Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Short melting range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine purification method for rubber vulcanization accelerant 2-mercaptobenzothiazole (M)

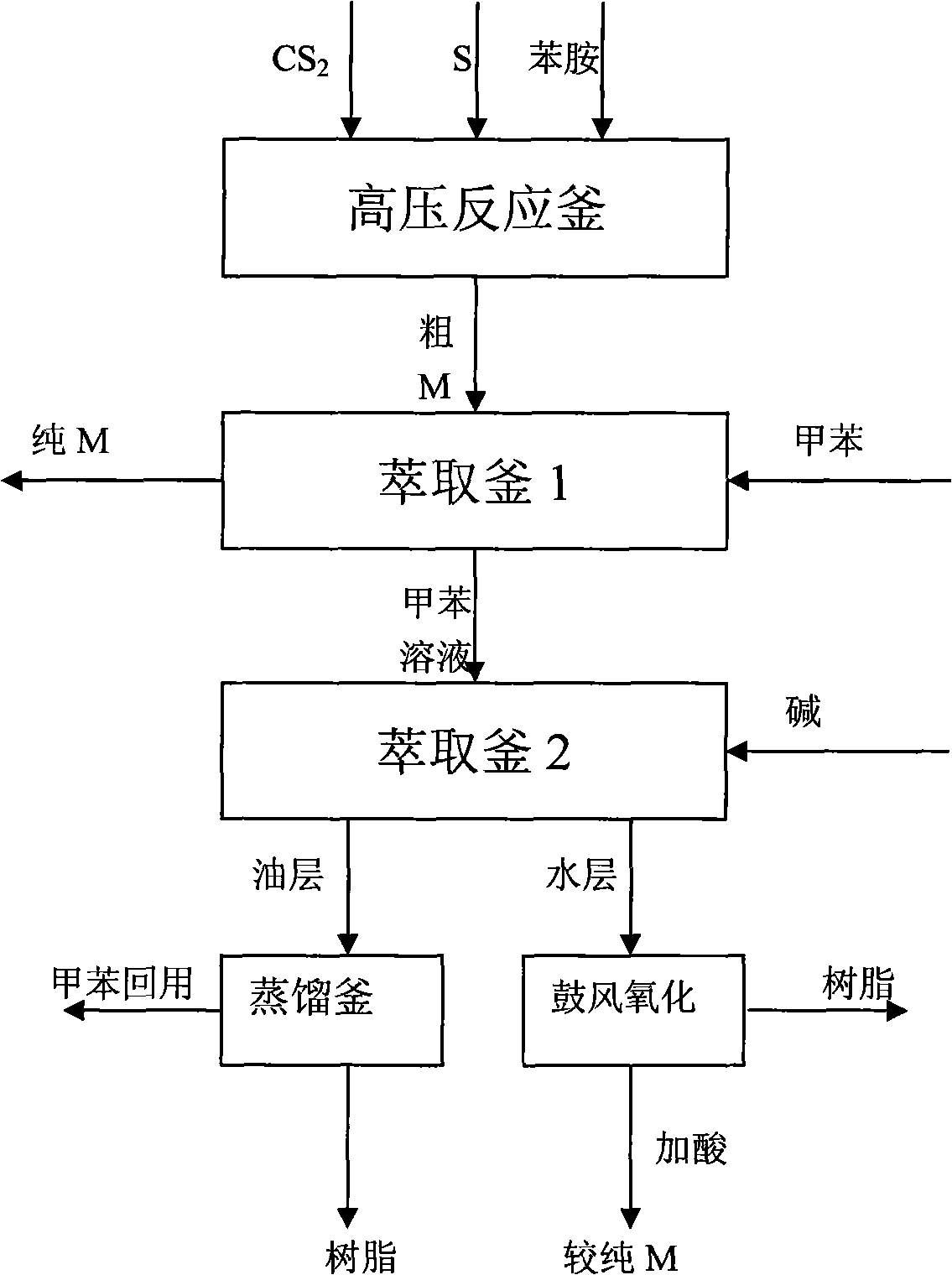

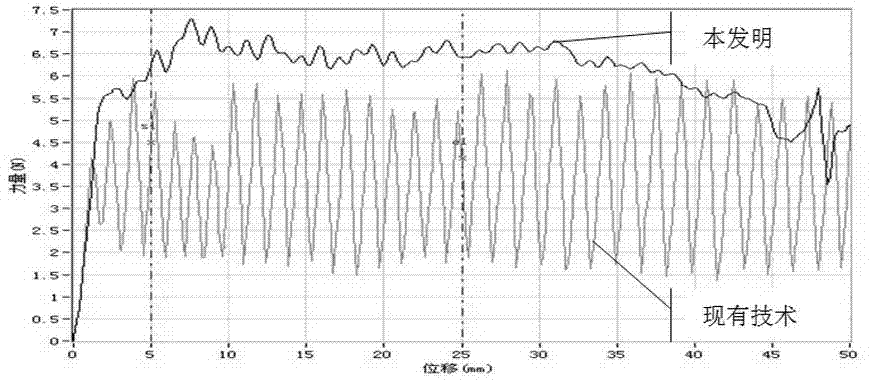

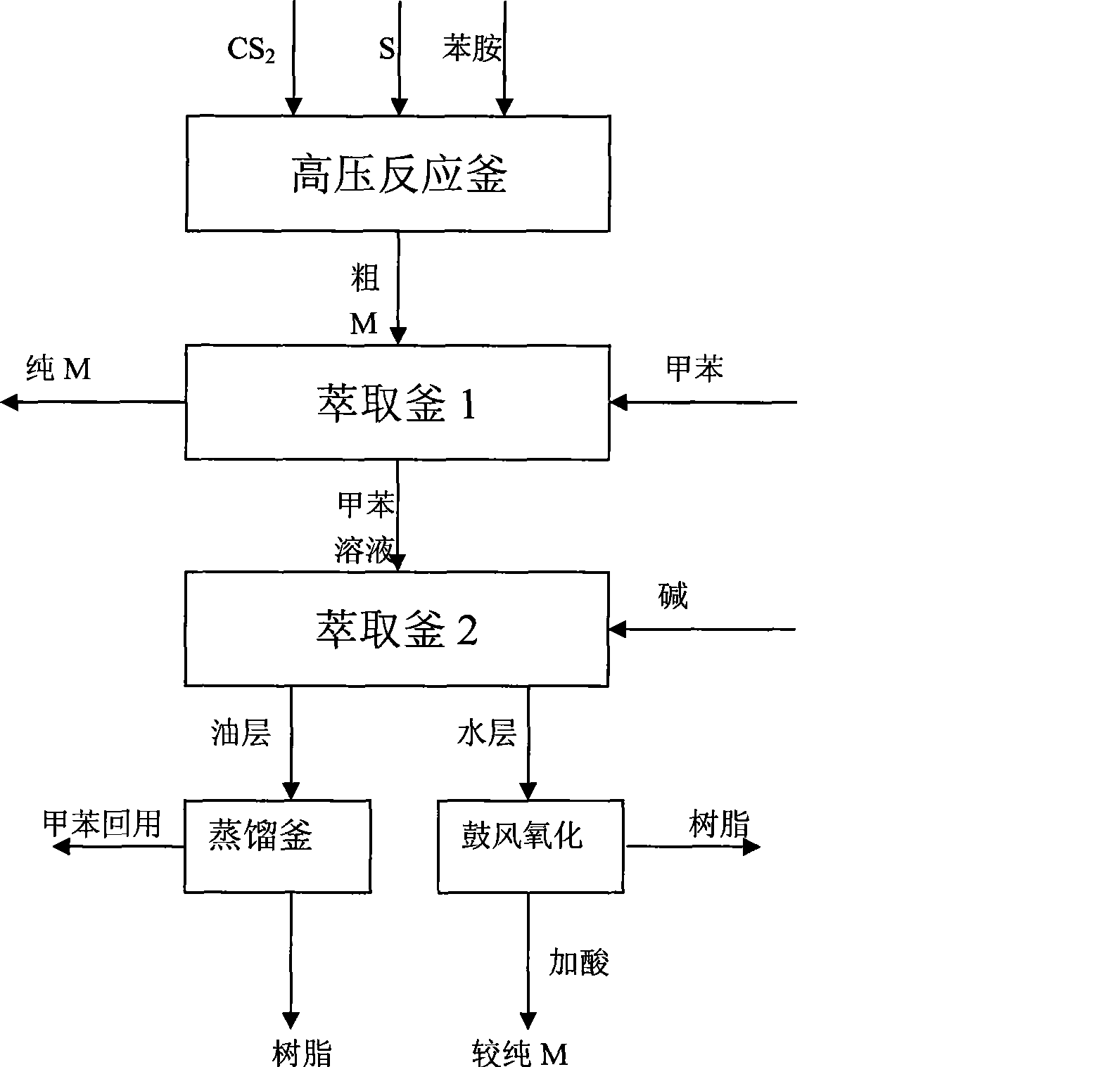

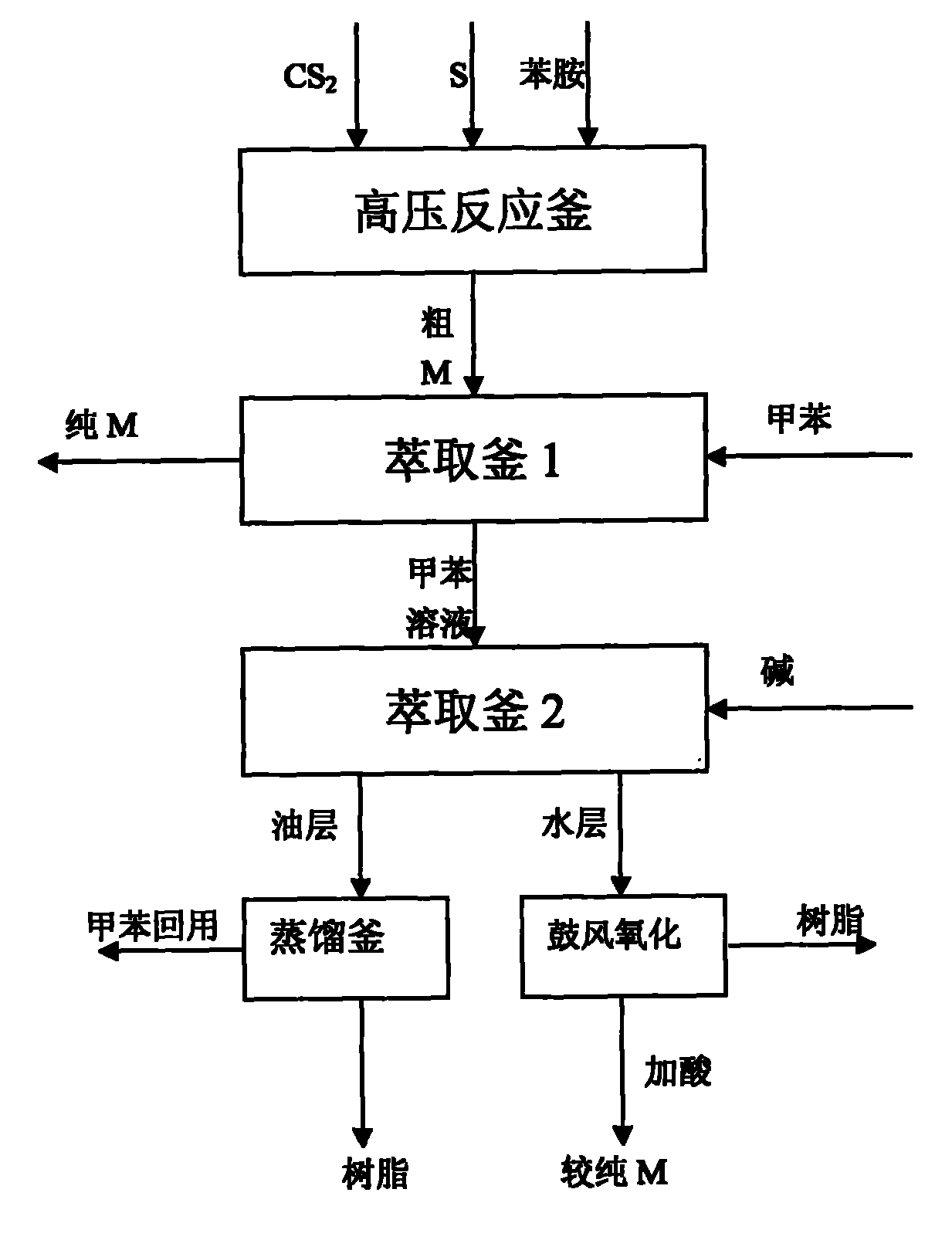

The invention relates to a method for refining a thiofide 2-mercaptobenzothiazole (M). The method is characterized in that an extraction method and an alkali dissolving and acid isolation method are creatively combined. The method comprises the following steps: crude thiofide M is extracted by using toluene for three times to remove resin impurities so as to obtain high-purity thiofide M; the thiofide M in the resin is purified by the alkali dissolving and acid isolation method; and the thiofideoluene is reclaimed by a distillation method. By adopting the processing, the thiofide M with high purity, high melting point and short melting period can be obtained.

Owner:山东戴瑞克新材料有限公司

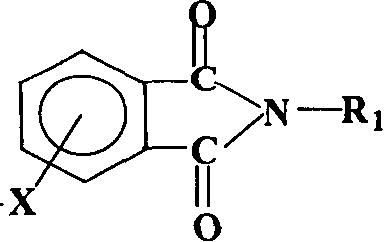

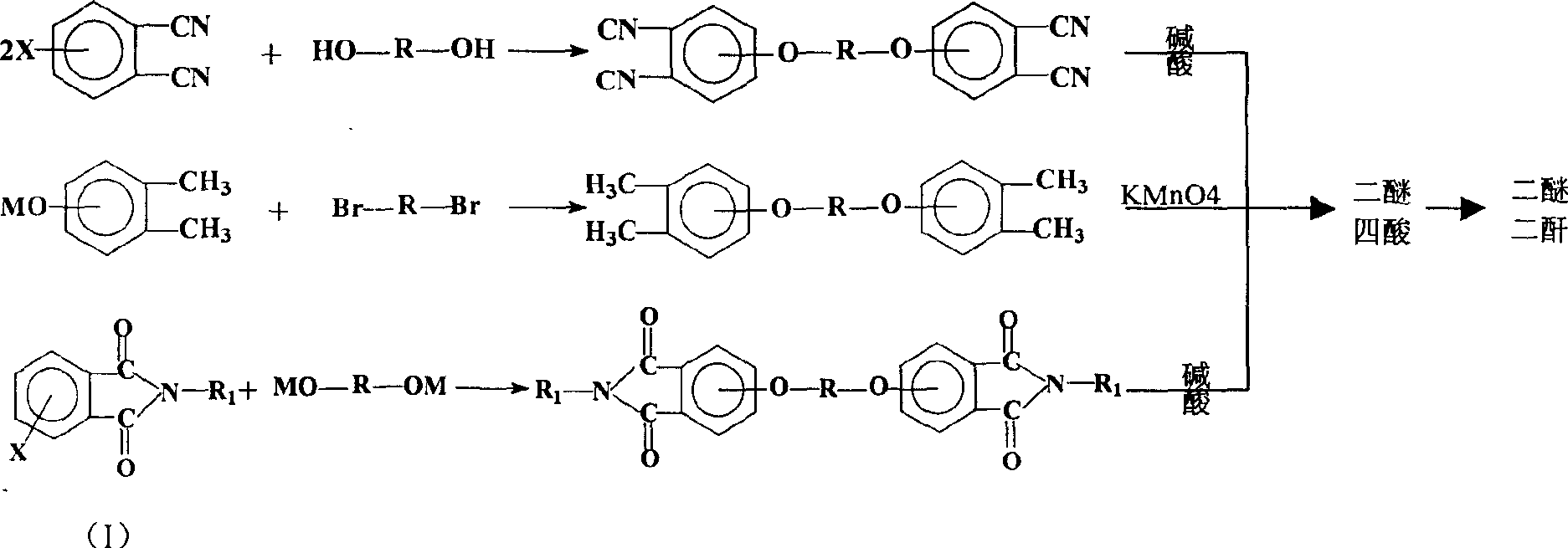

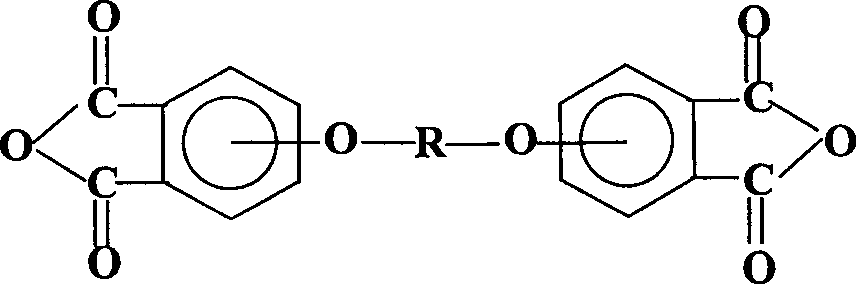

Process for synthesis of aryl bis-ether dianhydrides monomer

InactiveCN1634904AReduce usageShort melting rangeOrganic chemistryAcetic anhydrideReaction temperature

The invention relates to a method for synthesizing dianhydride monomer, especially a method for synthesizing aryl diether dianhydride by condensation, hydrolysis, acidification, and dehydration. In the invention, catalyst is added in the process of condensation for improving the yield of product; the solid content is 10-20%, reaction temperature is 7-100C., and reaction time is 15-48 hours; and the solvent consumption is reduced for reducing the impurity in condensed product. And diether tetracid in the diether dianhydride treated by dehydration is removed by dehydration in toluene or acetic acid and acetic anhydride and high temperature dehydration in vacuum oven sequentially, and the targeted product processed by said method has melting range less than 1C. and high purity.

