SnBiZn series low-temperature lead-free solder and preparation method thereof

A technology of lead-free solder and lead-free solder alloy, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve problems such as deformation, achieve improved oxidation resistance, fine grain size, and improved wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

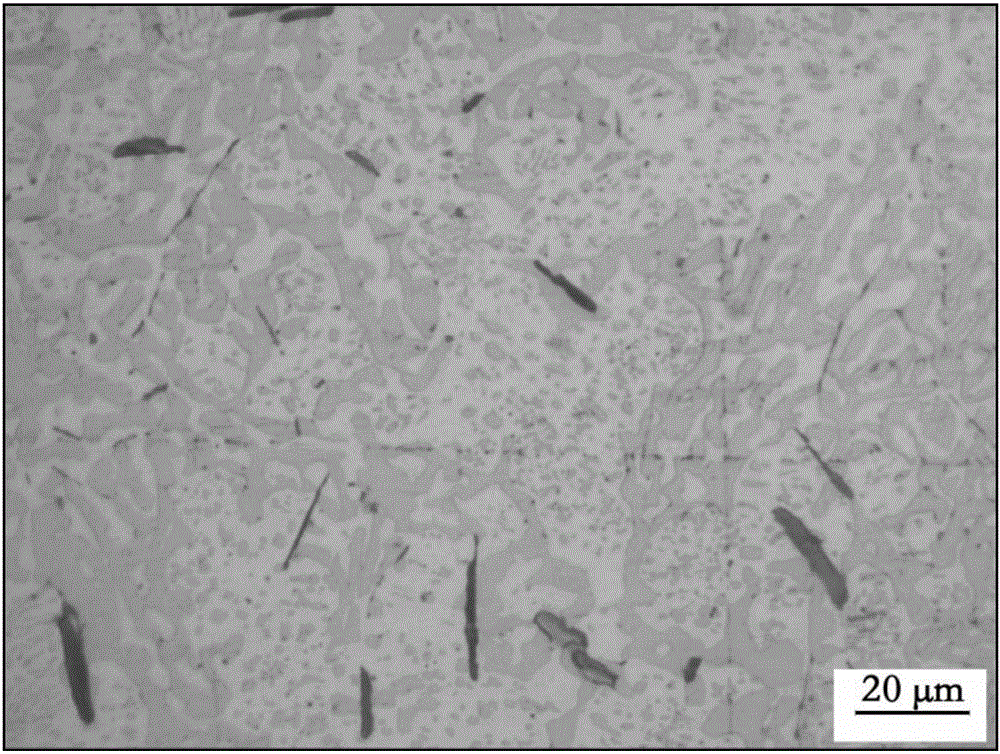

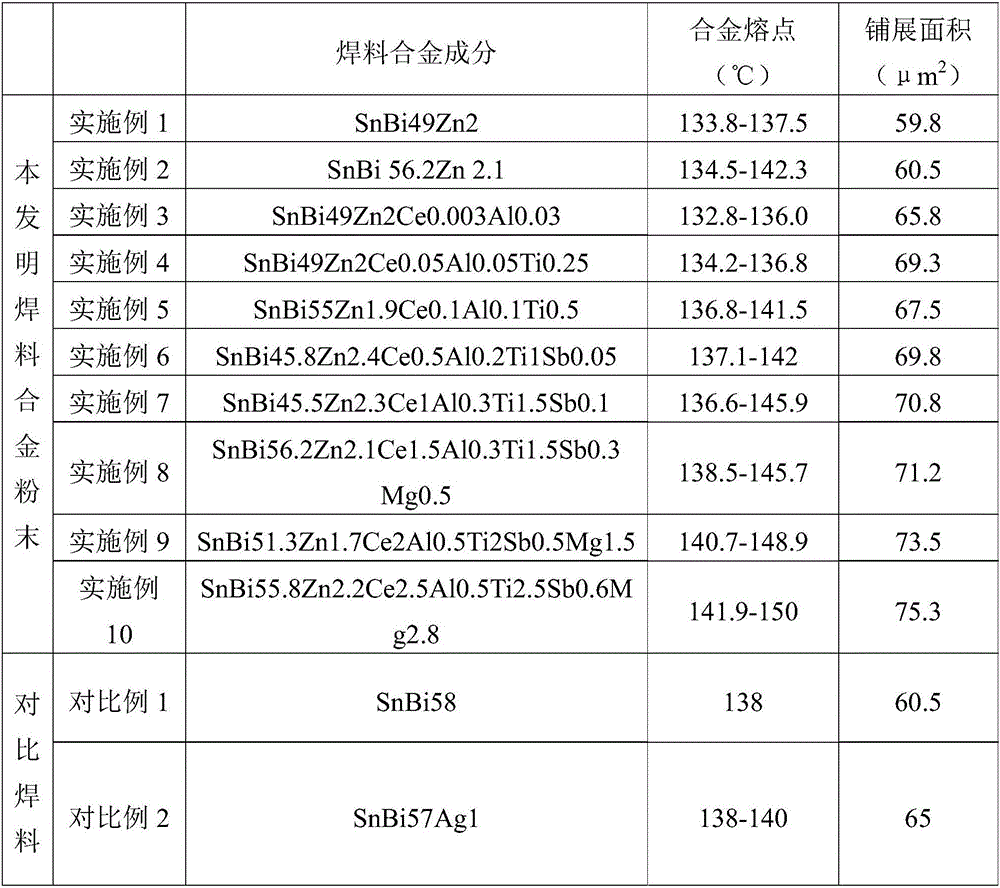

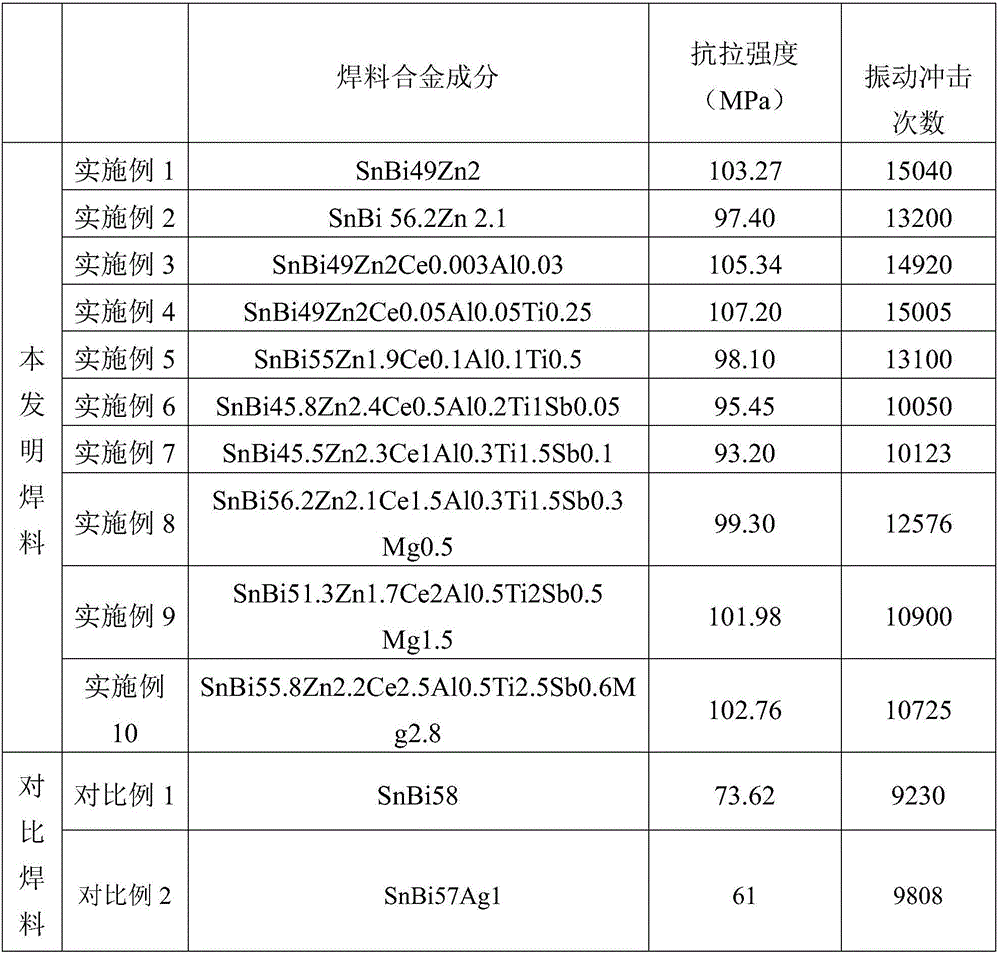

[0030] A lead-free solder alloy used in the field of low-temperature soldering. In terms of weight percentage, the lead-free solder alloy powder contains: Bi 49%, Zn 2.0%, and the rest is Sn. The lead-free solder alloy has a ternary eutectic structure, The melting point of the alloy is 133.8-137.5. The method for preparing the lead-free solder alloy comprises the following steps:

[0031] 1) Add metal Sn and Zn with a purity of 99.99wt.% into the vacuum melting furnace according to a certain alloy ratio, and vacuumize to 1×10 -1 Pa, filled with nitrogen; heat the alloy to 500-550 ° C to melt, and at the same time, add electromagnetic stirring to make the alloy composition uniform, and then vacuum cast to prepare the SnZn9 master alloy;

[0032] 2) Melting the prepared Sn-Zn master alloy, Sn, and Bi in a melting furnace according to the alloy ratio. Cover the surface of the alloy with an anti-oxidation solvent (rosin or KCl-LiCl molten salt), heat the alloy to 200°C, keep it ...

