Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "1-butyl-3-methylimidazolium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for unsaturated block copolymers and hydrogenated unsaturated block copolymers

Use is made, for selectively hydrogenating the olefinic double bonds of block copolymers, at least one block of which comprises olefinic double bonds, using a catalyst based on a metal from Group VIII in a medium comprising an organic solvent for the copolymer and an ionic liquid as solvent for the catalyst, of a water-immiscible ionic liquid, preferably an ionic liquid for which the anion is the hexafluorophosphate anion and the cation is the 1-butyl-3-methylimidazolium (bmim+) or 1-ethyl-3-methylimidazolium (emim+) cation.Applied to poly(styrene)-b-poly(butadiene)-b-poly(methyl methacrylate) block copolymers, the poly(butadiene) block of which predominantly possesses a 1,4-microstructure, this process results in copolymers for which the degree of hydrogenation is at least equal to 50% and which exhibit a melting point of greater than 30 °C.

Owner:ATOFINA

Method for preparing hexane diacid by liquid-phase catalytic oxidation of cyclohexanol

InactiveCN101302147AAvoid it happening againReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidHeteropoly acid

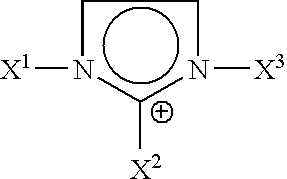

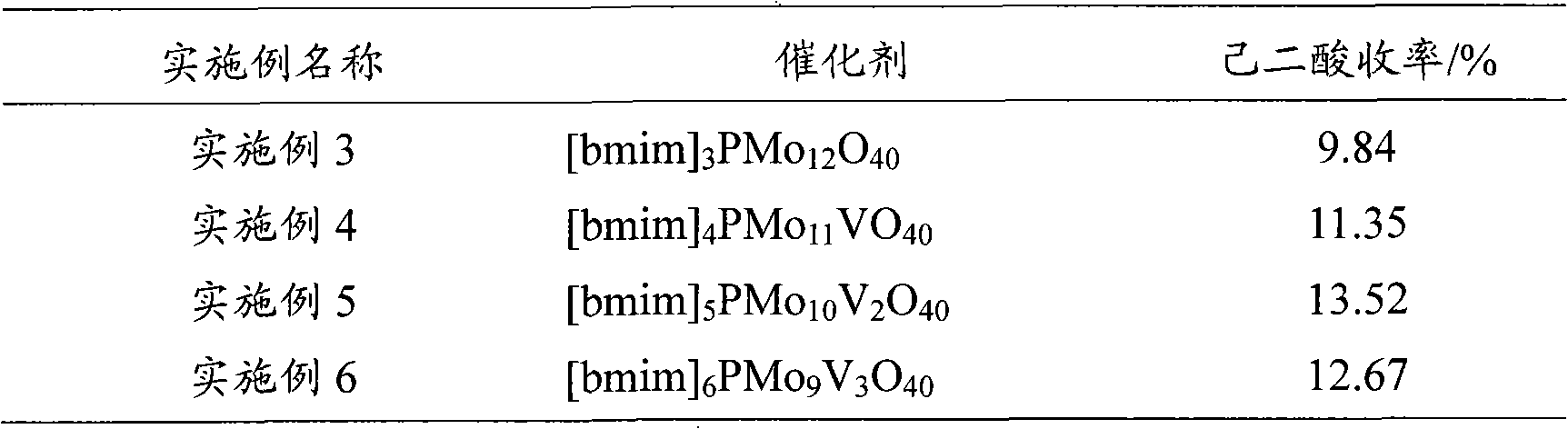

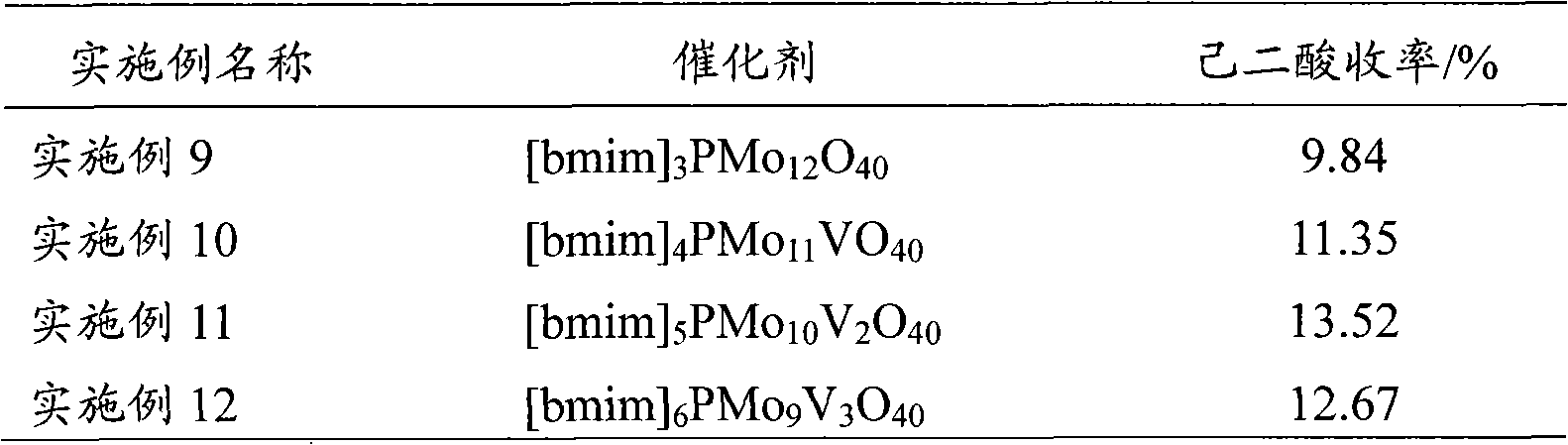

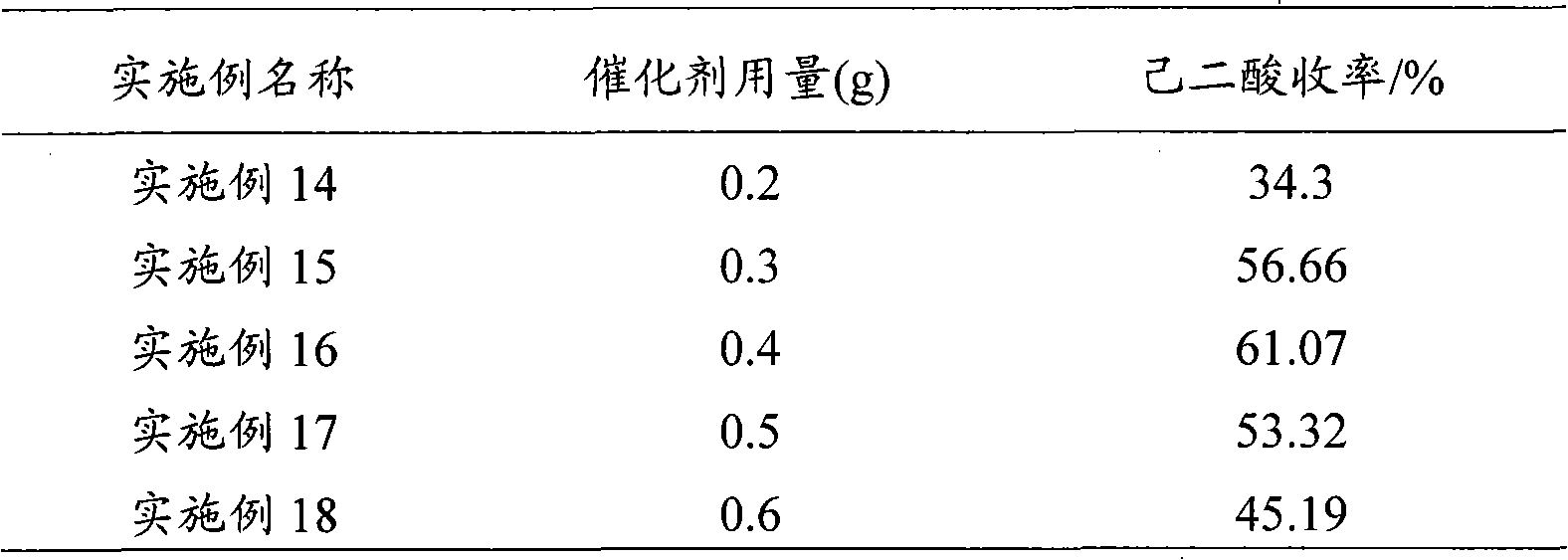

The invention provides a method for preparing adipic acid through liquid-phase catalytic oxidation of cyclohexanol. H2O2 is taken as oxidant, a heteropoly acid imidazole salt is taken as catalyst, the cyclohexanol undergoes the catalytic oxidation to prepare the adipic acid, the catalyst can be phosphotungstic acid 1-butyl-3-methylimidazolium bmim3PW12O40, phosphomolybdic acid 1-butyl-3-methylimidazolium bmim3PMo12O40, and molybdovanadophosphoric heteropolyacid 1-butyl-3-methylimidazolium bmim3+xPMo12-xVxO40 (x is equal to between 1 and 3) and so on, and the bmim represents a 1-butyl-3-methyl-imidazolium cation. Compared with the method of preparing the adipic acid by industrially using nitric acid (nitrate) to oxidize the cyclohexanol, the method can not produce poisonous oxynitride N2O, and avoids the harm to the environment; and in a reaction system, phase shift catalyst and addition agent are not used, which avoids the potential environmental pollution and has apparent economic and social significance.

