Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102 results about "N-phenylmaleimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-PHENYLMALEIMIDE is an imide. Amides/imides react with azo and diazo compounds to generate toxic gases. Flammable gases are formed by the reaction of organic amides/imides with strong reducing agents.

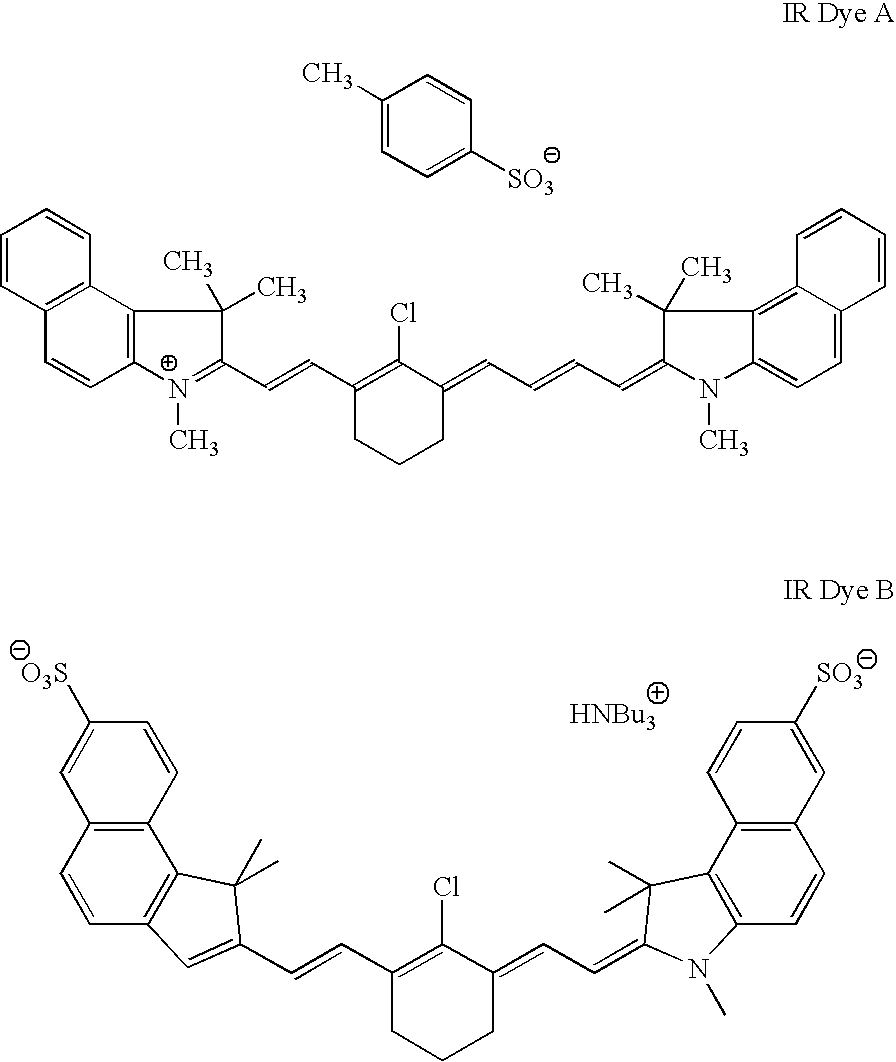

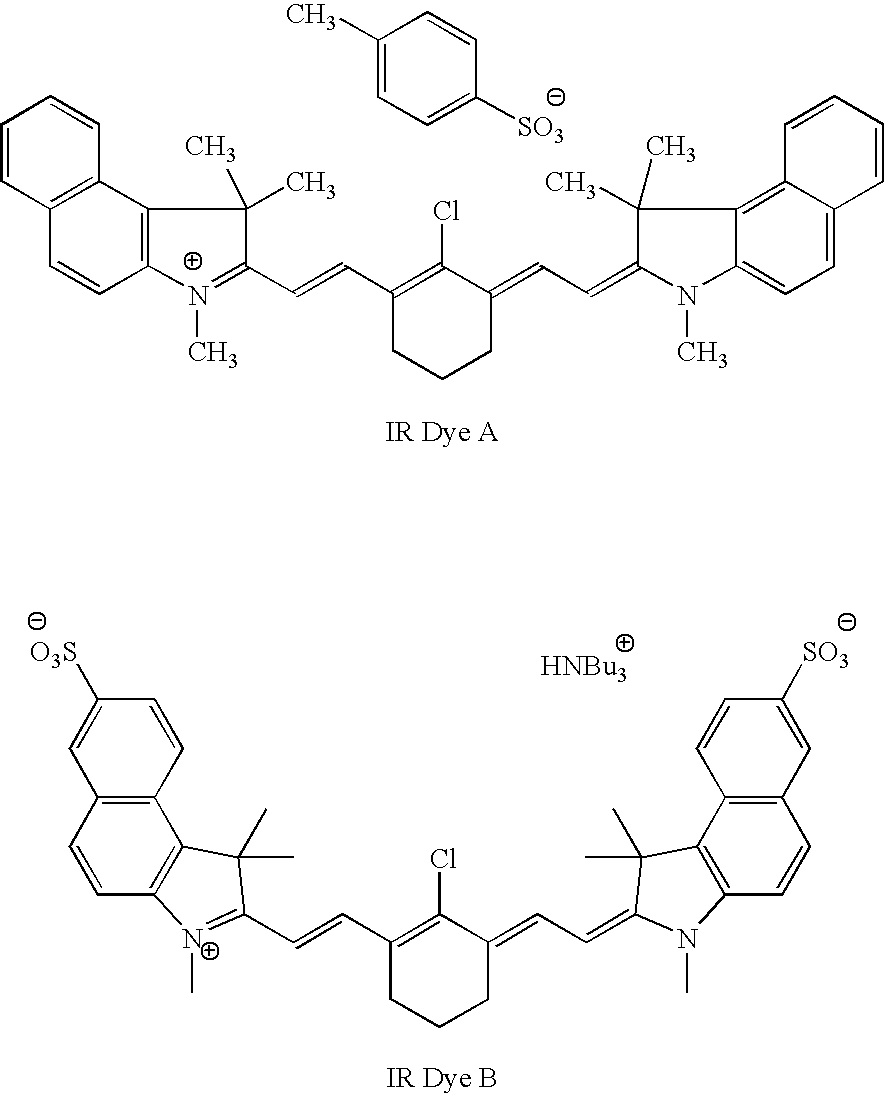

Multilayer imageable elements

InactiveUS6893783B2Increase the lengthPhotosensitive materialsRadiation applicationsN-phenylmaleimidePolymer science

Multilayer, positive working, thermally imageable elements are disclosed. The elements produce bakeable lithographic printing plates that are resistant to press chemistries. The elements have a substrate, an underlayer, and a top layer. The underlayer comprises a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, and a polymeric material that comprises, in polymerized form, (a) methacrylic acid; (b) N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; and (c) one or more monomers of the structure: [0001]in which:[0002]R1 is H or methyl; X is —(CH2)n—, where n is an integer from 2 to 12; —(CH2—CH2—O)p—CH2—CH2—, where p is an integer from 1 to 3; or —Si(R′)(R″)— where R′ and R″ are each independently methyl or ethyl; and m is 1, 2, or 3.

Owner:KODAK POLYCHROME GRAPHICS

Multilayer imageable elements

InactiveUS7186482B2Increase press run lengthIncrease the lengthPhotosensitive materialsRadiation applicationsN-phenylmaleimideHydrogen

Multilayer, positive working, thermally imageable, bakeable imageable elements have a substrate, an underlayer, and a top layer. The underlayer comprises a polymeric material that comprises, in polymerized form from about 5 mol % to about 30 mol % of recurring units derived from an ethylenically unsaturated polymerizable monomer having a carboxy group; from about 20 mol % to about 75 mol % of recurring units derived from N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; and from about 3 mol % to about 50 mol % of recurring units derived from a compound represented by the formula:CH2═C(R2)—C(O)—NH—CH2—OR1,in which R1 is C1 to C12 alkyl, phenyl, C1 to C12 substituted phenyl, C1 to C12 aralkyl, or Si(CH3)3; and R2 is hydrogen or methyl. Other materials, such as a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, may be present in the underlayer. The elements can be used to produce bakeable lithographic printing plates that are resistant to press chemistries.

Owner:EASTMAN KODAK CO

Multilayer imageable elements

InactiveUS7049045B2Increase the lengthPhotosensitive materialsRadiation applicationsN-phenylmaleimideN-benzylmaleimide

Multilayer, positive working, thermally imageable, bakeable imageable elements are disclosed. The elements have a substrate, an underlayer, and a top layer. The underlayer comprises a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, and a polymeric material that comprises, in polymerized form about 5 mol % to about 30 mol % of methacrylic acid; about 20 mol % to about 75 mol % of N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; optionally, about 5 mol % to about 50 mol % of methacrylamide; and about 3 mol % to about 50 mol % of a compound represented by the formula:CH2C(R2)C(O)NHCH2OR1, in which R1 is C1 to C12 alkyl, phenyl, C1 to C12 substituted phenyl, C1 to C12 aralkyl, or Si(CH3)3; and R2 is H or methyl. The elements produce bakeable lithographic printing plates that are resistant to press chemistries.

Owner:KODAK POLYCHROME GRPHICS

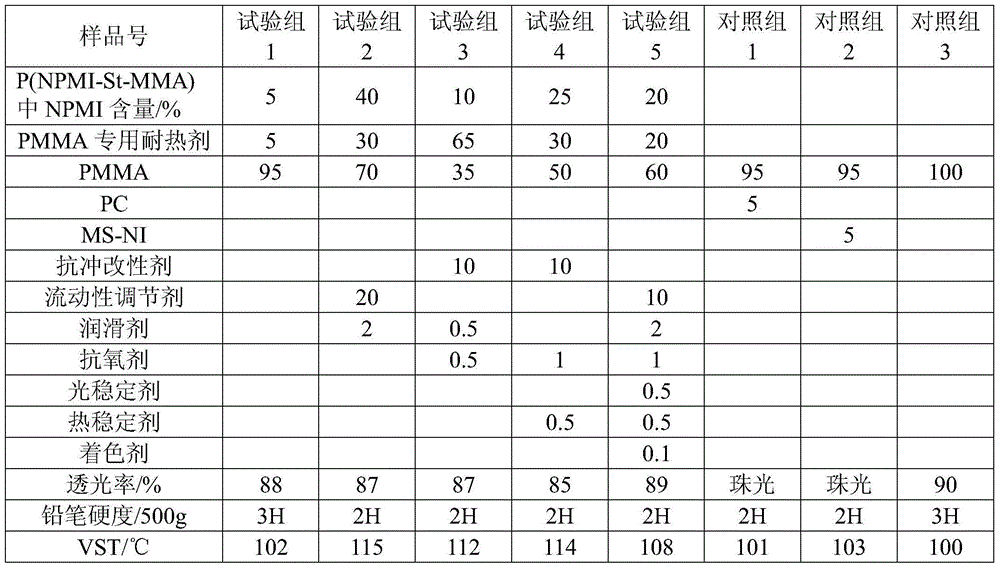

Heat-resisting, scraping-resisting and high-transmittance PMMA alloy resin and preparation method thereof

The invention relates to a heat-resisting, scraping-resisting and high-transmittance PMMA alloy resin composition. The PMMA alloy resin composition is prepared from the following raw materials in parts by weight: 10-95 parts of polymethyl methacrylate and 5-90 parts of a PMMA special heat-resisting agent, wherein the PMMA special heat-resisting agent is N-phenylmaleimide-styrene-methyl methacrylate terpolymer P (NPMI-St-MMA). The invention further provides a preparation method of the PMMA alloy resin composition. The preparation method has the advantages that the utilized N-phenylmaleimide-styrene-methyl methacrylate terpolymer has good compatibility with polymethyl methacrylate and is high in transparency after being blended, and the prepared alloy resin has the advantages of high transmittance, scraping resistance and heat resistance; the PMMA alloy resin composition can further contain processing aids including an impact modifier, a liquidity regulator, a lubricant and a demolding agent, and can be used for preparing PMMA alloy resin compositions for various purposes; the preparation process of the PMMA alloy resin is relatively simple and is beneficial to mass production.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Multilayer imageable elements

InactiveUS20050037292A1Increase press run lengthIncrease the lengthX-ray/infra-red processesPhoto-taking processesN-phenylmaleimideN-benzylmaleimide

Multilayer, positive working, thermally imageable, bakeable imageable elements are disclosed. The elements have a substrate, an underlayer, and a top layer. The underlayer comprises a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, and a polymeric material that comprises, in polymerized form about 5 mol % to about 30 mol % of methacrylic acid; about 20 mol % to about 75 mol % of N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; optionally, about 5 mol % to about 50 mol % of methacrylamide; and about 3 mol % to about 50 mol % of a compound represented by the formula: CH2C(R2)C(O)NHCH2OR1, in which R1 is C1 to C12 alkyl, phenyl, C1 to C12 substituted phenyl, C1 to C12 aralkyl, or Si(CH3)3; and R2 is H or methyl. The elements produce bakeable lithographic printing plates that are resistant to press chemistries.