Owner:NANJING UNIV OF TECH

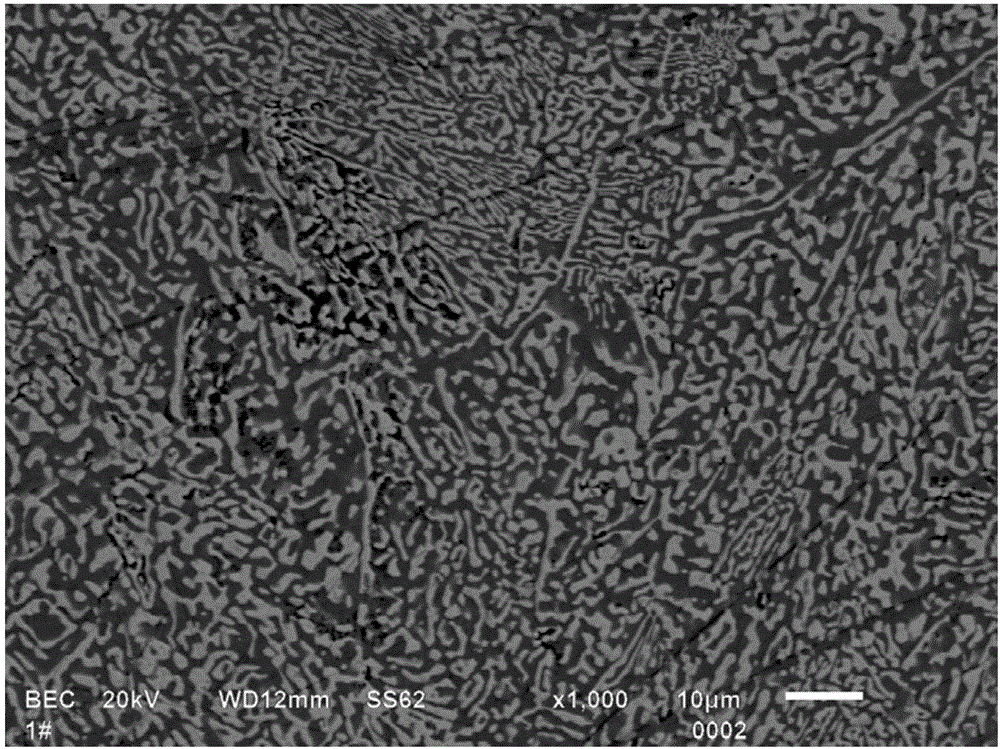

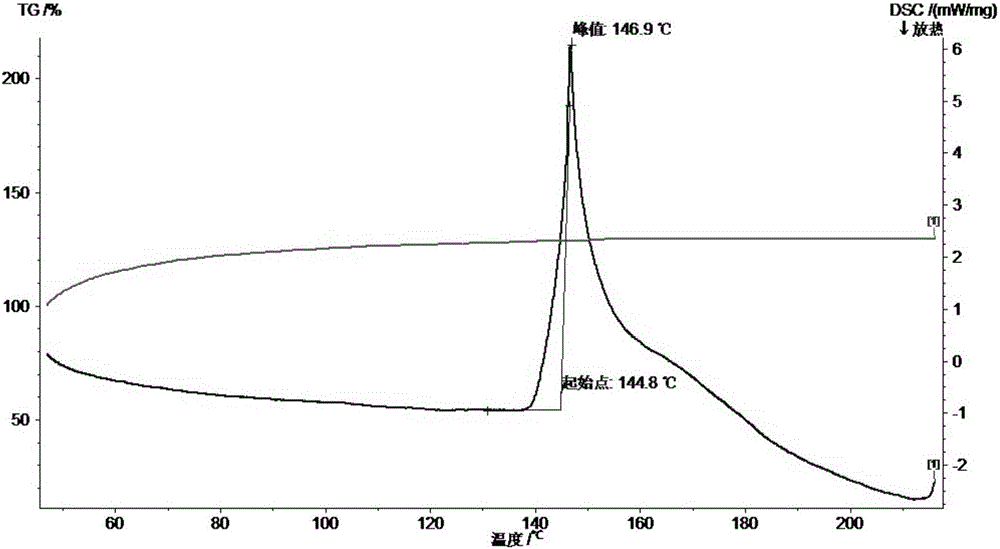

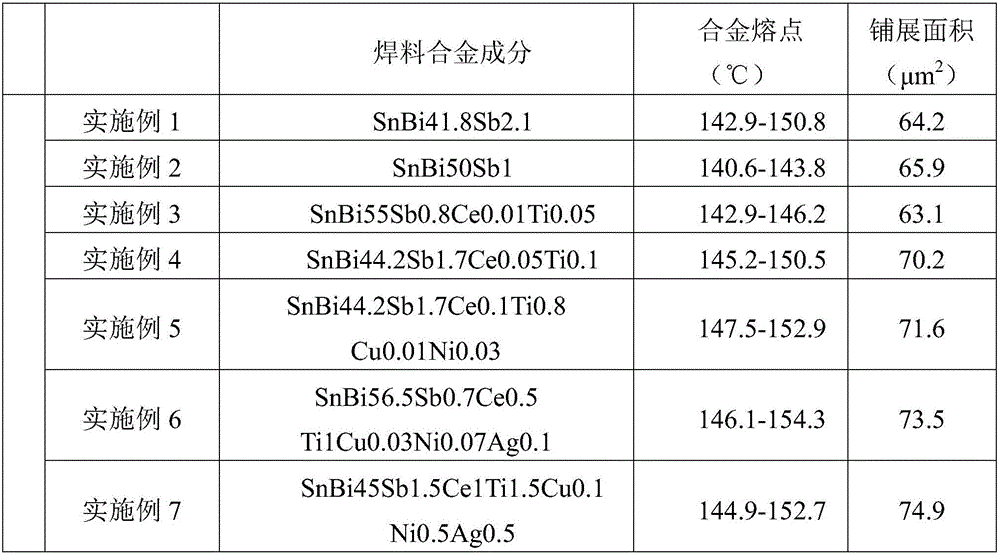

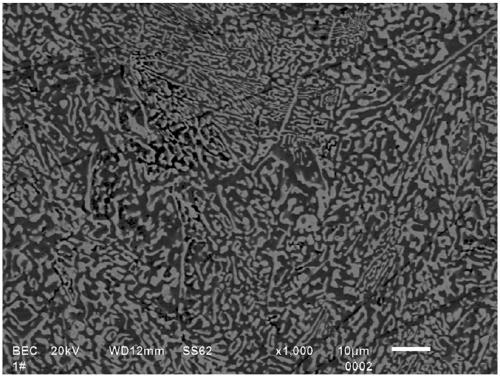

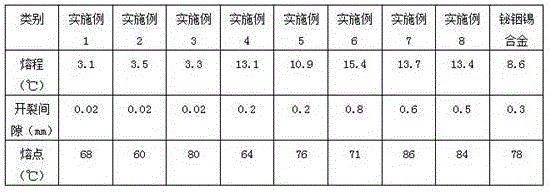

SnBiSb-series low-temperature lead-free solder and preparation method thereof

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

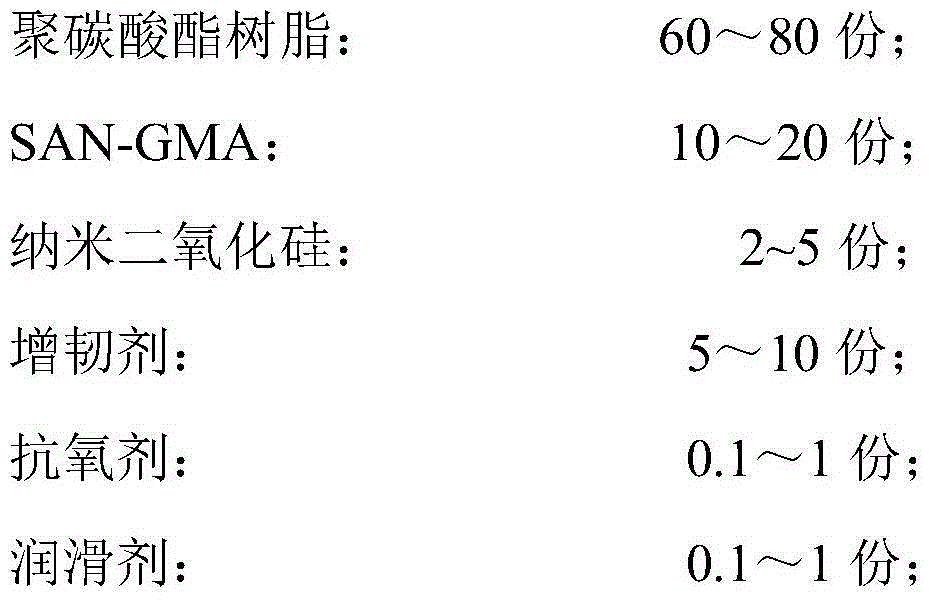

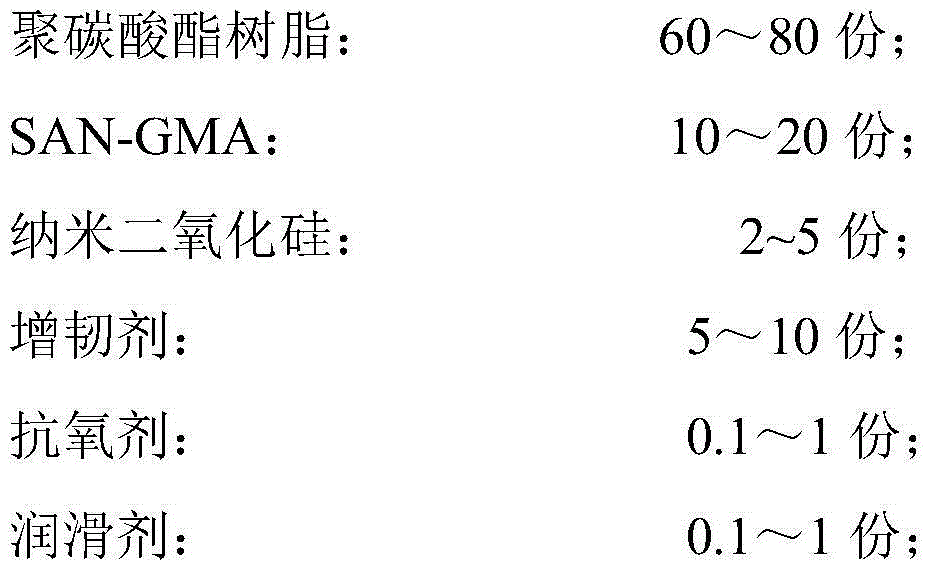

Polycarbonate composition for 3D printing technology and preparation method thereof

InactiveCN104830040AImprove heat transfer performanceShorten PC/ABS melting rangeAntioxidantDiameter ratio

The invention relates to a polycarbonate composition for 3D printing technology and a preparation method thereof. The composition is composed of the following components according to a certain ratio: polycarbonate resin, SAN-GMA, nano silicon dioxide, a flexibilizer, an antioxidant, and a lubricant. The diameter of the screw rod of an extruder used in alloy preparation is 58 mm, and the length / diameter ratio is 60. The preparation method comprises the following steps: adding PC resin, SAN-GMA resin, nano silicon dioxide, a flexibilizer, an antioxidant, and a lubricant into a mixing and stirring machine, mixing, transferring the mixture to a double-screw-rod extruder, blending, melting, extruding, and granulating to obtain the polycarbonate composition for 3D printing. Compared with the prior art, during the preparation process, the PC / ABS melting range is shortened, furthermore, nano silicon dioxide is added to enhance the heat transferring performance of the polycarbonate composition, and the warping problem during the 3D printing process is solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

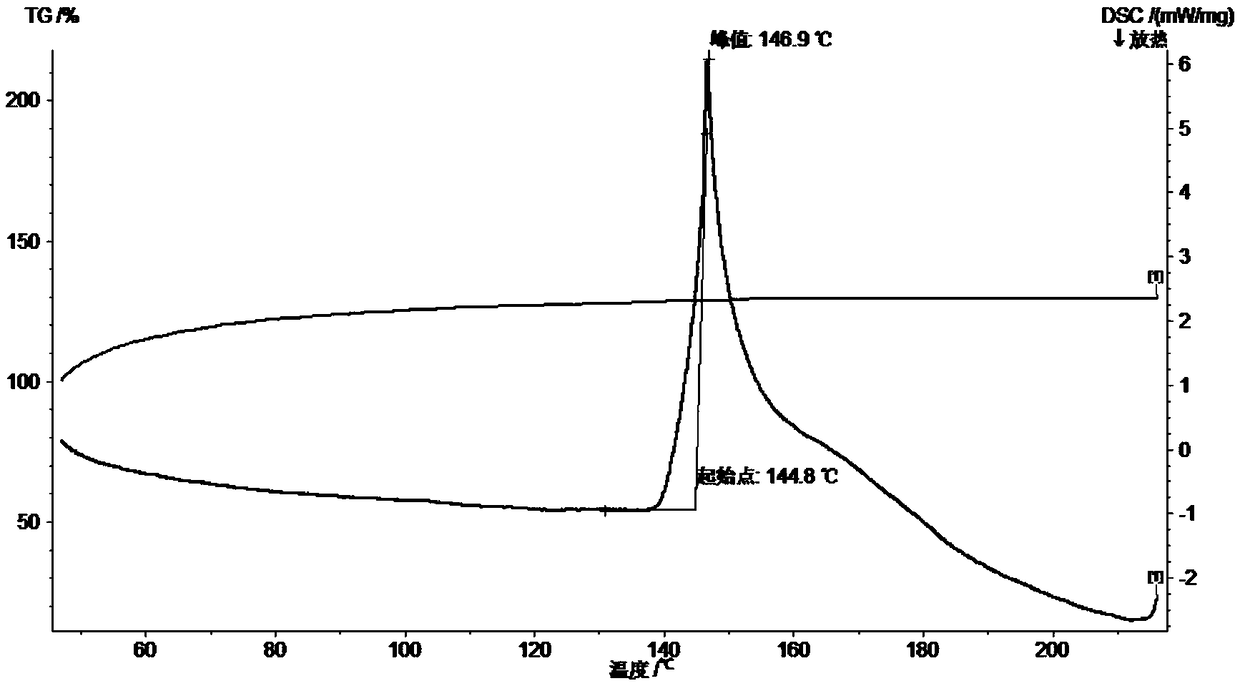

Low-melting-point copolyamide hot melt adhesive for clothes and processing method thereof

The invention discloses a low-melting-point copolyamide hot melt adhesive for clothes. The hot melt adhesive is prepared from the following raw materials in percentage by weight: 30-40% of dibasic acid or dibasic acid salt, 20-30% of diamine or diamine salt, 20-40% of lactam, 1-8% of a molecular weight modifier, 0.1-0.4% of a stabilizer and 2-6% of water. A processing method for the low-melting-point copolyamide hot melt adhesive comprises the following steps: adding the raw materials into a reaction still, pumping 0.1 Mpa of nitrogen, then slowly emptying to normal pressure, repeatedly replacing to completely remove air in the reaction still, increasing the temperature of the reaction still to 220-250 DEG C, enabling the pressure to be 1.0-1.8 Mpa, reacting for 1.5-3 hours, cooling to 170-190 DEG C, reducing the pressure to 0.003-0.1 Mpa, dehydrating, and discharging to obtain the polyamide hot melt adhesive of which the average molecular weight is 12,000-100,000, the opening time is 1.0-3.0 min, and the melting point is 80-90 DEG C. The hot melt adhesive provided by the invention has the benefits that the melting point is low, the opening time is short, the melting range is short and the wash durability is better.