Owner:ZHEJIANG UNIV OF TECH

Synthesizing method of polyimide

ActiveCN102219900AEasy to recycleImprove protectionFiber1-Butyl-3-methylimidazolium hexafluorophosphate

The invention discloses a synthesizing method of polyimide. The method comprises the following step that: an aromatic diamine compound and an aromatic dianhydride compound are subject to a polymerization reaction in an ionic liquid, such that polyimide is obtained. The ionic liquid can be any one of 1-ethyl-3-methylimidazolium tetrafluoroborate, 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium dicyanamide, 1-butyl-3-methylimidazolium tetrafluoroborate, 1-butyl-3-methylimidazolium hexafluorophosphate, 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, and 1-butyl-3-methylimidazolium trifluoromethanesulfonate. The operation of the method is simple, the product made with the method is easy to purify and has high dissolvability (the product can be dissolved in regular solvents of N, N-dimethylacetamide, or tetrahydrofuran). The method has advantages of high yield, stable performance, good application prospect, and is suitable for industrialized production. Withthe method, polyimide films or fibers can be produced.

Owner:BEIJING RADIATION APPL RES CENT

Methods of Improving the Strength of Carbon Fiber

InactiveCN102296457AHigh strengthSuitable for industrial implementationCarbon fibresFiberCarbon fibers

A method for improving the strength of carbon fibers, comprising: 1) soaking the carbon fibers in an aqueous solution of nitric acid, washing the carbon fibers with deionized water until the washing liquid is neutral after soaking; 2) preparing a carbon nanotube dispersion into a spraying liquid, carbon The nanotubes are functionalized carbon nanotubes, which are obtained from hydroxylated carbon nanotubes, carboxylated carbon nanotubes or aminated carbon nanotubes. The dispersion liquid is a mixture of ionic liquid and water, and the ionic liquid is obtained from 1,3 -Dimethylimidazole p-toluenesulfonate, 1-butyl-3-methylimidazole p-toluenesulfonate, 1-octyl-3-methylimidazole chloride or 5-bromo-2-methyl-3 - One of the nitropyridines, the content of carbon nanotubes in the spraying liquid is 16-48g / L; 3) The spraying liquid is applied with positive static electricity of 10-40kV, and the carbon fiber tow is flattened and grounded to form a spraying liquid acceptor, and then passes through Electrostatic spraying sprays the spray liquid on the carbon fiber surface. The tensile strength of carbon fiber can be increased by more than 100%.

Owner:CHINA PETROLEUM & CHEM CORP

Method for dissolving and extracting cellulose in bagasse

InactiveCN101649571ADissolution does not affectLow viscosityPaper material treatmentChlorideDissolution reaction

The invention discloses a method for dissolving and extracting cellulose in bagasse. The method comprises the following steps: (1) soaking bagasse with water, filtrating, using sodium hydroxide solution to activate, washing with deionized water to ensure the pH value to be 7, filtrating, drying, grinding; (2) adding ionic liquid 1-butyl-3-methylimidazolium chloride in the pretreated bagasse, heating to 80 DEG C, keeping temperature for 2-5min, adding pyridine while stirring, performing dissolution reaction at 70-100 DEG C for 30-240min, centrifugalizing to obtain cellulose solution; (3) addingthe obtained cellulose solution in deionized water, stirring, filtrating to obtain filter residue, washing the filter residue with deionized water and drying to obtain regenerated cellulose. The method of the invention is easy, the process is convenient, energy-saving and environmentally friendly, and the method greatly expands the reuse of agricultural wastes and the range of application of cellulose, thus having broad application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

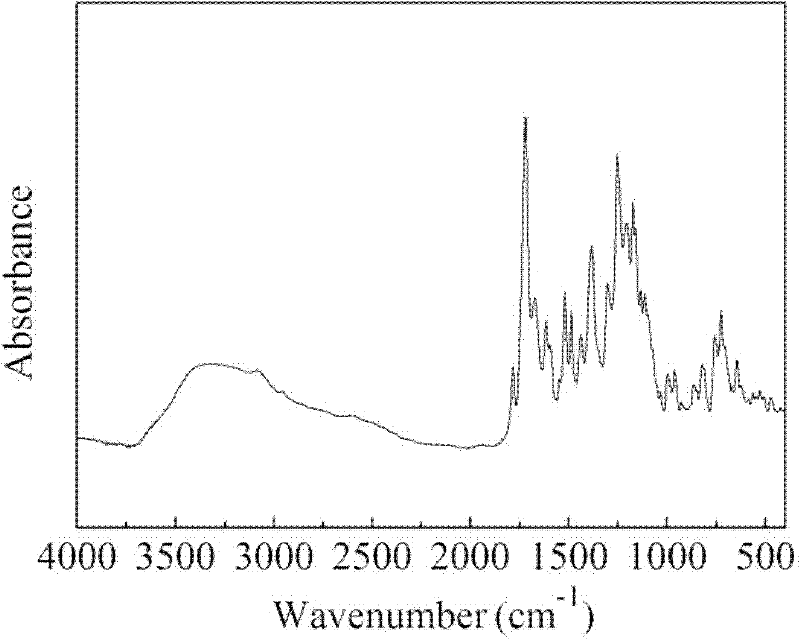

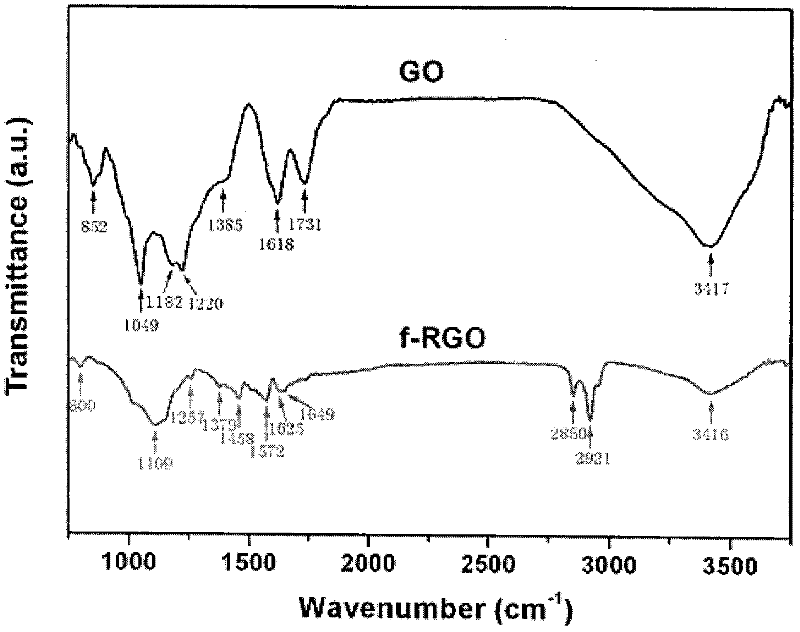

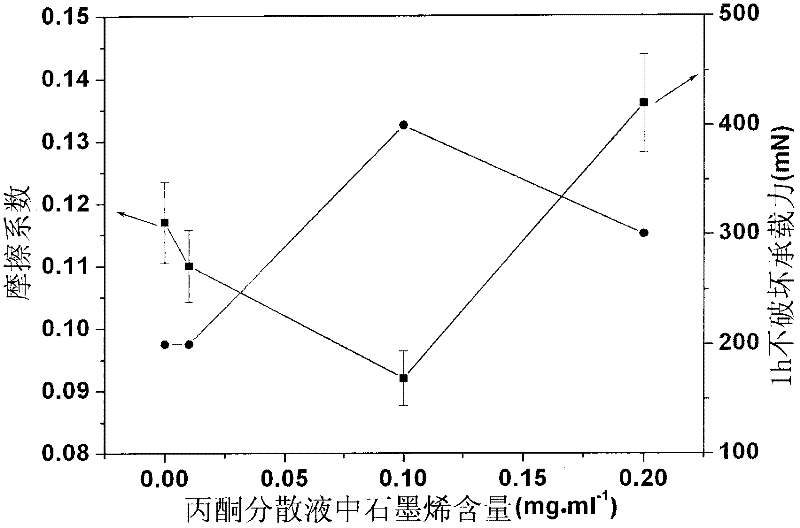

Graphene-containing ionic liquid nanometer composite lubricating membrane

ActiveCN102533406AImprove electrostatic adsorption capacityImprove bindingAdditivesTetrafluoroborateAcetone

The invention discloses a graphene-containing ionic liquid nanometer composite lubricating membrane. The graphene-containing ionic liquid nanometer composite lubricating membrane is prepared by the steps of carrying out non-covalent functionalization treatment to graphene through 1-butyl-3-methylimidazolium chloride ionic liquid so as to disperse the obtained graphene in water and an organic solvent stably, mixing and dispersing graphene and 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid in acetone, and preparing the graphene-containing ionic liquid nanometer composite lubricating membrane from the dispersion liquid through a static absorption manner finally. The nanometer composite lubricating membrane both has high micro-friction bearing capacity of the graphene and low micrometer / nanometer friction coefficient of the ionic liquid, and can be used for solving lubricating problems of micro-components such as MEMS (Micro-electromechanical System) and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

