Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

429results about How to "Smooth process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

River surge silt harmless and recycling treatment method

InactiveCN101870546ALower redox potentialSmooth processSludge treatment by de-watering/drying/thickeningSolid waste managementFiberResource utilization

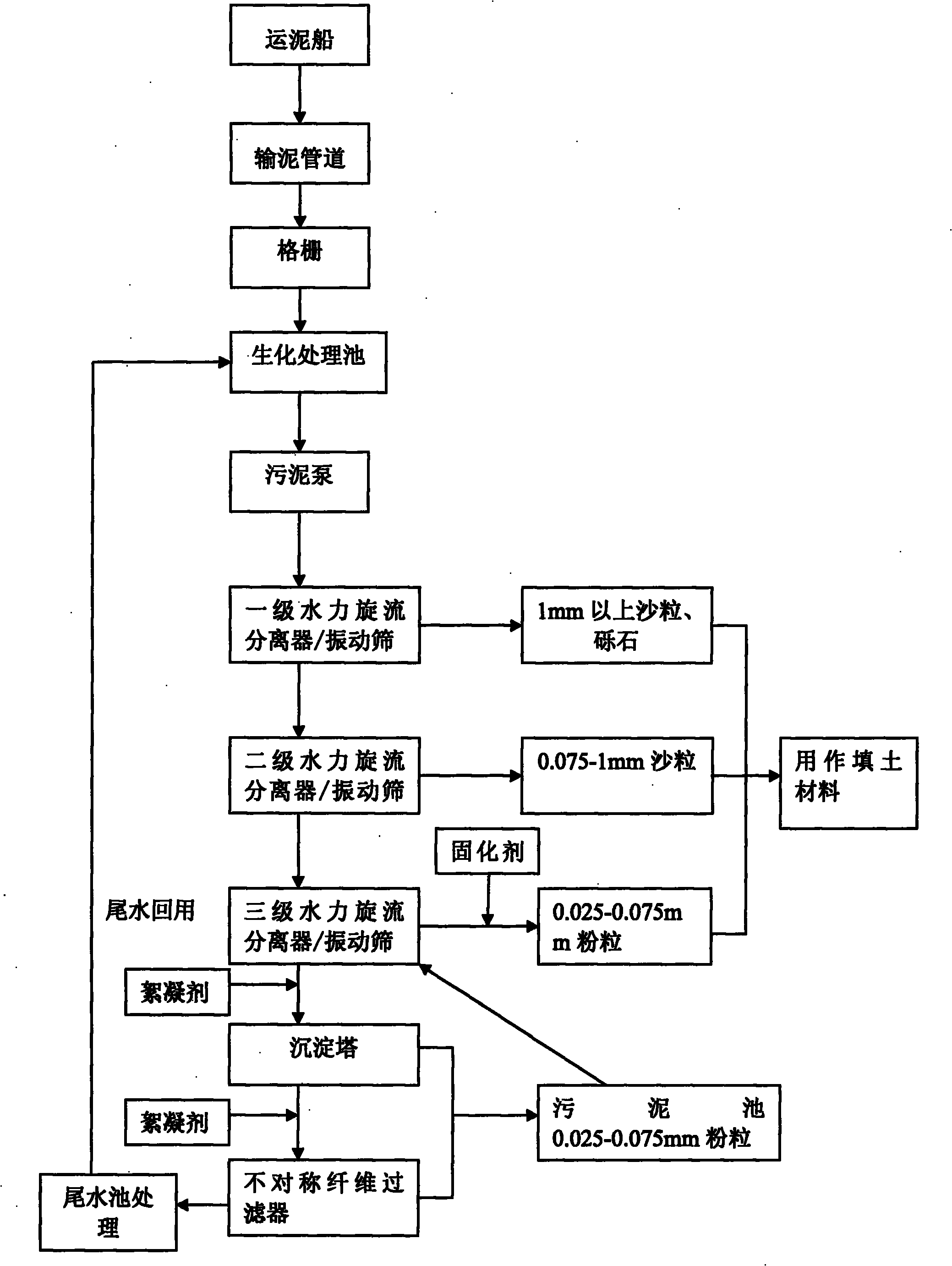

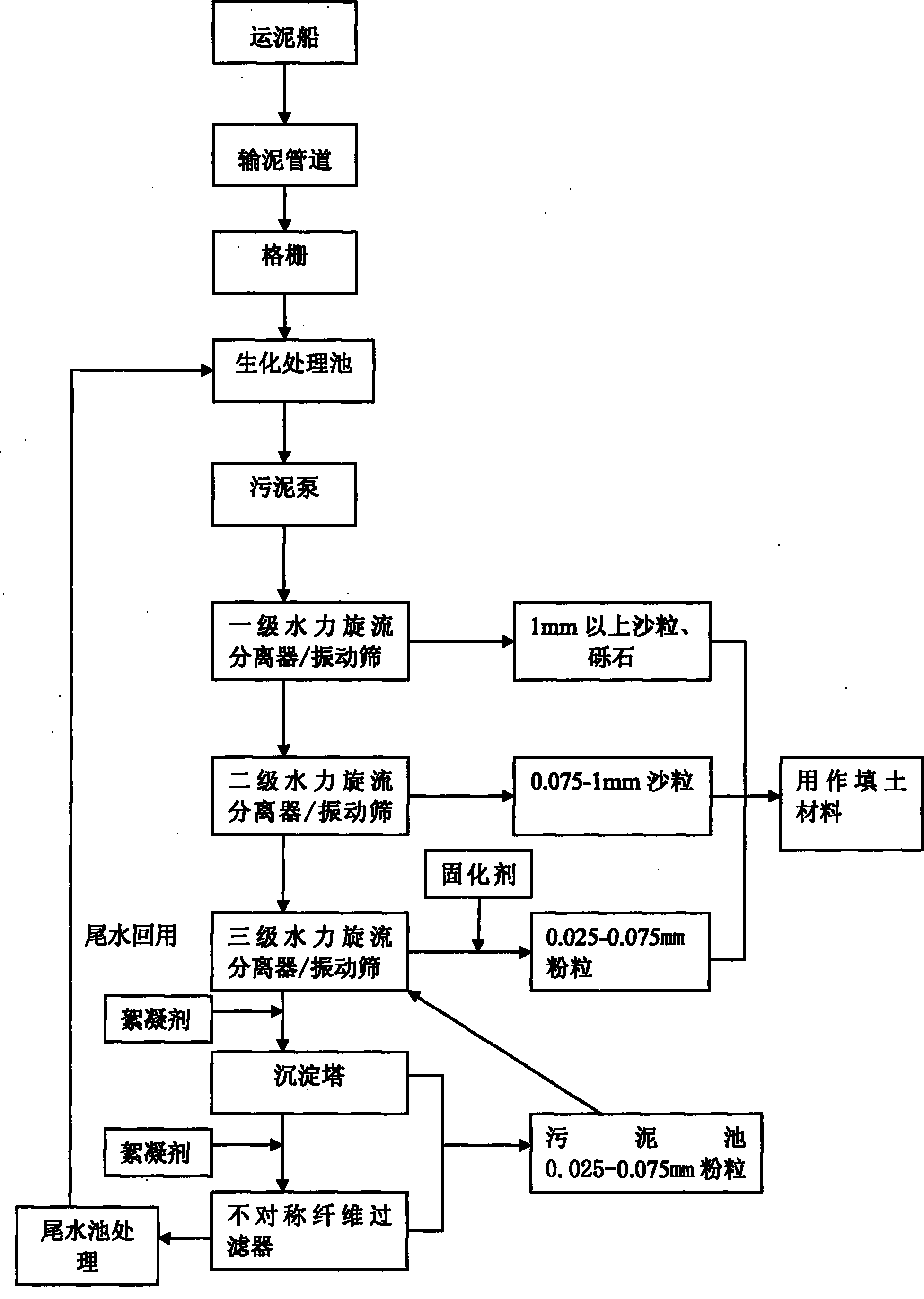

The invention provides a river surge silt d harmless and recycling treatment method. In the method, a dredger is utilized to suck silt, the silt is sent into a biochemical treatment pond from the ship through a silt transmission pipeline, compound enzyme is utilized to carry out bioremediation, gravels and sands with the particle size bigger than 1mm are filtered out by a primary hydrocyclone and a vibration screen, sands with the particle size of 0.075-1mm are filtered out by a secondary hydrocyclone and the vibration screen, powdery particles with the particle size of 0.025-0.075mm are filtered out by a third-level hydrocyclone and the vibration screen, powder particles are further separated out from outlet silt tail water through a sediment tower, sewage from the sediment tower is filtered by utilizing a fiber filter after flocculant is added into the sewage, and powdery particles are deposited from backflushing silt after being filtered by utilizing the sediment tower again, and the powdery particles are dehydrated by the third-level hydrocyclone and the vibration screen after entering a sludge pool and are cured by a curing agent after dehydration. The method has high resource utilization ratio, meets the requirements for the environmental protection, particularly carries out stage treatment on the silt, lowers the cost and enhances the efficiency.

Owner:GUANGZHOU BAOMINGLAI ENVIRONMENT SCI & TECH

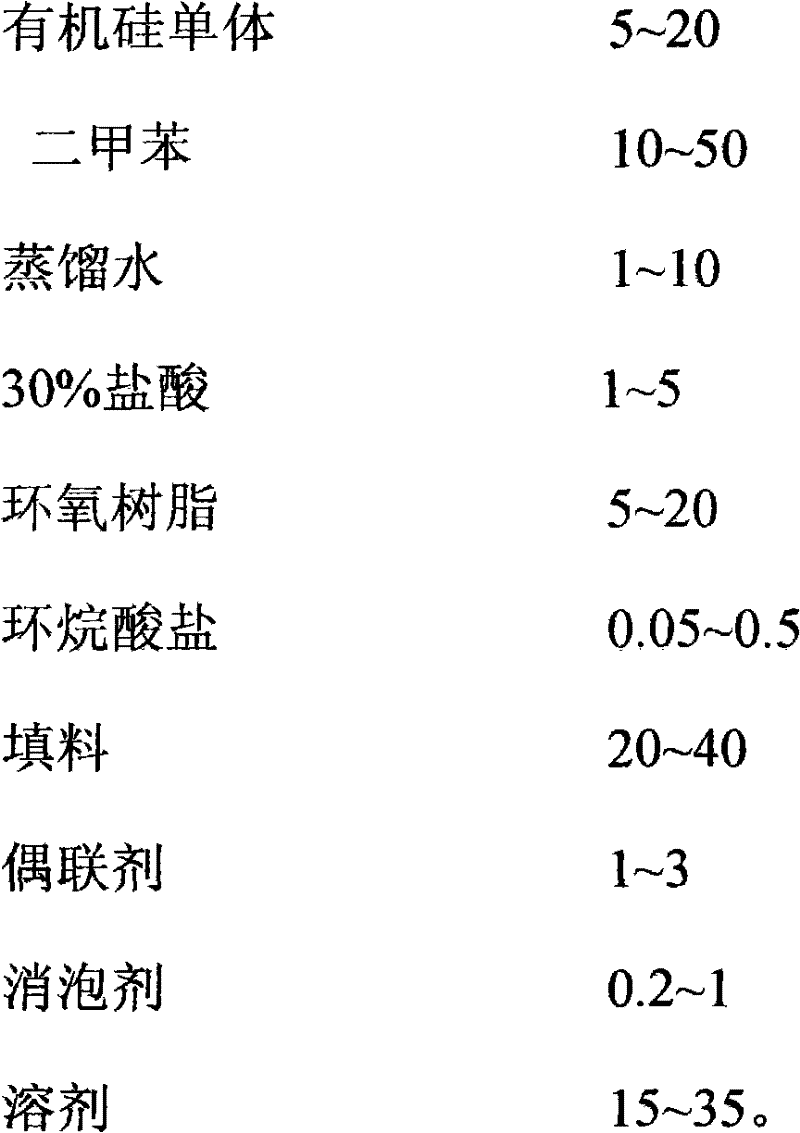

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

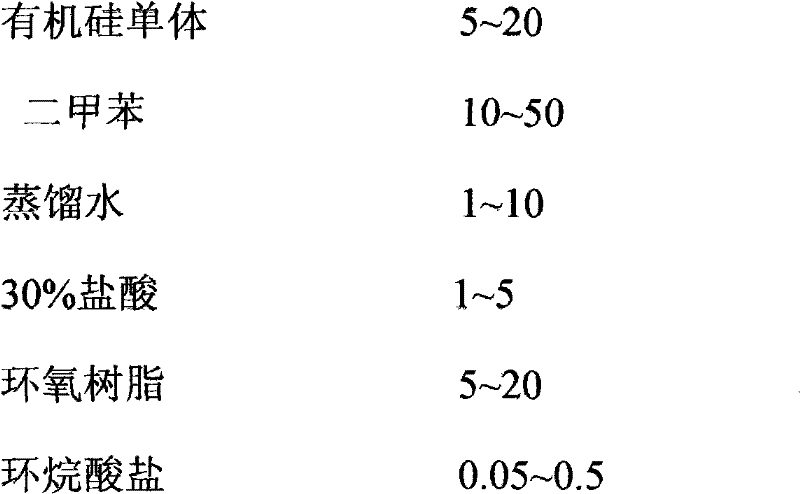

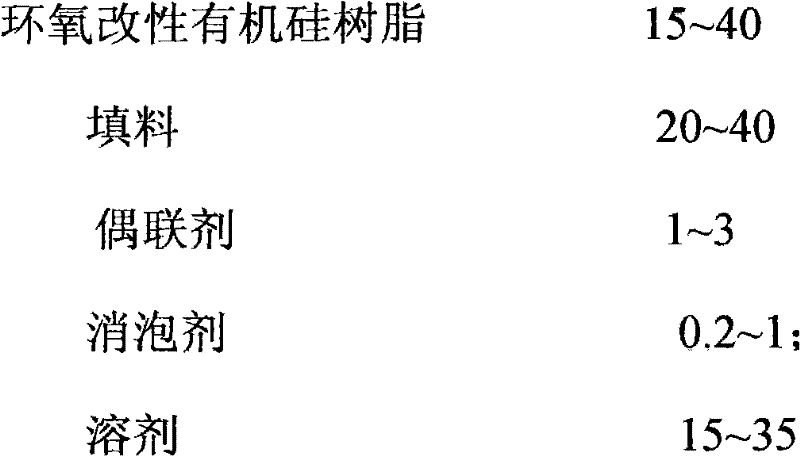

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

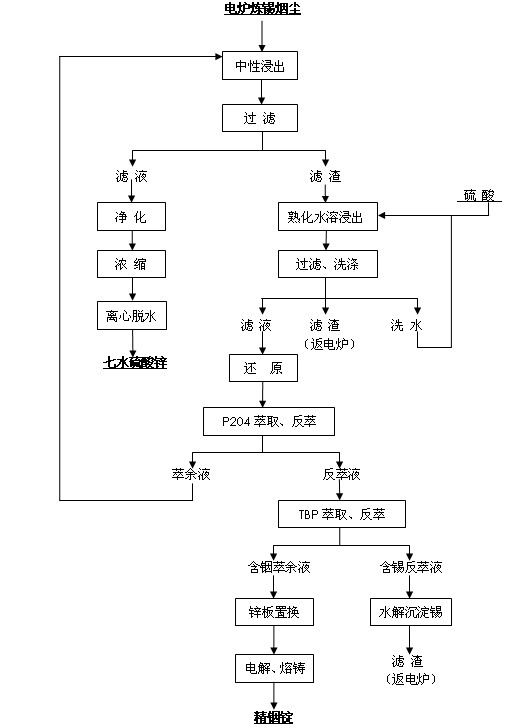

Multi-metal recycling method of electric furnace tin-smelting dust

InactiveCN102140580AImprove leaching rateEfficient extractionProcess efficiency improvementHigh concentrationIndium

The invention discloses a multi-metal recycling method of electric furnace tin-smelting dust. The method comprises the following steps: electric furnace tin-smelting dust is placed in a reaction kettle, sulfuric acid or / and raffinate are added to perform neutral leaching so that metals such as zinc are leached in the neutral solution and indium, tin and lead are left in residues; the neutral residues are placed in a reaction kettle, concentrated sulfuric acid is added for cure leaching, cleaning solution is added after the reaction to ensure that indium and a part of tin are leached in the solution and most of tin and lead are left in residues; extractant P204 is used to extract the indium and tin of the leachate and separate indium and tin from zinc, hydrochloric acid is used to perform backextraction to the extract so that tin and indium can be separated from the organic phase through backextraction and high concentration indium-tin mixed backextraction solution can be obtained; tributyl phosphate (TBP) extractant is used to extract tin to obtain material solution with indium and material solution with tin; and the material solution with indium is replaced by using a zinc plate and casted to obtain crude indium, the crude indium is electrolyzed and purified to obtain a refined indium product. The method combines the mature concentrated acid curing technology, extraction technology and other technologies into a whole, solves the separation problem of indium and tin and ensures that various high-value metals in the electric furnace dust can be recycled efficiently, continuously and largely; and the actual indium yield is more than 80% and the purity of the refined indium is more than 99.93%.

