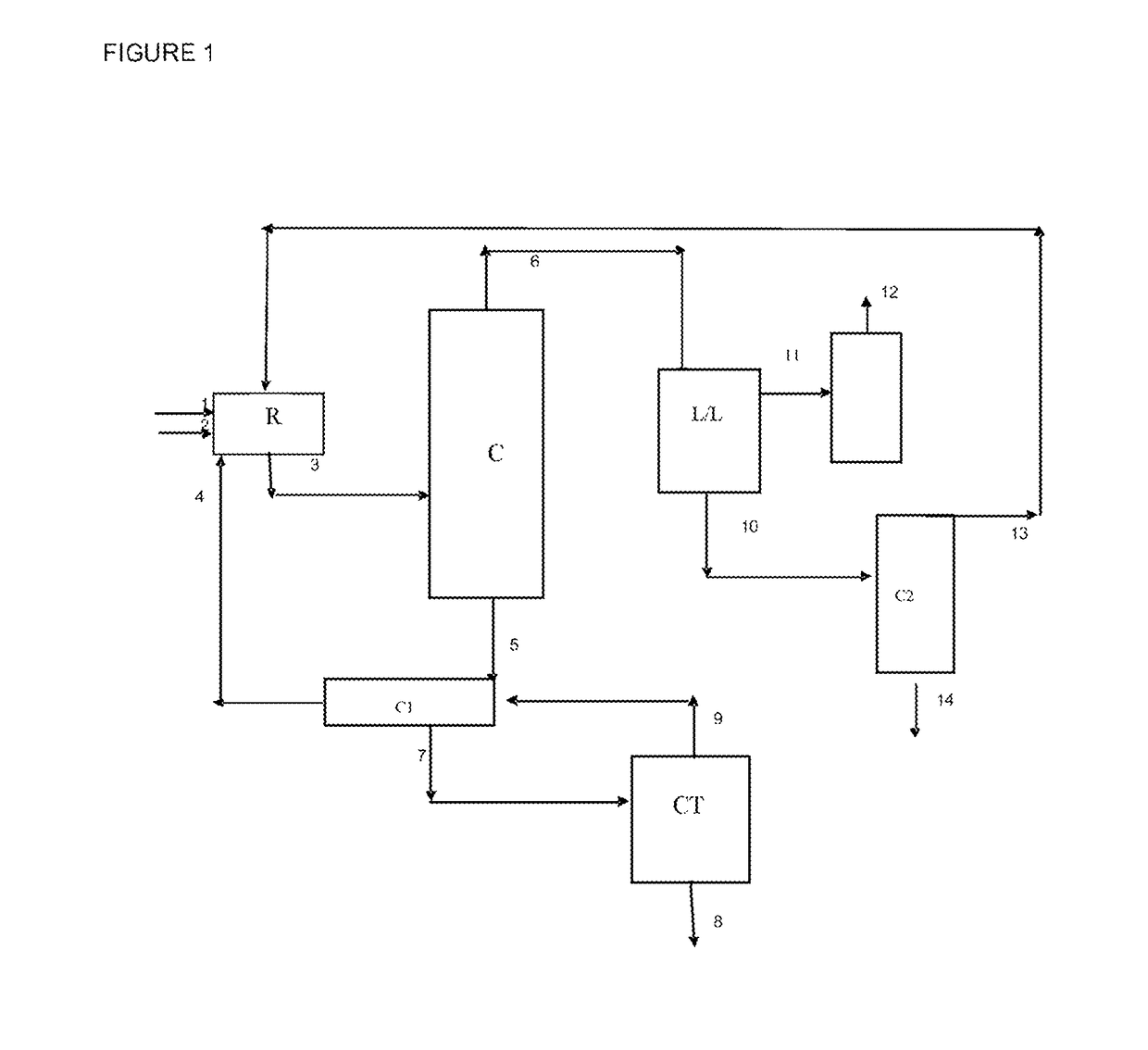

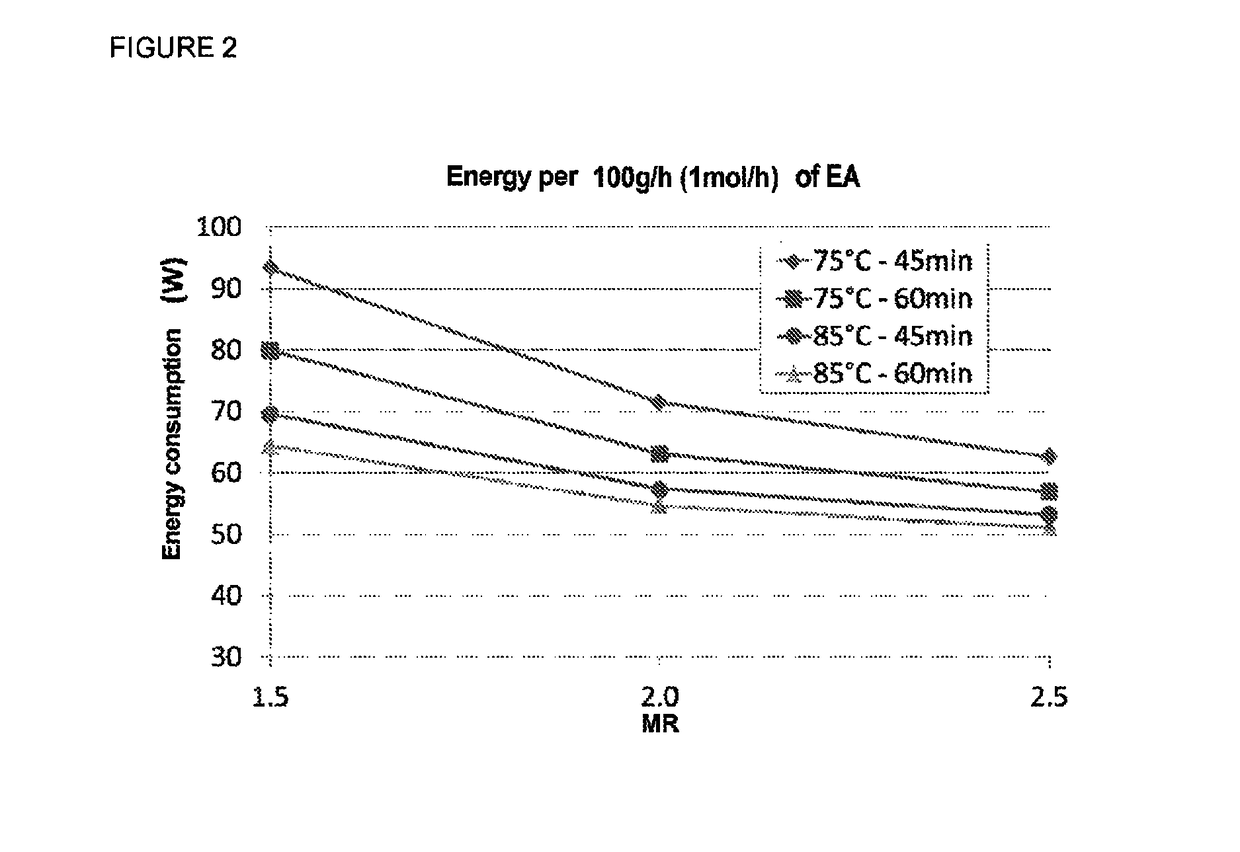

ActiveUS20160272570A1Reduce moistureReduce formationOrganic compound preparationCarboxylic acid esters preparationEnergy balancingPhotochemistry

The subject matter of the present invention is an improvement in the continuous production of methyl (meth)acrylate or of ethyl (meth)acrylate by direct esterification of (meth)acrylic acid with methanol or ethanol, under reaction conditions for which the acid is in excess relative to the alcohol, in particular with an acid / alcohol molar ratio of between 1.0 and 4, and under a pressure ranging from atmospheric pressure to 5 bar. The process of the invention makes it possible to minimize the formation of ethyl ethoxypropionate during the esterification reaction, and results in an improvement in the material balance, simplification of the purification train for the desired ester, and optimization of the energy balance.

Owner:ARKEMA FRANCE SA

Synergistic mixed solvents-based compositions for removal of paint, varnish and stain coatings

InactiveUS20160053203A1Less materialOrganic detergent compounding agentsChemical paints/ink removersSolvent basedStain

Compositions and methods are disclosed which are effective for removing or stripping varnish and paint or stains from surfaces such as wood or metal which comprises activating NMP and / or BLO with 1-20% by weight of ethyl 3-ethoxypropionate (EEP), preferably 2-15%, and optimally about 3-5%, and with 0.1-10% by weight of NOP / ALC EO, preferably 0.2-5%, most preferably 1 -3% by weight and / or 0.1-5% by weight of Silwett 77, preferably 0.2-3%, and most preferably 0.5-2% by weight,

Owner:NARAYANAN KOLAZI S

Temporary removable solvent based protective coating

InactiveUS20080268140A1Easy to disassembleEasy to wearTemporary coatingsPackagingDiacetone alcoholSucrose

