Graphene-containing ionic liquid nanometer composite lubricating membrane

An ionic liquid, nanocomposite technology, applied in lubricating compositions, petroleum industry, additives, etc., to solve lubrication problems and achieve the effect of excellent micro/nano tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of graphene:

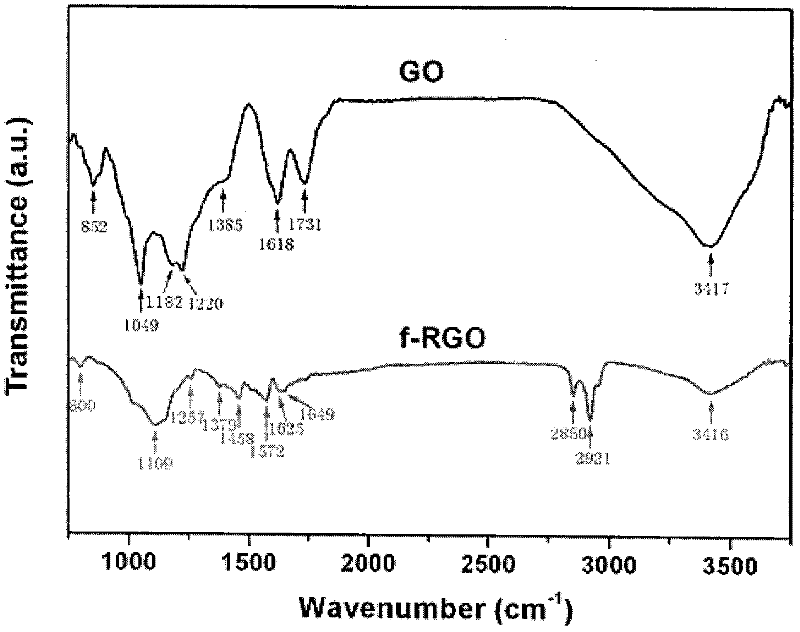

[0030] Prepare 25 mL of 1 mg·mL by ultrasonic dispersion -1 Graphene oxide deionized water dispersion, and then prepare 25mL of 10mg·mL -1 [BMIM][BF 4 ] deionized aqueous solution, the graphene oxide deionized water dispersion and [BMIM][BF 4 ] The deionized aqueous solution is fully mixed under the action of ultrasonic dispersion. Then 17mL of 85wt% hydrazine hydrate was added to the deionized water mixed solution, and stirred and reacted in a 95°C water bath for 2 hours. After the reaction, the solution was naturally cooled to room temperature, washed repeatedly with deionized water, filtered, and then removed by centrifugation. Contains excess [BMIM][BF 4 ] of the supernatant, the graphene after centrifugation was dried at room temperature. Raman spectrum (attached figure 1 ) and infrared absorption spectrum (attached figure 2 ) demonstrated the successful preparation of functionalized graphene.

[0031] Preparation of graphene and...

Embodiment 2

[0036] The preparation of graphene is identical with embodiment 1.

[0037] Under the action of ultrasonic vibration, 5 mg of graphene prepared in Example 1 was dispersed in 50 mL of 2 mg·mL -1 [BMIM][PF 6 ] in acetone solution to obtain 0.1mg·mL -1 / 2mg·mL -1 Dispersions of graphene and ionic liquids in acetone.

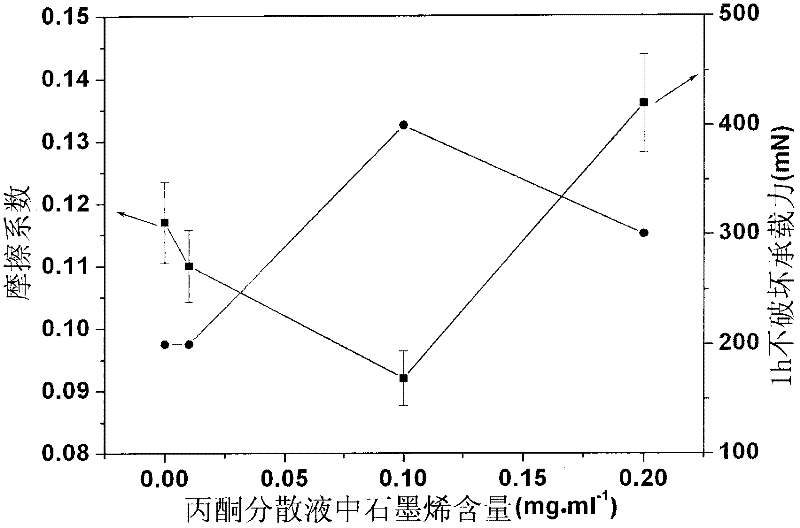

[0038] The preparation of the graphene-containing ionic liquid nanocomposite lubricating film was the same as in Example 1. Using the UMT-2MT micro-friction testing machine of the US CETR company under the experimental conditions of 100mN and 2Hz, the micro-friction coefficient when rubbing against a 3mmGCr15 steel ball is 0.09, and the bearing capacity without damage within 1h reaches 300mN (attached image 3 ).

Embodiment 3

[0040] The preparation of graphene is identical with embodiment 1.

[0041] Under the action of ultrasonic vibration, 5 mg of graphene prepared in Example 1 was dispersed in 25 mL of 2 mg·mL -1 [BMIM][PF 6 ] in acetone solution to obtain 0.2 mg·mL -1 / 2mg·mL -1 Dispersions of graphene and ionic liquids in acetone.

[0042] The preparation of the graphene-containing ionic liquid nanocomposite lubricating film was the same as in Example 1. Using the UMT-2MT micro-friction testing machine of the US CETR company under the experimental conditions of 100mN and 2Hz, the micro-friction coefficient when rubbing against a 3mmGCr15 steel ball is 0.136, and the bearing capacity without damage within 1h is 200mN (attached image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com