Owner:刘辉 +1

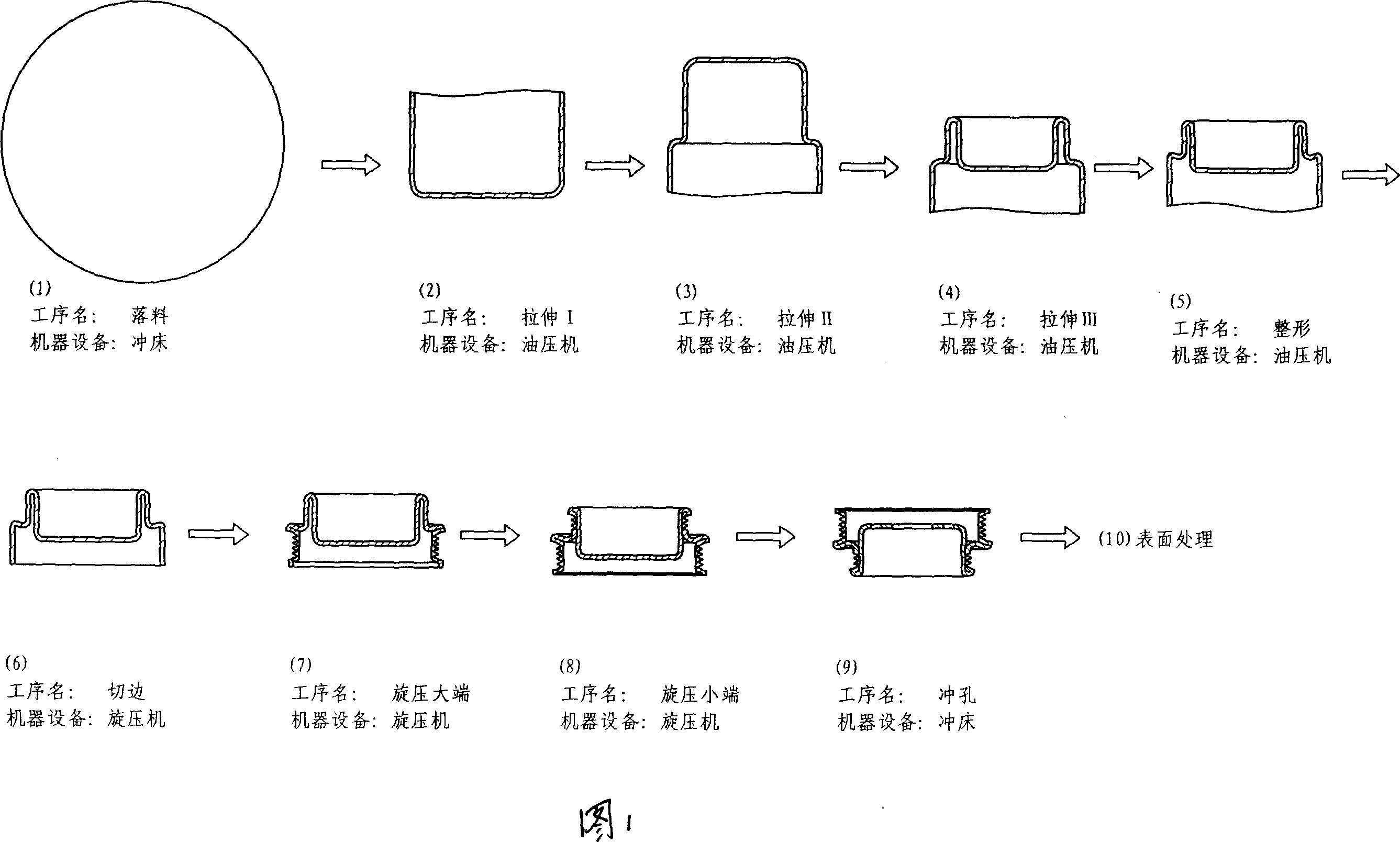

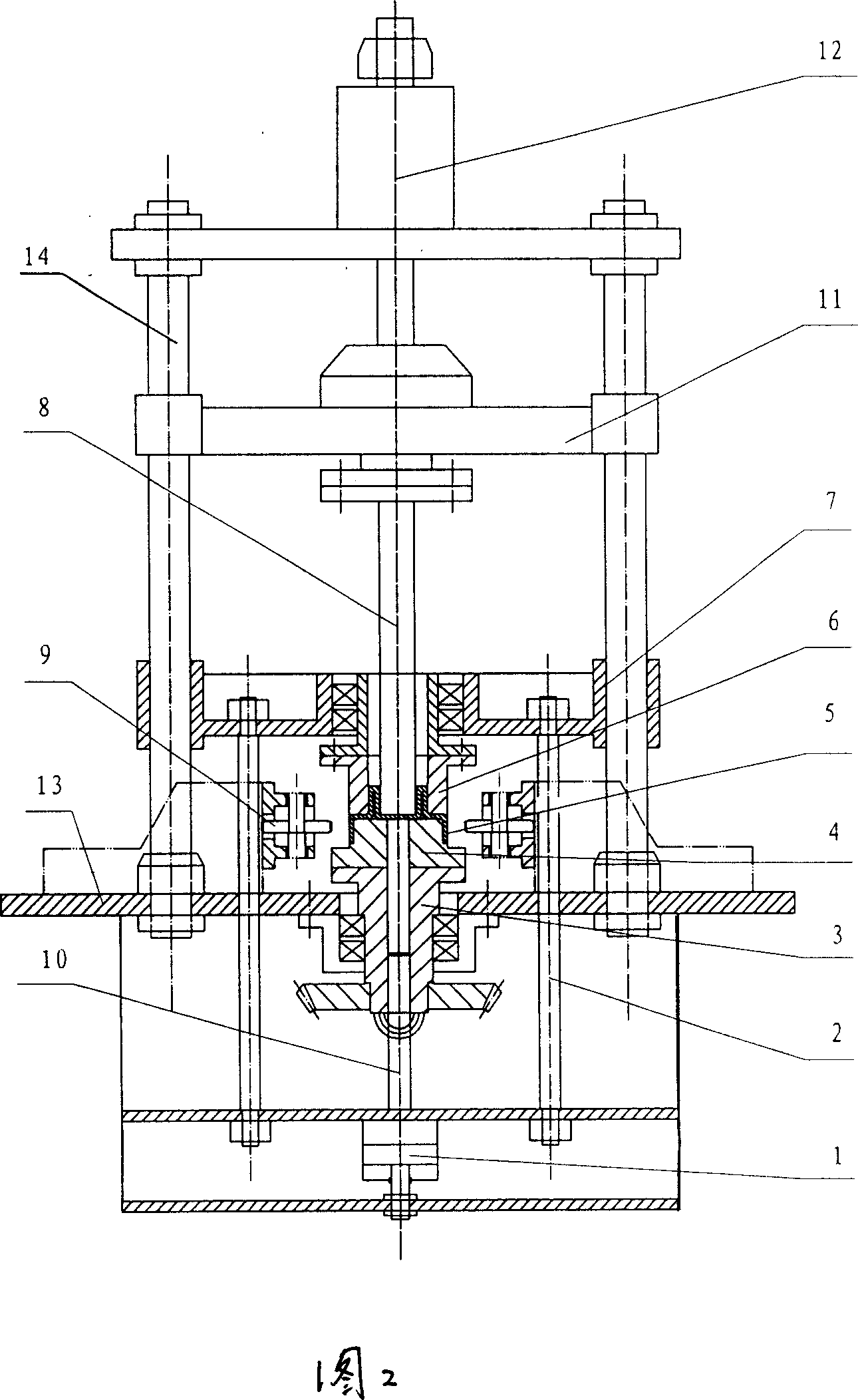

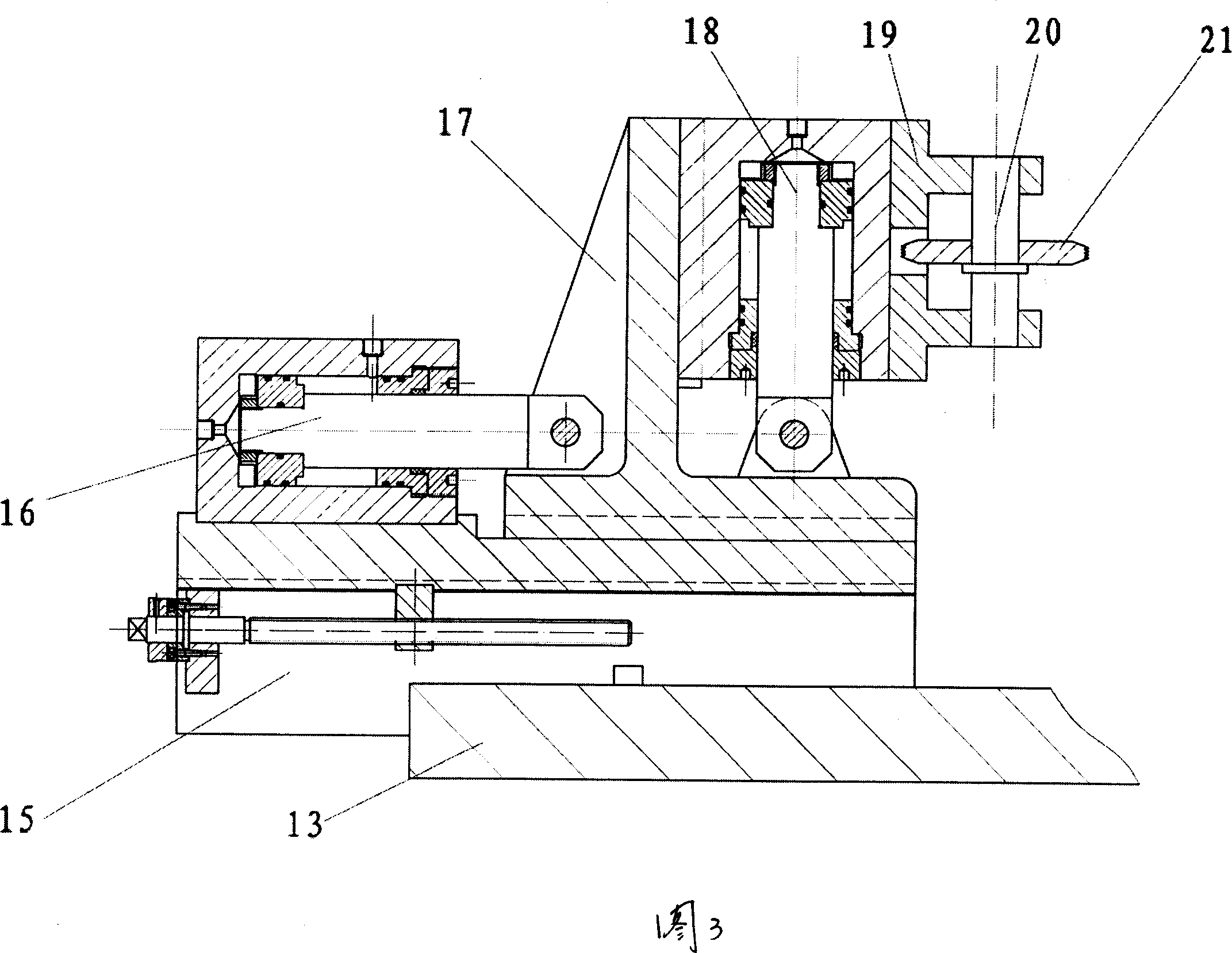

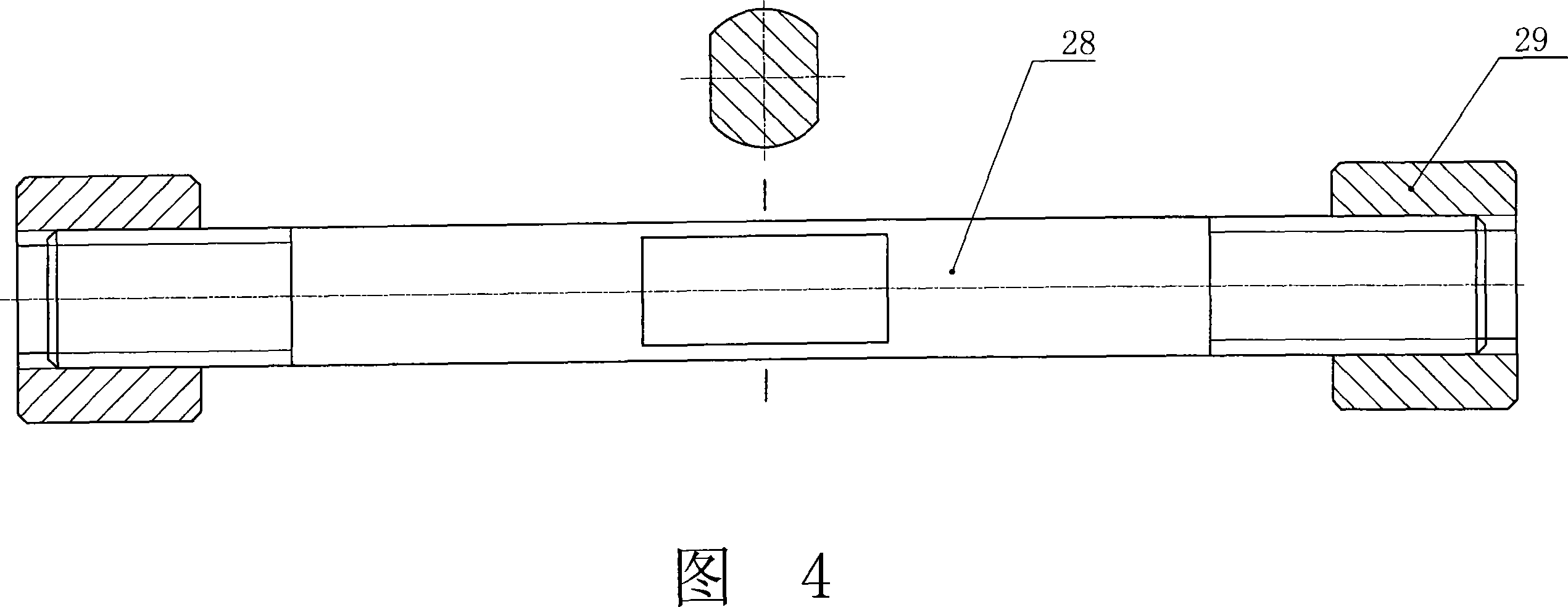

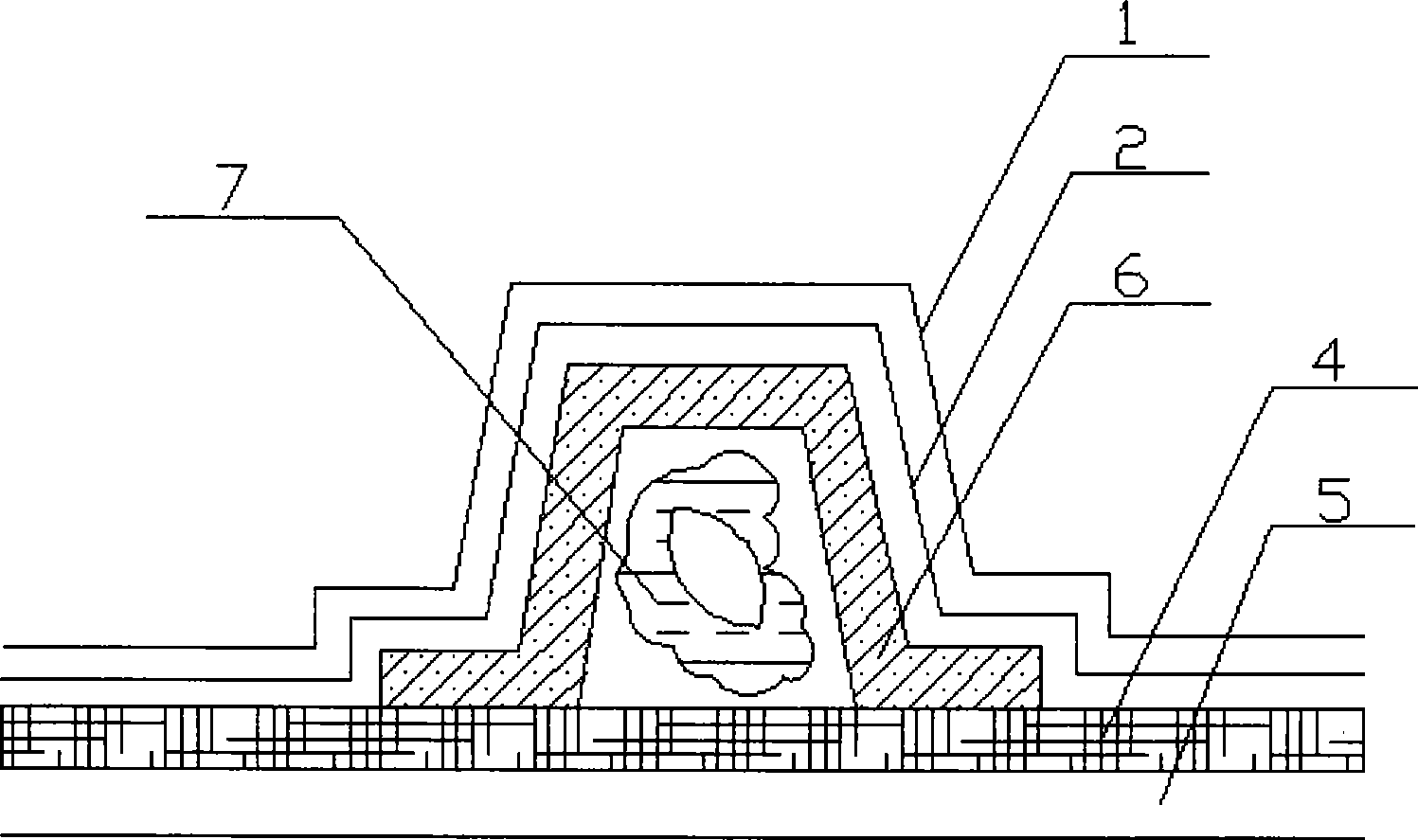

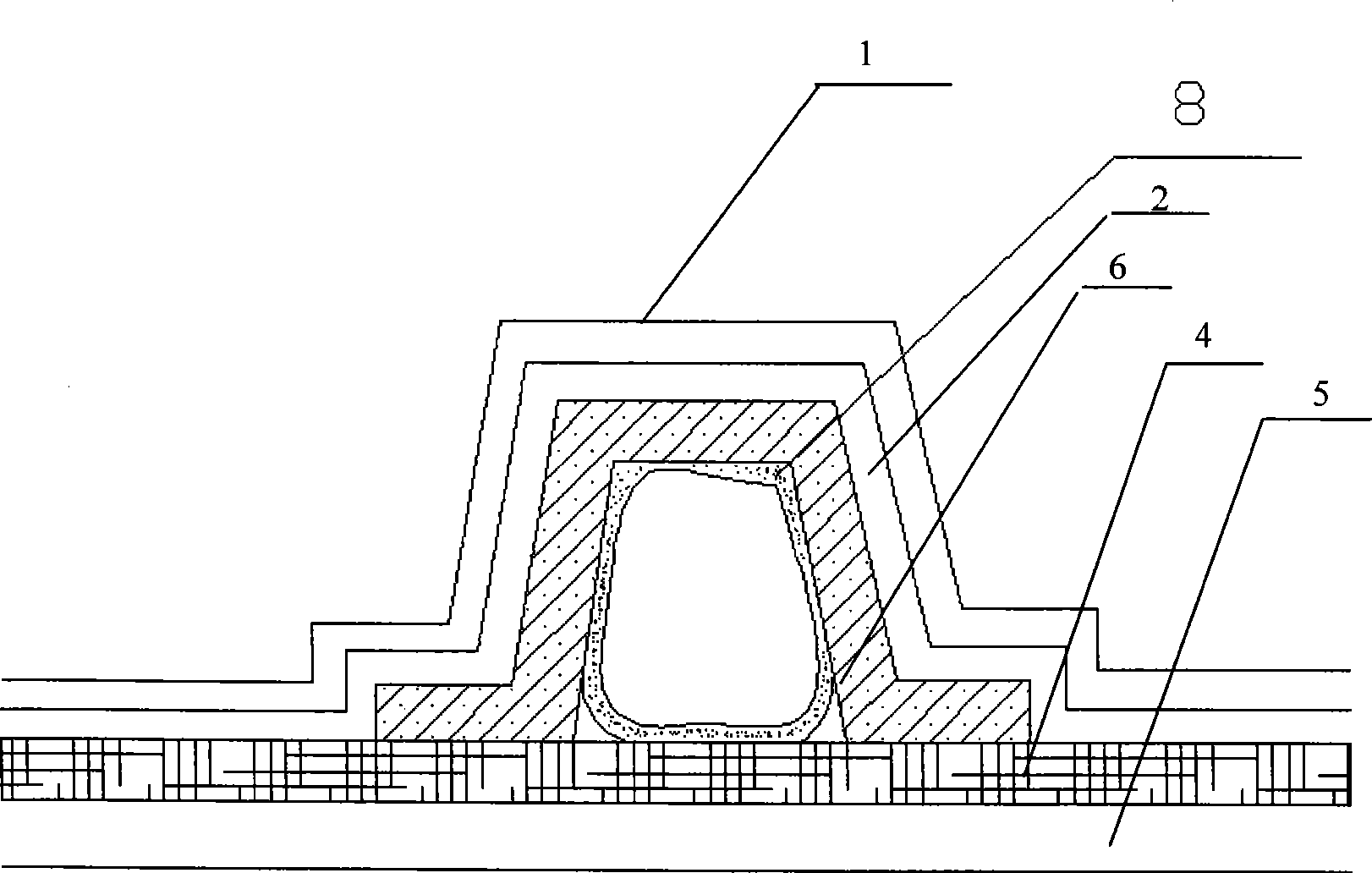

Two-stage coaxle multi-wedge type pulley and processing technology and equipment

InactiveCN1975208AHigh fastnessReduce jumpingPortable liftingGearing elementsPunchingWork in process

The inventive belt pulley comprises bull and pony wheels integral formed by spinning of flat cold-rolled sheets. The process of manufacturing the belt pulley consists in: blanking; multistretching; shaping; spinning; punching and surfacing. The blanking is stretched into the semi-finished products for the two-stage coaxial multi-wedge pulley on the oil press by the multistretching and the times of multistretching can depend on the product conditions. The shaped and edged semi-finished pulley once-through complete the following process: spinning the big end and then spinning the small end by the spinning process.

Owner:温州市南亚机械配件有限公司

Fluorinated graphite and preparation method thereof

The invention relates to the technical field of new materials, in particular to a preparation method of fluorinated graphite. The preparation method of the fluorinated graphite includes the following steps that S1, graphene and a first fluorinating agent perform fluorinating reaction under inert gas protection to obtain a fluorinated graphite coarse product, wherein the reaction temperature is 150-550 DEG C, the reaction time is 2-20 hours, the graphene is graphene powder or a graphene film, and the first fluorinating agent contains fluorine gas; S2, the fluorinated graphite coarse product and a second fluorinating agent perform fluorinating reaction under inert gas protection to obtain fluorinated graphite, wherein the reaction temperature is 150-400 DEG C, the reaction time is 2-10 hours, and the second fluorinating agent is gas-phase fluoride. By the adoption of the method, the fluorinated graphite with high fluoride content can be prepared, the fluorine content is close to the theoretical level, and the defect density is low.

Owner:湖北高地石墨烯科技有限公司

Inkjet printing process of cotton fabric

ActiveCN103469642AEnhanced wash resistance and sorptionSmooth printingDry-cleaning apparatus for textilesDyeing processPre treatmentSizing

The invention discloses an inkjet printing process of a cotton fabric. A technological process which comprises the processes of sizing pre-treatment, drying, inkjet printing, steaming and colour fixing, after treatment, washing and drying is adopted, preshrinking process treatment is carried out firstly before the sizing pre-treatment, so that the phenomenon that printed flowers are irregular owning to shrinkage of the cotton fabric in the inkjet printing process is effectively avoided; besides, idiosyncratic inkjet printing pigment ink is adopted for carrying out inkjet printing, cold water and hot water are alternate for multiple times in a washing process, chemical tolerance of a pigment is stimulated, and washing resistance and adsorption rate of the cotton fabric are improved. The inkjet printing process of the cotton fabric has the advantages of smooth printing, appropriate colouring depth, difficulty in colour fading and simple technology.