Owner:KODAK POLYCHROME GRPHICS

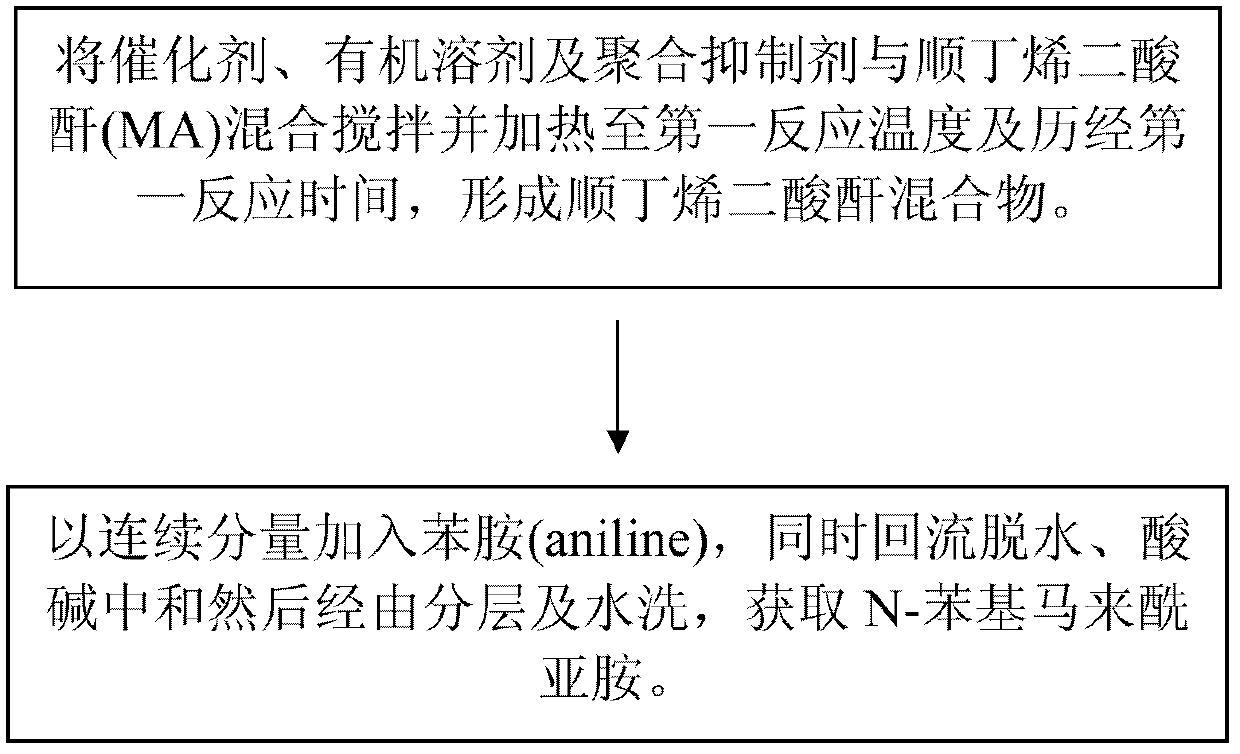

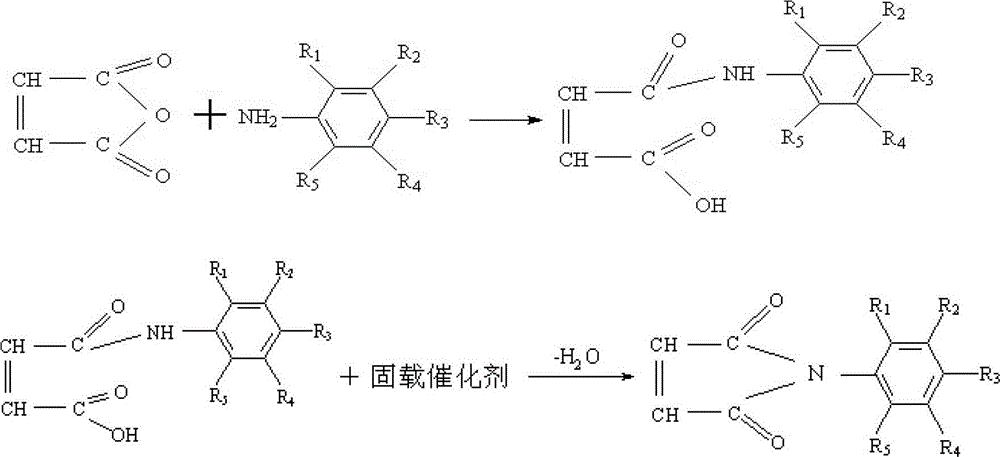

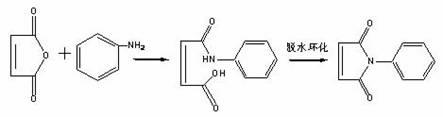

Preparation method of N-phenylmaleimide (PMI)

The invention provides a preparation method of N-phenylmaleimide (PMI). The preparation method comprises the following steps of: mixing and stirring a catalyst, an organic solvent, a polymerization inhibitor and maleic anhydride (MA) into a reaction kettle, and carrying out heat treatment on the mixture at the first reaction temperature for a first reaction time to form an MA mixture; then, continuously adding aniline into the heat-treated MA mixture in quantity, meanwhile, reflowing and dehydrating, and carrying out acid base neutralization; and layering, washing, cooling and crystallizing to obtain the N-PMI with high yield and purity.

Owner:JIH NONG SCI

Low-gloss and scratch-resistant nylon/acrylonitrile-butadiene-styrene resin blending material

ActiveCN102051042AGood scratch resistanceGood chemical resistanceN-phenylmaleimideBulk polymerization

The invention discloses a blending material, in particular to a low-gloss and scratch-resistant nylon / acrylonitrile-butadiene-styrene resin blending material. The blending material consists of the following components in part by weight: 35 to 75 parts of nylon, 0 to 35 parts of bulk polymerization acrylonitrile-butadiene-styrene (ABS) graft copolymer, 15 to 30 parts of ABS high glue powder, 3 to 10 parts of styrene-N-phenylmaleimide-maleic anhydride copolymer serving as compatibilizer, 2 to 10 parts of inorganic filler and the balance of antioxidant. The nylon / acrylonitrile-butadiene-styrene resin blending material prepared by the technical scheme has the characteristics of excellent scratch resistance, chemical resistance and mechanical property, low gloss, high liquidity and the like, and is very suitable for manufacturing automobile interior decorative materials of instrument boards, door sheets and the like.

Owner:SHANGHAI PRET COMPOSITES

Method for refining and molding N-phenylmaleimide

The invention discloses a method for refining and molding N-phenylmaleimide. The method comprises that an N-phenylmaleimide material liquid needing refining is added with a stabilizer; the mixture is refined by a rectification technology; and a rectification fraction is processed into sheets or particles so that molding of N-phenylmaleimide is realized. The method has a product yield of 95.2% and realizes content of 99.8wt% determined by a high performance liquid chromatography (HPLC). A molded product obtained by the method is convenient for packaging and storage. The method for production of N-phenylmaleimide is environmentally friendly, has simple processes and a low cost and is convenient for large-scale industrial production.

Owner:HAISO TECH

Immobilized type non-toxic catalyst and method for synthesizing N-phenylmaleimide and N-substitutional phenylmaleimide

InactiveCN102909074AImprove the level of catalytic activityHigh catalytic activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsN-phenylmaleimideHafnium

The invention provides an immobilized type non-toxic catalyst and a method for synthesizing N-phenylmaleimide and N-substitutional phenylmaleimide. The immobilized type non-toxic catalyst is formed by utilizing a porous zeolite molecular sieve as a carrier, impregnating the porous zeolite molecular sieve into water solution of titanium organic phosphonic chelate or zirconium organic phosphonic chelate or hafnium organic phosphonic chelate for 6-10 hours, reacting and bonding, drying and roasting. Pure products of the N-phenylmaleimide and N-substitutional phenylmaleimide are obtained by adding maleic anhydride and aniline or maleic anhydride and aniline derivatives into the immobilized type non-toxic catalyst as raw materials, sequentially acylating, dehydrating and cyclizing and recrystallizing. The immobilized type non-toxic catalyst is non-toxic and environment-friendly, the method of synthesizing the N-phenylmaleimide and N-substitutional phenylmaleimide is environment-friendly, convenient in operation procss and high in product purity and yield, and solvent used is non-toxic, convenient to recover and reusable.

Owner:WUHAN NEW CONCEPT CHEM

Heat-resistant high-flame-retardancy polypropylene composite material

The invention discloses a heat-resistant high-flame-retardancy polypropylene composite material which is prepared from graphene oxide modified polypropylene, an N-phenylmaleimide-styrene-acrylonitrile terpolymer, polyethylene, a silane coupling agent, a flame retardant, nano diatomite, nano zinc oxide, dibenzylidene sorbitol, p-chlorodibenzylidene sorbitol, sodium 2,2'-methylene-bis(4,6-di-tert-butylphenyl)phosphate, brucite powder, talcum powder, silicon micropowder, poly-4-methyl-1-amylene, epoxy soybean oil, an ethylene-octylene copolymer, lanthanum stearate, stearic acid, polytetrafluoroethylene and hexamethyl phosphoric triamide. The heat-resistant high-flame-retardancy polypropylene composite material disclosed by the invention has the advantages of favorable heat resistance, excellent flame retardancy and high strength, and has certain antistatic property.

