Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "3-Hydroxybenzoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-Hydroxybenzoic acid is a monohydroxybenzoic acid.

Nano rare earth m-hydroxy benzoic acid 8-hydroxyquinoline antibacterial agent and method for preparing same

InactiveCN1704403AImprove antibacterial propertiesDoes not affect processabilityBiocideOrganic chemistryBenzoic acidEscherichia coli

The invention relates to a process for preparing nano rare earth m-hydroxy benzoic acid 8-hydroxyquinoline antibacterial agent which comprises, mixing 0.01 mol of sodium m-hydroxybenzoate with 0.02 mol of 8-hydroxyquinoline with a magnetic stirrer to obtain mixed ligand solution, instilling the mixed ligand solution into 0.01 mol REC136 H2O at 40-70 deg. C, adjusting pH to above 6, reacting 2-6 hrs, ageing 0.5-4 hrs, filtering by suction, removing chloride ions (Cl-) through secondary distilled water washing, vacuum drying 4-10 hours.

Owner:SHANGHAI NORMAL UNIVERSITY

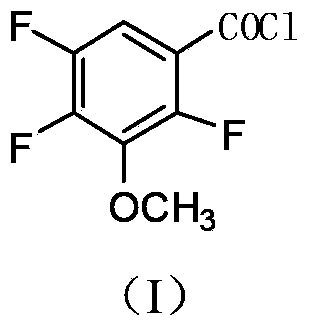

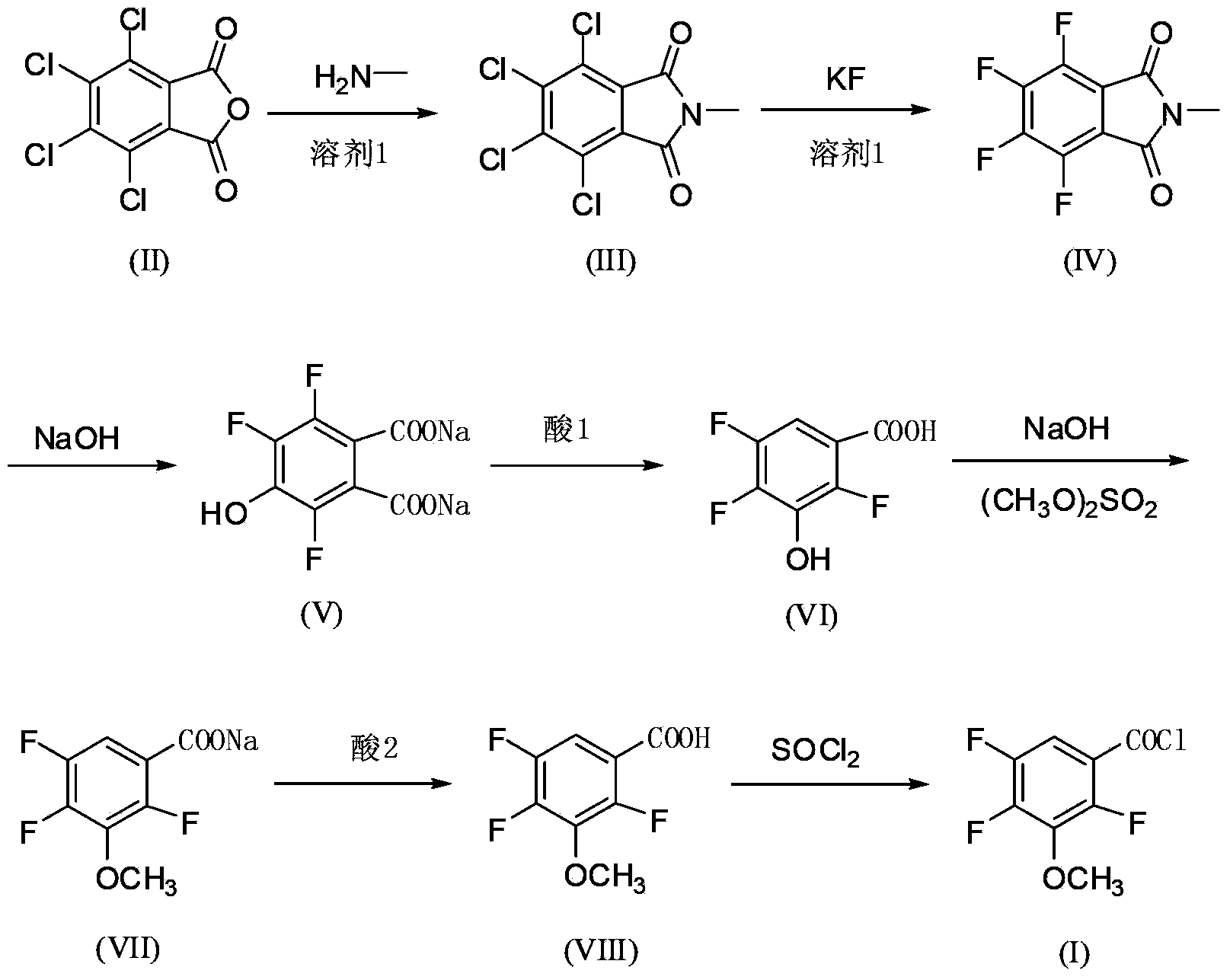

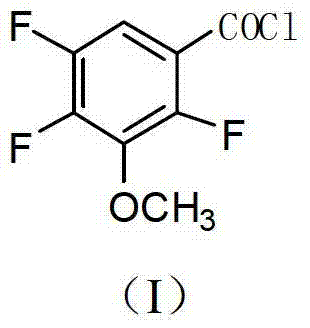

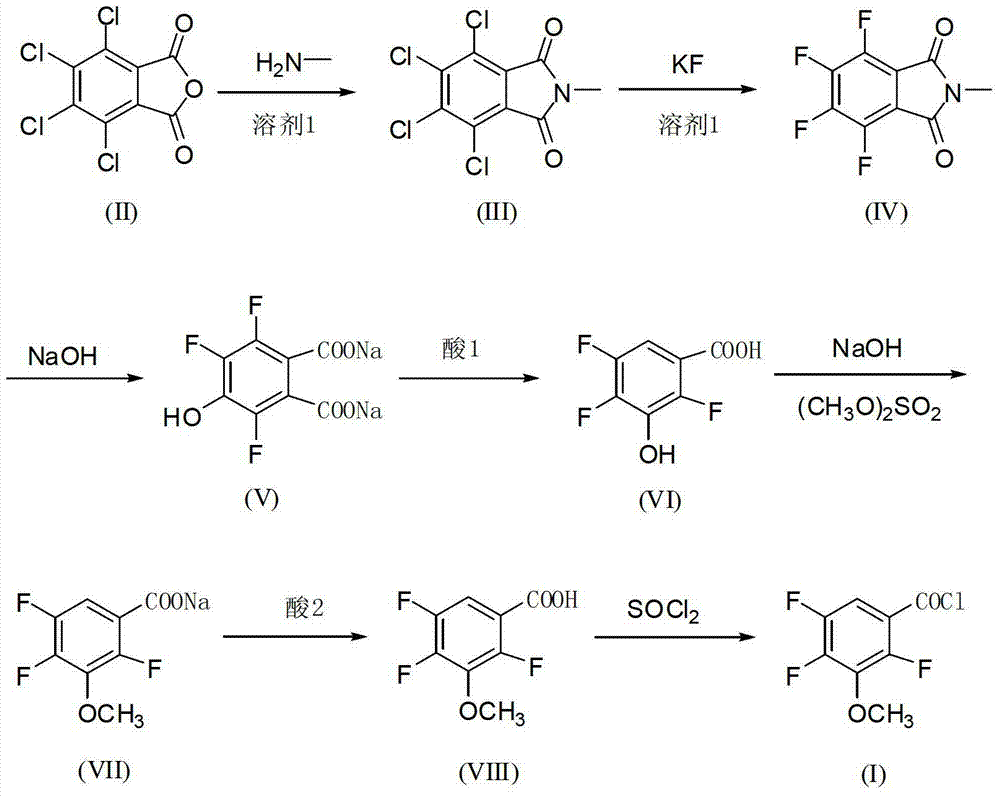

Industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride

ActiveCN103450013AAvoid pollutionSimple and fast operationOrganic compound preparationCarboxylic compound preparationN dimethylformamidePhthalate

The invention discloses an industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride. The industrial preparation method comprises the following steps: 1) using methylamine to react with tetrachlorophthalic anhydride to get N-methyl tetrachlorophthalimide; 2) enabling the N-methyl tetrachlorophthalimide obtained in the step 1) to react with an alkali metal fluoride to get N-methyl tetrafluorophthalimide; 3) enabling the N-methyl tetrafluorophthalimide obtained in the step 2) to perform mixed reaction with sodium hydroxide to get 2,4,5-trifluoro-3-hydroxy sodium phthalate and then performing decarboxylation and acidification to get 2,4,5-trifluoro-3-hydroxybenzoic acid; 4) enabling the 2,4,5-trifluoro-3-hydroxybenzoic acid obtained in the step 3) to react with dimethyl sulfate to get 2,4,5-trifluoro-3-methoxybenzoic acid sodium and then acidifying to get 2,4,5-trifluoro-3-methoxybenzoic acid; 5) enabling the 2,4,5-trifluoro-3-methoxybenzoic acid obtained in the step 4) to react with thionyl chloride and N,N-dimethylformamide to get the 2,4,5-trifluoro-3-methoxybenzoyl chloride.

Owner:YUEYANG YETOP FINE CHEM

Medical degradable package bag and preparation method of same

The invention discloses a medical degradable package bag and a preparation method of same. The medical degradable package bag includes, by weight, 50-60 parts of polypropylene, 8-15 parts of calcium carbonate, 1-4 parts of nano titanium dioxide, 10-20 parts of carboxyethyl cellulose, 7-9 parts of aluminum oxide, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of dimethylformamide, 60-65 parts of PVC, 2-3 parts of sodium tripolyphosphate, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of silica gel, and 4-6 parts of diethylene triamine, The medical degradable package bag has very excellent high-temperature-sterilization-resistant performance and has high mechanical performances, such as tensile strength and breaking strength, etc.; the package bag, when being wasted, can be auto-decomposed under effects of enriched oxygen and microorganisms to finally generate CO2 and H2O, so that the package bag is ecological and environment-friendly.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