Owner:溆浦县顺成服装有限公司

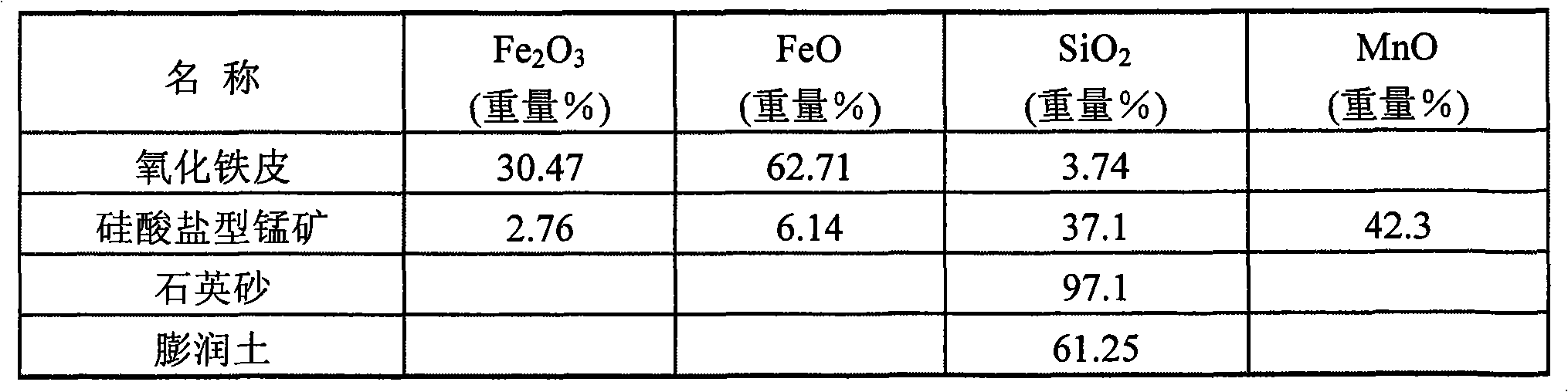

Composite slagging agent for semi-steel making and preparation method thereof and semi-steel making method

InactiveCN101928806AEasy to prepareIncrease the content of Mn elementManufacturing convertersProcess efficiency improvementBrown iron oxideSemi-steel

The invention provides a composite slagging agent for semi-steel making. The composite slagging agent contains iron oxide, MnO and SiO2, wherein the iron oxide is Fe2O3 and / or FeO. The invention also provides a preparation method for the composite slagging agent and a semi-steel making method. According to the composite slagging agent provided by the invention for semi-steel making, the preparation method is simple, the consumption of the composite slagging agent in the semi-steel making process is low, and the composite slagging agent can be used for slagging and dephosphorization in the semi-steel making so that the semi-steel making process is performed more smoothly; and meanwhile, the composite slagging agent can effectively improve the Mn element content of the final molten steel and correspondingly reduce the consumption of Mn-containing alloy added in a subsequent step of the steel making production so as to reduce the steel making production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Rubber composite for wear-resistant tire treads

The invention provides a rubber composite for wear-resistant tire treads. The rubber composite is prepared from, by weight, 4-30 parts of natural rubber, 4-40 parts of butadiene rubber, 4-40 parts of styrene butadiene rubber, 35-75 parts of high-dispersion white carbon black, 3-10 parts of white mineral oil, 1.0-2.5 parts of indirect zinc oxide, 1.0-2.0 parts of stearic acid, 1.0-2.0 parts of rubber protecting wax, 1.0-2.8 parts of silane coupling agent, 1.0-2.0 parts of anti-aging agent, 1.0-2.0 parts of tackifying resin, 1.0-2.0 parts of dispersing agent, 1.0-2.8 parts of common sulphur, 0.5-2.0 parts of accelerant CZ, 1.0-2.0 parts of accelerant DPG and 0.1-1.0 part of accelerant DM, by proportioning according to the formula prior to mixing via an internal mixer. The rubber composite is mixed via the internal mixer by means of blending the natural rubber and the synthetic rubber as main materials which are matched with the high-dispersion white carbon black as a reinforcing agent and through unique anti-aging system design, and accordingly tire treads produced by the rubber composite are excellent in wear-resisting property, good in tear resistance and high in tensile strength, and service lives of tires for taxies, family cars and the like can be prolonged.