Owner:ANHUI LANTONG TECH CO LTD

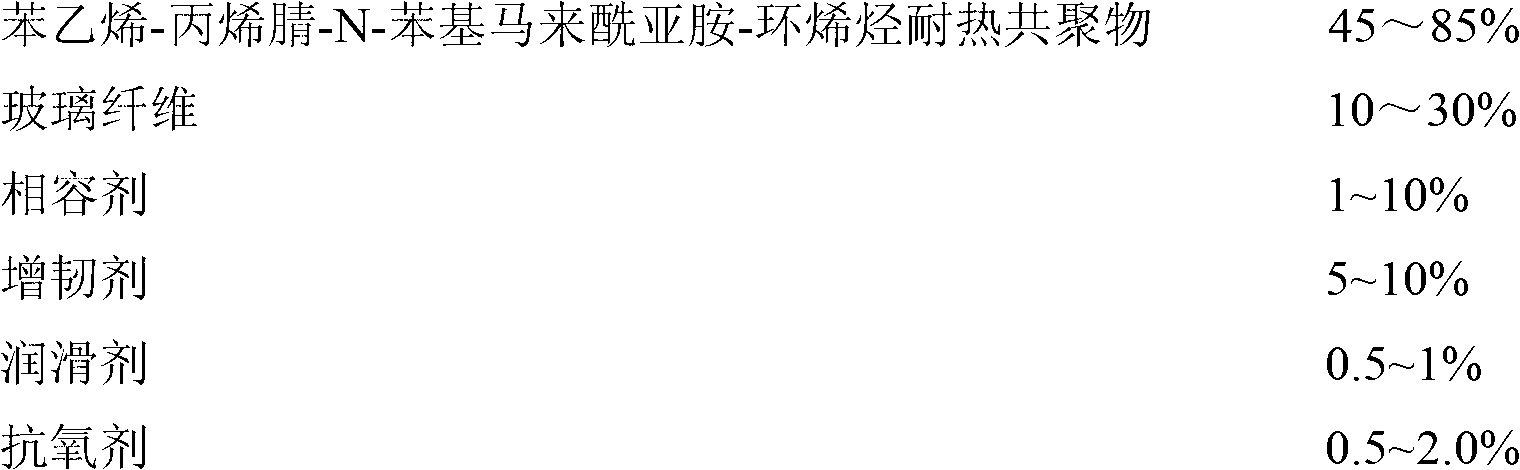

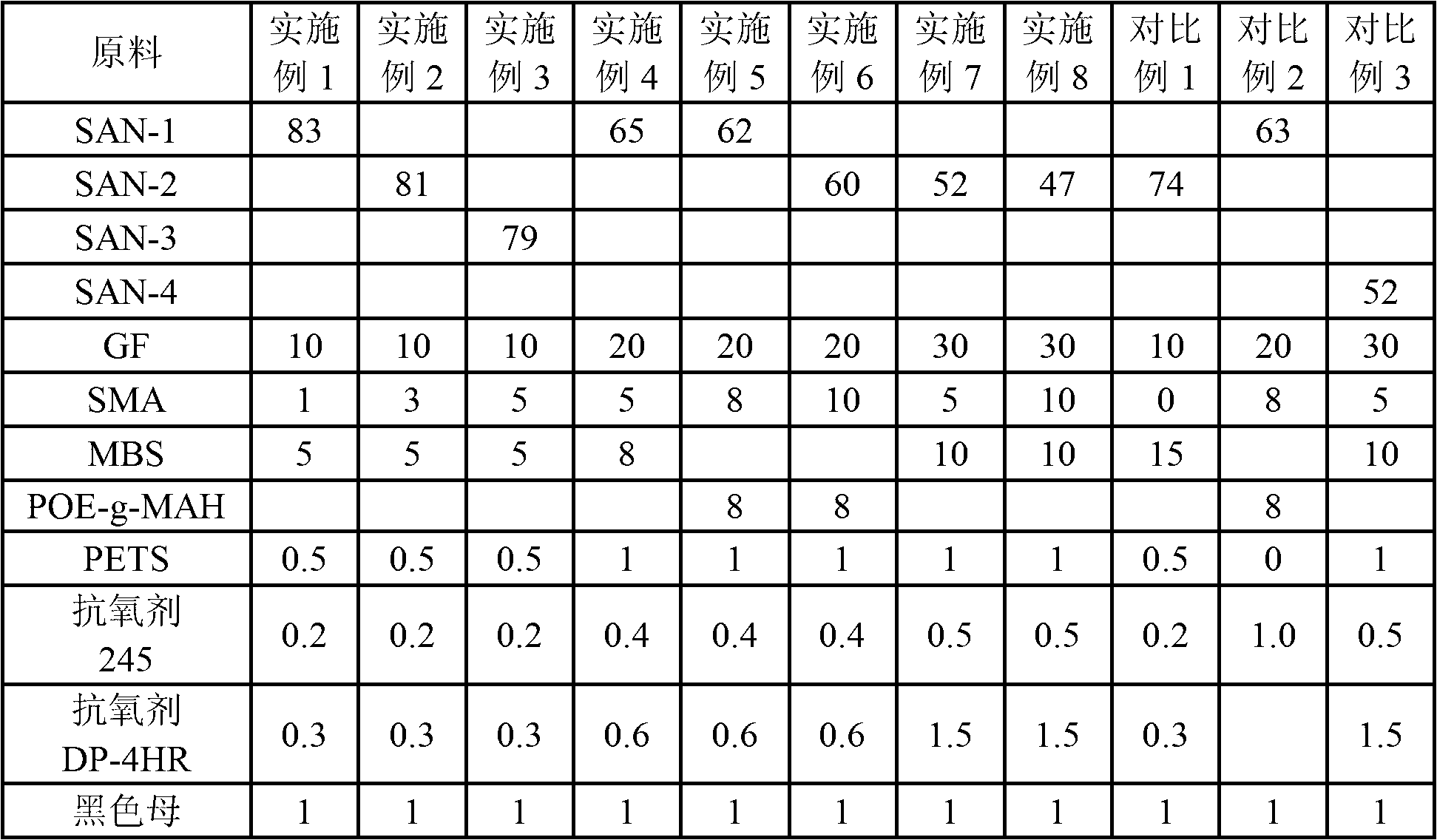

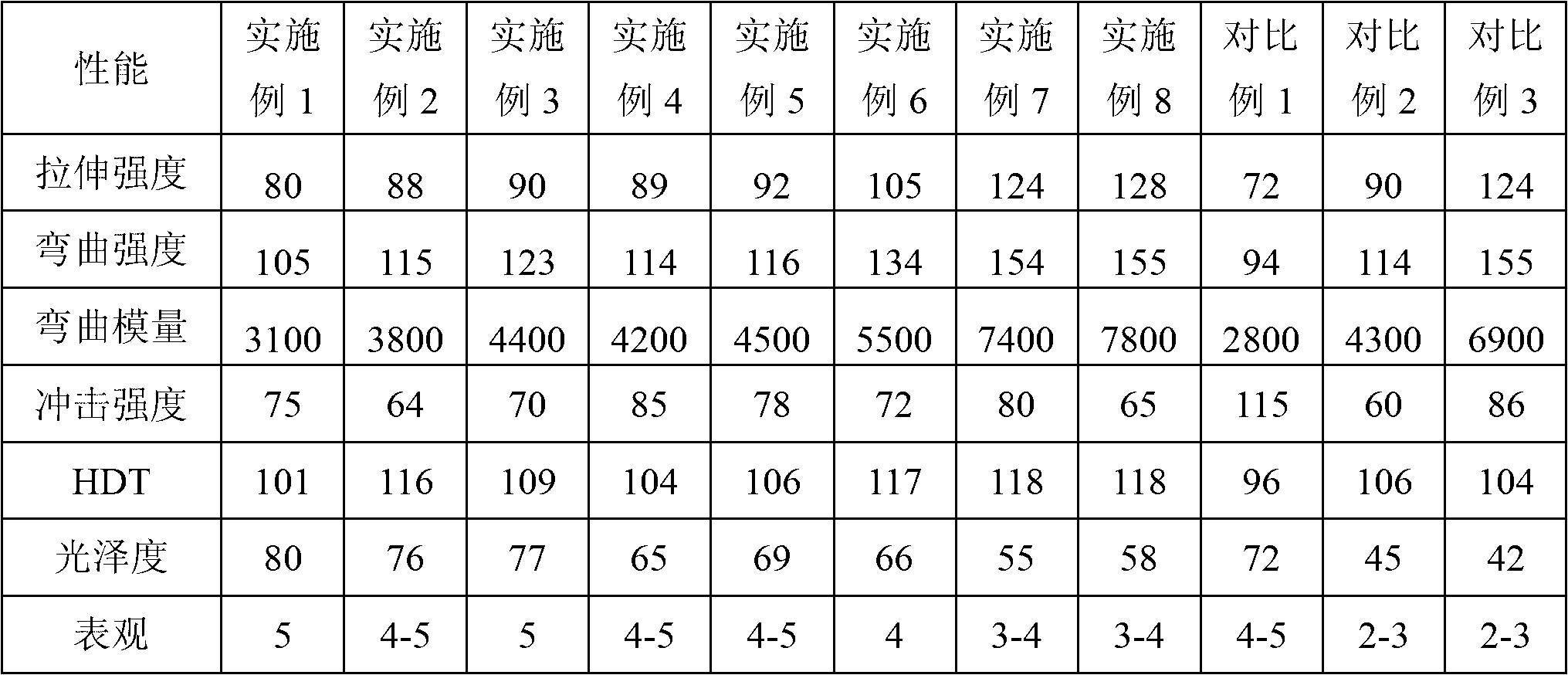

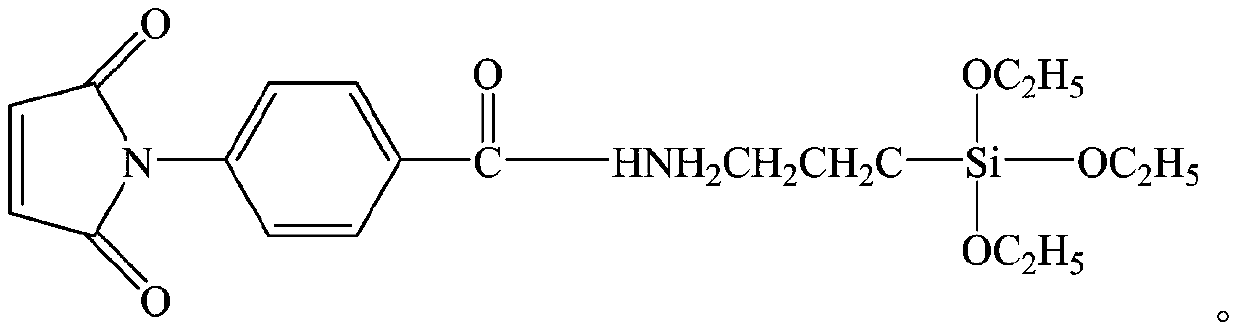

Glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin copolymer compound

ActiveCN102702639ASolve the problem of floating fibers on the surface of reinforced SAN resin with high glass fiber contentHigh heat distortion temperatureN-phenylmaleimideFiber

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

Preparation of special flame-proof heat-resistant material for ABS

The invention relates to a preparation method of the special material of flame retarding heat-proof ABS resin. The weight portions of all components of the special material contain are: 25 to 40 portions of styrene-acrylonitrile copolymeric resin, 5 to 20 portions of styrene-N-phenylmaleimide-acrylonitrile copolymer, 22 to 32.5 portions of ABS graft gelatine powder, 15 to 20 portions of brominated epoxy, 6 to 8 portions of antimony trioxide, 0.1 to 0.2 portion of di-stearyl pentaerythitoldiphosphite, 1.0 to 3.0 portions of N, N-Ethylene Bis-Stearamide, 0.1 to 0.3 portions of magnesium stearate, and 0.3 to 1.5 portions of polytetrafluoroethylene; the above components are added into a high speed mixer for high-speed mixing at room temperature, added into a concurrent double screw extruder for extrusion, and extruded and pelletized under the temperature between 190 to 230 DEG C, and cooled, finally the special material of flame retarding heat-proof ABS resin is prepared.