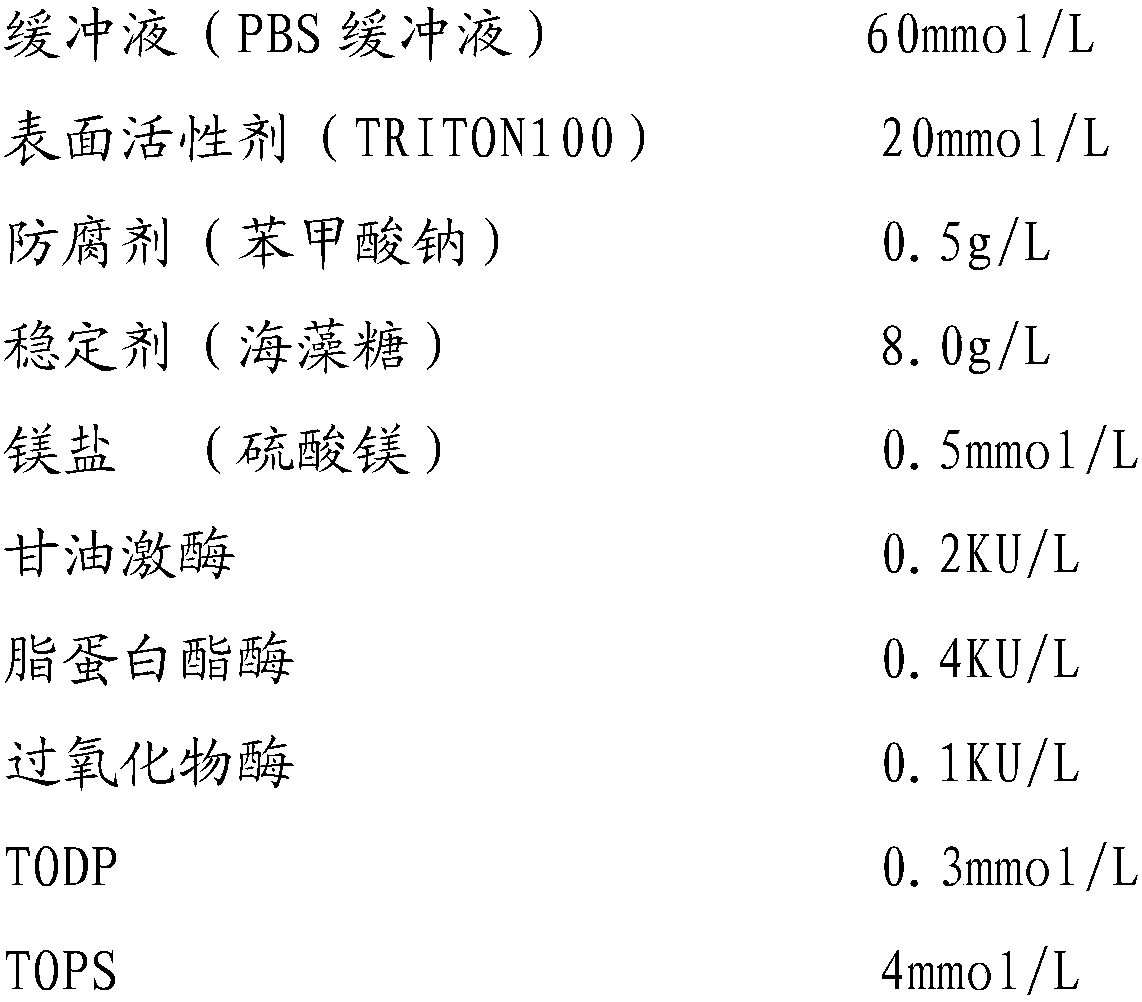

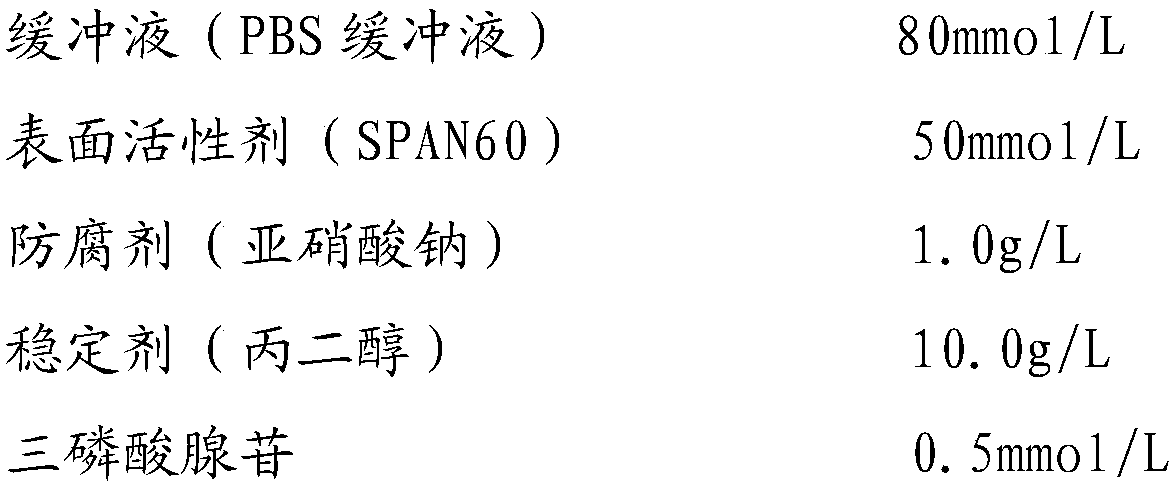

Triglyceride detecting kit

InactiveCN108467882AShorten the timeShort detection timeMicrobiological testing/measurementBiological material analysisMethylanilineSulfonate

The invention relates to the technical field of medical examination, and specifically relates to a triglyceride detecting kit. The kit comprises an agent R1 and an agent R2, wherein the agent R1 comprises glycerol kinase, lipoprotein lipase, peroxidase, composite chromogen and magnesium salt; the agent R2 comprises glycerophosphate oxidase, 4-ampyrone and triphosadenine; the composite chromogen comprises some of 3-methyl-N, N-aniline dipropyl sulfonate, N-ethyl-N-(3-sulfopropyl)-3-sodium methylaniline, N, N-bi(4-sulfobutyl)-3-methylaniline disodium salt, N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3-sodium methylaniline, and 2, 4, 6-tribromo-3-hydroxybenzoic acid. The kit in detecting of triglyceride is high in sensitivity, short in detecting time, and high in interference resistance.