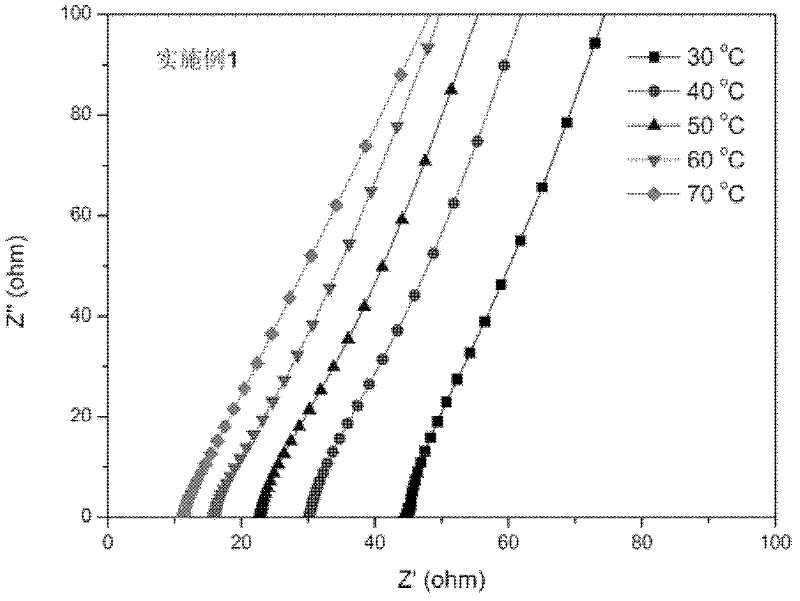

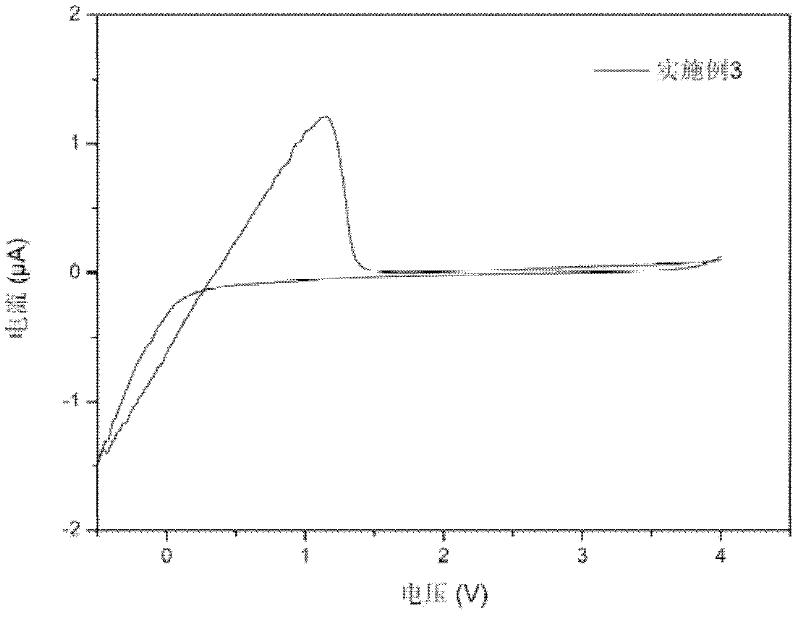

Gel-type polymer electrolyte and preparation method thereof

The invention relates to a gel-type polymer electrolyte and a preparation method thereof. The gel-type polymer electrolyte membrane is prepared by using amine terminated nitrile rubber as a matrix of the solid electrolyte, dissolving the matrix, lithium salt, epoxidized polysilsesquioxane, and 1-butyl-3-methylimidazolium trifluoro methane sulfonate in an organic solvent, pouring the solvent on a teflon template, and carrying out heat treatment in a baking oven after volatilizing tetrahydrofuran. Compared with the prior art, the operation is simple; the membrane forming is easy; and the prepared membrane is smooth and uniform, has good mechanical properties, high room-temperature conductivity, and stable electrochemical window, and the prepared membrane used as solid electrolyte materials for the lithium ion battery has an application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Water-washable silk composite fiber and preparation method thereof

InactiveCN104213247AUV resistantAntistaticConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolyesterFiber

Disclosed water-washable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 18-22 parts of silk, 11-13 parts of wool, 4-7 parts of cuprammonium rayon, 6-8 parts of polyester fiber, 8-10 parts of newdal fiber, 10-12 parts of bast fiber, 0.6-1.1 parts of nanometer TiO2, 6-9 parts of aloe viscose fiber, 0.7-0.9 parts of hydroxypropyl methyl cellulose, 0.8-1.4 parts of polypropylenglycol diglycidyl ether, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-3 parts of radix aucklandiae, 2-4 parts of cortex moutan, 3-5 parts of an auxiliary agent, and proper amount of water. By adding cuprammonium rayon and nanometer TiO2, the silk composite fiber has performances of resisting ultraviolet, resisting static electricity, resisting water washing and the like; and additionally by adding aloe viscose fiber, the Chinese herbal medicines and other compositions, the prepared silk composite fiber has the characteristics of resisting bacteria, diminishing inflammation, light and soft texture, excellent air permeability, high strength and high elasticity, and thus the silk composite fiber is repeatedly cleanable and keeps comfortableness, and is not flat or sunk after being used for a long time.

Owner:TONGCHENG SHUANGLONG SILK

Method for electrodepositing metal lanthanum in ionic liquid

The invention provides a method for electrodepositing metal lanthanum in an ionic liquid, relates to a method for electrodepositing metal lanthanum, and is used for solving the problem that a single metal lanthanum deposition layer can not be obtained in the ionic liquid 1-butyl-3-methylimidazolium trifluoro-methanesulfonate currently. The method comprises the following steps: adding anhydrous lanthanum chloride in the ionic liquid 1-methyl-3-ethyllimidazolium di(trifluoromethylsulfonyl)imine and evenly mixing, so as to obtain an electroplating liquid; and electroplating by using a constant current mode based on pretreated copper sheet as a cathode and platinum, graphite or titanium-based oxide as an anode, so as to obtain metal lanthanum deposited on the surface of a substrate. According to the invention, a La plated layer prepared by adopting an electrodeposition method is smooth and even, and the plating liquid components are simple and easy to control. In the invention, electrodeposited metal lanthanum can be applied to the field of functional material preparation.

Owner:HARBIN INST OF TECH

A method for increasing the strength of carbon fiber

A method for improving the strength of carbon fibers, which uses an electrostatic spraying method to coat carbon nanotubes on the surface of carbon fibers to make up for their surface structural defects, comprising: preparing a dispersion liquid for carbon nanotubes into a spraying liquid, and the dispersion liquid is a mixture of ionic liquid and water , the ionic liquid is taken from 1,3-dimethylimidazole-p-toluenesulfonate, 1-butyl-3-methylimidazole-p-toluenesulfonate, 1-octyl-3-methylimidazole chloride or 5- One of bromo-2-methyl-3-nitropyridine; the spray liquid is applied with 10-40kV positive static electricity, and the carbon fiber tow is flat and grounded to form a spray liquid receiver; the spray liquid is sprayed on the surface of the carbon fiber by electrostatic spraying, Based on the weight ratio of carbon fibers to carbon nanotubes, the spraying amount is controlled to be 1000:(0.5-10). The invention has the advantages of simple process, low cost, high efficiency, good repairing effect of carbon fiber surface structural defects and the like, and is easy to realize industrial application.

Owner:CHINA PETROLEUM & CHEM CORP

Method for raising dyeing performance of linen through modification by use of 1-butyl-3-methylimidazolium chloride ionic liquid

According to the invention, bast-fibre or fabric is used as a raw material and can be modified by the use of a 1-butyl-3-methylimidazolium chloride ionic liquid ([Bmim]Cl) to substantially raise the dyeing performance of direct dyestuff or reactive dye on linen. The advantage of the invention lies in that 1-butyl-3-methylimidazolium chloride ionic liquid ([Bmim]Cl) is a high-efficiency cellulose swelling agent and has a simple treatment process. In addition, it is safe and nontoxic when processing by the use of the ionic liquid, and the ionic liquid can be recovered and utilized after the treatment, so as to reduce discharge of a large amount of high-density alkali waste liquid after traditional treatment. The dyeing performance of the modified bast-fibre or fabric, such as ramie, flax and hemp can be raised. High dye uptake can be also reached even without the addition of salt, which helps minimize the amount of salt during the dyeing process and reduce the dyeing cost.

Owner:JIANGNAN UNIV

Moisture-absorbing air-permeable silk composite fiber and preparation method thereof

InactiveCN104213248AAntibacterialWith deodorizing adsorptionConjugated cellulose/protein artificial filamentsArtifical filament manufacturePyrophosphatePolyphenol

Disclosed moisture-absorbing air-permeable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-19 parts of silk, 13-15 parts of camel hair, 7-9 parts of coral fleece, 10-12 parts of ramie fiber, 8-11 parts of PTT short fiber, 5-7 parts of soybean fiber, 2.3-4.7 parts of milk protein fiber, 0.4-0.8 parts of tea polyphenol, 1.2-3.2 parts of plastic starch, 0.3-0.6 parts of sodium pyrophosphate, 1.2-2.4 parts of cocounut oil essence, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-2 parts of frankincense, 0.5-0.9 parts of sediment of human urine, 0.6-0.8 part of flos lonicerae, 2-4 parts of an auxiliary agent, and proper amount of water. By adding ramie fiber, the silk composite fiber has functions of resisting bacteria, inhibiting bacteria, eliminating and adsorbing odor, absorbing moisture and breathing, and the like, and by adding tea polyphenol, the improved silk composite fiber also has effects of resisting radiation, being smooth and light, keeping warm and resisting static electricity.