Owner:PETROCHINA CO LTD

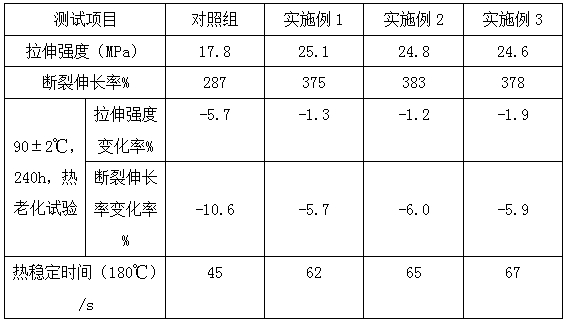

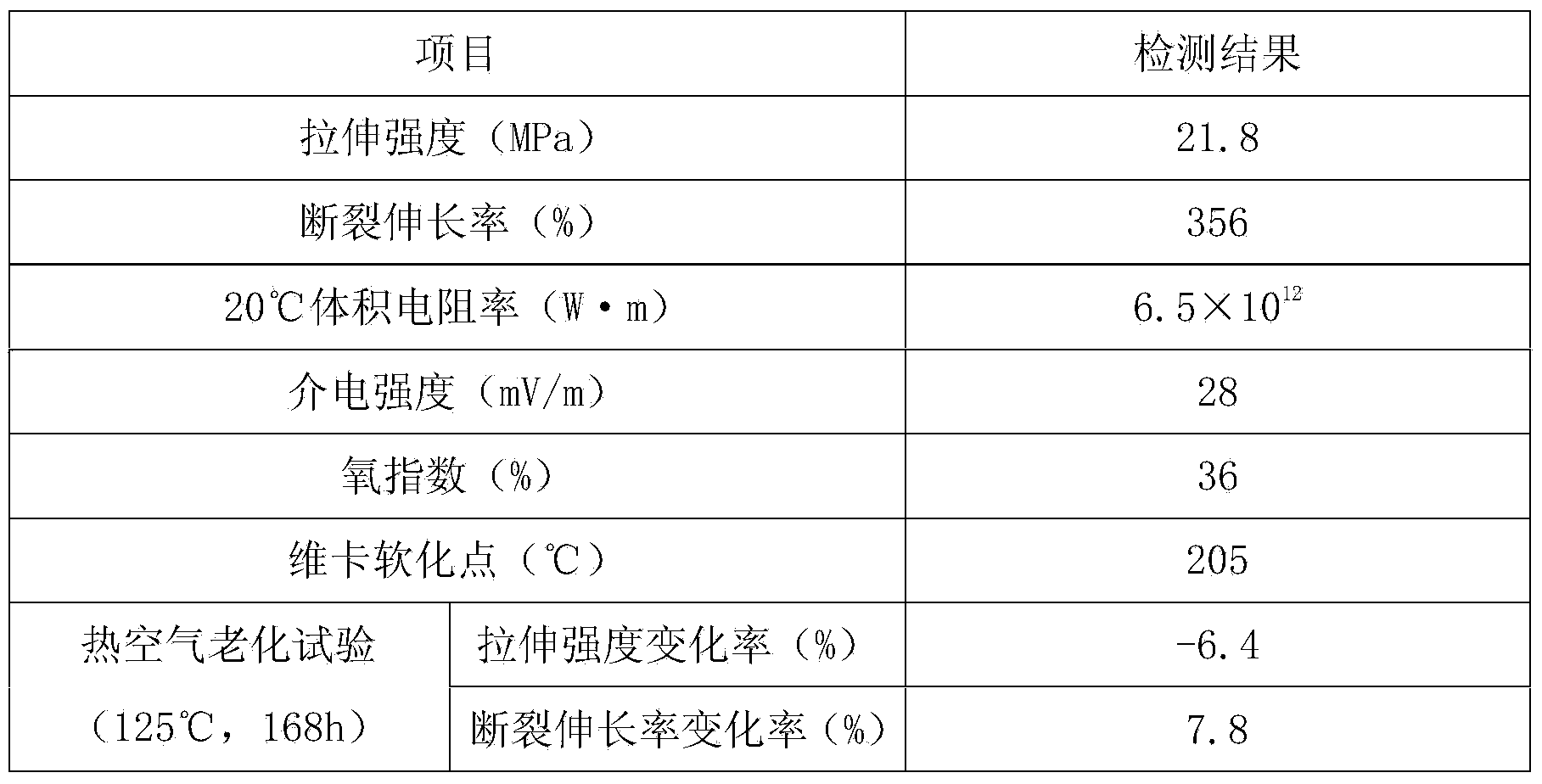

High-toughness high temperature resistant cable material

The invention relates to the technical field of wire and cable materials, in particular to a high-toughness high temperature resistant cable material which comprises the following components: an ethylene-propylene-diene monomer, polyethylene resin, vulcanizing silicone rubber, white carbon black, a heat-resistant filler, a toughened fiber, a composite flame retardant, a silane coupling agent, a lubricating dispersant and a Ca-Zn composite stabilizer, wherein the heat-resistant filler comprises the following components: calcined kaolin, nanometer aluminum oxide, N-phenylmaleimide and dibutyltindilaurate; and the lubricating disperse is a mixture of glyceryl tristearate and ethylene bis oleamide according to equal mass ratio. The toughed fiber is a special ceramic fiber subjected to surfaceroughening and dendronization. Through the use of the toughed fiber, the toughness, the high temperature resistance and the ageing resistance of the cable material are greatly improved.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

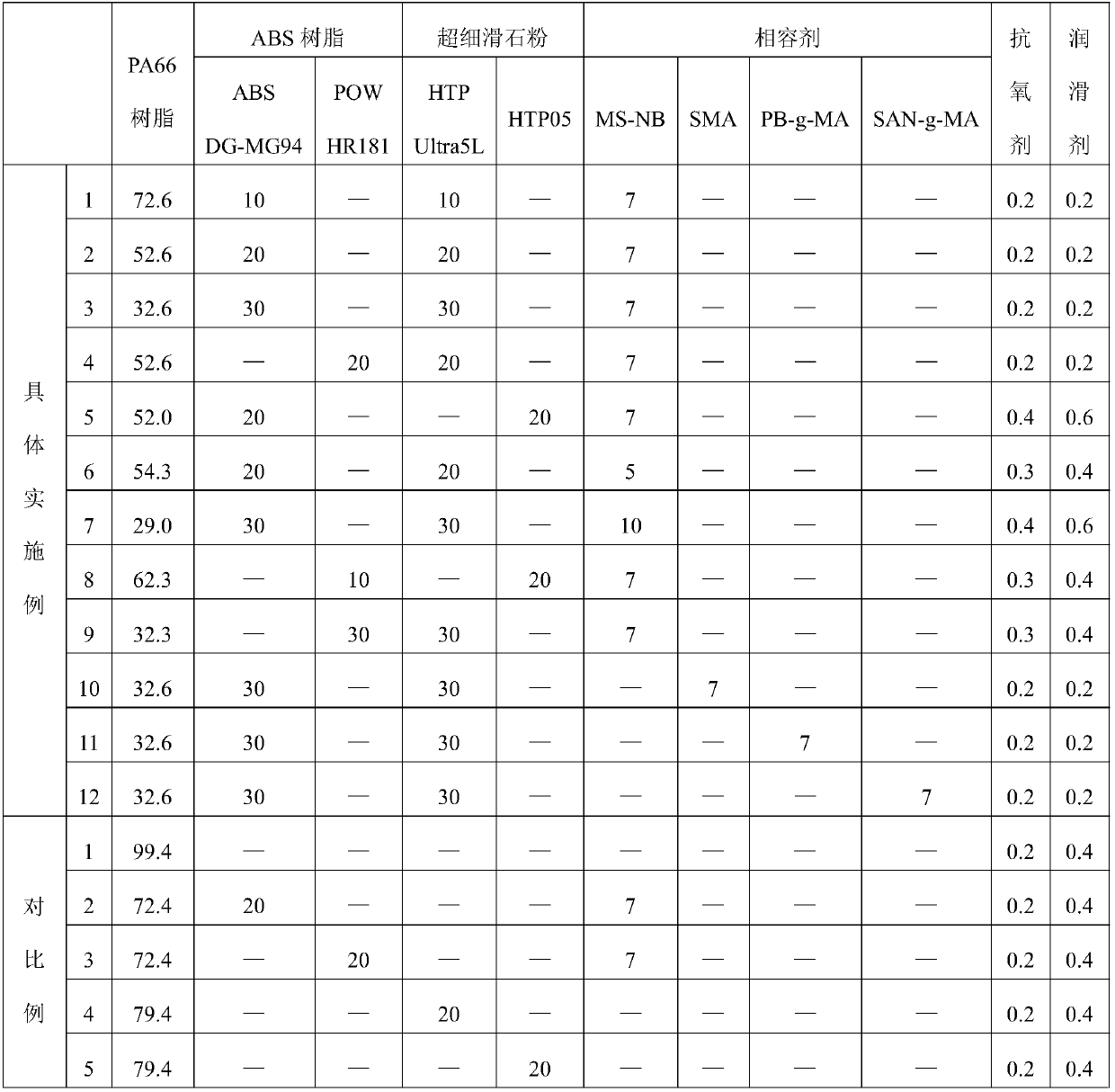

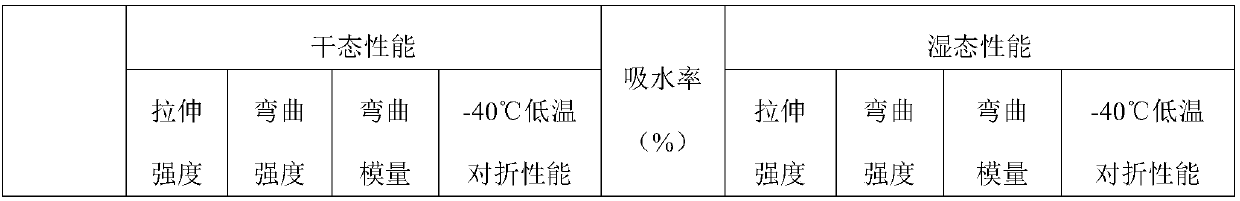

PA66 composite material with excellent low-temperature toughness, low water absorption and high rigidity and preparation method thereof

The invention discloses a PA66 composite material with excellent low-temperature toughness, low water absorption and high rigidity and a preparation method thereof. According to the preparation method, specific ABS resin, lamellar structure filler and compatilizer are added into the PA66 resin to improve the water absorption, rigidity and low-temperature toughness of the composite material, wherein the lamellar structure filler, especially ultrafine talc powder with ultralow grain size, is used, the water absorption of the PA66 composite material can be remarkably reduced, and the rigidity ofthe material under dry state and wet state can be improved; specific ABS resin and compatilizer styrene / N-phenylmaleimide / maleic anhydride copolymer are added based on the lamellar structure filler, the compatibility between nylon resin and ABS resin and between resin and filler can be improved, so that the water absorption of the PA66 composite material can be further reduced, the low-temperaturetoughness, especially the low-temperature toughness at negative 40 DEG C, of the composite material can be greatly improved. The composite material can be used under special work conditions, such ashigh humidity and low temperature extreme cold weather, and the application field of PA66 is expanded.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

A kind of copolymer composition of n-phenylmaleimide derivatives

ActiveCN107474185BImprove heat resistanceHigh heat resistanceGroup 4/14 element organic compoundsN-phenylmaleimideVacuum drying

The invention discloses a copolymer composition of an N-phenylmaleimide derivative. A method is characterized by comprising the following steps: heating an oil bath pan to 50 to 90 DEG C, and stirring the N-phenylmaleimide derivative, styrene, maleic anhydride and xylene under 50 to 90 DEG C for 20 to 60 minutes; adding the xylene, introducing in an N2 gas, stirring, and refluxing after heating to 90 to 120 DEG C; then adding an initiator, and heating to 125 DEG C for reacting, thus obtaining a primary product; dissolving the primary product into acetone under 125 DEG C, and adding methanol; carrying out vacuum drying on an obtained product, thus obtaining powdery resin.

Owner:江西省生宸源建材有限公司

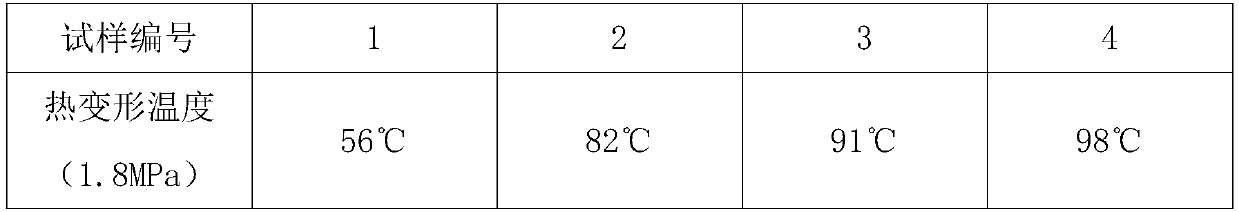

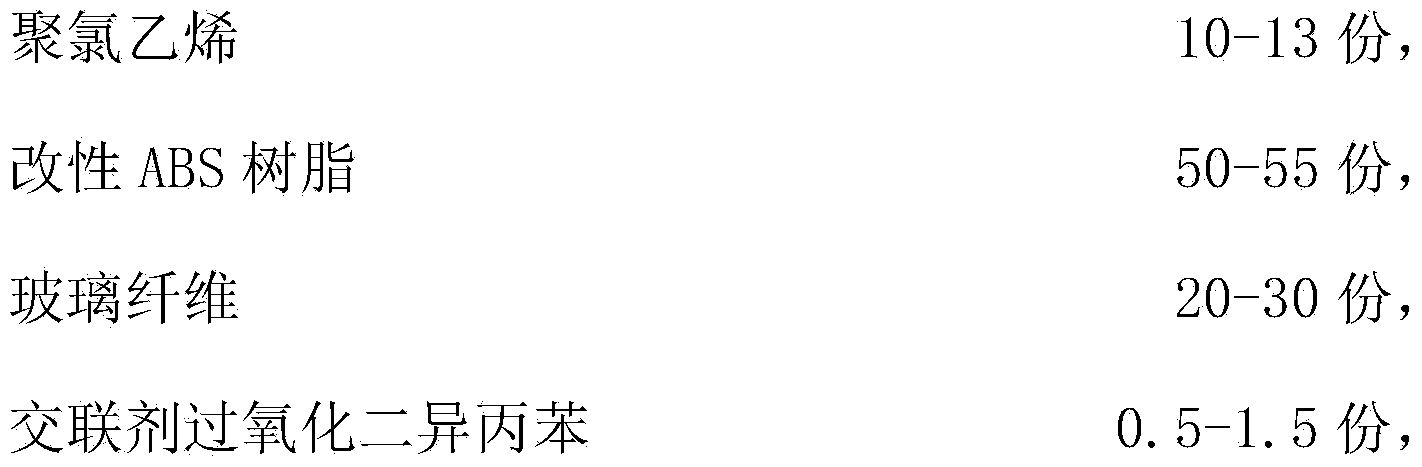

Modified acrylonitrile-butadiene-styrene (ABS) resin with low glossiness and high performance

