Two-stage coaxle multi-wedge type pulley and processing technology and equipment

A processing technology and pulley technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problem of poor fastness of two-stage coaxial multi-ribbed pulleys, fewer processing stations, and cannot be installed at one time Problems such as clip processing and molding, etc., to overcome the large error of coaxiality, smooth processing technology and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

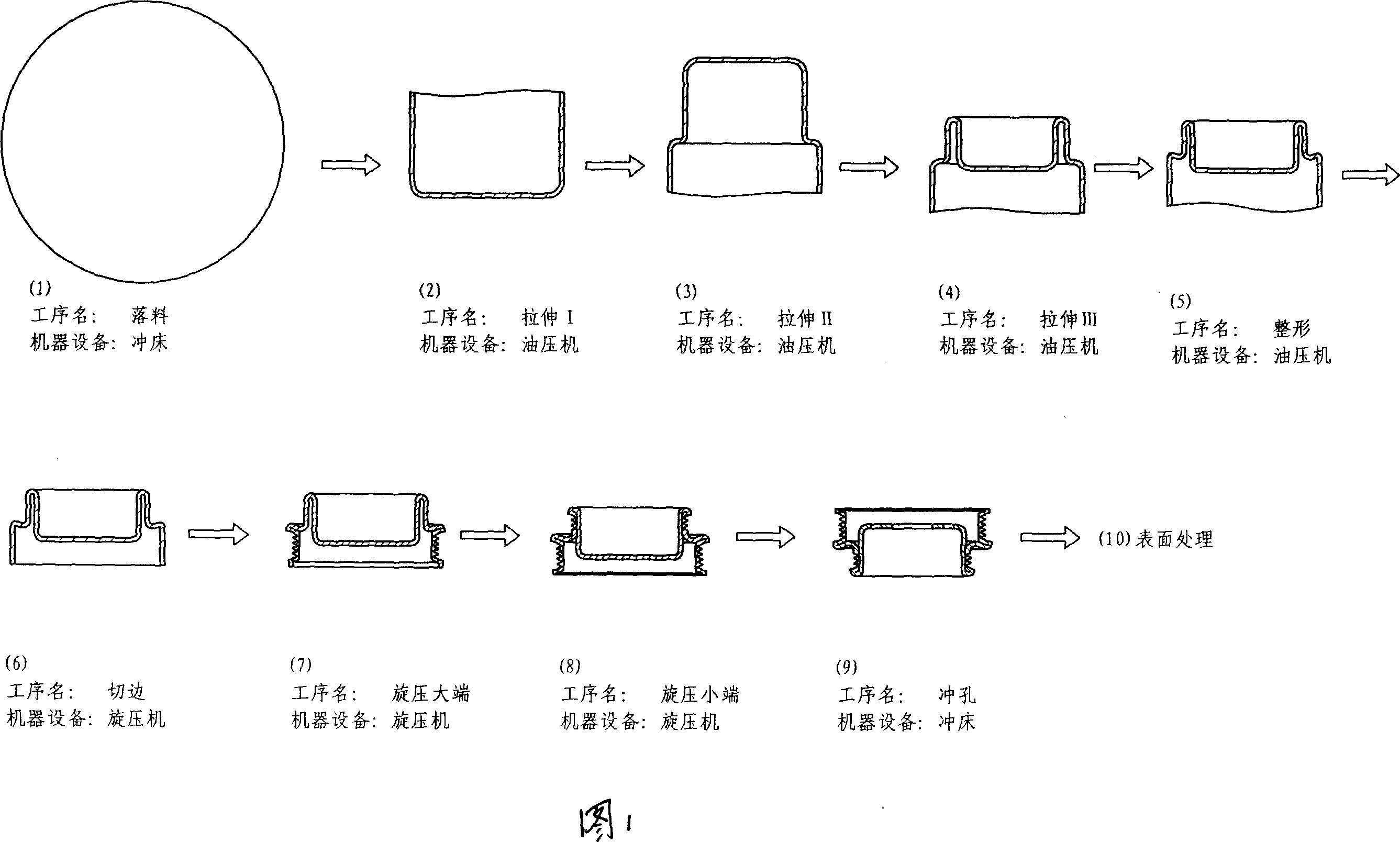

[0013] As shown in Figure 1, the processing technology of the two-stage coaxial multi-ribbed pulley includes:

[0014] Blanking: Punch the thin-rolled steel plate into a circular plate on a punching machine;

[0015] Multi-step stretching: This embodiment includes three stretches on the hydraulic press. The first step is to stretch the blanked material on the hydraulic press to form a cylindrical workpiece for the first time. The second step is to stretch the blank for the first time. The finished cylindrical workpiece is turned upside down on the hydraulic press and stretched into a blank with two-stage pulley contours, and the third step is to stretch the blank drawn in the second stage through the hydraulic press to form a semi-finished product of two-stage coaxial multi-ribbed pulley;

[0016] Shaping: Shaping the semi-finished product of two-stage coaxial multi-ribbed pulley after multi-channel stretching on a hydraulic press;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com