Owner:TONGCHENG SHUANGLONG SILK

Method for leaching metallic copper from waste printed circuit board by using ionic liquid

The invention discloses a method for leaching metallic copper from a waste printed circuit board by using ionic liquid. The method comprises the following steps of: cutting the waste printed circuit board into pieces; crushing by using a universal pulverizer; screening; baking a selected sample of which the grain size is 0.25-0.5mm; weighing the sample in a conical flask; adding 30 percent of hydrogen peroxide; then, adding ionic liquid 1-butyl-3-methylimidazolium hydrogen sulfate aqueous solution of which the concentration is 10-80 percent to enable solid-to-liquid ratio to be 1g:(7-55mL), wherein the volume ratio of the hydrogen peroxide to the ionic liquid 1-butyl-3-methylimidazolium hydrogen sulfate aqueous solution is 1:(1.5-6); capping a thermostatic waterbath vibration tank of 20-80 DEG C and leaching for 1-24 hours, wherein the vibration frequency is 50-250 turns per minute; performing suction filtration on obtained lixivium, washing, enabling volume to be constant, and measuring copper content. According to the method for leaching the metallic copper from the waste printed circuit board by using the ionic liquid, the copper in the waste printed circuit board is leached by using the ionic liquid 1-butyl-3-methylimidazolium hydrogen sulfate aqueous solution is used as a leaching agent, wherein the copper content reaches 90-95 percent.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of cellulose based conductive hydrogel

InactiveCN106519287AUniform network structureStable network structureBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a preparation method of a cellulose based conductive hydrogel. The preparation method comprises the following steps: (1) dissolving microcrystalline cellulose (MCC) with 1-Butyl-3-methylimidazolium chloride, reacting in a N2 protective atmosphere, and adding N,N-methylenebisacrylamide and benzoyl peroxide to prepare a pure microcrystalline cellulose hydrogel; and (2) soaking the pure microcrystalline cellulose hydrogel obtained in the step (1) in a mixed solution of FeCl3 and sodium p-benzenesulfonate, and immersing in a pyrrole water solution to prepare the cellulose based conductive hydrogel. The cellulose based conductive hydrogel prepared by the method has the advantages of uniform stable network structure, excellent conductivity, swelling property and heat stability, favorable electric conductivity and favorable swelling property; and the equilibrium swelling rate can be up to about 500%.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

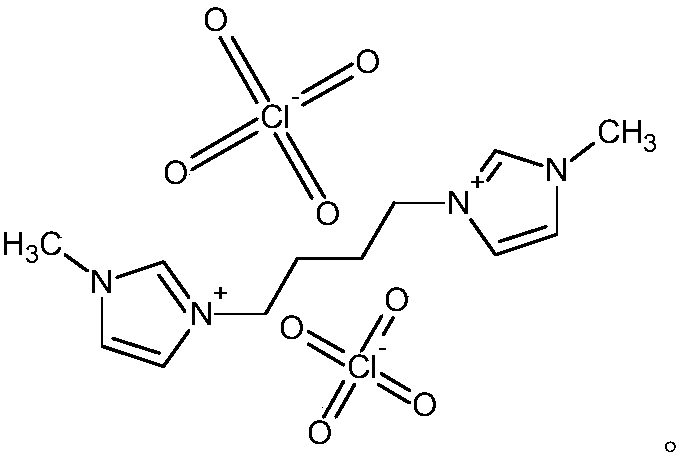

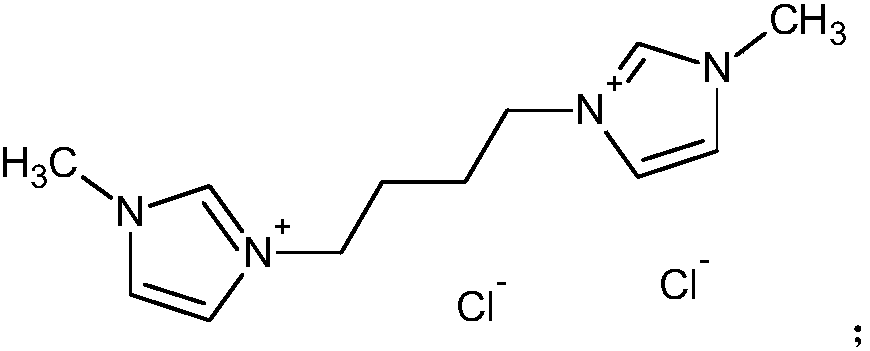

Preparation method of antibacterial cellulose fibers

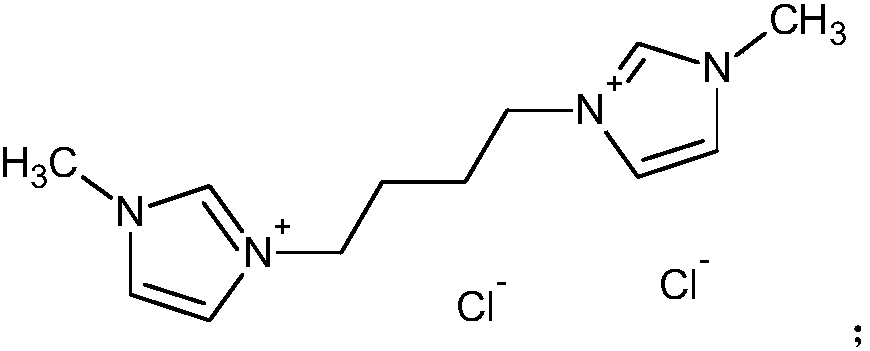

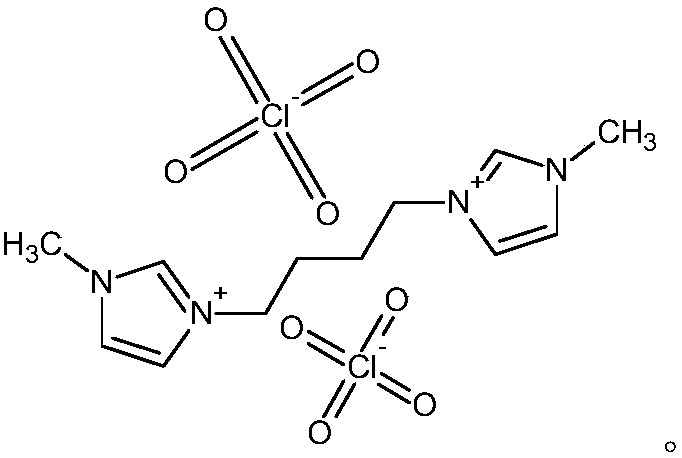

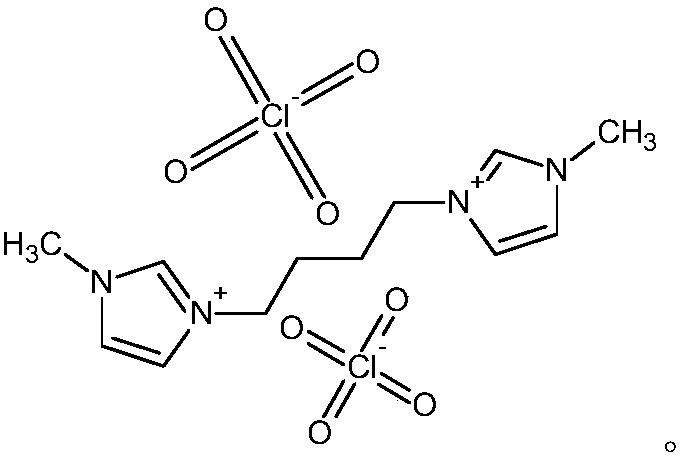

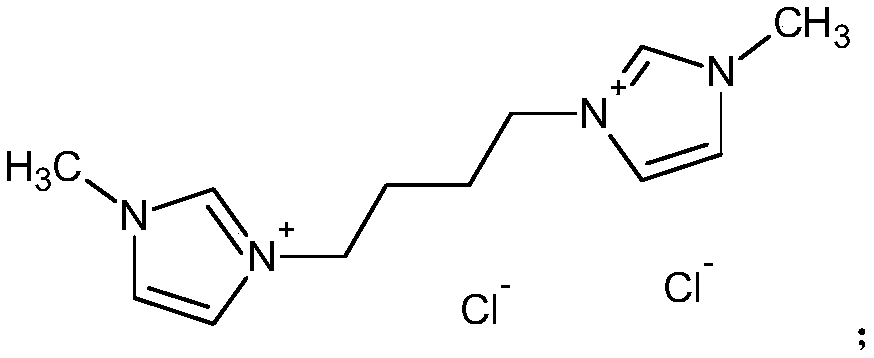

ActiveCN109183169ALow viscosityImprove mechanical propertiesMonocomponent cellulose artificial filamentSpinning solutions preparationPerchlorateCellulose fiber

The invention discloses a preparation method of antibacterial cellulose fibers. The preparation method comprises the following steps: a) after mixing a dispersant, an antibacterial agent and cellulose, dissolving a mixture in an ionic liquid water solution to prepare a mixed spinning raw solution, wherein the adding amount of the antibacterial agent is 0.1 to 1 weight percent of the cellulose; andb) filtering the mixed spinning raw solution, spinning, condensing, stretching, washing with water, bleaching, applying oil and drying to obtain the antibacterial cellulose fibers. The ionic liquid is obtained by mixing 1-butyl-3-methylimidazolium chloride, bi1,4-di[1-(3-methylimidazolium)]butyl dichloride and bi1,4-di[1-(3-methylimidazolium)]butyl diperchlorate. An experiment shows that the antibacterial cellulose fibers prepared by the invention have excellent mechanical property, antibacterial property and stability property; and a preparation process is simple, is low in cost, is environmentally friendly and has no pollution.

