Medical mask and application thereof

A mask and bio-based technology, applied in the field of medical masks, can solve the problems of increasing the risk of bacterial and virus infection, accelerating static dissipation, and the lack of electrostatic adsorption capacity of medical masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

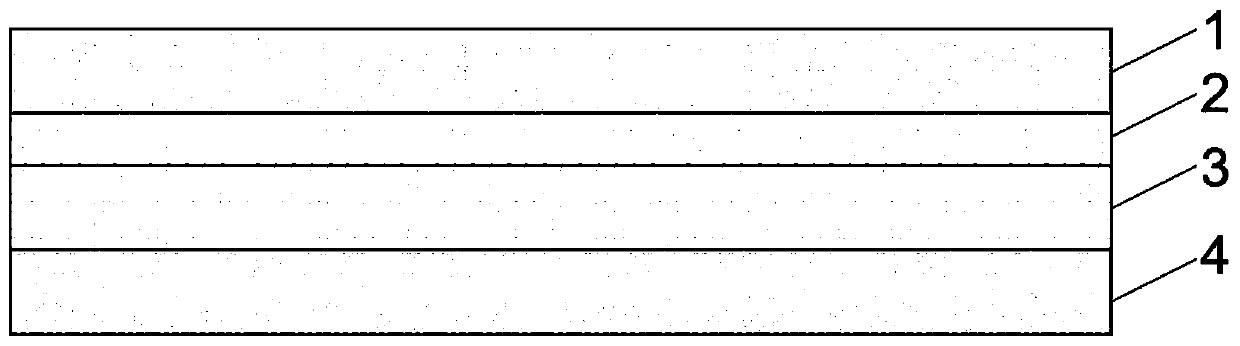

[0045] The present invention does not specifically limit the preparation method of the medical mask, and those skilled in the art can prepare it according to the conventional method for preparing a mask.