Owner:双星东风轮胎有限公司

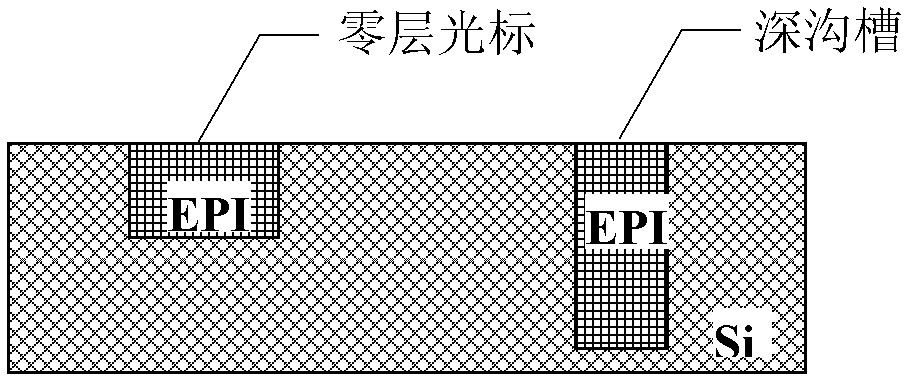

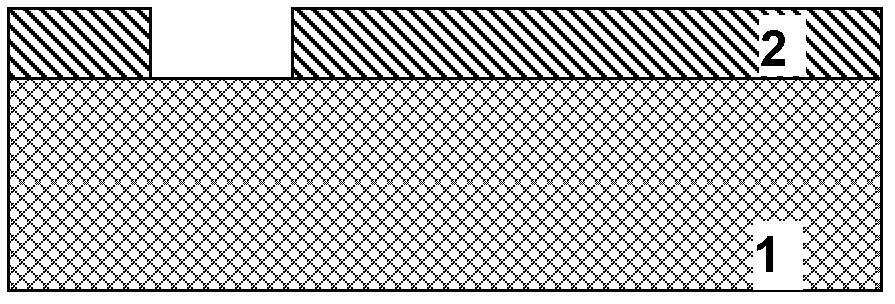

Method for producing zero layer photoetching marking of high-voltage device without barrier layers

ActiveCN103035511AEasy alignmentSmooth processSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEtchingLithographic artist

The invention discloses a method for producing zero layer photoetching marking of a high-voltage device without barrier layers. The method for producing the zero layer photoetching marking of the high-voltage device without the barrier layers comprises the following steps: (1) etching a zero layer lithography marking groove, (2) depositing a layer of medium layer and removing medium layers of regions outside the zero layer lithography marking groove, (3) etching a deep groove, (4) selectively growing an epitaxial layer on a silicon substrate, (5) removing anti-configuration epitaxial materials deposited on the silicon substrate in the epitaxial growth process of epitaxial layer, (6) etching away a medium layer inside the zero layer lithography marking groove by the adoption of the method of wet etching and leaving a zero layer lithography marking graph. Through the method for producing the zero layer photoetching marking of the high-voltage device without the barrier layers, lithography markings which are easy to recognize can be formed on the high-voltage device without the barrier layers, and therefore a follow-up film layer can be directed at conveniently, smooth of technological process can be guaranteed, and good yield of a product is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

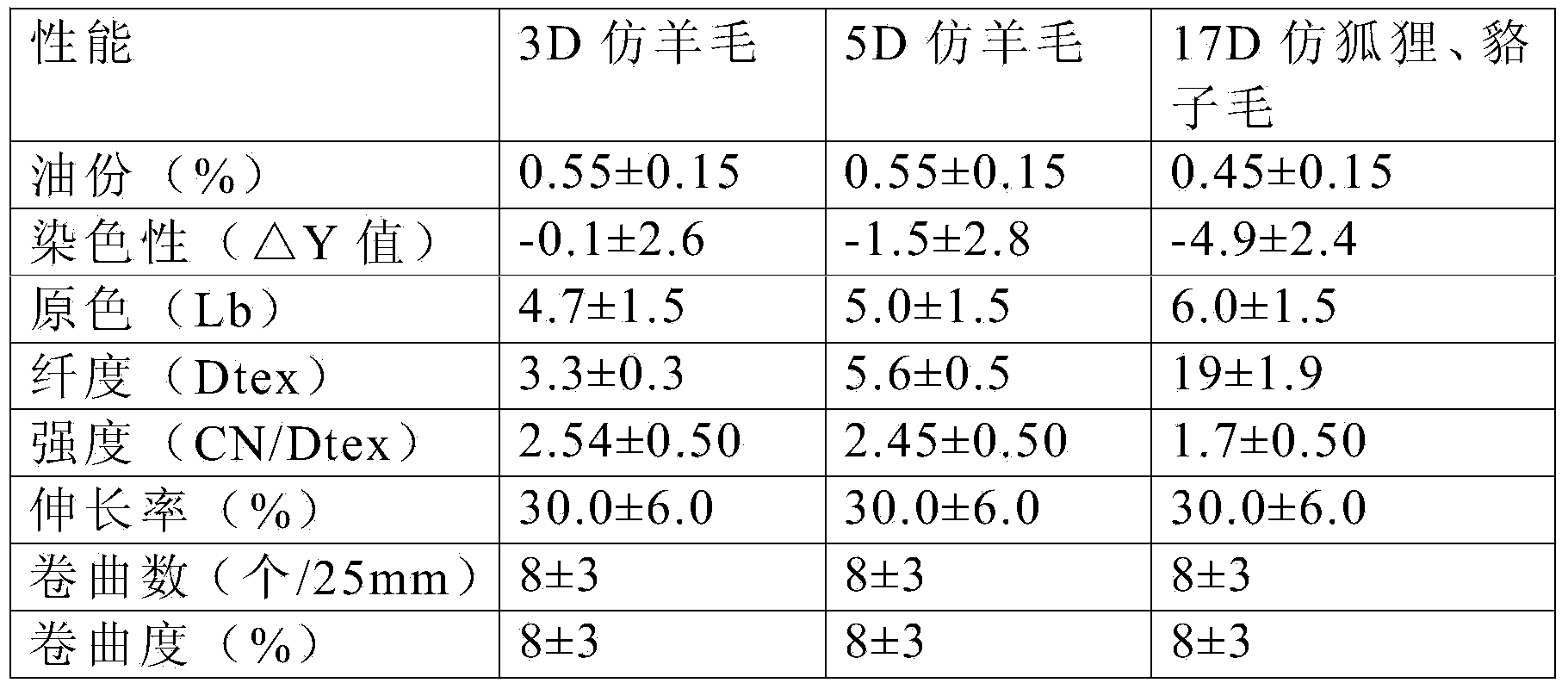

Flat acrylic fiber and production method thereof

ActiveCN103882547ALower glass transition temperatureGood flexibilitySpinnerette packsArtificial filament heat treatmentPolymer scienceDouble diffusion

The invention relates to a flat acrylic fiber and a production method thereof. The flat acrylic fiber consists of the following components in percentage by weight: 91-94 percent of acrylonitrile and 6-9 percent of vinyl acetate, wherein the length-width ratio of the flat acrylic fiber is (2-13):1. The method for producing the flat acrylic fiber comprises the following steps: carrying out copolymerization reaction on the acrylonitrile and the vinyl acetate to prepare dried polyacrylonitrile powder, dissolving the powder in a solvent to form a stock solution, extruding from a rectangular hole of a spinneret plate after heating, and performing double diffusion to form a nascent fiber in a coagulating bath; washing the nascent fiber by water, and drawing the fiber through a drawing machine; oiling tows; and drying the tows and setting, so as to obtain the flat acrylic fiber. The contents of the acrylonitrile and the vinyl acetate in a copolymer, the molecular weight of the copolymer and a specific process flow are adjusted, so that the prepared flat acrylic fiber is good in handfeel, the softness and handfeel of the fiber can be improved, the rebound resilience, hydrophobicity and spinnability of the fiber can be guaranteed, and the acrylic fiber is easy to color.

Owner:NINGBO ZHONGXIN ACRYLIC FIBERS

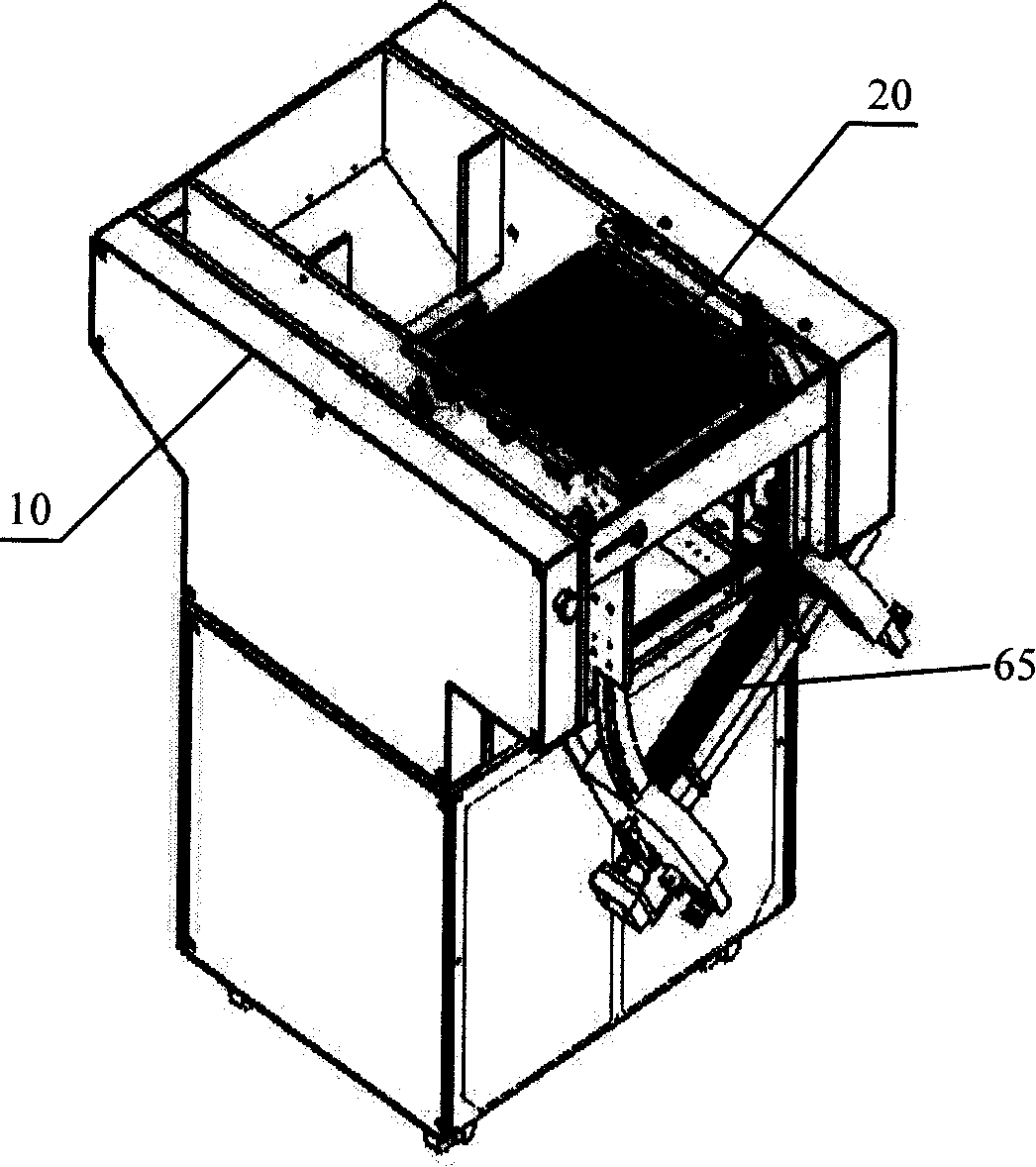

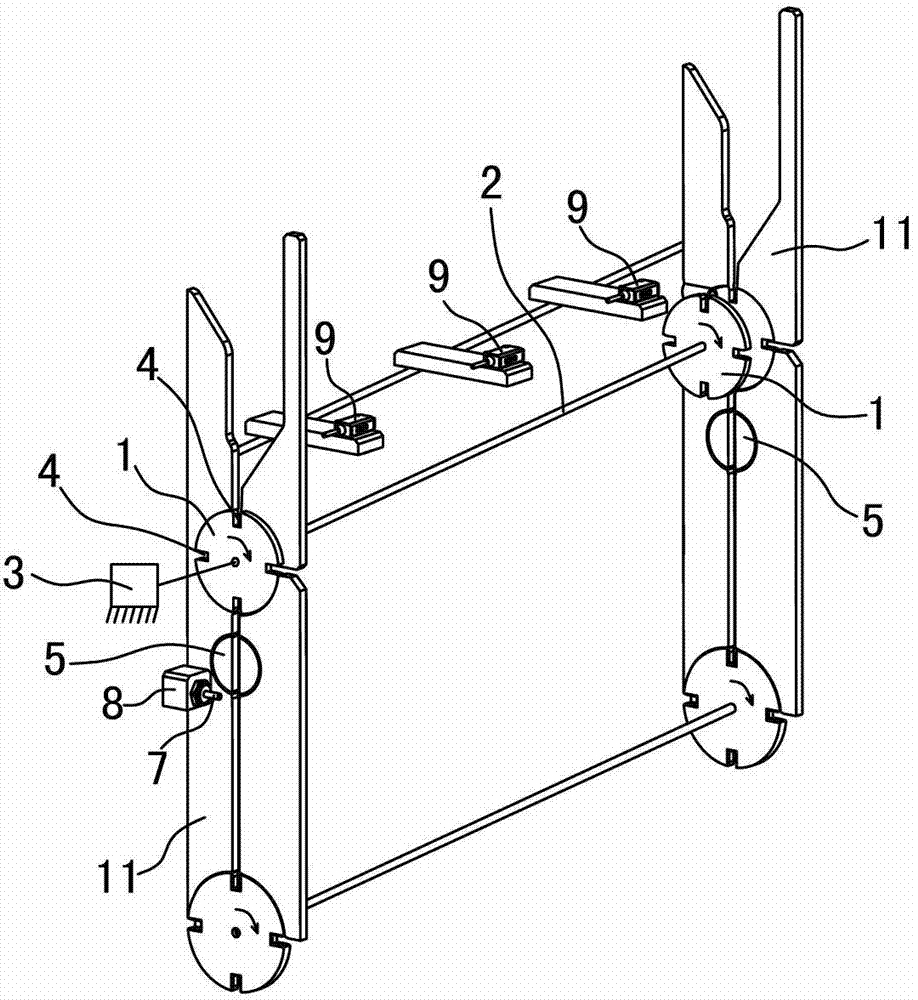

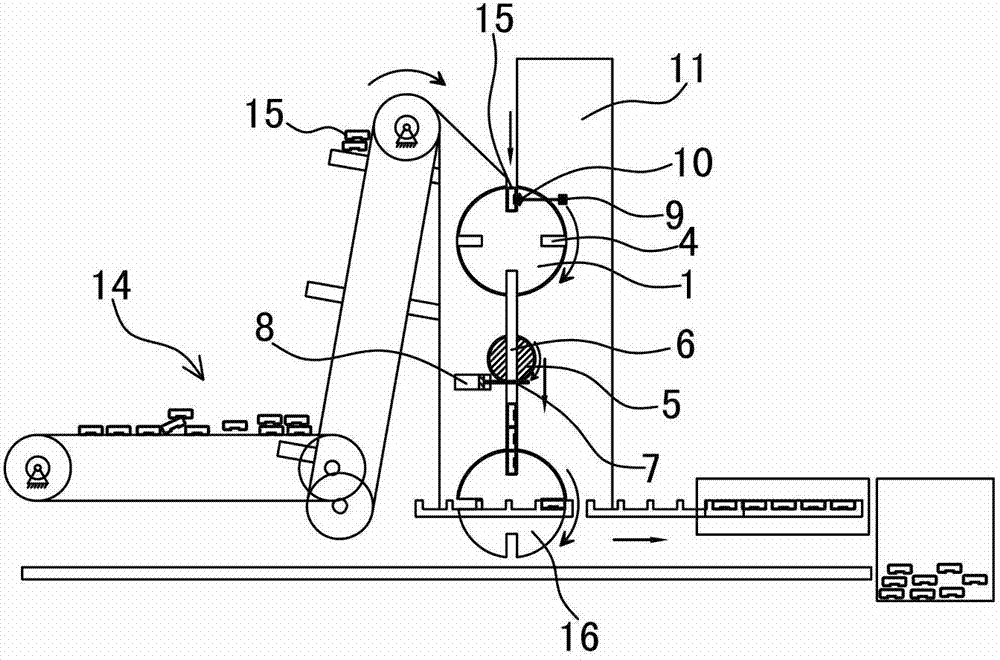

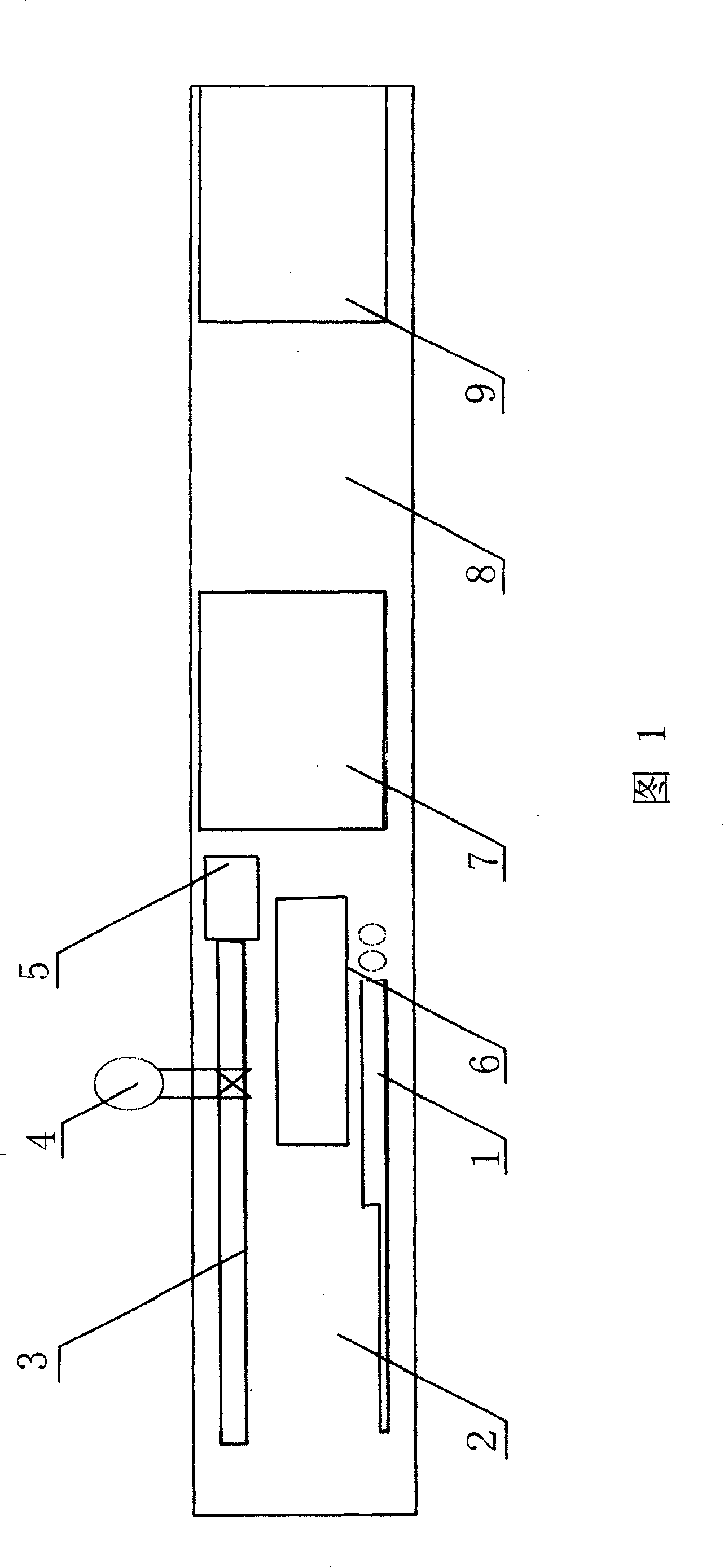

Integrated circuit punching and cutting forming machine material-receiving system automatic discharging tube machine