Owner:龙丝(上海)新材料科技有限公司

Preparation method of flame-retardant cellulose fiber

ActiveCN109208103ALow viscosityImprove mechanical propertiesArtificial filaments from cellulose solutionsFlame-proof filament manufactureOrganic solventPerchlorate

The invention discloses a preparation method of a flame-retardant cellulosic fiber. The preparation method comprises the following steps: a) mixing a flame retardant and cellulose to obtain a mixture,and then dissolving the mixture in an aqueous solution of an ionic liquid to prepare a mixed spinning stock solution; b) filtering the stock solution of the step a), performing spinning, solidification, stretching, water washing, bleaching, oiling and drying to obtain the flame-retardant cellulose fiber; wherein the ionic liquid is prepared by mixing 1-butyl-3-methylimidazolium chloride, bi-1,4-bis [1-(3-methylimidazolyl)] butyl dichloride and bi-1,4-bis[1-(3-methylimidazolyl) butyl diperchlorate. Experiments show that the flame-retardant cellulosic fiber prepared by the method has excellentmechanical properties, flame retardancy and stability, simple preparation process and low cost, does not need any organic solvent, is environment-friendly and pollution-free, does not need special equipment and harsh conditions, is easy to realize industrial production and has extremely high practical value.

Owner:龙丝(上海)新材料科技有限公司

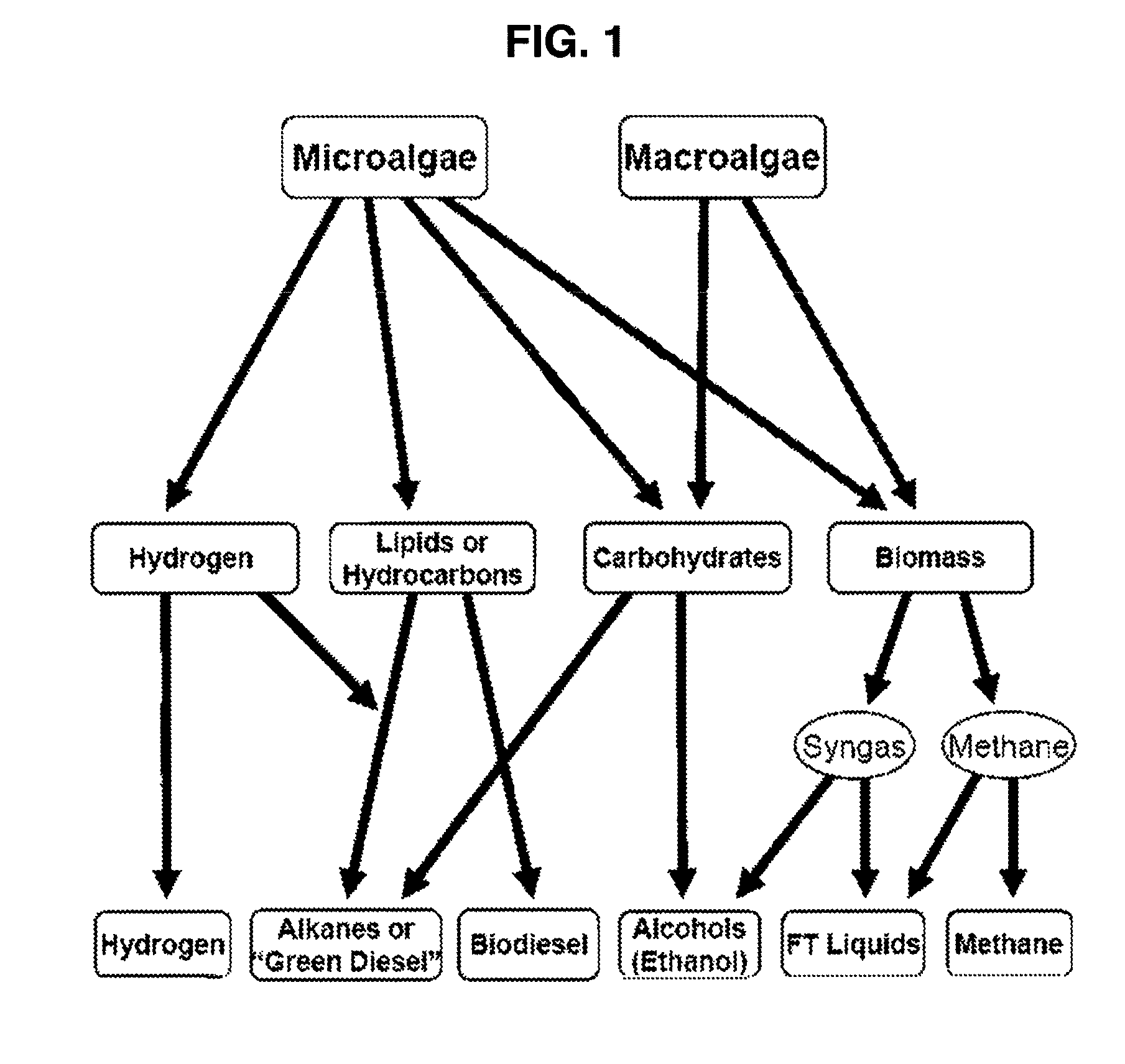

Lipid extraction from microalgae using a single ionic liquid

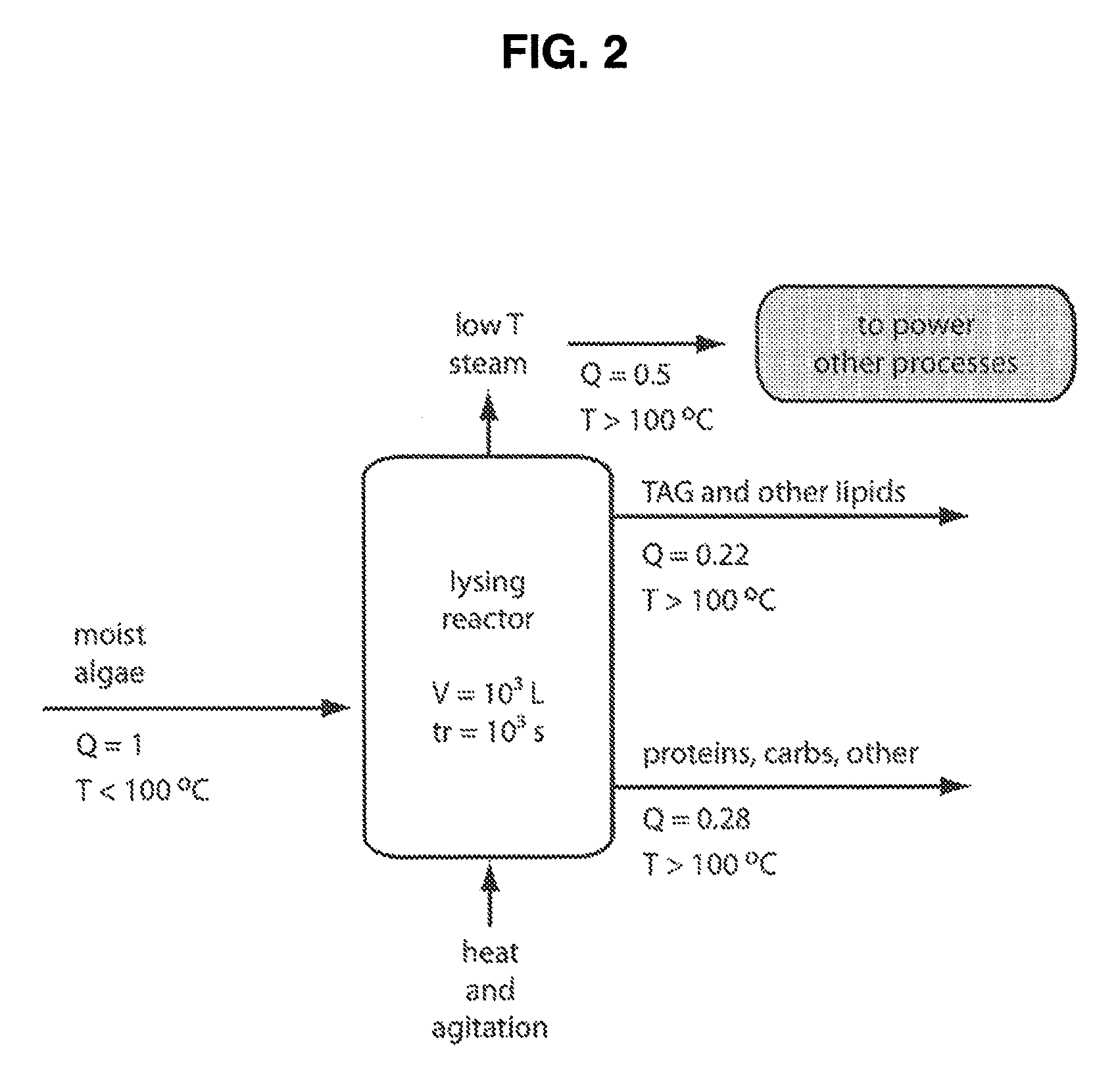

InactiveUS8450111B2Easy to recycleMaterial efficiencyUnicellular algaeBiomass after-treatmentCellular lipidLysis

A one-step process for the lysis of microalgae cell walls and separation of the cellular lipids for use in biofuel production by utilizing a hydrophilic ionic liquid, 1-butyl-3-methylimidazolium. The hydrophilic ionic liquid both lyses the microalgae cell walls and forms two immiscible layers, one of which consists of the lipid contents of the lysed cells. After mixture of the hydrophilic ionic liquid with a suspension of microalgae cells, gravity causes a hydrophobic lipid phase to move to a top phase where it is removed from the mixture and purified. The hydrophilic ionic liquid is recycled to lyse new microalgae suspensions.