Owner:温州华特热熔胶股份有限公司

Method for directly extracting and purifying rubber vulcanization accelerator MBT granules by methylbenzene

InactiveCN101717376AHigh purityHigh melting pointOrganic chemistryLiquid solutions solvent extractionVulcanizationPolymer science

The invention discloses a method for directly extracting and purifying rubber vulcanization accelerator MBT granules by methylbenzene. The method comprises the following steps: heating 10-500g of rough MBT (impurities are mainly resin and intermediate products) the mass percentage of which is 40-70 percent to be at 200-250 DEG C, and than leading into a reactor with 100-2000ml of 20-50 DEG C distilled water, quickly cooling the MBT to 30-80 DEG C, discharging water out of the reactor and drying the obtained MBT granules; adding 1000-8000ml of methylbenzene in the reactor, heating to 40-60 DEG C, extracting for 50-200min at the stirring rate of 50-150 turns / min, filtering, drying and obtaining vulcanization accelerator MBT with content higher than 96 percent. The invention has the advantages that the method has simple process and easy industrialization and the obtained MBT has high purity and melting point and short melting range.

Owner:KEMAI CHEM

Purification method of rubber vulcanization accelerator MBT (2-mercaptobenzthiazole)

InactiveCN102827101ARecycling consumes less energySimple methodOrganic chemistryPurification methodsPolymer science

The invention provides a purification method of a rubber vulcanization accelerator MBT (2-mercaptobenzthiazole), which comprises the following steps: pulverizing a crude product MBT synthesized under high pressure, and putting the pulverized MBT in a high-pressure kettle, wherein the mass percent of MBT in the crude product MBT is 80-90%; sealing the high-pressure kettle, vacuumizing, and charging a nitrogen protective atmosphere; pressing carbon bisulfide which is 2-5 times by weight of the crude product MBT into the reaction kettle; after sealing, starting stirring, heating to 120-180 DEG C, and keeping the temperature for 0.5-2 hours; cooling the reaction kettle to room temperature at the rate of 0.5-3 DEG C / min in a jacket cooling mode, filtering, washing, and drying to obtain the vulcanization accelerator MBT of which the content is higher than 98%; and distilling to recover the filtered mother liquor which can be circularly used in the reaction stage, wherein the recovery rate is up to higher than 96%. The method has the advantage of simple process, and the purity of the prepared high-content MBT is up to higher than 98%; no waste water is generated in the refinement process; and the extractant carbon bisulfide used as the reaction raw material has the advantage of low energy consumption for recovery, and can be returned to the reaction stage for circular use.

Owner:KEMAI CHEM

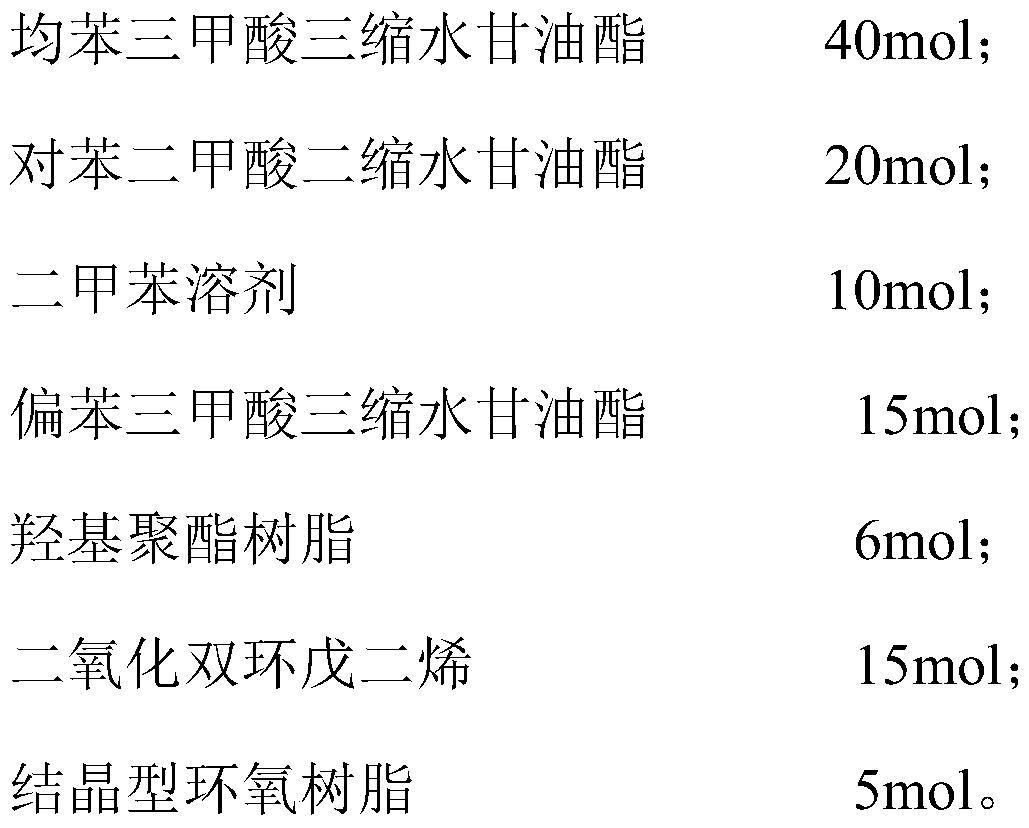

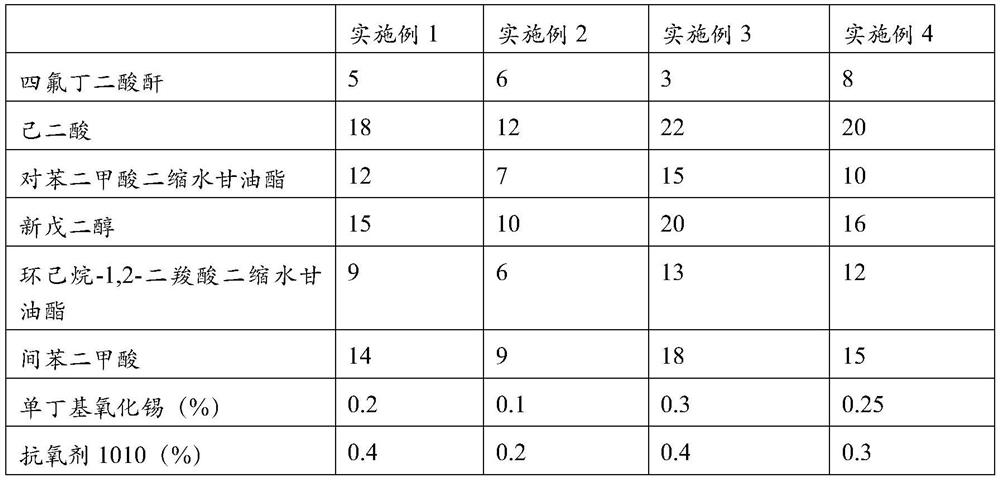

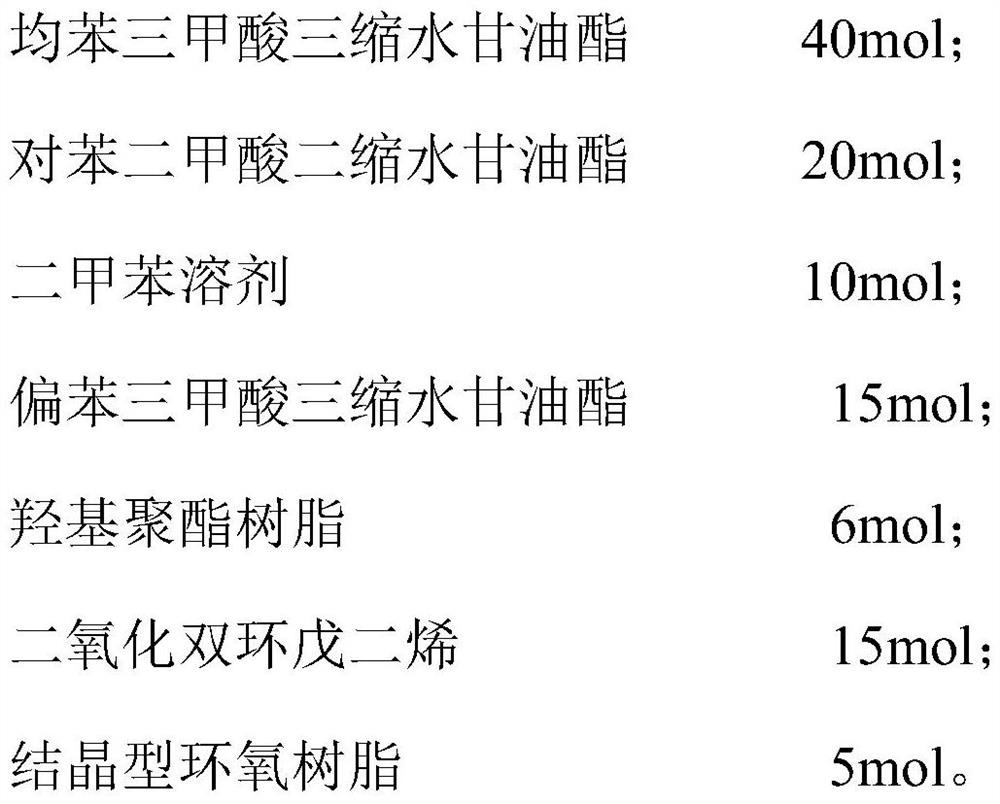

Compound curing agent used for polyester-type powder paint and production method and application thereof

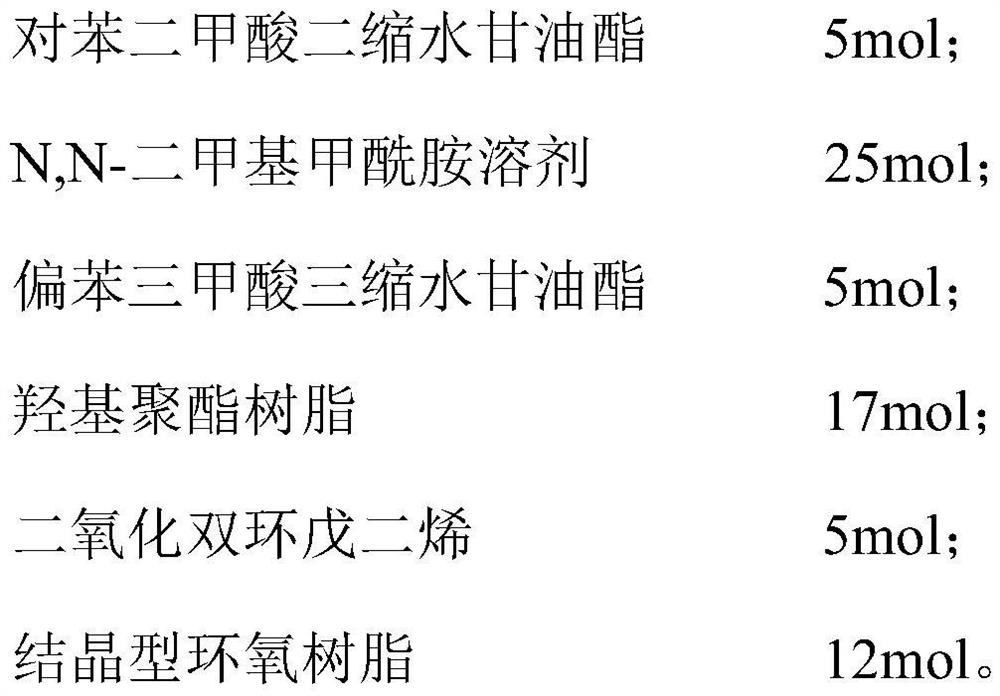

ActiveCN109852127AGood curing effectHigh epoxy equivalentPowdery paintsPolyester coatingsEpoxyTrimellitic acid

The invention belongs to the technical field of powder paint, particularly relates to a compound curing agent used for polyester-type powder paint, and further discloses a production method and application of the compound curing agent used for the polyester-type powder paint. The compound curing agent used for the polyester-type powder paint is mainly produced by using trimesic acid,tris(2,3-epoxypropy)ester and diglycidyl terephthalate as main raw materials and selectively adding 1,2,4-benzenetricarboxylic acid,tris(2,3-epoxypropy)ester, hydroxy polyester resin, bicyclopentadiene dioxide and / or crystalline epoxy resin for mixing reaction. The compound curing agent used for the polyester-type powder paint has a good curing effect, the mechanical performance of a produced coating is stable,and meanwhile, the coating has good boiling-resistant performance; and when the compound curing agent used for the polyester-type powder paint and polyester resin are cured, the performance of a product of the compound curing agent used for the polyester-type powder paint and the polyester resin totally reaches curing effects of current TGIC and HAA curing agents, and the compound curing agent used for the polyester-type powder paint and an existing TGIC or HAA product can be mixed for use, so that the comprehensive performance is more excellent.