InactiveCN101164844AAvoid damageOrderly rowsConveyorsSemiconductor/solid-state device manufacturingPunchingEngineering

The present invention provides an integrated circuit punching-forming machine material-collecting system automatic tube-arranging machine. It includes machine frame, feeding mechanism, material-taking conveying device, direction detector, rotating mechanism and material-discharging mechanism, etc. The material-taking conveying device is mounted on the machine frame, said material-taking conveying device includes an inclined stage and a horizontal stage, the lower end of said inclined stage is connected with feeding mechanism, on the horizontal stage successively are distributed the direction detector, 90deg and 180deg rotating mechanism and direction acknowledge instrument. In the lower portion of bent position of horizontal stage tail end a material-discharging mechanism is set, and a separation device is set, said separation device is connected with the material-discharging mechanism. Said tube-arranging machine can be used for making the material-collecting tubes be automatically arranged in good order according to identical direction, and can be used for transferring them to the lower portion of material mouth so as to receive punching-formed integrated circuits and make them be successively filled into the material-collecting tube.

Owner:苏州均华精密机械有限公司

Manufacturing method of flexible display

ActiveCN103531722ASolve the separation problemFacilitate strippingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePolymer thin films

The invention discloses a manufacturing method of a flexible display, wherein the method comprises the following steps: etching a glass substrate to form a channel used for auxiliary fixation of an organic polymer thin layer, and cleaning the glass substrate; coating one face, provided with the channel, of the glass substrate with an organic polymer potion to form the flattened organic polymer thin layer; machining a TFT device on the organic polymer thin layer; machining an OLED lighting device on the TFT device; pasting a flexible packaging film used for preventing the devices from contacting air on the surface of the organic polymer thin layer provided with the OLED lighting device; and cutting the flexible packaging film along the edges of the flexible display with a designed size, and putting the glass substrate into a liquid or steam environment to enable the flexible display to fall off from the glass substrate, thereby forming the flexible display. The method provided by the invention ensures that the flexible display falls off from the glass substrate very well, operation is convenient, cost is low, and the lighting device is prevented against bad influences.

Owner:TCL CORPORATION

Method for extracting alkannin from alkanet

InactiveCN101434530ASmooth processEasy to operateQuinone separation/purificationPlant ingredientsChemistryAqueous solution

The invention discloses a method for extracting alkannin from alkanet, which is characterized in that the alkanet is mixed with an aqueous solution containing alcohol in accordance with a certain ratio of material to liquid and put into a pulp refiner for homogenate extraction. Solid-liquid separation is carried out to a mixture obtained after the homogenate to obtain an extracting solution. Solid contents are then mixed with the aqueous solution containing alcohol according to a certain ratio of material to liquid and put into the pulp refiner for the homogenate extraction to obtain an extracting solution. The extracting solutions are merged and then decompression condensed to obtain a crude product of alkannin. The operation technology is mainly characterized by smooth process, simple operation, extraction at room temperature for avoidance of the degradation of alkannin, recyclable reagents used, low energy consumption, low production costs and high yield.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

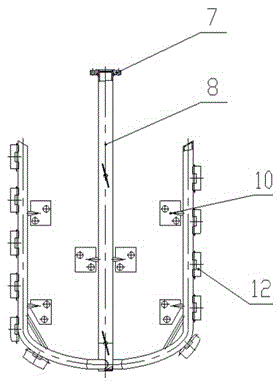

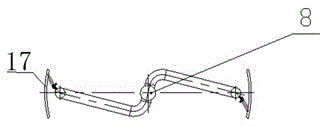

Hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer

InactiveCN105561841ALarge mixing rangeStir wellTransportation and packagingRotary stirring mixersElectric machineryReducer

The invention relates to a hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer comprises a motor, a speed reducer, a transmission shaft, cover-type nuts, fixing bases, end sockets, a coupler, a rotating-anchor-type stirrer body, fixing-type stirrer bodies, rotating stirrer blades, fixing stirrer blades, scratch boards, device flanges and a tank. The fixing-type stirrer bodies are installed at the top ends of the end sockets on the two sides of a stirring shaft of the rotating-anchor-type stirrer body, the scratch boards are installed on the outer sides of supports on the two sides of the rotating-anchor-type stirrer body, and the rotating stirrer blades and the fixing stirrer blades are correspondingly and alternately installed on the stirring shaft and fixing shafts. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer has the advantages that the angle positions of all the blades can be installed according to the requirement of technology operation to meet the requirements of the different working conditions; the stirring range of the stirrer is wide and almost free of dead corners, and full stirring can be guaranteed; when materials with different production technologies are stirred, the device is flexible in assembling, reliable in fixing and quite convenient to disassemble, assemble, replace, wash and maintain.

Owner:SHANGHAI SANQIANG VESSEL NANTONG CO LTD

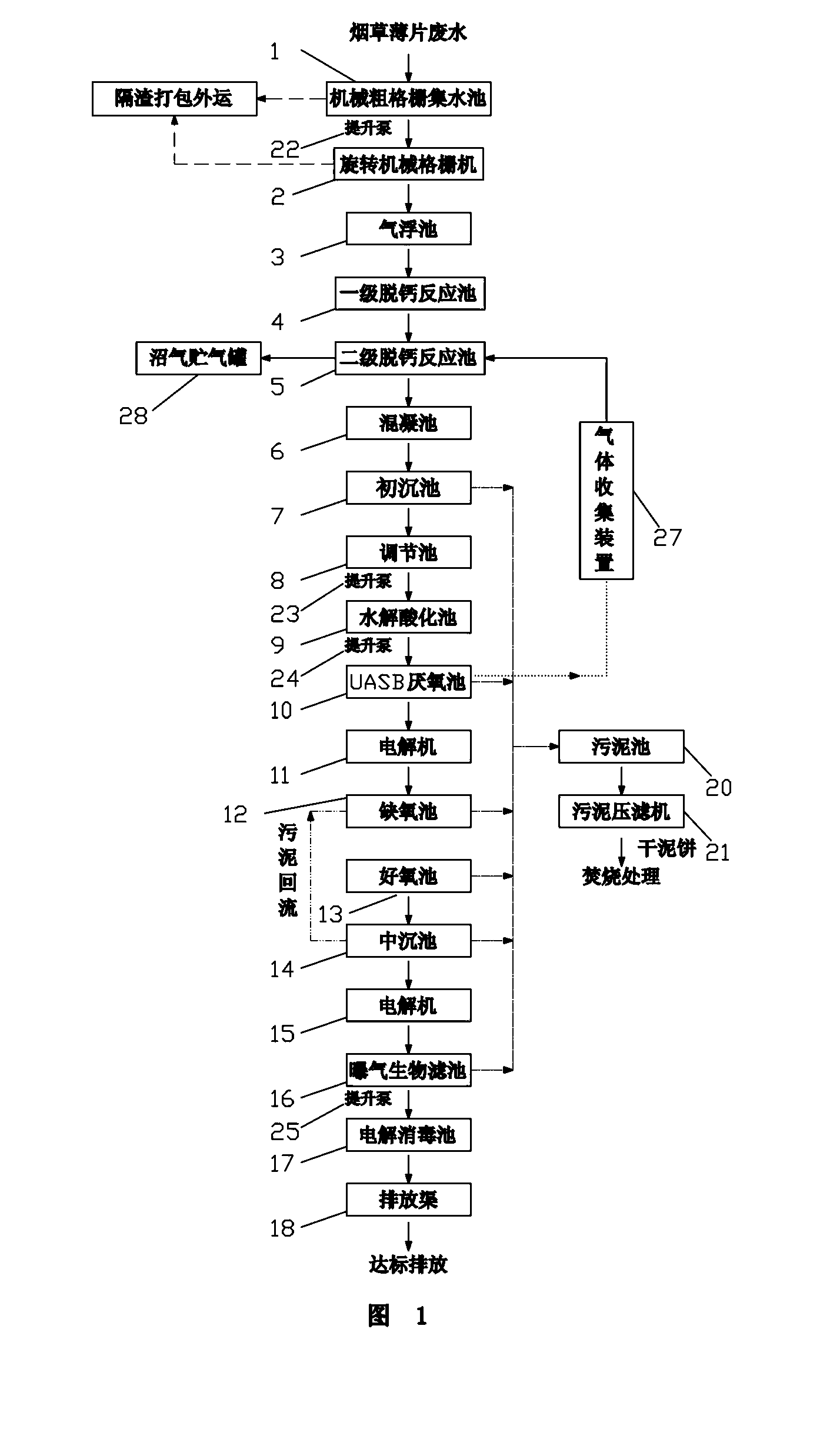

Treatment method of tobacco sheet production wastewater

InactiveCN103241910AHigh activityPrevent fouling of equipmentMultistage water/sewage treatmentSlagAnaerobic treatment

The invention provides a treatment method of tobacco sheet production wastewater. The treatment method comprises the following steps of: removing slag, carrying out chemical de-calcification, carrying out anaerobic treatment, carrying out electrolysis, carrying out A / O treatment, carrying out secondary electrolysis, biochemically processing by using a biological aerated filter, and disinfecting and treating sludge. The treatment method of tobacco sheet production wastewater is used for treating the tobacco sheet production wastewater by combining a chemical de-calcification technology, a biochemical technology, an electrochemical technology and a BAF (Biological Aerated Filter) technology, so that the cost is lower and the efficiency is higher, and therefore, the wastewater can be exhausted after reaching the standards.

Owner:BOYING XIAMEN SCI & TECH

Health food for protecting liver and adjusting blood fat and method for preparing the same

InactiveCN1466990AHigh activityReduce cholesterolDigestive systemUnknown materialsCordycepsActive component

A health-care food for protecting liver and regulating blood fat is prepared through extracting active components from red sage root, peach kernel and gynostemma pentaphyllum in sub-boiling water, adding chitosan, flocculating setting, filter, mixing with fermented cordyceps powder, spray drying, adding starch and dextrin, mixing, granulating, drying, tabletting and coating.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

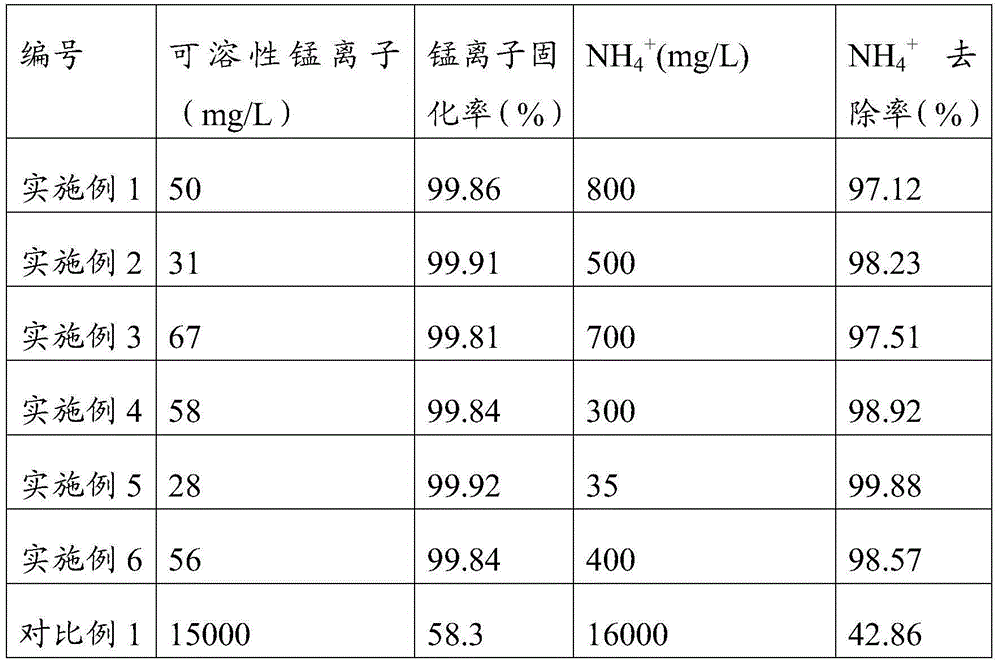

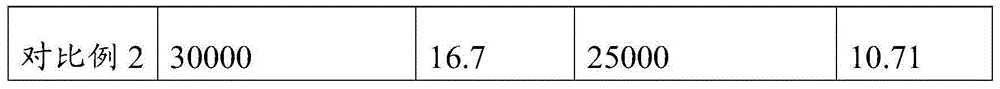

Hazard-free treatment technology for electrolytic manganese residues

ActiveCN104357662AReduce wasteThreat to healthProcess efficiency improvementElectrolysisWater resources

The invention discloses a hazard-free treatment technology for electrolytic manganese residues. The technology comprises the following steps: washing the manganese residues in a high-pressure manner by using slurry water, and basically enabling the manganese residues to form slurry liquid; injecting the manganese residue slurry liquid into a filter chamber of a membrane press filter to be filtered to obtain a filter cake, and performing two-section acid leaching on the filter cake under a prepressing state; keeping the prepressing state, and injecting multi-stage washing liquid into the filter chamber to be washed in a multi-section manner; injecting alkali liquid of which the pH is 9 to 10.5 into the filter chamber to solidify manganese ions, and inflating the air into a filter liquid passage in a stage manner during the solidifying treatment; performing the high-pressure press filtering on substances in the filter chamber, and after the solidifying treatment is finished, discharging the residues. Through the adoption of the technology provided by the invention, the soluble manganese ions in the electrolytic manganese residues can be further extracted, and at the same time, the manganese ions in the filter cake are converted into the insoluble manganese to be deposited, so that the remained manganese ions in the waste residues cannot be permeated into the ground surface or the underground water to pollute the underground water resources in the stacking process.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