Owner:山东康华生物医疗科技股份有限公司

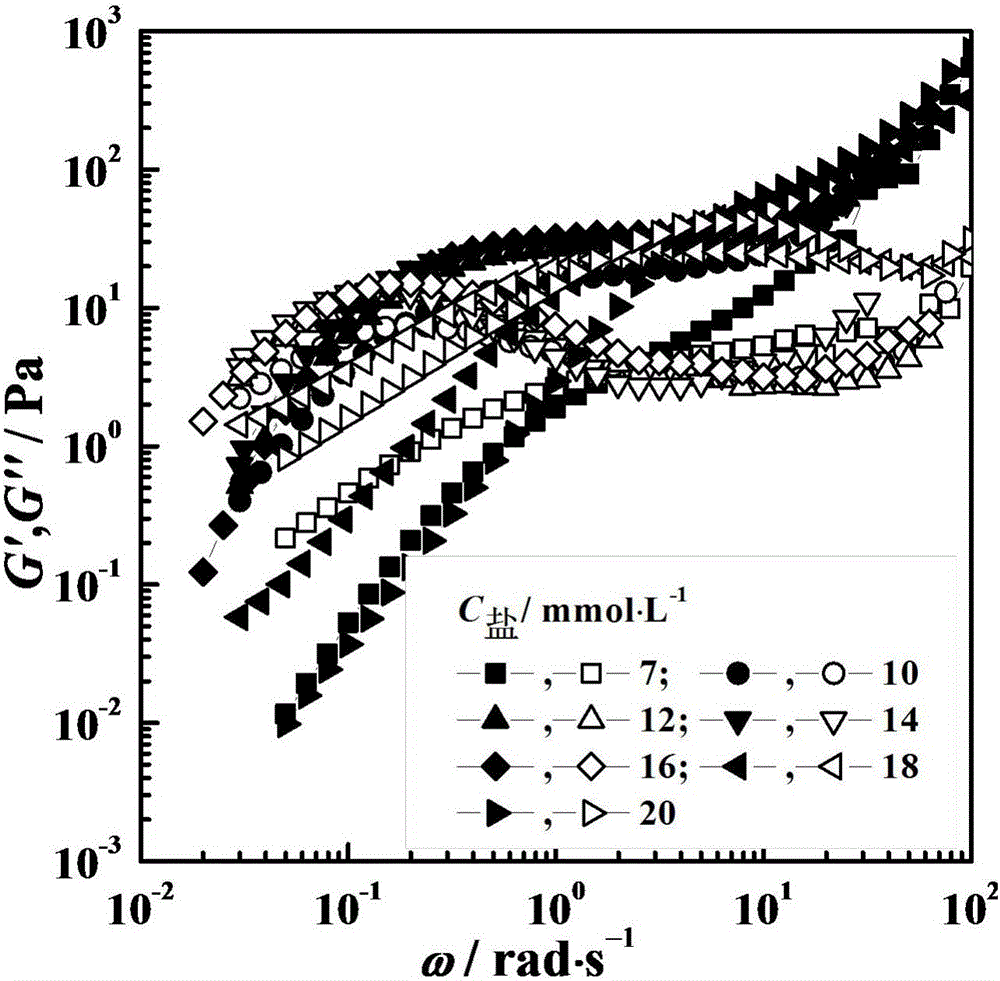

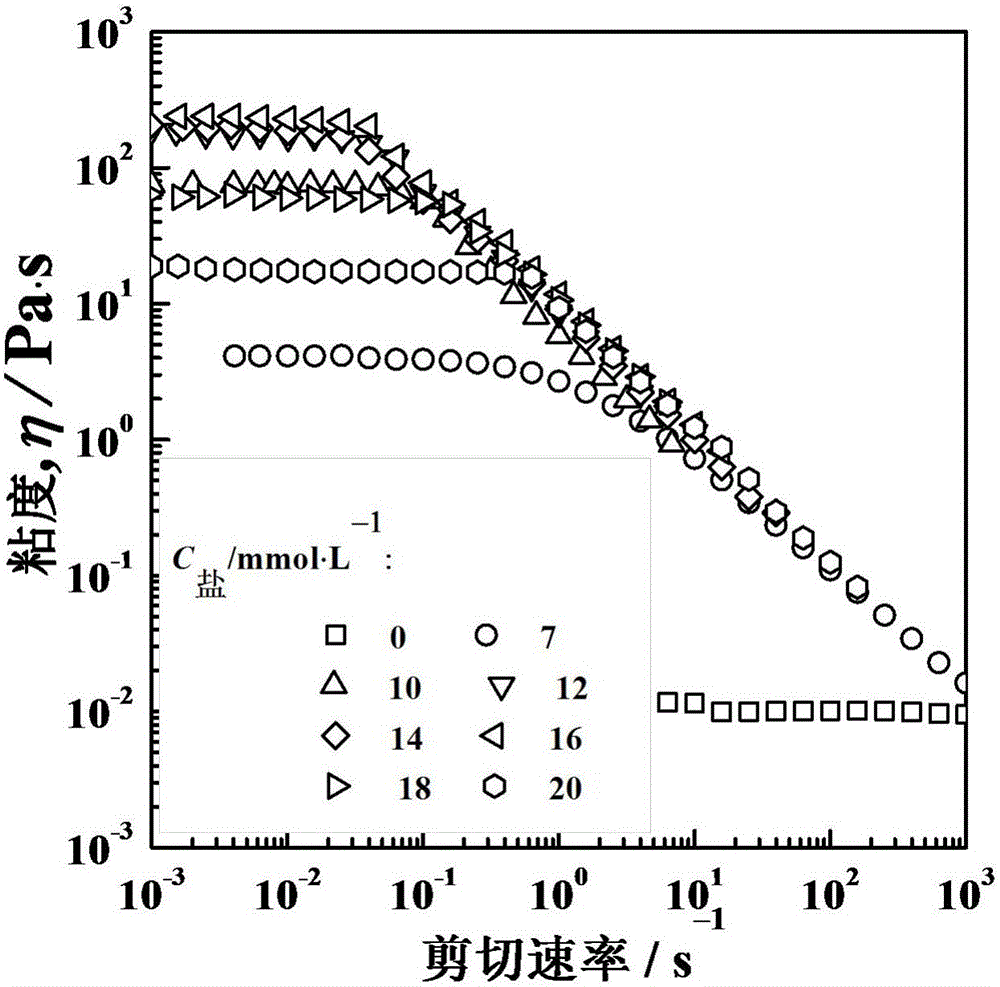

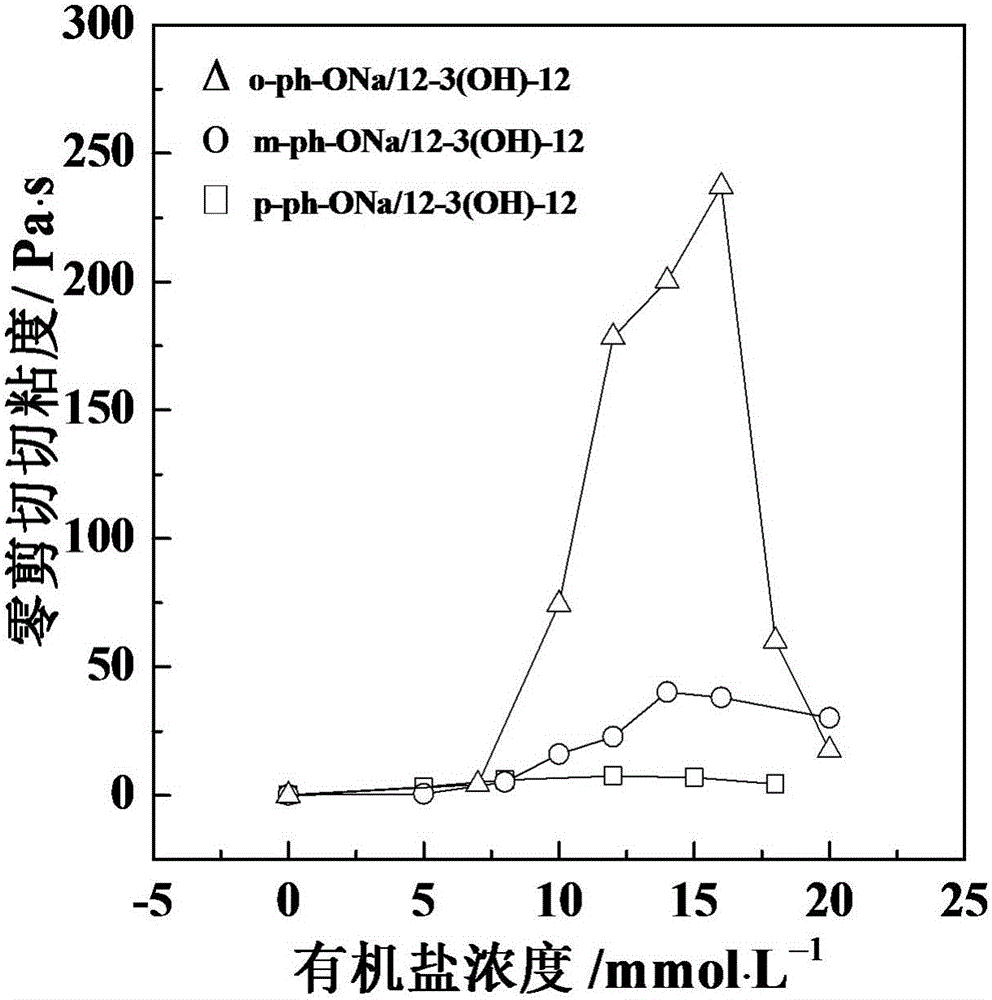

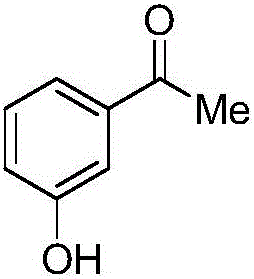

Viscoelastic system formed by functional Gemini surface active agent

InactiveCN106000217AAffect self-organizing behaviorRich in self-organizing behaviorTransportation and packagingMixingSurface-active agentsHydroxybenzoate

The invention discloses a viscoelastic system formed by a functional Gemini surface active agent and belongs to the technical field of a surface active agent. According to a preparation method of a viscoelastic surface active agent solution provided by the invention, organic salt comprises sodium o-hydroxybenzoate, 3-hydroxy-benzoic aci monosodium salt and sodium p-Hydroxybenzoate; Gemini surface active agent with hydroxyl group is taken as the main component and is compounded with few organic salts, and then the viscoelastic surface active agent solution is obtained; the preparation of the viscoelastic surface active agent solution comprises the two processes of compounding and testing viscoelastic property; Gemini cationic surface active agent is prepared into the solution in certain concentration and then is compounded with the salt at different ratio, thus, the viscoelastic surface active agent solution is acquired.

Owner:JIANGNAN UNIV

Starch-novolac epoxy resin blended fully-degradable zip lock bag and preparation method thereof

InactiveCN106243636AHigh strengthFacilitate the realization of large-scale industrial productionEpoxyMagnesium stearate

The invention discloses a starch-novolac epoxy resin blended fully-degradable zip lock bag and a preparation method thereof. The starch-novolac epoxy resin blended fully-degradable zip lock bag is prepared from, by weight, 50-60 parts of novolac epoxy resin, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titania, 10-20 parts of benzoin ethyl ether, 7-9 parts of nano-montmorillonite, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 60-65 parts of corn starch, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-ditert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate and 4-6 parts of plant saponin. The product is produced according to a safe formula, and can be used for manufacturing food packaging bags and the like; during use, the product is high in strength, resistant to water and oil and durable, large-scale industrial production can be achieved, grasping is easy, popularization is convenient, the waste product can be automatically degraded under the effects of rich oxygen and microorganisms, carbon dioxide and water are finally generated, and the starch-novolac epoxy resin blended fully-degradable zip lock bag is ecological and environmentally friendly.

Owner:ANHUI MEIXIANG PLASTIC

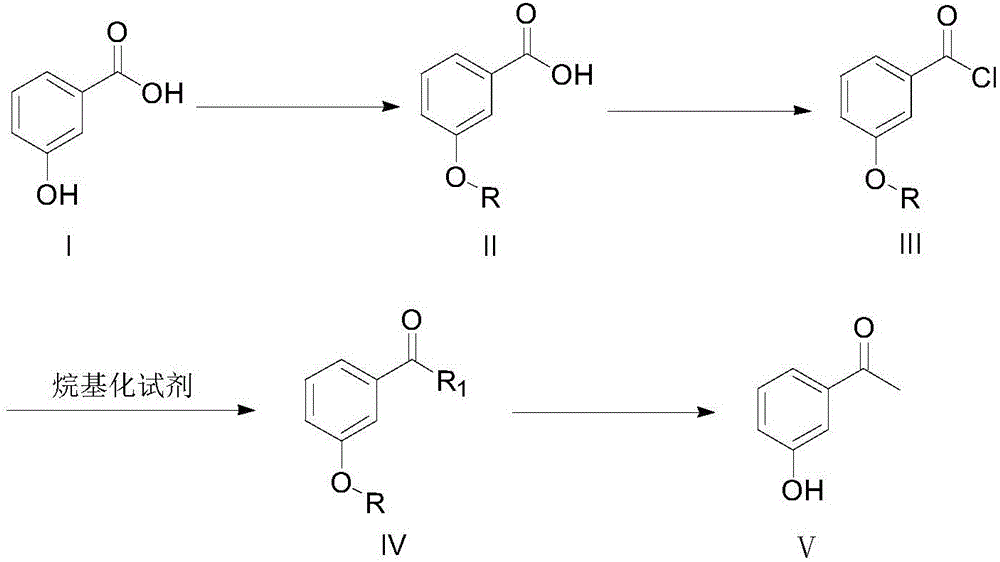

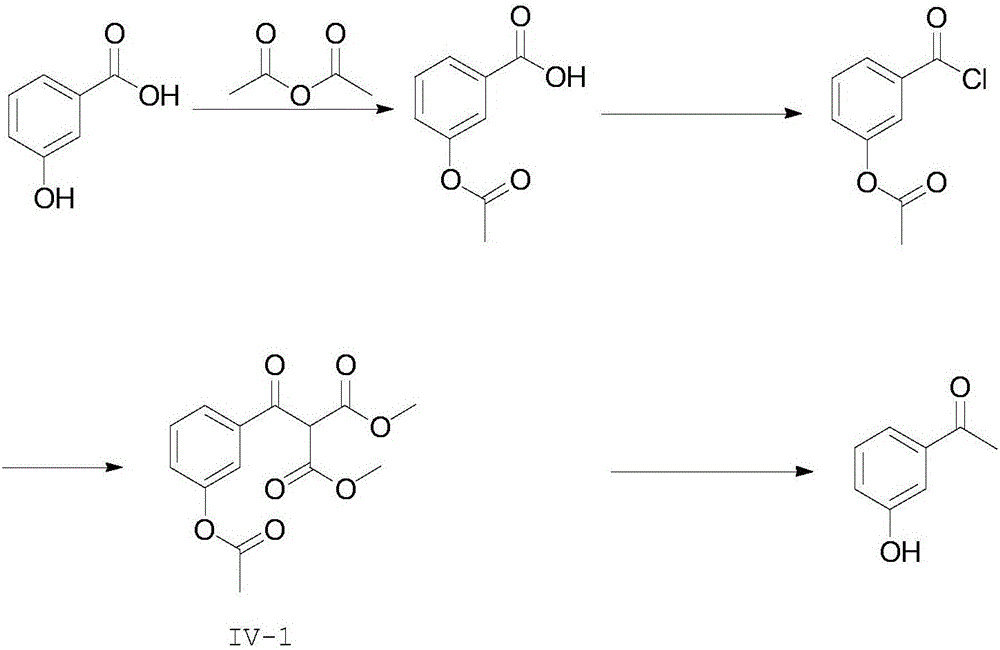

3-hydroxyacetophenone synthesis method

ActiveCN105967986AWide variety of sourcesImprove securityOrganic compound preparationCarbonyl compound preparation by condensationSynthesis methodsNitration

The invention provides a 3-hydroxyacetophenone synthesis method. The method includes the steps that 3-hydroxybenzoic acid is subjected to hydroxyl protection through an esterification or etherification reaction, then a chloroformylation reaction and an alkylation reaction are conducted, finally hydrolysis is conducted, and the 3-hydroxyacetophenone is obtained. According to the method, raw materials are cheap, easy to obtain and wide in source, high-temperature and high-pressure operation does not exist, equipment requirement is low, and equipment investment is low; peroxide, heavy nitride and the like do not exist, and high safety is achieved; compared with a nitration-iron powder reduction-diazotization route commonly adopted in the nation, the synthesis method has huge environment-friendly advantages. Besides, according to the method, the amount of wastewater is less than 5% that of an original process, the total route yield is 90%, and the method has huge technological advantages.

Owner:BEIJING RISUN TECH CO LTD

Environment-friendly plastic package bag

InactiveCN106243434AHigh strengthImprove toughnessFlexible coversWrappersN-phenylmaleimidePolyolefin

The invention discloses an environment-friendly plastic package bag. The package bag is prepared from, by weight, 40-65 parts of polyolefin plastic, 35-45 parts of corn straw fiber, 5-8 parts of chitosan, 3.5-4.5 parts of methylisothiazolinone, 2-3 parts of bamboo charcoal micro mist, 4-6 parts of methyl phenyl polyborosiloxane, 2.0-2.5 parts of polysebacic polyanhydride, 5.5-7.5 parts of N-phenylmaleimide, 5-7 parts of hexamethoxy methyl melamine resin, 8-10 parts of diethyl malonate, 6-8 parts of decabromodiphenyl ether, 6-8 parts of dibasic lead phosphite, 0.1-0.2 part of coupling agent of organic titanate, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate, 4-6 parts of plant saponin, 0.1-0.2 part of polyamide wax micro mist and 1-3 parts of antibacterial agent. The package bag has good strength and toughness and is good in optical performance and easy to oxidize and degrade.

Owner:安徽浩峯塑业有限公司

Aromatic wood-plastic composite material

The invention discloses an aromatic wood-plastic composite material. The aromatic wood-plastic composite material is prepared from, by weight, 40-65 parts of PVC resin powder, 35-45 parts of straw, 5-8 parts of polyethylene, 3.5-4.5 parts of polyphenyl ether, 2-3 parts of benzoin, 4-6 parts of mica powder, 2.0-2.5 parts of zinc borate, 5.5-7.5 parts of asbestos, 5-7 parts of walnut shell powder, 8-10 parts of bamboo powder, 6-8 parts of ginkgo leaves, 6-8 parts of aralia echinocaulis powder, 0.1-0.2 part of eaglewood powder, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate, 4-6 parts of plant saponins, 0.1-0.2 part of terpilenol and 1-3 parts of white latex. The wood-plastic composite material can continuously emit hidden fragrance, and a plate made from the material has the good strength and the better waterproofness, corrosion resistance and mould resistance, can be used both indoors and outdoors, resists aging and cannot crack or deform.