Owner:STREAMLINE AUTOMATION LLC

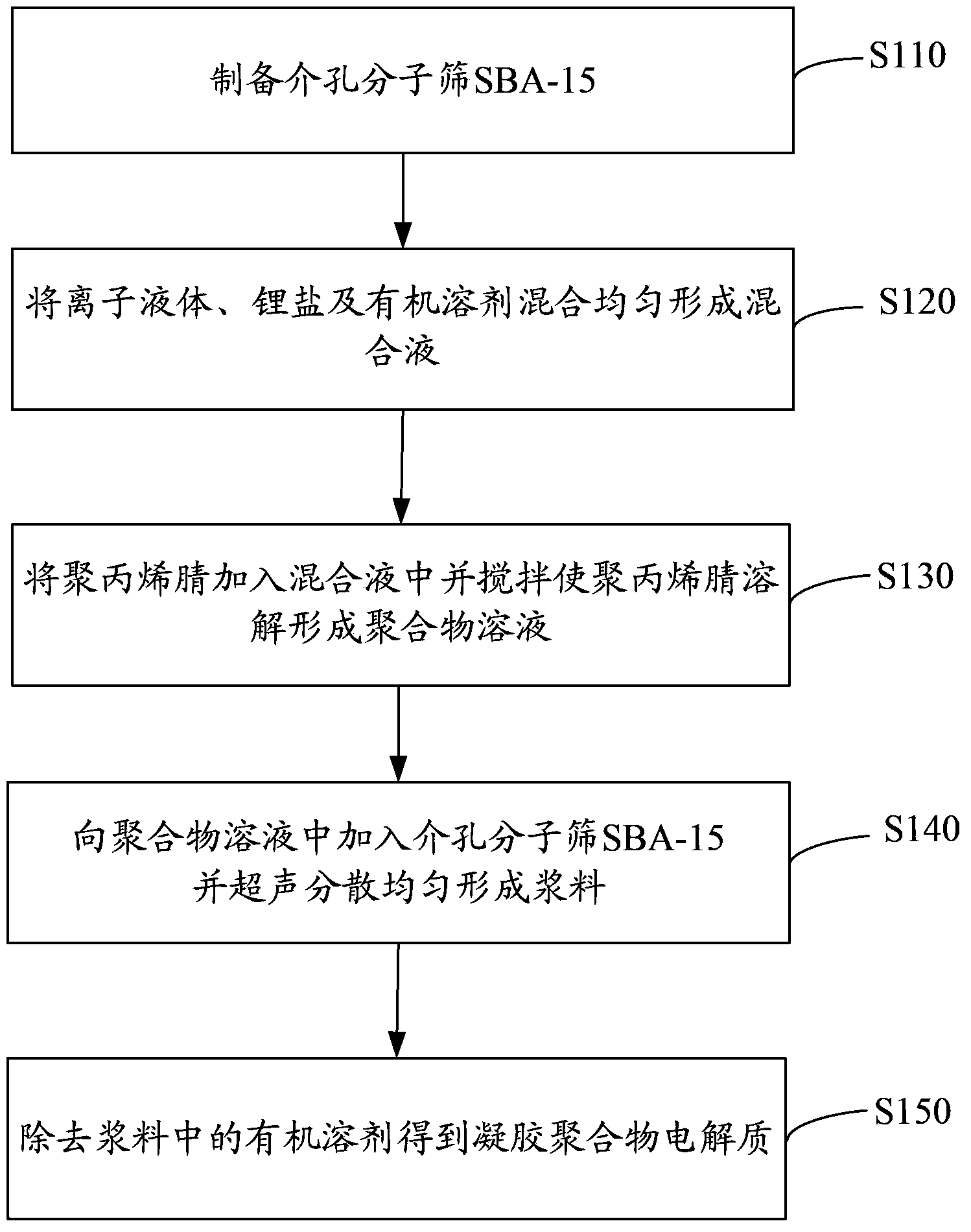

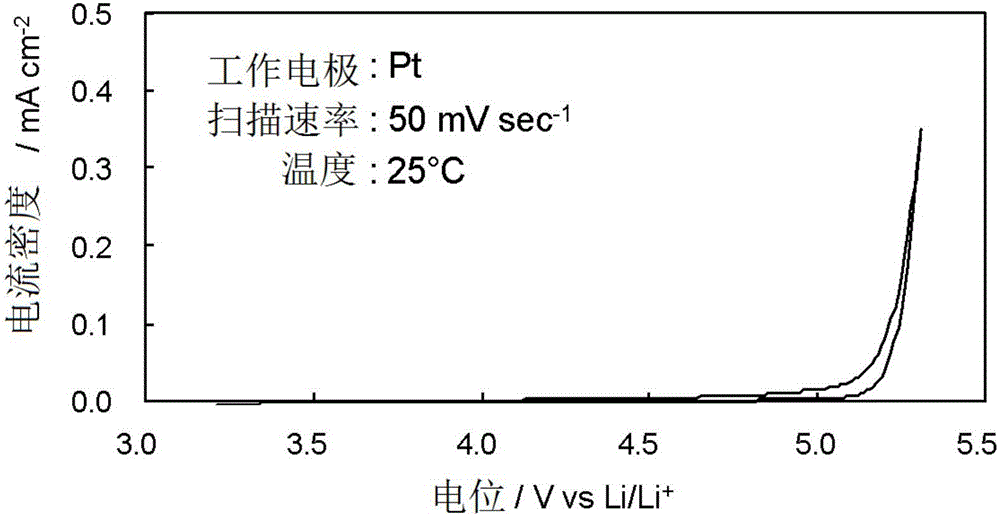

Gel polymer electrolyte and preparation method thereof

InactiveCN103579671AElectrolyte accumulators manufactureElectrolyte immobilisation/gelificationTriflic acid1-Butyl-3-methylimidazolium hexafluorophosphate

A gel polymer electrolyte comprises polyacrylonitrile, an ionic liquid, a lithium salt and mesoporous molecular sieve SBA-15; the ionic liquid is at least one selected from 1-butyl-3-methylimidazolium tetrafluoroborate, 1-butyl-3-methylimidazolium hexafluorophosphate, 1-butyl-3-methylimidazolium trifluoromethanesulfonate and 1-butyl-3-methylimidazolium bis[(trifluoromethyl)sulfonyl]imide; the lithium slat is at least one selected from lithium tetrafluoroborate, lithium hexafluorophosphate, lithium trifluoromethanesulfonate and lithium bis(trifluoromethanesulfonyl)imide; polyacrylonitrile is the base material, the lithium salt, the ionic liquid and mesoporous molecular sieve SBA-15 are dissolved in polyacrylonitrile; and the mass ratio of polyacrylonitrile, the ionic liquid, the lithium salt and mesoporous molecular sieve SBA-15 is 1:(0.8-1.5):(0.1-0.3):(0.04-0.08). The gel polymer electrolyte is relatively high in electrical conductivity. The invention also provides a preparation method of the gel polymer electrolyte.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Ionic liquid and plastic crystal

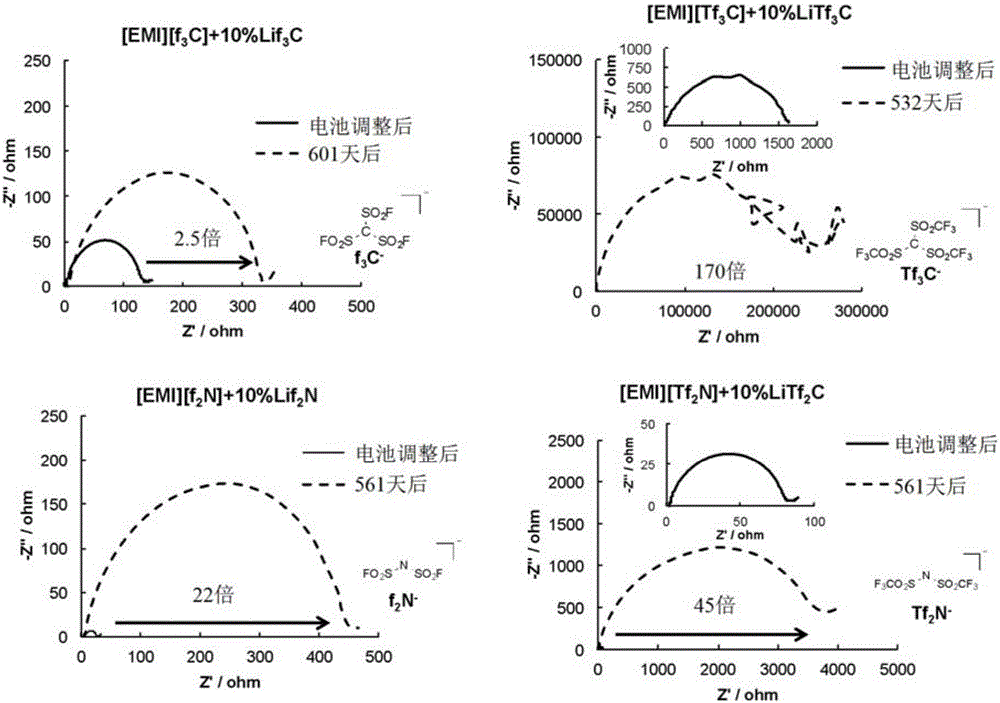

ActiveCN106715389AInhibit the need for coolingGood storage efficiencyOrganic chemistryNegative electrodes1-hexyl-3-methylimidazoliumPlastic crystal