Embodiment 2

[0035] A lead-free solder alloy used in the field of low-temperature soldering, the lead-free solder alloy powder contains: Bi 56.2%, Zn 2.1%, the rest is Sn in weight percent, the melting point of the lead-free solder alloy is 134.5-142.3°C. The method for preparing the lead-free solder alloy is the same as that in Example 1 except that the alloy ratio is different.

Embodiment 3

[0037] A lead-free solder alloy used in the field of low-temperature soldering, the lead-free solder alloy powder contains: Bi 49%, Zn 2.0%, Ce 0.003%, Al 0.03%, the rest is Sn, the lead-free solder The alloy is a near-eutectic structure with a melting point of 132.8-136.0°C. The method for preparing the lead-free solder alloy comprises the following steps:

[0038] 1) Add metals Sn and Zn, Sn and Ce, Sn and Al with a purity of 99.99wt.% into the vacuum melting furnace according to a certain alloy ratio, and vacuumize to 1×10 -2 Pa, after being filled with nitrogen; the alloys were heated to 500-550°C, 690-780°C, and 400-500°C to melt, and electromagnetic stirring was added at the same time to make the alloy composition uniform, and then vacuum casting to prepare SnZn9, SnCe10, SnAl5 master alloy;

[0039] 2) Melting the prepared Sn-Zn, Sn-Ce, Sn-Al master alloys and metals Sn and Bi in a melting furnace according to the alloy ratio. Cover the surface of the alloy with an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com