Preparation method of fluorine layer-containing polyimide composite material and equipment for method

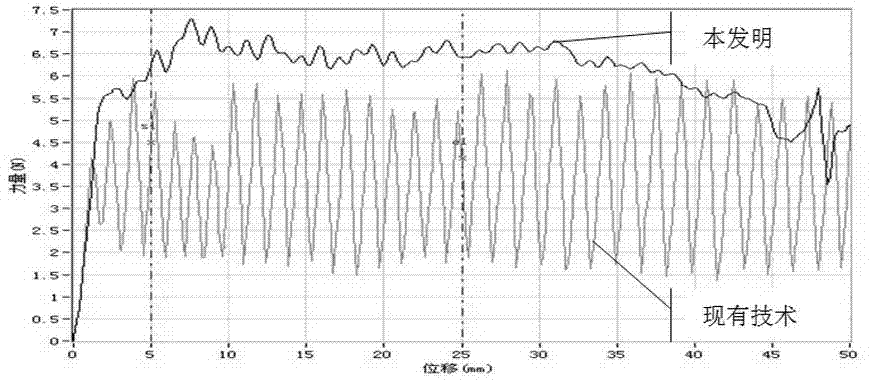

A technology of composite materials and polyimide, which is applied in the field of preparation of polyimide composite materials with fluorine-containing layer, can solve the problems of high melting point, poor melting processing performance of fluorine materials, slow speed, etc., and achieve accurate thickness control and equipment High precision, overcome the effect of low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Equipment for preparing fluorine-containing layer polyimide composite materials

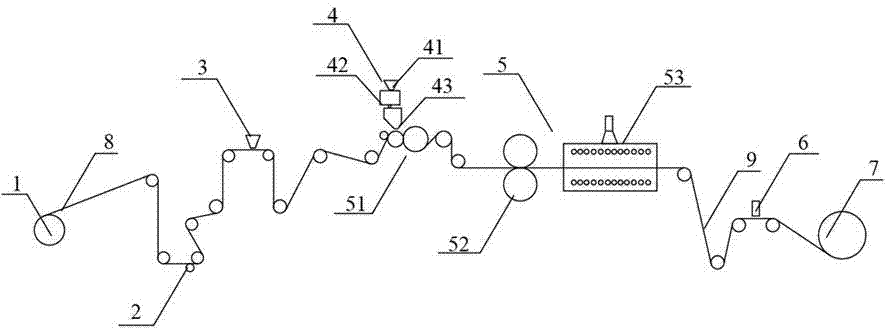

[0045] Such as figure 1 As shown, the equipment of the present invention consists of an unwinding device 1 , a deviation correcting device 2 , a corona treatment device 3 , an extrusion casting system 4 , a molding system 5 , a static elimination device 6 , and a winding device 7 . The unwinding device includes a drive motor, a frequency converter, and a tension controller; the rewinding device includes a drive motor, a frequency converter, a tension controller, and a meter counter. Unwinding device and winding device can control the pulling speed of polyimide film. The extrusion casting system includes a stocker 41 , a screw extruder 42 , and an extrusion die 43 ; the molding system includes a cooling device 51 , a shaping device 52 and a sintering device 53 . Correspondingly set some transmission rollers at each position.

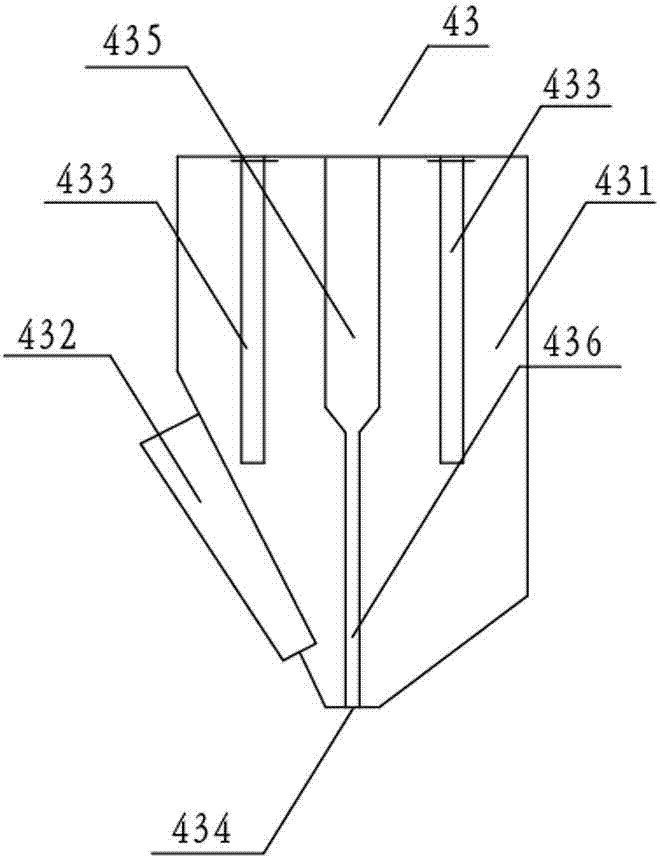

[0046] attached figure 2 It is a schematic struct...

Embodiment 2

[0050] Example 2 Preparation of polyimide composite material with fluorine-containing layer

[0051] Adopt the equipment of embodiment one

[0052] First, 60Kg polyimide film with a width of 550mm and a thickness of 0.025mm is drawn according to a specific route; 50Kg of dry polyperfluoroethylene propylene particles are added to the stocker for use; the width of the extrusion die is adjusted to 520 mm ; The temperature of the cooling system is 50°C, the temperature of the shaping system is 205°C, and the temperature of the sintering system is 350°C.

[0053] Then the polyimide film is unwinded at a speed of 40m / min through an unwinding device, a deviation correction device, and corona treatment, and the extrusion rate of the screw extruder is gradually adjusted to 0.65Kg / min, and the polyimide film is passed through When extruding the casting system, the polyperfluoroethylene propylene melt is extruded from the extrusion die and compounded onto the polyimide film;

[0054] F...

Embodiment 3

[0063] Example 3 Preparation of polyimide composite material with fluorine-containing layer

[0064] Adopt the equipment of embodiment one

[0065] First, 60Kg polyimide film with a width of 550mm and a thickness of 0.025mm is pulled according to a specific route; 40Kg of dry polytetrafluoroethylene particles are added to the stocker for use; the width of the extrusion die is adjusted to 520 mm; The cooling system temperature is 50°C, the setting system temperature is 260°C, and the sintering system temperature is 380°C.

[0066] Then the polyimide film is unwinded at a speed of 50m / min through an unwinding device, a deviation correction device, and corona treatment, and the extrusion rate of the screw extruder is gradually adjusted to 0.29Kg / min, and the polyimide film is passed through When extruding the casting system, the PTFE melt is extruded from the extrusion die and compounded onto the polyimide film.

[0067] Finally, the polyimide film compounded with polytetrafluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com