Owner:安徽钰锦生态木材料有限公司

Acid-alkali resistant rubber material formula

The invention discloses an acid-alkali resistant rubber material formula, comprising the following components in parts by weight: 100 parts of ethylene propylene rubber, 50 parts of styrene butadiene rubber, 40 parts of chlorinated polyethylene, 50 parts of neoprene, 7 parts of zinc oxide, 3 parts of magnesium oxide, 25 parts of butadiene-styrene rubber, 3 parts of an acid-absorbing agent DHT-4A, 7 parts of decabrominated dipheny ethane, 4 parts of microcrystalline paraffin, 4 parts of chlorinated polyethylene, 10 parts of barium carbonate, 8 parts of vermicular carbon, 8 parts of polyglycerol ricinoleate, 0.2 part of wintergreen oil, 6 parts of 3-hydroxybenzoic acid, 12 parts of carbon black, 2 parts of lauryl alcohol sulfate, 6 parts of plant saponin, 0.3 part of ginger juice, 2 parts of white mica powder, 0.2 part of terpineol, 3 parts of sulfur, 15 parts of naphthenic oil and 1 part of methacrylic ester. The rubber manufactured according to the acid-alkali resistant rubber material formula disclosed by the invention is hardly corroded, and is oil-resistant, high-pressure-resistant and acid-alkali resistant.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

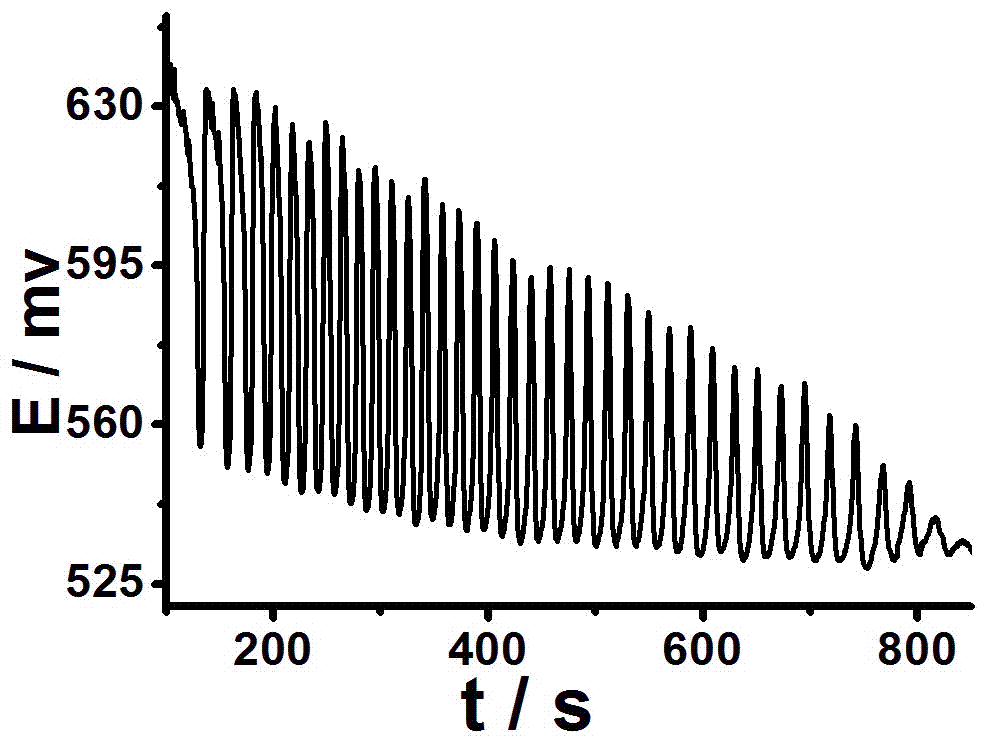

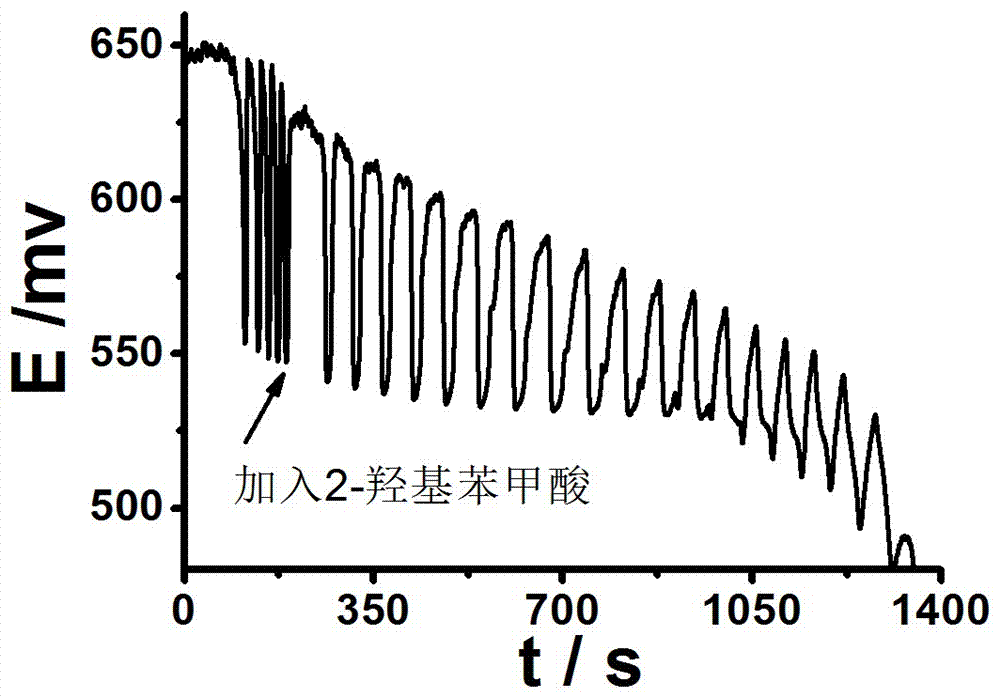

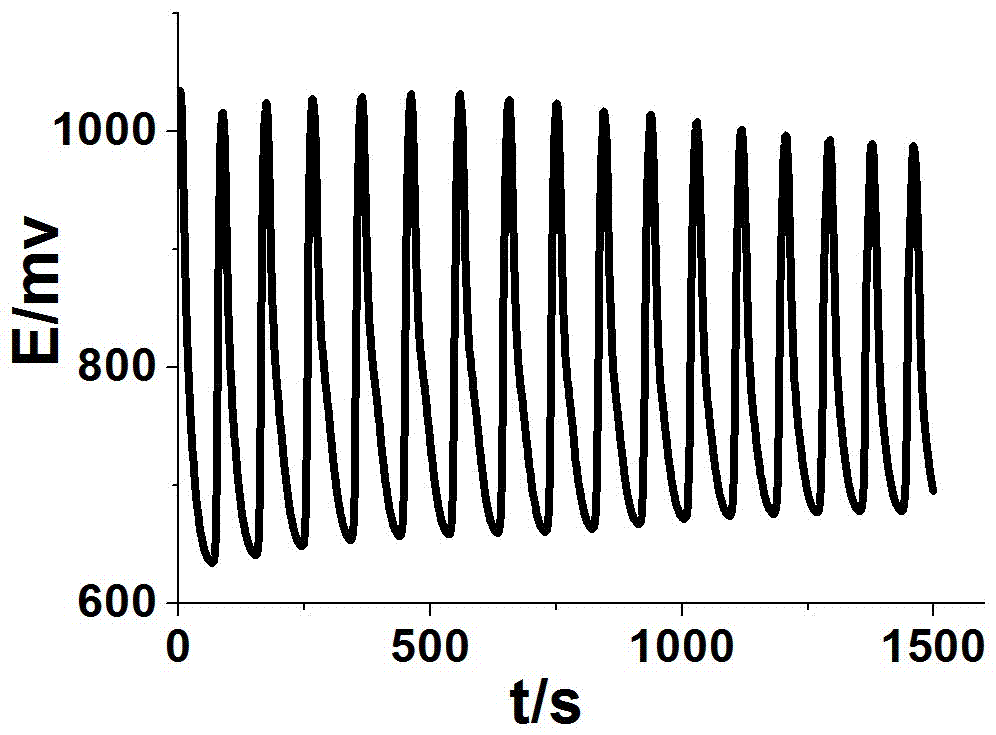

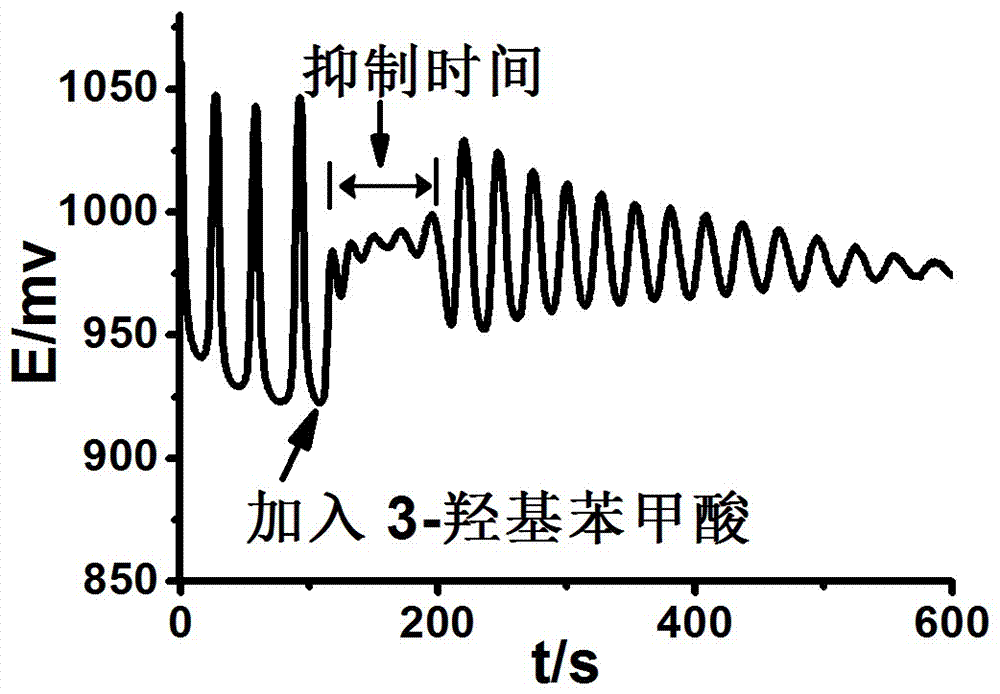

Method for identifying aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid

ActiveCN107045008ATime suppressionPreparing sample for investigationMaterial electrochemical variablesHydroxybenzoic acid2-Hydroxybenzoic acid

The invention discloses a method for identifying aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid. The method is characterized by comprising the following steps: taking a 'H2SO4-KIO3-[NiL](ClO4)2-propanedioic acid-H2O2' nonlinear oscillating chemical system as an identification solution, and further distinguishing and identifying the aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid according to oscillation response of the aromatic isomers on the system, wherein L in [NiL](ClO4)2 refers to 5,7,7,12,14,14-hexamethyl-1,4,8,11-tetraazamacrocyclo-4,11-diene. An oscillation spectrum provided by the identification method is intuitive, and the method is capable of conveniently and rapidly identifying the aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid, can be widely applied to other isomers and is simple in equipment, high in accuracy and easy in operation and observation.