Owner:安徽泰达新材料股份有限公司

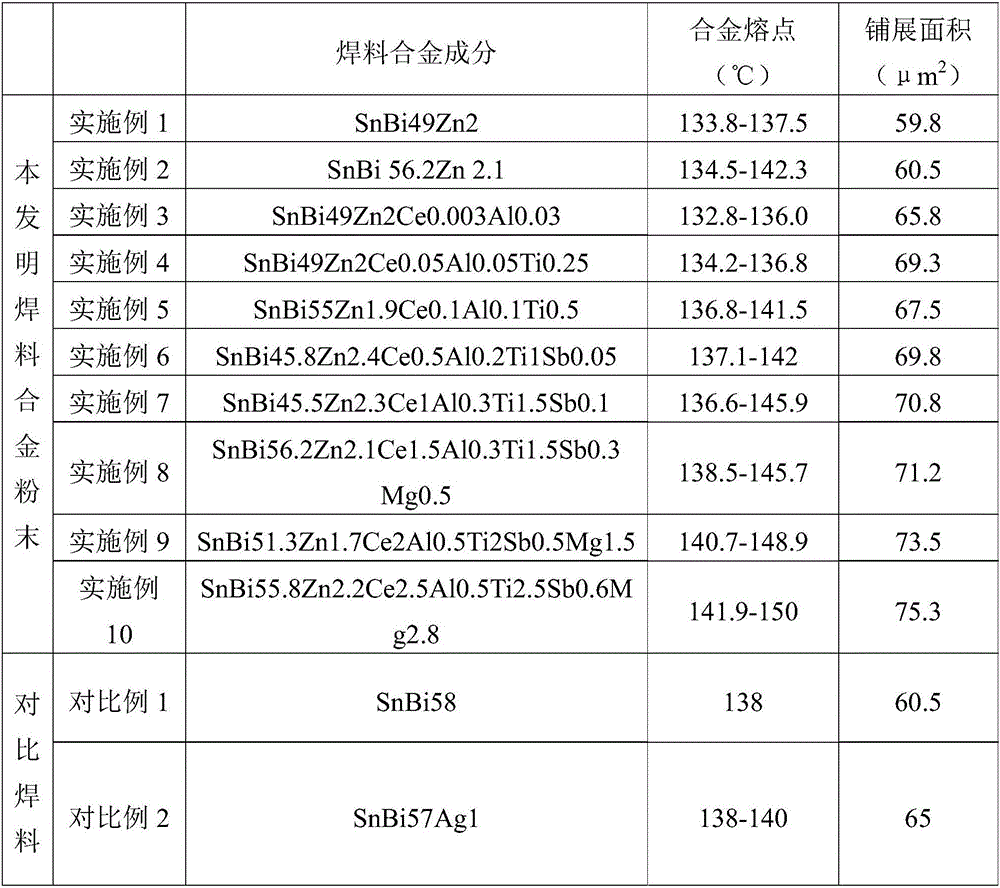

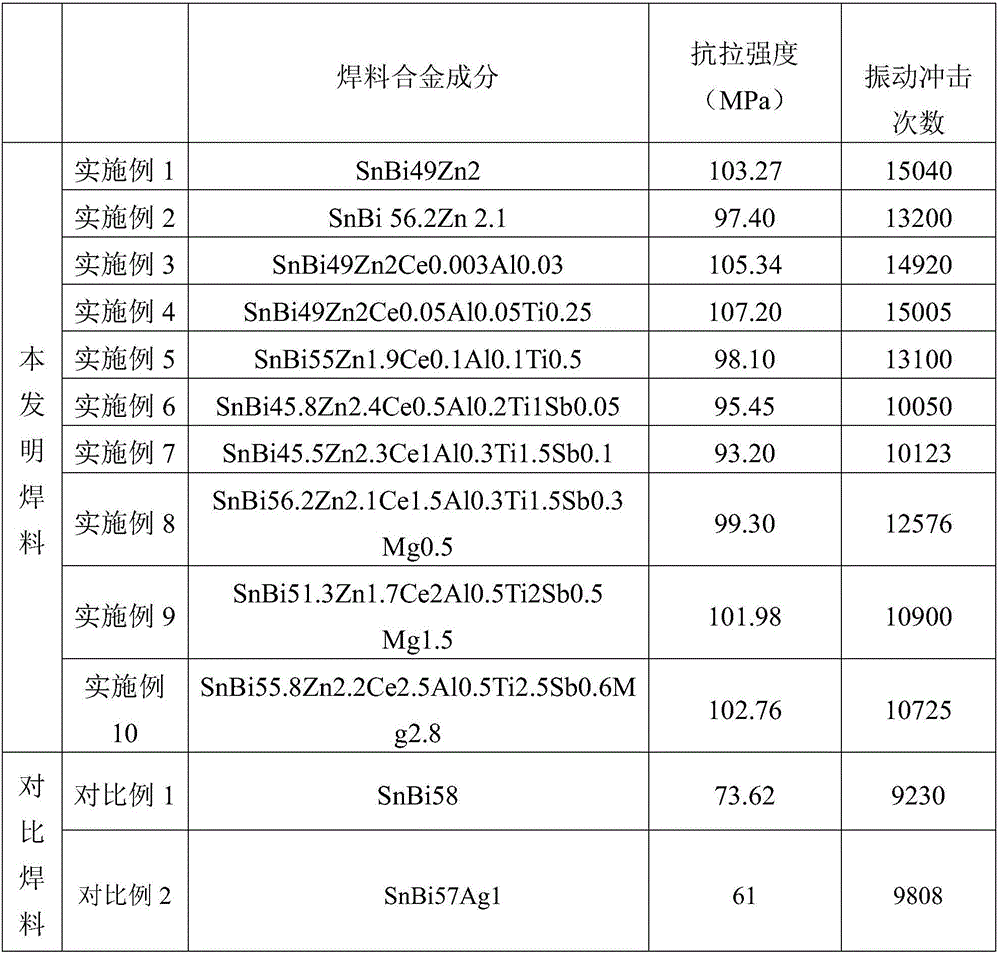

SnBiZn series low-temperature lead-free solder and preparation method thereof

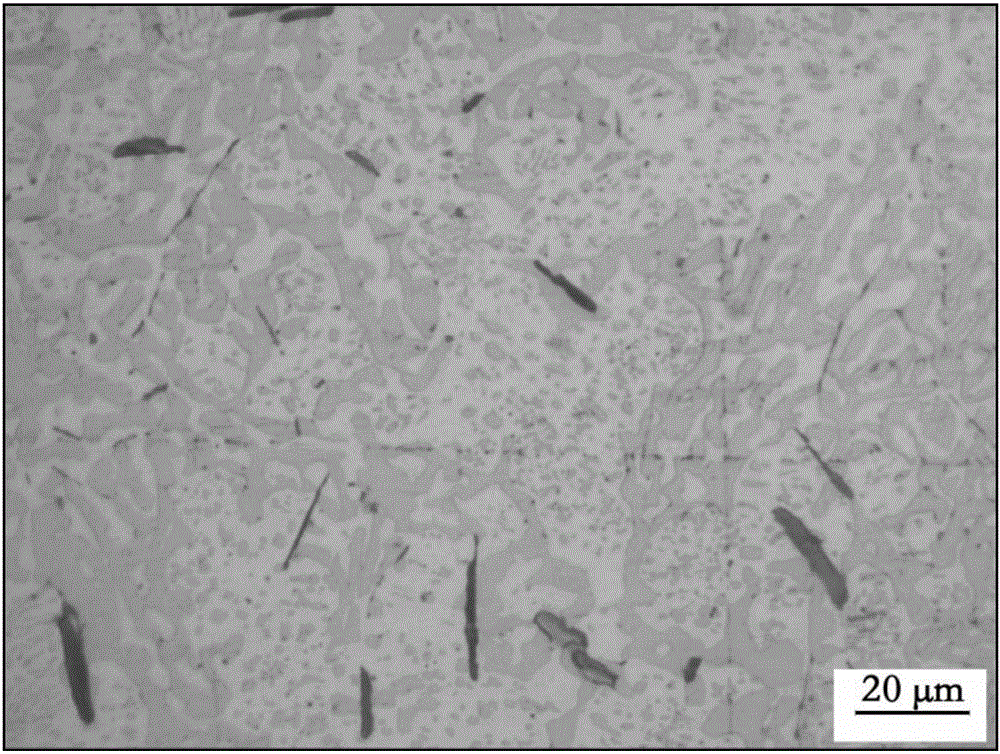

ActiveCN106181108AFine grainHigh bonding strengthWelding/cutting media/materialsSoldering mediaSolder ballMechanical property

The invention discloses SnBiZn series low-temperature lead-free solder and a preparation method thereof and belongs to the technical field of low-temperature soft solder. The lead-free solder is composed of, by weight, 45.5-56.2% of Bi, 1.7-2.4% of Zn, and the balance Sn, wherein the weight percentage of Bi and Zn meets the relational expression b=0.0123a<2>-1.27a+34.652+c, a is the weight percentage of Bi, b is the weight percentage of Zn, and the value range of c is -0.2<=c<=0.2. The invention further discloses the preparation method of the lead-free solder. Solder alloy is eutectic or near-eutectic structures, the melting point is low, and the SnBiZn series low-temperature lead-free solder has excellent mechanical properties and solder joint reliability and is suitable for the field of low-temperature of soft solder.

Owner:BEIJING COMPO ADVANCED TECH

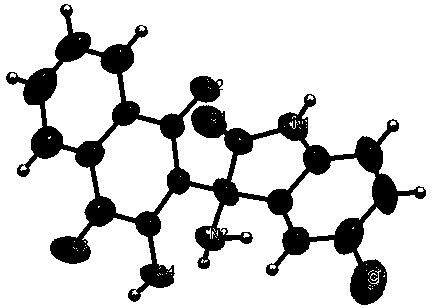

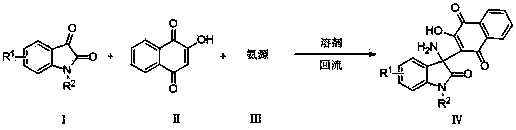

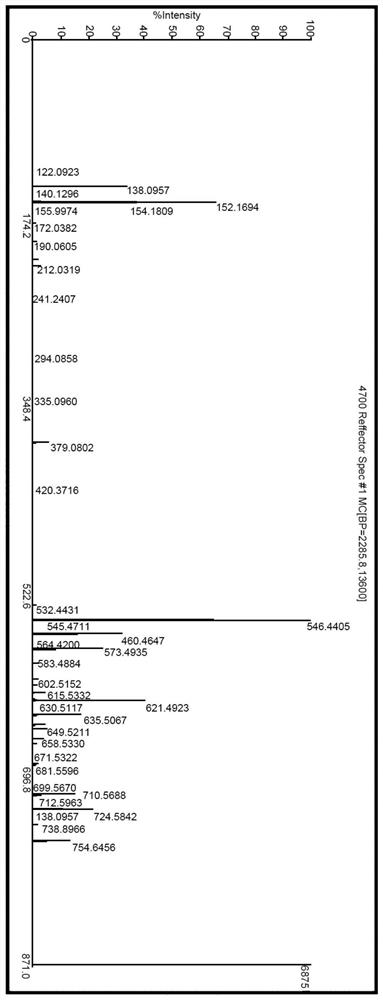

2-(3-amino-2-oxoindolin-3-yl)-3-hydroxyl-1,4-naphthoquinone derivative and preparation method thereof

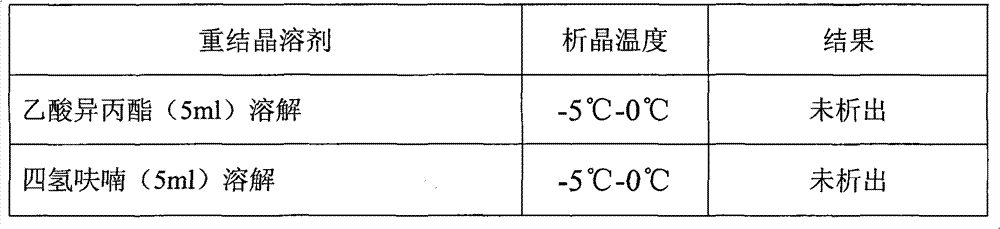

ActiveCN104030966AShort melting rangeMild reaction conditionsPolycrystalline material growthOrganic chemistrySingle crystalSolvent

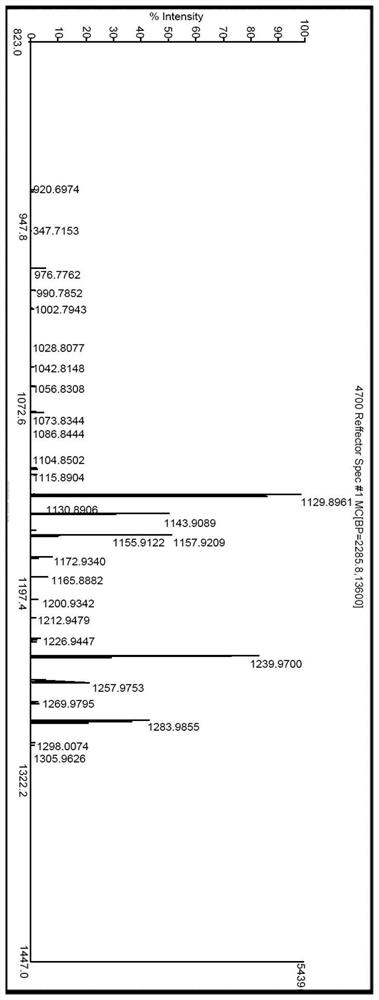

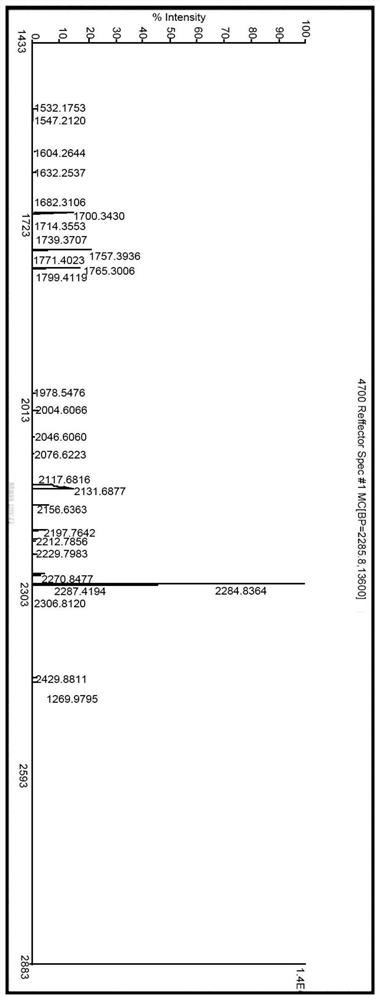

The invention provides a 2-(3-amino-2-oxoindolin-3-yl)-3-hydroxyl-1,4-naphthoquinone derivative and a preparation method thereof, and belongs to the technical field of compound synthesis. The preparation method comprises the following steps: dissolving isatin derivative as shown in the formula (I), 2-hydroxyl-1,4-naphthoquinone as shown in the formula (II) and an ammonia source as shown in the formula (III) in a solvent; sufficiently stirring to react under a reflux state; tracking by TLC (thin layer chromatography) until the raw materials are completely reacted; cooling, performing suction filtering, and baking to obtain the target product. The preparation method has the advantages of mild reacting condition, simple operation, convenience in post-treatment and high yield which is over 98 percent at most and the melting range of the prepared product is short; the structures of corresponding compounds are certified by IR (infrared radiation), 1HNMR (1H nuclear magnetic resonance), 12CNMR (12C nuclear magnetic resonance) and ESI-MS (electrospray ionization mass spectrometry), and monocrystal can be cultured by a part of target products.

Owner:乐陵市博奥泡沫制品有限公司

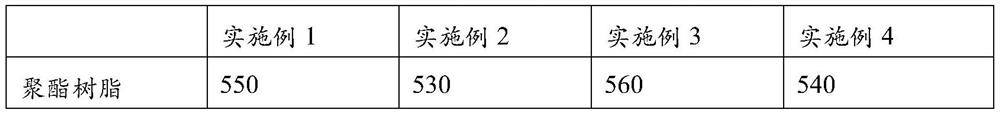

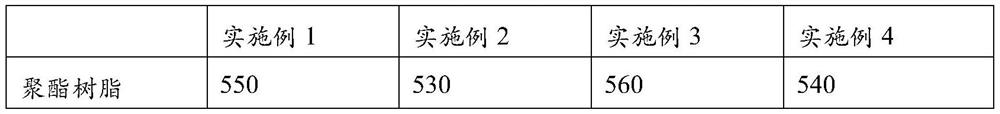

Long-acting weather-resistant chlorine salt corrosion-resistant polyester powder coating and preparation method thereof

ActiveCN112048235AGood linear structureLow softening pointAnti-corrosive paintsPowdery paintsWeather resistanceFirming agent

The invention belongs to the technical field of preparation of polyester powder coatings, and particularly relates to a long-acting weather-resistant chlorine salt corrosion-resistant polyester powdercoating and a preparation method thereof. The powder coating comprises the following main raw materials in parts by weight: 530-560 parts of polyester resin, 45-60 parts of TGIC, 10-15 parts of triglycidyl trimellitate, 120-180 parts of titanium dioxide, 80-120 parts of barium sulfate, 8-12 parts of a brightening agent and 7-10 parts of leveling agent. The polyester resin used in the powder coating is good in linear structure, and excellent flowing performance is guaranteed; more trifunctional curing agents TGIC are used in the powder coating and matched with triglycidyl trimellitate with a low melting point and excellent water resistance to jointly serve as a low-temperature curing agent, the crosslinking density and water resistance of a coating film are further improved, and finally long-acting weather resistance and chlorine salt corrosion resistance are guaranteed. The final powder coating product can be used for low-temperature curing at 160 DEG C, and the prepared coating filmhas excellent long-acting weather resistance and chlorine salt corrosion resistance, and is especially suitable for infrastructure spraying of expressways, such as guardrails and bridges.

Owner:安徽鑫友高分子新材料科技有限公司

New energy-saving process for refining thiofide MBT

The invention relates to a new energy-saving process for refining thiofide MBT. The process is characterized by comprising the following steps of: dissolving 40 to 90 percent coarse MBT into 10 percent alkali solution of sodium hydroxide, and performing oxidation for 40 to 50 minutes to obtain M sodium salt; and dripping dilute sulfuric acid with specific gravity of 0.8 to 1.0, oxidizing for 30 minutes, filtering, adding dilute sulfuric acid with specific gravity of 1.1 to 1.3, and performing neutralization to obtain the refined MBT. The process has the advantages that: the purity of the refined MBT reaches over 99 percent, and the refined MBT has high melting point and melting range; and the yield of the MBT is improve by six percent, and 580 yuan per ton of electricity is saved.

