Composite slagging agent for semi-steel making and preparation method thereof and semi-steel making method

A composite slag-forming agent and semi-steel technology, applied in the field of semi-steel steelmaking, can solve the problems of low Mn element content and large dosage, and achieve the effects of increasing the Mn element content, a simple preparation method, and reducing the production cost of steelmaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the composite slagging agent provided by the present invention comprises: crushing and grinding silicate-type manganese ore, iron oxide scale, quartz sand and binder until the particle size is below 1 mm, and mixing uniformly to obtain a mixture, and pressing the mixture into balls After the pellets are dried, they are roasted, preferably naturally dried, and the pellets are not easy to form cracks.

[0015] According to the preparation method of the composite slagging agent provided by the present invention, the above-mentioned equipment for grinding and mixing and equipment for pressing pellets can adopt various equipment known to those skilled in the art, for example, the grinding and mixing equipment can use crushers and ball mills; The equipment for pressing the pellets can adopt a symmetrical pellet press or a granulator.

[0016] According to the preparation method of the composite slagging agent provided by the present invention, prefer...

Embodiment 1

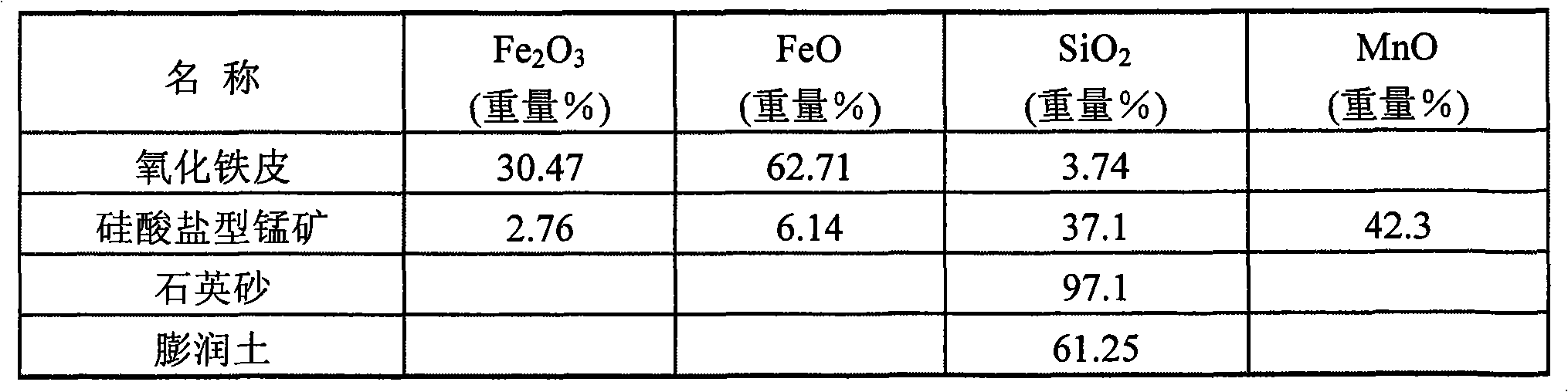

[0029] The main composition of iron oxide scale, silicate manganese ore, quartz sand and bentonite as binder are shown in Table 1.

[0030] Table 1

[0031]

[0032] 1. Preparation of composite slagging agent

[0033]Add the iron oxide scale, silicate manganese ore powder, quartz sand, and bentonite in the above Table 1 in a mass ratio of 10:50:35:5 into a roller sand mixer for grinding and mix and stir evenly, the resulting mixture The particle size is below 1.0mm. The mixture is then added to a symmetrical briquetting machine, under the condition that the pressure of the symmetric briquetting machine is 15Mpa, the pellets with a diameter of 10-50mm are extruded, and the pellets are naturally dried for 48 hours, and heated at a temperature of 300 Roasting under the condition of 0.5°C for 0.5 hours, a pellet-shaped composite slagging agent was obtained, and the water content of the composite slagging agent was 4% by weight.

[0034] The composition of the obtained compos...

Embodiment 2

[0048] Add the iron oxide scale, silicate manganese ore powder, quartz sand, and bentonite in the above Table 1 in a mass ratio of 15:40:40:5 into a roller sand mixer for grinding and mix and stir evenly, the resulting mixture The particle size is below 1.0mm. The mixture is then added to a symmetrical briquetting machine, under the condition that the pressure of the symmetric briquetting machine is 15Mpa, the pellets with a diameter of 10-50mm are extruded, the pellets are naturally dried for 48 hours, and heated at a temperature of 250 Roasting under the condition of 1.0°C for 1.0 hour, a pellet-shaped composite slagging agent was obtained, and the water content of the composite slagging agent was 2% by weight.

[0049] The composition of the obtained composite slagging agent is detected by chemical analysis method, and the main component of the composite slagging agent is: Fe 2 o 3 5.83 wt%, FeO 13.6 wt%, MnO 17.22 wt%, SiO 2 59.42% by weight.

[0050] The drop strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com