Owner:ANHUI UNIVERSITY

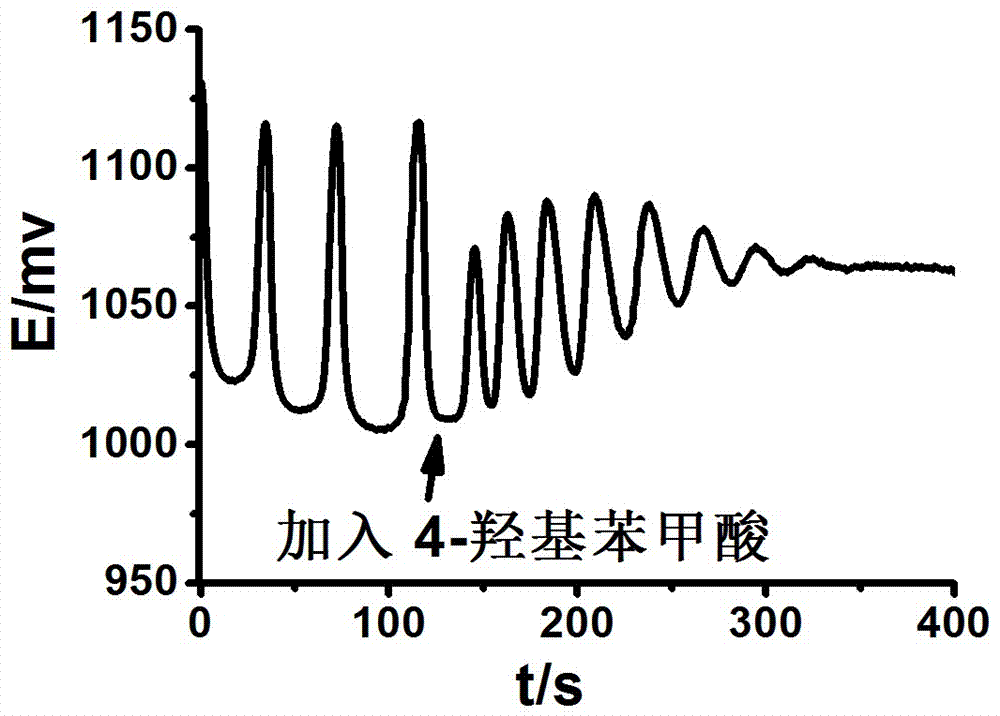

Identification method for aromatic isomeride 3-hydroxybenzoic acid and 4-hydroxybenzoic acid

The invention discloses an identification method for aromatic isomeride 3-hydroxybenzoic acid and 4-hydroxybenzoic acid. The identification method is characterized in that a 'H2SO4-NaBrO3-[CuL](ClO4)2-malic acid' nonlinear chemical oscillation system serves as identification solution, distinguishing identification of aromatic for isomeride is achieved according different oscillatory responses of the aromatic isomeride 3-hydroxybenzoic acid and 4-hydroxybenzoic acid for the system, and L in the [CuL](ClO4)2 is 5, 7, 7, 12, 14, 14-hexamethyl-1, 4, 8, 11-tetraazacyclotetradecane-4, 11-diene. An oscillation spectrum provided by the identification method is more intuitive, the aromatic isomeride 3-hydroxybenzoic acid and 4-hydroxybenzoic acid can be conveinetly and rapidly identified, the oscillation spectrum can be widely applied to other isomerides, and the method is simple in device, high in accuracy and easy to operate and observe.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

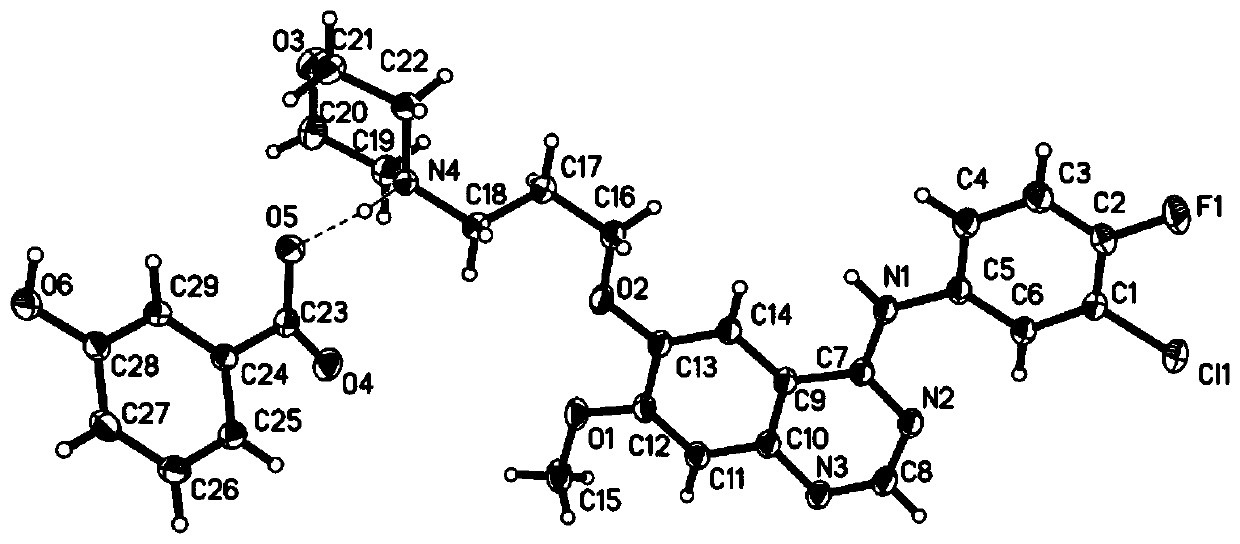

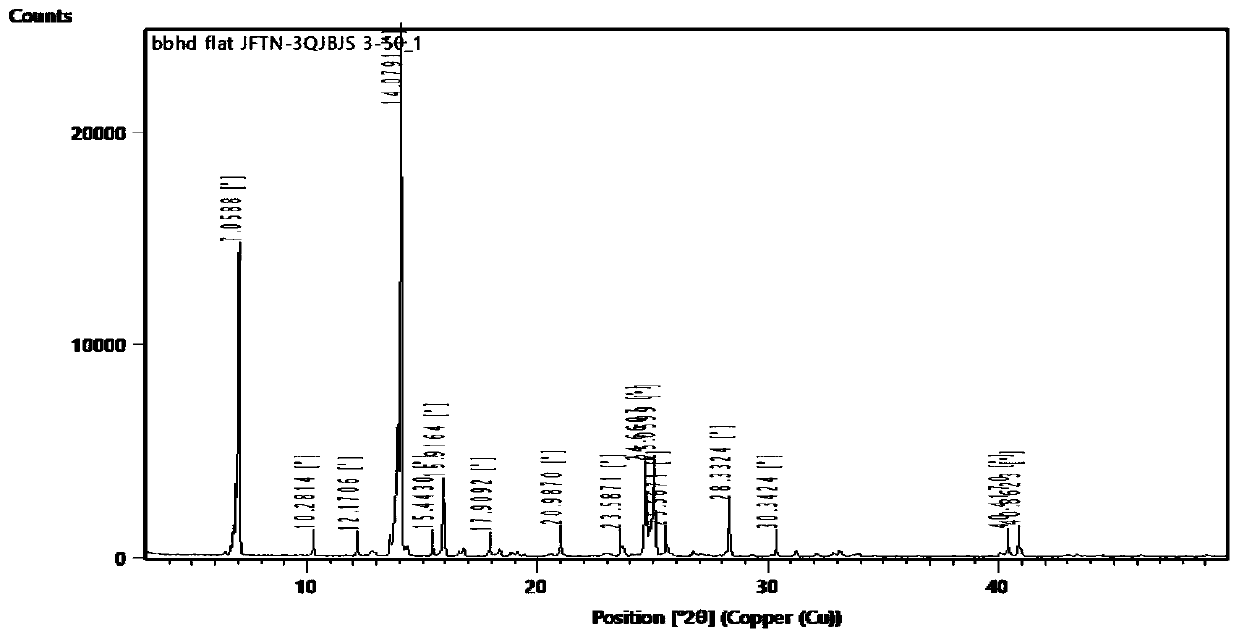

Gefitinib and 3-hydroxybenzoic acid eutectic

InactiveCN110128356AGood chemical stabilityImprove solubilityOrganic active ingredientsOrganic chemistry methodsSolubilityBioavailability

The invention provides a gefitinib and 3-hydroxybenzoic acid eutectic, and concretely relates to the gefitinib and 3-hydroxybenzoic acid eutectic, and a preparation method and an application thereof.The X-ray diffraction spectrum of the gefitinib and 3-hydroxybenzoic acid eutectic has characteristic peaks at 2theta of 7.06 + / - 0.2 DEG, 14.08 + / - 0.2 DEG, 15.92 + / - 0.2 DEG, 24.66 + / - 0.2 DEG, 25.06 + / - 0.2 DEG and 28.33 + / - 0.2 DEG. The eutectic has a good chemical stability, has a higher solubility than a gefitinib crystal or its solvate, and has an excellent bioavailability; and the preparation method allows the eutectic to be obtained by a simple grinding process, and has the advantages of simplicity in operation, and stable yield.

Owner:LUNAN PHARMA GROUP CORPORATION

Delicate-fragrant-type environment-friendly wall surface coating

InactiveCN106366713AImprove adhesionPrevent disengagementAnti-corrosive paintsCarvacryl acetateOxide

The invention discloses a delicate-fragrant-type environment-friendly wall surface coating which includes, by weight, 2-3 parts of polypropylene oxide glycol, 1-2 parts of propyl gallate, 0.8-1 part of Chinese tallow oil, 0.7-1 part of n-salicylaniline, 1-2 parts of calcium lactate, 2-3 parts of palm wax, 3-4 parts of poly(1,2-propylene glycol adipate), 0.7-2 parts of polybenzimidazole, 5-7 parts of attapulgite, 10-13 parts of potassium feldspar powder, 100-140 parts of butyl acrylate, 160-200 parts of vinyl acetate, 5-7 parts of walnut shell powder, 8-10 parts of triethanolamine, 6-8 parts of nano silicon dioxide powder, 6-8 parts of powder of aralia echinocaulis, 0.1-0.2 parts of agalloch powder, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of lauryl sulfate, 4-6 parts of plant saponin, 0.1-0.2 parts of terpilenol and 1-3 parts of nano diatomite. The coating contains a composite component of modified plastic, which can improve adhesion force of the coating when being added to the coating, so that a problem of stripping off of the coating is solved. The coating can release a delicate fragrance continuously and also has the anti-corrosion, anti-mildewing and anti-aging properties, and has the effect of adsorption and indoor air purification.