This invention is for a composition of clear or pigmented coating that is temporary and removable. It is especially designed to protect the surface of an automobile from the damaging effects of the environment and also from damage caused by normal daily use. The coating is a composition of 40 to 80% of cellulose acetate butyrate ester, 15 to 60% of an acrylic polymer and 2 to 10% of a sucrose acetate isobutyrate. The remover is a combination of tetrahydrofurfuryl alcohol, dibasic ester, diacetone alcohol, ethyl 3 ethoxypropionate; 2,2,4 trimethyl-1,3 pentanoldiol monoisobutyrate, and white mineral oil.

Owner:NATHE HEINRICH W

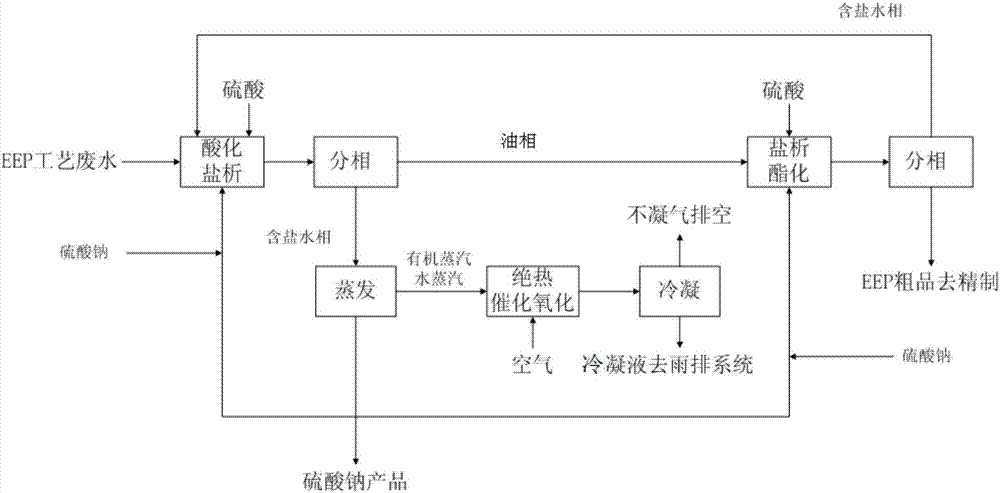

Recycling and purifying treatment method of sodium ethoxypropionate-containing wastewater

ActiveCN107010772ASolve the way outImplement resourcesOrganic compound preparationWater contaminantsSalting outFixed bed

The invention discloses a recycling and purifying treatment method of sodium ethoxypropionate-containing wastewater. The method comprises: carrying out acidification salting-out on sodium ethoxypropionate wastewater, and carrying out phase separation to obtain an oil phase and a first salt-containing water phase; esterifying the oil phase to produce an esterification reaction solution containing EEP and water, carrying out phase separation to obtain a second salt-containing water phase and crude EPP, mixing the second salt-containing water phase with the sodium ethoxypropionate-containing wastewater, and carrying out acidification salting-out; and evaporating the first salt-containing water phase to make water steam containing organic matters enter a fixed bed reactor and undergo an adiabatic catalytic oxidation reaction, condensing obtained oxidized mixed gas, discharging obtained condensate, and directly discharging obtained non-condensable gas to air. The invention realizes the recycling of the sodium ethoxypropionate in the EEP production wastewater and realizes the purifying treatment of the wastewater.

