Method for synthesizing decynediol ethoxylate

A technology of ethoxylates and synthesis methods, which is applied in the field of chemical synthesis, can solve the problems of restricting the application of products in high-end fine chemical products, low unsaturation, high chroma, etc., and achieve high product unsaturation, fast reaction rate, The effect of low chroma of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

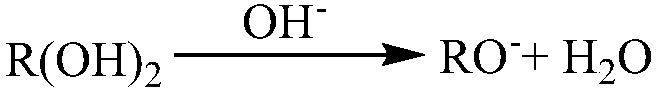

Method used

Image

Examples

Embodiment 1

[0056] Add 226g TMDD, 1181g 1-butyl-3-methylimidazolium dihydrogen phosphate and 7.923g triethylamine into a 2L stirred autoclave, heat the reactor to 60°C, and start stirring at the same time to fully mix TMDD and the catalyst .

[0057] After stirring for 20 minutes, replace the air in the reactor with nitrogen for five times, then vacuumize, and then raise the temperature of the reactor to 140°C.

[0058] Feed ethylene oxide into the reaction kettle, keep the pressure in the kettle stable at 0.2MPa by controlling the gas flow meter, continue feeding ethylene oxide until the cumulative amount reaches 10mol, and stop feeding ethylene oxide.

[0059] The temperature in the kettle was controlled simultaneously by the inner coil of the kettle and the outer jacket of the kettle, so that the reaction temperature in the kettle was stabilized at 140° C. until the pressure in the kettle was stabilized and the reaction was completed, and the temperature was lowered to 60° C. Add 600m...

Embodiment 2

[0063] Add 226g of TMDD, 1300g of 1-butyl-3-methylimidazolium bisulfate and 7.923g of trimethylamine into a 2L stirred autoclave. The temperature of the reactor is raised to 60°C, and at the same time, stirring is started to fully mix TMDD and the catalyst.

[0064] After stirring for 20 minutes, replace the air in the reactor with nitrogen for five times, then vacuumize, and then raise the temperature of the reactor to 130°C.

[0065] Feed ethylene oxide into the reaction kettle, keep the pressure in the kettle stable at 0.2MPa by controlling the gas flow meter, continue feeding ethylene oxide until the cumulative amount reaches 10mol, and stop feeding ethylene oxide.

[0066] The temperature in the kettle was controlled simultaneously by the inner coil of the kettle and the outer jacket of the kettle, so that the reaction temperature in the kettle was stabilized at 130° C. until the pressure in the kettle was stabilized and the reaction was completed, and the temperature was ...

Embodiment 3

[0070] Add 226g TMDD, 1211g 1-butyl-3-methylimidazolium trifluoromethanesulfonate and 7.923g triethylamine into a 2L stirred autoclave, heat the reactor to 60°C, and start stirring at the same time to make TMDD and catalyst Mix well.

[0071] After stirring for 20 minutes, replace the air in the reactor with nitrogen for five times, then vacuumize, and then raise the temperature of the reactor to 120°C.

[0072] Feed ethylene oxide into the reaction kettle, keep the pressure in the kettle stable at 0.2MPa by controlling the gas flow meter, continue feeding ethylene oxide until the cumulative amount reaches 10mol, and stop feeding ethylene oxide.

[0073] The temperature in the kettle was controlled simultaneously by the inner coil of the kettle and the outer jacket of the kettle, so that the reaction temperature in the kettle was stabilized at 120° C. until the pressure in the kettle was stabilized and the reaction was completed, and the temperature was lowered to 60° C. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com