Owner:安徽钰锦生态木材料有限公司

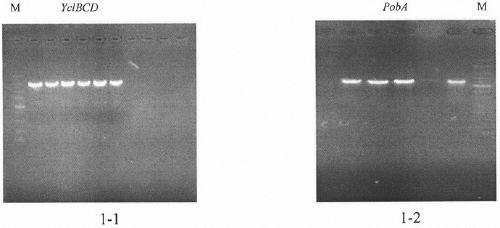

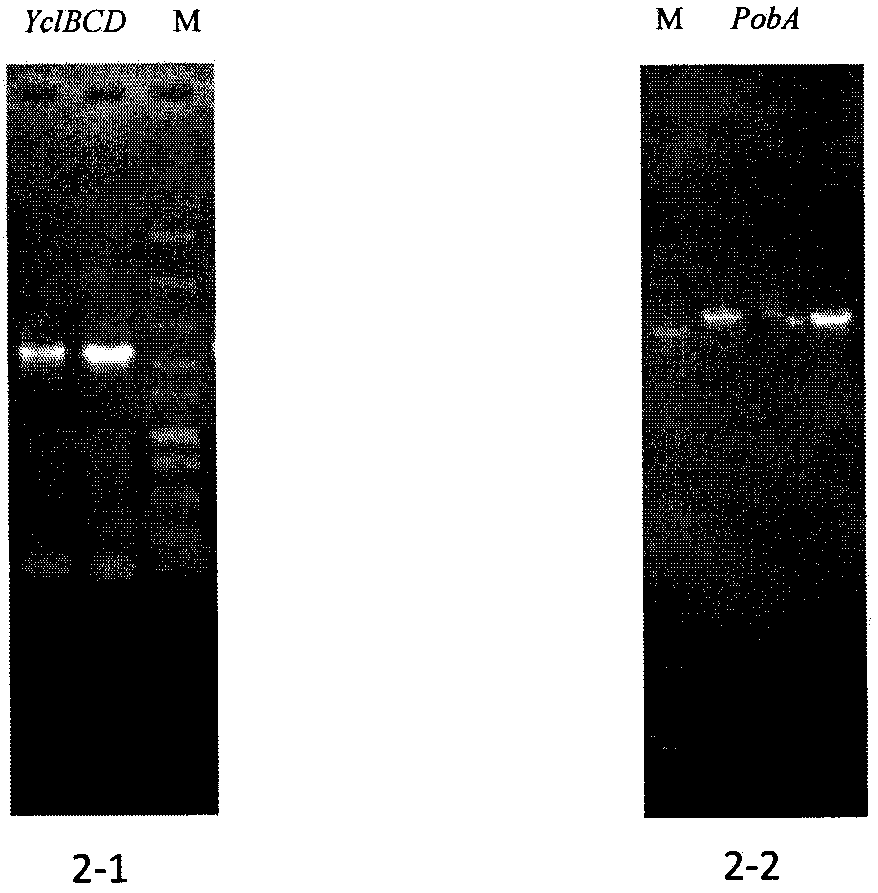

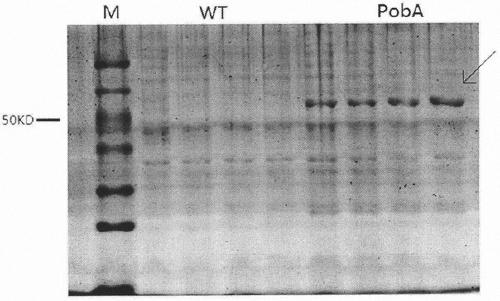

Gene engineer bacterium for producing protocatechuic acid (3, 4-dihydroxybenzoic acid) by using phenol and construction method thereof

The invention discloses a genetically engineered bacterium for producing protocatechuic acid (3, 4-dihydroxybenzoic acid) by using phenol as raw material and a construction method thereof. The engineering strain contains p-hydroxybenzoic acid decarboxylase gene yclBCD and hydroxylase gene pobA, phenol is used as raw material, phenol is carboxylated to obtain p-hydroxybenzoic acid by biological transformation, and then 3-hydroxybenzoic acid is oxidized to obtain protocatechuic acid (3, 4-dihydroxybenzoic acid). Compared with the traditional methods such as plant extraction and chemical synthesis, this method is convenient and quick, and will not pollute the environment, and can reasonably utilize phenol to save energy and protect the environment. It is of great significance to the production of protocatechuic acid.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wear-resistant plastic bag

The invention relates to a wear-resistant plastic bag. The wear-resistant plastic bag comprises, by weight, 30-40 parts of toluene diisocyanate, 20-30 parts of polypropylene resin, 20-30 parts of polyurethane resin, 10-15 parts of zinc-aluminum alloy powder, 5-10 parts of chitosan, 6-7 parts of polyimide glass fibers, 5-10 parts of silicon carbide, 6-8 parts of 3-hydroxybenzoic acid, 1-2 parts ofpolytetrafluoroethylene, 0.5-1 part of silica powder, 0.5-1 part of a toughening agent, 0.2-0.6 part of a curing agent, 0.2-0.5 part of a cosolvent and 0.5-1 part of a mildew inhibitor. The wear-resistant plastic bag of the invention has the advantages of high mechanical strength, high stability, strong corrosion resistance, good degradation effect, and no influences on the surrounding environment.

Owner:常州中源工程技术有限公司

Starch-polyamide fiber blended full-degradable zip lock bag and preparation method thereof

InactiveCN106279785ADoes not reduce bacteriostasisLong antibacterial timeEscherichia coliStaphylococcus aureus

The invention discloses a starch-polyamide fiber blended full-degradable zip lock bag and a preparation method thereof. The zip lock bag is prepared from, by weight, 50-60 parts of polyamide fibers, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titania, 10-20 parts of benzoin ethyl ether, 7-9 parts of nano-motmorillonite, tetrabutyl titanate, 12-14 parts of chitosan, 60-65 parts of corn starch, 2-3 part of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate and 4-6 parts of plant saponin. The materials of the starch-polyamide fiber blended full-degradable zip lock bag are used for making food packing bags and the like, the antibacterial property to escherichia coli and staphylococcus aureus reaches 95% or above, the antibacterial time is long, further treatment on the composite material cannot weaken the antibacterial property, the validity period of antibacterial property is long up to one year or above, waste products can be automatically decomposed under the action of oxygen enrichment and microorganisms and finally generate carbon dioxide and water, and the bag is ecological and environmentally friendly.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

