Production workshop for 55mPHC tubular pile

A technology for workshops and pipe piles is applied in the field of buildings to achieve the effects of ensuring safety, saving area and space, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

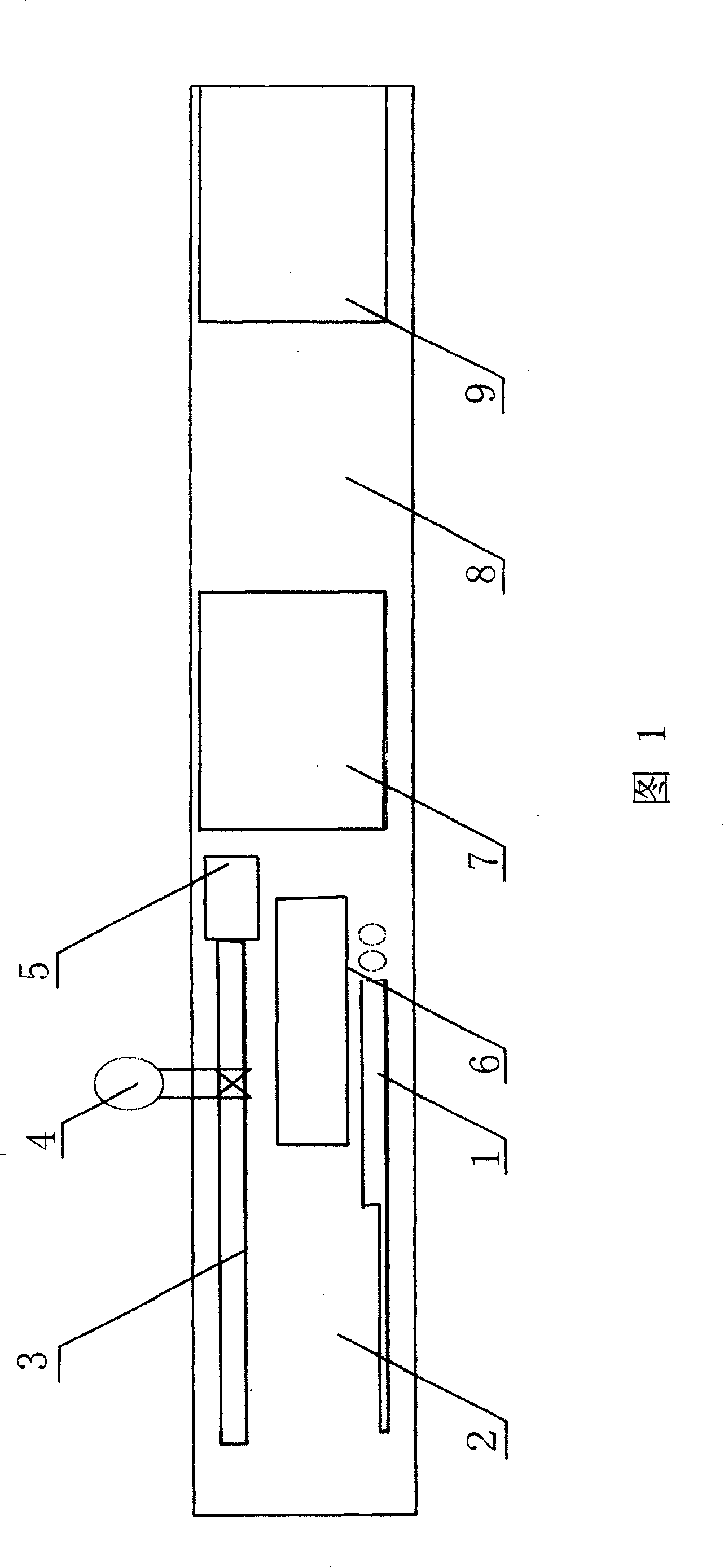

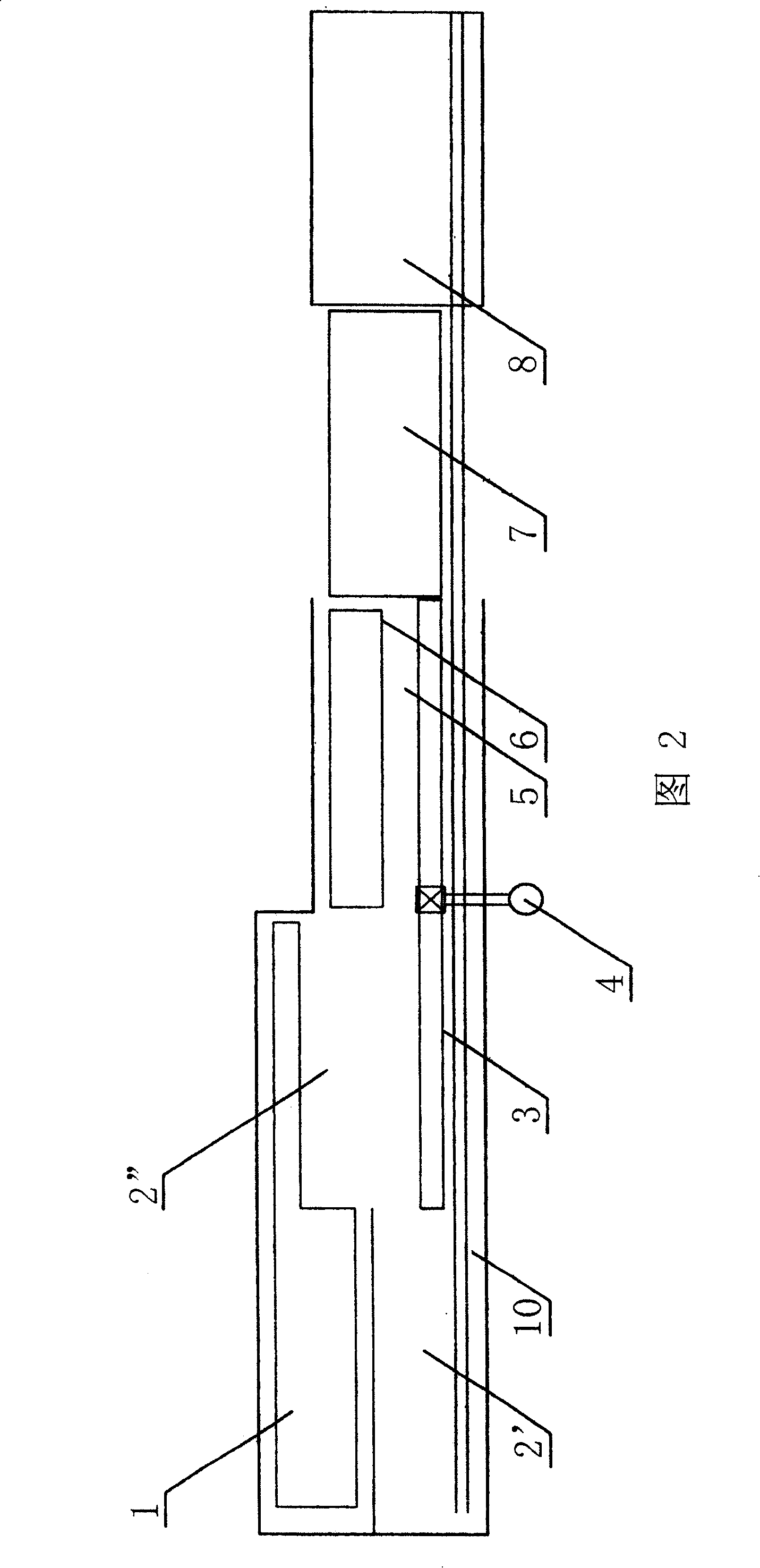

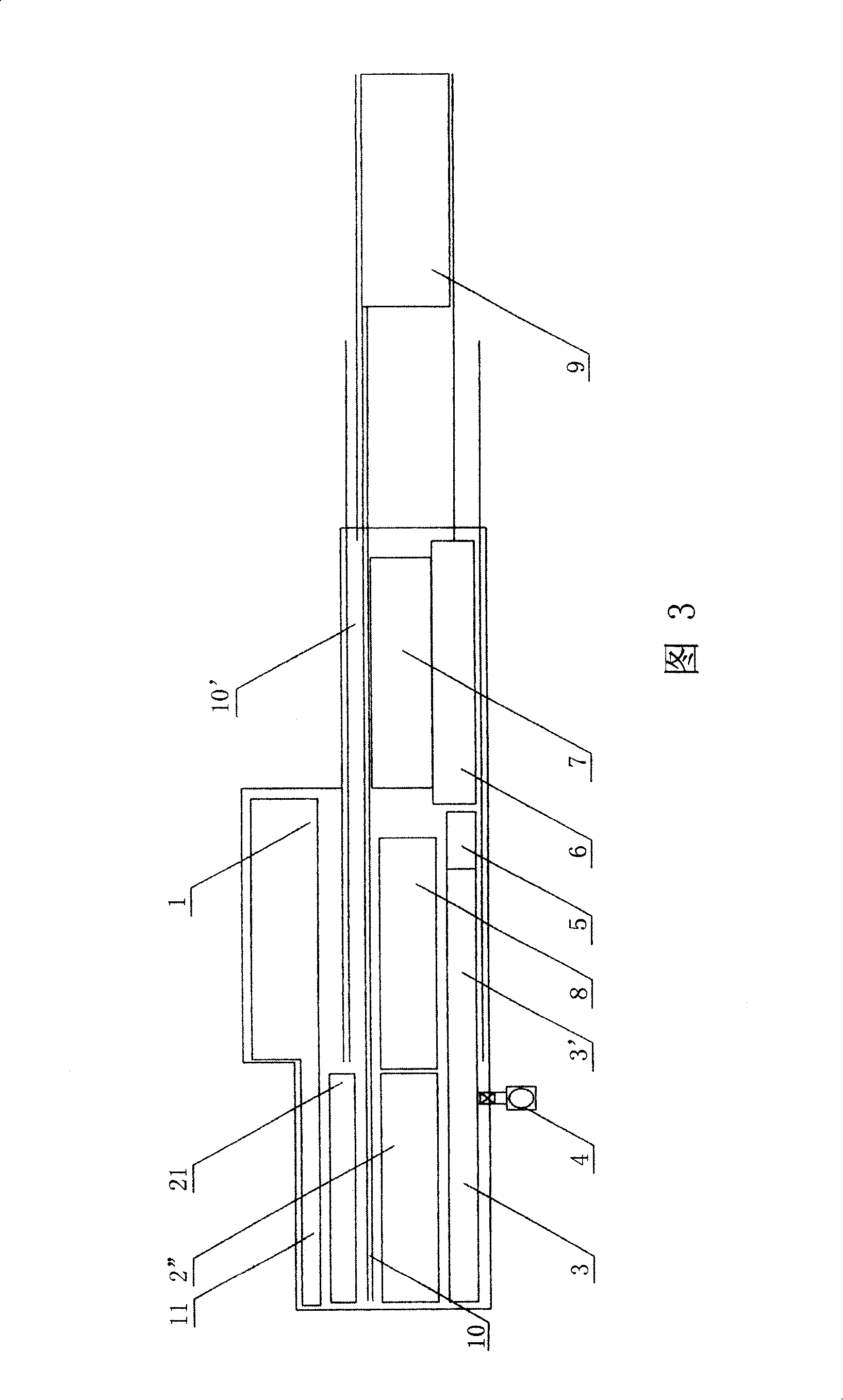

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

[0021] Referring to Fig. 3, the production workshop of a kind of 55mPHC pipe pile of the present invention, this workshop comprises workshop building and is positioned at the driving and plane working area in workshop building, and plane working area comprises reinforcement cage processing area 1, reinforcement cage stacking area 21 , lower mold stacking and reinforcement cage mold entry area 2″, concrete distribution area 3, concrete mixing building 4, mold clamping area 3′, tensioning area 5, centrifugal area 6, normal pressure curing area 7, upper mold stacking and form removal Zone 8 and autoclave zone 9.

[0022] The entire plane work area is divided into two parts, one includes steel bar processing area 1, steel cage stacking area 21, lower mold stacking and steel cage entering mold area 2", concrete distribution area 3, concrete mixing area 3, mold clamping area 3', tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com