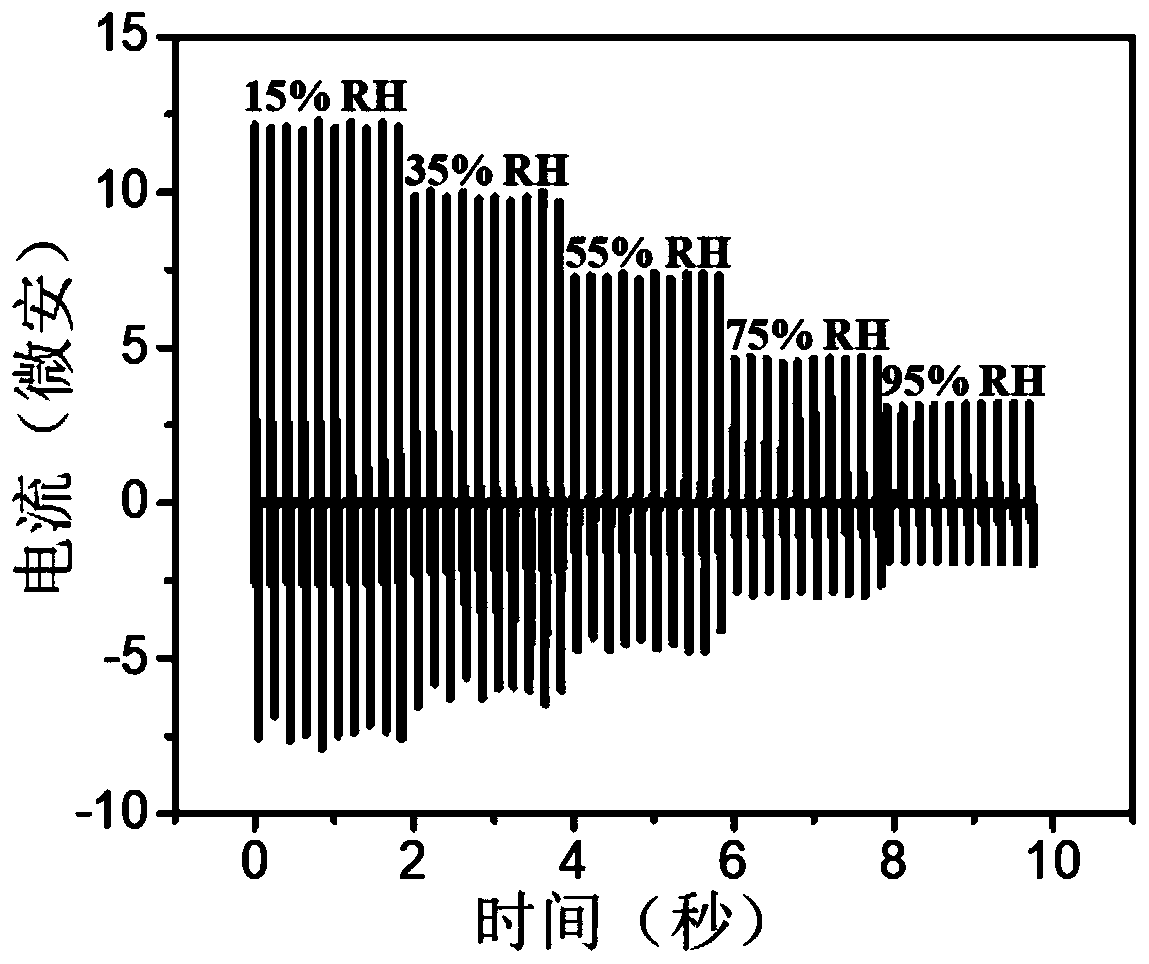

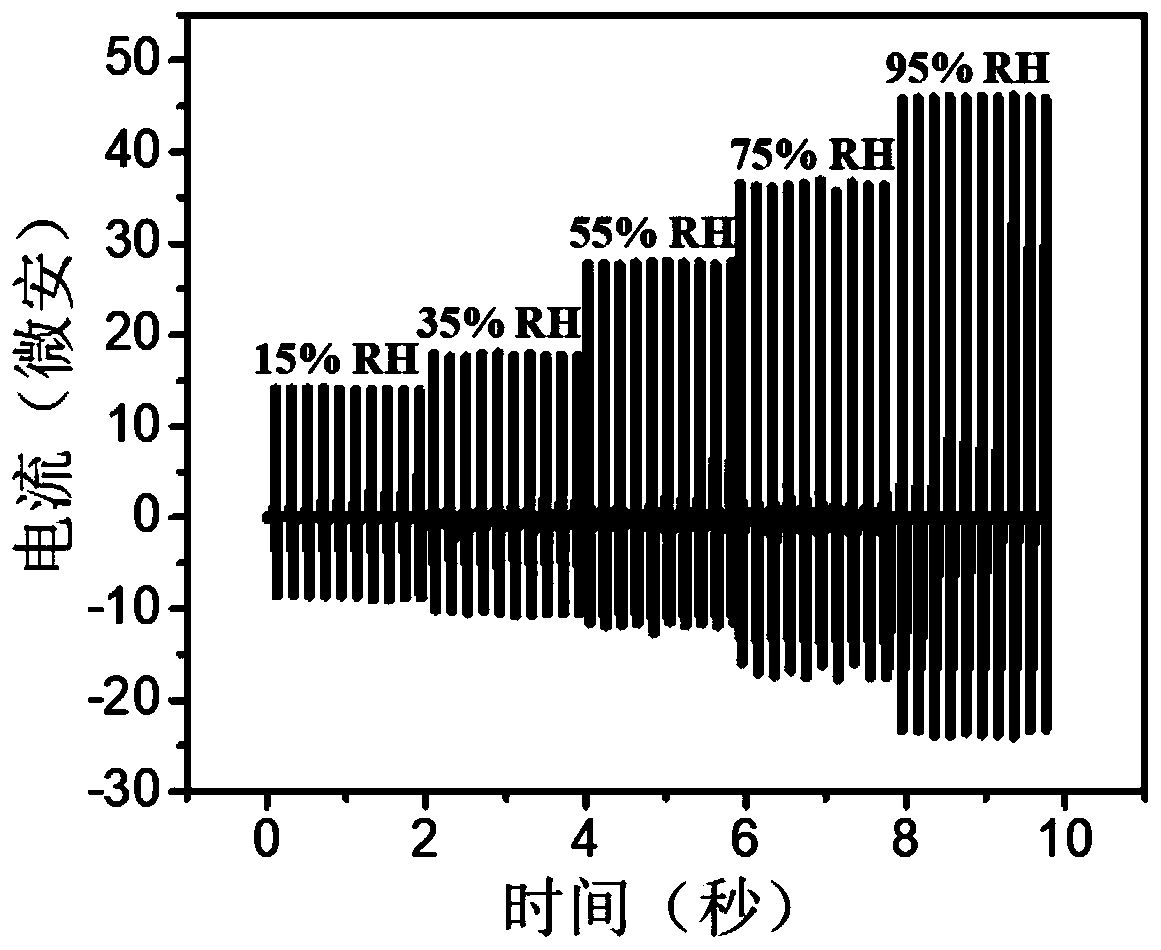

[0046] The medical mask provided by the present invention is provided with a layer of bio-based composite fiber melt-blown layer. The bio-based composite fiber melt-blown is rich in hydroxyl groups and can form hydrogen bonds with water molecules in the environment under high humidity, thereby fixing water Molecules participate in triboelectrification. Due to the extremely strong electropositiveness of water molecules, this increases the overall charge of the bio-based composite fiber melt-blown layer, thereby increasing its electrostatic adsorption capacity, and the greater the humidity of the environment, the more water vapor exhaled by the human body. The middle layer of the mask The more the overall charge will be, the stronger the adsorption capacity will be.

[0047] ...

Embodiment 1

[0050] Accurately weigh 10 parts by weight of tapioca starch, 0.5 parts by weight of carrageenan and 1 part by weight of polyester fiber, mix them evenly, place them in a screw extruder, melt them at 180°C, and then cool the melt through a drafting air duct The fibers are formed by drafting and shaping, and the fibers are evenly adsorbed to the web-forming conveyor belt after passing through the diffusion air duct, forming a continuous mesh fiber layer. The continuous mesh fiber layer is prepared into a cloth with a hot rolling mill to obtain a bio-based composite fiber melt-blown cloth. The porosity of the bio-based composite fiber melt-blown cloth is 90%, and the average pore diameter is 2.3 μm.

[0051] Taking single-layer polypropylene melt-blown cloth (thickness 0.15mm) as the control group, polypropylene melt-blown cloth (thickness 0.15mm) and bio-based composite fiber melt-blown cloth (thickness 0.15mm) as the experiment For the control group and the experimental group,...

Embodiment 2

[0054] Accurately weigh 10 parts by weight of sodium alginate and 1 part by weight of polyester fiber, mix them and place them in a screw extruder, melt them at 180°C, cool the melt through a drafting air duct, and then hot-roll it into cloth. Cut to make a sodium alginate-based melt-blown cloth (thickness: 0.15mm, porosity: 84%, average pore size: 2.0μm). Taking the traditional polypropylene melt blown cloth (thickness 0.15mm) as a comparison, use a humidifier to spray water vapor on the two at the same time for 10 minutes, and then absorb polyester resin (PET) powder at the same time. The results show that: The area is "15cm×8cm" The sodium alginate melt-blown cloth can absorb PET powder with a total mass of 1.24g, while the polypropylene melt-blown cloth can only absorb 0.11g PET powder, indicating that the sodium alginate-based melt-blown cloth can perform well under high humidity Electrostatic adsorption properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com