Owner:NANJING UNIV OF TECH

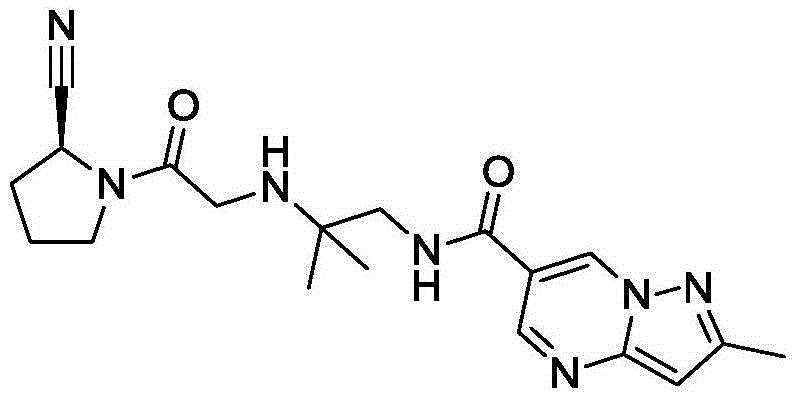

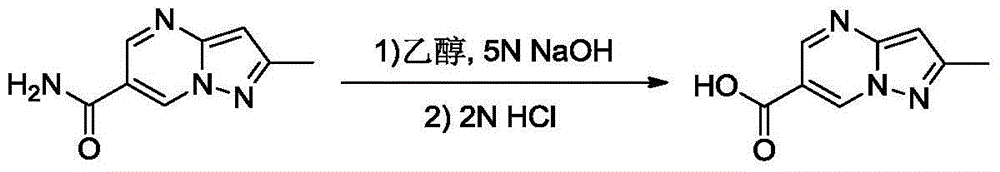

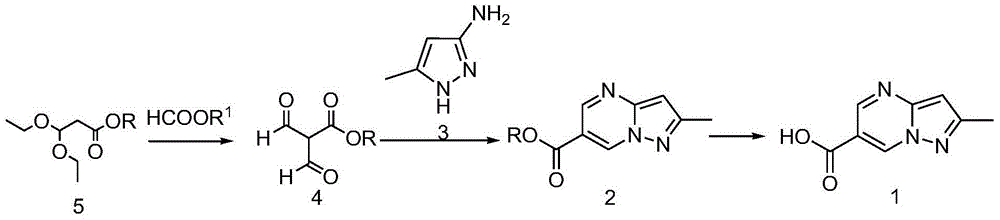

Preparation method of Anagliptin intermediate

InactiveCN105315284AEfficient manufacturingNo pollution in the processOrganic chemistryFormateCarboxylic acid

The invention provides a preparation method of an Anagliptin intermediate. The preparation method comprises following steps: (1) in the presence of an alkali, 3,3-diethoxy propionate (compound 5) is reacted with a formate (HCOOR1) so as to obtain a compound 4; (2) the compound 4 and 3-amino-5-methyl-1H-pyrazole (compound 3) are subjected to cyclization reaction in an acid solvent so as to obtain a compound 2; and (3) the compound 2 is subjected to esterolysis in the presence of an alkali so as to obtain 2-methylpyrazolo[1,5-a]pyrimidine-6-carboxylic acid (compound 1); wherein R is used for representing a group selected from methyl, ethyl, propyl, or benzyl, and R1 is used for representing a group selected from methyl, ethyl, propyl, or benzyl. Operation of the preparation method is simple; the raw materials are cheap and easily available; the preparation method is suitable for industrialized large-scale production, and is green and friendly to the environment; and no environmental pollution is caused.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

Shock-absorption synthetic rubber and preparation method thereof

The invention discloses a shock-absorption synthetic rubber which is prepared from the following raw materials in parts by weight: 10.5-12.6 parts of methyl methacrylate, 2.3-5.7 parts of silver-coated glass microsphere core-shell composite particle, 2.6-4.8 parts of rosin polyoxyethylene sulfonate, 1.5-1.8 parts of polyethyleneglycol octyl phenyl ether, 5.3-7.8 parts of ethyl 3-ethoxypropionate, 4.3-5.2 parts of pine tar, 2.5-3.7 parts of magnesium oxide and 1.3-1.8 parts of coupling agent. The environment-friendly rubber material has the advantages of simple formula and technique, low production cost, high damping, high elasticity and favorable high / low temperature resistance, and can not release bromides or other harmful substances. The rubber product can not generate any corrosive action on electronic components after being used for a long time. The shock-absorption synthetic rubber is especially suitable for manufacturing shock-absorption sleeves and other products of disk drives and other electronic and electric products. The shock-absorption synthetic rubber has high damping capacity, and thus, still has high shock absorption effect under the condition of strong shocks when the automobile runs at high speed or passes over a deceleration strip.

Owner:张桂华

Particle size control for acetylenic agents useful in condition monitoring systems

ActiveCN101072750ASuitable for mass productionShorten the timeUrea derivatives preparationCarbamic acid derivatives preparationNitrocelluloseAcetylenic Compounds

Precipitation of polyacetylenic agents can be effected with control of a particle size parameter such as mean size or spread, by mixing a warm solution of the acetylenic agent with a cold precipitation fluid and appropriate selection of a constituent of the cold precipitation fluid and / or of the temperature conditions and collecting the precipitated acetylenic agent. Precipitation additives such as nitrocellulose or gelatin can usefully be employed. Solvents such as aqueous methanol and ethyl 3-ethoxypropionate can be useful. Polyacetylenic agents, e.g. substituted diacetylenics are useful to provide visual changes in condition-monitoring indicators such as time-temperature indicators, ''TTIs'', useful as freshness indicators for radiation exposure monitoring and for other purposes. Controlled, small and / or consistent particle sizes of such polyacetylenic agents are helpful in providing consistent commercial properties, especially in inks in which they may be formulated.

