Silicon dioxide microsphere modified multi-scale hybrid carbon fiber and preparation method and application thereof

A technology of silica and nano-silica, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of harsh reaction conditions, influence of carbon fiber body strength, cumbersome process, etc., to increase electrostatic adsorption capacity and improve interface Effects of combined strength and interfacial toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

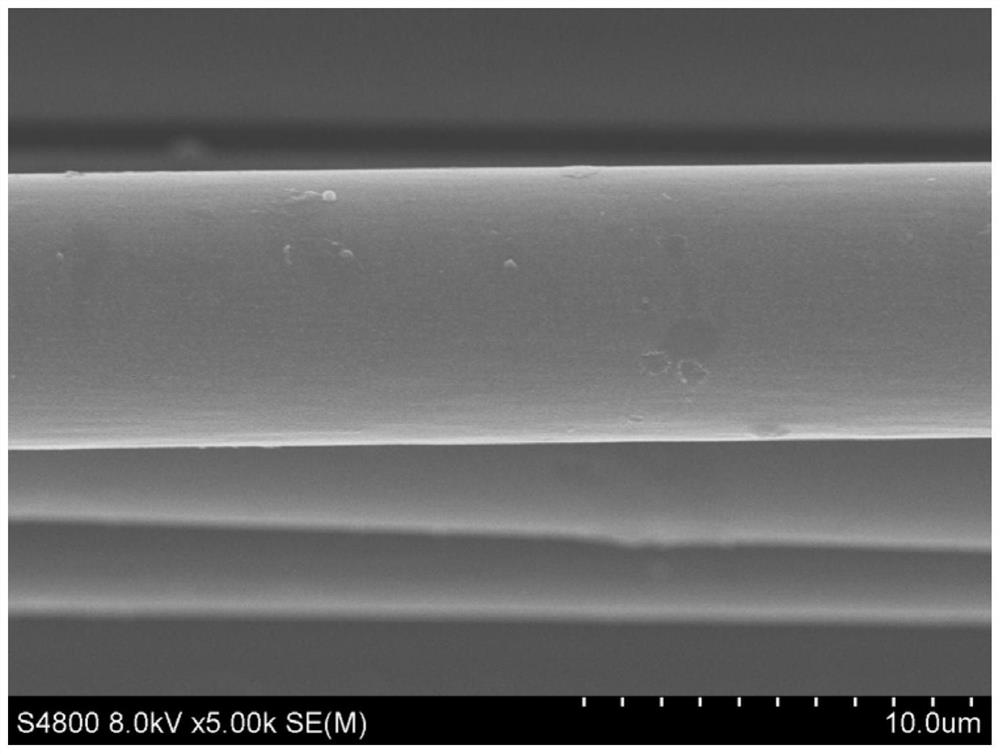

[0053] (1) Carbon fiber surface oxidation treatment: After removing the sizing agent on the surface of the commercially available carbon fiber with acetone, it was oxidized with concentrated nitric acid for 2 hours, washed with deionized water, and then vacuum-dried to obtain surface oxidized carbon fiber (CFO);

[0054](2) Preparation of phosphazene-modified carbon fiber: add 15g of hexachlorocyclotriphosphazene (HCCP) into 2500mL of anhydrous acetonitrile, stir and dissolve; take a bundle of carbon oxide fiber (CFO) of about 30g and add it to the HCCP / acetonitrile solution, drop 100 mL of triethylamine was added, and the reaction was stirred at 50° C. for 2 h to obtain carbon fiber CFO-HCCP grafted with HCCP.