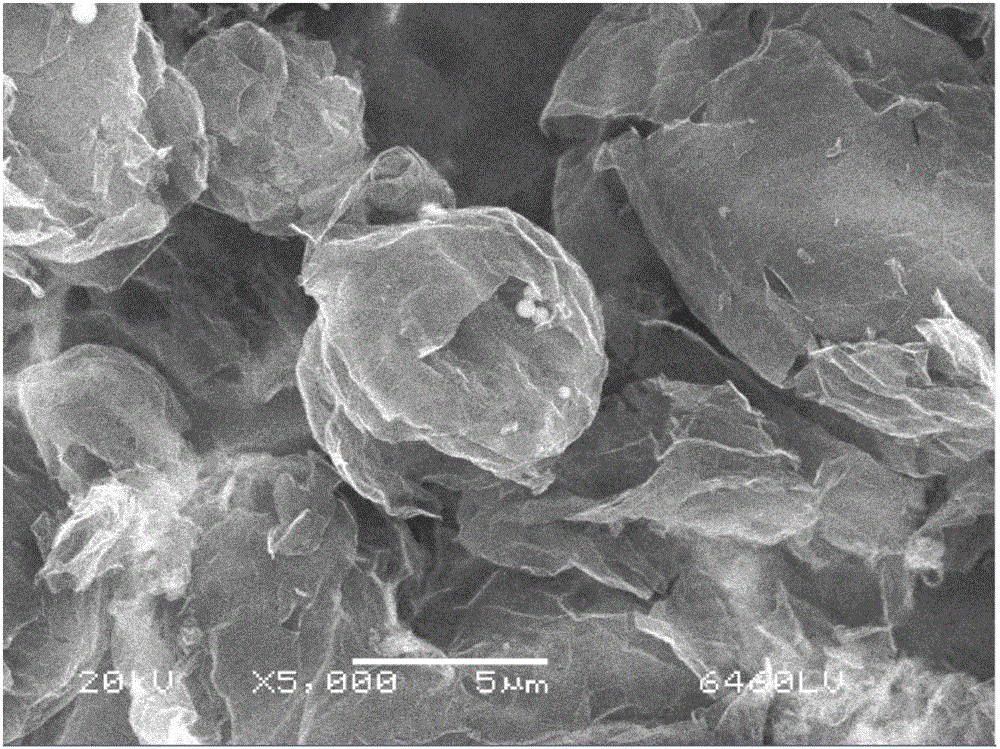

Method used for preparing sericite powder used for cosmetics

InactiveCN104909380AUniversally applicableHigh selectivityCosmetic preparationsToilet preparationsDispersityFlocculation

The invention discloses a method used for preparing sericite powder used for cosmetics. The method comprises following steps: shear flocculation, wherein a sericite quartz powder ore pulp with a mass concentration of 10 to 60% is delivered into a stirring sanding dispersing multifunction machine for shearing and stirring, and an inhibitor, a pH value regulating agent, a surface conditioning agent, and a cation collector are added successively so as to complete preliminary modification of sericite and formation of hydrophobic flocculation; flotation and purification, wherein after shear flocculation, the sericite quartz powder ore pulp is delivered into a flotation machine so as to obtain ore concentrate via floatation, wherein floatation concentration is controlled to be 3 to 20%, ore pulp pH value is controlled to be 2 to 3; and aging and modification, wherein obtained ore concentration I and II are subjected to dewatering and drying, and aging at high temperature so as to obtain the modified sericite powder used for cosmetics. The technological process of the method is coherent; operation is simple; the prepared cosmetic pigment is high in purity, excellent in dispersity, glossiness, malleability, and skin paste performance; skin feeling is fresh; the performance of the sericite powder is capable of satisfying quality requirements of extender pigments used for cosmetics; and the method can be used for matured industrialized large-scaled production.

Owner:WUHAN UNIV OF TECH +1

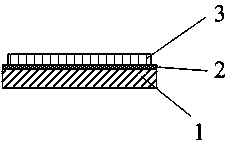

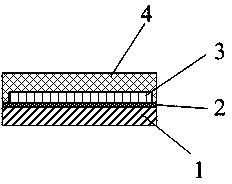

Stripping method of flexible substrate for displayer

ActiveCN103515313AFacilitate strippingSimple and fast operationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlexible display

The invention discloses a stripping method of a flexible substrate for a displayer. The stripping method includes the steps of coating a layer of sticking substances on a clean first base, enabling the surface, coated with the sticking substances, of the first base to be attached to a second base smaller than the first base in size, coating organic polymer liquid medicine on the first base and the second base to form a flat organic polymer thin film layer, enabling a TFT device and a light-emitting device to be machined on the organic polymer thin film layer, carrying out encapsulation, carrying out cutting on the flexible substrate along the edge of the second base, and placing the cut flexible substrate into a certain environment to enable the flexible substrate to fall off to form the flexible displayer. According to the stripping method, the flexible substrate can be well stripped from the bases, operation is easy and convenient, cost is low, and the stripping method will not cause adverse effects on the light-emitting device.

Owner:TCL CORPORATION

Wear-resisting rubber material for tires

The invention discloses a wear-resisting rubber material for tires. The wear-resisting rubber material comprises the following raw materials in parts by weight: 45-50 parts of butadiene styrene rubber, 10-15 parts of butadiene rubber, 10-15 parts of natural rubber, 20-25 parts of isoprene rubber, 0.5-0.8 part of sulfur powder, 2-3 parts of accelerant nonanoyloxybenzene sulfonate (NOBS), 1.3-1.7 parts of accelerant DM, 0.5-0.9 part of accelerant tetramethyl thiuram monosulfide (TMTM), 10-15 parts of nano-cellulose whisker, 10-15 parts of barite powder, 20-23 parts of calcite powder, 7-9 parts of brucite powder, 5-8 parts of aluminium nitride, 30-35 parts of carbon black N234, 1-1.2 parts of single alkoxy titanate coupling agent, 1-1.2 parts of plasticizer dicyclohexyl phthalate (DCHP), 3-7 parts of octyl epoxy stearate, 0.3-1.2 parts of anti-aging agent 264, and 1-2 parts of anti-aging agent MB. The wear-resisting rubber material for the tires has excellent wear-resisting and ageing-resistant properties, so that the wear-resisting rubber material can adapt to the service environment of the tires, and the cost is also reduced.

Owner:ZHAOQING JUNHONG CO LTD

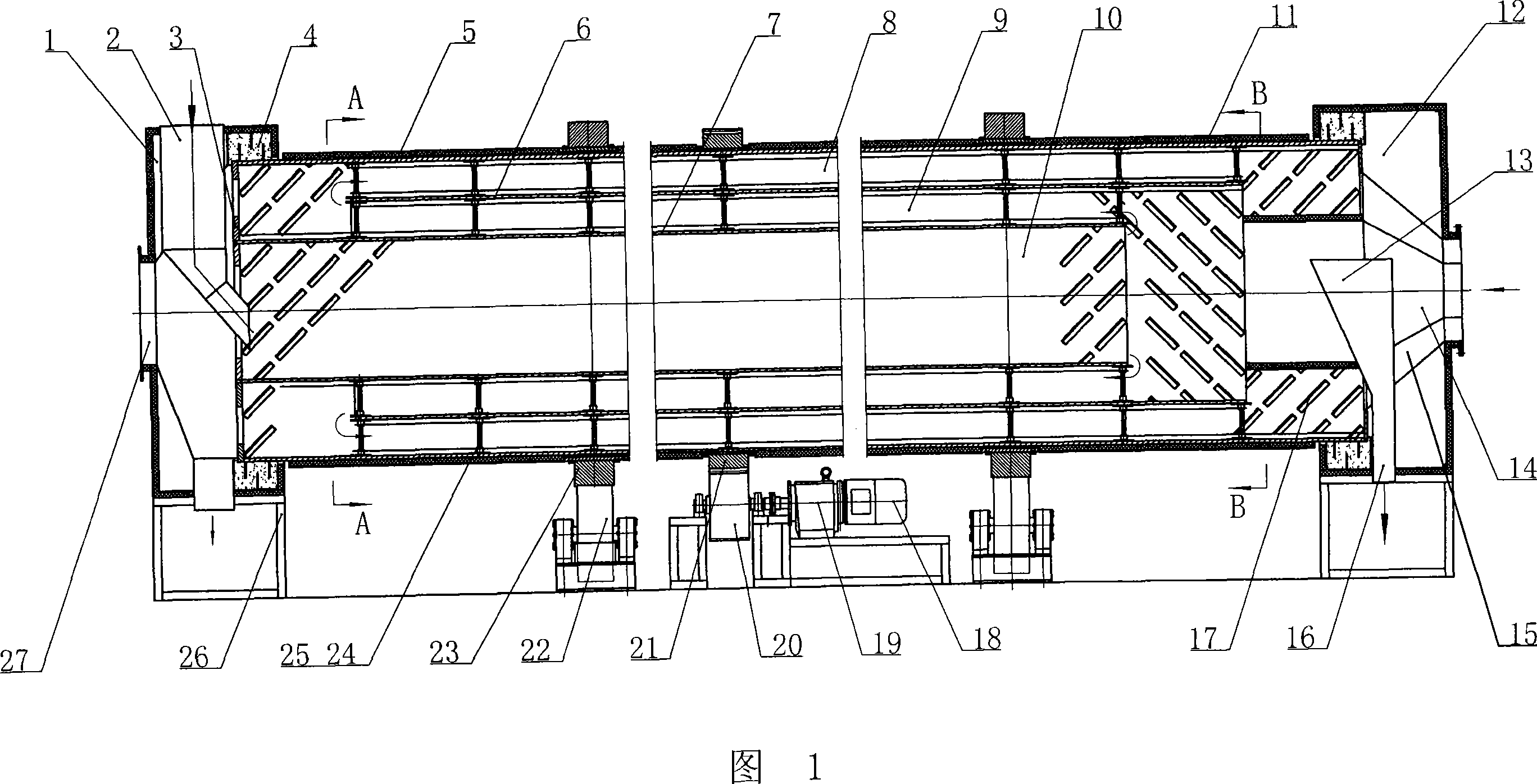

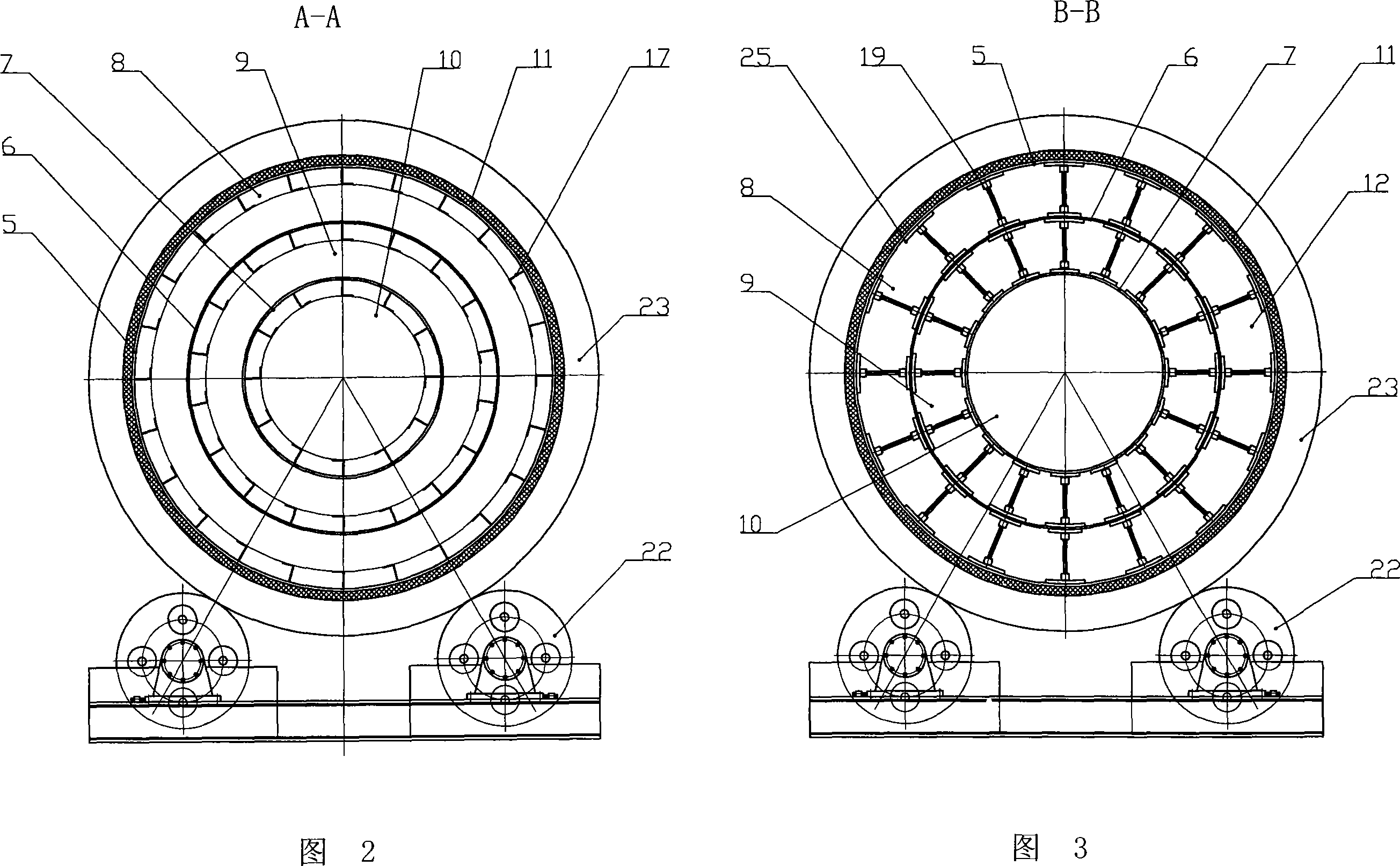

Three return journey barrel type drying machines

InactiveCN101216241AAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineEngineering

An improved three-pass cylinder drying machine comprises a machine body composed of a bracket, a sealed tank and a cylinder body, and a driving device, a supporting device and a controller, wherein the axial line of the cylinder body of the machine body is parallel to the horizontal surface, an inner cylinder and an outer cylinder that are concentrically arranged are assembled together in a staggered way to form the cylinder body, the formed cavities are used as three drying and precipitation units, the adjacent wallboards of the inner, middle and outer cylinders are connected and positioned via regulating and supporting plates and reinforced buffer plates, a heat insulating cover is disposed at the outer periphery of the wallboard of the outer cylinder, three material homogenizing and spreading machines are respectively disposed at the inner surfaces of the inner, middle and outer wallboards in a screw propulsion way and has reversed helical lines, and gears at the outer periphery of the machine body are aligned with the center of gravity of the cylinder. The inventive three-pass cylinder drying machine effectively solves the shortcomings of the conventional cylinder drying machine, including high deformation and misplacement liability and high axial dislocation liability; and has the advantages of reasonable structural design, stable performance, large precipitation range for one time, high thermal efficiency, saved energy consumptionand wide application range.