Owner:ZIBO GAOHUI CHEM

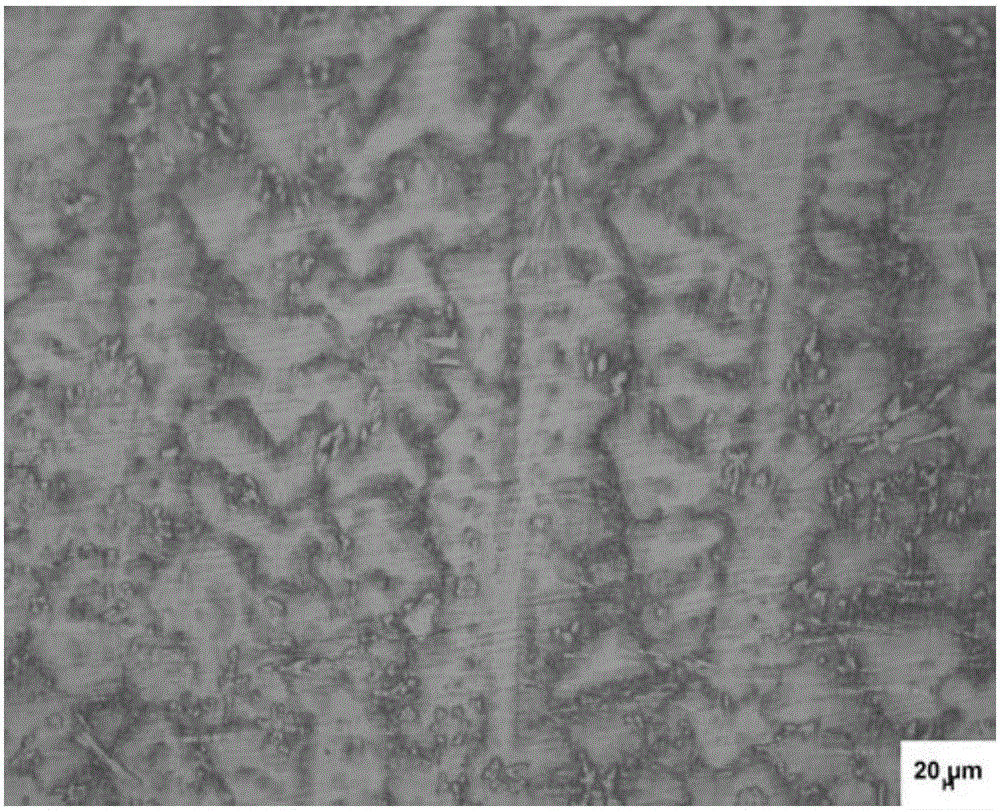

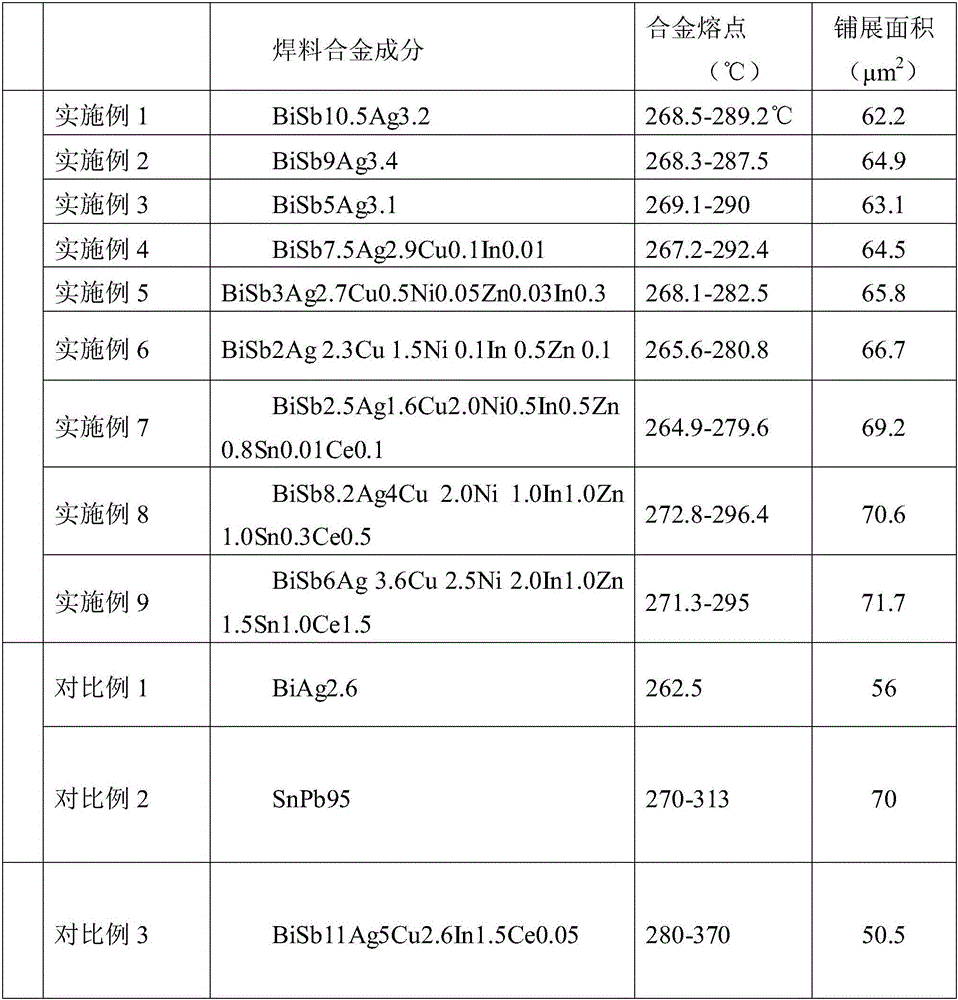

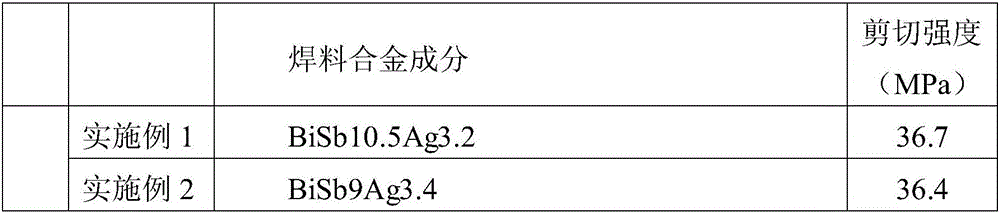

BiSbAg-series high-temperature lead-free solder and preparation method thereof

ActiveCN106392366ASolve the brittleness problemImprove brittlenessWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention discloses a BiSbAg-series high-temperature lead-free solder and a preparation method thereof and belongs to the technical field of high-temperature soft solders. The lead-free solder contains the following components in percentage by weight: 2.0-10.5% of Sb, 1.6-4.0% of Ag and the balance of Bi and a small number of unavoidable impurities, and the weight percentages of Sb and Ag in the solder alloy meet a relational expression, namely b=-0.046a<2>+0.67a+1.11+c, wherein the value of a is the weight percentage of Sb, the value of b is the weight percentage of Ag, and the value of c is larger than or equal to 1.0 and smaller than or equal to 1.0. The invention also discloses a preparation method of the lead-free solder. A microstructure of the solder alloy disclosed by the invention is a quasi-peritectic or approximate quasi-peritectic structure, and the solder alloy is small in melting range, favorable in mechanical property and reliability and suitable for the field of high-temperature soft solders.

Owner:BEIJING COMPO ADVANCED TECH

A kind of snbisb series low-temperature lead-free solder and preparation method thereof

ActiveCN106216872BFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMaterials science

The invention discloses a SnBiSb low-temperature lead-free solder and a preparation method thereof, belonging to the technical field of low-temperature solder. The weight percentage composition of this lead-free solder is: Bi 32.8-56.5%, Sb 0.7-2.2%, the rest is Sn, and the weight percentage of Bi and Sb satisfies the relationship b=0.006a 2 ‑0.672a+19.61+c, wherein a is the weight percentage of Bi, b is the weight percentage of Sb, and the range of c is ‑1.85≤c≤1.85. The invention also discloses a preparation method of the lead-free solder. The solder alloy of the invention is a pereutectic or near-eutectic structure, has a low melting point, has excellent mechanical properties and reliability, and is suitable for the field of low-temperature soldering.

Owner:BEIJING COMPO ADVANCED TECH

Method for purifying rubber vulcanization accelerator MBT (2-mercaptobenzothiazole)

The invention discloses a method for purifying a rubber vulcanization accelerator MBT (2-mercaptobenzothiazole). The method comprises the following steps: completely dissolving crude M by using a sodium hydroxide solution with the weight concentration of 30%, controlling the final pH of the sodium salt solution to be 9.5, adding deionized water to dilute, controlling the weight concentration of the sodium salt solution to be 3-8%, blowing and oxidizing for 1.5-2.5 hours, dropwise adding a sulfuric acid solution with the weight concentration of 1-3% at the speed of 1-3L / min at the same time till the pH is 9 and the solution is clear and transparent, filtering, heating the sodium salt solution to 25-95 DEG C till a clear and transparent state is achieved, dropwise adding a sulfuric acid solution with the weight concentration of 5-10% to neutralize till the pH is 5-7, filtering, dewatering, washing and drying the solid to obtain the finished product MBT. The method disclosed by the invention has the advantages that the method is simple in process and easy in industrialization; the purity of the prepared high content MBT is up to more than 99%.

Owner:SHANDONG SUNSINE CHEM

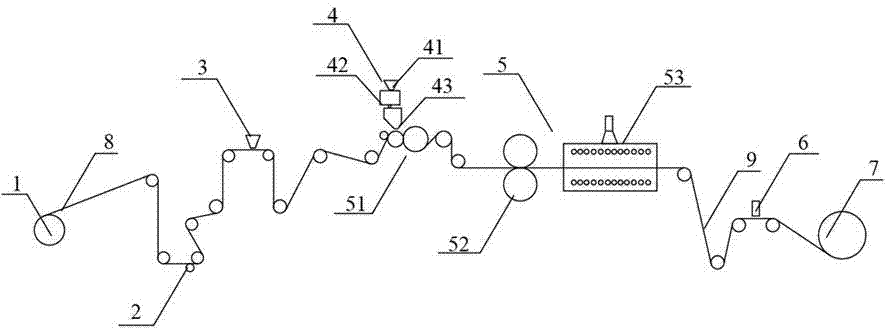

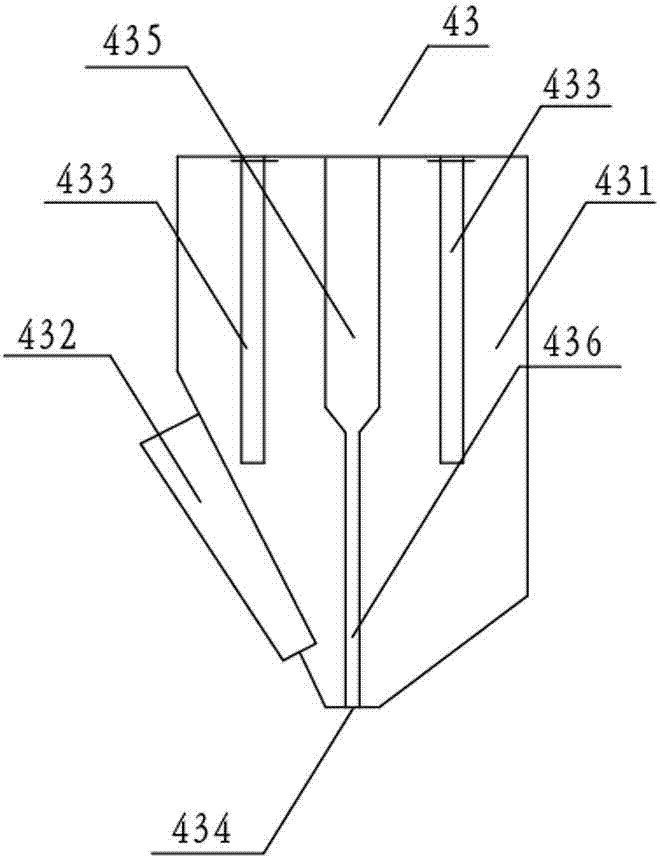

Preparation method of fluorine layer-containing polyimide composite material and equipment for method

The invention discloses a preparation method of a fluorine layer-containing polyimide composite material and equipment for the method. The preparation method comprises the following steps: a polyimide thin film subjected to surface treatment passes through devices such as an unreeling system, a correcting device, and a corona treatment device, and passes through an extruding pouring system filled with a fluorine-containing material at a speed of 0.5-100m, and the fluorine-containing material is compounded to the polyimide thin film; and the polyimide thin film compounded by the fluorine-containing material enters a main molding system to further control the thickness of the fluorine-containing material and the fluorine-containing material is sintered on the surface of the polyimide thin film, so that the fluorine layer-containing polyimide thin film is prepared. According to the preparation method disclosed by the invention, multilayer compounding and single / double-sided compounding are realized, and composite materials with different thicknesses of fluorine layers can be prepared, the process is concise, and the precision and the efficiency are high.

Owner:苏州凯姆勒绝缘材料有限公司

A kind of synthetic method of 25-hydroxy-7-dehydrocholesterol

The present invention relates to a 25-hydroxy-7-dehydrocholesterol synthetic method, a 25-hydroxy-7-keto-cholesterol derivative is used as a raw material for mechanical milling reaction in a ball mill pot under the effect of sulfonyl hydrazide and a base in the absence of an organic solvent, and then hydrolysis reaction is performed to obtain 25-hydroxy-7-dehydrocholesterol synthetic method. According to the method, in the absence of a solvent, mechanical milling reaction is performed, no dust is spilled over in the grinding process, reaction controllability is good, reaction efficiency is high, the solvent recovery operation in the post-processing process can be avoided, operation is simplified, environmental pollution is reduced, the reaction selectivity is good, yield is high, operation is simple, cost is low, post-treatment is simple, three-waste is less, product is easy to separate, purity is high, the yield is up to 89%, the melting process is short, and the product purity is high.

Owner:ZHEJIANG UNIV OF TECH +2

Fine purification method for rubber vulcanization accelerant 2-mercaptobenzothiazole (M)

The invention relates to a method for refining a thiofide 2-mercaptobenzothiazole (M). The method is characterized in that an extraction method and an alkali dissolving and acid isolation method are creatively combined. The method comprises the following steps: crude thiofide M is extracted by using toluene for three times to remove resin impurities so as to obtain high-purity thiofide M; the thiofide M in the resin is purified by the alkali dissolving and acid isolation method; and the thiofideoluene is reclaimed by a distillation method. By adopting the processing, the thiofide M with high purity, high melting point and short melting period can be obtained.

Owner:山东戴瑞克新材料有限公司

Hindered amine light stabilizer intermediate and preparation method of hindered amine light stabilizer

ActiveCN112239458AAvoid generatingReduce pollutionOrganic chemistryHindered amine light stabilizersTriazine

The invention provides a hindered amine light stabilizer intermediate and a preparation method of a hindered amine light stabilizer. The hindered amine light stabilizer intermediate is 2-chloro-4,6-di(N-butyl-N-1,2,2,6,6-pentamethyl-4-piperidyl amino)-1,3,5-triazine, and the preparation method comprises the following steps: in the presence of hydrogen, carrying out hydrogenation substitution reaction on 1,2,2,6,6-pentamethyl-4-piperidone and n-butyl amine, carrying out substitution reaction on the obtained intermediate 1 and cyanuric chloride to obtain 2-chloro-4,6-di(N-butyl-N-1,2,2,6,6-pentamethyl-4-piperidyl amino)-1,3,5-triazine. Formaldehyde or formic acid does not need to be adopted in the preparation process, the method has the advantages of being small in environmental pollution and equipment corrosion, and after the method is used for reaction preparation of the hindered amine light stabilizer, the target product is high in purity, good in color and luster and short in meltingrange.