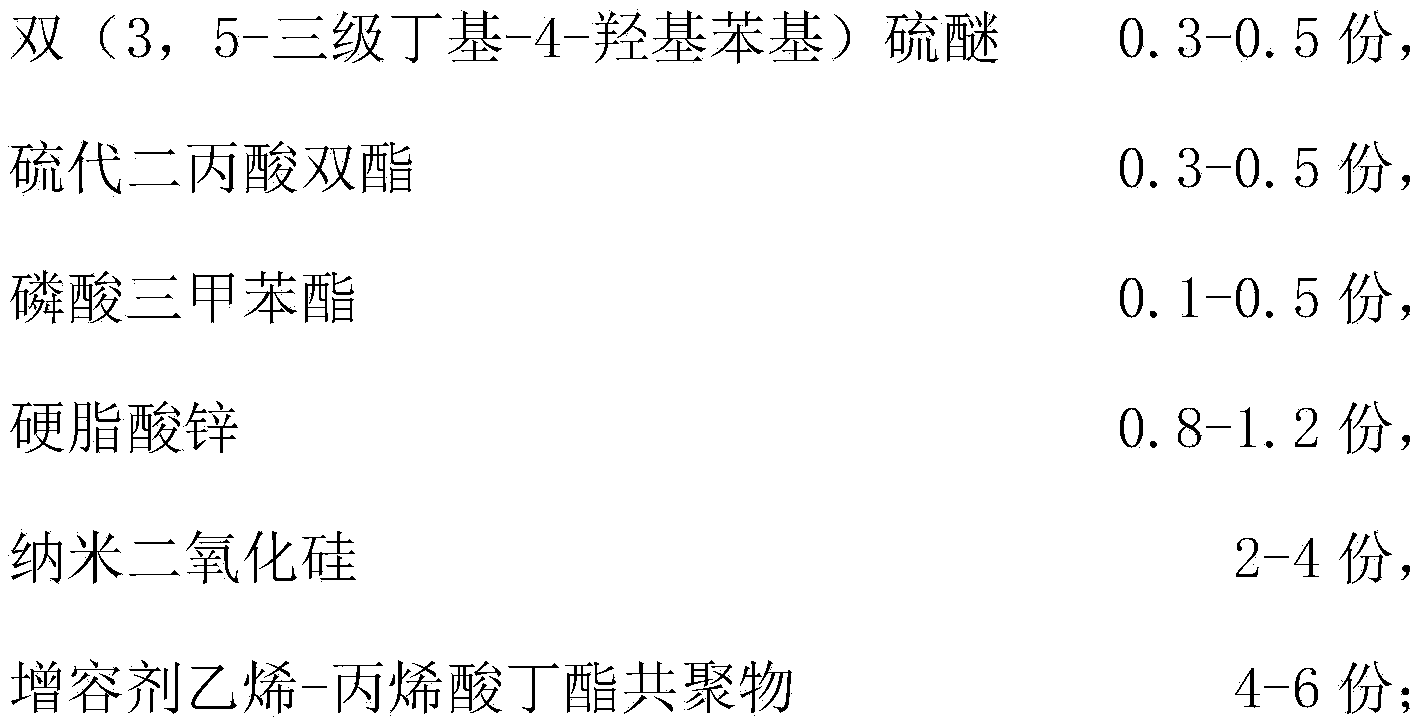

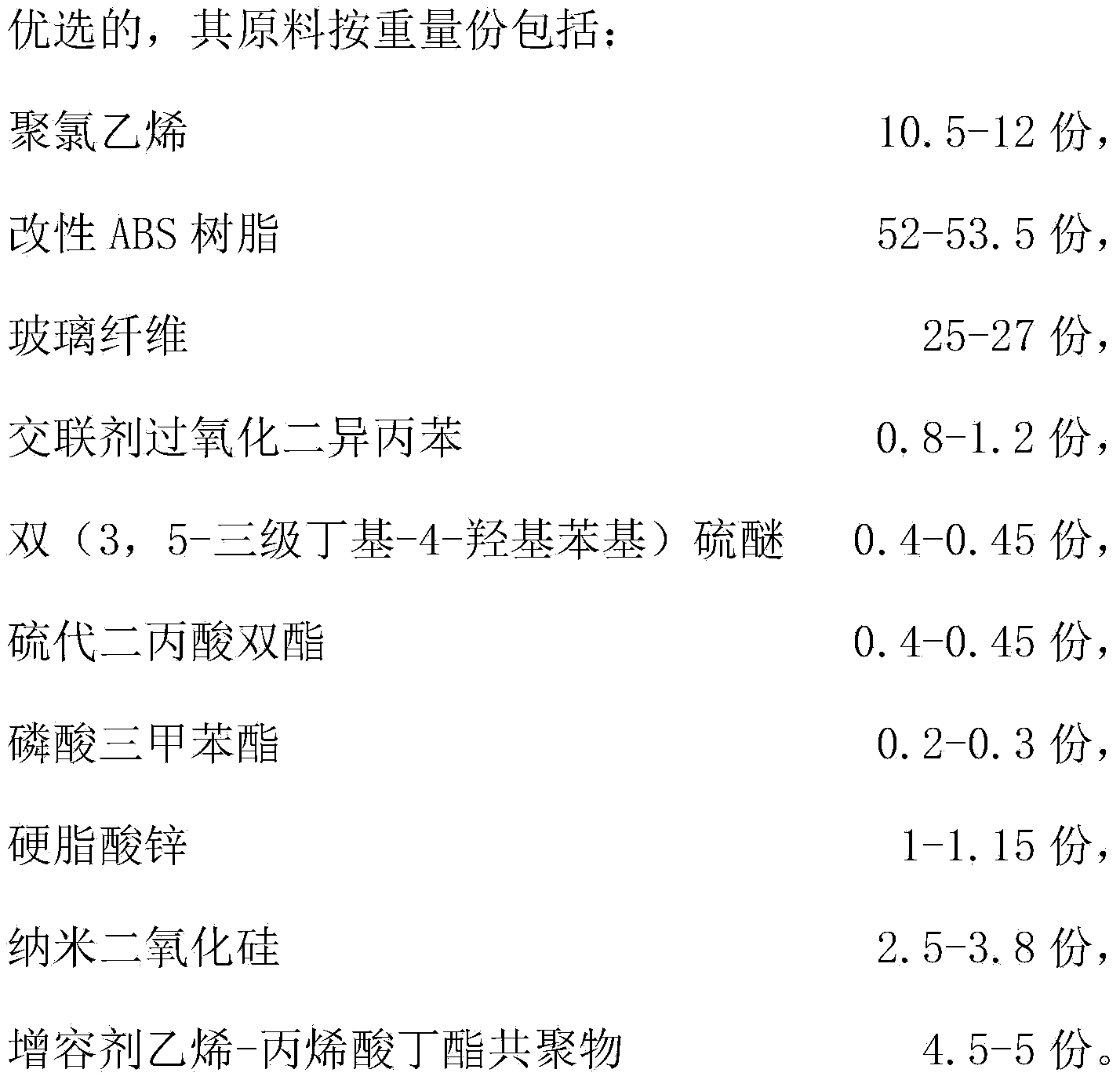

The invention discloses modified acrylonitrile-butadiene-styrene (ABS) resin with low glossiness and high performance. The modified ABS resin comprises the following raw materials in parts by weight: 10-13 parts of polyvinyl chloride, 50-55 parts of modified ABS resin, 20-30 parts of glass fiber, 0.5-1.5 parts of a crosslinking agent dicumyl peroxide, 0.3-0.5 part of bi(3,5-tert-butyl-4-hydroxycyclohexyl phenyl) thioether, 0.3-0.5 part of thio-propionic acid diester, 0.1-0.5 part of tricresyl phosphate, 0.8-1.2 parts of zinc stearate, 2-4 parts of nanosilicon dioxide, and 4-6 parts of a compatibilizer ethylene-butyl acrylate copolymer, wherein the modified ABS resin is obtained by using N-phenylmaleimide-grafted ABS resin, and the filament diameter of the glass fiber is 5-15 microns. The modified ABS resin has excellent heat resistance, impact resistance and compatibility, good processability, good surface roughness and good extinction effect, and the bending strength and the bending modulus are also significantly enhanced.

Owner:ANHUI WANDONG CHEM

Method for synthesizing N-phenylmaleimide through catalysis of acid ionic liquid

The invention relates to a method for synthesizing N-phenylmaleimide, which comprises the following steps of: adding N-phenyl maleamic acid, an organic solvent, an acid ionic liquid catalyst and a polymerization inhibitor into a reaction container, performing cyclodehydration, pouring reaction liquid into a weakly alkaline aqueous solution, washing until neutrality, washing with water, and performing rotary evaporation by using a rotary evaporator to obtain crude N-phenylmaleimide; and adding cyclohexane into the obtained crude N-phenylmaleimide, extracting by controlling the temperature to be between 40 and 80DEG C, and cooling and filtering to obtain the N-phenylmaleimide. The prepared target product has high purity and yield and low production cost. The acid ionic liquid can be recycled, and is suitable for industrial production. The catalyst and the solvent in the synthesis process can be recycled, three wastes are reduced, and the cost is reduced; and through detection of gas chromatography and high performance liquid chromatography, the purity of the product is over 97 percent and the yield of the product is about 97 percent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

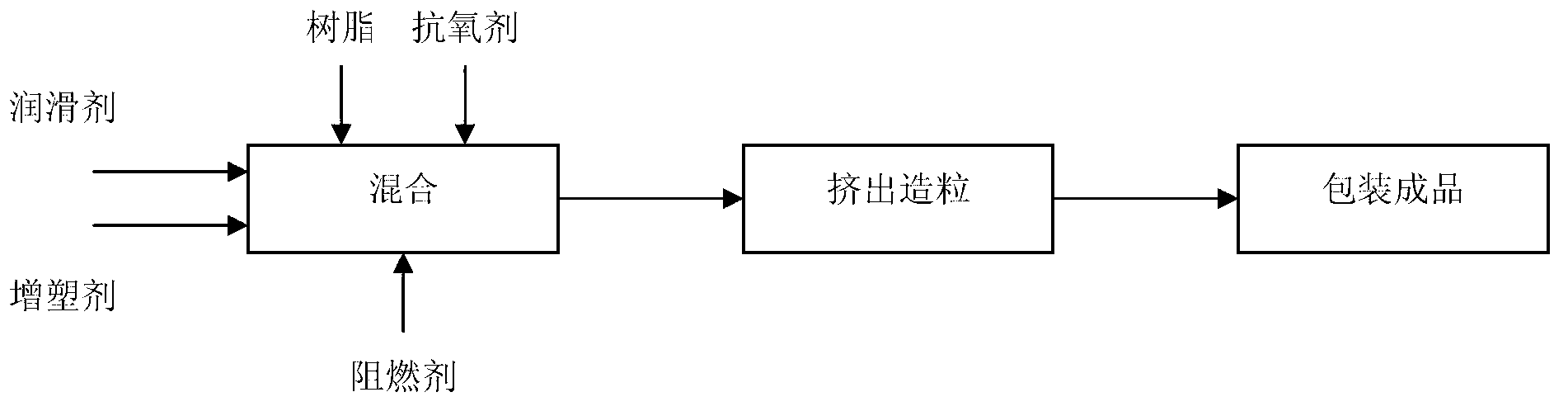

Environmentally-friendly weather and aging resistant flame-retardant resin composition and preparation method thereof

InactiveCN103275452AImprove performanceThe technical route is simple and reasonableN-phenylmaleimideAntioxidant

The invention relates to an environmentally-friendly weather and aging resistant flame-retardant resin composition and a preparation method thereof. The composition comprises chlorinated polyethylene rubber grafted butyl acrylate, 100 parts by weight of styrene and an N-phenylmaleimide resin, 0.002-0.02 parts by weight of an antioxidant, 0.02-0.05 parts by weight of a plasticizer, 0.003-0.05 parts by weight of a lubricant and 0.02-0.15 parts by weight of a flame retardant. Technical problems comprising the material performance decrease and unsuitableness for the outdoor use caused by the addition of large amounts of expensive assistants comprising an environmentally-friendly flame retardant, an antioxidant, an ultraviolet ray absorber and the like to environmentally-friendly weather and aging resistant flame-retardant high-molecular materials in the prior art are solved in the invention. A Chinese blank is filled up, a foreign technological monopoly is broken through, and the high-molecular material which has the characteristics of weather resistance, ageing resistance, flame retardation and good comprehensive performances and can be used in the outdoor manner for a long term is provided in the invention. The composition has the advantages of simple and reasonable technical route, time saving, labor saving, environmental protection, mild technology, short production period, energy saving, consumption reduction, safety, and low production cost, and a cost 20-30% lower than an imported material.

