Degumming agent and preparation method and application thereof

A technology of glue and main solvent, applied in the field of polymer solvent materials, can solve the problems of unsatisfactory cleaning effect, strong acidity and alkalinity of glue remover, high toxicity, etc., and achieves short cleaning time, low cost, and use method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

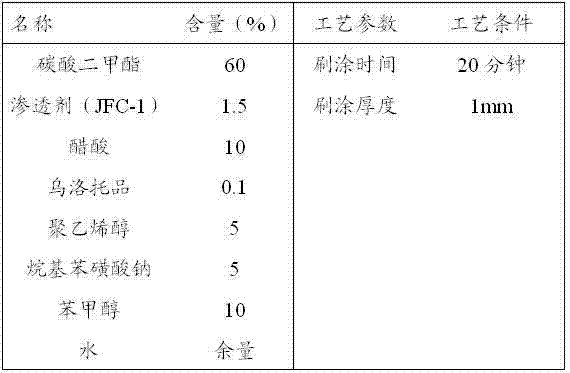

[0039] Table 1 Glue remover formulation and process conditions

[0040]

[0041] Preparation method: weigh the main solvent according to the above formula and put it into a container, and then weigh the activator, corrosion inhibitor, volatilization inhibitor, emulsifier and thickener of the formula and add them to the main solvent separately and stir at the same time The finished product is obtained uniformly.

[0042] When using, brush the adhesive remover evenly on the surface of the sign with the adhesive layer at room temperature, with a thickness of 1mm, keep it for 20 minutes, wipe off the swollen adhesive layer, and then rinse it with water.

[0043] Test results: The glue removal rate on the surface of the substrate is 95%, and the surface of the metal substrate does not have any changes such as corrosion.

[0044]

Embodiment 2

[0046] Table 2 Glue remover formulation and process conditions

[0047]

[0048] Preparation method: weigh the main solvent according to the above formula and put it into a container, and then weigh the activator, corrosion inhibitor, volatilization inhibitor, emulsifier and thickener of the formula and add them to the main solvent separately and stir at the same time The finished product is obtained uniformly.

[0049] When using, brush the adhesive remover evenly on the surface of the sign with the adhesive layer at room temperature, with a thickness of 2mm, keep it for 25 minutes, wipe off the swollen adhesive layer, and then rinse it with water.

[0050] Test results: The glue removal rate on the surface of the substrate is 98%, and the surface of the metal substrate does not have any changes such as corrosion.

[0051]

Embodiment 3

[0053] Table 3 Glue remover formulation and process conditions

[0054]

[0055] Preparation method: weigh the main solvent according to the above formula and put it into a container, and then weigh the activator, corrosion inhibitor, volatilization inhibitor, emulsifier and thickener of the formula and add them to the main solvent separately and stir at the same time The finished product is obtained uniformly.

[0056] When in use, evenly brush the adhesive remover on the surface of the sign with the adhesive layer at room temperature, with a thickness of 3mm, keep it for 30 minutes, wipe off the swollen adhesive layer, and then rinse it with water.

[0057] Test results: The glue removal rate on the surface of the substrate is 100%, and there is no corrosion and other changes on the surface of the metal substrate.

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com