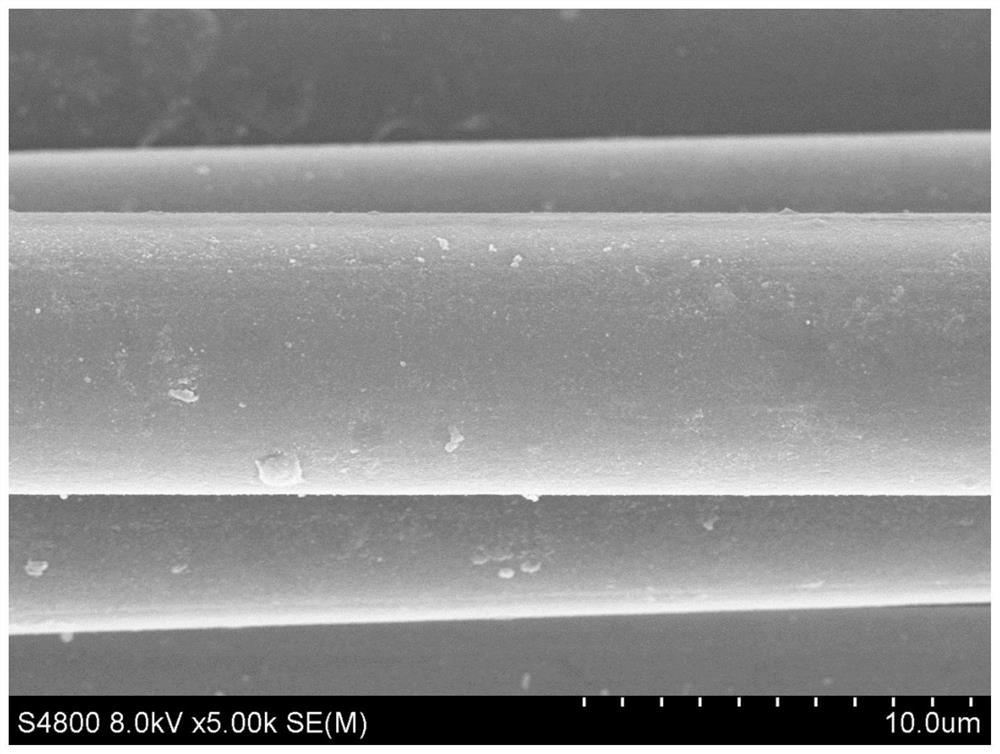

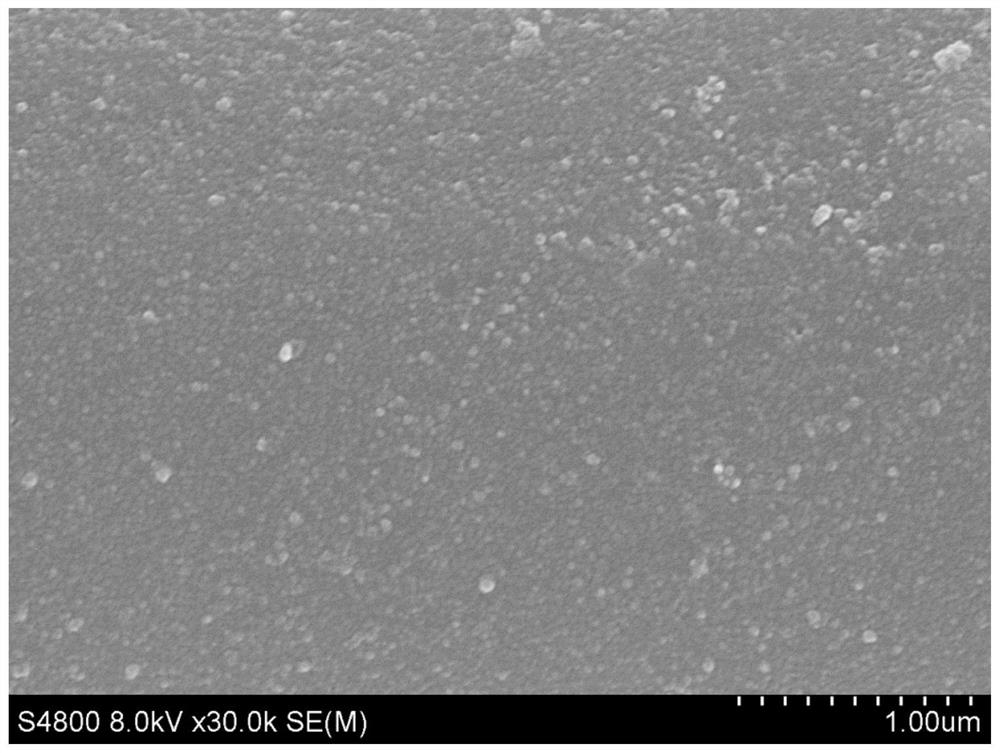

[0055] (3) Add 26.5g polyethyleneimine (1800g / mol) into the solution after the reaction in step (2), stir and dissolve, continue to react for 6h, take out the modified carbon fiber, wash 3 times with anhydrous acetonitrile to obtain polyphosphazene Coating modified ca...

Embodiment 2

[0062] (1) Carbon fiber surface oxidation treatment: After removing the sizing agent from the surface of the commercially available carbon fiber with acetone, it was oxidized with concentrated nitric acid for 1 hour, washed with deionized water, and then vacuum-dried to obtain surface oxidized carbon fiber (CFO);

[0063] (2) Preparation of phosphazene-modified carbon fiber: Add 10g of hexachlorocyclotriphosphazene (HCCP) into 2000mL of anhydrous acetonitrile, stir to dissolve; take about 20g of a bundle of carbon oxide fiber (CFO) into the HCCP / acetonitrile solution, drop 65 mL of triethylamine was added, and the reaction was stirred at 50° C. for 2 h to obtain carbon fiber CFO-HCCP grafted with HCCP.

[0064] (3) Add 17.6g polyethyleneimine (1800g / mol) into the solution after step (2) reaction, stir to dissolve, continue to react for 5h, take out the modified carbon fiber, wash 3 times with anhydrous acetonitrile to obtain polyphosphazene Coated modified carbon fiber.

[00...

Embodiment 3

[0071] (1) Carbon fiber surface oxidation treatment: After removing the sizing agent from the surface of the commercially available carbon fiber with acetone, it was oxidized with concentrated nitric acid for 1 hour, washed with deionized water, and then vacuum-dried to obtain surface oxidized carbon fiber (CFO);

[0072] (2) Preparation of phosphazene modified carbon fiber: add 15g of hexachlorocyclotriphosphazene (HCCP) into 3000mL of anhydrous acetonitrile, stir and dissolve; take a bundle of carbon oxide fiber (CFO) of about 20g into the HCCP / acetonitrile solution, drop 5 mL of triethylamine was added, and after stirring and reacting for 5 h at 50° C., the carbon fiber CFO-HCCP grafted with HCCP was obtained.

[0073] (3) Add 37.5g polyethyleneimine (600g / mol) into the solution after the reaction in step (2), stir and dissolve, continue to react for 8h, take out the modified carbon fiber, wash 3 times with anhydrous acetonitrile to obtain polyphosphazene Coated modified ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com