Owner:曹广文

Antibacterial rubber glove and preparation method thereof

InactiveCN107417992AGood antibacterial functionHigh mechanical strengthGlovesProtective garmentN-phenylmaleimideVulcanization

The invention relates to the field of rubber preparation, and discloses an antibacterial rubber glove and a preparation method thereof. The preparation method comprises the following steps: soaking the natural rubber in a liquid antibacterial agent and taking out after 2 to 3 hours to obtain an antibacterial rubber raw material; blending the antibacterial rubber raw material, polyethylene wax, zinc oxide, pentaerythritol and N-phenylmaleimide, and carrying out the first banburying at 60-80 DEG C to obtain a first compound refining rubber; blending the first refining compound rubber, nano silver, an antioxidant and an accelerator, carrying out the second banburing under the temperature 85-95 DEG C to obtain a second compound refining rubber; adding the second compound refining rubber into a vulcanizer, after carrying out extrusion, vulcanization and molding, so as to obtain the antibacterial rubber glove. The antibacterial rubber glove solves the problem that the surface of the glove and the inner layer cannot effectively inhibit the growth and reproduction of harmful bacteria during a glove using process or a finished glove using process.

Owner:WUHU BLUE SKY ENG PLASTIC CO LTD

Environment-friendly plastic package bag

InactiveCN106243434AHigh strengthImprove toughnessFlexible coversWrappersN-phenylmaleimidePolyolefin

The invention discloses an environment-friendly plastic package bag. The package bag is prepared from, by weight, 40-65 parts of polyolefin plastic, 35-45 parts of corn straw fiber, 5-8 parts of chitosan, 3.5-4.5 parts of methylisothiazolinone, 2-3 parts of bamboo charcoal micro mist, 4-6 parts of methyl phenyl polyborosiloxane, 2.0-2.5 parts of polysebacic polyanhydride, 5.5-7.5 parts of N-phenylmaleimide, 5-7 parts of hexamethoxy methyl melamine resin, 8-10 parts of diethyl malonate, 6-8 parts of decabromodiphenyl ether, 6-8 parts of dibasic lead phosphite, 0.1-0.2 part of coupling agent of organic titanate, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate, 4-6 parts of plant saponin, 0.1-0.2 part of polyamide wax micro mist and 1-3 parts of antibacterial agent. The package bag has good strength and toughness and is good in optical performance and easy to oxidize and degrade.

Owner:安徽浩峯塑业有限公司

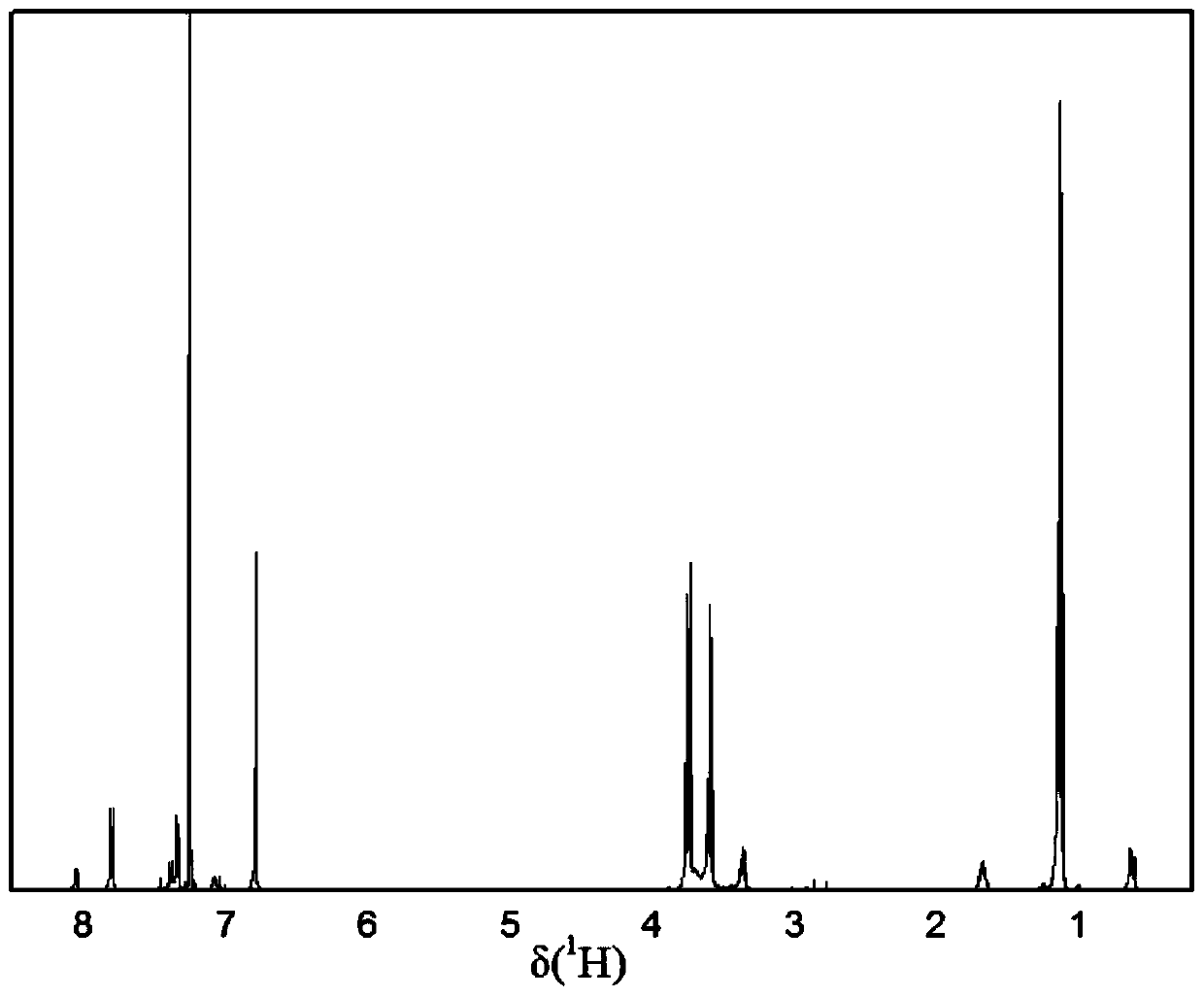

Alpha-methylstyrene/styrene/N-phenylmaleimide/maleic anhydride tetrapolymer and preparation method thereof

The invention belongs to the technical field of polymer heat-resistant modifiers and relates to an alpha-methylstyrene / styrene / N-phenylmaleimide / maleic anhydride tetrapolymer synthesized by one-step method and a preparation method thereof. The invention adopts a solution polymerization one-step feeding method to prepare the alpha-methylstyrene / styrene / N-phenylmaleimide / maleic anhydride tetrapolymer, and the chemical structure of the heat-resistant agent involved is a tetrapolymer of alpha-methylstyrene, styrene, N-phenylmaleimide and maleic anhydride. In the tetrapolymer, the mass fraction of N-phenylmaleimide is 10-60%, the mass fraction of styrene is 20-80%, the mass fraction of alpha-methylstyrene is 10-50%, and the mass fraction of maleic anhydride is 1-10%. The product shows a single glass transition temperature, which is higher than that of the common N-phenylmaleimide copolymers, and the product yield is relatively high. The tetrapolymer is mainly applied to ABS and other resins. The preparation method provided by the invention has such characteristics as high simplicity in preparation, short reaction time, low equipment investment and high economic return.

Owner:EAST CHINA UNIV OF SCI & TECH

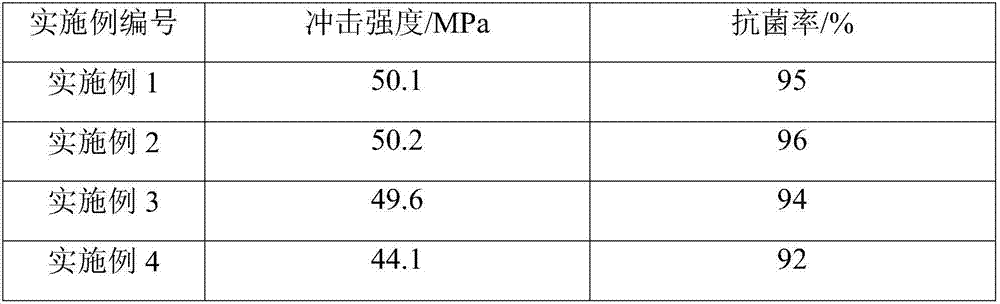

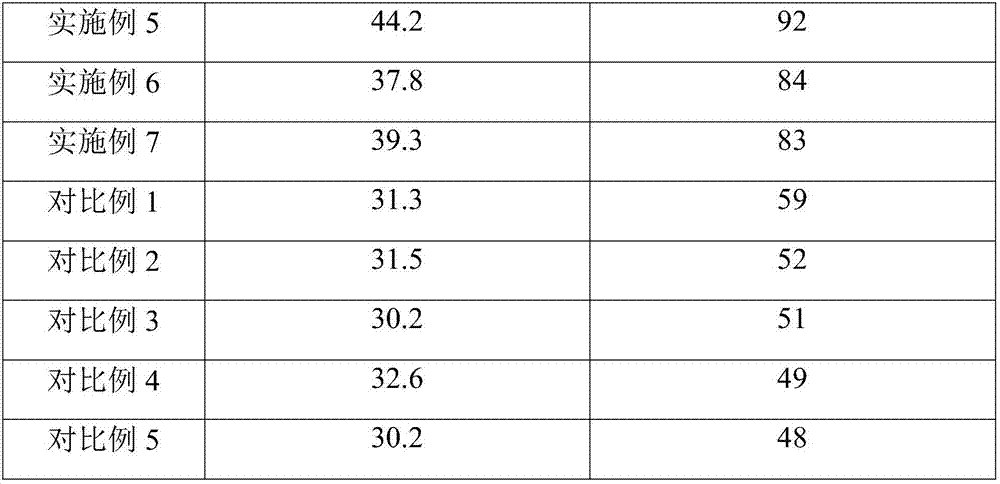

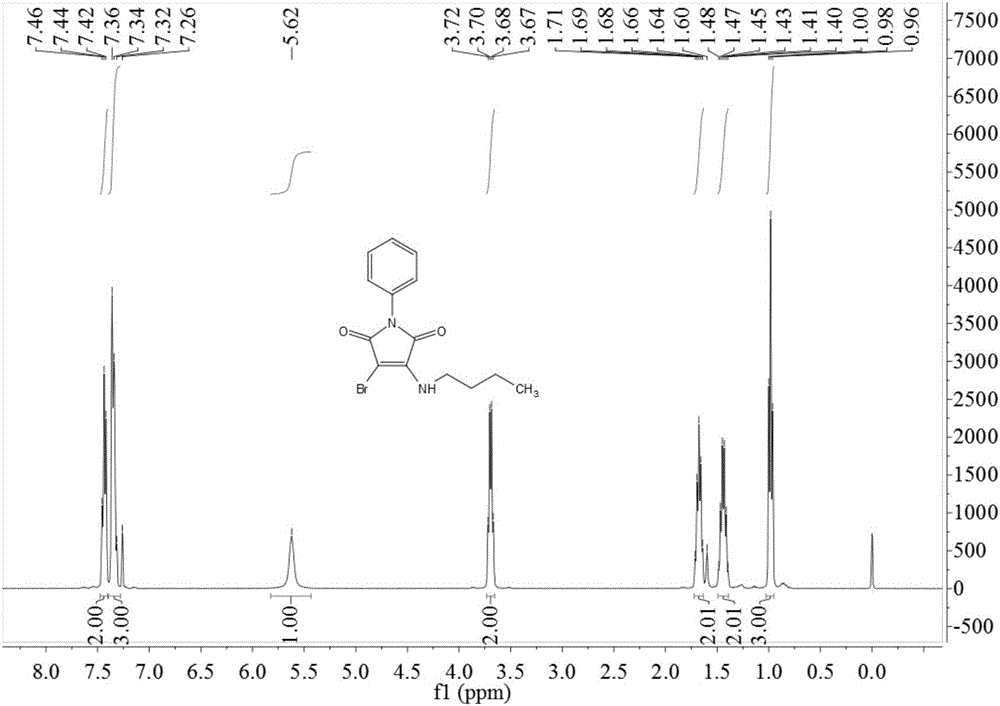

Modified Chinese medical stone for moistureproof bacteriostatic cable material and preparation method thereof

