Preparation method of N-phenylmaleimide (PMI)

A maleimide and phenyl technology, applied in the field of preparation of N-phenylmaleimide, can solve the problems of complex process, difficult reaction, troublesome filtration steps, etc., and achieves simple preparation method and improved yield and purity, energy and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

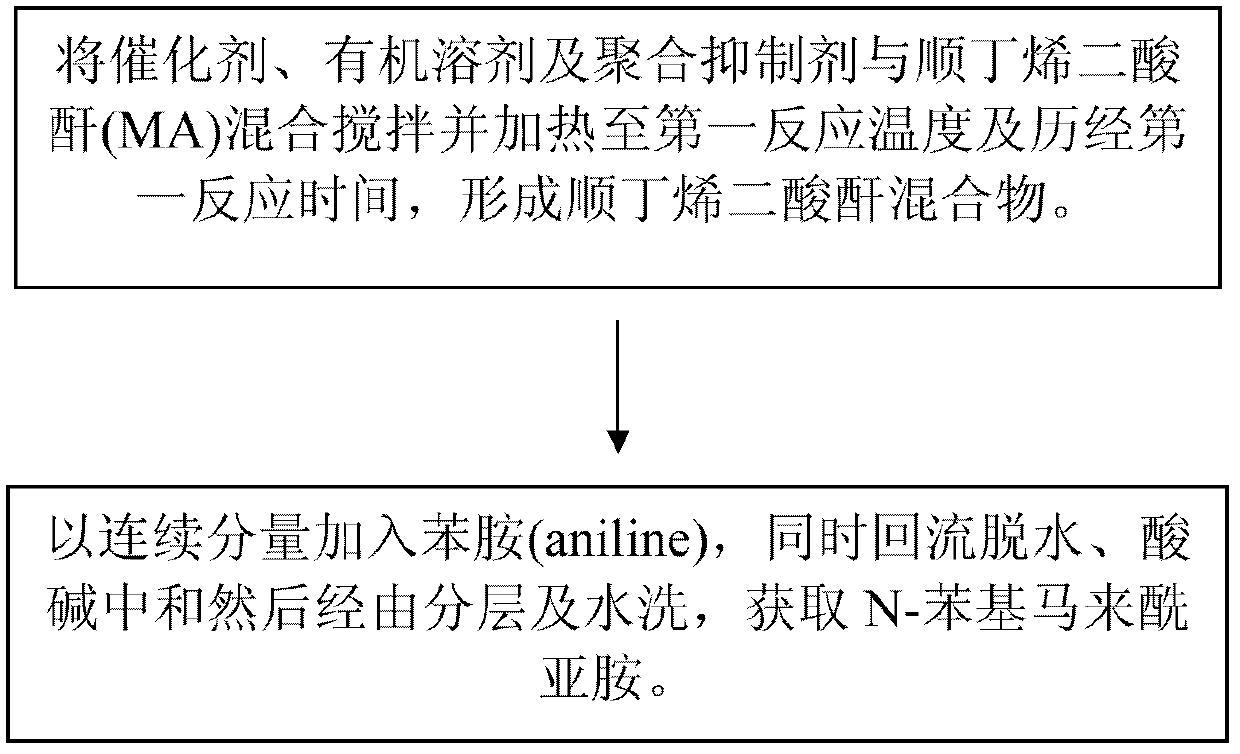

[0019] The preparation method of N-phenylmaleimide provided by the invention is as figure 1 shown, including the following steps:

[0020] Firstly, the catalyst, the organic solvent, the polymerization inhibitor and the maleic anhydride are mixed and stirred in the reactor and heated to the first reaction temperature and the first reaction time to form the maleic anhydride mixture;

[0021] Add aniline to the heat-treated maleic anhydride mixture in a continuous amount, and reflux dehydration at the same time. After the reaction is completed, add sodium carbonate for acid-base neutralization, and then obtain N - phenylmaleimide.

[0022] The preparation method of N-phenylmaleimide provided by the present invention will be further illustrated by the following examples, and these examples do not limit the content disclosed above in the present invention.

Embodiment 1

[0024] In a 1-liter four-necked bottle, add 400 milliliters (ml) of toluene, 1 mole (mole), that is, 98 grams (g) of maleic anhydride, 4 g of p-toluenesulfonic acid, 2 g of dimethylformamide and 0.5 g of Methoxyhydroquinone, heated at 115°C to 125°C to completely dissolve the powder to form a maleic anhydride mixture; then gradually add 1 mole (93g) of aniline in 4 times within 0.5 hours to 1 hour Add the heat-treated maleic anhydride mixture, and carry out reflux dehydration simultaneously; After the reaction is completed, add 5g of sodium carbonate (Na 2 CO 3 ) for acid-base neutralization, stirred for 10 minutes to 30 minutes, so that the pH value (pH value) was between 6 and 7, left to stand to be separated, then washed the toluene layer with water and crystallized by cooling, to obtain 155g and a purity of 98% N-phenylmaleimide.

Embodiment 2

[0026] Add 400ml of toluene, 1 mole (98g) of maleic anhydride, 5g of phosphoric acid carrier, 2g of dimethylformamide and 0.5g of methoxyhydroquinone to a 1-liter four-neck bottle, After heating at ℃ to make the powder completely dissolve, a maleic anhydride mixture is formed; then gradually add 1 mole (93 g) of aniline to the heat-treated maleic anhydride mixture in 4 times within 0.5 hours to 1 hour, and Simultaneously carry out reflux dehydration; after the reaction is completed, add 5g of sodium carbonate for acid-base neutralization, stir for 10 minutes to 30 minutes, make the pH (pH value) between 6 and 7, let stand to be separated, and then wash the toluene layer And cooled and crystallized to obtain 138g of N-phenylmaleimide with a purity of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com