Owner:RIANLON +1

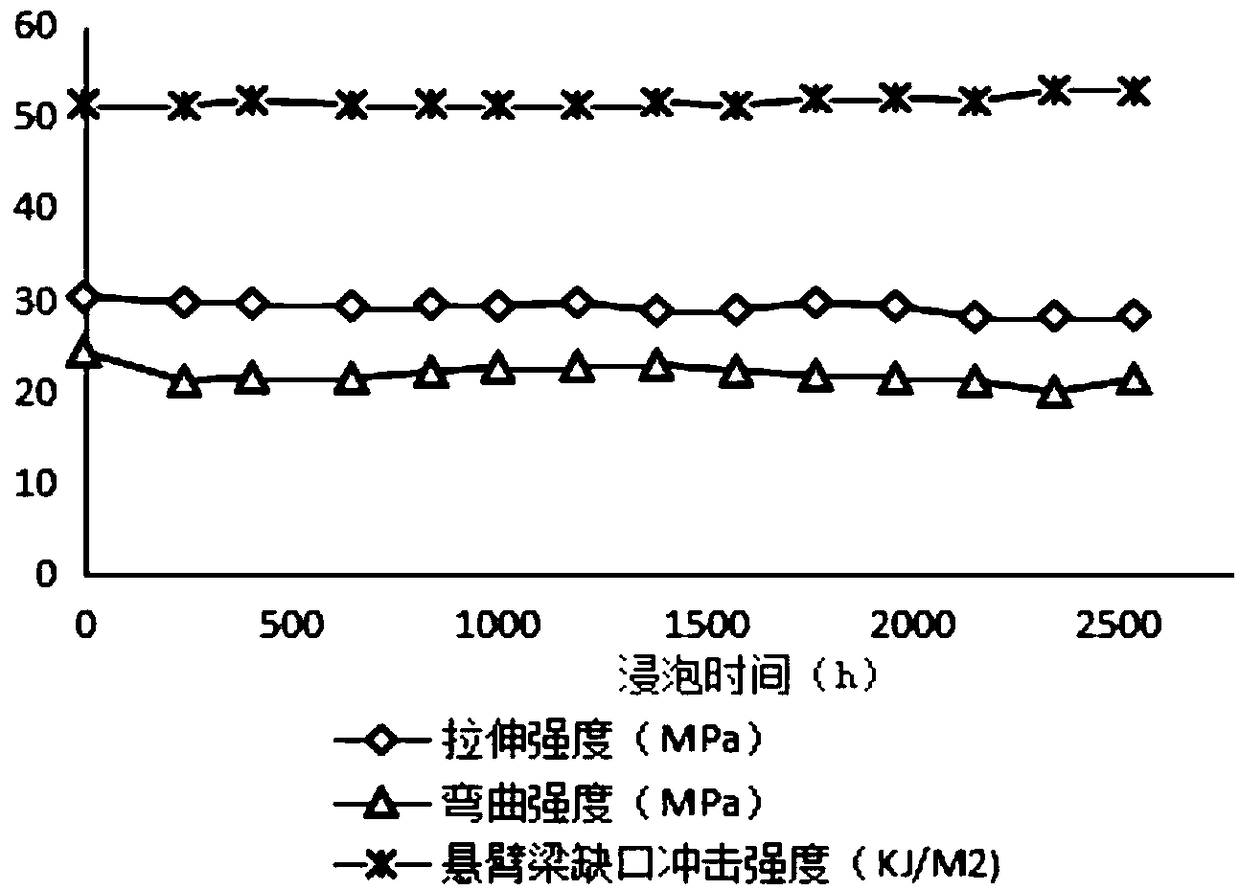

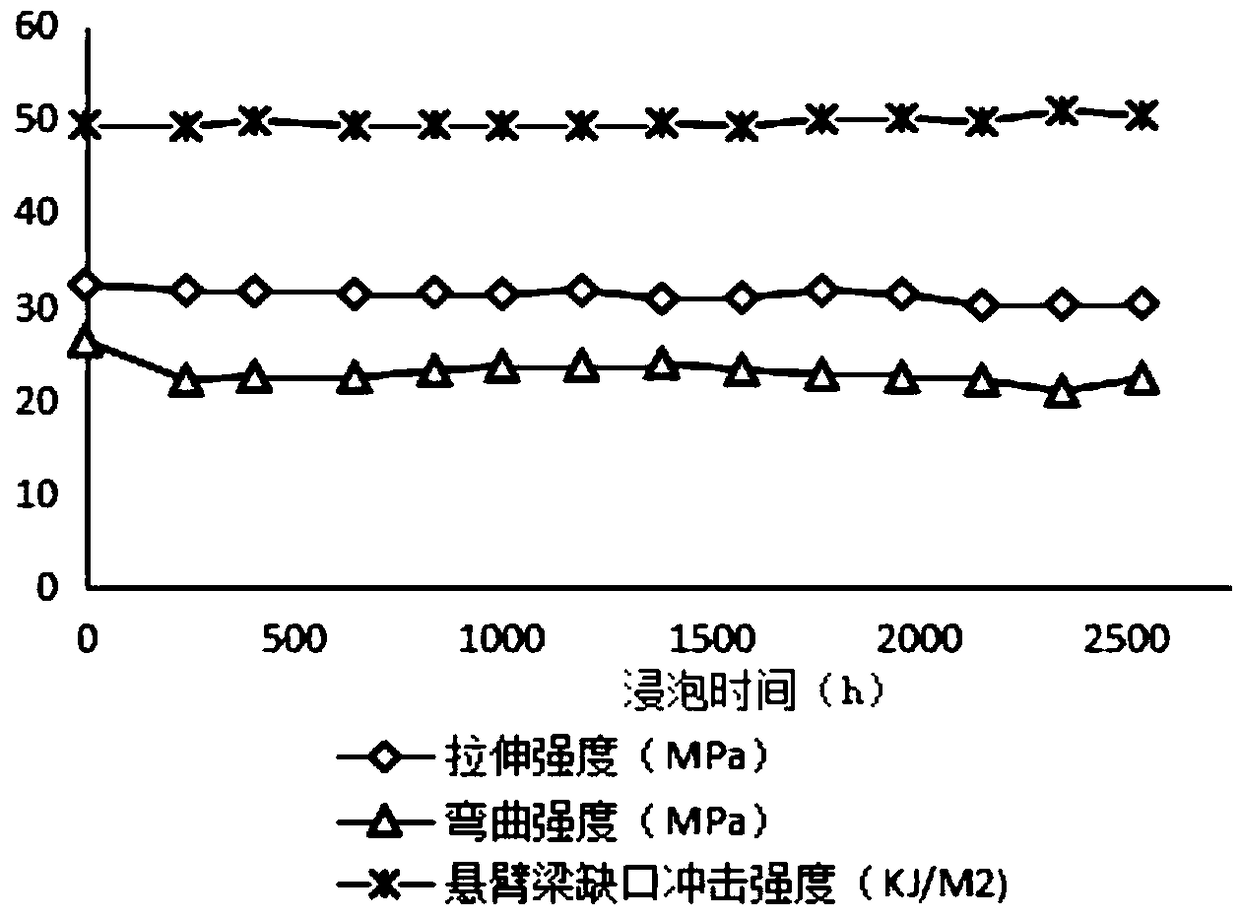

Modified PA11 material, pipe and preparation method thereof

InactiveCN109233267AGood chemical resistanceGood heat resistance and mechanical propertiesAntioxidantMaterials science

The invention discloses a modified PA11 material. The modified PA11 material comprises a PA11 resin, a filling agent, an antioxidant and a lubricating agent, wherein the PA11 resin is filled with nanometer minerals; the mechanical performance and the heat resistance of the PA11 material are outstanding while outstanding chemical resistance remains based on the small size effect of the nanometer minerals and the boundary adhering, in addition, the PA11 materials is resistant to blasting under high and low temperature, so that the PA11 material is applicable to high and low temperature environments. The invention further discloses a pipe and a preparation method thereof. The pipe is prepared from the modified PA11 material. The prepared pipe is outstanding in 65# cooling liquid resistance and is applicable to the high and low temperature environments.

Owner:ORINKO NEW MATERIAL CO LTD

Preparing method for novel environment-friendly low-temperature alloy

The invention discloses a preparing method for a novel environment-friendly low-temperature alloy. The novel environment-friendly low-temperature alloy comprises elements including, by weight, 30-60 parts of tin, 18-32 parts of bismuth, 15-27 parts of antimony, 1.5-3.5 parts of copper, 0.8-1.7 parts of cobalt and 2.2-2.7 parts of manganese. The low-temperature alloy is good in ductility, the melting range is short, and the low-temperature alloy can be widely applicable to preparing of mother boards in various industries and is particularly used for manufacturing mother boards of copper pot artware or precision artware, the mother board manufacturing difficulty can be lowered, the manufacturing precision is improved, the manufacturing cost is low, and the preparing method is suitable for industrial production.

Owner:HAINAN VOCATIONAL COLLEGE OF SCI & TECH

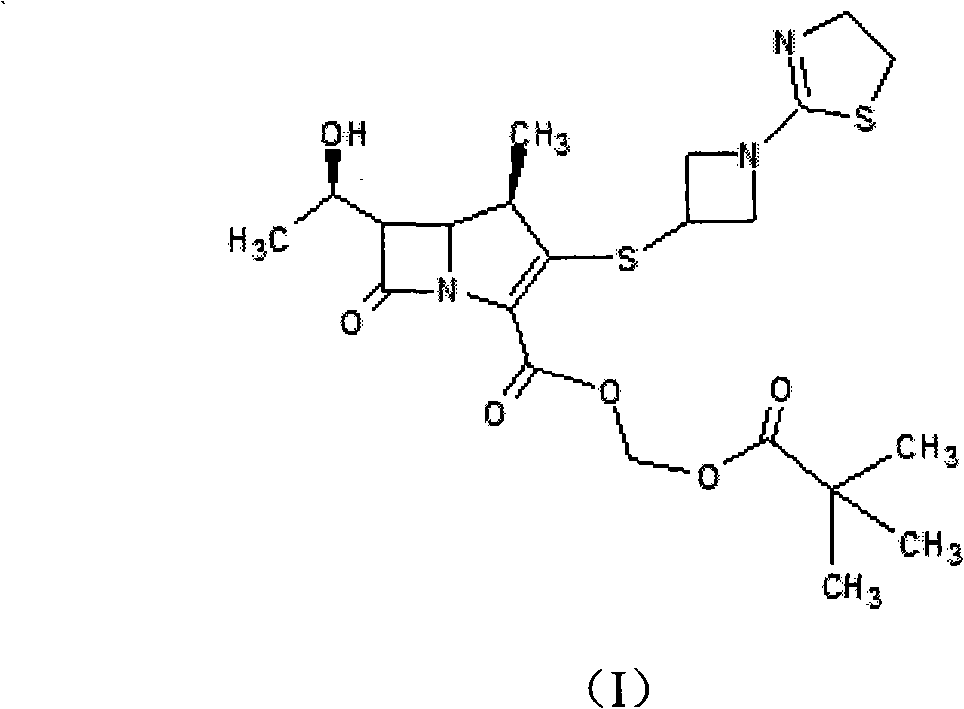

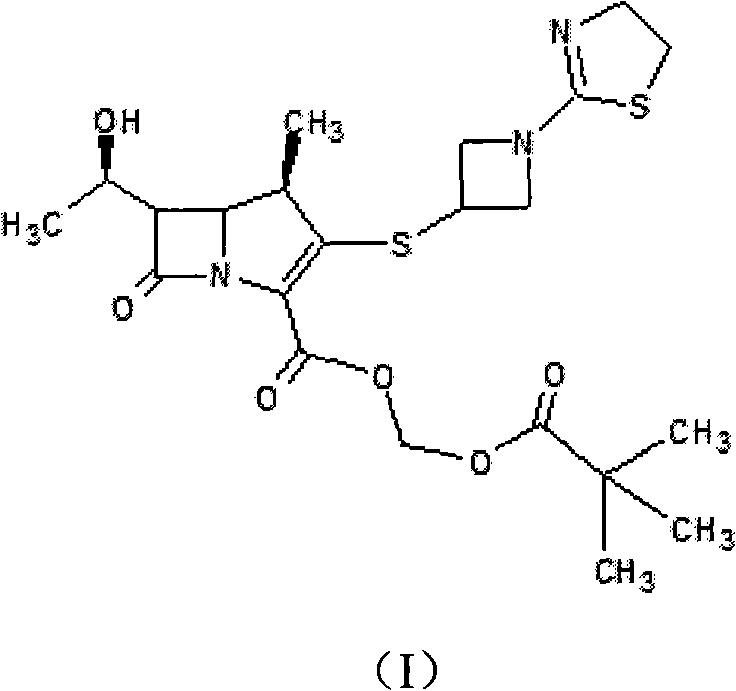

Method for purifying tebipenem by recrystallizing

InactiveCN102276611BEasy to operateShort crystallization timeOrganic chemistryRoom temperatureTebipenem

The invention discloses a method for purifying tebipenem by recrystallizing. Acetone and isopropyl ether are adopted as recrystallizing solvents, the operation is simple, heating or cooling equipment is not required, crystallization is realized at room temperature, crystallization time is short, and recrystallization yield is high and over 75 percent, so that the method is suitable for industrialproduction, the recrystallized product has short melting range, high purity which is over 99.9 percent by virtue of HPLC (high performance liquid chromatography) detection, and can be used as a raw material medicament in accordance with requirements to prepare a medicinal preparation for safe administration of patients.

Owner:深圳万乐药业有限公司

Long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and preparation method thereof

ActiveCN112048235BGood linear structureLow softening pointAnti-corrosive paintsPowdery paintsWeather resistanceLow temperature curing

The invention belongs to the technical field of polyester powder coating preparation, and in particular relates to a long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and a preparation method. The main raw materials of the powder coating of the present invention are: 530-560 parts of polyester resin, 45-60 parts of TGIC, 10-15 parts of trimesic acid triglycidyl ester, 120-180 parts of titanium dioxide, and 80-120 parts of barium sulfate , 8‑12 parts of brightening agent, 7‑10 parts of leveling agent. The polyester resin used in the powder coating of the present invention has a good linear structure, which ensures excellent fluidity; the powder coating uses a larger amount of trifunctional curing agent TGIC, and is matched with triglycidyl trimesic acid with a low melting point and excellent water resistance Esters are used as low-temperature curing agents to further improve the crosslinking density and water resistance of the coating film, and finally ensure long-term weather resistance and chloride salt corrosion resistance. The final powder coating product can be used for low-temperature curing at 160°C. The coating film prepared by it has good long-term weather resistance and chlorine salt corrosion resistance, and is especially suitable for infrastructure spraying on highways such as guardrails and bridges.

Owner:安徽鑫友高分子新材料科技有限公司

Resolution method of levocetirizine chiral intermediates

ActiveCN102351810BEasy to operateImprove efficiencyOptically-active compound separationBulk chemical productionSpecific rotationSolvent

A resolution method of a levocetirizine chiral intermediates belongs to the technical field of fine organic chemical engineering. The method comprises the following specific steps: adding racemic 1-[(4-chlorophenyl)benzyl]piperazine and chiral ionic liquid in a reaction container to react at 10-100 DEG C for 1-10 hours, extracting with toluene for layering, adjusting the pH value of the aqueous phase with 10wt% of sodium hydroxide solution to 11-12, extracting with toluene again, and concentrating to crystallize after the post-treatment, thus obtaining the product. The chiral ionic liquid is used as the solvent and resolving agent, the technology is easy to operate, the efficiency is high, the yield of three wastes is low, the yield of the product is more than 34%, the melting range of the product is narrow, the melting point is 94-96 DEG C, the specific rotation [alpha] D is not more than -21.5 degrees (C1, toluene), the optical purity is not less than 99.0%, and the content is not less than 99.0%. The post-treatment is convenient, the ionic liquid can be used repeatedly and the resolution method is an economical, practical, green and environmentally friendly technology.

Owner:浙江永合新材料科技有限公司

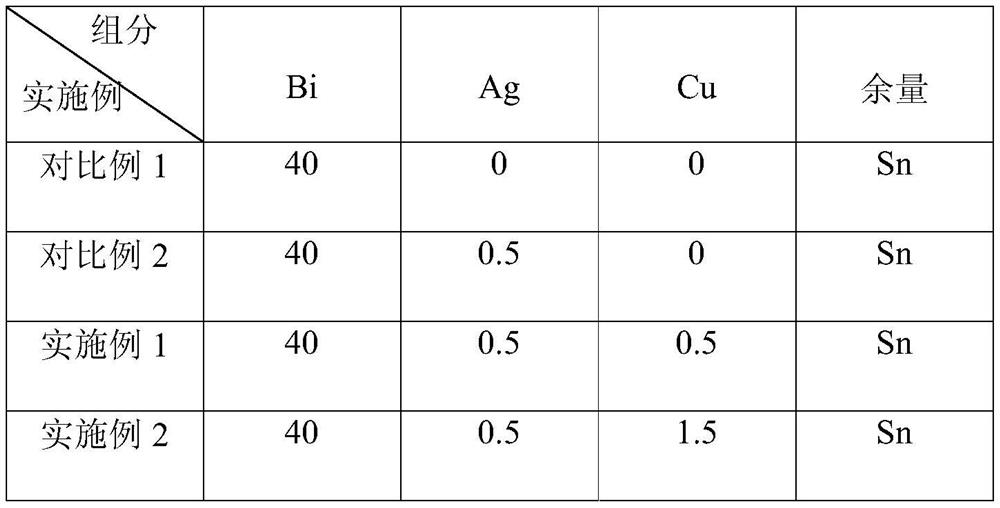

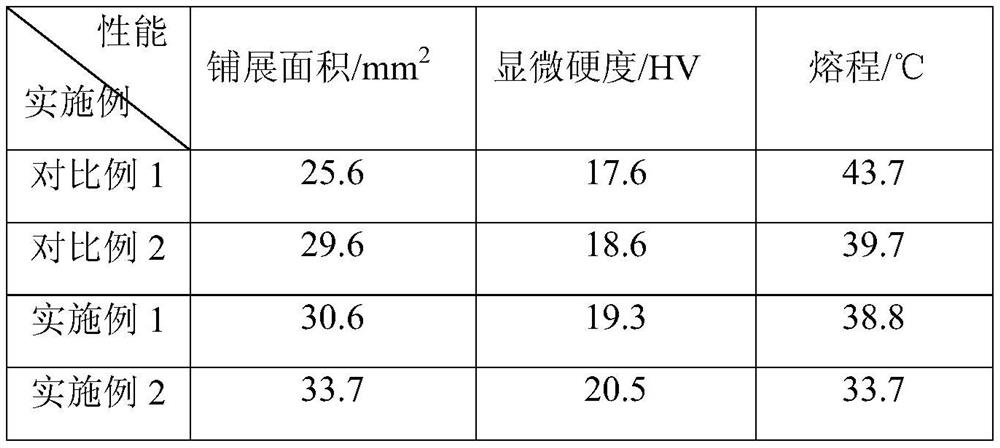

A kind of sn-bi series low-silver lead-free solder alloy and preparation method thereof

ActiveCN109352208BShort melting rangeSolidification segregation inhibitionWelding/cutting media/materialsSoldering mediaFiller metalTin

The invention belongs to the field of solder alloys, and discloses a Sn-Bi low-silver lead-free solder alloy and a preparation method thereof. The solder alloy is composed of Sn, Bi, Ag and Cu, and the components in the solder alloy are calculated by mass percentage: Bi 40%, Ag 0.5%, 0.5%≤Cu≤1.5%, and the balance is tin. Its preparation method is as follows: after pure Sn is completely melted, add pure Bi grains to stir and smelt, then add Sn-20Ag and Sn-20Cu alloys to stir and smelt evenly, add rosin after heat preservation to remove scale residues, and cast to obtain Sn-Bi low-silver Lead-free solder alloy. The invention significantly reduces the melting range of the brazing filler metal by simultaneously adding two alloying elements, Ag and Cu, on the basis of the Sn-40Bi alloy, and greatly improves the wettability and microhardness of the brazing filler metal.