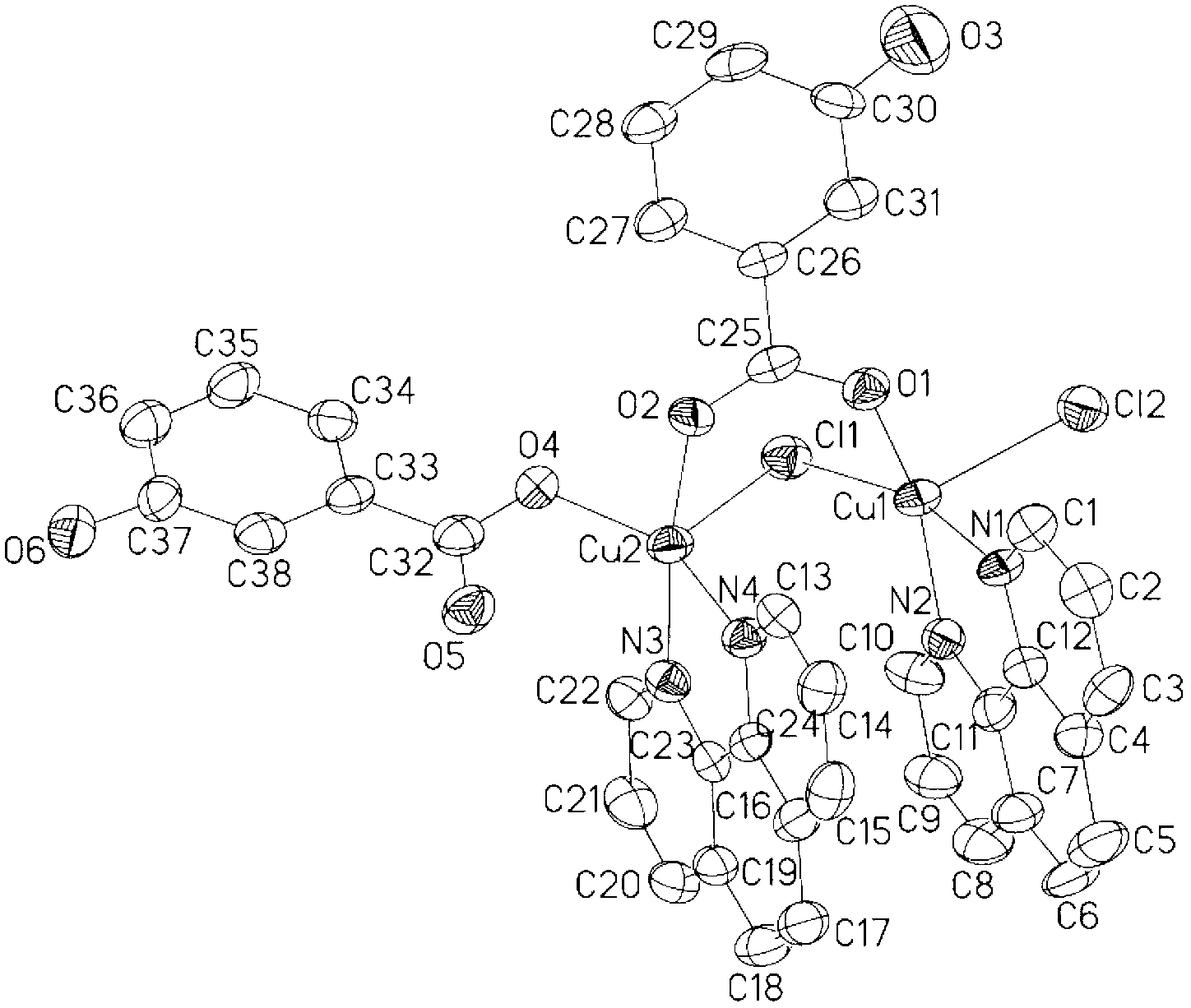

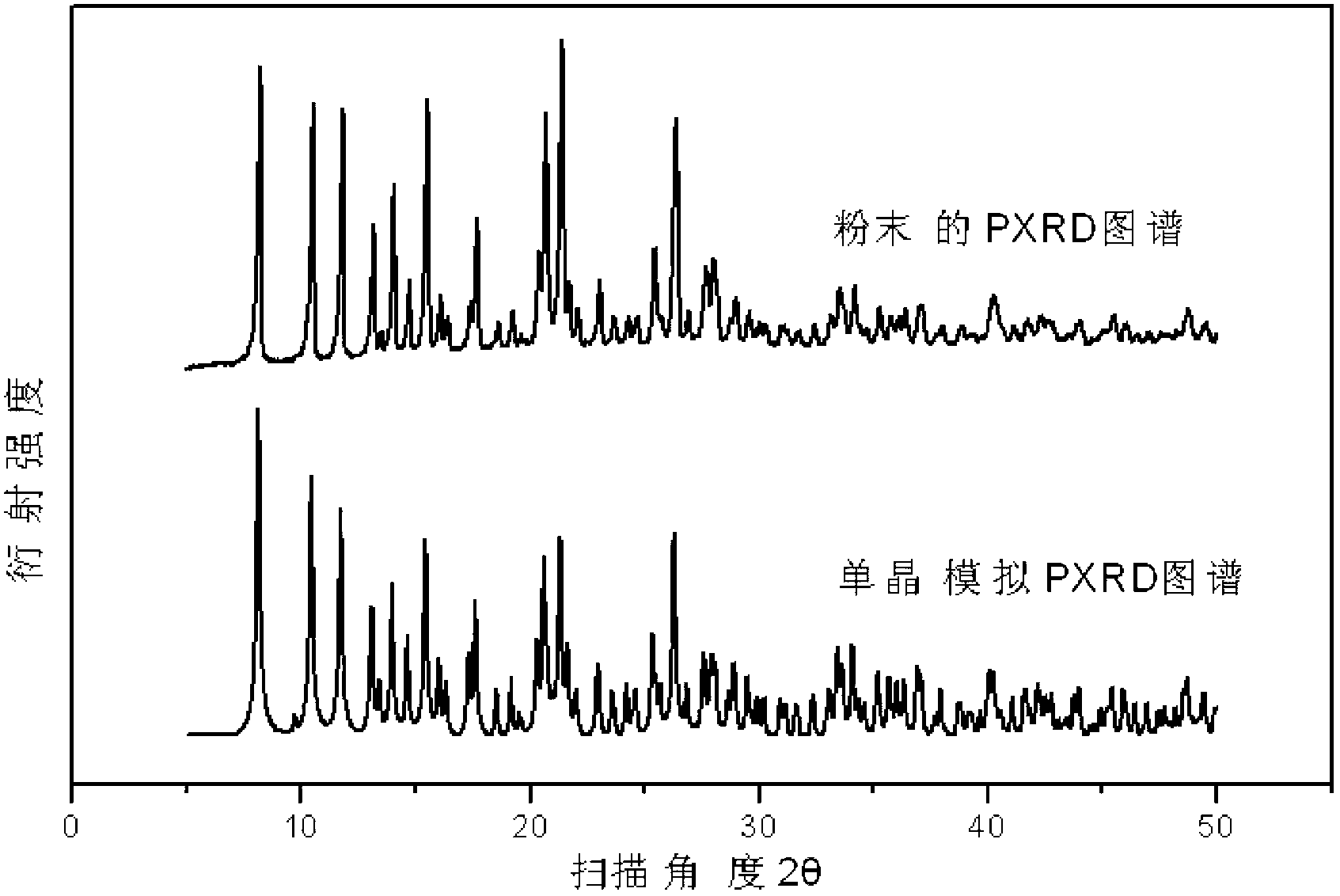

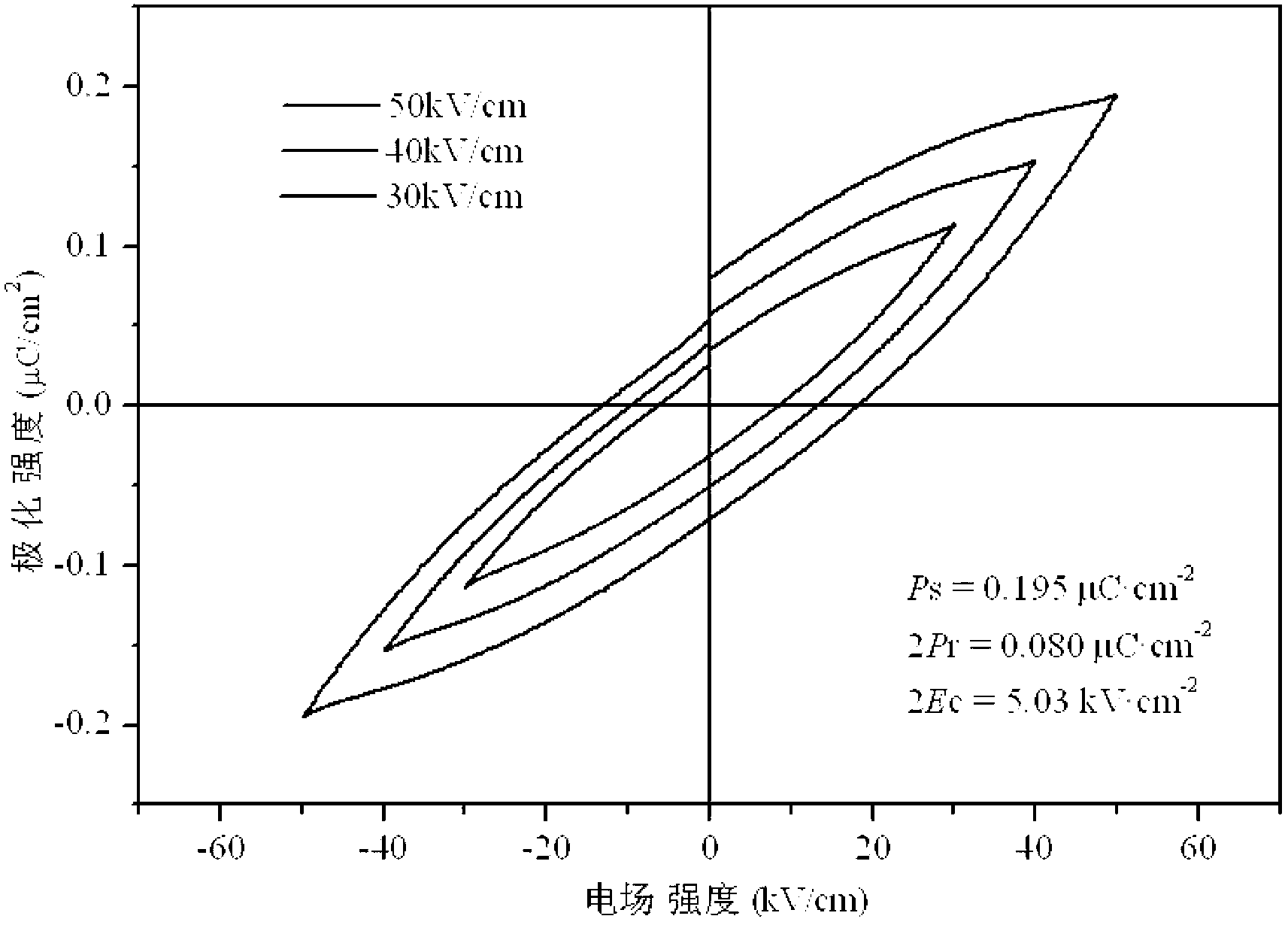

O-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material and preparation method thereof

InactiveCN103254218AGood ferroelectric propertiesAchieve nucleationCopper organic compoundsCopper chlorideNucleation

The invention discloses an o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material and a preparation method thereof. The molecular formula of the o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material is Cu2(C12H8N2)2Cl2(C7H5O3)2. The ferroelectric function material is dark blue powder with the purity being not less than 99% and has a C2v point group structure. The ferroelectric characteristic parameters are respectively as follows: the remanent polarization 2Pr equals to 0.08muC*cm<-2>, the coercive electric field 2Ec equals to 5.03kv*cm<-1>; and the saturated polarization Ps equals to 0.195muC*cm<-2>. The ferroelectric function material has good ferroelectric characteristics. According to the ferroelectric function material, m-hydroxybenzoic acid solution and copper chloride solution are stirred for reacting, and then o-phenanthroline solution is added to realize nucleation and growth of o-phenanthroline m-hydroxybenzoic acid copper. The o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material is simple and practicable in process, low in facility request, low in raw material cost, high in productivity, less in pollution and the like.

Owner:NINGBO UNIV

Toughening wood-plastic composite

The invention discloses a toughening wood-plastic composite. The toughening wood-plastic composite comprises the following components in parts by weight: 40-65 parts of high-density polyethylene (HDPE), 35-45 parts of straw, 5-8 parts of polyethene, 3.5-4.5 parts of polyphenylenoxide, 2-3 parts of benzoin, 4-6 parts of methylphenyl polyborosiloxane, 2.0-2.5 parts of tetra-n-propylzirconate, 5.5-7.5 parts of asbestos, 5-7 parts of walnut shell powder, 8-10 parts of camphorwood powder, 6-8 parts of ginkgo leaves, 6-8 parts of aralia echinocaulis powder, 0.1-0.2 part of agalloch powder, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of lauryl sulfate, 4-6 parts of a toughening additive, 0.1-0.2 part of terpineol and 1-3 parts of white glue. The wood-plastic composite provided by the invention can continuously give out delicate fragrance. Boards have good intensity, and particularly have the characteristics of being flame-resistant, anticorrosive and moldproof, can be used indoors and outdoors, can resist ageing, are free from cracking or deforming, and have high tenacity.

Owner:安徽浩峯塑业有限公司

Starch-polyethylene resin blended fully-degradable garbage bag and production method thereof

InactiveCN106243451AHigh strengthFacilitate the realization of large-scale industrial productionMagnesium stearateOxygen

The invention discloses a starch-polyethylene resin blended fully-degradable garbage bag and a production method thereof. The garbage bag comprises, by weight, 50-60 parts of polyethylene resin, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titanium dioxide, 10-20 parts of benzoin ethyl ether, 7-9 parts of nanometer montmorillonite, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie bones, 60-65 parts of corn starch, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of lauryl sulfate and 4-6 parts of plant saponin. The garbage bag is produced according to a safe formula, can be used for manufacturing food packaging bags, and has the advantages of realization of large strength, good water resistance, good oil resistance and good durability in use, facilitation of realization of large-scale industrial production, easiness in knowing, and convenience in promotion; and the garbage bag automatically decomposes under the action of rich oxygen and microbes after being wasted in order to finally generate carbon dioxide and water, so the garbage bag is ecologic and environmentally-friendly.

Owner:ANHUI MEIXIANG PLASTIC

Wall protective board material

The invention discloses a wall protective board material, which includes, by weight, 40-65 parts of cement, 35-45 parts of calcium silicate, 5-8 parts of polyethylene, 3.5-4.5 parts of titanium dioxide, 2-3 parts of benzoin, 4-6 parts of mica powder, 2.0-2.5 parts of zinc borate, 5.5-7.5 parts of gypsum, 5-7 parts of fly ash, 8-10 parts of barium carbonate, 6-8 parts of vermicular graphite carbon, 6-8 parts of expanded perlite, 0.1-0.2 parts of wintergreen oil, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of lauryl sulfate, 4-6 parts of plant saponin, 0.1-0.2 parts of terpilenol, and 1-3 parts of white latex. The material has temperature maintenance and heat insulation effects and has good fireproof performance.

Owner:安徽钰锦生态木材料有限公司

Industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride

ActiveCN103450013BAvoid pollutionSimple and fast operationOrganic compound preparationCarboxylic compound preparationN dimethylformamidePhthalate

Owner:YUEYANG YETOP FINE CHEM

Silk and glass fiber blended antifungal aviation food bag and preparation method thereof

InactiveCN106189269AHigh strengthFacilitate the realization of large-scale industrial productionAntifungalAviation

The invention discloses a silk and glass fiber blended antifungal aviation food bag and a preparation method thereof. The aviation food bag is prepared from, by weight, 50-60 parts of glass fiber, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titania, 10-20 parts of benzoin ethyl ether, 7-9 parts of nano-montmorillonite, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 60-65 parts of silk, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate and 4-6 parts of plant saponins. The product is produced according to a safe formula and can be used for preparing the aviation food package bag and the like, the product is high in strength, resistant to water and oil and durable in use in the use process, large-scale industrial production is easy, grasping is easy, popularization is convenient, the abandoned product can automatically decompose into carbon dioxide and water under the effect of rich oxygen and microorganisms, and the food bag is ecological and environmentally friendly.

Owner:ANHUI MEIXIANG PLASTIC

Medical high-temperature water-soluble plastic film and preparation method thereof

The invention discloses a medical high-temperature water-soluble plastic film and a preparation method thereof. The medical high-temperature water-soluble plastic film is prepared from the following components in parts by weight: 50-60 parts of polyvinyl alcohol, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titania, 1-2 parts of nanometer antimony trioxide, 7-9 parts of sodium alkyl benzene sulfonate, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of xylitol, 60-65 parts of phosphate starch, 2-3 parts of urea, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of citric acid, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of polyvinyl pyrrolidone and 4-6 parts of water-soluble wax sheets. The plastic film disclosed by the invention has the effects of resisting bacteria and removing odor, is slowly dissolved in water when the temperature exceeds 90 DEG C, has high water solubility, is simple in preparation process, uniform in film-forming thickness and high in flatness and is widely applied to medical washing bags.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

Silk-novolac-epoxy-mixed full-degradation food bag and preparing method thereof

InactiveCN106280498AHigh strengthFacilitate the realization of large-scale industrial productionEpoxyPlant saponin

The invention discloses a silk-novolac-epoxy-mixed full-degradation food bag and a preparing method thereof. The silk-novolac-epoxy-mixed full-degradation food bag is prepared from, by weight, 50-60 parts of phenolic resin, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titanium dioxide, 10-20 parts of benzoin ethyl ether, 7-9 parts of nanometer montmorillonite, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie bones, 60-65 parts of silk, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl citric acid three butyl ester, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of lauryl sulfate and 4-6 parts of plant saponin. The product is produced with a safe formula, and can be used for making a food packaging bag and the like, and the product is large in strength, resistant to water and oil and durable; meanwhile, large-scale industrial production can be achieved, and the food bag and the preparing method are easy to grasp and convenient to popularize; a wasted product can be automatically decomposed under the effects of oxygen enrichment and microorganisms, carbon dioxide and water are automatically generated, and ecological environmental protection is achieved.