InactiveCN105440309AGood antibacterial effectImprove mildew resistanceN-phenylmaleimideSilicon dioxide

The invention discloses a modified Chinese medical stone for a moistureproof bacteriostatic cable material and a preparation method thereof. The modified Chinese medical stone is prepared from 44-56 parts by weight of Chinese medical stone, 25-35 parts by weight of volcanic rock, 11-19 parts by weight of calamine, 15-25 parts by weight of hydrophobic fumed silica, 4-6 parts by weight of tristearin, 3-5 parts by weight of hexadecyltrimethoxysilane, 1-2 parts by weight of N-phenylmaleimide, 3-6 parts by weight of ceresine, 2-3 parts by weight of diazolidinyl urea, 3-5 parts by weight of chitin, 4-6 parts by weight of 2-ethylhexyl 4-(dimethylamino)benzoate, 4-8 parts by weight of mosquito-repellent incense ash, 1-2 parts by weight of 4-hydroxybenzoic acid hydrazide and 3-6 parts by weight of a composite auxiliary agent. The modified Chinese medical stone has excellent bacteriostasis, water resistance and mildew resistance and has good heat resistance, impact resistance and aging resistance.

Owner:ZHONGGUAN CABLE CO LTD

Method for synthesizing N-phenylmaleimide and special catalyst for method

ActiveCN106432038AReduce generationLess residual acidOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsN-phenylmaleimideOrganic solvent

The invention discloses a synthesis method of N-phenylmaleimide (N-PMI). Under the action of a catalyst, the N-phenylmaleimide is directly synthesized by aniline and maleic anhydride in an organic solvent; the mass ratio of the organic solvent to maleic anhydride is (0.2-0.45) to 1; the mass ratio of aniline to maleic anhydride is (0.8-0.9) to 1; the reaction temperature is 135 DEG C-140 DEG C; and the reaction time is 0.8h-1h. By adopting the method provided by the invention, wastewater can be effectively reduced; and after the reaction is finished, the amount of acid remained in an N-PMI solution is few, so that the amount of water and alkali, which are used for water washing and neutralization in a post-treatment process, can be reduced. The synthesis method is a environment-friendly process route.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polrvinyl chloride heat-resistance modifier and preparation method thereof

The invention discloses a polrvinyl chloride heat-resistance modifier and a preparation method thereof. The heat-resistance modifier is a methyl methacrylate-alpha-methyl styrene-N-phenylmaleimide terpolymer. Methyl methacrylate and alpha-methyl styrene account for 60 to 80 percent of the total mass of the modifier, N-phenylmaleimide terpolymer accounts for 20 to 40 percent of the total mass of the modifier, and the mass ratio of methyl methacrylate to alpha-methyl styrene is 1:1; and in a polymerization process, the mass ratio of monomer to water is (30-40):(60-70), the polymerization temperature is 60 to 80 DEG C, a peroxide initiator, an alkyl sulfate or alkane sulfonate emulsifier and a thiol molecular weight regulator are added at the same time, the reaction time is 6 to 9 hours, and a pressure type spray dryer is used for spray drying in a post-treatment process. Compared with the conventional heat-resistance modifier, the performance is high, the form of product particles is desirable, the yield is high, fewer raw material varieties are adopted, the cost is low, the spray drying post-treatment process is simple, and the Vicat softening point of the prepared heat-resistance modified resin is obviously improved, and the processability is high.

Owner:SHANDONG SHUNTIANLI PLASTIC

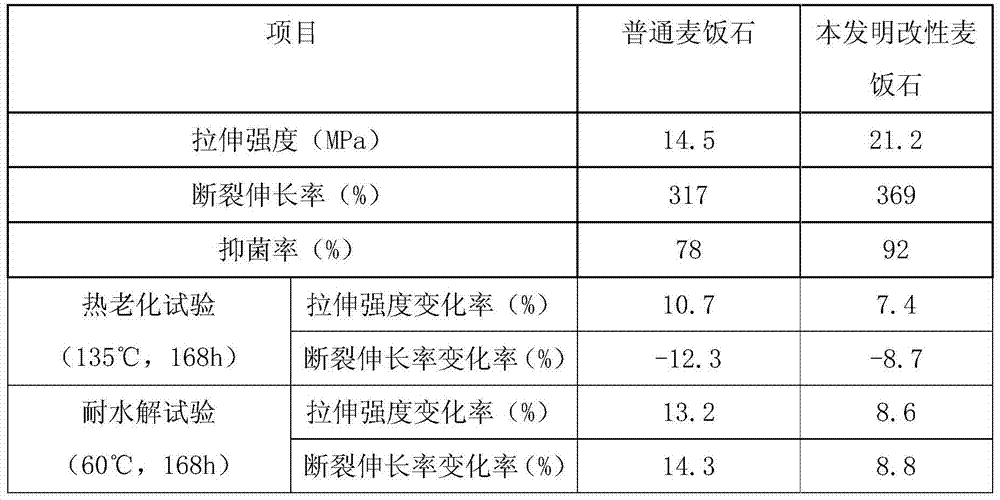

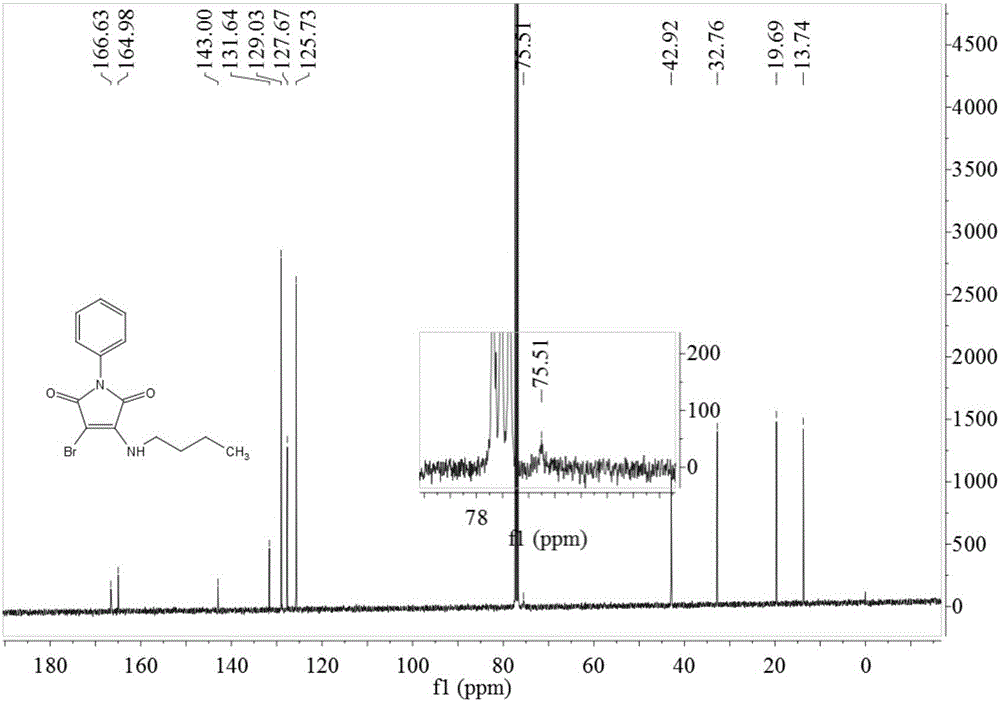

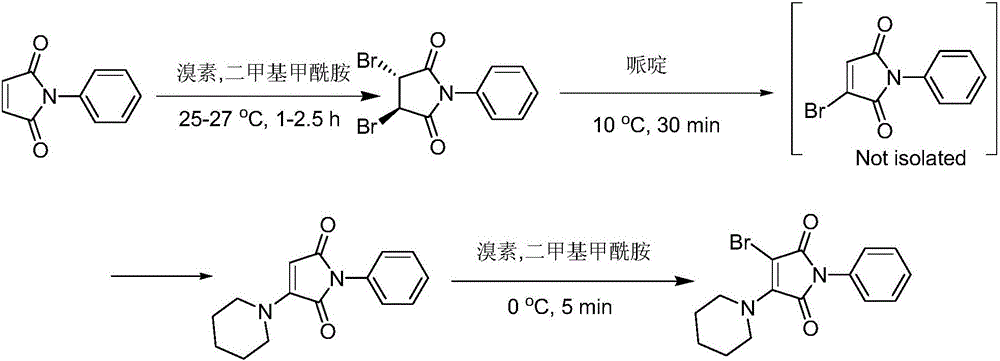

Preparation method of 3-n-butylamine-4-bromo-N-phenylmaleimide

InactiveCN106243009ADelayed reaction timeReduced responseOrganic chemistryN-phenylmaleimideWastewater

The invention relates to a preparation method of 3-n-butylamine-4-bromo-N-phenylmaleimide. the preparation method comprises the following steps: adding N-phenylmaleimide, n-butylamine and a brominating agent into a solvent, reacting at room temperature of minus 100 DEG C for 1-3 h, adding water and stirring after the end of the reaction, extracting, drying, concentrating, and recrystallizing to obtain 3-n-butylamine-4-bromo-N-phenylmaleimide. Yield of 3-n-butylamine-4-bromo-N-phenylmaleimide is high; reaction operation is simple; reaction route is short; and there is less ''three wastes'' (waste gas, wastewater and residue). The preparation method is easy for industrial production.

Owner:DONGHUA UNIV

Heat-resistant modified plastic

The invention relates to a heat-resistant modified plastic which comprises the following components in parts by weight: 40-70 parts of ABS (acrylonitrile-butadiene-styrene), 3-8 parts of interfacial coupling agent, 3-10 parts of toughener, 0.5-1.0 part of dispersing and lubricating agent, 5-10 parts of decabromodiphenyl oxide and 10-15 parts of N-phenylmaleimide. The heat-resistant modified plastic provided by the invention has excellent heat resistance, can be widely used in automobile industry, and is often used for manufacturing daily necessities, such as automobile parts, home appliance industry, architectural decoration industry, crash helmets, motorcycle fenders, heelpieces, snowfield sporting goods, toys, clocks, loudspeaker shells, suitcases, buttons, cosmetic cases and the like, and advertising products of nameplates, ornaments and the like.