Owner:SOUTH CHINA UNIV OF TECH

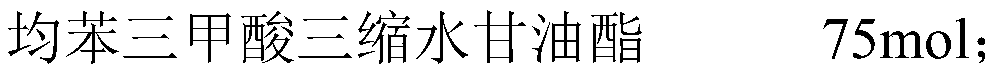

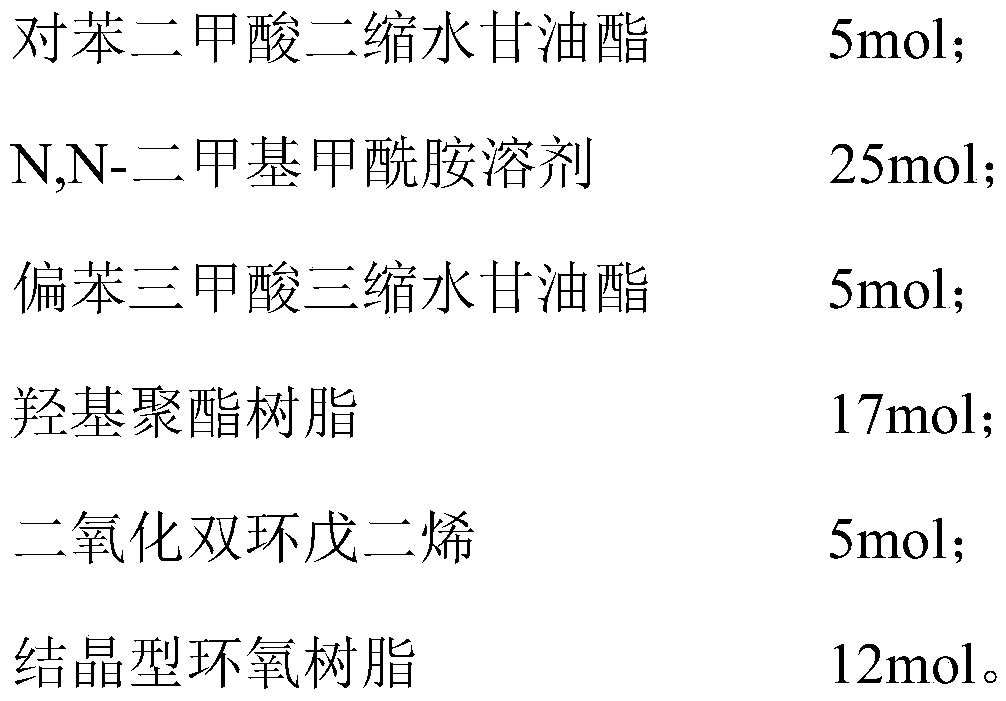

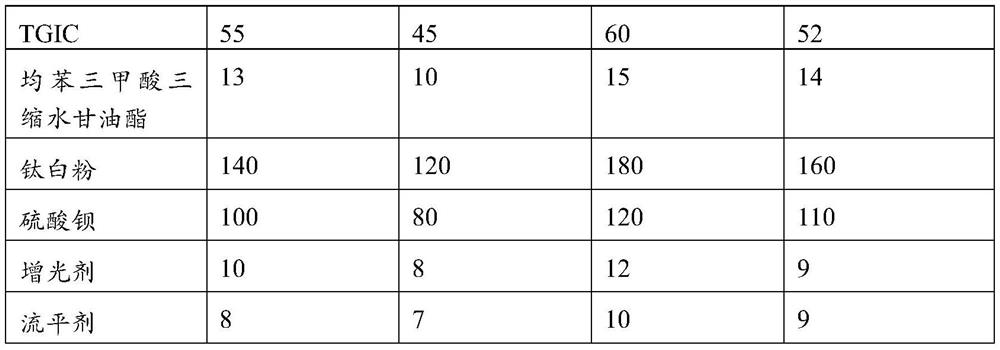

Composite curing agent for polyester powder coating and its preparation method and application

ActiveCN109852127BImprove curing effectHigh epoxy equivalentPowdery paintsPolyester coatingsPolymer scienceFirming agent

The invention belongs to the technical field of powder coatings, in particular to a composite curing agent for polyester powder coatings, and further discloses its preparation method and application. The composite curing agent for polyester resin powder coatings according to the present invention mainly consists of trimellitic acid triglycidyl ester and terephthalic acid diglycidyl ester as main raw materials, and selectively adds trimellitic acid triglycidyl ester It is prepared by mixed reaction of glycidyl ester, hydroxyl polyester resin, dicyclopentadiene dioxide and / or crystalline epoxy resin. The composite curing agent for the polyester resin powder coating has a good curing effect, and the mechanical properties of the obtained coating are stable, and also has good water boiling resistance; when it is cured with the polyester resin, its product performance fully reaches The curing effect of the current TGIC and HAA curing agent can be mixed with the existing TGIC or HAA products, and the comprehensive performance is better.

Owner:安徽泰达新材料股份有限公司

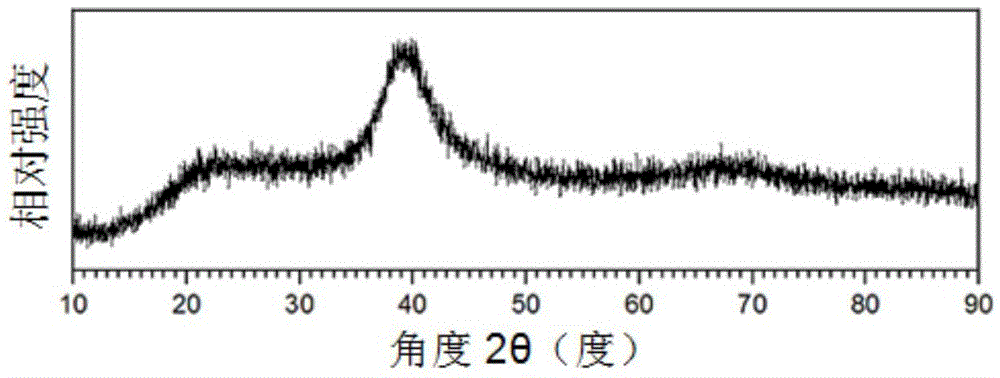

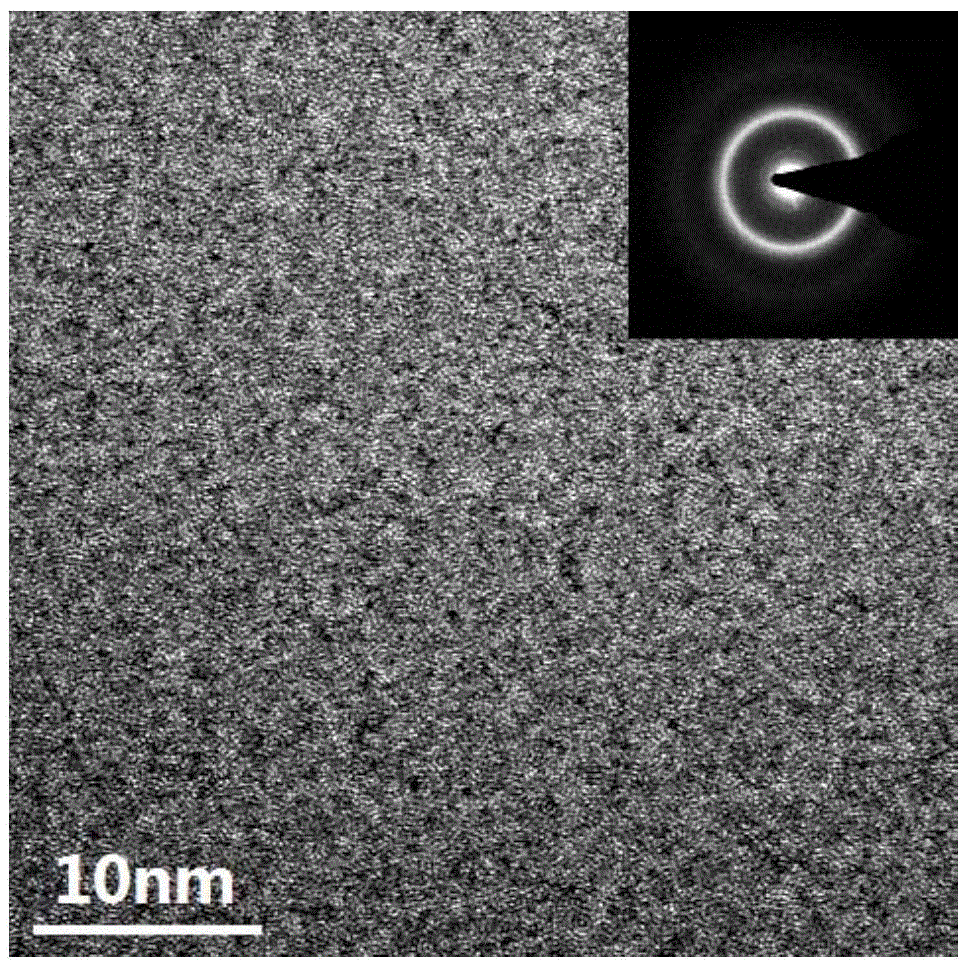

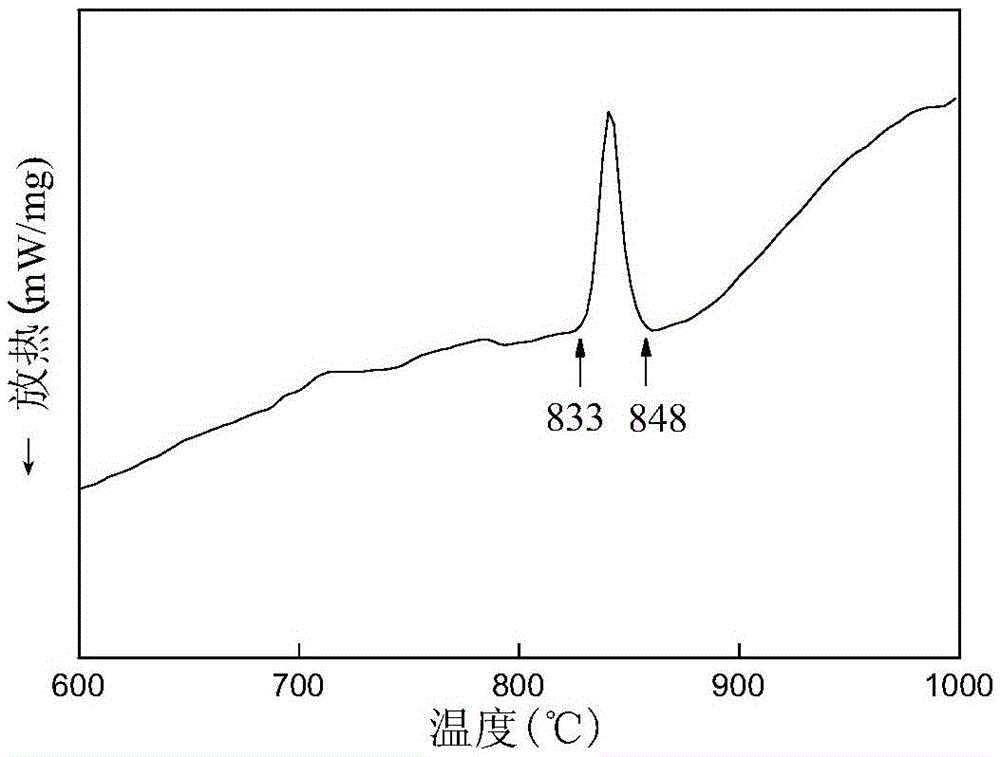

A kind of ti-zr-cu-ni-co-mo amorphous solder and preparation method thereof

ActiveCN103949802BLow melting pointShort melting rangeWelding/cutting media/materialsSoldering mediaIngotQuenching

The invention belongs to the field of welding materials and discloses a Ti-Zr-Cu-Ni-Co-Mo amorphous brazing filler metal and a preparing method thereof. The brazing filler metal is formed by the following components in mass percent of 24-27% of Zr, 12-14% of Cu, 11-13% of Ni, 1.8-4.2% of Co, 1.2-2,8% of Mo and the balance of Ti. The preparing method comprises the steps of burdening according to the content of the components, then adopting a tungsten electric arc smelting method to prepare a brazing filler metal alloy ingot, crushing the alloy ingot into small particles, placing into a quartz tube for heating and melting, and preparing in a high-vacuum single-roll rotary quenching system to obtain the Ti-Zr-Cu-Ni-Co-Mo amorphous brazing filler metal by adopting a fast solidification technology. The brazing filler metal has the advantages of low melting point, short melting range, high connection strength in brazing of a TiAl joint and the like.