The present invention provides an ionic liquid or plastic crystal comprising anions and cations, said anions including [C(SO2F)3]- and said cations including at least one type selected from the group consisting of 1-ethyl-3-methylimidazolium ([EMI]+), N,N-diethyl-N-methyl-(2-methoxyethyl ) ammonium ([DEME]+), N-methyl-N-propylpyrrolidinium ([Py13]+), N-methyl-N-propylpiperidinium ([PP13]+), tetramethylammonium ([N1111]+), tetraethylammonium ([N2222]+), triimethyl hexyl ammonium ([N6111]+), triethylhexylammonium ([N6222]+), N-methyl-N-ethylpyrrolidinium ([Py12]+), 1-butyl-3-methylimidazolium ([C4mim]+), and 1-hexyl-3-methylimidazolium ([C6mim]+).

Owner:NAT INST OF ADVANCED IND SCI & TECH

Long-acting slow-release fragrant silk composite fiber and preparation method thereof

InactiveCN104213245AFresh and long-lasting fragranceFeel goodConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsStearic acidLemon juice

Disclosed long-acting slow-release fragrant silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-23 parts of silk, 5-8 parts of white eider, 8-10 parts of acrylic fiber, 4-7 parts of basalt fiber, 6-8 parts of pearl fiber, 9-12 parts of kendir fiber, 7-9 parts of aloe viscose fiber, 1.2-2.5 parts of matricaria chamomilla extraction liquid, 1.1-2.3 parts of lemon juice, 0.4-0.7 parts of zinc acetate, 1-2 parts of talcum powder, 0.7-0.9 parts of stearic acid, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 105-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 2-4 parts of wild chrysanthemum flower, 1-3 parts of scutellaria baicalensis, 3-5 parts of an auxiliary agent, and proper amount of water. The original taste of conventional silk is changed, and the prepared silk composite fiber has the characteristics of durable refreshing fragrance, resistance to worm damaging, good handfeel, high elasticity and the like, gives people refreshing feeling and does not generate yellowing phenomenon.

Owner:TONGCHENG SHUANGLONG SILK

Preparation method for cellulose graphene composite filament yarn

ActiveCN109267164AImprove conductivityImprove antistatic performanceElectroconductive/antistatic filament manufactureArtificial filaments from cellulose solutionsCelluloseFiltration

Owner:龙丝(上海)新材料科技有限公司

Ionic liquid and plastic crystal

InactiveUS20170256820A1Suppress needLow viscosityOrganic chemistryNegative electrodes1-hexyl-3-methylimidazoliumPlastic crystal

The present invention provides an ionic liquid or plastic crystal comprising an anion and a cation, the anion comprising [C(SO2F)3]−, and the cation comprising at least one member selected from the group consisting of 1-ethyl-3-methylimidazolium ([EMI]+), N,N-diethyl-N-methyl-(2-methoxyethyl)ammonium ([DEME]+), N-methyl-N-propylpyrrolidinium ([Py13]+), N-methyl-N-propylpiperidinium ([PP13]+), tetramethylammonium ([N1111]+), tetraethylammonium ([N2222]+), trimethylhexylammonium ([N6111]+), triethylhexylammonium ([N6222]+), N-methyl-ethylpyrrolidinium ([Py12]+), 1-butyl-3-methylimidazolium ([C4mim]+), and 1-hexyl-3-methylimidazolium ([C6mim]+).

Owner:NAT INST OF ADVANCED IND SCI & TECH

Down feather composite fibers with jasmine fragrance and preparation method thereof

InactiveCN104294399AAnti-staticAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberNicotiana langsdorffii

The invention discloses down feather composite fibers with a jasmine fragrance, and is characterized in that the down feather composite fibers comprise the following raw materials in parts by weight: 13-16 parts of goose down, 16-21 parts of ox hair, 8-10 parts of glass fibers, 5-8 parts of polynosic, 3-6 parts of conductive fibers, 3-6 parts of jasmine, 1-3 parts of fructus toosendan, 2-4 parts of radix paeoniae rubra, 6-9 parts of mineral wool fibers, 18-22 parts of tobacco straws, 1.2-3.1 parts of triethyl acetyl citrate, 2.1-3.2 parts of propyl acetate, 0.2-0.5 parts of triethyl citrate, 0.6-1.4 parts of a nano pearl powder, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 3-5 parts of an auxiliary agent, and a proper amount of water. With addition of jasmine, fructus toosendan, radix paeoniae rubra and other components, the down feather composite fibers not only have the jasmine fragrance, but also can effectively remove dirt on the feather composite fibers, and have better conditioning and nursing effects on down feather; and the prepared down feather composite fibers have the advantages of static electricity resistance, large elasticity, good filling power, bacteria resistance, bacteriostasis, wash durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