Owner:江西省佳晨实业有限公司

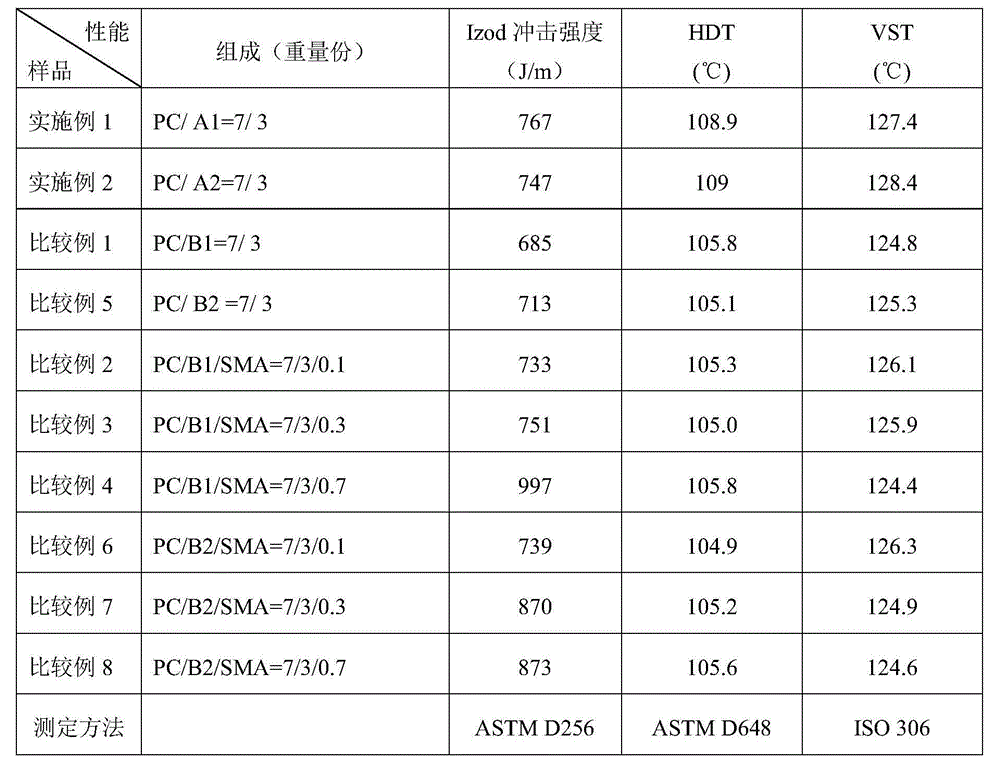

Polycarbonate/ABS composition, alloy, and preparation method thereof

ActiveCN105315638AImprove impact performanceImprove heat resistanceN-phenylmaleimideBulk polymerization

The invention relates to a polycarbonate / ABS alloy with improved impact properties and heat resistance. The polycarbonate / ABS alloy is mainly used for solving a problem of polycarbonate / ABS alloy prepared via the prior art that balance of impact properties and heat resistance is impossible to achieve via using of a compatilizer. The polycarbonate / ABS composition comprises, by weight, a) 50 to 99 parts of polycarbonate with a weight-average molecular weight ranging from 2*10<4> to 8*10<4>g / mol; b) 1 to 50 parts of bulk polymerization ABS containing 1 to 10wt% of N-phenylmaleimide and 5 to 20% of rubber, wherein average particle size of the bulk polymerization ABS ranges from 1 to 10<mu>m; and c) 0.01 to 1 part of an antioxidant. The polycarbonate / ABS composition is prepared via mixing extrusion. The preparation method is capable of solving the problem preferably, and the polycarbonate / ABS composition can be applied in industrial production such as automobile and household electrical appliance polycarbonate / ABS alloy.

Owner:CHINA PETROLEUM & CHEM CORP +1

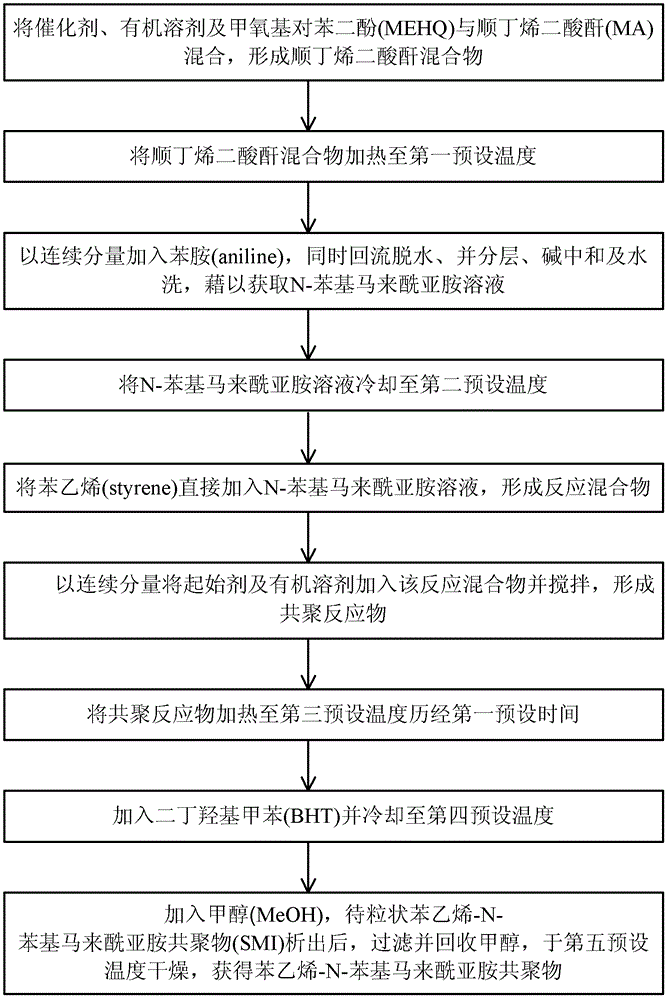

Preparation method of styrene-N-phenylmaleimide copolymer

The invention provides a preparation method of a styrene-N-phenylmaleimide (SMI) copolymer with a high molecular weight. The method comprises: adding aniline gradually into a heat treated maleic anhydride (MA) mixture, conducting reflux dehydration, layering, alkali neutralization and washing to obtain N-phenyl maleimide (PMI), then adding styrene directly and mixing them, and adding an initiator and an organic solvent gradually, thus obtaining the high molecular weight styrene-N-phenylmaleimide copolymer.

Owner:JIH NONG SCI

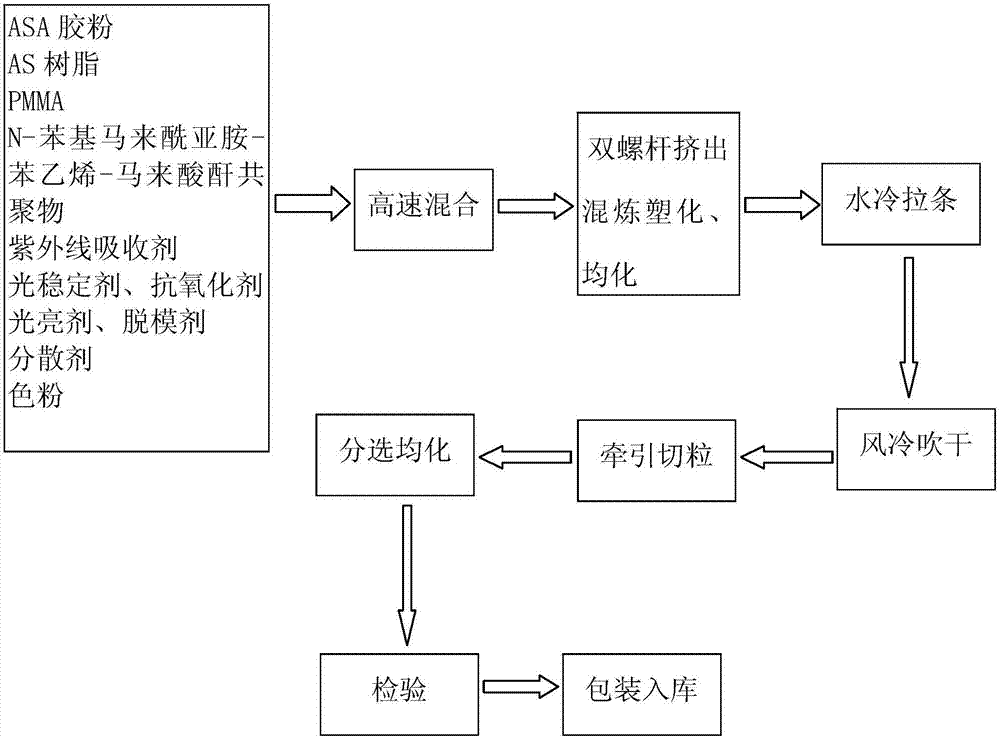

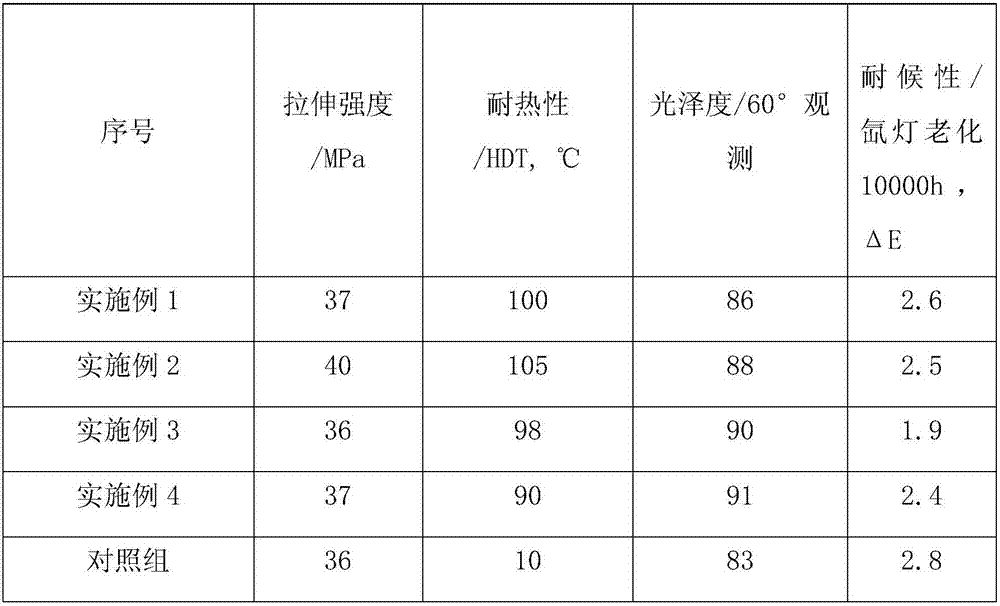

Highlight high-weather-resistance and heat-resistant ASA composite material and preparation method thereof

InactiveCN107488307AImprove mechanical propertiesHigh tensile strengthN-phenylmaleimideWeather resistance

The invention discloses a highlight high-weather-resistance and heat-resistant ASA composite material, relating to the technical field of high polymer materials. A coextruded material contains the following raw materials in parts by weight: 25-35 parts of ASA rubber powder, 30-45 parts of AS resin, 30-40 parts of PMMA, 30-40 parts of an n-phenylmaleimide-styrene-maleic anhydride copolymer, 0.1-0.3 part of a ultraviolet absorber, 0.3-0.5 part of a light stabilizer, 0.3-0.8 part of an antioxidant, 0.5-1.5 parts of a brightener, 0.1-0.3 part of a demolding agent, 0.3-0.6 part of a dispersing agent and 1-3 parts of a toner. The invention further discloses a preparation method of the highlight high-weather-resistance and heat-resistant ASA composite material. The highlight high-weather-resistance and heat-resistant ASA composite material has excellent weather resistance, good heat resistance and high luster and is unlikely to fade.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

High temperature resisting material for communication optical cable sheath and preparation method of high temperature resisting material

InactiveCN104292646AImprove high temperature resistanceGood physical and mechanical propertiesFibre mechanical structuresAluminum silicateUltra fine

The invention discloses a high temperature resisting material for a communication optical cable sheath and a preparation method of the high temperature resisting material. The high temperature resisting material is prepared from the following raw materials in parts by weight: 50-70 parts of polypropylene, 25-45 parts of polybenzimidazole, 15-20 parts of basic magnesium carbonate hydrate, 3-5 parts of dimethyl-biphenyl diisocyanate, 2-4 parts of N-phenylmaleimide, 16-22 parts of polytetrafluoroethylene, 10-15 parts of silicified graphite, 18-26 parts of terephthalic acid p-phenylenediamine, 10-15 parts of calcium molybdate, 15-20 parts of diisononyl phthalate, 12-18 parts of nanometer titanium phosphate, 10-15 parts of ultra fine aluminum silicate, 4-8 parts of pentaerythritol phosphate, 2-3 parts of lithium stearate, 3-5 parts of calcium acetyl acetone, 4-6 parts of low molecular weight polybutene, 1-2 parts of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate, and 2-3 parts of bisphenol A-bi(diphenyl phosphate). The sheath material provided by the invention has excellent high temperature resisting property, and can still maintain relatively high physics mechanical property after long time working in high temperature environment, and phenomena of softening, decomposition and poor performance cannot occur; meanwhile, the high temperature resisting material has the excellent wearing resistance, corrosion resistance, and aging resistance, so that the comprehensive property of the sheath is greatly improved, and the service life is prolonged.

Owner:安徽电信器材贸易工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com