Owner:沈阳清井环保机械工程有限公司

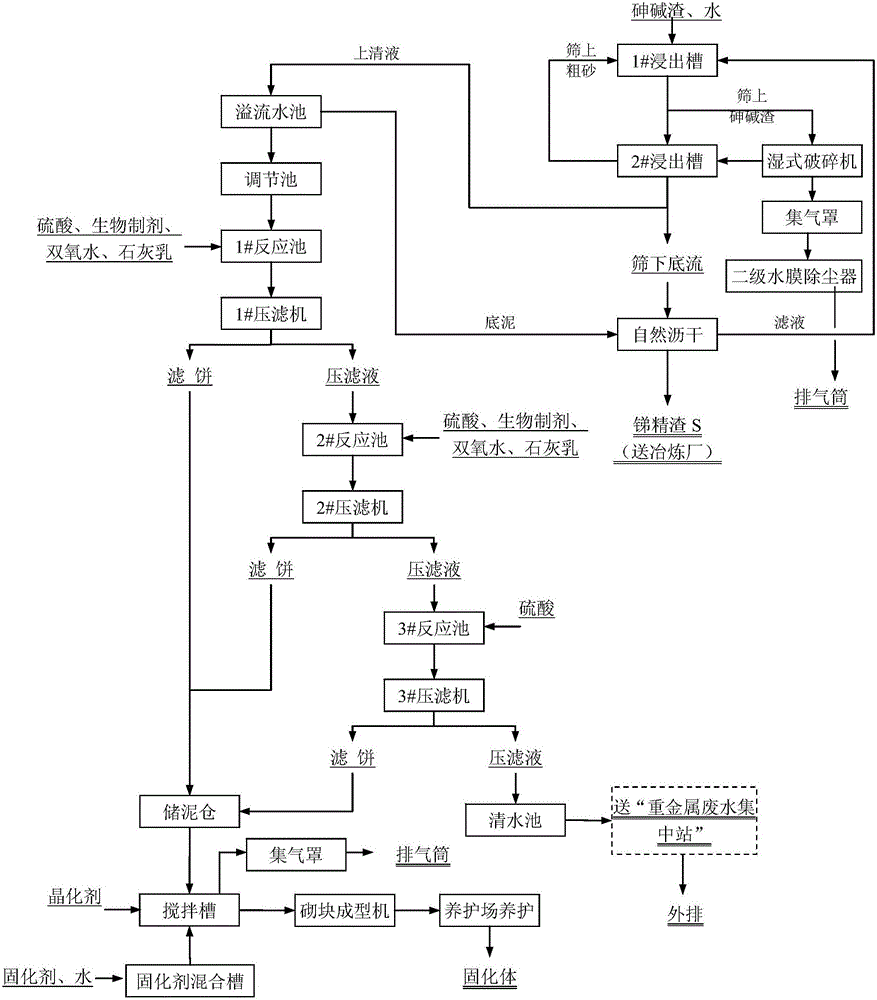

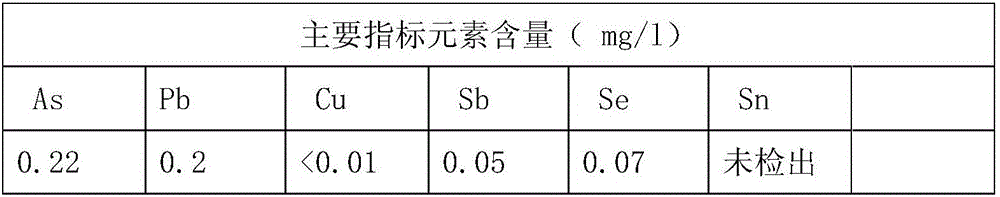

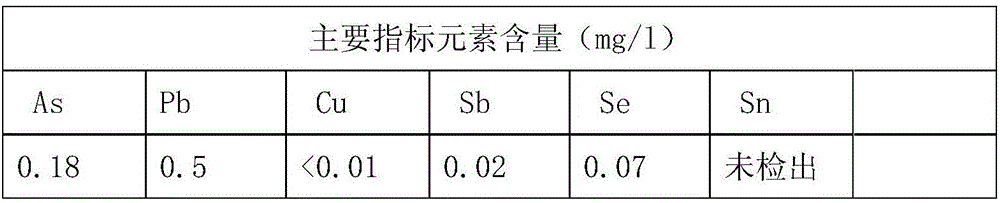

Technology for normal-temperature wet-process harmless treatment of arsenic soda slag

ActiveCN106319233AEfficient recyclingEffectively fixedTransportation and packagingSolid waste disposalHydrometallurgyMaterials science

The invention belongs to the field of wet metallurgy and relates to a treatment method of arsenic soda slag produced in a pyrogenic antimony smelting process. The arsenic soda slag is subjected to wet crushing, water is added in the normal-temperature state, the mixture is subjected to solid-liquid separation, metal antimony in the slag is recovered, a high-arsenic leaching liquid after solid-liquid separation is subjected to arsenic precipitation with concentrated sulfuric acid, a biological agent, hydrogen peroxide and lime milk, and water after arsenic removal reaches the standard to be discharged. Produced high-arsenic slag is detoxicated through addition of a crystallization agent, and then a solidified body is prepared through addition of a solidification agent and can reach toxic leaching requirements of general solid waste according to a toxic leaching test. With the technology, environmental pollution caused by storage of the arsenic soda slag can be greatly reduced, the comprehensive utilization rate of mineral resources can be increased, and the valuable metal recovery rate is high. Through one-year production practice, various substances can be effectively recycled at the normal temperature with the technology, and As can be efficiently fixed. Material recrystallization does not occur in the whole technological process, so that the whole technology can be conducted smoothly, and necessary conditions are provided for industrial application.

Owner:HUNAN CHENZHOU MINING CO LTD

Method for extracting hemicellulose from plant fiber

The invention aims at solving the problem of high cost of ethanol extraction of hemicellulose and provides a method for extracting the hemicellulose from plant fiber. The method is characterized by comprising the following steps of dissolving the plant fiber in an alkaline solution with the mass fraction of 5%-15%, then removing large particle impurities in the alkaline solution obtained by squeezing by adopting a conventional pre-filtration method, further enabling the alkaline solution to enter a ceramic membrane device through a pump to perform cross-flow filtration, adding an acid into an obtained concentrated solution for neutralization, collecting the precipitated hemicellulose, and drying to obtain the hemicellulose, wherein the alkaline solution after pre-filtration contains 50-100g / l of alkali and 40-60g / l of hemicellulose. The whole process basically adopts a pure physical method to extract the hemicellulose, the purity of the obtained hemicellulose is high, and the operation cost is low.