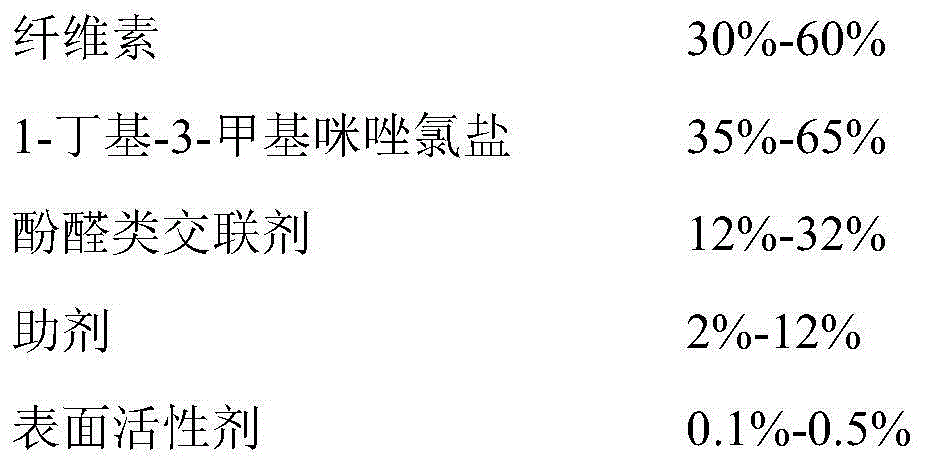

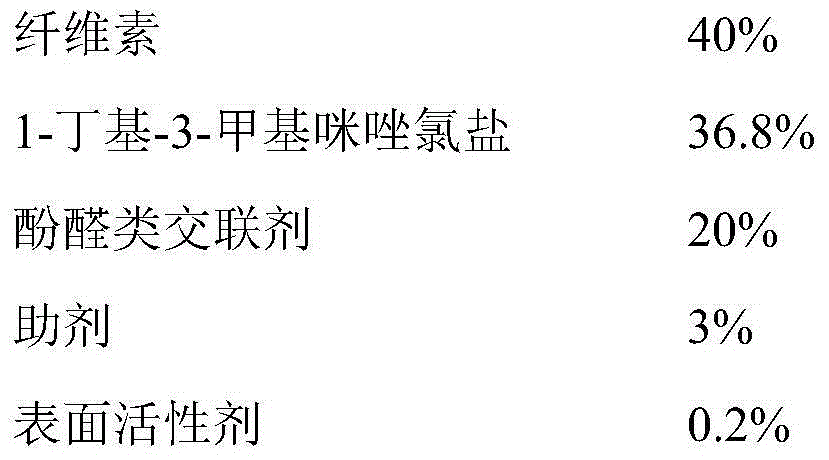

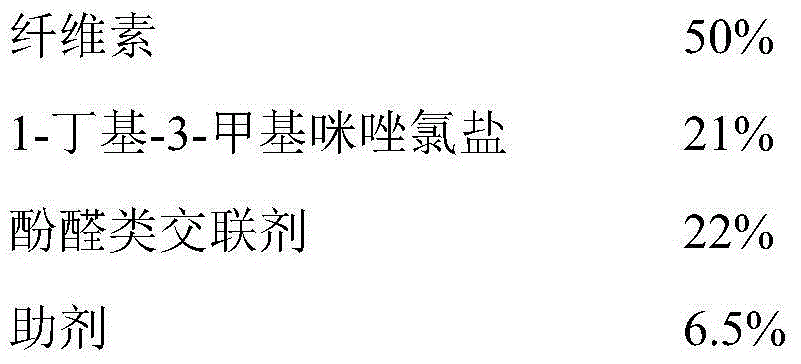

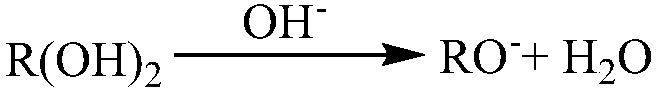

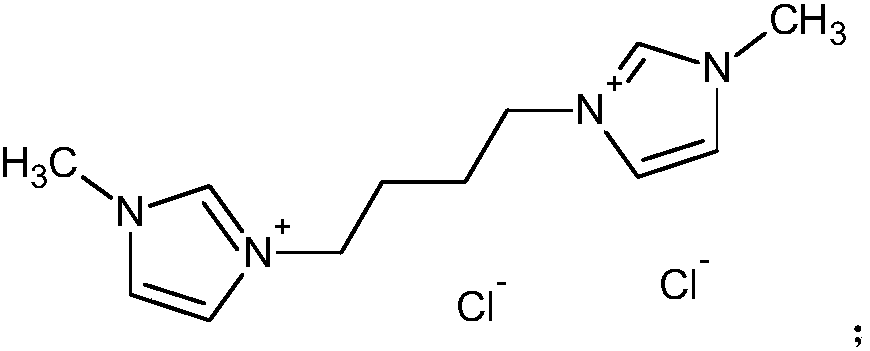

Compound cellulose indepth water shutoff modifying and flooding agent for oil production and preparation method thereof

InactiveCN104449616AReduce harmShorten crosslinking timeDrilling compositionCelluloseSurface-active agents

The invention provides a compound cellulose indepth water shutoff modifying and flooding agent for oil production and a preparation method of the compound cellulose indepth water shutoff modifying and flooding agent. The preparation method is characterized in that compound cellulose serves as the raw material for preparing a compound gel type indepth water shutoff profile control agent; the field application result shows that a product synthesized by the agent has the characteristics of causing little damage, being temperature resistant and delaying crosslinking time; the product can be automatically repaired after being broken during percolation, so that injected water can be greatly prevented from flowing all around between pre-crosslinked particles, and as a result, the temperature resisting and salt resisting effects are realized; compound cellulose indepth water shutoff modifying and flooding agent for oil production is prepared from the components of cellulose, 1-butyl-3-methylimidazolium, a phenolic aldehyde crosslinking agent, additives and a surface active agent.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

High-elasticity conductive fiber and preparation method thereof

ActiveCN102953137BEvenly arrangedEvenly dispersedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberCarbon nanotube

The invention discloses high-elasticity conductive fiber comprising the raw materials of: carbon nano-tubes, ionic liquid, and a high-elasticity polymer. A weight ratio of the carbon nano-tubes to the high-elasticity polymer is 1:8-20, and a weight ratio of the carbon nano-tubes to the ionic liquid is 4-6:1, wherein the ionic liquid is a salt of 1-butyl-3-methylimidazole selected from 1-butyl-3-methylimidazole trifluoromethanesulfonate, 1-butyl-3-methylimidazolium bis[(trifluoromethyl)sulfonyl]imide, and 1-butyle-3-methylimidazolium hexafluorophosphate or mixture thereof. The invention also discloses a preparation method of the high-elasticity conductive fiber. The high-elasticity conductive fiber provided by the invention has both the high conductivity of carbon nano-tubes, and the mechanical properties of polymer fiber. Also, the high-elasticity conductive fiber can be uniaxially stretched by 100% with no substantial change in electrical properties.

Owner:THE HONG KONG POLYTECHNIC UNIV

Silk composite fiber with anticancer function and preparation method thereof

InactiveCN104213246AInhibition of divisionPrevent proliferationConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberYarn

Disclosed silk composite fiber with the anticancer function is characterized by being prepared from the following raw materials in parts by weight: 17-21 parts of tussah silk, 10-13 parts of waste eider down, 7-9 parts of cashmere fiber, 11-13 parts of rose fiber, 8-10 parts of alga fiber, 5-8 parts of taxus chinensis fiber, 4-7 parts of far-infrared ceramic fiber, 5.3-6.8 parts of nylon yarn fiber, 20-30 parts of rice washing water, 2-4 parts of dimethyl siloxane, 0.2-0.4 part of soda ash, 3-5 parts of acetyl tributyl citrate, 1.2-3.5 parts of kaolin, 95-105 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 100-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, and 3-6 parts of an auxiliary agent. By adding taxus chinensis fiber, once the inside-contained paclitaxel smell forms microcirculation in human body capillary micropores, cancer cell division is effectively inhibiting and cance cell propagation is prevented. Additionally, a plurality of other beneficial compositions are added, and the prepared silk composite fiber is rich in elasticity, bulkiness and flexibility, and the added Chinese herbal medicines are pleasant in smell, are capable of promoting sleep and are free of toxic and side effects.

Owner:TONGCHENG SHUANGLONG SILK

Antibiotic and healthy composite down wadding and preparation method thereof

InactiveCN105970348AGood warmth retentionHigh strengthFibre treatmentConjugated cellulose/protein artificial filamentsPOMEGRANATE SEED OILPolyester

The invention discloses antibiotic and healthy composite down wadding and a preparation method thereof. The antibiotic and healthy composite down wadding is prepared from the following raw materials in parts by weight: 17-23 parts of white duck down, 5-8 parts of bamboo pulp fibers, 6-9 parts of polyester fibers, 4-7 parts of chitin, 0.3-0.7 part of tea saponin, 4.1-5.8 parts of a carbon nano-tube, 2-4 parts of vermiculite, 0.4-0.7 part of zinc nitrate, 3.2-4.6 parts of methyltrimethoxy silane, 16-20 parts of chlorinated 1-butyl-3-methylimidazolium, 0.05-0.1 part of pomegranate seed oil, 0.05-0.1 part of thyme oil, 0.02-0.04 part of garlic oil, 0.02-0.04 part of ginger oil, 0.02-0.04 part of sodium cocoyl glycinate and 0.1-0.2 part of isopropyl myristate. The composite down wadding is good in heat retention property, strength, flexibility and weather resistance, and moderate in compressibility, air permeability and moisture permeability, also has the efficacies of bacterium resistance, disinfection and ageing resistance and is good in processability and using performance.

Owner:ANHUI LION GOOSE PROD

Preparation method of salicylic acid molecular imprinted cellulose acetate blended membrane and application of blended membrane

InactiveCN104741009AAvoid the problem of insufficient blocking forceInhibit sheddingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCellulose acetatePolyethylene glycol

The invention relates to a preparation method of a cellulose acetate blended membrane and in particular relates to a preparation method of a salicylic acid molecular imprinted cellulose acetate blended membrane and application of the blended membrane to removal of salicylic acid in an aqueous solution. According to the preparation method, cellulose acetate (CA) is used as matrix, sulfonated polysulfone (SPS) is used as a functional polymer, polyethylene glycol-4000 (PEG 4000) or ionic liquid 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) is used as an additive, the imprinted blended membrane having the specific recognition property to salicylic acid molecules is synthesized, is used for performing selective recognition and separation on the salicylic acid in the aqueous solution, and has relatively high adsorbability and selectivity on the salicylic acid molecules.

Owner:JIANGSU UNIV

Method for synthesizing decynediol ethoxylate

ActiveCN108517031APolymerization reaction conditions are mildIncrease reaction rateBulk chemical productionPhosphateEther

The invention discloses a method for synthesizing decynediol ethoxylate. 2,4,7,9-tetramethyl-5 decyne-4,7-diol and ethylene oxide are used as raw materials, ethoxylated decynediol is synthesized through polymerization, acidic ionic liquid 1-butyl-3-methylimidazolium phosphate dihydrogen salt is used as an acidic catalyst and solvent, one or more of the organic bases are used as basic catalysts forreaction, and a product and the catalysts are separated by using ether as an extracting agent to obtain ethoxylated 2,4,7,9-tetramethyl-5-decyne-4,7-diol. The acid-base catalysts have good protectioneffect on the triple bond of alkynol, the product has high product unsaturation, by-products are few and product chroma is low. The components of the whole process are easy to separate, the catalystsand solvent can be recycled, the production cost is low, the process is green and environmentally friendly, and the method can be used for industrial production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for preparing cellulose and graphene compound short fibers

ActiveCN109183170AImprove antistatic performanceImprove antibacterial propertiesElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentCelluloseFiber

The invention discloses a method for preparing cellulose and graphene compound short fibers. The method comprises the following steps: (a) mixing a dispersant, graphene oxide and cellulose, dissolvingin an ionic liquid aqueous solution to prepare a blend spinning solution, wherein the addition amount of the graphene oxide is 0.1-0.3 percent by weight of the cellulose; and (b) filtering, spinning,solidifying, stretching, rinsing, bleaching, oiling, cutting and drying the blend spinning solution to obtain the cellulose and graphene compound short fibers, wherein the ionic liquid is prepared bymixing 1-butyl-3-methylimidazolium chloride, bi-1,4-bis[1-(3-methylimidazole)] butyldichloride and bi-1,4-bis[1-(3-methylimidazole)] butyl diperchlorate. Experiments indicate that the cellulose and graphene compound short fibers have excellent mechanical performance, anti-electrostatic performance and stable performance, and are simple in preparation process, low in cost, environment-friendly andpollution-free.

Owner:龙丝(上海)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com