Owner:TEMPTIME CORP

Solvent blend for replacement of ketones

InactiveUS20110315929A1Improve propertiesExceeding performanceCoatingsDissolvingPropionateHydrocarbon mixtures

A three-part solvent composition that contains A) a C1 to C4 lactate ester, B) ethyl 3-ethoxy propionate and C) a C7-C12 hydrocarbon mixture is disclosed that is a homogeneous liquid at zero degrees C. A contemplated solvent blend provides performance properties that can replace toxic ketones, but does not contain any ketone groups in any of the components.

Owner:VERTEC BIOSOLVENTS

Process for producing light (meth)acrylic esters

ActiveUS9908838B2Reduce moistureReduce formationOrganic compound preparationCarboxylic acid esters separation/purificationEnergy balancingMeth-

The subject matter of the present invention is an improvement in the continuous production of methyl (meth)acrylate or of ethyl (meth)acrylate by direct esterification of (meth)acrylic acid with methanol or ethanol, under reaction conditions for which the acid is in excess relative to the alcohol, in particular with an acid / alcohol molar ratio of between 1.0 and 4, and under a pressure ranging from atmospheric pressure to 5 bar. The process of the invention makes it possible to minimize the formation of ethyl ethoxypropionate during the esterification reaction, and results in an improvement in the material balance, simplification of the purification train for the desired ester, and optimization of the energy balance.

Owner:ARKEMA FRANCE SA

Preparation method of ethyl 3-ethoxypropionate

PendingCN111004123AImprove conversion ratePromote regenerationOrganic compound preparationCarboxylic acid esters preparationChemical industryPtru catalyst

The embodiment of the invention discloses a preparation method of ethyl 3-ethoxypropionate, and relates to the technical field of chemical industry synthesis. According to the scheme, low-acidity absolute ethyl alcohol and ethyl acrylate are subjected to an addition reaction under the catalytic action of a strongly basic ion exchange resin to prepare ethyl 3-ethoxypropionate, wherein the acidity of the reactant is within 10ppm and cannot affect the catalyst, so that the conversion rate of the catalyst is high so as to achieve high yield (the conversion rate and the yield of the scheme are morethan 98%). According to the invention, the method has the advantages of simplicity, mild conditions, few side reactions and easy regeneration of the catalyst; and the product easily achieves the purity of more than 99.8%, can be further processed into an electronic grade, can be used in photoelectric industry, greatly simplifies the separation process, and is convenient for continuous production.

Owner:SHENZHEN PRECHEM FINE CHEM CO LTD

Preparation method of 3-ethoxyl ethyl propionate

ActiveCN101423475BReduce recyclingHigh yieldOrganic compound preparationCarboxylic acid esters preparationChemical synthesisDistillation

The invention belongs to the technical field of chemical synthesis, and in particular relates to a method for preparing 3-ethoxy ethyl propionate. The method comprises a synthesizing step and a refining step, wherein the synthesizing step adopts ethanol and ethyl acrylate as raw materials to carry out addition under the action of a catalyst, and the catalyst adopts alkali metal or alkali alcoholate. The method has the following advantages: 1, the method adopts one of the raw materials as solvent to react, so as to reduce solvent recovery and consumption in the production process; 2, the reaction catalyst uses basic catalyst such as sodium metal and the like, so as to improve reaction yield greatly; 3, the dosage of the reaction catalyst is reduced to about 2 percent, so as to lower amountof salt greatly after the reaction is finished, and reduce byproducts; 4, the reaction time can be shortened to 3 hours, so as to improve production efficiency; and 5, fore zeolite obtained in distillation can be used for next reaction, so as to achieve circular application, so that the proposal reaches green chemical requirement.

Owner:LINHAI LIANSHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/51b50b1f-9431-4451-a541-de2331bd227a/US20060142392A1-20060629-C00001.png)

![Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/51b50b1f-9431-4451-a541-de2331bd227a/US20060142392A1-20060629-C00002.png)

![Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives Process for preparing (2s)-3-(4-{2-[amino]-2-oxoethoxy}phenyl)-2-ethoxypropanoic acid derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/51b50b1f-9431-4451-a541-de2331bd227a/US20060142392A1-20060629-C00003.png)