Owner:YIBIN HIEST FIBER +1

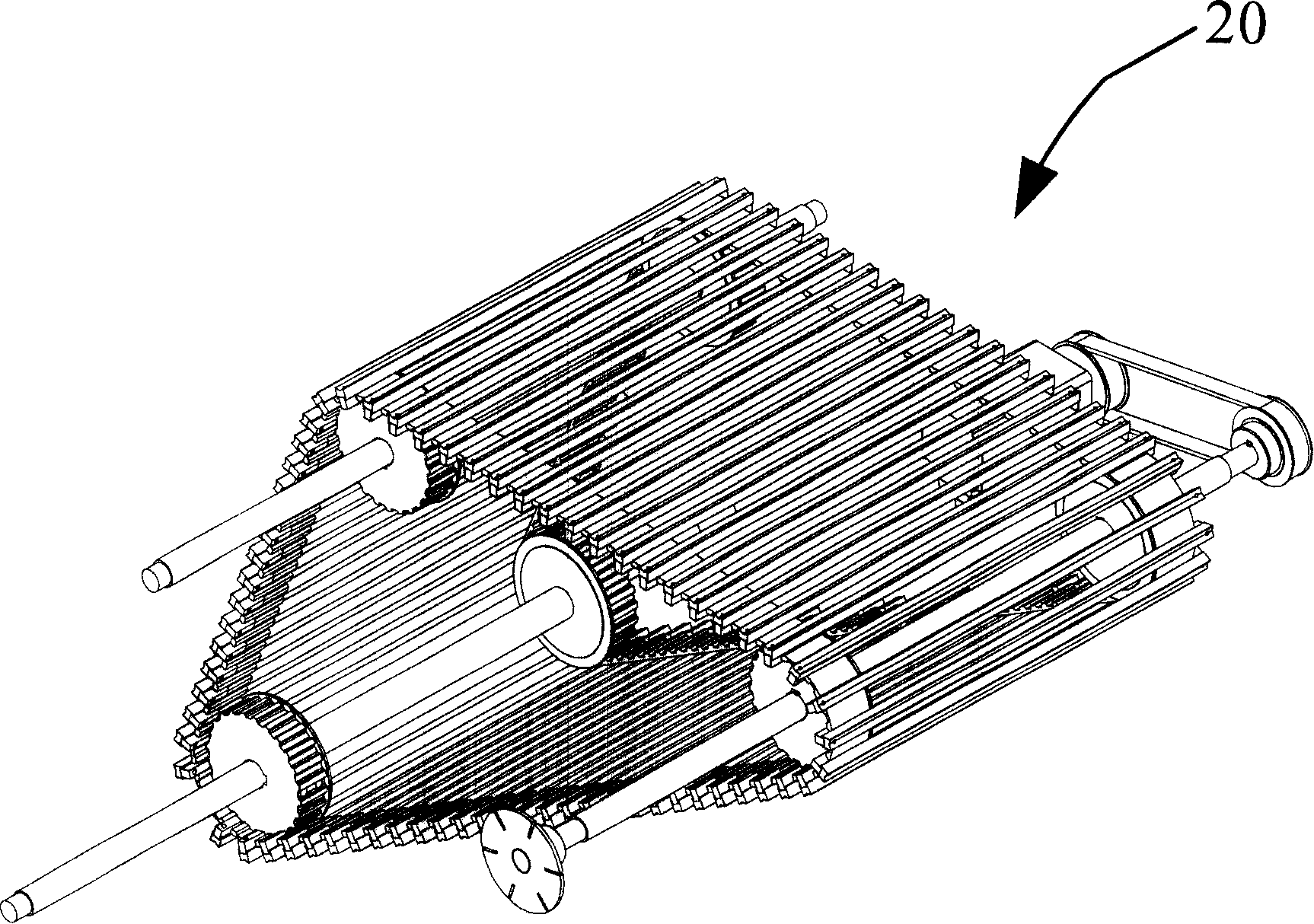

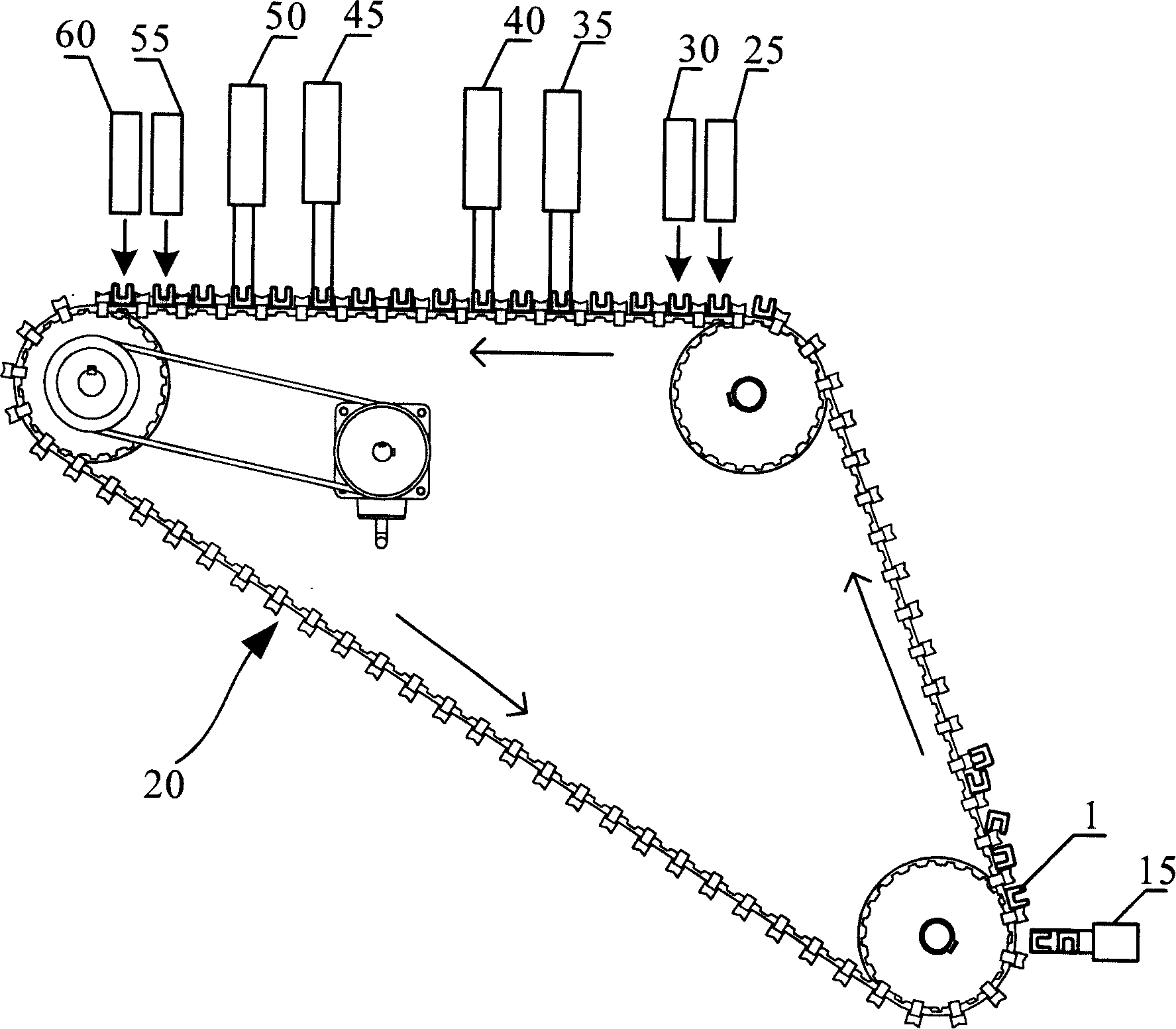

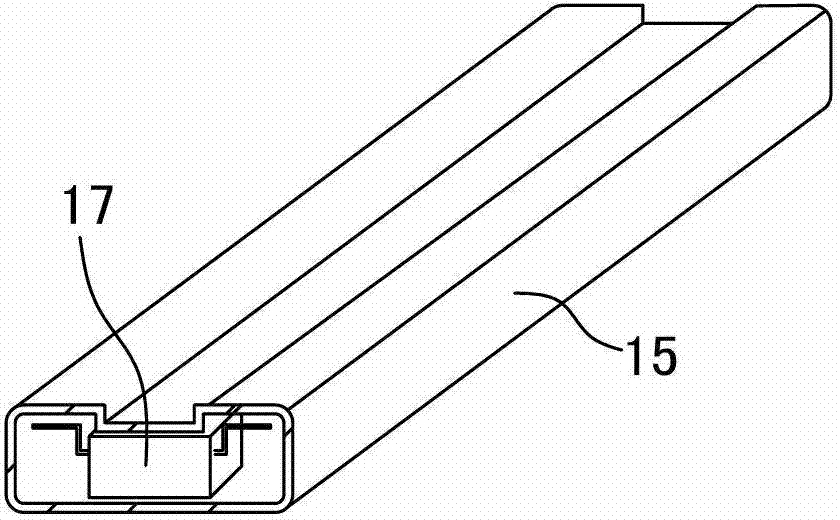

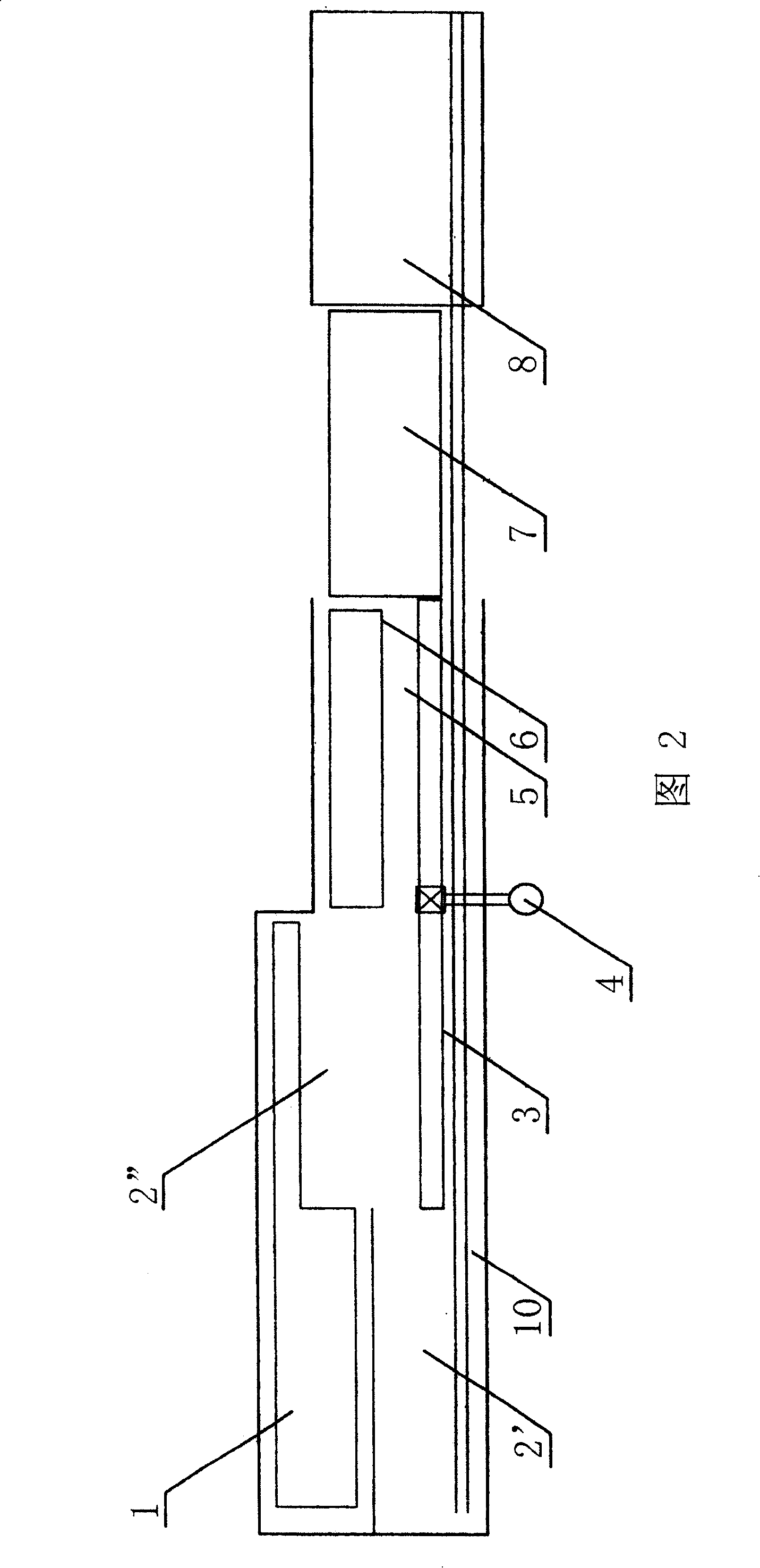

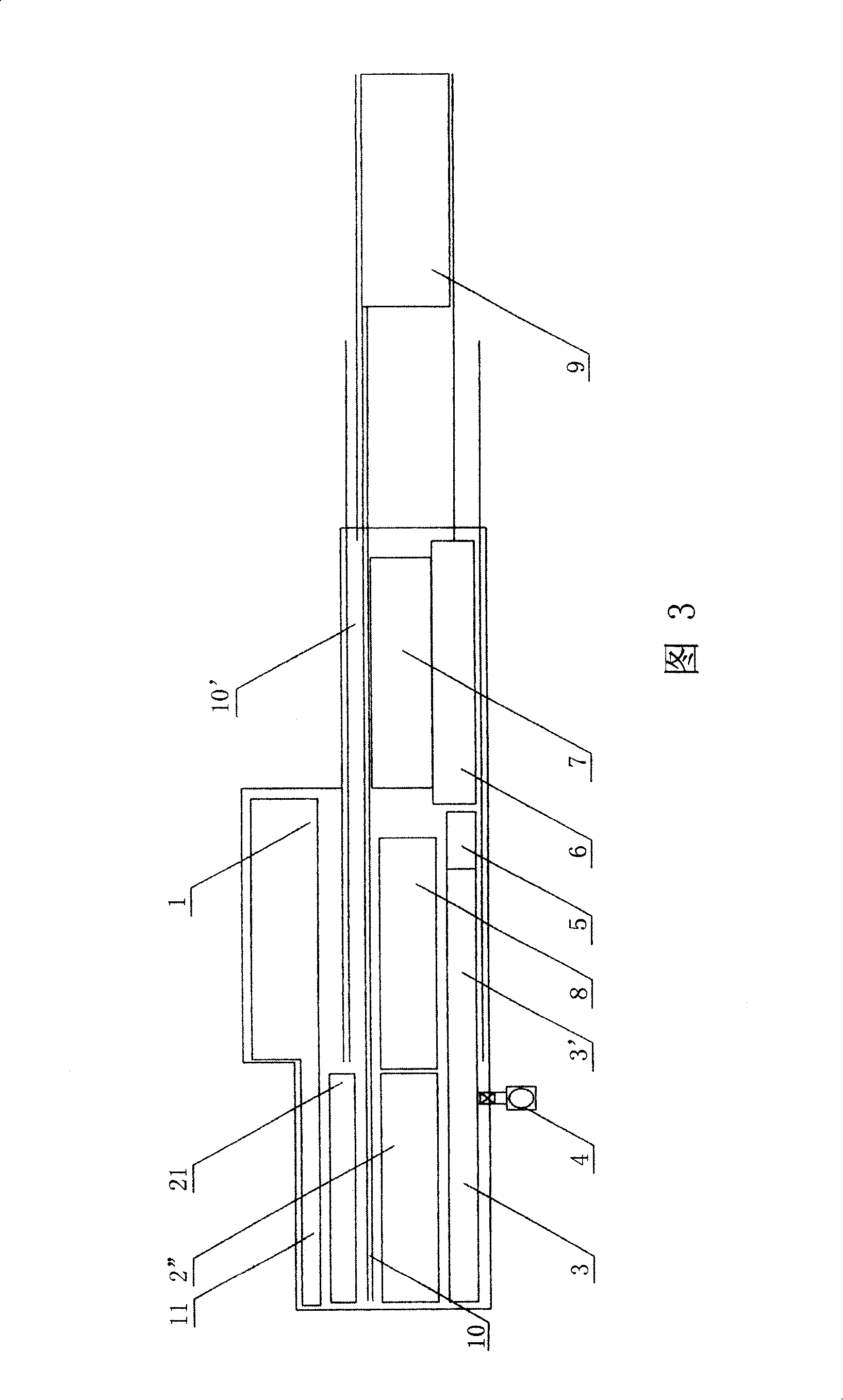

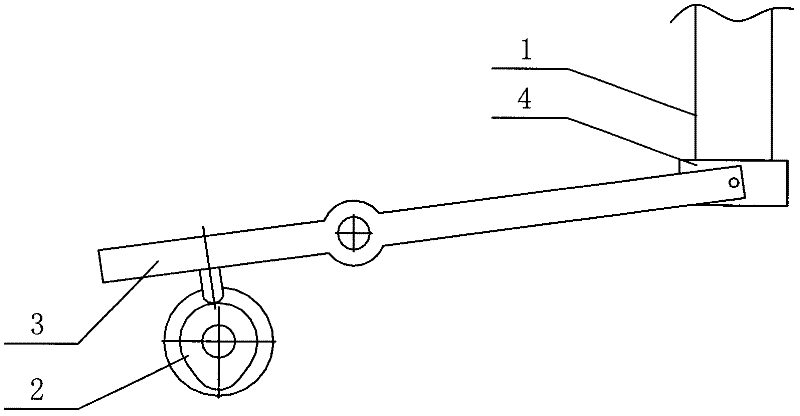

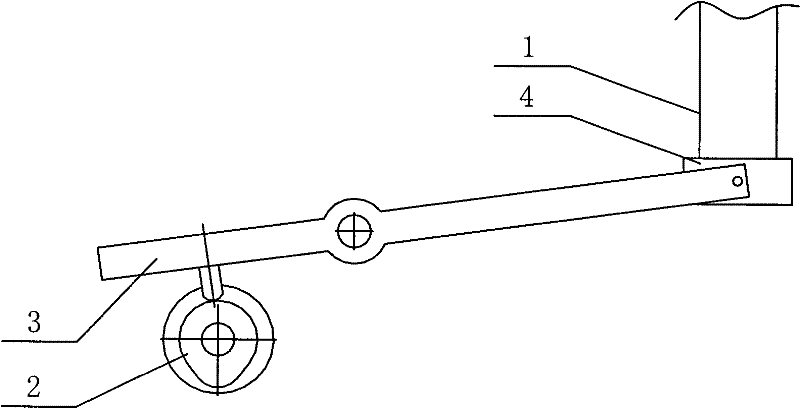

Automatic pipe layout mechanism for receiving pipes of integrated circuits

The invention discloses an automatic pipe layout mechanism for receiving pipes of integrated circuits. The automatic pipe layout mechanism is characterized by consisting of a single pipe separation mechanism and a reversing mechanism, wherein the single pipe separation mechanism comprises at least two single pipe separation wheels in the same structure, at least one single pipe groove is arranged on the peripheral surface of each of the single pipe separation wheels, and at least one detection unit for detecting the forward direction of the receiving pipes is arranged corresponding to the receiving pipes; and the reversing mechanism comprises at least one reversing wheel, a reversing groove is arranged on the reversing wheel in the radial direction correspondingly to the receiving pipes, and a stopper is arranged at the lowest position of the reversing wheel. According to the automatic pipe layout mechanism for the receiving pipes of the integrated circuits, the layout of the receiving pipes can be completely automated, the layout efficiency can be greatly increased, the human resources can be saved, and the accident of equipment and the damage on the integrated circuit product can be avoided, so that the whole process flow can be more smooth.

Owner:苏州均华精密机械有限公司

Extraction of soya isoflavone, concentrated soya protein and soya oligose

InactiveCN1680357AReduce energy consumptionReduce lossesSugar derivativesPlant peptidesResource utilizationSlag

Process for extracting soy isoflavone, soy concentrated protein and soy oligosaccharide is carried out by: 1) breaking bean oil cake, supersonic circulating extracting and centrifugal filtering with material ratio 1:10 of broken bean oil cake powder and solvent, and obtaining extract and bean oil cake slag; 2) concentrating the extract and recovering solvent, adding pankrin into concentrate, and obtaining purified liquid and protein milk curd by centrifugal and natural method; 3) passing the purified liquid through macro-porous adsorptive resin bed, and obtaining water eluent and alcohol eluent; 4) concentrating alcohol eluent and recovering alcohol, spraying and drying concentrate, and obtaining soy isoflavone; 5) mixing bean oil cake slag with protein milk curd, drying, breaking, and obtaining soy concentrated protein; 6) de-coloring water eluent, filtering, concentrating, and obtaining soy oligosaccharide; 7) recovering process assistant, regenerating or purifying circulating utilizing. It achieves no waste discharge and resource utilization.

Owner:重庆工学院

Method for producing diammonium phosphate by using extract spent acid resulted from phosphoric acid purification

The invention relates to a method for producing diammonium phosphate by using extract spent acid resulted from phosphoric acid purification. The method comprises the following steps: adding a modified frequency modulator on an extract spent acid conveying pump and ensuring the conveying amount of the extract spent acid to be constant; mixing the extract spent acid with common raw material phosphoric acid, and causing the content of sesquioxide in the complex acid to be lower than 3 percent; adding surfactant in the complex acid to increase the fluidity and the surface activity of a reaction slurry and reduce the viscosity of the reaction slurry; and according to a conventional method, using ammonia to neutralize the complex acid so as to obtain the diammonium phosphate. The method is a precedent in realizing the recovery of high-content impurity acid and the production of fine-quality diammonium phosphate products meeting national standards, when compared with a conventional process. The procedures in the method are unhindered, thereby being favorable for reasonably utilizing the phosphorus resource and conforming to the requirement of recycling economy. The method is suitable for enterprises producing the diammonium phosphate of purified phosphoric acid by using extracting agent.

Owner:WENGFU (GRP) CO LTD

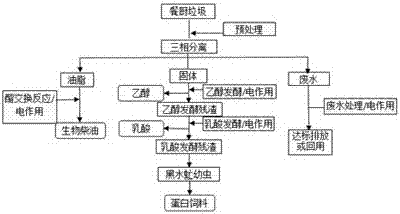

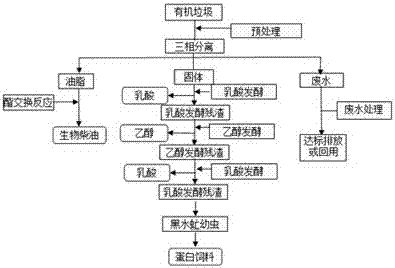

Kitchen waste high-value-application method

PendingCN107345176AReduce secondary pollutionHigh yieldFatty acid esterificationTreatment by combined electrochemical biological processesLactic acid fermentationChemistry

The invention relates to a kitchen waste high-value-application method. The method comprises the following steps: S1, pretreatment: performing a hydro-thermal treatment on the kitchen waste, performing a three-phase separation on the treated kitchen waste; S2, preparation of biodiesel with grease: preparing the biodiesel by performing a transesterification on the grease prepared by three-phase separation in the S1 and short-chain alcohol under the action of a catalyst; S3, solid kitchen waste treatment: continuously performing alcohol fermentation and / or lactic acid fermentation on the solid kitchen waste prepared by the three-phase separation in the S1, feeding insects with the fermented residues; S4, waste water treatment: performing waste water treatment on waste water prepared by three-phase separation in the S1 and waste water generated by fermentation in the S3. By adopting the kitchen waste high-value-application method, the kitchen waste is treated comprehensively by combining a plurality of means to obtain high-valued products, and the treated kitchen waste is low in residue, and is high in utilization rate.

Owner:SOUTH CHINA AGRI UNIV

Production workshop for 55mPHC tubular pile

ActiveCN101224602AReduce the impactImprove efficiencyAuxillary shaping apparatusEngineeringCentrifuge

The invention discloses a production workshop for a 55m PHC tubular pile, the workshop plans to adopt a traveling crane on the basis of the original planar layout, the procedures of mold-closing and stretching-centrifugal operation-steam curing under normal pressure-removal from mold are arranged in two areas, which minimizes the movement distance of a template in one circle ( the movement distance of an upper die (in two areas) is that 55m multiplied by 2 is equal to 110m ), so the efficiency is high; the normal pressure curing area is besides the centrifuge, thus guaranteeing the security and smaller influence of the noise on workers. The technical improvement leads the workshop provided by the invention to be reasonable in layout, smooth in technique; besides, the production efficiency can be improved while the space can be saved.

Owner:中交三航局第三工程有限公司 +1

Vacuum introduction manufacture method of parts with vacuum reinforced rib structure

The invention provides a manufacturing method of a component with vacuum stiffener structure by vacuum guiding. The method comprises the following steps of: (1) preparing a mould, cleaning out the surface of the mould, and then spraying a mold release agent for at least one time and drying the mould release agent completely; (2) laying a reinforced material layer on the mould which is processed by step (1) according to required size and the thickness of the layer; (3) placing the stiffener on the reinforced material layer; and (4) laying demoulding cloth and high permeable medium on the layers of the stiffener and the reinforced material and laying out an inlet and an outlet for resin. The method is characterized in that a balloon is put into the stiffener in the step (3) and the balloon is filled with air. The method has the advantages that the function and integrity of ships, large components of locomotives and vehicles, or an enginery room cover are improved, the manufacture cycle of a product is shortened, and the manufacture cost is reduced.

Owner:DONGHUA UNIV +1

Automatic discharging device for punching machine

The invention discloses an automatic discharging device for a punching machine, which is applied on a punching head of the punching machine and comprises a cam and a rocking bar driven by the cam, wherein a guiding and discharging seat is arranged at the tail end of the rocking bar; the guiding and discharging seat is in sleeved connection with the punching head and moves together with the punching head; and the linear speed of the guiding and discharging seat, which is produced by the swinging amplitude of the rocking bar, is lower than recovery speed after punching of the punching head. As the speed after punching and recovery of the punching head is higher than the lifting speed of the guiding and discharging seat, relative displacement is produced between the punching head and the guiding and discharging device; and thus, the blank material tightly sleeved on the punching head after punching automatically fall down to the position of a mold under the resistance of the guiding and discharging seat, and the smooth implementation of each process is ensured.

Owner:无锡市金杨新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com