Owner:SOUTH CHINA UNIV OF TECH

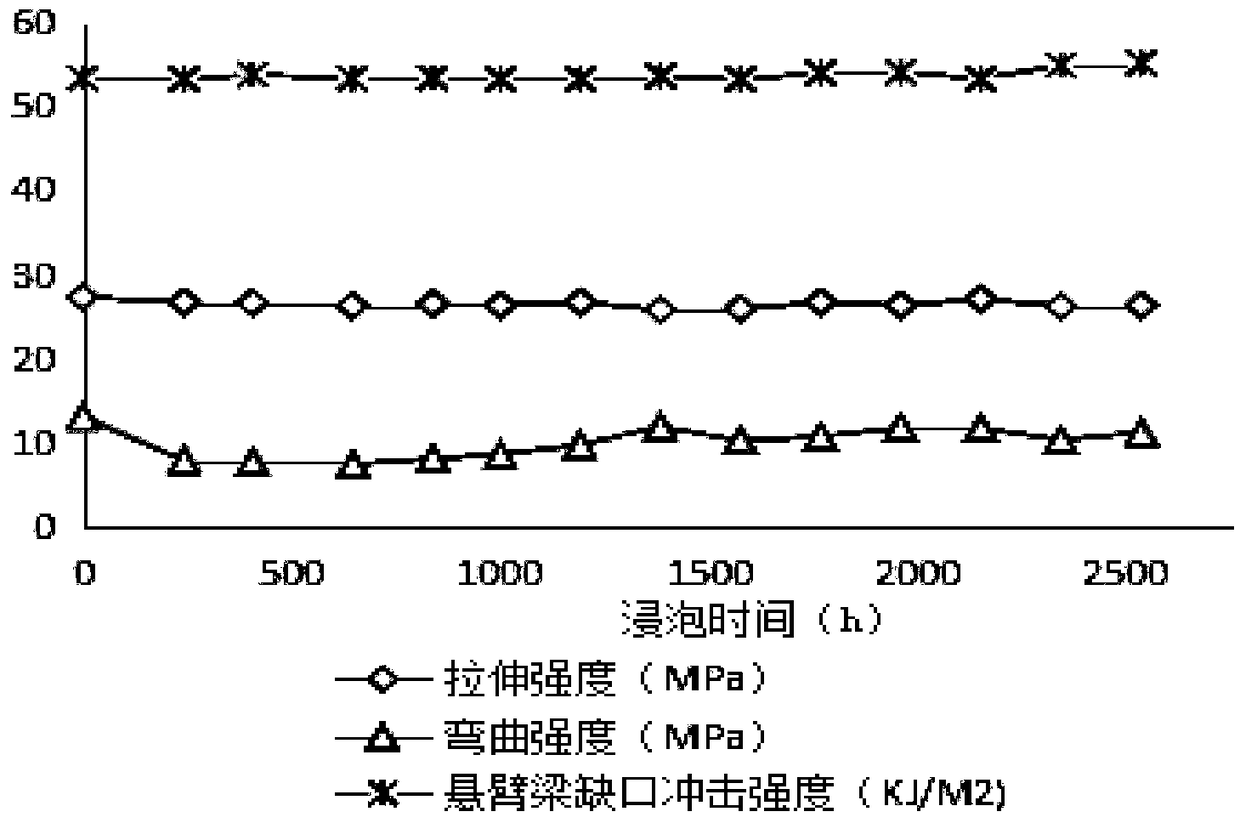

A kind of reinforced nylon material for injection molding of products with high precision and complex structure and its preparation method

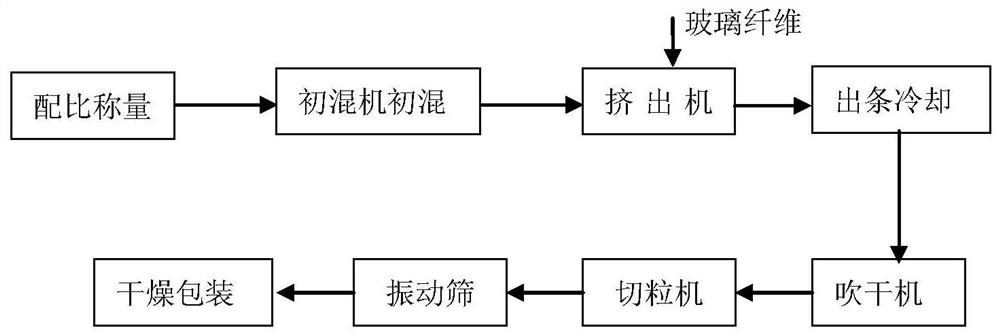

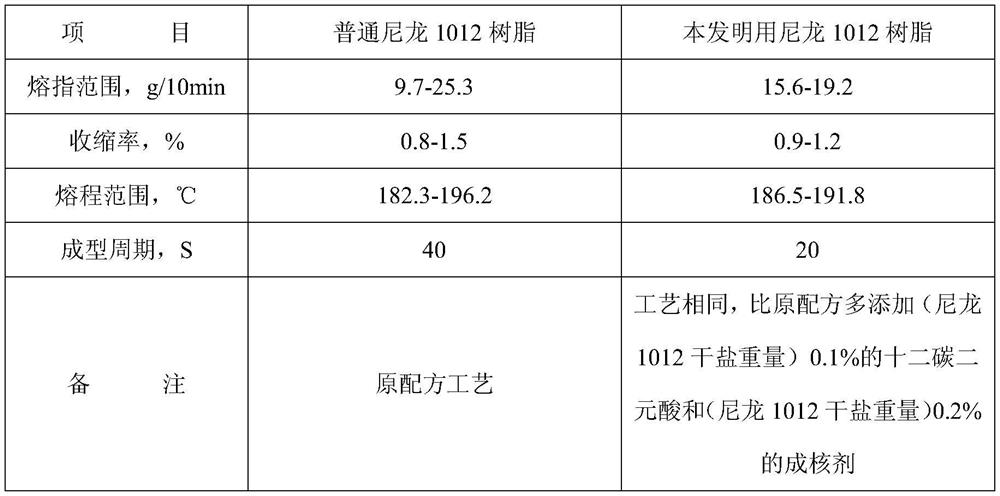

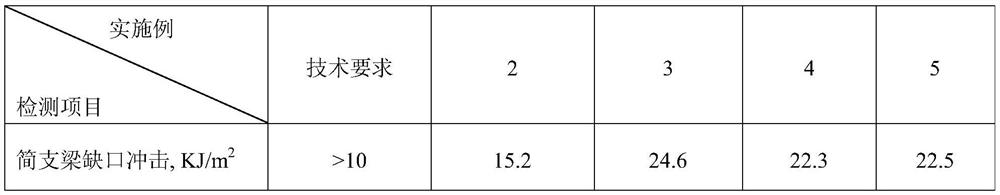

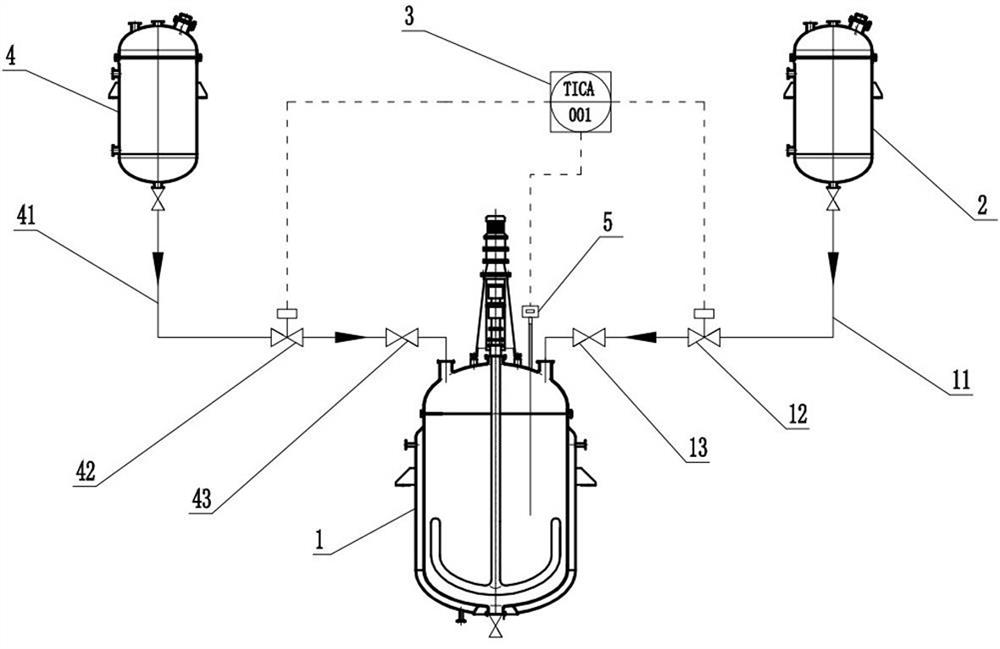

The invention discloses a reinforced nylon material for injection molding of products with high precision and complicated structure and a preparation method thereof. The invention firstly synthesizes medium-low-viscosity long-carbon-chain nylon 1012 as a base material, then adds an appropriate amount of compound processing aids, uses glass fibers for reinforcement, and utilizes a screw extruder to produce a reinforced nylon material suitable for injection molding with high precision and complex structures. The performance index of the reinforced nylon material for injection molding produced by the present invention: tensile strength>100MPa; bending strength>100MPa; notch impact>10KJ / m2; vertical and horizontal shrinkage ratio<0.1; excellent mold release performance, which can meet some sizes Demand for reinforced nylon materials for injection molding of products with high precision requirements and complex structures.

Owner:SHANDONG DONGCHEN ENG PLASTIC

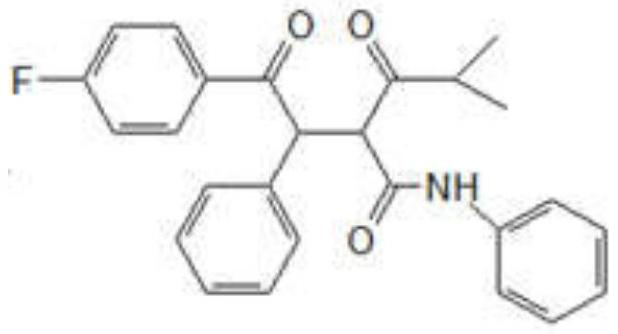

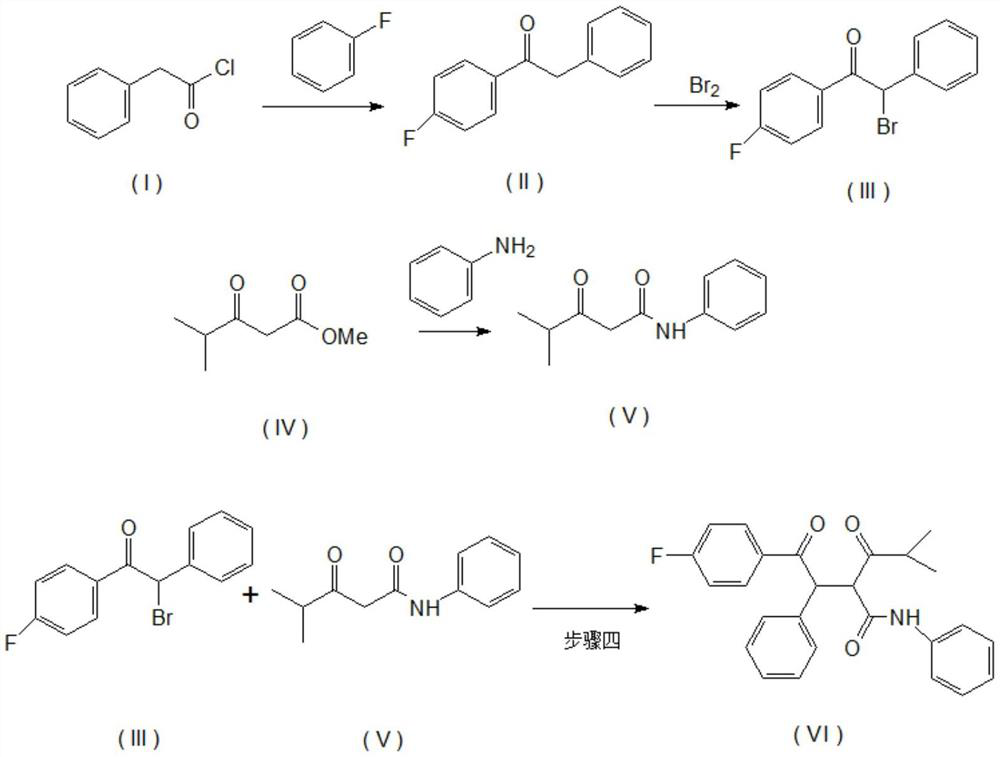

Refining method of atorvastatin parent nucleus M4

PendingCN114195670AAvoid damageReduce generationCarboxylic acid amide separation/purificationSolventBiology

The invention belongs to the technical field of medicine synthesis processes, and particularly relates to a refining method of atorvastatin parent nucleus M4. The DCS reaction kettle system is adopted to adjust the pH value of the system, so that the target product M4 can be effectively prevented from being damaged under acid-base conditions, unknown impurities are reduced, and the refining qualification rate is increased. According to the method disclosed by the invention, inorganic salts such as potassium carbonate, potassium bicarbonate and potassium chloride in the atorvastatin mother nucleus M4 (namely a compound VI) crude product 1 synthesized by a convergence method can be removed in the pulping process, and a mixed solvent is utilized in the recrystallization process, so that impurities are effectively removed and reduced, and the refining yield is improved. The process disclosed by the invention is simple in post-treatment, large in productivity, and suitable for industrial production, and the obtained product is high in chemical purity, low in impurity content, high in melting point, short in melting range and good in stability, and the recovered solvent and the crystallization mother liquor can be recycled.

Owner:河南豫辰药业股份有限公司

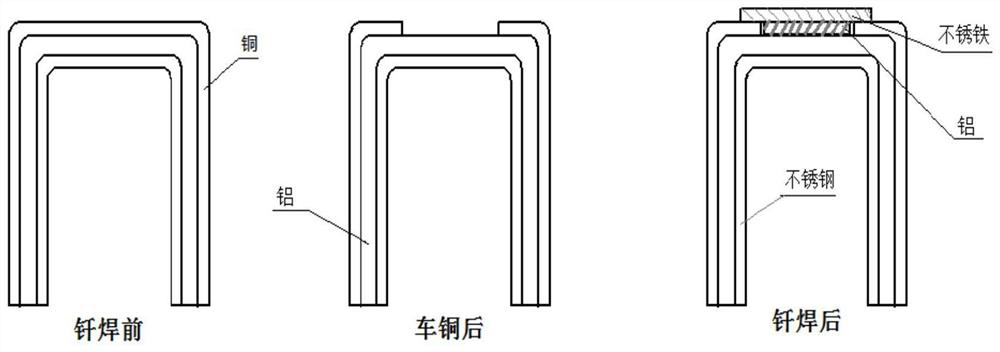

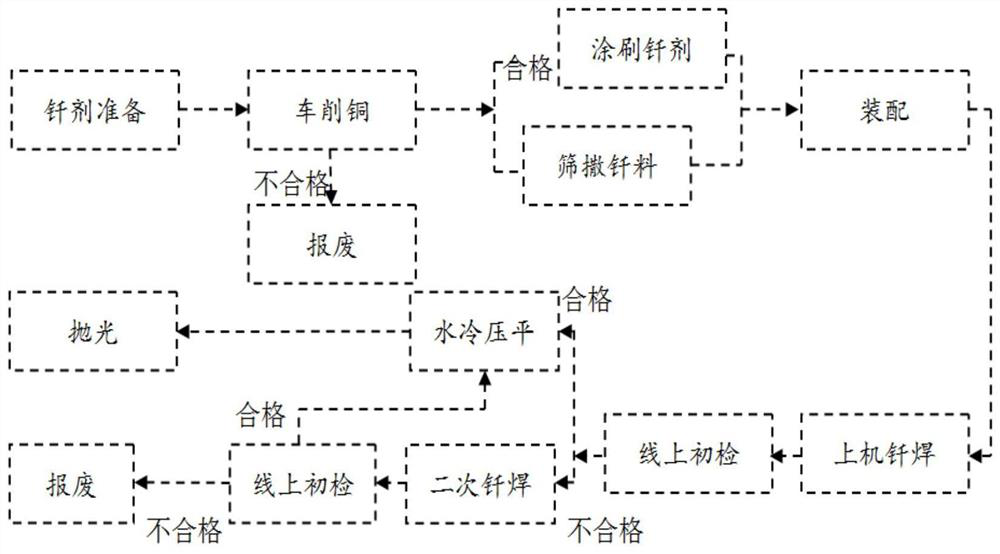

A kind of composite brazing material and brazing process

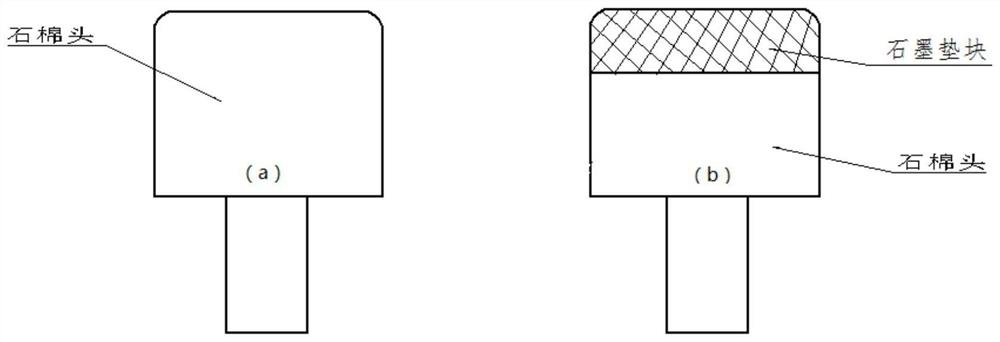

ActiveCN110181194BLow liquidus temperatureSmall particlesWelding/cutting media/materialsSoldering mediaGraphiteSilicon

The invention discloses a composite brazing material and a brazing process, which relate to the technical field of welding. This composite brazing material can be used for brazing connection of copper-aluminum-stainless steel composite material and aluminum and stainless iron. And specifically, the composite brazing material includes composite brazing flux and aluminum-silicon solder; the composite brazing flux includes cesium fluoroaluminate with a mass ratio of 60% to 90% and a melting range of 440 to 480°C , Potassium fluoroaluminate with a mass ratio of 40% to 10%. The brazing material has a low liquidus temperature, thereby effectively reducing the brazing temperature. The solder particles are smaller and the melting range is shorter, which greatly shortens the melting time. The compound flux can effectively improve the fluidity of the solder after melting. A graphite pad is set above the lower die head of the brazing machine, which can save the copper layer turning process before welding, so that the weldment can pass 10 times of 350 ℃ dry burning test and 30 times of 300 ℃ dry burning test after welding, effectively improving the quality of the weldment Yield rate, stable and improved weldment quality.

Owner:广州有研焊接材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com