Owner:安徽浩峯塑业有限公司

Plant fiber-reinforced composite plastic

The invention discloses a plant fiber-reinforced composite plastic. The plant fiber-reinforced composite plastic is prepared from, by weight, 50-60 parts of polyvinylchlorid, 40-65 parts of pineapple leaf fiber base, 8-15 parts of calcium carbonate, 10-20 parts of carboxyethyl cellulose, 7-9 parts of nanometre montmorillonite, 35-45 parts of basalt fiber, 60-65 parts of wood fiber, 3.5-4.5 parts of methylisothiazolinone, 2-4 parts of camphorwood powder, 2-4 parts of aralia echinocaulis hand.-mazz. powder, 0.1-0.2 part of thymelaeaceae powder, 9-13 parts of melamine cyanurate, 8-10 parts of carborundum powder, 14-20 parts of sodium carboxymethylcellulose, 3-7 parts of sepiolite, 10-20 parts of asbestos powder, 13-15 parts of acetyl tributyl citrate, 2-3 parts of 2-(2-ethoxyethoxy)ethyl acetate, 1-2 parts of magnesium stearate, 4-6 parts of 3-hydroxybenzoic acid, 4-6 parts of diethylenetriamine, 0.2-0.4 part of palladium nitrate, 0.2-0.4 part of yttrium(III)-oxide and 2-3 parts of gelatin. The plant fiber-reinforced composite plastic has the advantages of being environmentally friendly, stable in size, high in tensile strength and impact strength, and low in cost.

Owner:桐城市弘业塑胶有限公司

Starch-polyamide anti-aging and anti-fogging greenhouse film and preparation method thereof

InactiveCN106279786ALong anti-aging timeHigh anti-fog effective timeClimate change adaptationGreenhouse cultivationPolyamidePlant saponin

The invention discloses starch-polyamide anti-aging and anti-fogging greenhouse film and a preparation method thereof. The starch-polyamide anti-aging and anti-fogging greenhouse film is prepared from, by weight, 50-60 parts of polyamide, 8-15 parts of calcium carbonate, 1-4 parts of nano-titanium dioxide, 10-20 parts of triphenyl phosphate, 7-9 parts of sodium alkyl benzene sulfonate, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of chitosan, 60-65 parts of corn starch, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-di-tert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of polyvinyl pyrrolidone and 4-6 parts of plant saponin. According to the greenhouse film prepared from the materials, the anti-aging time is long, the film does not need to be replaced in three years after being arranged on a greenhouse in a covering mode, the effective anti-fogging time of the greenhouse film reaches up to 900 h, and a wide application prospect is achieved.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

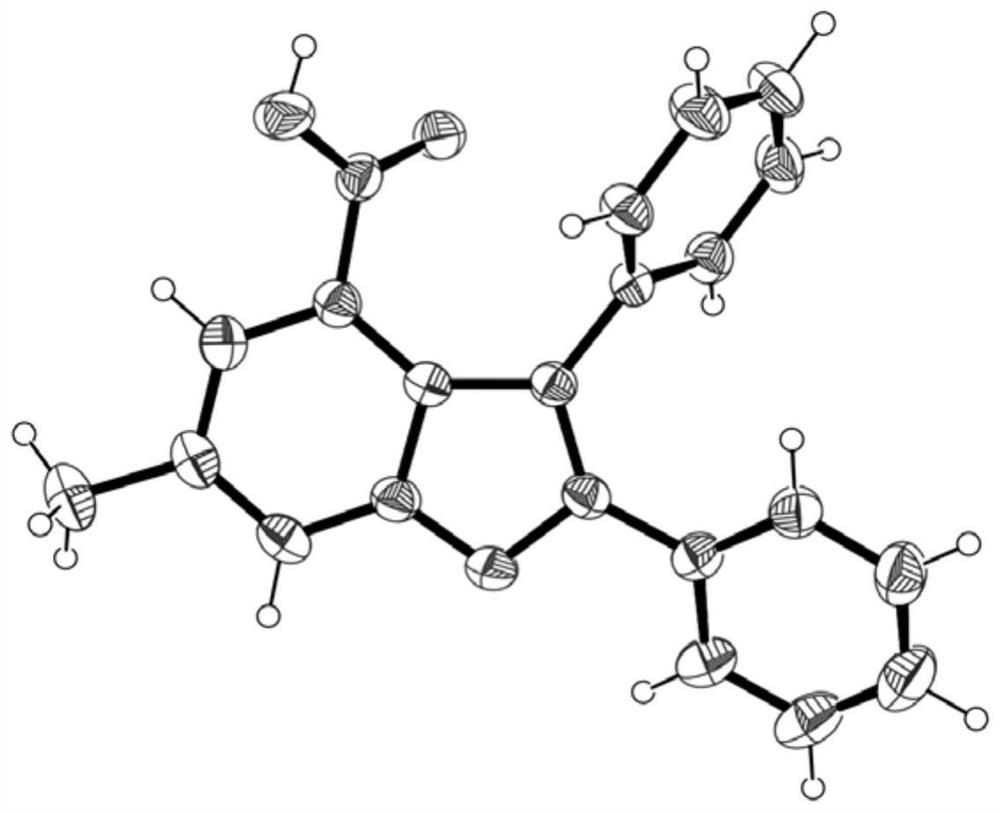

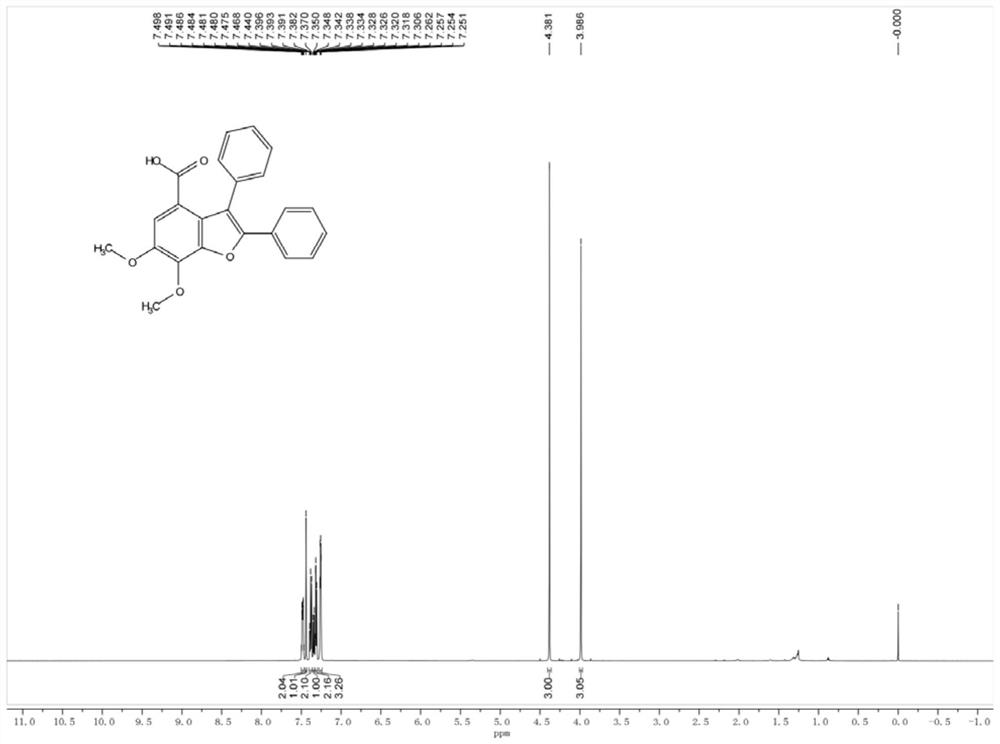

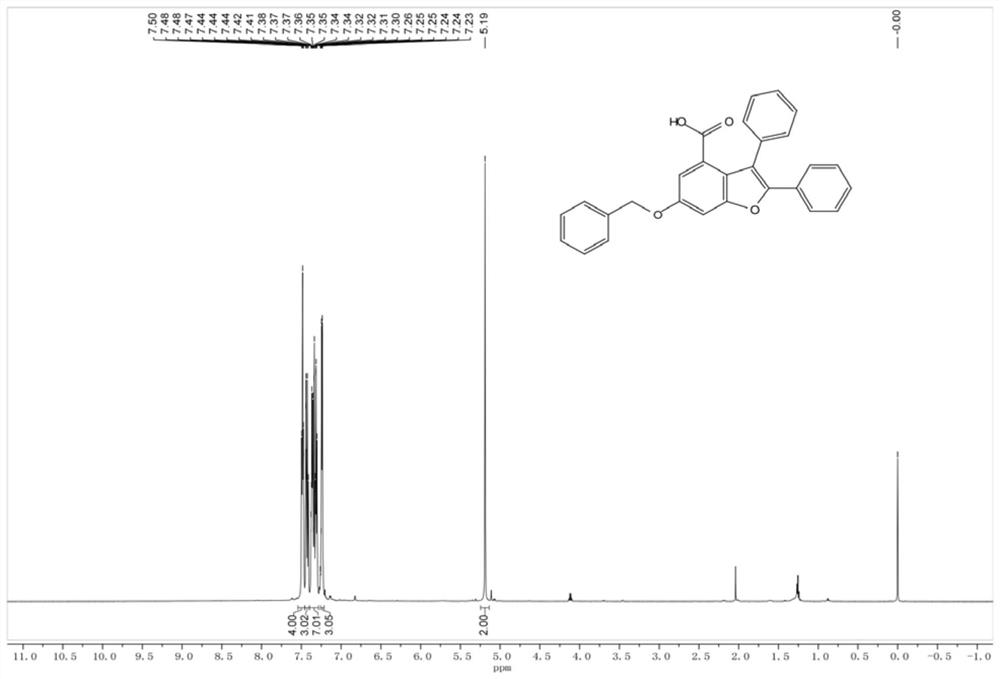

Method for preparing polysubstituted benzofuran-4-formic acid compound through ruthenium catalysis

The invention belongs to the technical field of organic synthesis, and discloses a method for preparing a polysubstituted benzofuran-4-formic acid compound through ruthenium catalysis. An m-hydroxybenzoic acid compound, a diaryl alkyne compound, a ruthenium catalyst, an additive and a solvent are subjected to a heating reaction in an air or oxygen environment, and a reaction product is separated and purified, so that the polysubstituted benzofuran-4-formic acid compound is obtained. The ruthenium catalytic system used in the method has high catalytic activity, so that air or oxygen can be used as a green oxidant in the reaction, and toxic, dangerous or expensive oxidants are prevented from being used. The reaction raw materials are easy to obtain, the solvent amount is small, the solvent is insensitive to water, operation is easy, convenient and safe, the method can be well amplified to the gram-level scale, and industrialization is convenient to achieve. The reaction is taken as a key step, the natural product diptoindonesin G with biological activity can be conveniently synthesized, and the diptoindonesinG has a good application prospect.

Owner:GUANGZHOU UNIVERSITY

Fiber-base wood-plastic composite material

The invention discloses a fiber-base wood-plastic composite material which comprises the following components in parts by weight: 40-65 parts of pineapple leaf fiber base, 35-45 parts of basalt fiber, 5-8 parts of polyethylene, 3.5-4.5 parts of methyl isothiazolinone, 2-3 parts of benzoin, 4-6 parts of methylphenyl polyborosiloxane, 2.0-2.5 parts of polysebacic anhydride, 5.5-7.5 parts of asbestos, 5-7 parts of hexamethoxymethyl melamine resin, 8-10 parts of camphor powder, 6-8 parts of ginkgo leaf, 6-8 parts of Aralia echinocaulis powder, 0.1-0.2 part of agalloch powder, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate, 4-6 parts of plant saponin, 0.1-0.2 part of polyamide wax micropowder and 1-3 parts of white latex. The wood-plastic composite material disclosed by the invention continuously emits a faint fragrance; the board has the characteristics of antimicrobial property, corrosion resistance and mildew resistance, can be used indoors and outdoors, can resist aging, and can not generate cracking or deformation.

Owner:安徽浩峯塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com