A kind of snbisb series low-temperature lead-free solder and preparation method thereof

A technology of lead-free solder and lead-free solder alloy, which is applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc. It can solve problems such as deformation, SnBi solder brittleness and poor reliability, and low melting point of alloys. Small size, share the stress together, and increase the electrode potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

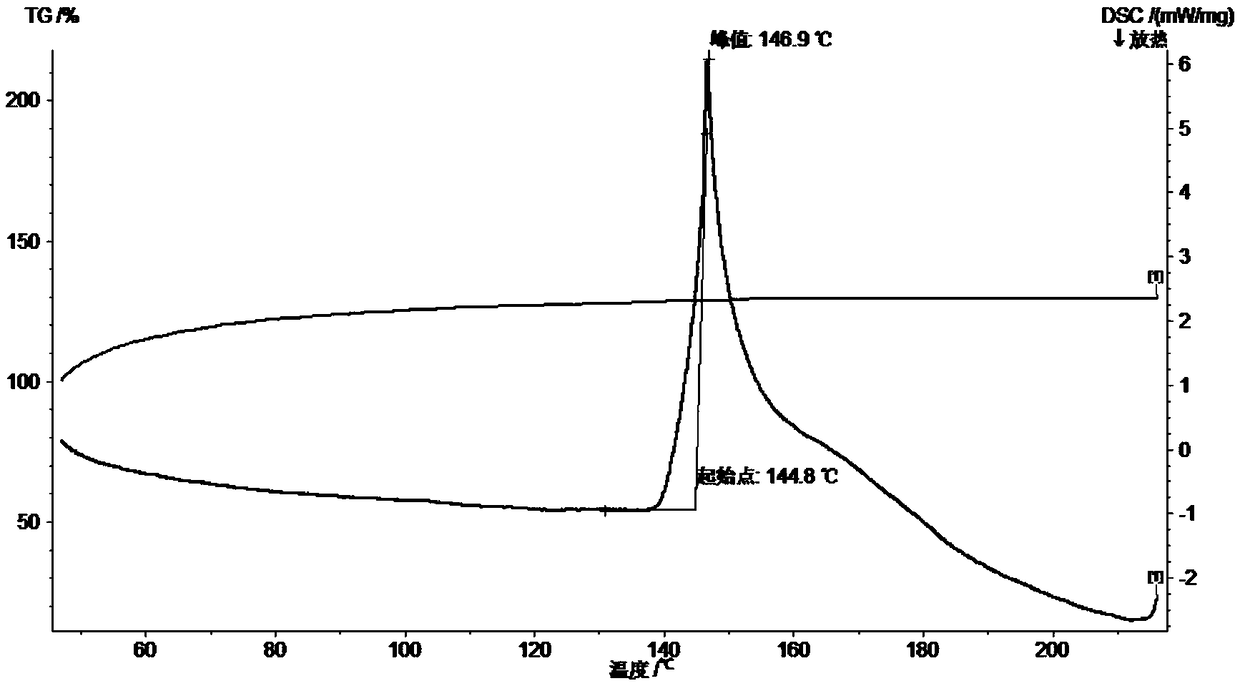

[0035] A lead-free solder alloy used in the field of low-temperature soldering. In terms of weight percentage, the lead-free solder alloy powder includes: Bi 41.8%, Sb 2.1%, and the rest are Sn and unavoidable impurities. The lead-free solder alloy is nearly Pereutectic structure, the melting point of the alloy is 142.9-150.8°C. The method for preparing the lead-free solder alloy comprises the following steps:

[0036] 1) Add metal Bi and Sb with a purity of 99.99wt.% into the vacuum melting furnace at an alloy ratio of 80:20 by weight, and vacuumize to 1×10 -1 Pa, filled with nitrogen; heat the alloy to 650-700 ° C to melt, and at the same time, add electromagnetic stirring to make the alloy composition uniform, and then vacuum cast to prepare the Bi-Sb20 master alloy;

[0037] 2) The prepared Bi-Sb master alloy and metals Sn and Bi are melted in a melting furnace according to the alloy ratio. Cover the surface of the alloy with an anti-oxidation solvent, the anti-oxidation...

Embodiment 2

[0039] A lead-free solder alloy used in the field of low-temperature soldering. In terms of weight percentage, the lead-free solder alloy powder includes: Bi 50%, Sb 1.0%, and the rest are Sn and unavoidable impurities. The lead-free solder alloy is composed of Eutectic structure with a melting point of 140.6-143.8°C. The method for preparing the lead-free solder alloy is the same as that in Example 1 except that the alloy ratio is different.

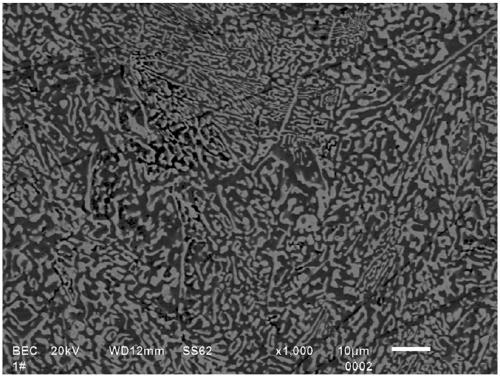

[0040] Such as figure 1 Shown is the SEM photo of the structure of the solder alloy prepared in this embodiment, and it can be seen from the figure that the alloy is an eutectic structure.

Embodiment 3

[0042] A lead-free solder alloy for low-temperature soldering field, the lead-free solder alloy powder contains: Bi 55%, Sb 0.8%, Ce 0.01%, Ti 0.05%, and the rest is Sn and unavoidable impurities , the lead-free solder alloy has a near-eutectic structure and a melting point of 142.9-146.2°C. The method for preparing the lead-free solder alloy comprises the following steps:

[0043] 1) Add metal Bi and Sb with a purity of 99.99wt.% into the vacuum melting furnace at an alloy ratio of 80:20 by weight, and vacuumize to 1×10 -2 Pa, filled with nitrogen, heated to 650-700 ° C to melt, and at the same time, electromagnetically stirred to make the alloy composition uniform, and then vacuum cast to prepare a Bi-Sb20 master alloy;

[0044] 2) Metals Sn and Ce, Sn and Ti with a purity of 99.99wt.% were added to the vacuum melting furnace according to a certain alloy ratio, and the vacuum treatment was carried out to 1×10 -2 Pa, filled with nitrogen; heat the alloy to 690-780°C and 155...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com